Titanium Carbide Nanofibers-Reinforced Aluminum Compacts, a New Strategy to Enhance Mechanical Properties

Abstract

:1. Introduction

2. Experimental Details

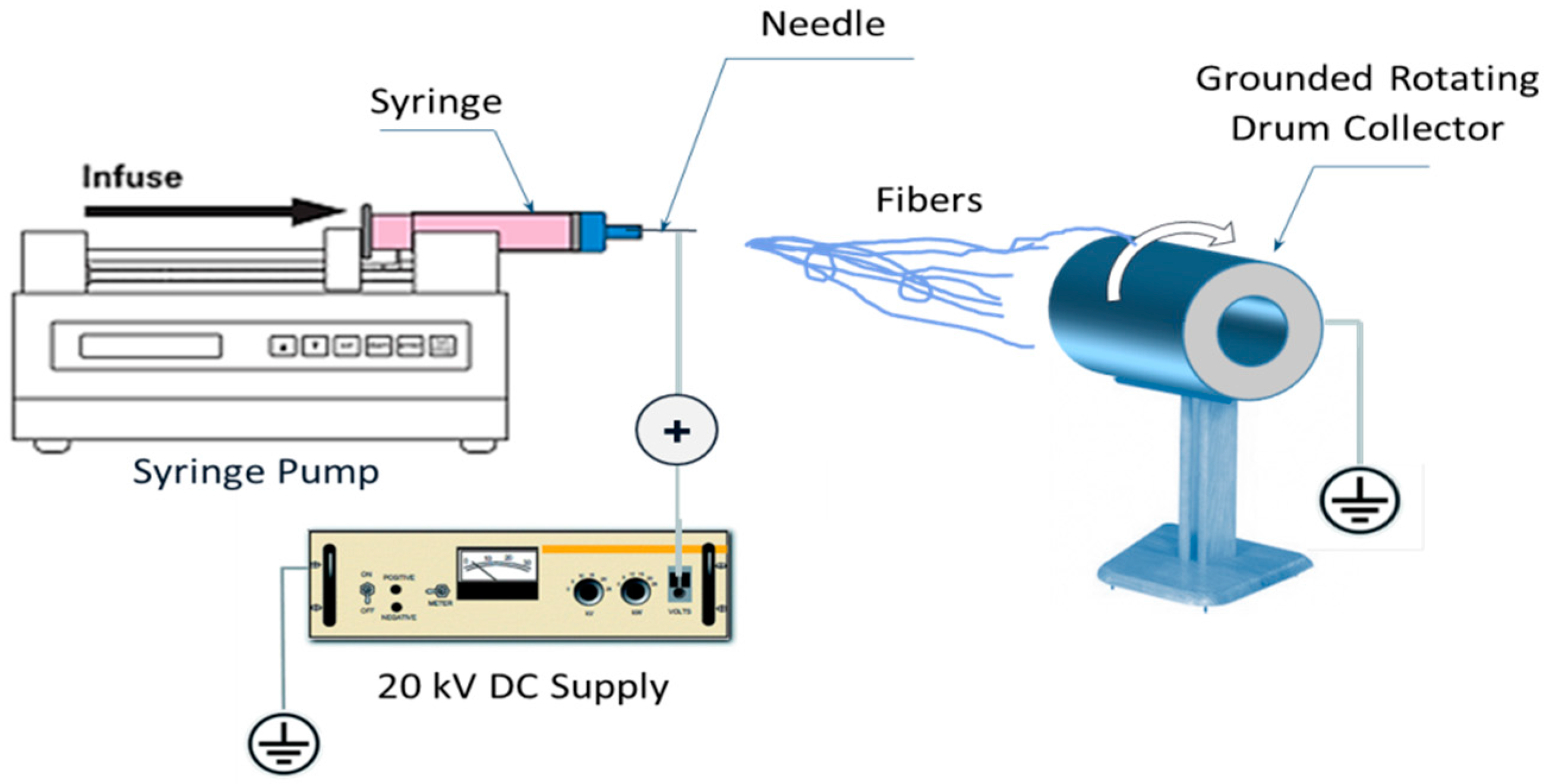

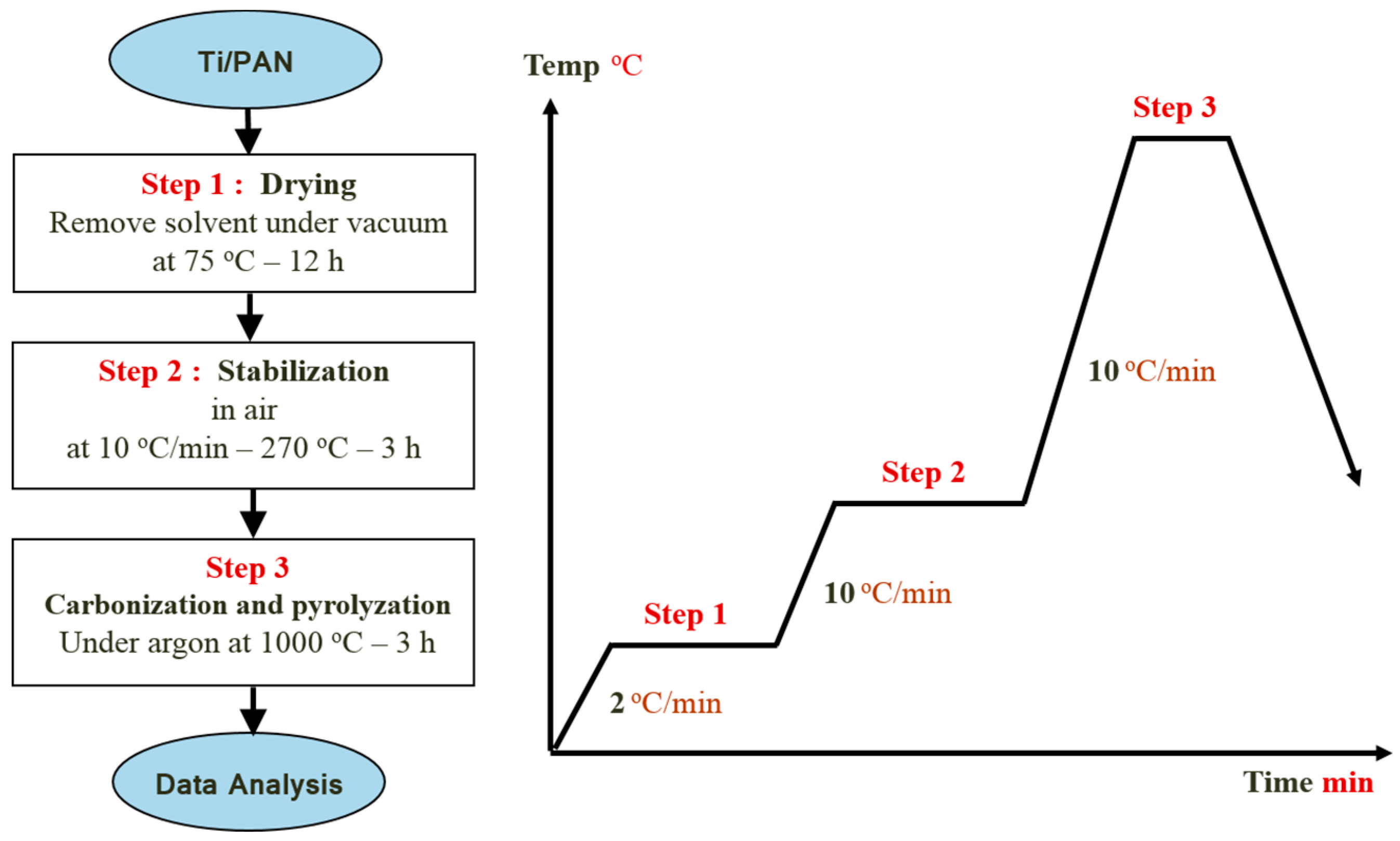

2.1. Electrospinning Process

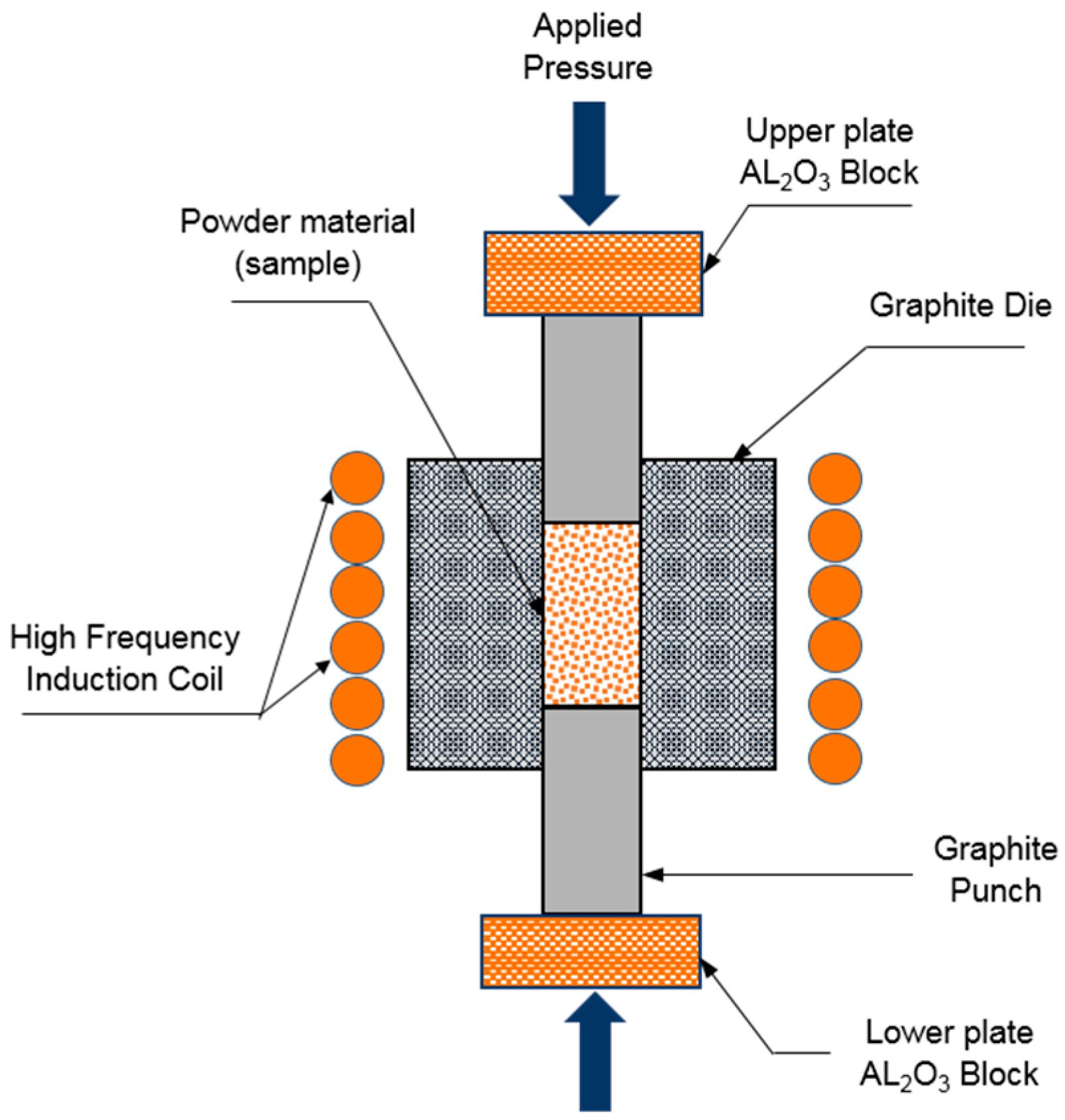

2.2. Mixing Process

2.3. Composites Characterization

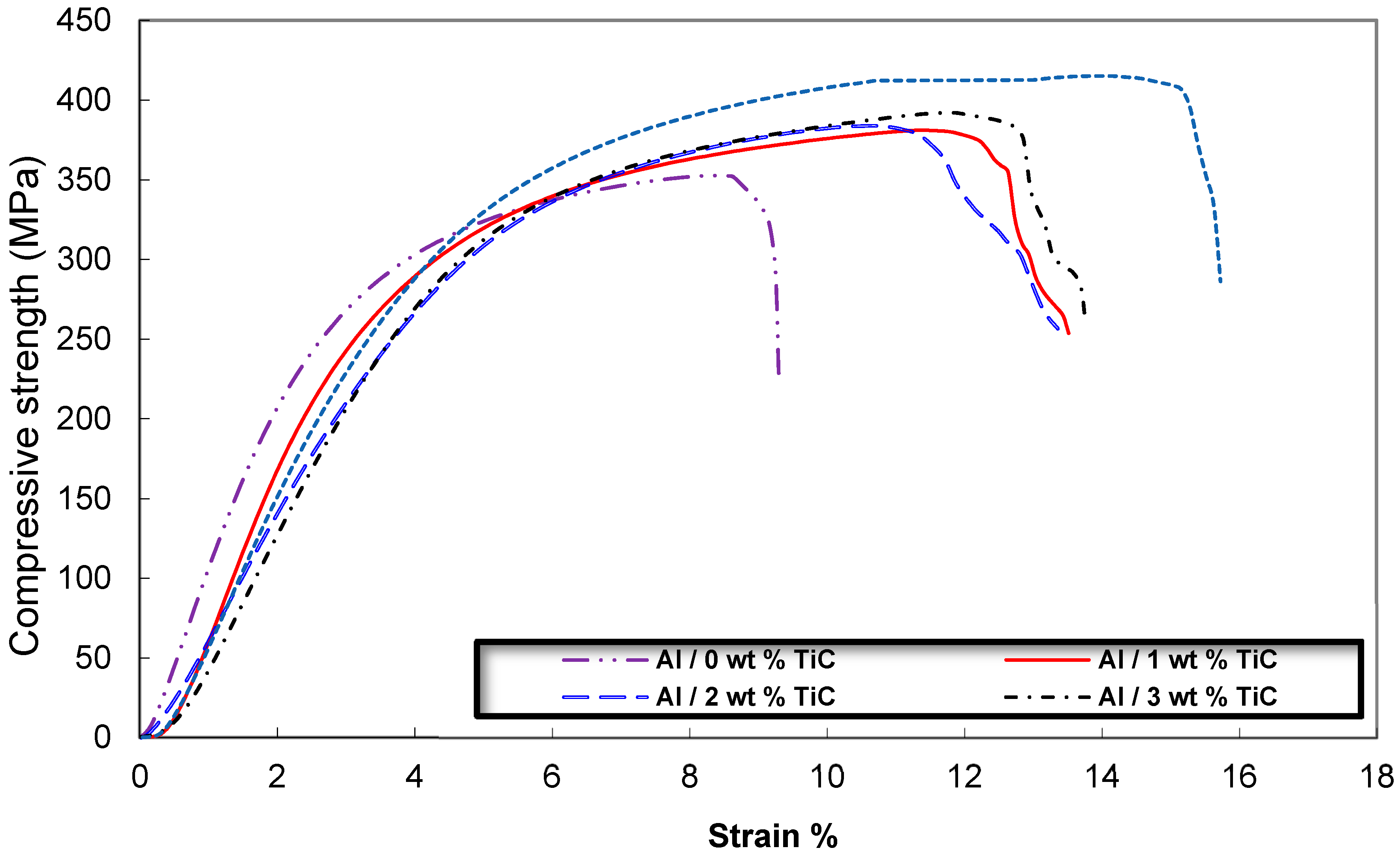

3. Results and Discussion

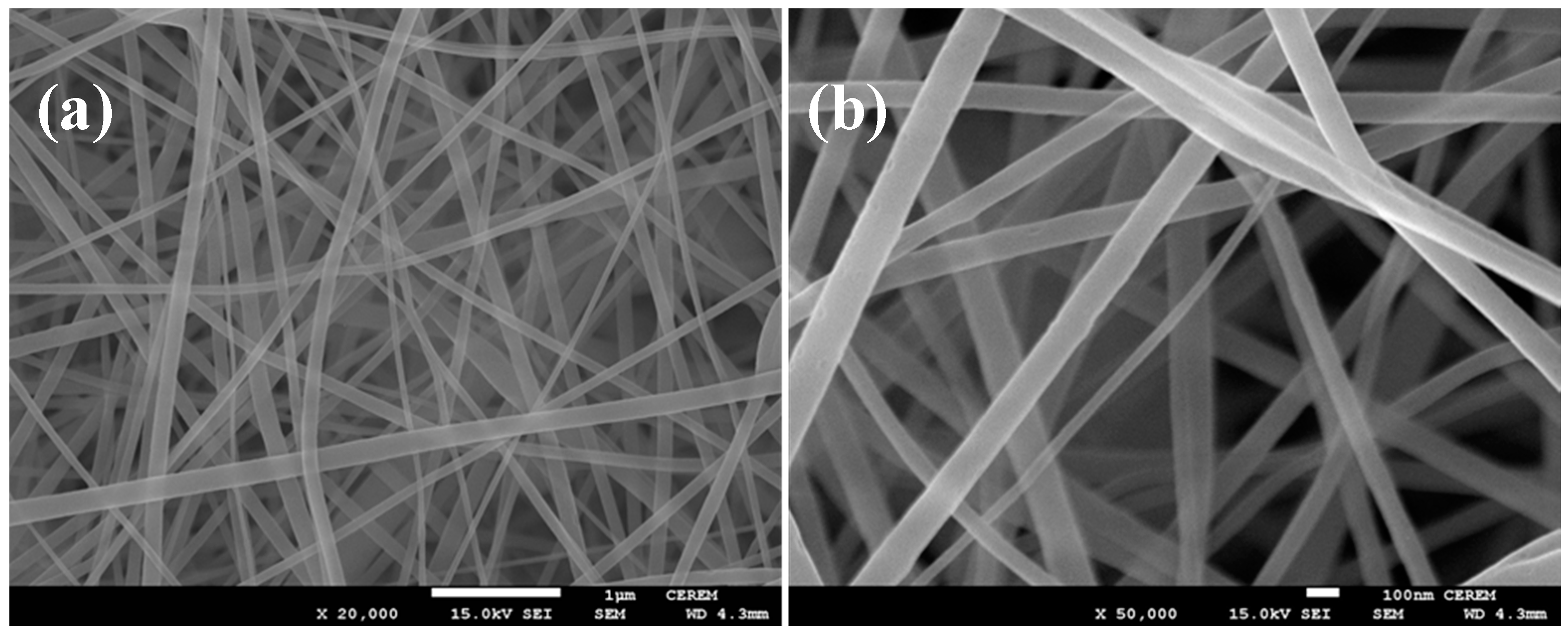

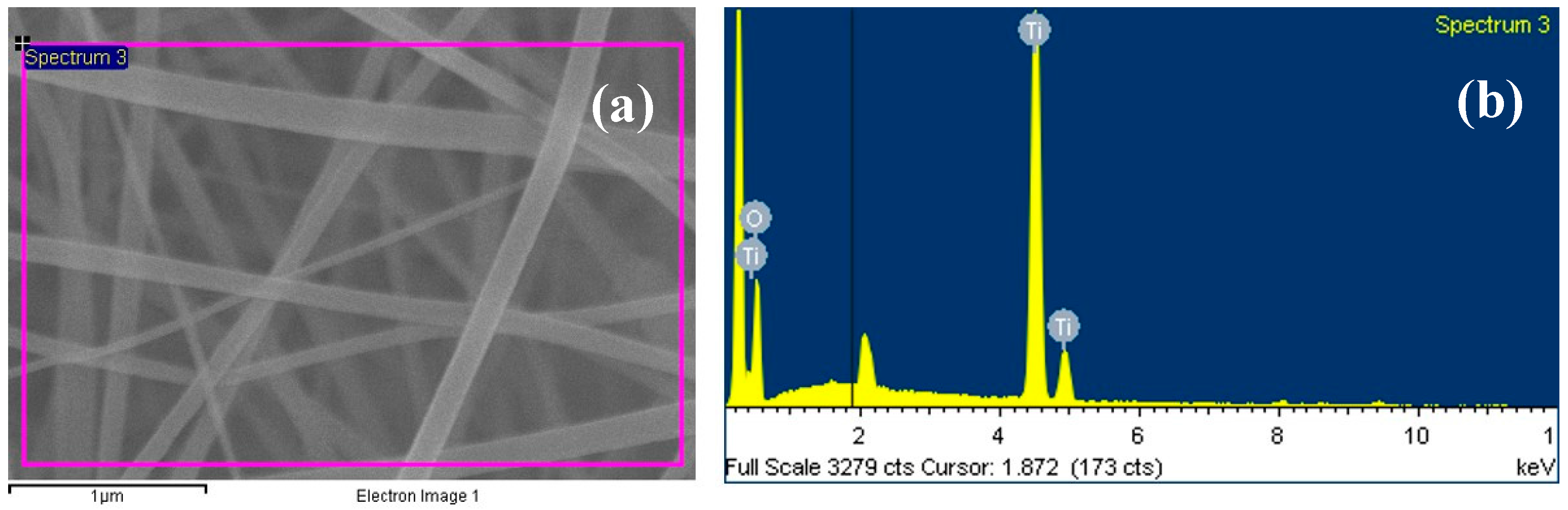

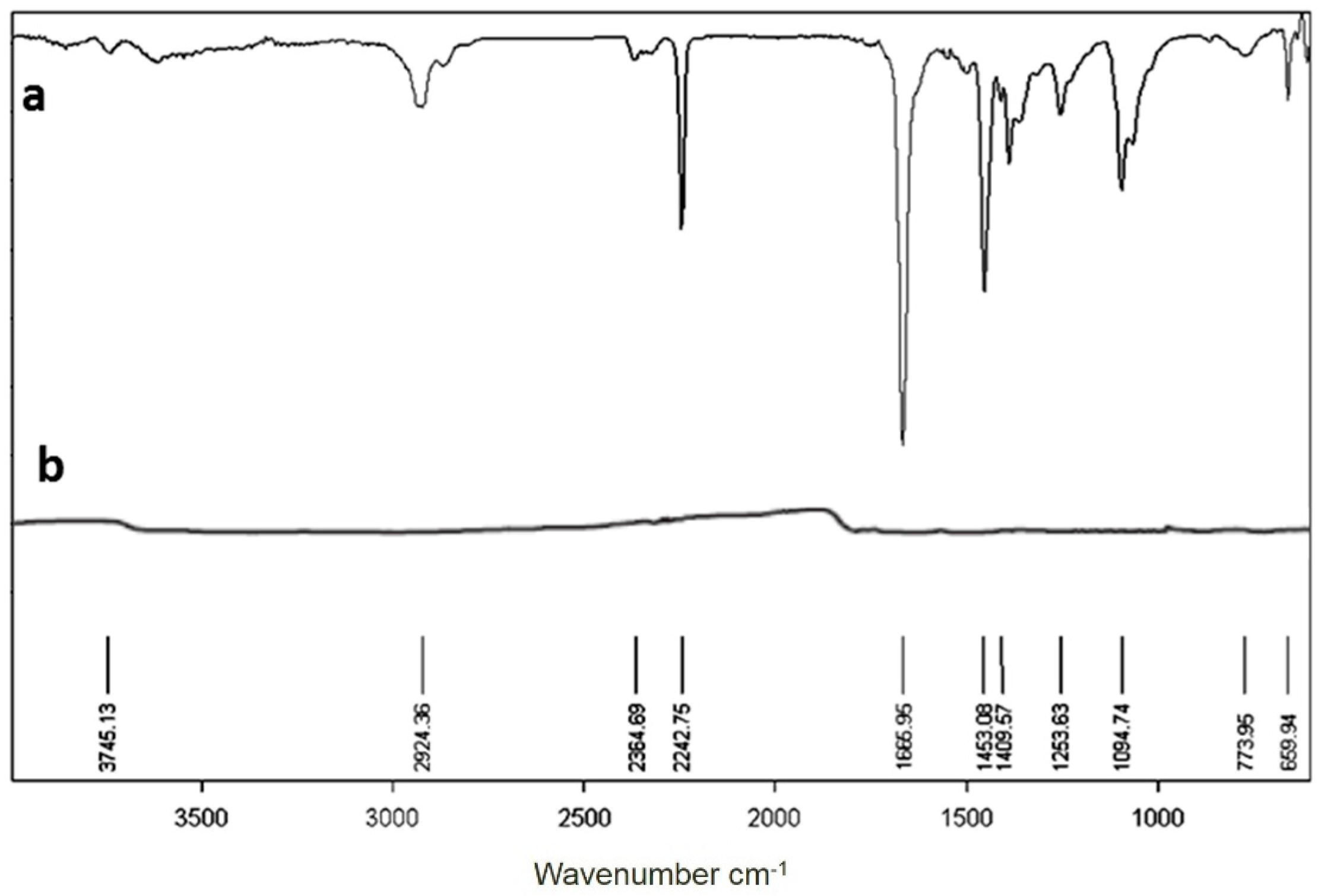

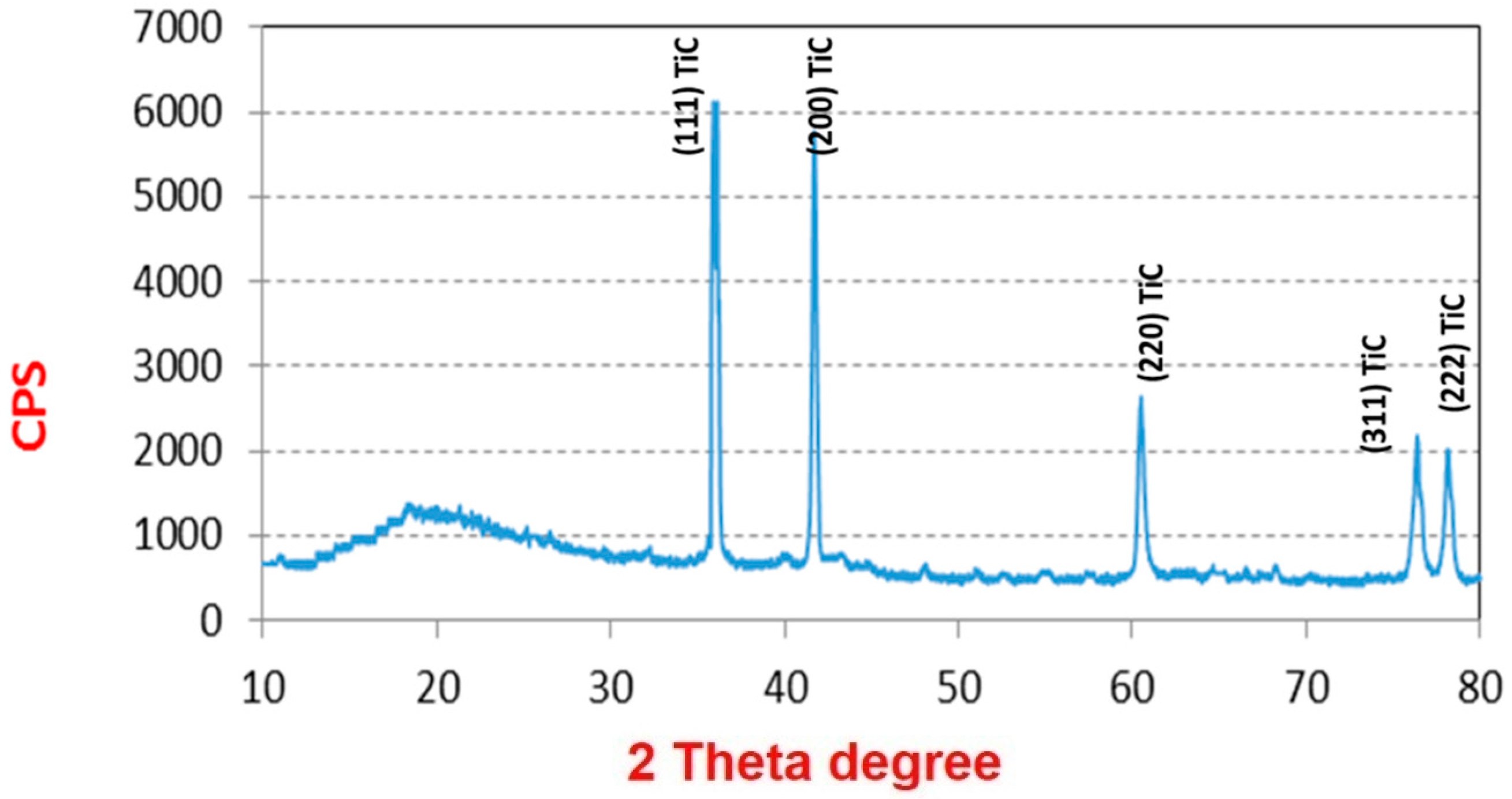

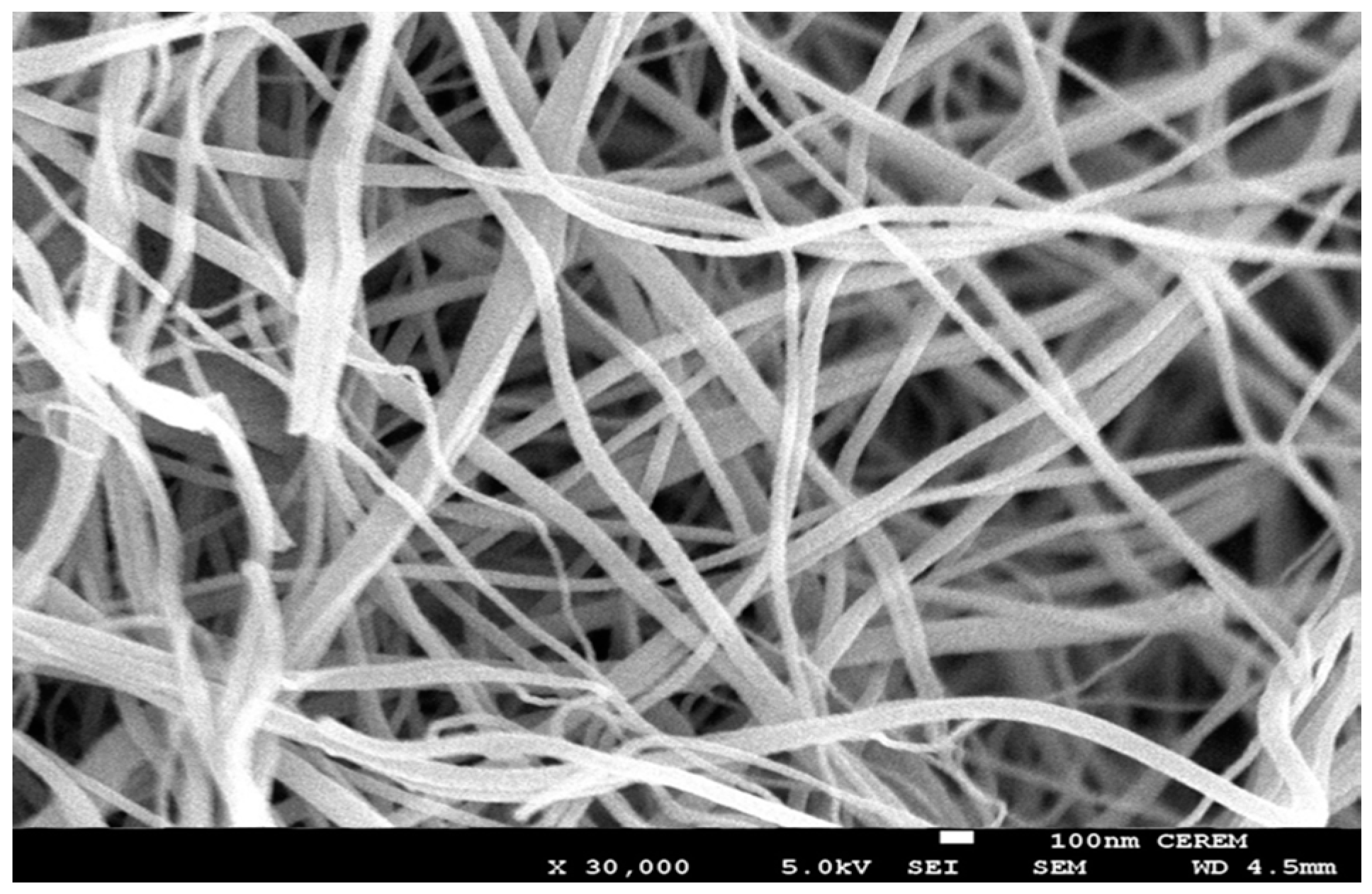

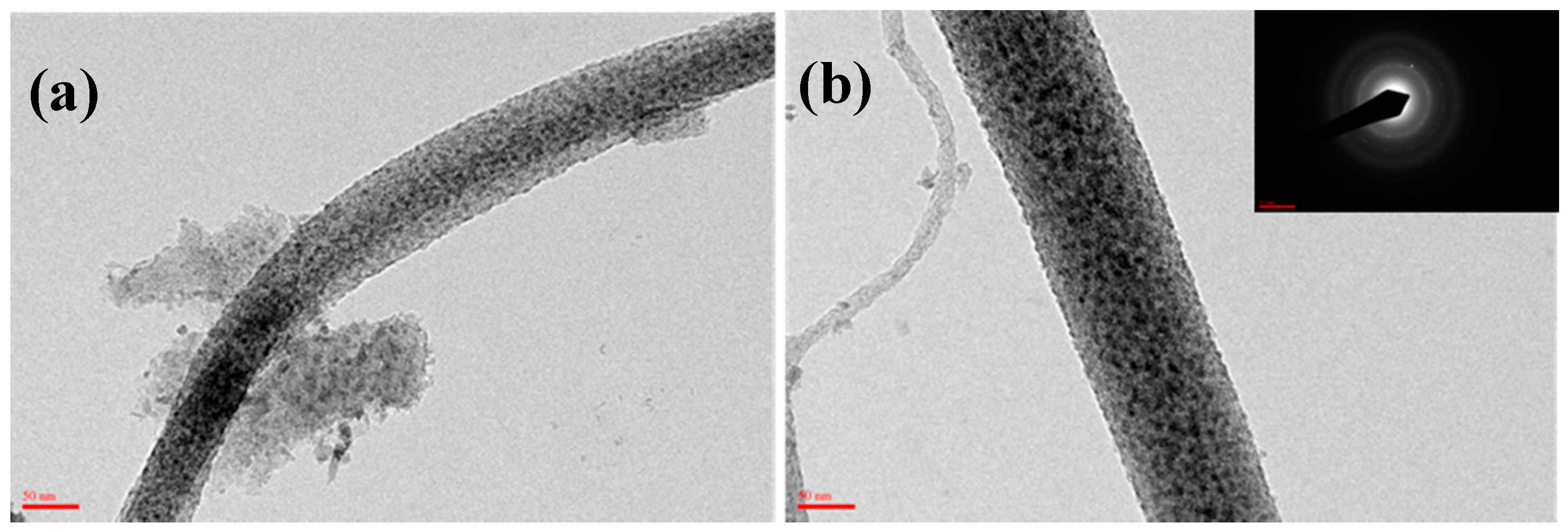

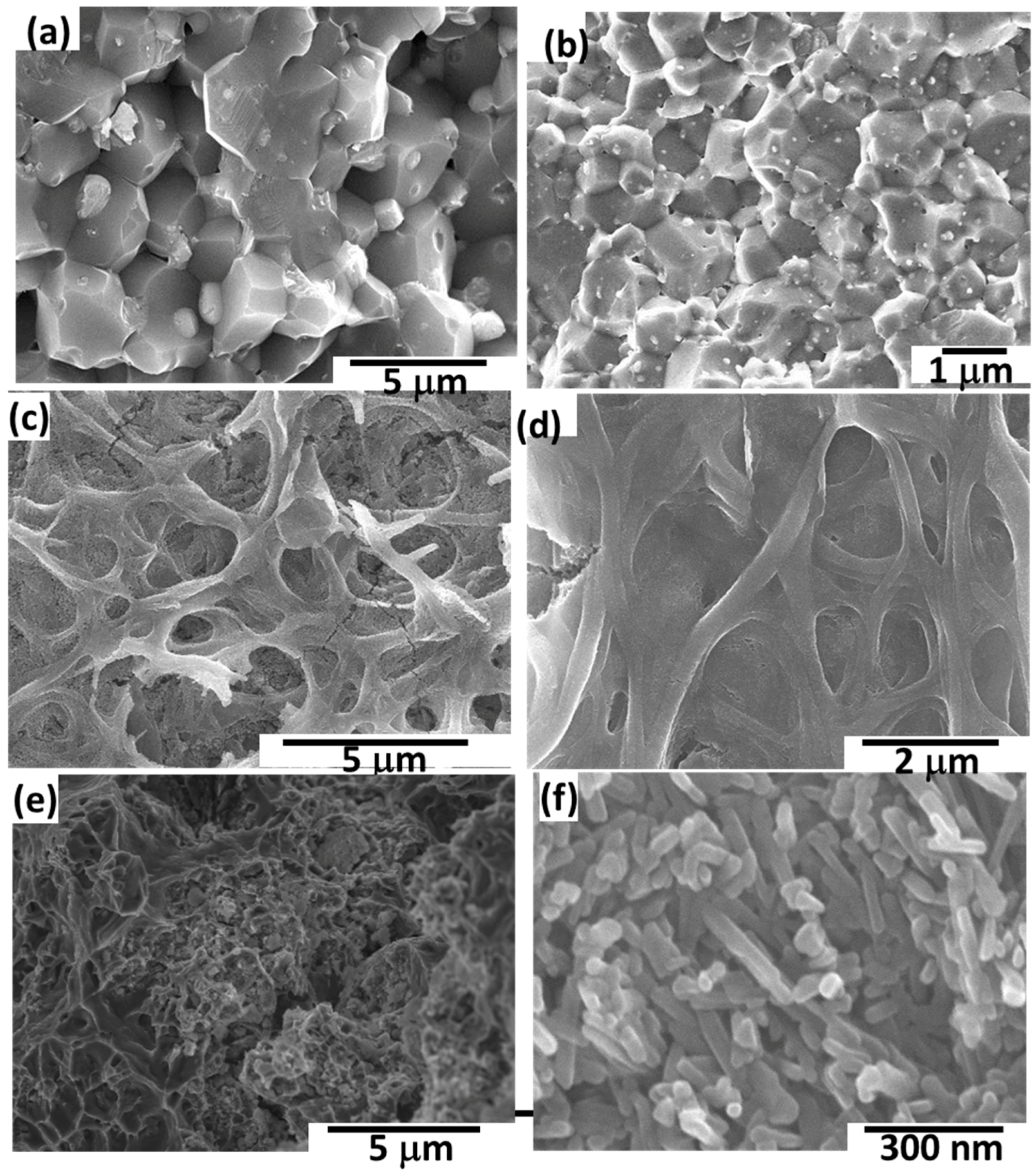

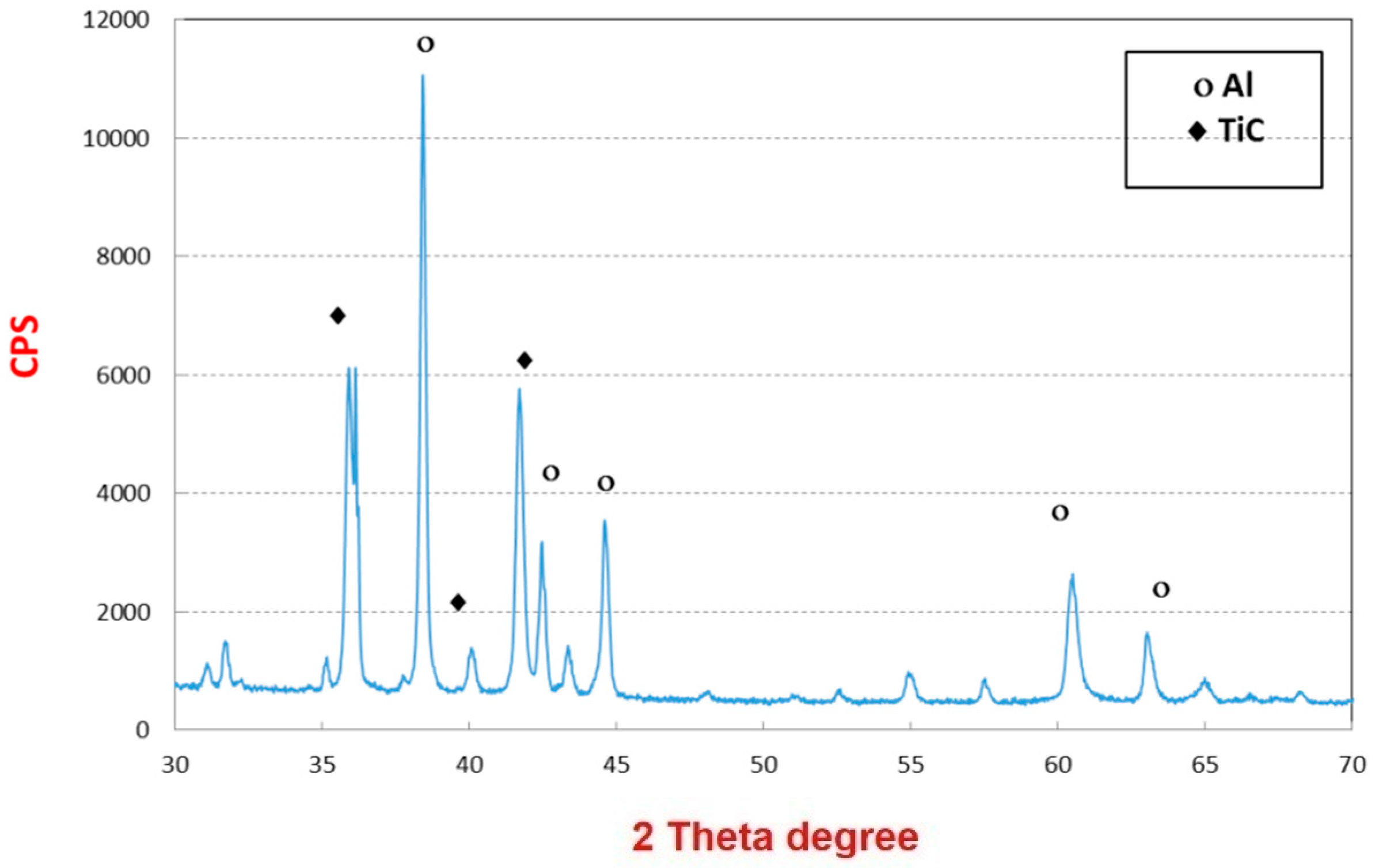

3.1. Electrospinning of the PAN/Ti Precursor Composite Nanofibers

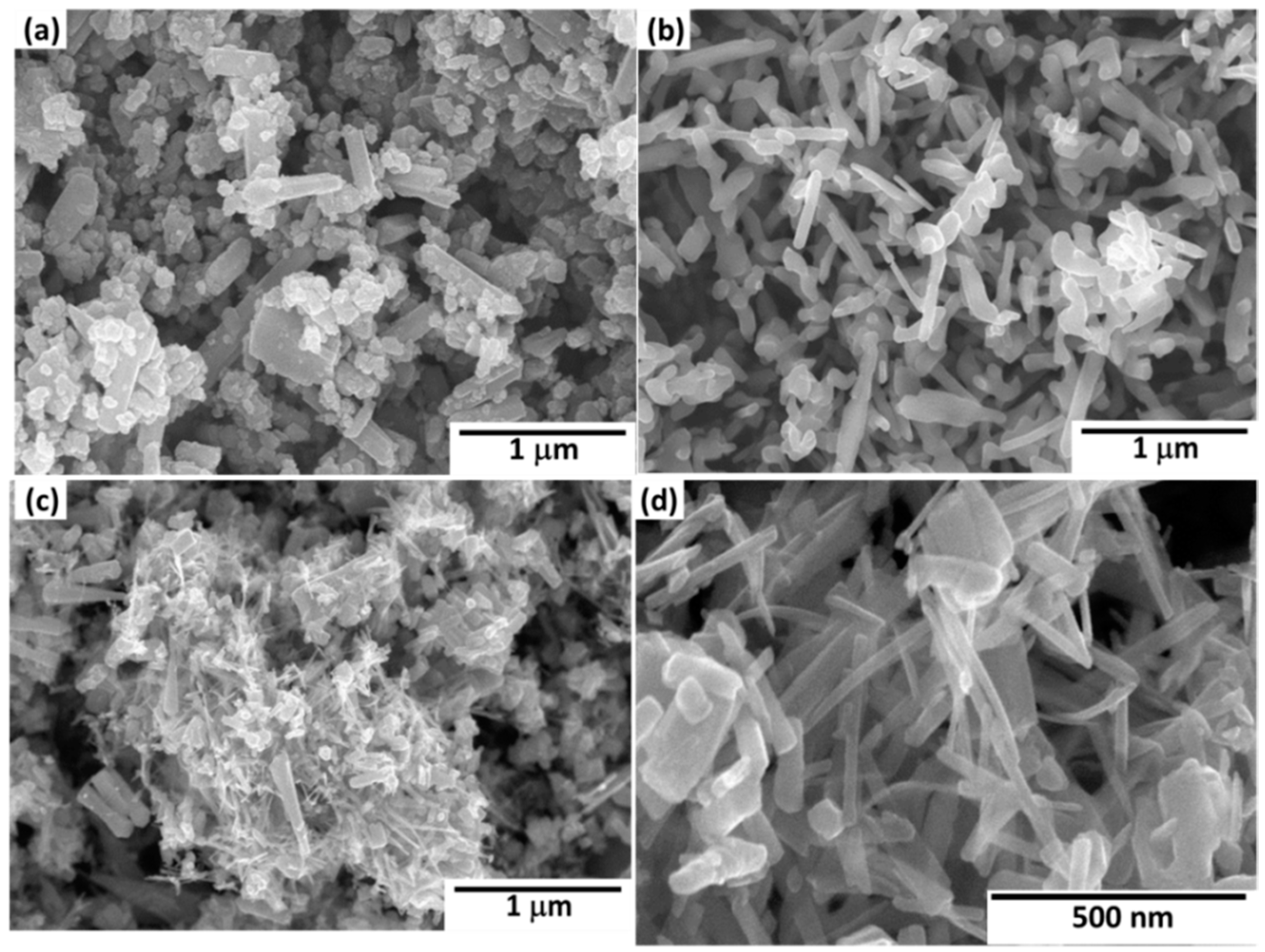

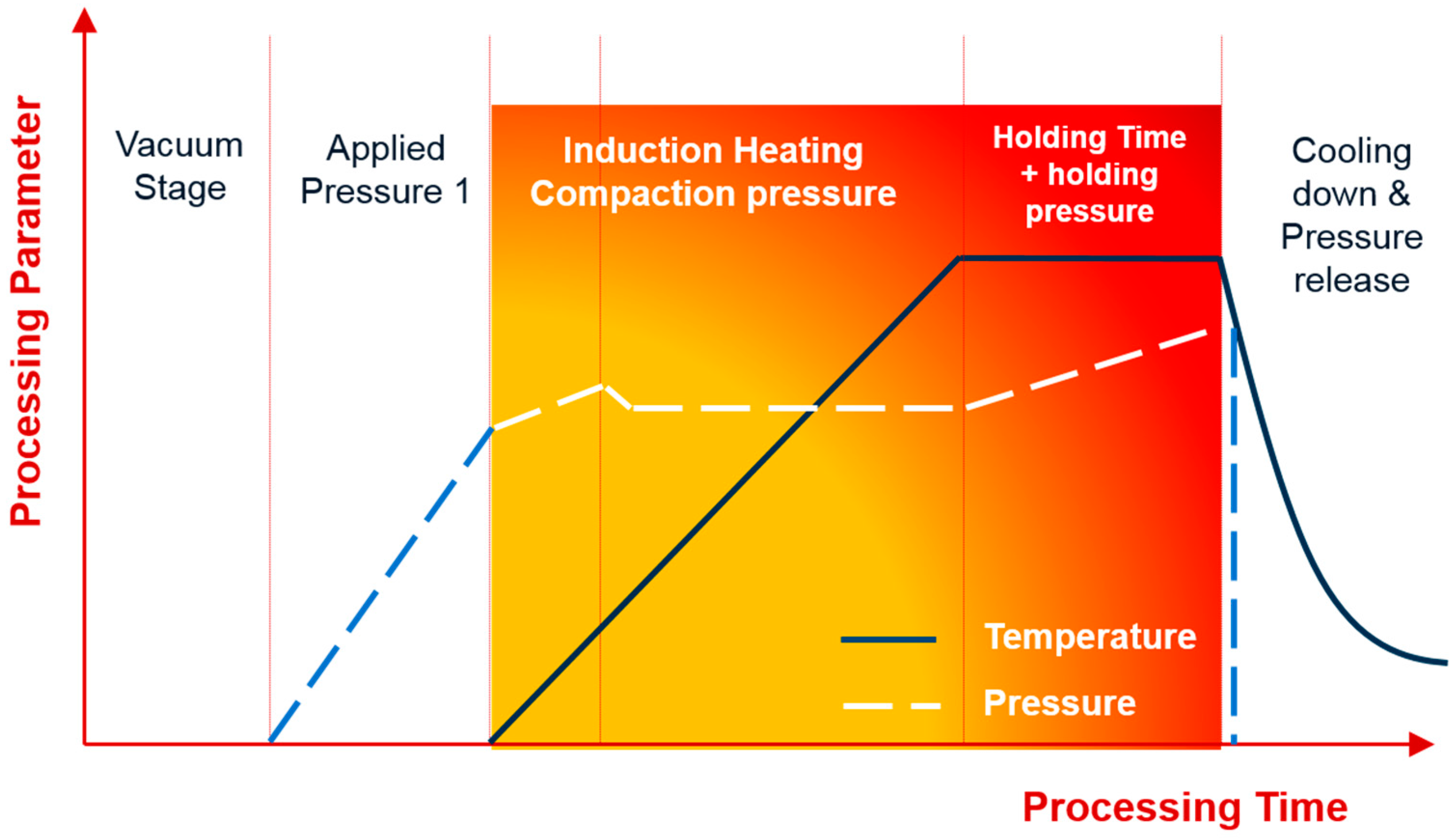

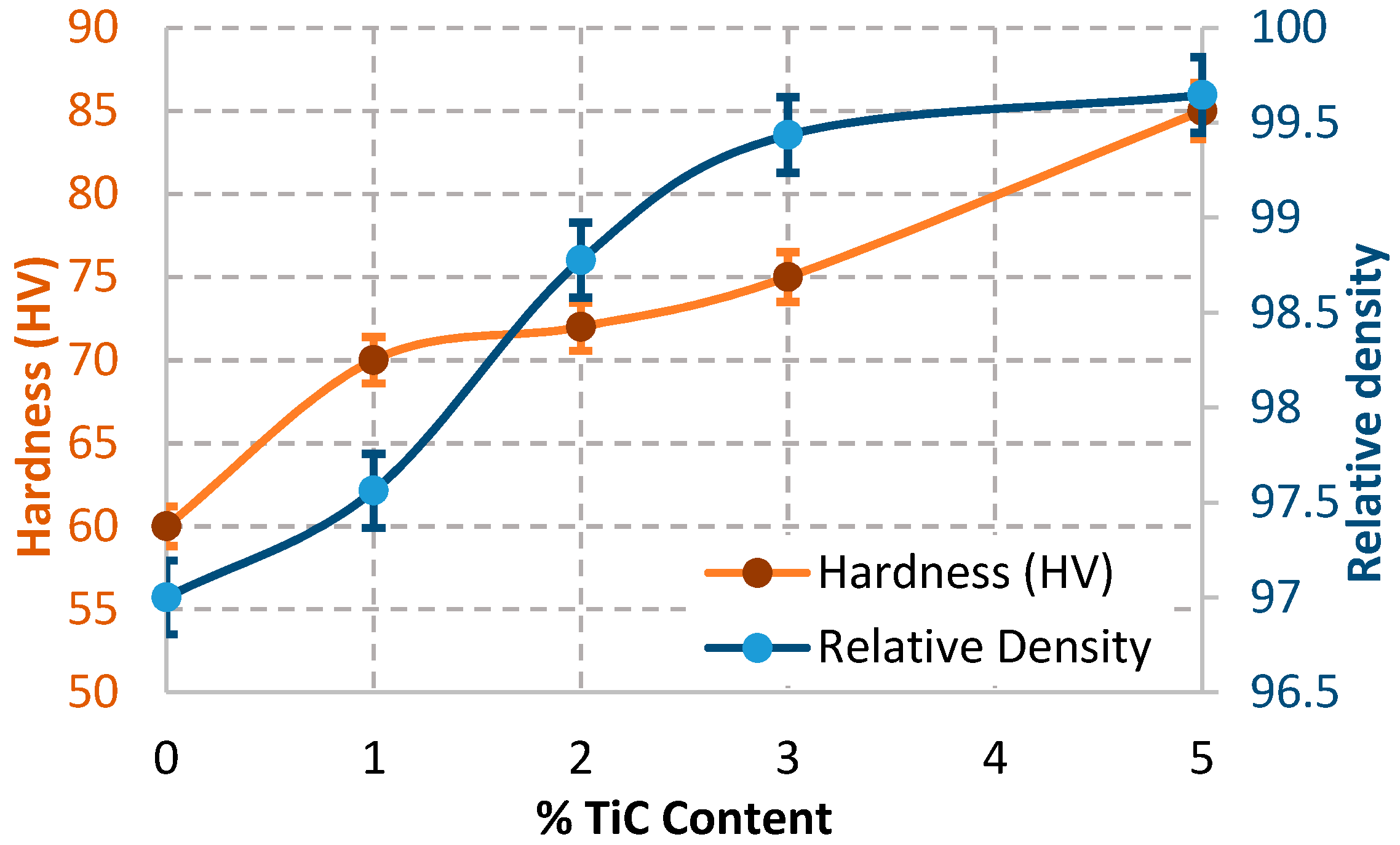

3.2. Consolidation of Al-TiC Composites

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Clyne, T.W.; Withers, P.J. An Introduction to Metal Matrix Composites; Cambridge University Press: Cambridge, UK, 1993. [Google Scholar]

- Miracle, D.B. Metal matrix composites—From science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Chawla, N.; Chawla, K. Metal Matrix Composites; Springer: New York, NY, USA, 2006. [Google Scholar]

- Huang, L.J.; Geng, L.; Peng, H.X.; Zhang, J. Room temperature tensile fracture characteristics of in situ TiBw/Ti6Al4V composites with a quasi-continuous network architecture. Scr. Mater. 2011, 64, 844–847. [Google Scholar] [CrossRef]

- Huang, L.J.; Wang, S.; Dong, Y.S.; Zhang, Y.Z.; Pan, F.; Geng, L.; Peng, H.X. Tailoring a novel network reinforcement architecture exploiting superior tensile properties of in situ TiBw/Ti composites. Mater. Sci. Eng. A 2012, 545, 187–193. [Google Scholar] [CrossRef]

- Peng, H.X.; Fan, Z.; Evans, J.R.G. Bi-continuous metal matrix composites. Mater. Sci. Eng. A 2001, 303, 37–45. [Google Scholar] [CrossRef]

- Binner, J.; Chang, H.; Higginson, R. Processing of ceramic–metal interpenetrating composites. J. Eur. Ceram. Soc. 2009, 29, 837–842. [Google Scholar] [CrossRef] [Green Version]

- Hansen, N. Strengthening of aluminium by a three-dimensional network of aluminium-oxide particles. Acta Metall. 1969, 17, 637–642. [Google Scholar] [CrossRef]

- Zhang, D.L.; Koch, C.C.; Scattergood, R.O. The role of new particle surfaces in synthesiszing bulk nanostructured metallic materials by powder metallurgy. Mater. Sci. Eng. A 2009, 516, 270–275. [Google Scholar] [CrossRef]

- Carvalho, O.; Miranda, G.; Soares, D.; Silva, F.S. CNT-reinforced aluminum composites: Processing and mechanical properties. Ciênc. Tecnol. Mater. 2013, 25, 75–78. [Google Scholar] [CrossRef]

- Zhu, X.; Zhao, Y.G.; Wu, M.; Wang, H.Y.; Jiang, Q.C. Effect of initial aluminum alloy particle size on the damage of carbon nanotubes during ball milling. Materials 2016, 9, 173. [Google Scholar] [CrossRef]

- Carvalho, O.; Miranda, G.; Soares, D.; Silva, F.S. Carbon nanotube dispersion in aluminum matrix composites—Quantification and influence on strength. Mech. Adv. Mater. Struct. 2016, 23, 66–73. [Google Scholar] [CrossRef]

- Montazeri, A.; Javadpour, J.; Khavandi, A.; Tcharkhtchi, A.; Mohajeri, A. Mechanical properties of multi-walled carbon nanotube/epoxy composites. Mater. Des. 2010, 31, 4202–4208. [Google Scholar] [CrossRef]

- Bhaduri, A.; Gopinathan, V.; Ramakrishnan, P.; Miodownik, A.P. Processing and properties of SiC particulate reinforced Al–6.2Zn–2.5Mg–1.7Cu alloy (7010) matrix composites prepared by mechanical alloying. Mater. Sci. Eng. A 1996, 221, 94–101. [Google Scholar] [CrossRef]

- Sun, Z.Q.; Zhang, D.; Li, G.B. Evaluation of dry sliding wear behavior of silicon particles reinforced aluminum matrix composites. Mater. Des. 2005, 26, 454–458. [Google Scholar]

- Slipenyuk, A.; Kuprin, V.; Milman, Y.; Goncharuk, V.; Eckert, J. Properties of P/M processed particle reinforced metal matrix composites specified by reinforcement concentration and matrix-to-reinforcement particle size ratio. Acta Mater. 2006, 54, 157–166. [Google Scholar] [CrossRef]

- Dudina, D.V.; Georgarakis, K.; Li, Y.; Aljerf, M.; LeMoulec, A.; Yavari, A.R.; Inoue, A. A magnesium alloy matrix composite reinforced with metallic glass. Compos. Sci. Technol. 2009, 69, 2734–2736. [Google Scholar] [CrossRef]

- Lee, M.H.; Kim, J.H.; Park, J.S.; Kim, J.C.; Kim, W.T.; Kim, D.H. Fabrication of Ni–Nb–Ta metallic glass reinforced Al-based alloy matrix composites by infiltration casting process. Scr. Mater. 2004, 50, 1367–1371. [Google Scholar] [CrossRef]

- Scudino, S.; Surreddi, K.B.; Sager, S.; Sakaliyska, M.; Kim, J.S.; Löser, W.; Eckert, J. Production and mechanical properties of metallic glass-reinforced Al-based metal matrix composites. J. Mater. Sci. 2008, 43, 4518–4526. [Google Scholar] [CrossRef]

- Jiang, Z.; Rhine, W.E. Preparation of TiN and TiC from a Polymer Precursor. Chem. Mater. 1991, 3, 1132–1137. [Google Scholar] [CrossRef]

- Severini, F.; Formaro, L.; Pegoraro, M.; Posca, L. Chemical modification of carbon fiber surfaces. Carbon 2002, 40, 735–741. [Google Scholar] [CrossRef]

- Paris, O.; Loidl, D.; Peterlik, H. Texture of PAN- and pitch-based carbon fibers. Carbon 2002, 40, 551–555. [Google Scholar] [CrossRef]

- Liang, C.Y.; Pearson, F.G.; Marchessault, R. The tertiary CH and CD vibrational frequencies in polyacrylonitrile and α-deutero polyacrylonitrile. Spectrochim. Acta 1961, 17, 568–571. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, J.; Wu, G. Evolution of structure and properties of PAN precursors during their conversion to carbon fibers. Carbon 2003, 41, 2805–2812. [Google Scholar]

- Laffont, L.; Monthioux, M.; Serin, V.; Mathur, R.B.; Guimon, C.; Guimon, M.F. An EELS study of the structural and chemical transformation of PAN polymer to solid carbon. Carbon 2004, 42, 2485–2494. [Google Scholar] [CrossRef]

- Chen, J.C.; Harrison, I.R. Modification of polyacrylonitrile (PAN) carbon fibre precursor via post-spinning plasticization and stretching in dimethyl formamide (DMF). Carbon 2002, 40, 25–45. [Google Scholar] [CrossRef]

- Khalil, A.; Almajid, A.A. Effect of high-frequency induction heat sintering conditions on the microstructure and mechanical properties of nanostructured magnesium/hydroxyapatite nanocomposites. Mater. Des. 2012, 36, 58–68. [Google Scholar] [CrossRef]

- Kim, S.W.; Khalil, K.A. High frequency induction heating sintering of mechanically alloyed alumina-yttria stabilized zirconia nano-bioceramics. J. Am. Ceram. Soc. 2006, 89, 1280–1285. [Google Scholar] [CrossRef]

- Khalil, K.A.; Kim, S.W. Effect of processing parameters on the mechanical and microstructural behavior of ultra-fine Al2O3- (ZrO2+8%Mol Y2O3) bioceramic, densified by high frequency induction heat sintering. Int. J. Appl. Ceram. Tec. 2006, 3, 322–330. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khalil, K.A.; Sherif, E.-S.M.; Nabawy, A.M.; Abdo, H.S.; Marzouk, W.W.; Alharbi, H.F. Titanium Carbide Nanofibers-Reinforced Aluminum Compacts, a New Strategy to Enhance Mechanical Properties. Materials 2016, 9, 399. https://doi.org/10.3390/ma9050399

Khalil KA, Sherif E-SM, Nabawy AM, Abdo HS, Marzouk WW, Alharbi HF. Titanium Carbide Nanofibers-Reinforced Aluminum Compacts, a New Strategy to Enhance Mechanical Properties. Materials. 2016; 9(5):399. https://doi.org/10.3390/ma9050399

Chicago/Turabian StyleKhalil, Khalil Abdelrazek, El-Sayed M. Sherif, A. M. Nabawy, Hany S. Abdo, Wagih W. Marzouk, and Hamad F. Alharbi. 2016. "Titanium Carbide Nanofibers-Reinforced Aluminum Compacts, a New Strategy to Enhance Mechanical Properties" Materials 9, no. 5: 399. https://doi.org/10.3390/ma9050399