Influence of Interleaved Films on the Mechanical Properties of Carbon Fiber Fabric/Polypropylene Thermoplastic Composites

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

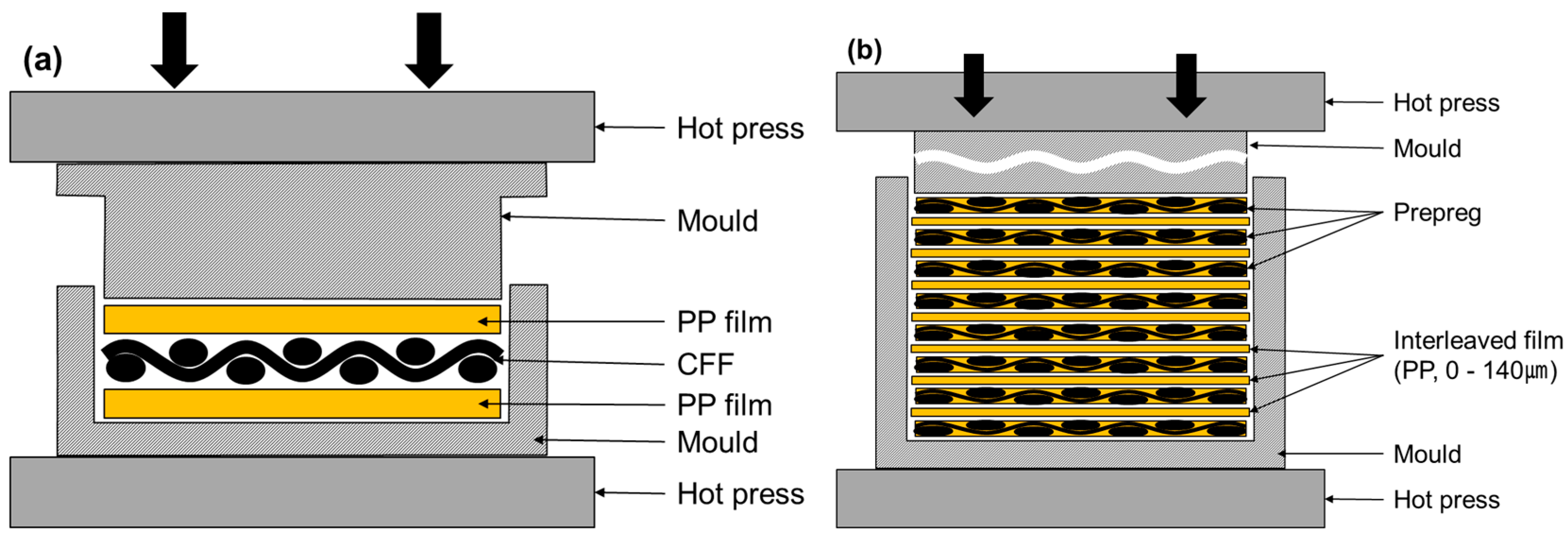

2.2. Preparation of the Prepreg and Laminated Composite

2.3. Composites Characterization

3. Results and Discussion

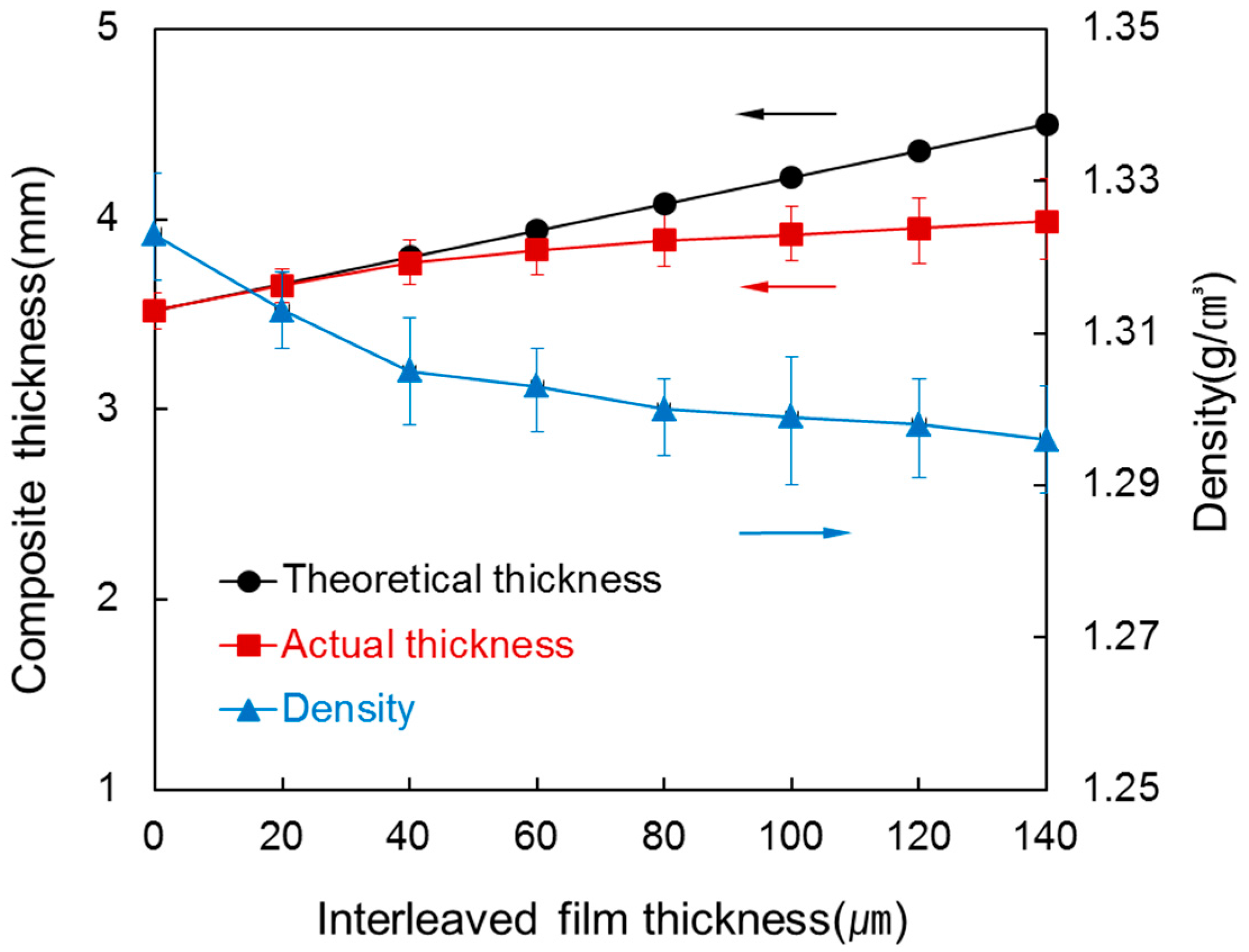

3.1. Thickness and Density

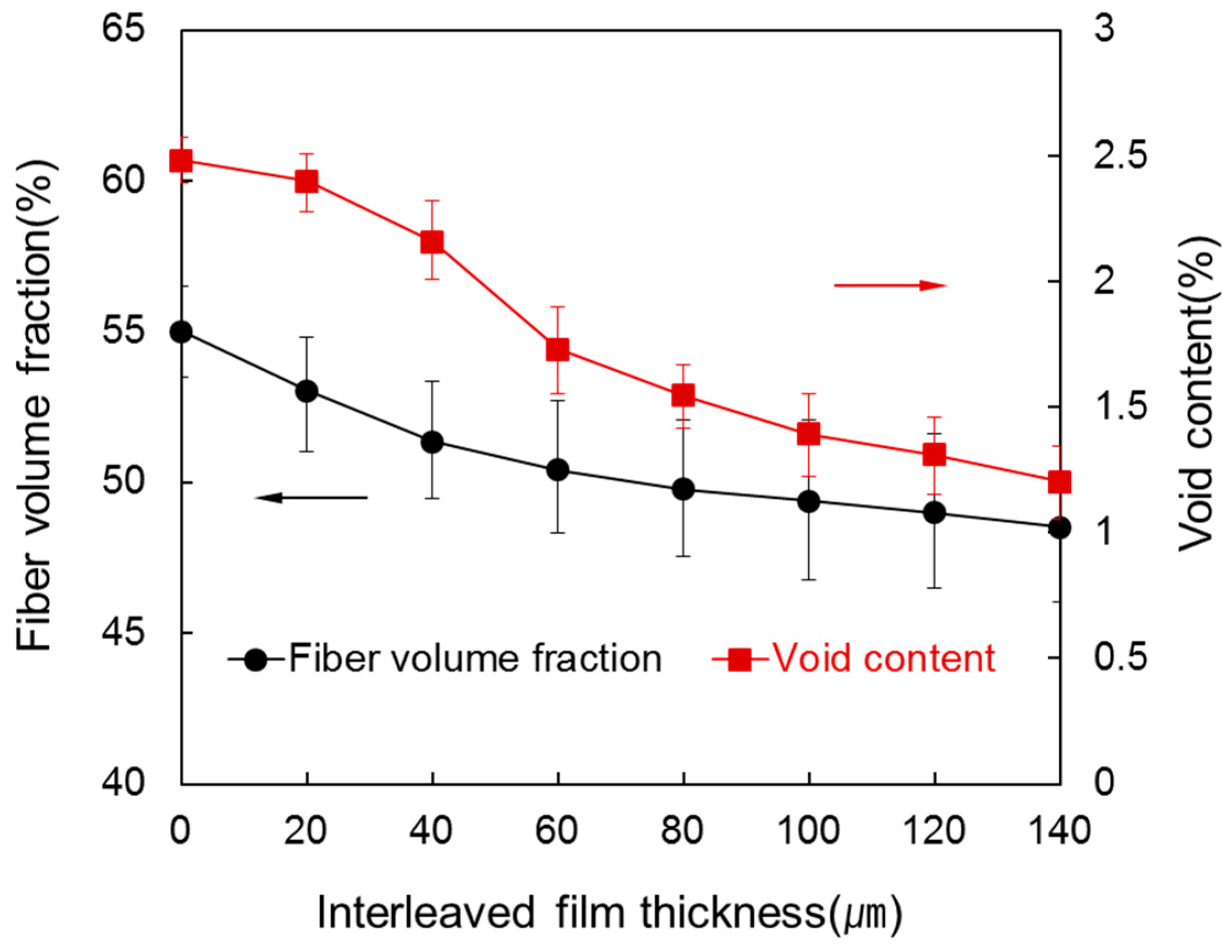

3.2. Fiber Volume Fraction and Void Content

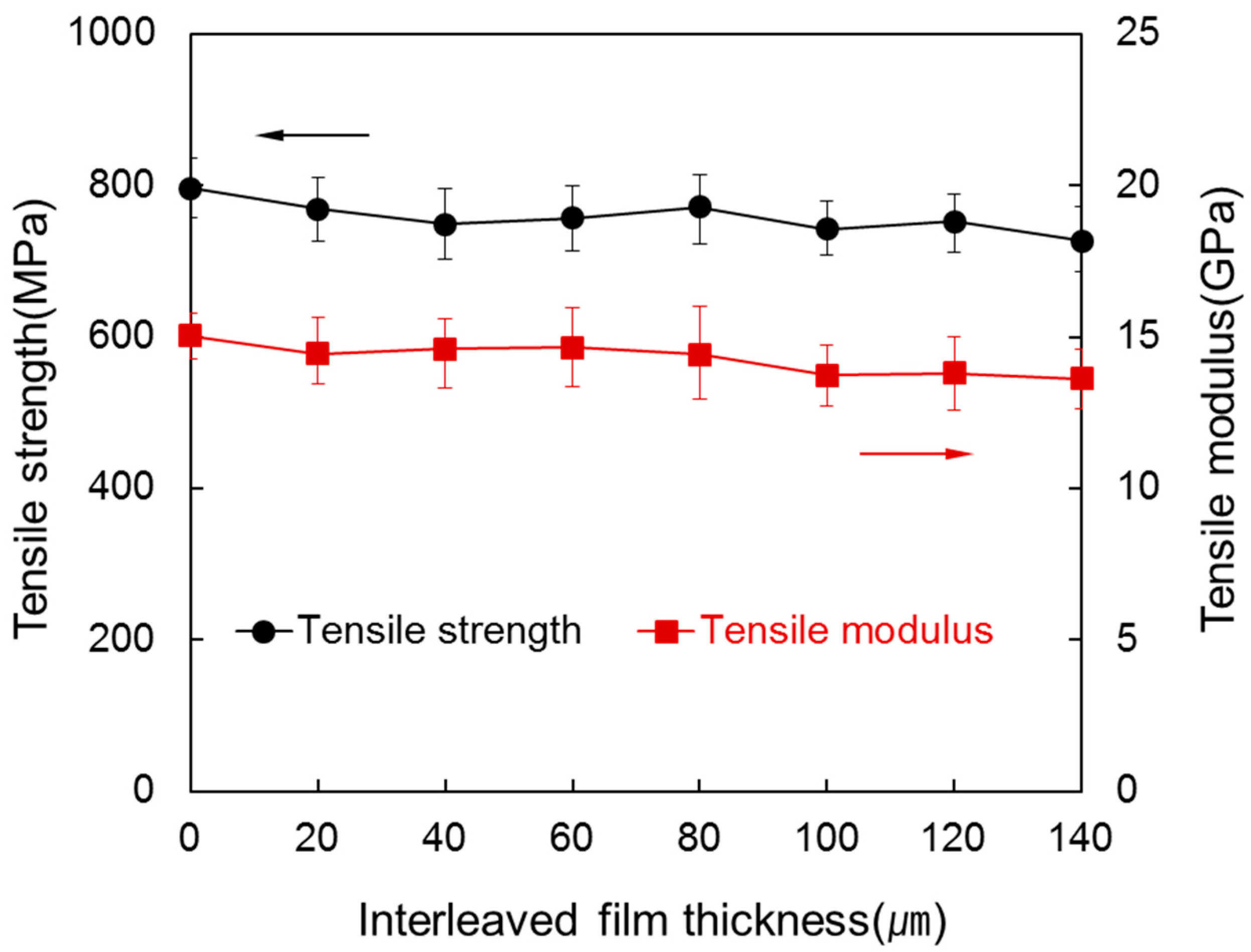

3.3. Tensile Properties

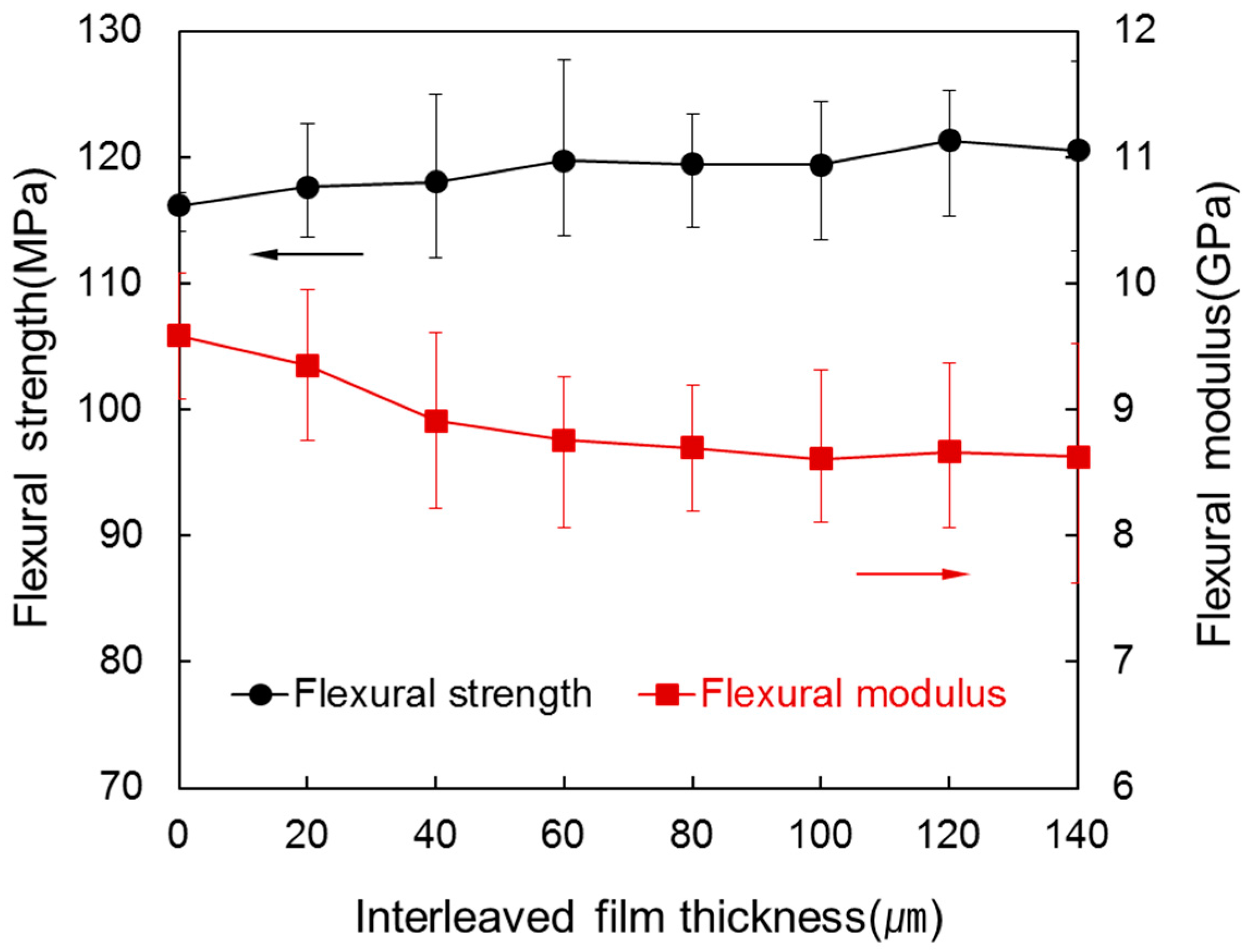

3.4. Flexural Properties

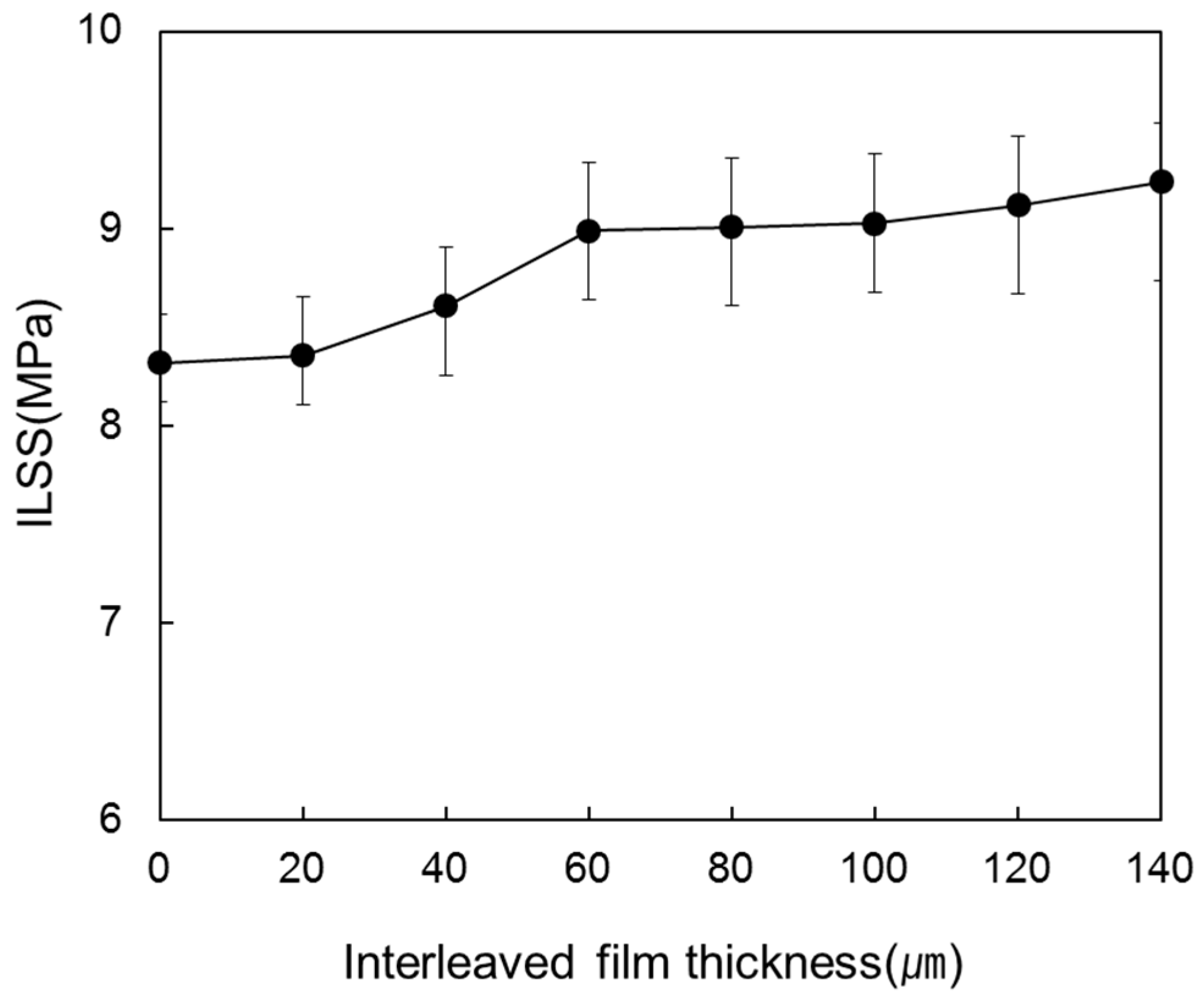

3.5. Interlaminar Shear Strength

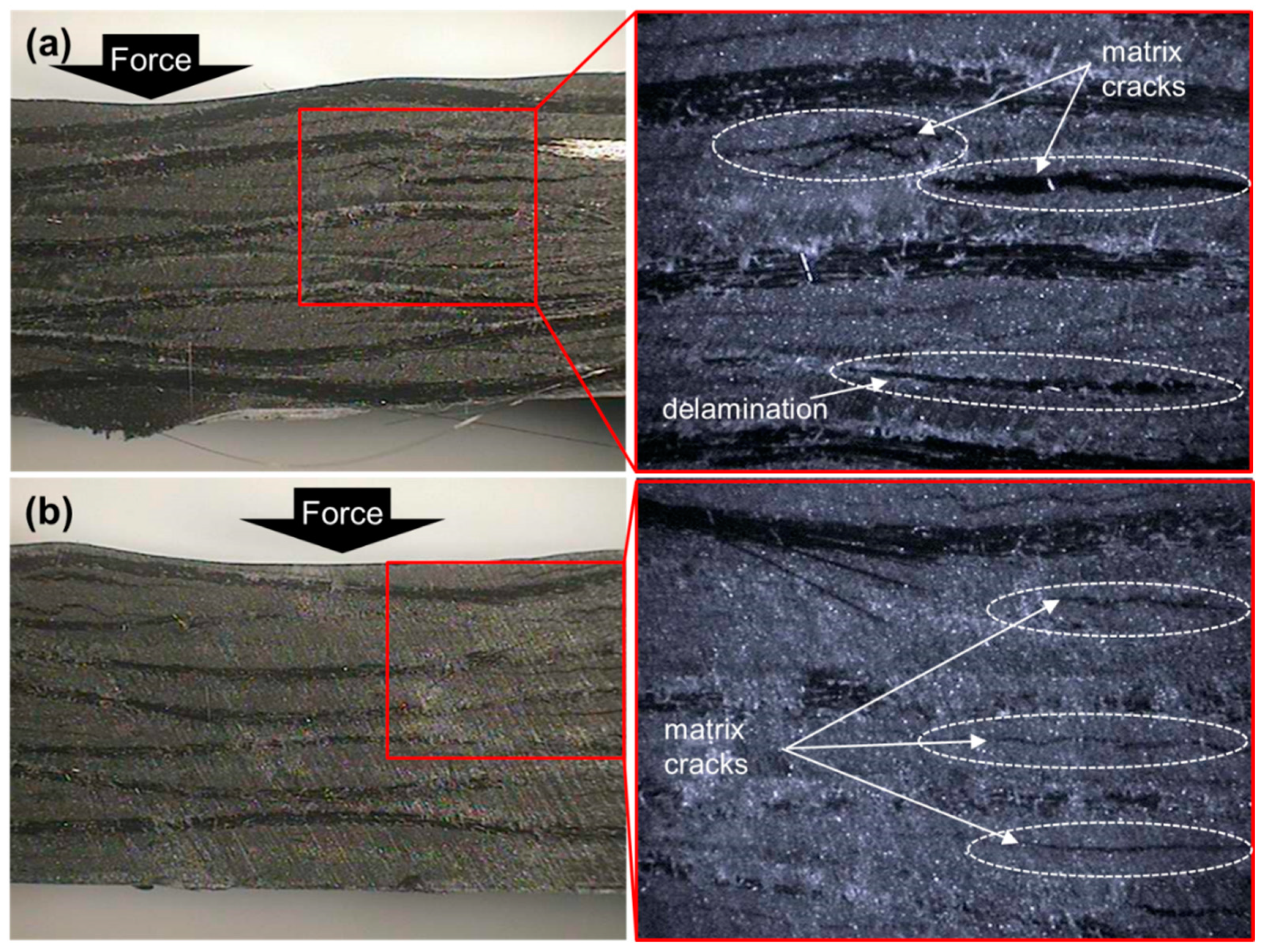

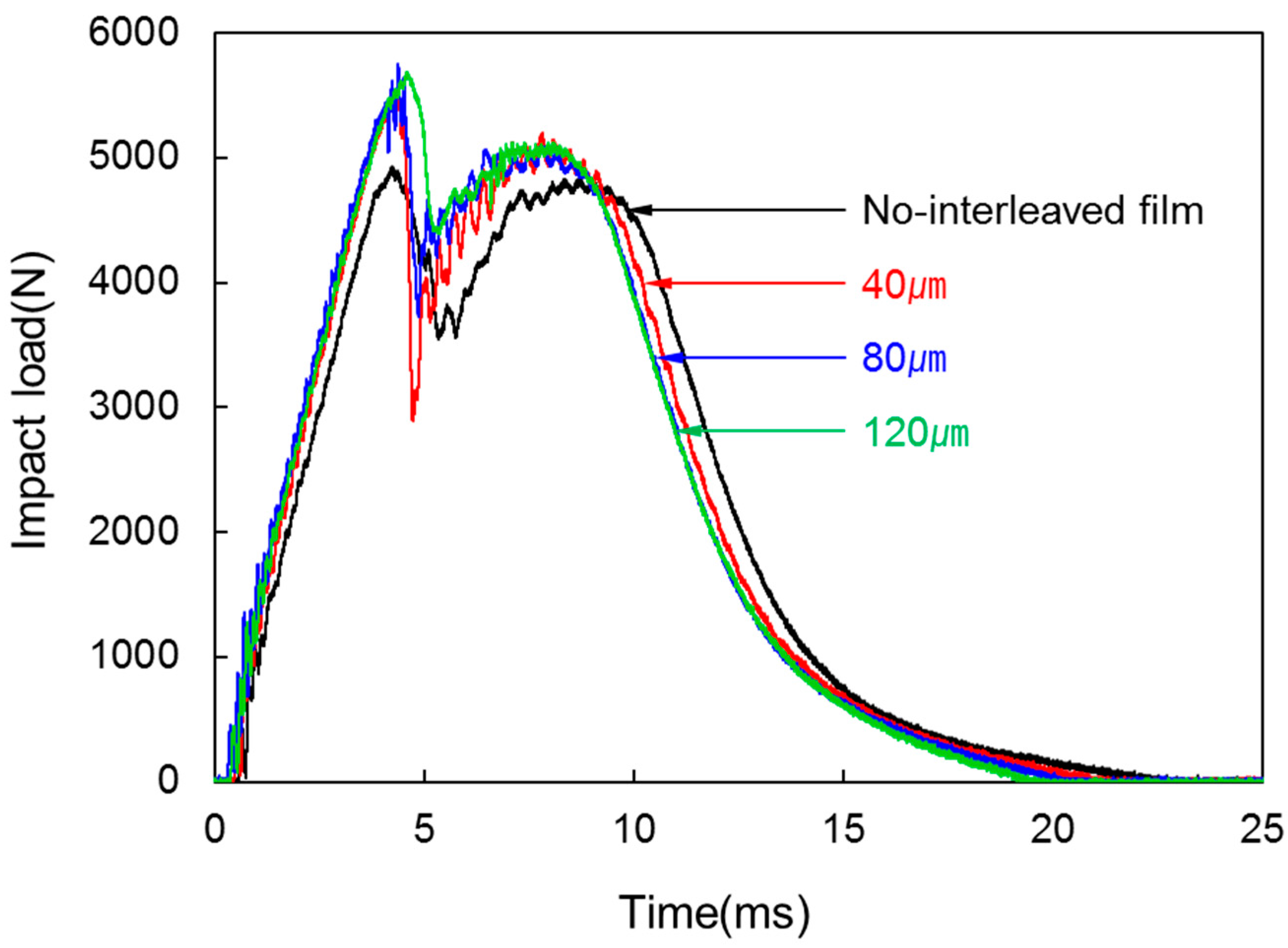

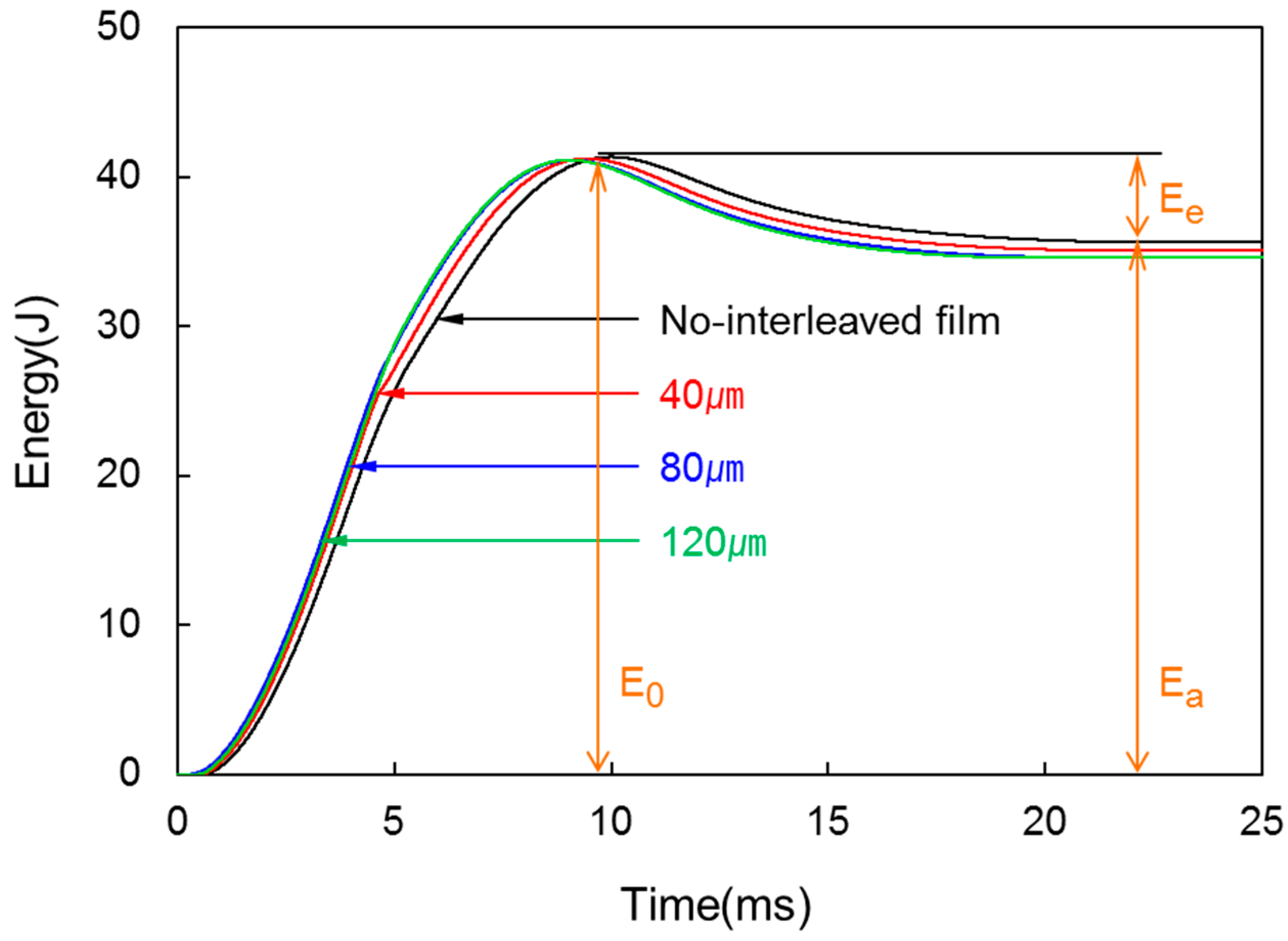

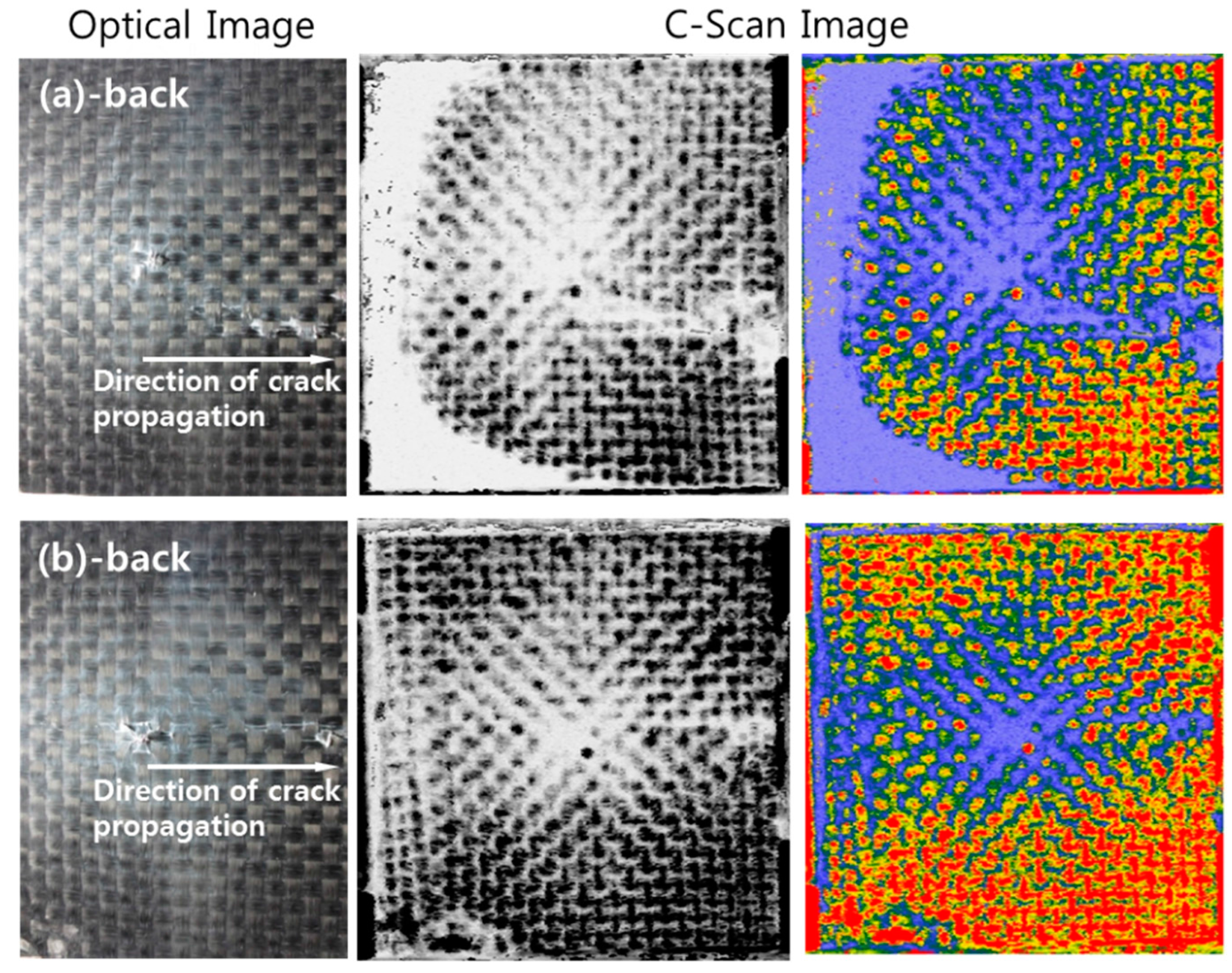

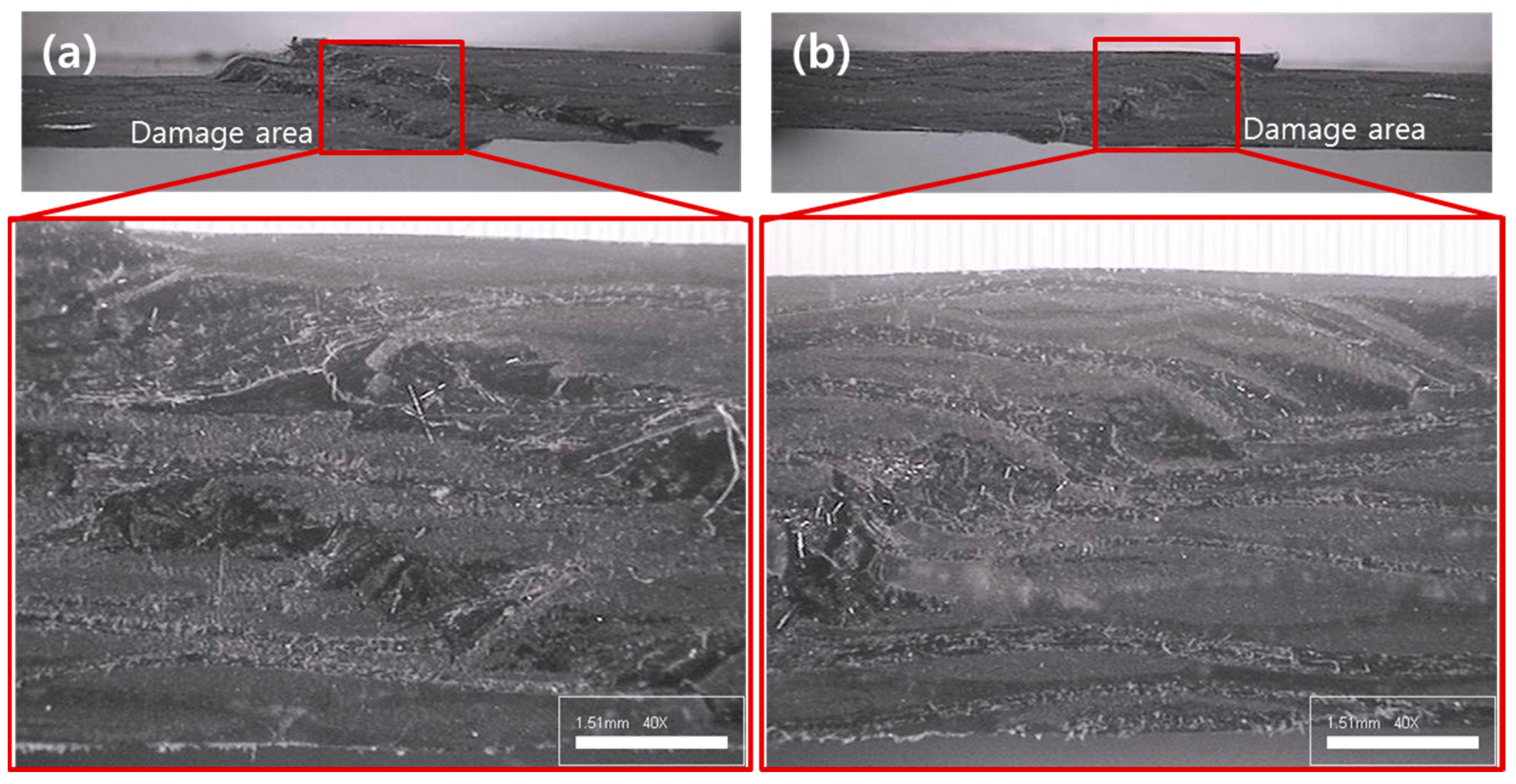

3.6. Drop Weight Impact Property

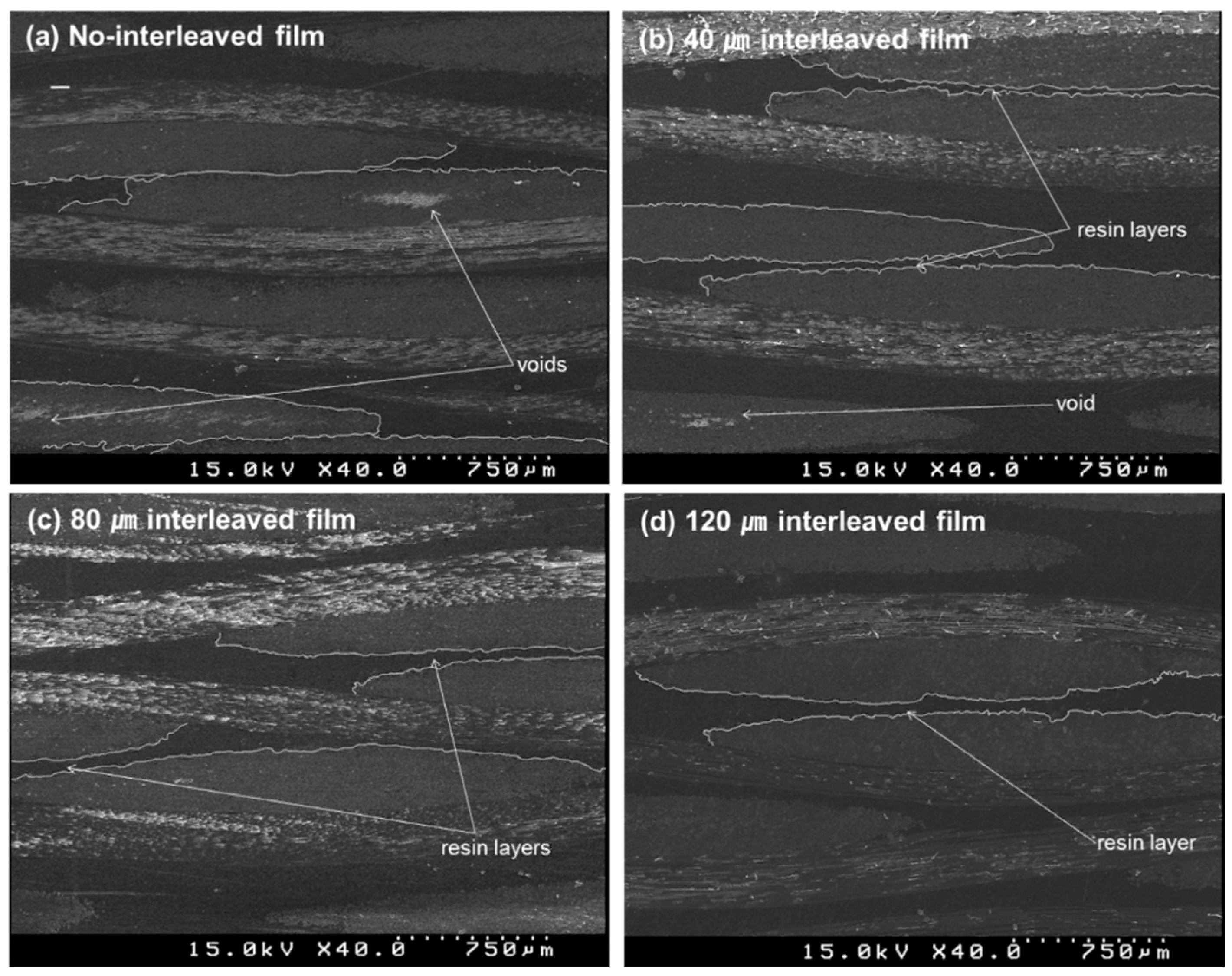

3.7. SEM Analysis

4. Conclusions

- When the interleaved film thickness was increased up to 140 µm, as the amount of squeezed out surplus resin increased, the thickness of the composite specimen increased by 13.35% from 3.52 mm to 3.99 mm. The density decreased by 2.04% from 1.32 g/cm3 to 1.29 g/cm3. In addition, there was an 11.78% decrease in the fiber volume fraction from 55.01% to 48.52% and a 51.45% decrease in void content from 2.48% to 1.20%.

- Tensile strength decreased by 8.75% from 796.82 MPa to 727.04 MPa, flexural strength slightly increased by 3.79% from 116.15 MPa to 120.58 MP and flexural modulus decreased greatly by 10.03% from 9.58 GPa to 8.62 GPa. ILSS increased by 11.06% from 8.32 MPa to 9.24 MPa. Impact load increased by 15.38% from 4932.07 N to 5690.85 N.

- In the case of the composite with inserted interleaved film, Vf decreases and then tensile strength, tensile modulus and flexural modulus decreased so that stiffness declined. However, fracture toughness improved due to an increase in ILSS and impact properties.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Morgan, P. Carbon Fibers and Their Composites; CRC Press: Boca Raton, FL, USA, 2005; pp. 533–544. [Google Scholar]

- EL-Dessouky, H.M.; Lawrence, C.A. Ultra-lightweight carbon fibre/thermoplastic composite material using spread tow technology. Compos. Part B 2013, 50, 91–97. [Google Scholar] [CrossRef]

- Hamada, H.; Fujihara, K.; Harada, A. The influence of sizing conditions on bending properties of continuous glass fiber reinforced polypropylene composites. Compos. Part A 2000, 31, 979–990. [Google Scholar] [CrossRef]

- Han, S.H.; Oh, H.J.; Kim, S.S. Evaluation of fiber surface treatment on the interfacial behavior of carbon fiber-reinforced polypropylene composites. Compos. Part B 2014, 60, 98–105. [Google Scholar] [CrossRef]

- Russo, P.; Acierno, D.; Simeoli, G.; Iannace, S.; Sorrentino, L. Flexural and impact response of woven glass fiber fabric/polypropylene composites. Compos. Part B 2013, 54, 415–421. [Google Scholar] [CrossRef]

- Goodman, K.E.; Loos, A.C. Thermoplastic prepreg manufacture. J. Thermoplast. Compos. Mater. 1990, 3, 34–40. [Google Scholar] [CrossRef]

- Long, A.C. Design and Manufacture of Textile Composites; CRC Press: Boca Raton, FL, USA, 2005; pp. 205–217. [Google Scholar]

- Peltonen, P.; Lahteenkorva, K.; Paakkonen, E.J.; Jarvela, P.K.; Törmälä, P. The influence of melt impregnation parameters on the degree of impregnation of a polypropylene/glass fiber prepreg. J. Thermoplast. Compos. Mater. 1992, 5, 318–343. [Google Scholar] [CrossRef]

- Kim, J.; Shioya, M.; Kobayashi, H.; Kaneko, J.; Kido, M. Mechanical properties of woven laminates and felt composites using carbon fibers. Part 1: In-plane properties. Compos. Sci. Technol. 2004, 64, 2221–2229. [Google Scholar] [CrossRef]

- Saez, S.S.; Barbero, E.; Zaera, R.; Navarro, C. Compression after impact of thin composite laminates. Compos. Sci. Technol. 2005, 65, 1911–1919. [Google Scholar] [CrossRef]

- Sela, N.; Ishai, O. Interlaminar fracture toughness and toughening of laminated composite materials: A review. Composites 1989, 20, 423–425. [Google Scholar] [CrossRef]

- Soutis, C. Fibre reinforced composites in aircraft construction. Prog. Aerosp. Sci. 2005, 41, 143–151. [Google Scholar] [CrossRef]

- Gao, C.; Yu, L.; Liu, H.; Chen, L. Development of self-reinforced polymer composites. Prog. Polym. Sci. 2012, 37, 767–780. [Google Scholar] [CrossRef]

- Mouritz, A.; Leong, K.; Herszberg, I. A review of the effect of stitching on the in-plane mechanical properties of fiber-reinforced polymer composites. Compos. Part A 1997, 28, 979–991. [Google Scholar] [CrossRef]

- Dransfield, K.; Baillie, C.; Mai, Y. Improving the delamination resistance of CFRP by stitching—A review. Compos. Sci. Technol. 1994, 50, 305–317. [Google Scholar] [CrossRef]

- Karbhari, V.; Locurcio, A. Progressive crush response of hybrid felt/fabric composite structures. J. Reinf. Plast. Comp. 1997, 16, 243–269. [Google Scholar]

- Wicks, S.; Villoria, R.G.; Wardle, B.L. Interlaminar and intralaminar reinforcement of composite laminates with aligned carbon nanotubes. Compos. Sci. Technol. 2010, 70, 20–28. [Google Scholar] [CrossRef]

- Garcia, E.J.; Wardle, B.L.; Hart, A.J. Joining prepreg composite interfaces with aligned carbon nanotubes. Compos. Part A 2008, 39, 1065–1070. [Google Scholar] [CrossRef]

- Sohn, M.S.; Hu, X.Z.; Kim, J.K.; Walker, L. Impact damage characterisation of carbon fibre/epoxy composites with multi-layer reinforcement. Compos. Part B 2000, 31, 681–691. [Google Scholar] [CrossRef]

- Duarte, A.; Herszberg, I.; Paton, R. Impact resistance and tolerance of interleaved tape laminates. Compos. Struct. 1999, 47, 753–758. [Google Scholar] [CrossRef]

- Hine, P.J.; Ey, R.H.; Ward, I.M. The use of interleaved films for optimising the production and properties of hot compacted, self reinforced polymer composites. Compos. Sci. Technol. 2008, 68, 1413–1421. [Google Scholar] [CrossRef]

- Taketa, I.; Ustarroz, J.; Gorbatikh, L.; Lomov, S.V.; Verpoest, I. Interply hybrid composites with carbon fiber reinforced polypropylene and self-reinforced polypropylene. Compos. Part A 2010, 41, 927–932. [Google Scholar] [CrossRef]

- Swolfs, Y.; Crauwels, L.; Van Breda, E.; Gorbatikh, L.; Hine, P.; Ward, I.; Verpoest, I. Tensile behaviour of intralayer hybrid composites of carbon fibre and self-reinforced polypropylene. Compos. Part A 2014, 59, 78–84. [Google Scholar] [CrossRef]

- Kishi, H.; Kuwata, M.; Matsuda, S.; Asami, T.; Murakami, A. Damping properties of thermoplastic-elastomer interleaved carbon fiber-reinforced epoxy composites. Compos. Sci. Technol. 2004, 64, 2517–2523. [Google Scholar] [CrossRef]

- Matsuda, S.; Hojo, M.; Ochiai, S.; Murakami, A.; Akimoto, H.; Ando, M. Effect of ionomer thickness on mode Ι interlaminar fracture toughness for ionomer toughened CFRP. Compos. Part A 1999, 30, 1311–1319. [Google Scholar] [CrossRef]

- Tanimoto, T. Interleaving methodology for property tailoring of CFRP laminates. Compos. Interface 2002, 1, 25–39. [Google Scholar] [CrossRef]

- Yadav, S.N.; Kumar, V.; Verma, S.K. Facture toughness behavior of carbon fibre epoxy composite with Kevlar reinforced interleave. Mater. Sci. Eng. B Adv. 2006, 132, 108–112. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillo, J.; Valente, M.; Valente, T.; Cioffi, S.; Iannace, S.; Sorrentino, L. Effect of basalt fiber hybridization on the impact behavior under low impact velocity of glass/basalt woven fabric/epoxy resin composites. Compos. Part A 2013, 47, 109–123. [Google Scholar] [CrossRef]

- Yasaee, M.; Bond, I.P.; Trask, R.S.; Greenhalgh, E.S. Damage control using discrete thermoplastic film inserts. Compos. Part A 2012, 43, 978–989. [Google Scholar] [CrossRef]

- Yasaee, M.; Killock, C.; Hartley, J.; Bond, I.P. Control of compressive fatigue delamination propagation of impact damaged composites using discrete thermoplastic interleaves. Appl. Compos. Mater. 2015, 22, 559–572. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Ferreira, J.A.M.; Santos, P.; Richardson, M.O.W.; Santos, J.B. Impact response of Kevlar composites with filled epoxy matrix. Compos. Struct. 2012, 94, 3520–3528. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.W.; Lee, J.S. Influence of Interleaved Films on the Mechanical Properties of Carbon Fiber Fabric/Polypropylene Thermoplastic Composites. Materials 2016, 9, 344. https://doi.org/10.3390/ma9050344

Kim JW, Lee JS. Influence of Interleaved Films on the Mechanical Properties of Carbon Fiber Fabric/Polypropylene Thermoplastic Composites. Materials. 2016; 9(5):344. https://doi.org/10.3390/ma9050344

Chicago/Turabian StyleKim, Jong Won, and Joon Seok Lee. 2016. "Influence of Interleaved Films on the Mechanical Properties of Carbon Fiber Fabric/Polypropylene Thermoplastic Composites" Materials 9, no. 5: 344. https://doi.org/10.3390/ma9050344