Nanomechanical Behavior of Multi-Walled Carbon Nanotubes Particulate Reinforced Aluminum Nanocomposites Prepared by Ball Milling

Abstract

:1. Introduction

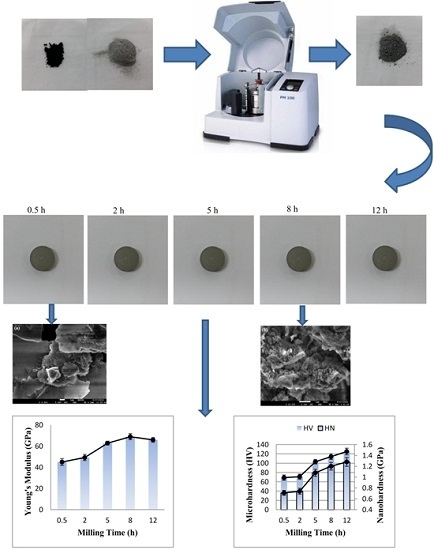

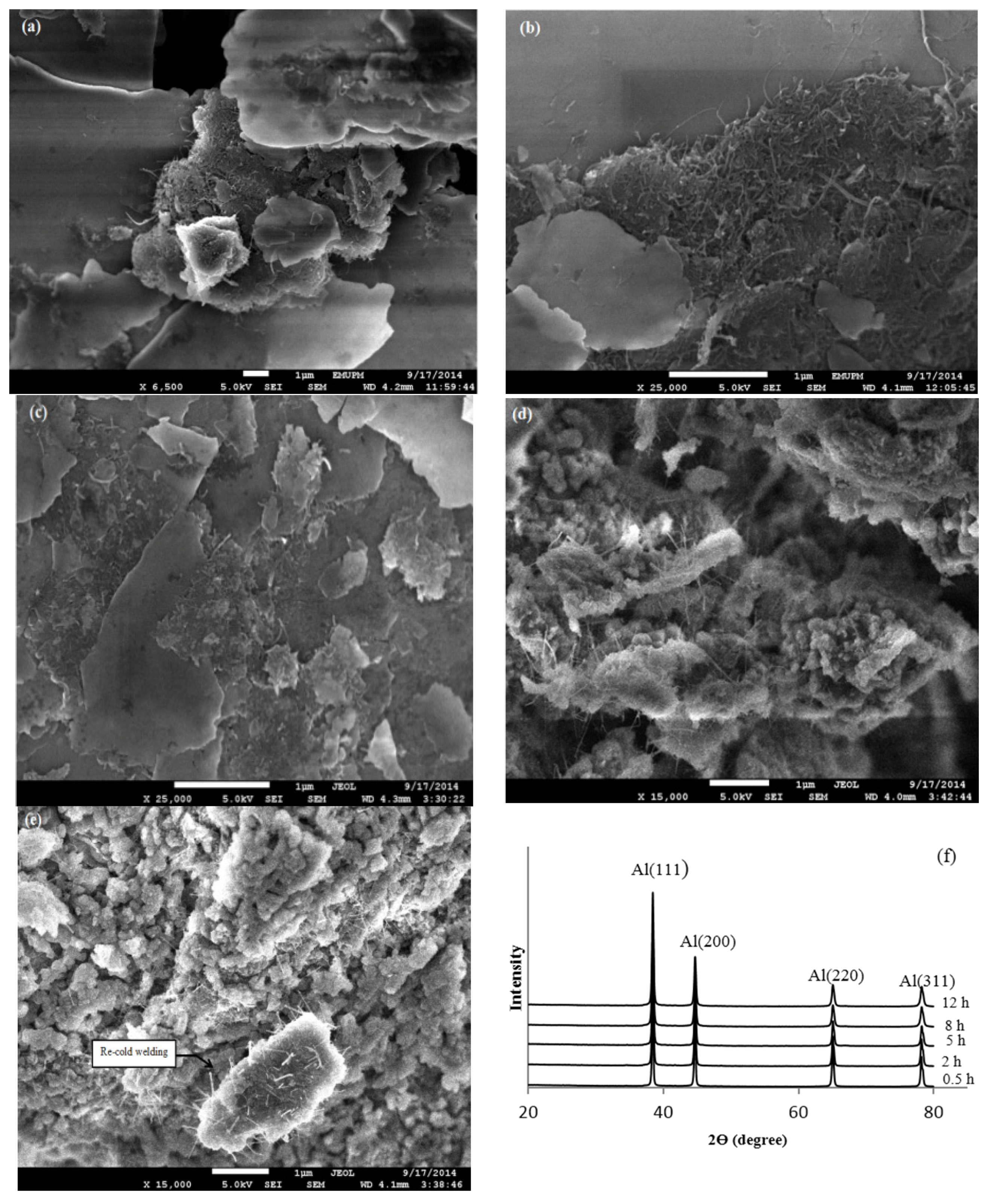

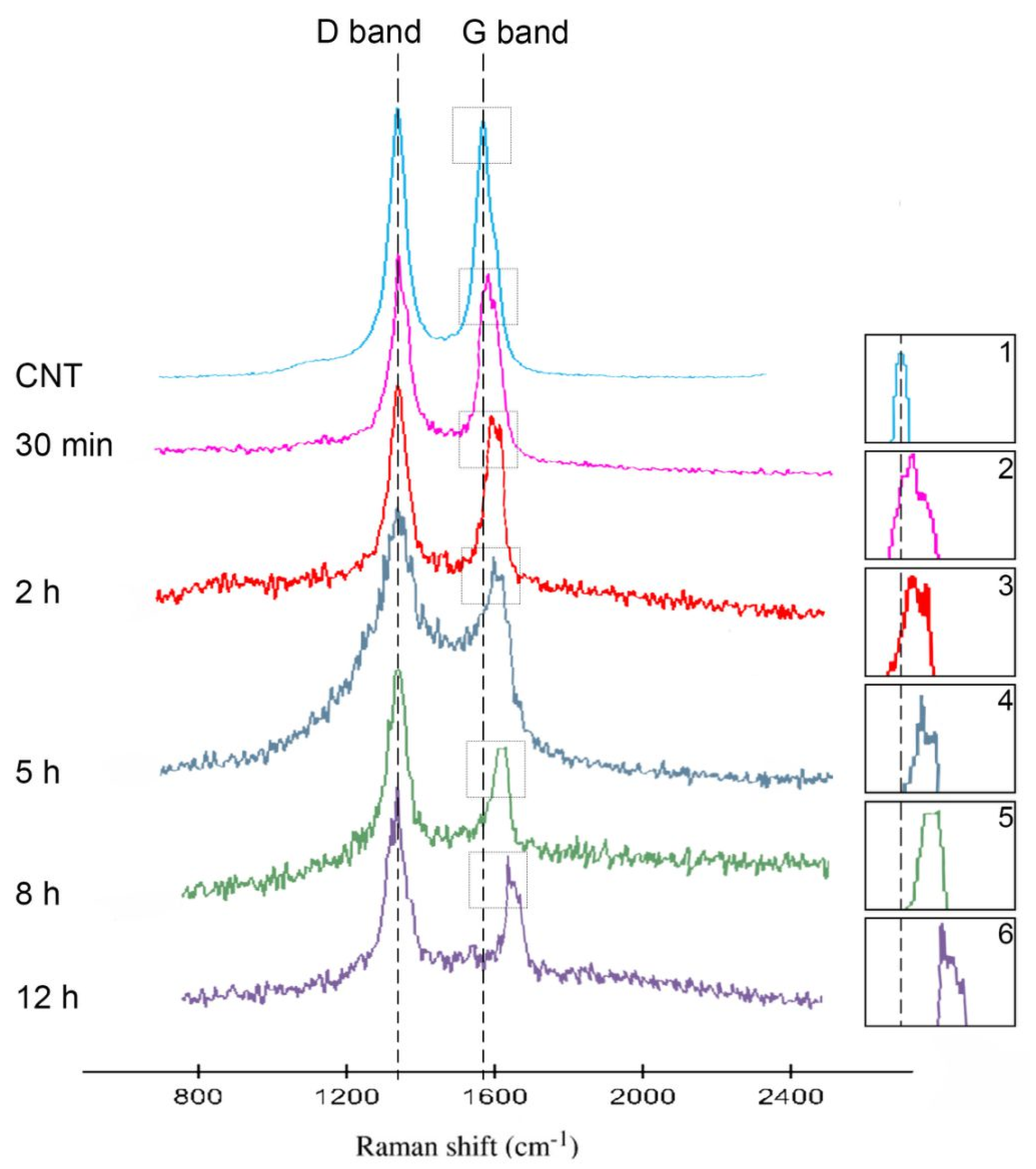

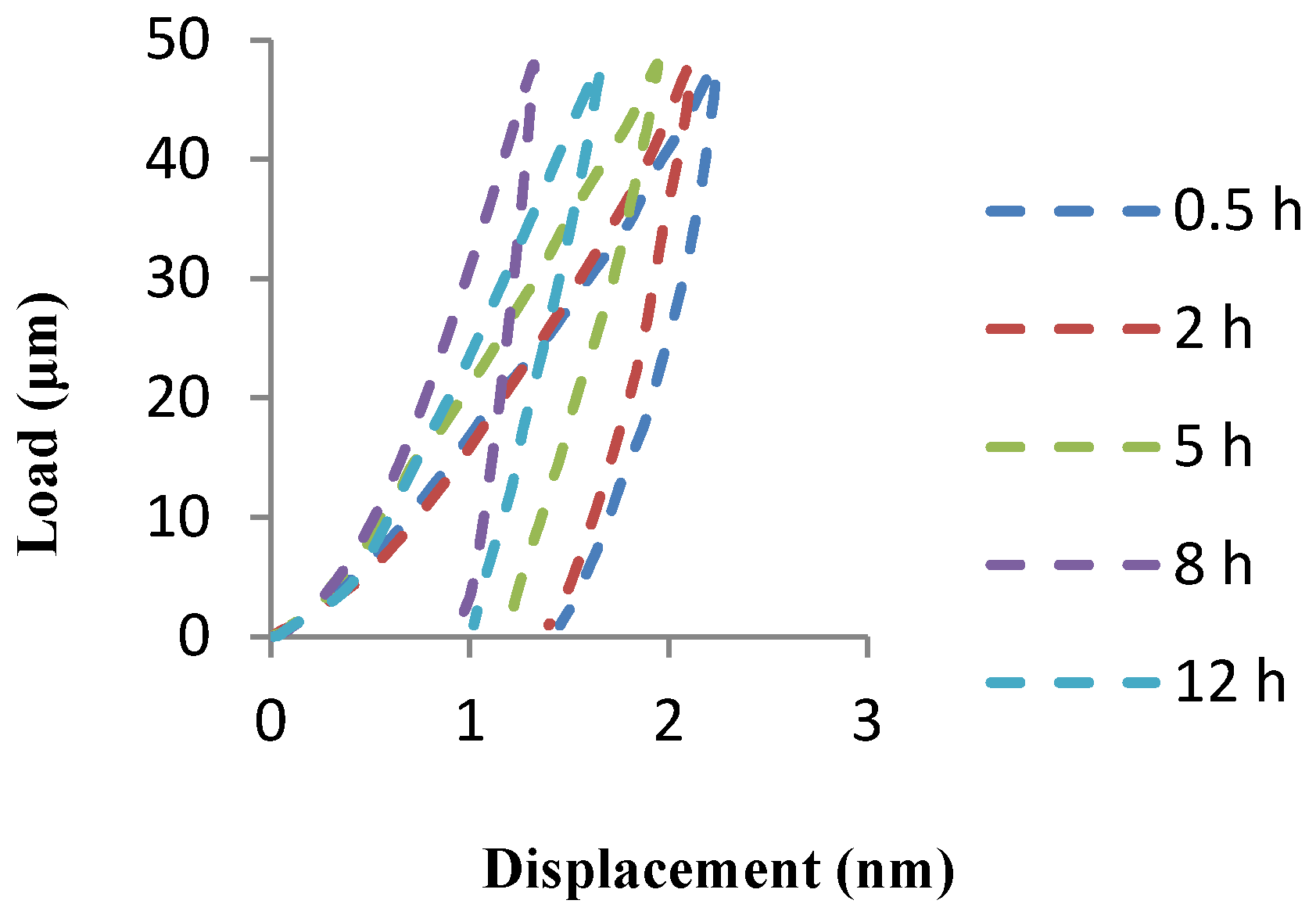

2. Results and Discussion

3. Materials and Methods

3.1. Materials

3.2. Microstructural Characterization

3.3. Hardness and Nanoindentation Measurements

4. Conclusions

- Dispersion of CNTs within the matrix plays a prominent role on enhancement of mechanical properties of nanocomposite specimens depending on the degree of dispersion within matrix.

- Uniform dispersion of CNTs at longer milling time along with grain refining enhances the elastic modulus (+23%) and hardness (+44%) of nanocomposite specimens. While, the presence of CNT clusters at shorter aging time contributes to the lower values of hardness and Young’s modulus.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kainer, K.U. Metal Matrix Composites: Custom-Made Materials for Automotive and Aerospace Engineering; John Wiley & Sons: New York, NY, USA, 2006. [Google Scholar]

- Rohatgi, P.; Schultz, B. Light weight metal matrix nanocomposites—Stretching the boundaries of metals. Mater. Lett. 2007, 2, 16–19. [Google Scholar]

- Macke, A.; Schultz, B.F.; Rohatgi, P. Metal matrix composites offer the automotive industry an opportunity to reduce vehicle weight, improve performance. Adv. Mater. Process. 2012, 170, 19–23. [Google Scholar]

- Surappa, M.K. Aluminum matrix composites: Challenges and opportunities. Sadhana 2003, 28, 319–334. [Google Scholar] [CrossRef]

- Esawi, A.M.K.; Morsi, K.; Sayed, A.; Taher, M.; Lanka, S. Effect of carbon nanotube (CNT) content on the mechanical properties of CNT-reinforced aluminum composites. Compos. A 2010, 42, 2237–2241. [Google Scholar]

- Raviathul, B.M.; Srivastava, V.C.; Mukhopadhyay, N.K. Microstructural characteristics and mechanical properties of carbon nanotube reinforced aluminum alloy composites produced by ball milling. Mater. Des. 2014, 64, 542–549. [Google Scholar]

- Bakshi, S.R.; Keshri, A.K.; Agarwal, A. A comparison of mechanical and wear properties of plasma sprayed carbon nanotube reinforced aluminum composites at nano and macro scale. Mater. Sci. Eng. A 2011, 528, 3375–3384. [Google Scholar] [CrossRef]

- Casati, R.; Vedani, M. Metal matrix composites reinforced by nanoparticles—A review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Ostovan, F.; Matori, K.A.; Toozandehjani, M.; Oskoueian, A.; Yusoff, H.M.; Yunus, R.; Ariff, A.H.M.; Quah, H.J.; Lim, W.F. Effects of CNTs content and milling time on mechanical behavior of MWCNT-reinforced aluminum nanocomposites. Mater. Chem. Phys. 2015, 166, 160–166. [Google Scholar] [CrossRef]

- Suryanarayana, C. Recent developments in mechanical alloying. Rev. Adv. Mater. Sci. 2008, 18, 203–211. [Google Scholar]

- Razavi, H.Z.; Hafizpour, H.R.; Simchi, A. An investigation on the compressibility of aluminum/nano-alumina composite powder prepared by blending and mechanical milling. Mater. Sci. Eng. A 2007, 454–455, 89–98. [Google Scholar] [CrossRef]

- Ostovan, F.; Matori, K.A.; Toozandehjani, M.; Oskoueian, A.; Yusoff, H.M.; Yunus, R.; Ariff, A.H.M. Microstructural evaluation of ball-milled nano Al2O3 particulate-reinforced aluminum matrix composite powders. Int. J. Mater. Res. 2015, 106, 636–640. [Google Scholar]

- Fogagnolo, J.B.; Velasco, F.; Robert, M.H.; Torralba, J.M. Effect of mechanical alloying on the morphology, microstructure and properties of aluminum matrix composite powders. Mater. Sci. Eng. A 2003, 342, 131–143. [Google Scholar] [CrossRef]

- Chu, K.; Jia, C.C.; Jiang, L.K.; Li, W.S. Improvement of interface and mechanical properties in carbon nanotube reinforced Cu–Cr matrix composites. Mater. Des. 2013, 45, 407–411. [Google Scholar] [CrossRef]

- Deng, C.; Zhang, P.; Ma, Y.; Zhang, X.; Wang, D. Dispersion of multiwalled carbon nanotubes in aluminum powders. Rare. Met. 2009, 28, 175–180. [Google Scholar] [CrossRef]

- Esawi, A.M.K.; Morsi, K. Dispersion of carbon nanotubes (CNTs) in aluminum powder. Compos. A. 2007, 38, 646–650. [Google Scholar] [CrossRef]

- Nayan, N.; Murty, S.V.S.; Sharma, S.C.; Kumar, K.S.; Sinha, P.P. Calorimetric study on mechanically milled aluminum and multiwall carbon nanotube composites. Mater. Charact. 2011, 62, 1087–1093. [Google Scholar] [CrossRef]

- Esawi, A.M.K.; Morsi, K.; Sayed, A.; Abdel Gawad, A.; Borah, P. Fabrication and properties of dispersed carbon nanotube-aluminum composites. Mater. Sci. Eng. A 2009, 508, 167–173. [Google Scholar] [CrossRef]

- Ci, L.; Ryu, Z.; Jin-Phillipp, N.Y.; Rühle, M. Investigation of the interfacial reaction between multi-walled carbon nanotubes and aluminum. Acta. Mater. 2006, 54, 5367–5375. [Google Scholar] [CrossRef]

- Thomson, K.E.; Jiang, D.; Ritchie, R.O.; Mukherjee, A.K. A preservation study of carbon nanotubes in alumina-based nanocomposites via Raman spectroscopy and nuclear magnetic resonance. Appl. Phys. A 2007, 89, 651–654. [Google Scholar] [CrossRef]

- Ram, H.R.A.; Koppad, P.G.; Kashyap, K.T. Nanoindentation studies on MWCNT/aluminum alloy 6061 nanocomposites. Mater. Sci. Eng. A 2013, 559, 920–923. [Google Scholar] [CrossRef]

- Lahiri, D.; Bakshi, S.R.; Keshri, A.K.; Liu, Y.; Agarwal, A. Dual strengthening mechanisms induced by carbon nanotubes in roll bonded aluminum composites. Mater. Sci. Eng. A 2009, 523, 263–270. [Google Scholar] [CrossRef]

- Mazilkin, A.A.; Straumal, B.B.; Rabkin, E.; Baretzky, B.; Enders, S.; Protasova, S.G. Softening of nanostructured Al–Zn and Al–Mg alloys after severe plastic deformation. Acta. Mater. 2006, 54, 3933–3939. [Google Scholar] [CrossRef]

- Varol, T.; Canakci, A. Effect of particle size and ratio of B4C reinforcement on properties and morphology of nanocrystalline Al2024-B4C composite powders. Powder. Tech. 2013, 246, 462–472. [Google Scholar] [CrossRef]

- Pérez-Bustamante, R.; Pérez-Bustamante, F.; Estrada-Guel, I.; Licea-Jiménez, L.; Miki-Yoshida, M.; Martínez-Sánchez, R. Effect of milling time and CNT concentration on hardness of CNT/Al2024 composites produced by mechanical alloying. Mater. Charact. 2013, 75, 13–19. [Google Scholar] [CrossRef]

- Kim, H.; Babu, J.S.S.; Kang, C.G. Fabrication of A356 aluminum alloy matrix composite with CNTs/Al2O3 hybrid reinforcements. Mater. Sci. Eng. A 2013, 573, 92–99. [Google Scholar] [CrossRef]

- Pérez-Bustamante, P.; Gonzalez-Ibarra, M.J.; Gonzalez-Cantu, J.; Estrada-Guel, I.; Herrera-Ramirez, J.M.; Miki-Yoshida, M. AA2024-CNTs composites by milling process after T6-temper condition. Alloys. Comp. 2012, 536, S17–S20. [Google Scholar] [CrossRef]

- Pérez-Bustamante, R.; Gomez-Esparza, C.D.; Estrada-Guel, I.; Miki-Yoshida, M.; Licea-Jimenez, L.; Perez-Garcia, L.A. Microstructural and mechanical characterization of Al-MWCNT composites produced by mechanical milling. Mater. Sci. Eng. A 2009, 502, 159–163. [Google Scholar] [CrossRef]

- Brown, L.M.; Ham, R.K. Strengthening Methods in Crystals; Elsevier: Amsterdam, The Netherlands, 1971; pp. 9–135. [Google Scholar]

- Torralba, J.M.; Da Costa, C.E.; Velasco, F.J. P/M aluminum matrix composites: An overview. Mater. Process. Tech. 2003, 133, 203–206. [Google Scholar] [CrossRef]

- Fogagnolo, J.B.; Ruiz-Navas, E.M.; Robert, M.H.; Torralba, J.M. The effects of mechanical alloying on the compressibility of aluminum matrix composite powder. Mater. Sci. Eng. A 2003, 355, 50–55. [Google Scholar] [CrossRef]

- Khakbiz, M.; Akhlaghi, F.J. Synthesis and structural characterization of Al-B4C nanocomposite powders by mechanical alloying. Alloys. Comp. 2009, 479, 334–341. [Google Scholar] [CrossRef]

- Lloyd, D.J. Particle-reinforced aluminum and magnesium matrix composites. Int. Mater. Rev. 1994, 39, 1–24. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

| Milling Time (h) | As Received | 0.5 | 2 | 5 | 8 | 12 |

|---|---|---|---|---|---|---|

| IG/ID | 0.97 | 0.95 | 0.82 | 0.74 | 0.59 | 0.55 |

| Position of G-band | 1567 | 1575 | 1585 | 1605 | 1621 | 1655 |

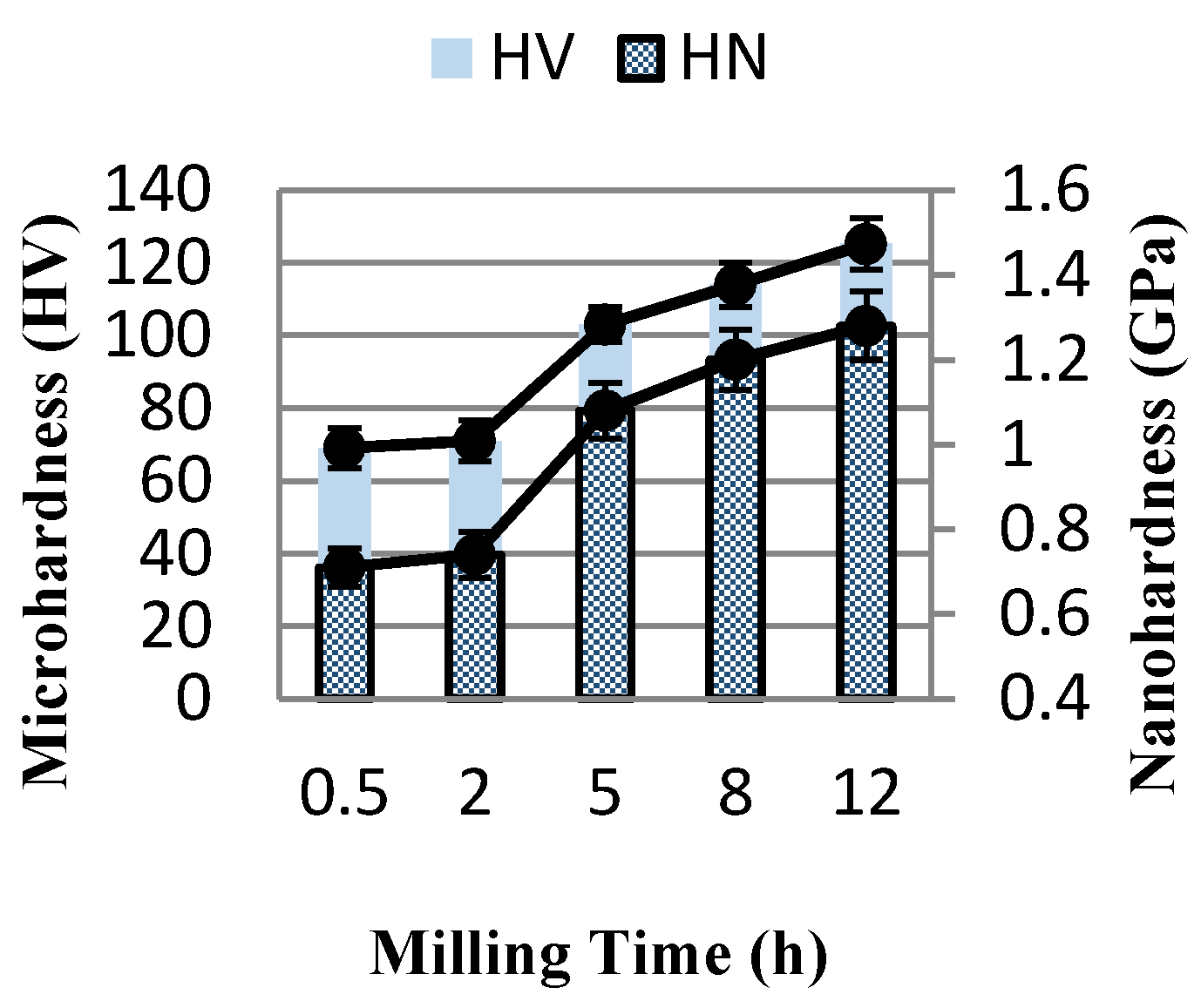

| Composite | Milling Time (h) | Micro Hardness (HV) | Nano Hardness (GPa) | Young’s Modulus (GPa) |

|---|---|---|---|---|

| Al-2 wt %CNTs | 0.5 | 69 | 0.71 | 45 |

| 2 | 71 | 0.74 | 49.3 | |

| 5 | 103 | 1.08 | 62.8 | |

| 8 | 114 | 1.2 | 68.9 | |

| 12 | 125.2 | 1.28 | 65.9 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ostovan, F.; Matori, K.A.; Toozandehjani, M.; Oskoueian, A.; Yusoff, H.M.; Yunus, R.; Mohamed Ariff, A.H. Nanomechanical Behavior of Multi-Walled Carbon Nanotubes Particulate Reinforced Aluminum Nanocomposites Prepared by Ball Milling. Materials 2016, 9, 140. https://doi.org/10.3390/ma9030140

Ostovan F, Matori KA, Toozandehjani M, Oskoueian A, Yusoff HM, Yunus R, Mohamed Ariff AH. Nanomechanical Behavior of Multi-Walled Carbon Nanotubes Particulate Reinforced Aluminum Nanocomposites Prepared by Ball Milling. Materials. 2016; 9(3):140. https://doi.org/10.3390/ma9030140

Chicago/Turabian StyleOstovan, Farhad, Khamirul Amin Matori, Meysam Toozandehjani, Arshin Oskoueian, Hamdan Mohamed Yusoff, Robiah Yunus, and Azmah Hanim Mohamed Ariff. 2016. "Nanomechanical Behavior of Multi-Walled Carbon Nanotubes Particulate Reinforced Aluminum Nanocomposites Prepared by Ball Milling" Materials 9, no. 3: 140. https://doi.org/10.3390/ma9030140