Reinforcing Low-Volume Fraction Nano-TiN Particulates to Monolithical, Pure Mg for Enhanced Tensile and Compressive Response

Abstract

:1. Introduction

2. Results

2.1. Density and Porosity Measurements

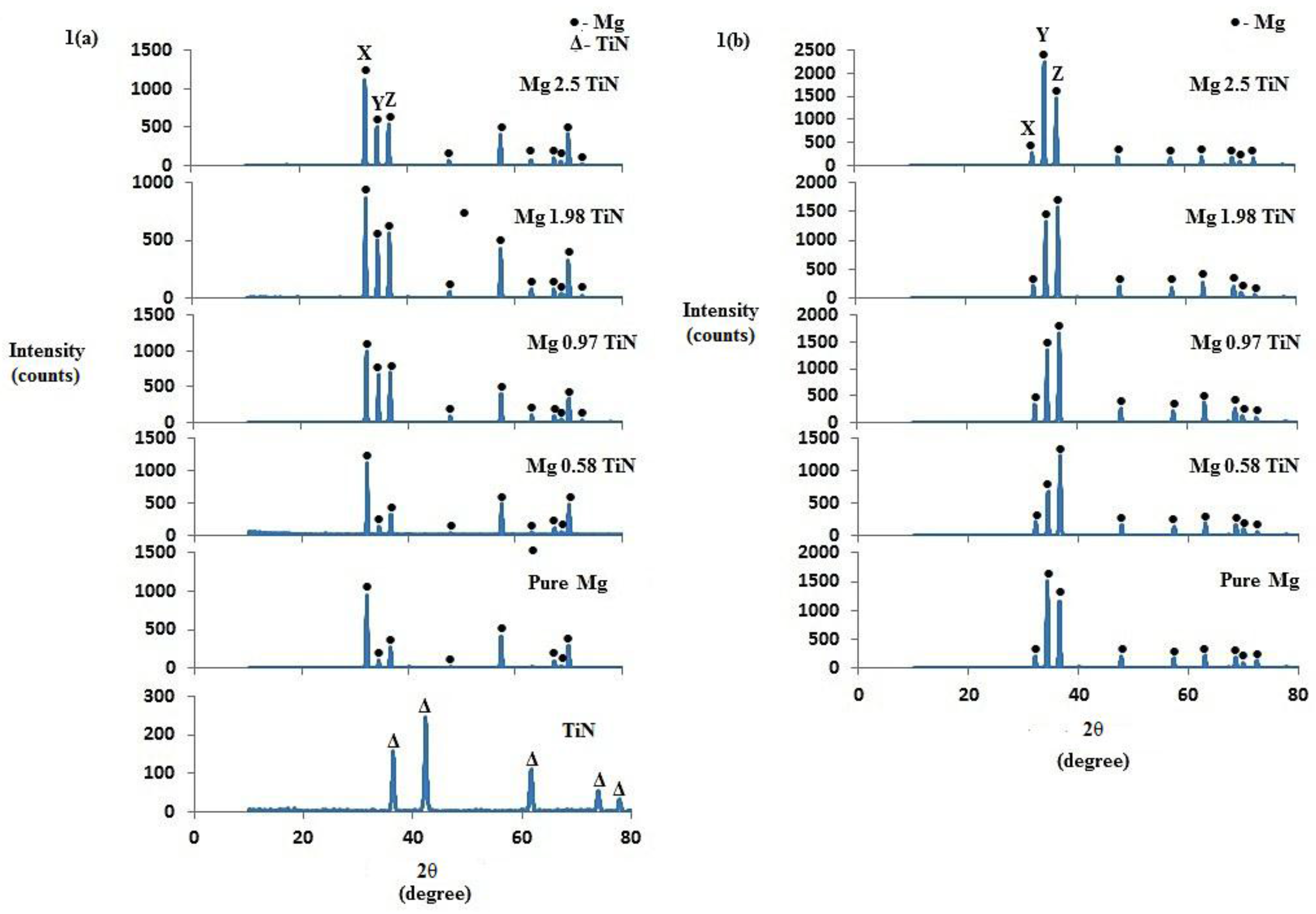

2.2. X-ray Diffraction Studies

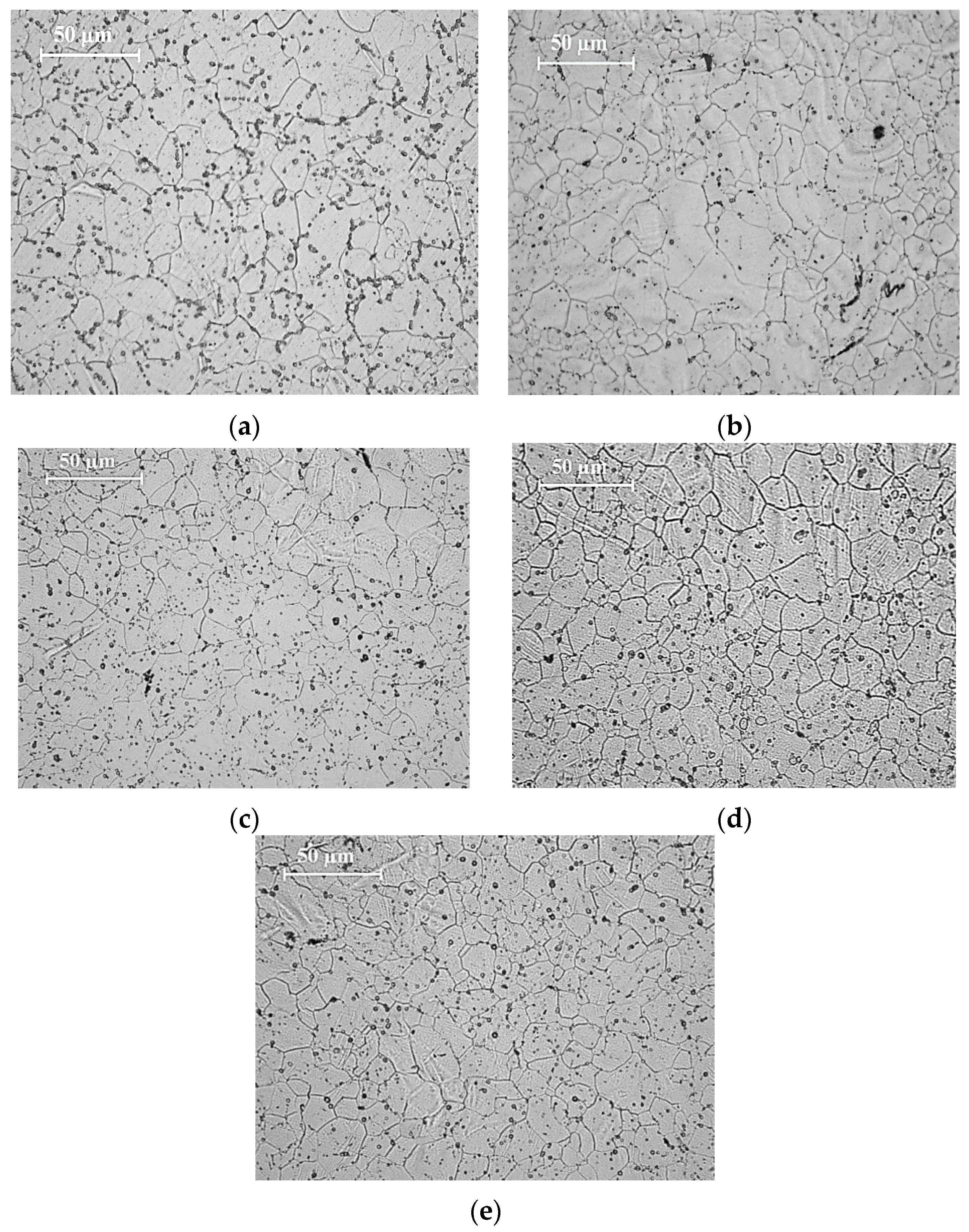

2.3. Microstructural Characterization

2.4. Coefficient of Thermal Expansion (CTE)

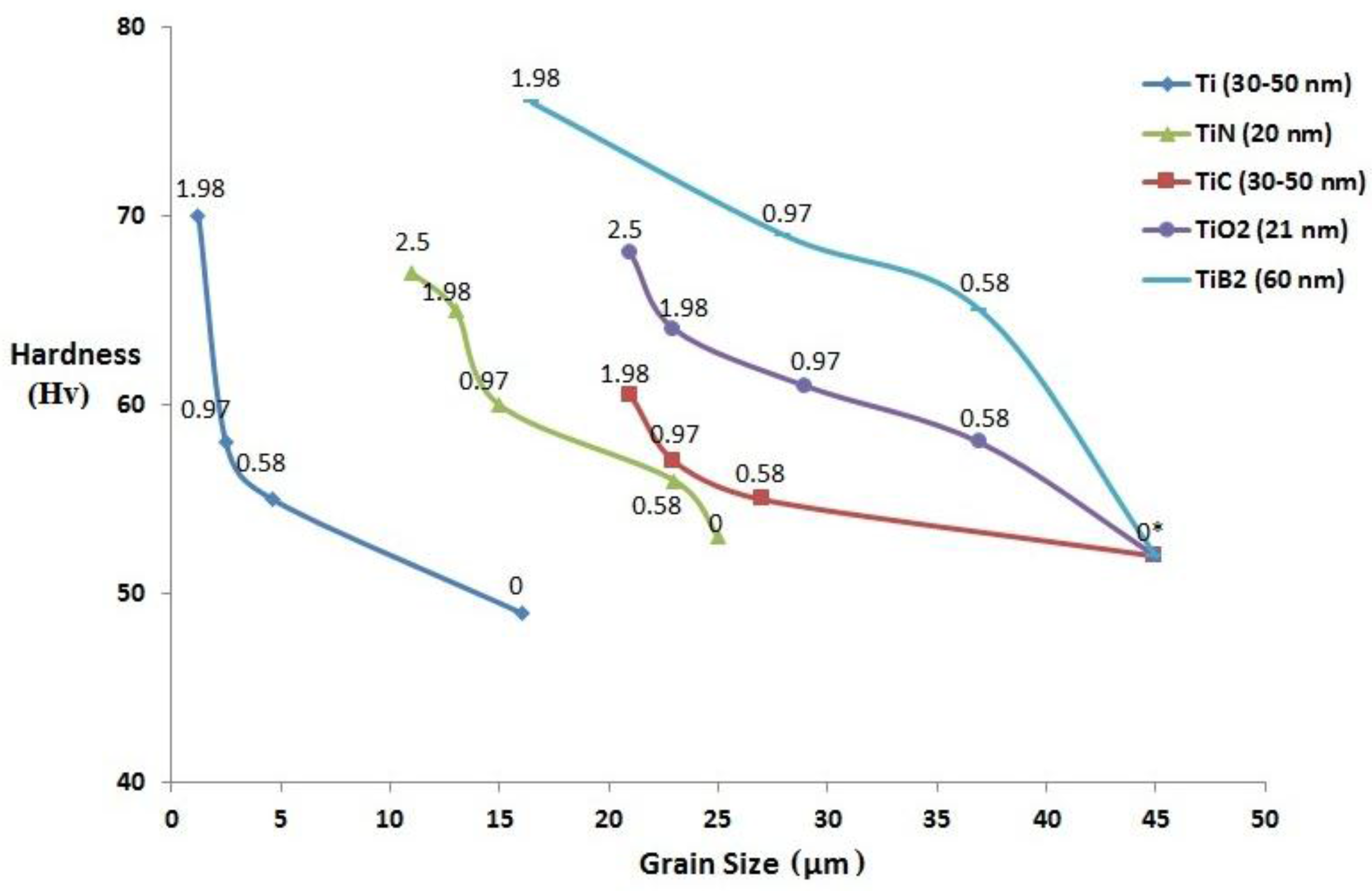

2.5 Microhardness Test

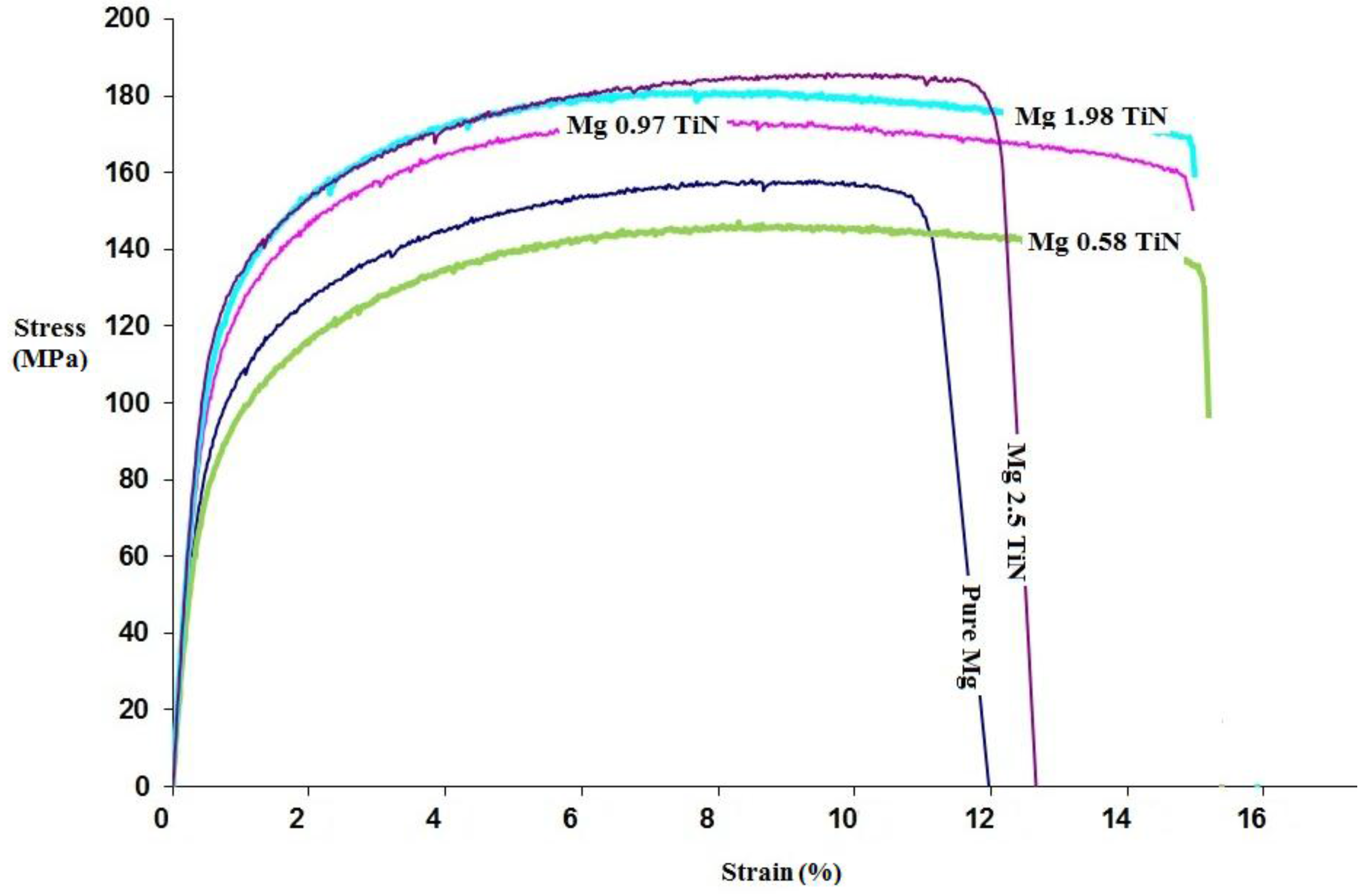

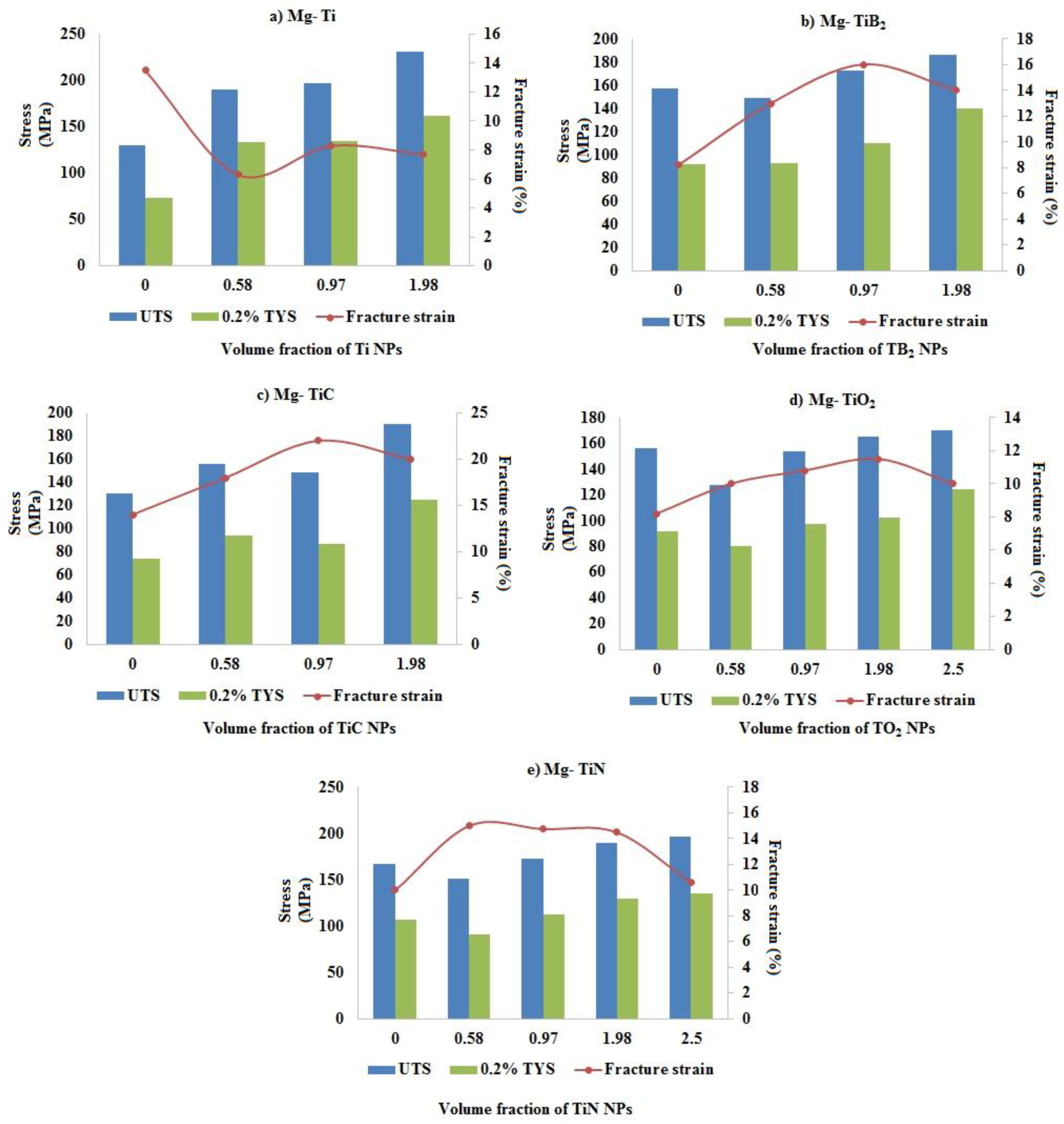

2.6. Tensile Test

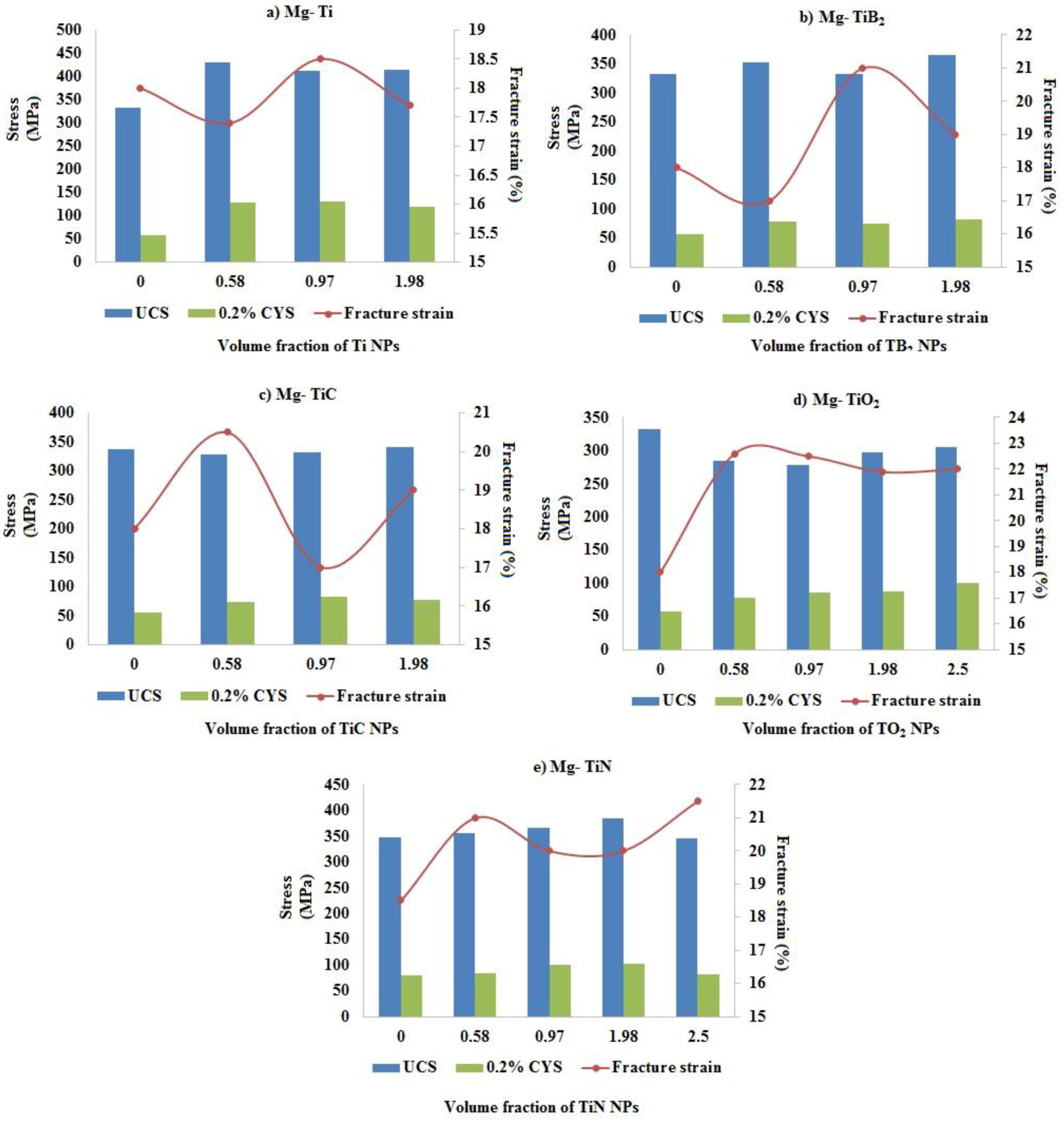

2.7. Compression Test

3. Discussion

3.1. Microstructural Characteristics

3.2. Mechanical Properties

3.2.1. Microhardness

3.2.2. Tensile Properties

3.2.3. Compressive Properties

4. Materials and Methods

4.1. Materials

4.2. Processing

4.2.1. Primary Processing

4.2.2. Secondary Processing

4.3. Materials Characterization

4.3.1. Density Measurements

4.3.2. X-ray Diffraction Studies

4.3.3. Microstructural Characterization

4.3.4. Coefficient of Thermal Expansion (CTE)

4.3.5. Microhardness Test

4.3.6. Tensile Test

4.3.7. Compression Test

4.3.8. Fracture Behavior

5. Conclusions

- (a)

- Utilizing the adopted synthesis methodology (disintegrated melt deposition technique followed by hot extrusion), near dense Mg-Ti based nanocomposites containing low-volume fraction Ti (metal) and ceramics of Ti NPs can be synthesized. It is observed that with a marginal increase in the density of pure Mg, the presence of Ti-based NPs significantly improves its mechanical properties.

- (b)

- Microstructural characterization indicate significant grain refinement of pure Mg with the addition of TiN NPs and Mg 2.5 vol. % TiN exhibited a minimum grain size of ~11 μm, which is 57% lower than that of pure Mg. Among the Mg-Ti based nanocomposites, Mg 1.98 vol. % Ti (metal) nanocomposites exhibited the lowest grain size of ~1.5 μm.

- (c)

- Microhardness values of pure Mg increases with the addition of TiN NPs and Mg 2.5 vol. % TiN exhibited the maximum hardness value of ~67 HV, which is 26% greater than that of pure Mg. Among the Mg-Ti based nanocomposites, Mg 1.98 vol. % TiB2 exhibited the maximum hardness value of ~76 HV.

- (d)

- Room temperature tensile properties of Mg-TiN nanocomposites indicate an increase in the strength properties of pure Mg with addition of ≥ (greater than or equal to) 0.97 TiN NPs. Mg 2.5 vol. % TiN nanocomposites exhibited the maximum 0.2%TYS and UTS of ~135 MPa and ~196 MPa, respectively, which are ~26% and ~17% greater than that of pure Mg.

- (e)

- X-ray diffraction studies indicated that addition of up to 1.98 vol. % TiN NPs has the ability to modify the basal texture of hot extruded pure Mg. The tensile fracture strain values of pure Mg was found to increase with up to 1.98 vol. % TiN NPs addition and Mg (0.58, 0.97, 1.98) vol. % TiN exhibited the maximum tensile fracture strain values of ~15%. With further addition of TiN NPs (2.5 vol. %), strong basal texture of pure Mg was observed and the tensile fracture strain values of Mg 2.5 vol. % TiN was found to decrease to ~10.5%. Further, critical quantity of Ti (ceramic) NPs contribute to modifying the basal texture of pure Mg and thereby enhance the fracture strain values, whereas no textural changes of pure Mg reinforced with metallic Ti NPs was observed.

- (f)

- Among the major strengthening mechanisms of Mg MMNCs containing Ti-based NPs, Hall-Petch strengthening contribution was found to play a vital role. Mg-Ti (metal) nanocomposites exhibited the maximum 0.2%TYS with significant Hall-Petch contributions and Mg 1.98 vol. % Ti possessed 0.2% TYS as high as ~162 MPa. Among the Mg-Ti (ceramic) nanocomposites, Mg 1.98 TiB2 exhibited 0.2%TYS as high as ~140 MPa.

- (g)

- Room temperature compression properties of Mg-TiN nanocomposites indicate that, with the addition of up to 1.98 vol. % TiN the 0.2% CYS, UCS and compressive fracture strain values of pure Mg was found to increase. Mg 1.98 vol. % TiN exhibited the highest 0.2CYS, UCS and compressive fracture strain values of ~103 MPa, ~385 MPa, and ~21%, respectively, which are ~28%, ~11%, and ~7% greater than that of pure Mg. With further addition of TiN (2.5 vol. %) NPs, the compression strength properties were found to decrease with 0.2%CYS and UCS of ~82 MPa and ~342 MPa, respectively. Mg-Ti (ceramic) nanocomposites were found to exhibit higher compressive fracture strain, whereas strengthening was predominantly observed in Mg-Ti (metal) nanocomposites.

- (h)

- Further, addition of up to 1.98 vol. % TiN NPs aids in minimizing the TCA value of pure Mg and Mg (0.58 and 0.97) TiN exhibited the minimum TCA value of ~1.10.

Abbreviations

Tensile yield strength of monolithic pure Mg (MPa) | |

Orowan strengthening contribution (MPa) | |

Hall-Petch strengthenig contribution (MPa) | |

Forest strengthening contribution (MPa) | |

Taylor strengthening contribution (MPa) | |

Strengthening due to load transfer (MPa) | |

Theoretical density (g/cc) | |

Experimental density (g/cc) | |

| 0.2% TYS | 0.2% Tensile Yield Strength (MPa) |

| 0.2% CYS | 0.2% Compressive Yield Strength (MPa) |

| CTE | Coefficient of thermal expansion (μ/K) |

Average Diameter of the NPs (m) | |

| MMNCs | Metal Matrix Nanocomposites |

| NPs | Nanoparticulates |

| r | Average radius of NPs (m) |

| TCA | Tensile Compression Asymmetry |

| UCS | Ultimate Compression Strength (MPa) |

| UTS | Ultimate Tensile Strength (MPa) |

| XRD | X-Ray Diffraction |

Volume fraction of NPs (%) |

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kirkland, N.; Birbilis, N.; Staiger, M. Assessing the corrosion of biodegradable magnesium implants: A critical review of current methodologies and their limitations. Acta Biomater. 2012, 8, 925–936. [Google Scholar] [CrossRef] [PubMed]

- Goh, C.; Wei, J.; Lee, L.C.; Gupta, M. Development of novel carbon nanotube reinforced magnesium nanocomposites using the powder metallurgy technique. Nanotechnology 2006, 17. [Google Scholar] [CrossRef]

- Itoi, T.; Takahashi, K.; Moriyama, H.; Hirohashi, M. A high-strength Mg-Ni-Y alloy sheet with a long-period ordered phase prepared by hot-rolling. Scr. Mater. 2008, 59, 1155–1158. [Google Scholar] [CrossRef]

- Nguyen, Q.; Gupta, M.; Srivatsan, T. On the role of nano-alumina particulate reinforcements in enhancing the oxidation resistance of magnesium alloy AZ31B. Mater. Sci. Eng. A 2009, 500, 233–237. [Google Scholar] [CrossRef]

- Shaw, B.; Wolfe, R. Corrosion of magnesium and magnesium-base alloys. ASM Handb. Corros. Mater. 2005, 13, 205–227. [Google Scholar]

- Cramer, S.D.; Covino, B.S., Jr.; Moosbrugger, C.; ASM International Handbook Committee. ASM Handbook; Asm International: Materials Park, OH, USA, 2005; Volume 13. [Google Scholar]

- Gupta, M.; Meenashisundaram, G.K. Insight Into Designing Biocompatible Magnesium Alloys and Composites: Processing, Mechanical and Corrosion Characteristics; Springer: Singapore, Singapore, 2015. [Google Scholar]

- Farraro, K.F.; Kim, K.E.; Woo, S.L.; Flowers, J.R.; McCullough, M.B. Revolutionizing orthopaedic biomaterials: The potential of biodegradable and bioresorbable magnesium-based materials for functional tissue engineering. J. Biomech. 2014, 47, 1979–1986. [Google Scholar] [CrossRef] [PubMed]

- Staiger, M.P.; Pietak, A.M.; Huadmai, J.; Dias, G. Magnesium and its alloys as orthopedic biomaterials: A review. Biomaterials 2006, 27, 1728–1734. [Google Scholar] [CrossRef] [PubMed]

- Zreiqat, H.; Howlett, C.; Zannettino, A.; Evans, P.; Schulze-Tanzil, G.; Knabe, C.; Shakibaei, M. Mechanisms of magnesium-stimulated adhesion of osteoblastic cells to commonly used orthopaedic implants. J. Biomed. Mater. Res. 2002, 62, 175–184. [Google Scholar] [CrossRef] [PubMed]

- Manivasagam, G.; Dhinasekaran, D.; Rajamanickam, A. Biomedical implants: Corrosion and its prevention-a review. Recent Pat. Corros. Sci. 2010, 2, 40–54. [Google Scholar] [CrossRef]

- Xin, Y.; Hu, T.; Chu, P.K. In vitro studies of biomedical magnesium alloys in a simulated physiological environment: A review. Acta Biomater. 2011, 7, 1452–1459. [Google Scholar] [CrossRef] [PubMed]

- Esen, Z.; Dikici, B.; Duygulu, O.; Dericioglu, A.F. Titanium-magnesium based composites: Mechanical properties and in vitro corrosion response in Ringer's solution. Mater. Sci. Eng. A 2013, 573, 119–126. [Google Scholar] [CrossRef]

- Habibi, M.K.; Joshi, S.P.; Gupta, M. Hierarchical magnesium nano-composites for enhanced mechanical response. Acta Mater. 2010, 58, 6104–6114. [Google Scholar] [CrossRef]

- Meenashisundaram, G.K.; Gupta, M. Low volume fraction nano-titanium particulates for improving the mechanical response of pure magnesium. J. Alloys Compd. 2014, 593, 176–183. [Google Scholar] [CrossRef]

- Buhagiar, J.; Dong, H. Corrosion properties of S-phase layers formed on medical grade austenitic stainless steel. J. Mater. Sci. Mater. Med. 2012, 23, 271–281. [Google Scholar] [CrossRef] [PubMed]

- Ivanova, E.P.; Bazaka, K.; Crawford, R.J. New Functional Biomaterials for Medicine and Healthcare; Woodhead Publishing: Cambridge, UK, 2014. [Google Scholar]

- Meenashisundaram, G.K.; Sankaranarayanan, S.; Gupta, M. Enhancing overall tensile and compressive response of pure Mg using nano-TiB2 particulates. Mater. Charact. 2014, 94, 178–188. [Google Scholar] [CrossRef]

- Arsiwala, A.; Desai, P.; Patravale, V. Recent advances in micro/nanoscale biomedical implants. J. Controll. Release 2014, 189, 25–45. [Google Scholar] [CrossRef] [PubMed]

- Reed-Hill, R.E.; Abbaschian, R. Physical Metallurgy Principles; Cengage Learning: Stamford, CA, USA, 1973. [Google Scholar]

- Tun, K.; Jayaramanavar, P.; Nguyen, Q.; Chan, J.; Kwok, R.; Gupta, M. Investigation into tensile and compressive responses of Mg-ZnO composites. Mater. Sci. Technol. 2012, 28, 582–588. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, Q.; Wang, Y.; Ma, B.; Zhao, F. Fabrication of TiB2 particulate reinforced magnesium matrix composites by powder metallurgy. Mater. Lett. 2004, 58, 3509–3513. [Google Scholar] [CrossRef]

- Chawla, N.; Jones, J.; Andres, C.; Allison, J. Effect of SiC volume fraction and particle size on the fatigue resistance of a 2080 Al/SiC p composite. Metall. Mater. Trans. A 1998, 29, 2843–2854. [Google Scholar] [CrossRef]

- Smithells, C. Smithells Metal Reference Book, 7th ed.; Butterworth-Heinemann: Boston, MA, USA, 1992. [Google Scholar]

- Milman, V.; Warren, M. Elastic properties of TiB2 and MgB2. J. Phys. Condens. Matter 2001, 13, 5585. [Google Scholar] [CrossRef]

- Emamy, M.; Mahta, M.; Rasizadeh, J. Formation of TiB2 particles during dissolution of TiAl3 in Al–TiB2 metal matrix composite using an in situ technique. Compos. Sci. Technol. 2006, 66, 1063–1066. [Google Scholar] [CrossRef]

- Tao, X.; Du, J.; Yang, Y.; Li, Y.; Xia, Y.; Gan, Y.; Huang, H.; Zhang, W.; Li, X. TiC nanorods derived from cotton fibers: Chloride-assisted VLS growth, structure, and mechanical properties. Cryst. Growth Des. 2011, 11, 4422–4426. [Google Scholar] [CrossRef]

- Shackelford, J.F.; Alexander, W. CRC Materials Science and Engineering Handbook; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Ferguson, J.; Sheykh-Jaberi, F.; Kim, C.-S.; Rohatgi, P.K.; Cho, K. On the strength and strain to failure in particle-reinforced magnesium metal-matrix nanocomposites (Mg MMNCs). Mater. Sci. Eng. A 2012, 558, 193–204. [Google Scholar] [CrossRef]

- Dieter, G.E.; Bacon, D. Mechanical Metallurgy; McGraw-Hill: New York, NY, USA, 1986; Volume 119. [Google Scholar]

- Gale, W.F.; Totemeier, T.C. Smithells Metals Reference Book; Butterworth-Heinemann: Boston, MA, USA, 2003. [Google Scholar]

- Han, B.; Dunand, D. Microstructure and mechanical properties of magnesium containing high volume fractions of yttria dispersoids. Mater. Sci. Eng. A 2000, 277, 297–304. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, D. A model for predicting the particle size dependence of the low cycle fatigue life in discontinuously reinforced MMCs. Scripta Mater. 2004, 51, 863–867. [Google Scholar] [CrossRef]

- Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials; Cambridge University Press: Cambridge, UK, 2009; Volume 2. [Google Scholar]

- Goh, C.; Wei, J.; Lee, L.; Gupta, M. Properties and deformation behaviour of Mg-Y2O3 nanocomposites. Acta Mater. 2007, 55, 5115–5121. [Google Scholar] [CrossRef]

- Vogt, R.; Zhang, Z.; Li, Y.; Bonds, M.; Browning, N.; Lavernia, E.; Schoenung, J. The absence of thermal expansion mismatch strengthening in nanostructured metal–matrix composites. Scripta Mater. 2009, 61, 1052–1055. [Google Scholar] [CrossRef]

- Chawla, N.; Habel, U.; Shen, Y.-L.; Andres, C.; Jones, J.; Allison, J. The effect of matrix microstructure on the tensile and fatigue behavior of SiC particle-reinforced 2080 Al matrix composites. Metall. Mater. Trans. A 2000, 31, 531–540. [Google Scholar] [CrossRef]

- Meenashisundaram, G.K.; Nai, M.H.; Gupta, M. Effects of primary processing techniques and significance of hall-petch strengthening on the mechanical response of magnesium matrix composites containing TiO2 nanoparticulates. Nanomaterials 2015, 5, 1256–1283. [Google Scholar] [CrossRef]

- Watanabe, H.; Ishikawa, K. Effect of texture on high temperature deformation behavior at high strain rates in a Mg-3Al-1Zn alloy. Mater. Sci. Eng. A 2009, 523, 304–311. [Google Scholar] [CrossRef]

- Ulacia, I.; Dudamell, N.; Gálvez, F.; Yi, S.; Pérez-Prado, M.; Hurtado, I. Mechanical behavior and microstructural evolution of a Mg AZ31 sheet at dynamic strain rates. Acta Mater. 2010, 58, 2988–2998. [Google Scholar] [CrossRef]

| Sl. No | Material | Reinforcement | Density Measurements | CTE (×10−6/K) | |||

|---|---|---|---|---|---|---|---|

| (Wt %) | (Vol %) | Theoretical Density (g/cm3) | Experimental Density (g/cm3) | Porosity (%) | |||

| 1 | Mg | Nil | Nil | 1.7400 | 1.7356 | 0.2530 | 27.00 |

| 2 | Mg 0.58 TiN | 1.78 | 0.58 | 1.7612 | 1.7589 | 0.1322 | 25.54 |

| 3 | Mg 0.97 TiN | 2.95 | 0.97 | 1.7750 | 1.7695 | 0.3382 | 24.63 |

| 4 | Mg 1.98 TiN | 5.9 | 1.98 | 1.8125 | 1.8050 | 0.4123 | 24.58 |

| 5 | Mg 2.5 TiN | 7.37 | 2.5 | 1.8315 | 1.8225 | 0.4917 | 22.61 |

| Material | Section | Plane | I/Imax |

|---|---|---|---|

| Pure Mg | T | 10–10 Prism | 1.000 |

| 0002 Basal | 0.104 | ||

| 10–11 Pyramidal | 0.278 | ||

| L | 10–10 Prism | 0.136 | |

| 0002 Basal | 1.000 | ||

| 10–11 Pyramidal | 0.764 | ||

| Mg 0.58 TiN | T | 10–10 Prism | 1.000 |

| 0002 Basal | 0.131 | ||

| 10–11 Pyramidal | 0.295 | ||

| L | 10–10 Prism | 0.166 | |

| 0002 Basal | 0.551 | ||

| 10–11 Pyramidal | 1.000 | ||

| Mg 0.97 TiN | T | 10–10 Prism | 1.000 |

| 0002 Basal | 0.674 | ||

| 10–11 Pyramidal | 0.685 | ||

| L | 10-10 Prism | 0.195 | |

| 0002 Basal | 0.813 | ||

| 10–11 Pyramidal | 1.000 | ||

| Mg 1.98 TiN | T | 10–10 Prism | 1.000 |

| 0002 Basal | 0.596 | ||

| 10–11 Pyramidal | 0.661 | ||

| L | 10–10 Prism | 0.147 | |

| 0002 Basal | 0.842 | ||

| 10-11 Pyramidal | 1.000 | ||

| Mg 2.5 TiN | T | 10–10 Prism | 1.000 |

| 0002 Basal | 0.460 | ||

| 10–11 Pyramidal | 0.464 | ||

| L | 10–10 Prism | 0.130 | |

| 0002 Basal | 1.000 | ||

| 10–11 Pyramidal | 0.651 |

| Sl. No | Material | Grain Size (× 10−6 m) | Aspect Ratio (× 10−6 m) | Microhardness (HV) |

|---|---|---|---|---|

| 1 | Mg | 25.5 ± 2 | 1.25 ± 0.2 | 53 ± 1 |

| 2 | Mg 0.58 TiN | 23 ± 2.5 (↓9%) | 1.81 ± 0.1 | 56 ± 1.5 (↑6%) |

| 3 | Mg 0.97 TiN | 15 ± 2.5 (↓41%) | 1.28 ± 0.2 | 60 ± 1.5 (↑13%) |

| 4 | Mg 1.98 TiN | 13 ± 3.5 (↓49%) | 1.32 ± 0.4 | 65 ± 2.5 (↑23%) |

| 5 | Mg 2.5 TiN | 11 ± 3.5 (↓57%) | 1.35 ± 0.4 | 67 ± 3 (↑26%) |

| Material | 0.2%TYS (Mpa) | UTS (Mpa) | Fracture Strain (%) | Energy absorbed (MJ/m3) |

|---|---|---|---|---|

| Pure Mg | 107 ± 5 | 167 ± 7 | 10 ± 1 | 14 ± 2 |

| Mg 0.58 TiN | 91 ± 5 (↓15%) | 151 ± 4 (↓10%) | 15 ± 1 (↑50%) | 20 ± 1 (↑43%) |

| Mg 0.97 TiN | 112 ± 2 (↑5%) | 173 ± 1 (↑4%) | 15 ± 2 (↑50%) | 24 ± 2.5 (↑71%) |

| Mg 1.98 TiN | 130 ± 7 (↑21%) | 190 ± 11 (↑14%) | 14.5 ± 1 (↑45%) | 26 ± 4 (↑85%) |

| Mg 2.5 TiN | 135 ± 8 (↑26%) | 196 ± 14 (↑17%) | 10.6 ± 1.2 (↑5%) | 19.8 ± 1 (↑43%) |

| Material | 0.2% CYS (Mpa) | UCS (Mpa) | Fracture Strain (%) | Energy Absorbed (MJ/m3) |

|---|---|---|---|---|

| Pure Mg | 80.4 ± 2.5 | 347 ± 4 | 18.5 ± 1.5 | 37.3 ± 2 |

| Mg 0.58 TiN | 83.4 ± 2 (↑4%) | 355 ± 8 (↑2%) | 21 (↑13%) | 42.5 ± 2 (↑14%) |

| Mg 0.97 TiN | 101 ± 3 (↑26%) | 365.5 (↑5%) | 20 ± 1 (↑7%) | 43 ± 1 (↑15%) |

| Mg 1.98 TiN | 103 ± 5 (↑28%) | 385 ± 13 (↑11%) | 20 ± 1 (↑7%) | 42 ± 3 (↑13%) |

| Mg 2.5 TiN | 82 ± 3 | 345 ± 1 | 21 ± 1.5 (↑13%) | 42 ± 1 (↑12%) |

| Reinforcement or Nanoparticulates | Properties | ||||||

|---|---|---|---|---|---|---|---|

| Crystal Type | Density (g/cc) | Average Particle Size Utilized in Mg MMNC (nm) | Melting point (°C) | Young’s modulus (GPa) | Vicker’s hardness (GPa) | CTE (10−6/K) | |

| Ti [24] | hcp | 4.5 | 40 | 1667 | 120 | 0.830–3.420 | 8.9 |

| TiB2 [25,26] | Hexagonal | 4.52 | 60 | 2790 | 530 | 34 | 7.9 |

| TiC [27] | Cubic | 4.93 | 40 | 3067 | 300–480 | 29–32 | 7.4 |

| TiO2 [28] | tetragonal | 4.23 | 21 | 1843 | 230 | 7–11 | 9 |

| TiN [28] | Cubic | 5.22 | 20 | 2930 | 390 | 24 | 9.35 |

| Volume Fraction (%) | Orowan Stress σOrowan (MPa) and Interparticulate Spacing λ (nm) | Reinforcement Size (in nm) | |||

|---|---|---|---|---|---|

| TiN (20 nm) (Present study) | TiO2 (21 nm) | Ti and TiC (40 nm) | TiB2 (60 nm) | ||

| 0.58 | σOrowan | 36.83 | 35.08 | 18.41 | 12.27 |

| λ | 68.30 | 71.70 | 337.00 | 205.00 | |

| 0.97 | σOrowan | 46.25 | 44.05 | 23.12 | 15.41 |

| λ | 54.40 | 57.10 | 108.00 | 163.00 | |

| 1.98 | σOrowan | 65.09 | 62.00 | 32.54 | 21.69 |

| λ | 38.70 | 40.60 | 77.30 | 116.00 | |

| 2.5 | σOrowan | 73.42 | 69.93 | NA | |

| λ | 34.20 | 36.03 | |||

| Material | Volume Fraction (%) | Experimental 0.2%TYS (MPa) | σOrown (MPa) | σHall-Peth (MPa) |

|---|---|---|---|---|

| Mg-Ti | 0.58 | 134.00 | 18.41 | 130.00 |

| 0.97 | 135.00 | 23.12 | 177.10 | |

| 1.98 | 162.00 | 32.54 | 250.40 | |

| Mg-TiB2 | 0.58 | 93.00 | 12.27 | 46.03 |

| 0.97 | 110.00 | 15.41 | 52.91 | |

| 1.98 | 140.00 | 21.69 | 68.93 | |

| Mg-TiC | 0.58 | 94.00 | 18.41 | 53.88 |

| 0.97 | 87.00 | 23.12 | 58.34 | |

| 1.98 | 125.00 | 32.54 | 61.10 | |

| Mg-TiO2 | 0.58 | 80.00 | 35.08 | 46.03 |

| 0.97 | 97.00 | 44.05 | 52.00 | |

| 1.98 | 102.00 | 62.00 | 58.38 | |

| 2.50 | 124.00 | 69.93 | 61.10 | |

| Mg-TiN (Present study) | 0.58 | 91.00 | 36.83 | 58.38 |

| 0.97 | 112.00 | 46.25 | 72.30 | |

| 1.98 | 130.00 | 65.09 | 77.65 | |

| 2.50 | 135.00 | 73.42 | 84.42 |

| Material | 0.2% TYS | 0.2% CYS | TCA |

|---|---|---|---|

| Pure Mg | 107 ± 5 | 80.4 ± 2.5 | 1.33 |

| Mg 0.58 TiN | 91 ± 5 | 83.4 ± 2 | 1.09 |

| Mg 0.97 TiN | 112 ± 2 | 101 ± 3 | 1.10 |

| Mg 1.98 TiN | 130 ± 7 | 103 ± 5 | 1.26 |

| Mg 2.5 TiN | 135 ± 8 | 82 ± 3 | 1.64 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meenashisundaram, G.K.; Nai, M.H.; Almajid, A.; Gupta, M. Reinforcing Low-Volume Fraction Nano-TiN Particulates to Monolithical, Pure Mg for Enhanced Tensile and Compressive Response. Materials 2016, 9, 134. https://doi.org/10.3390/ma9030134

Meenashisundaram GK, Nai MH, Almajid A, Gupta M. Reinforcing Low-Volume Fraction Nano-TiN Particulates to Monolithical, Pure Mg for Enhanced Tensile and Compressive Response. Materials. 2016; 9(3):134. https://doi.org/10.3390/ma9030134

Chicago/Turabian StyleMeenashisundaram, Ganesh Kumar, Mui Hoon Nai, Abdulhakim Almajid, and Manoj Gupta. 2016. "Reinforcing Low-Volume Fraction Nano-TiN Particulates to Monolithical, Pure Mg for Enhanced Tensile and Compressive Response" Materials 9, no. 3: 134. https://doi.org/10.3390/ma9030134

APA StyleMeenashisundaram, G. K., Nai, M. H., Almajid, A., & Gupta, M. (2016). Reinforcing Low-Volume Fraction Nano-TiN Particulates to Monolithical, Pure Mg for Enhanced Tensile and Compressive Response. Materials, 9(3), 134. https://doi.org/10.3390/ma9030134