High-Strength Ultra-Fine-Grained Hypereutectic Al-Si-Fe-X (X = Cr, Mn) Alloys Prepared by Short-Term Mechanical Alloying and Spark Plasma Sintering

Abstract

:1. Introduction

2. Results

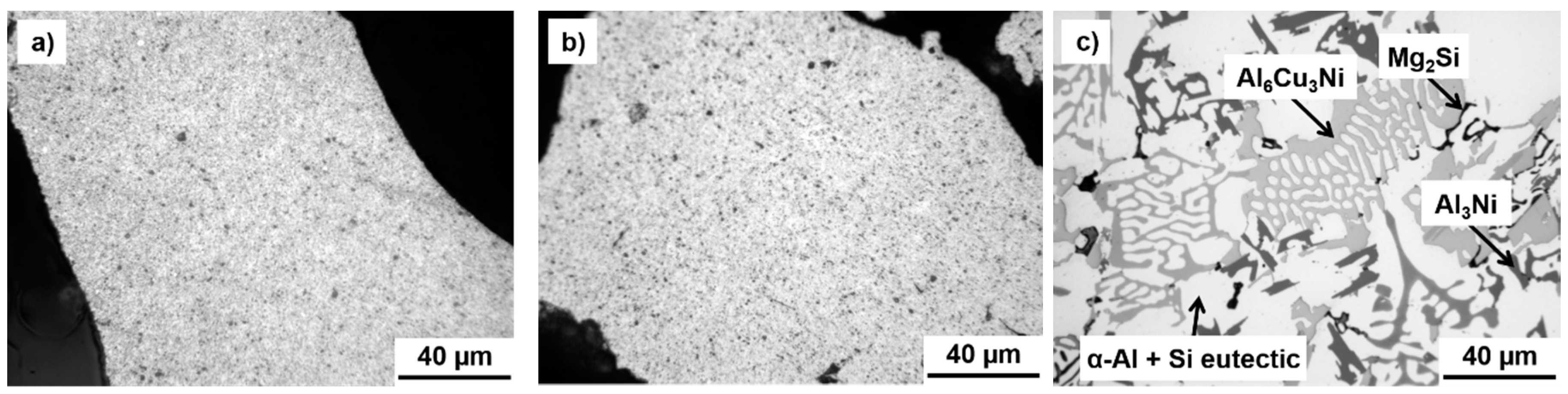

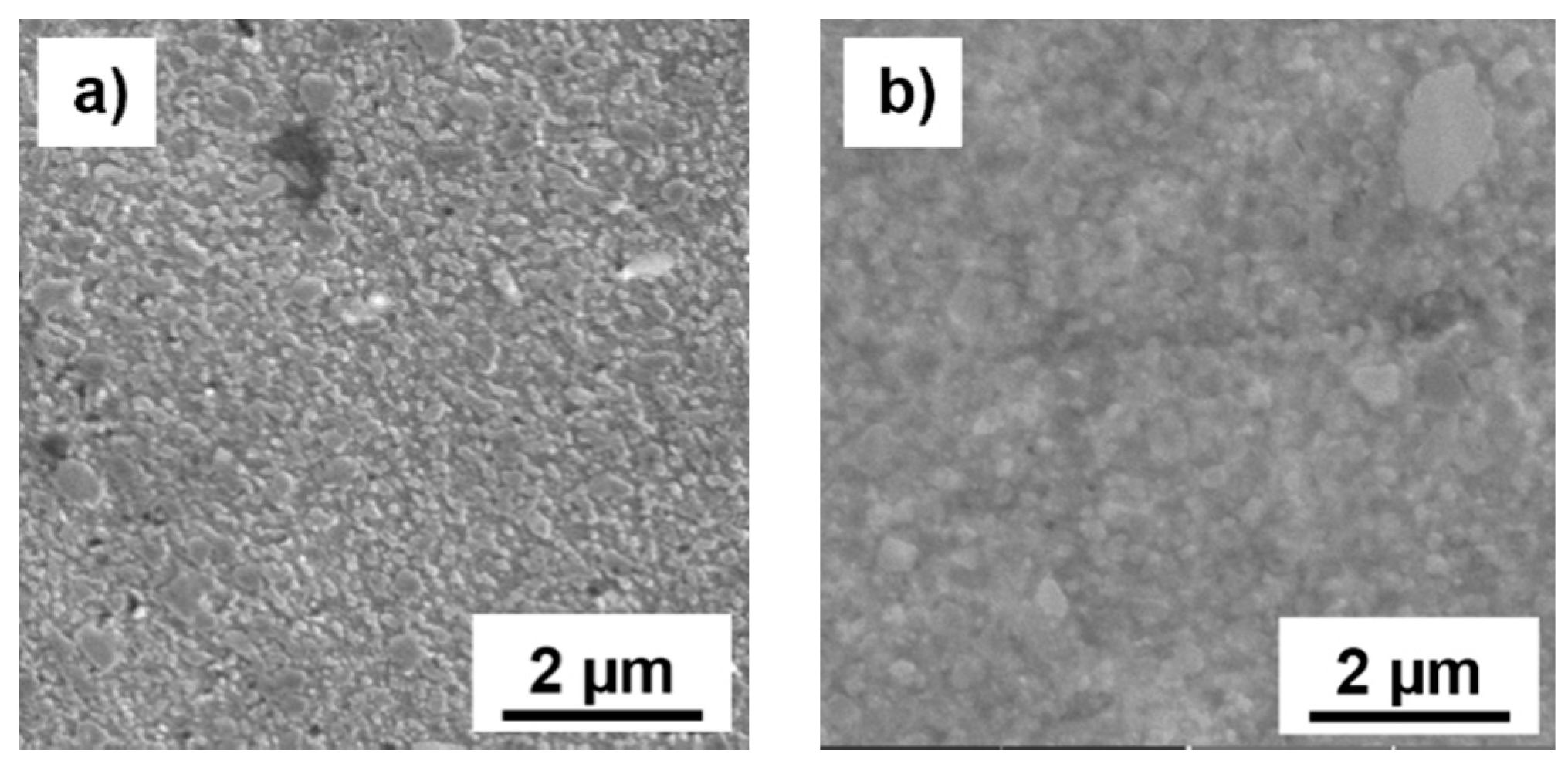

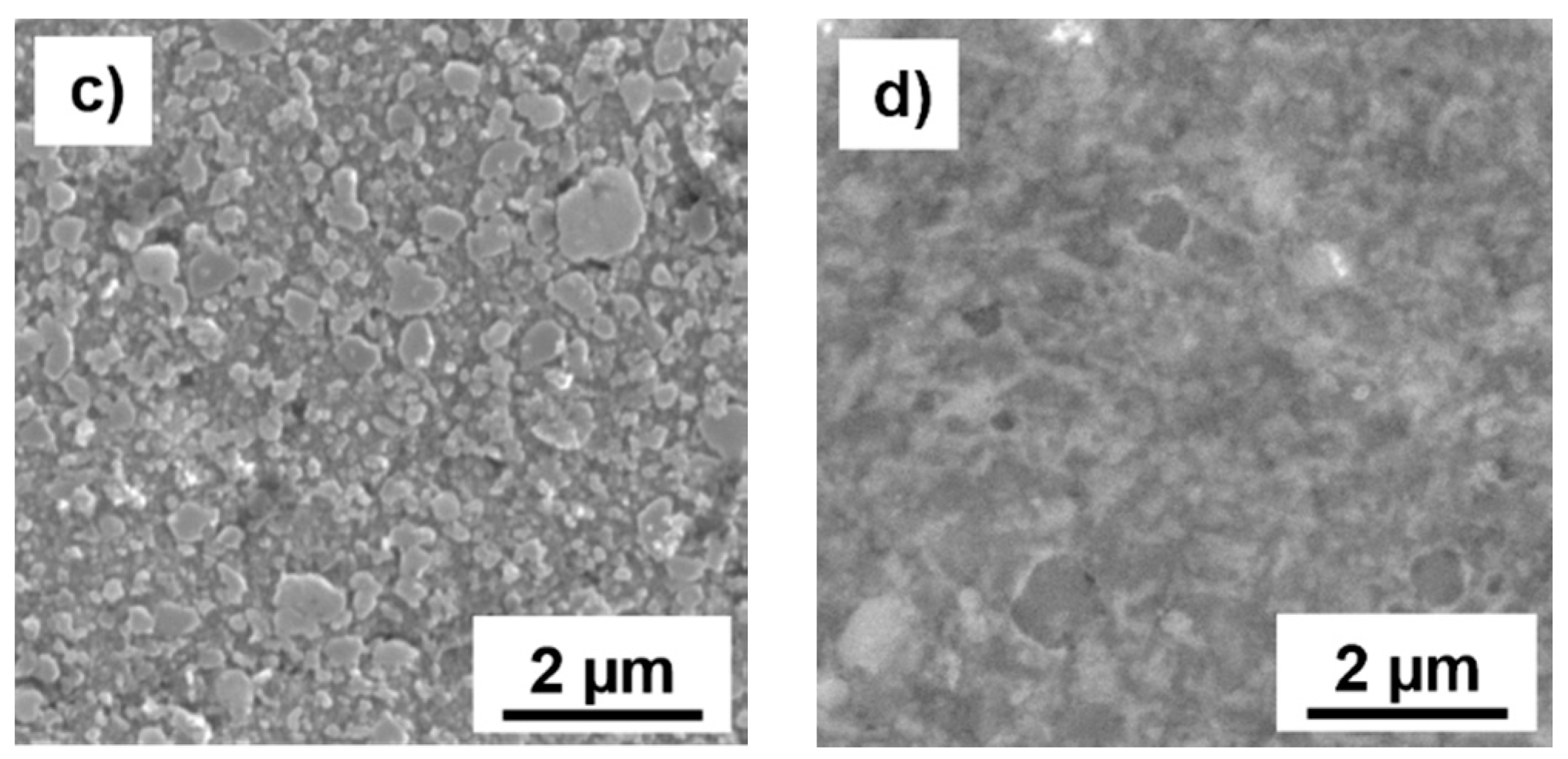

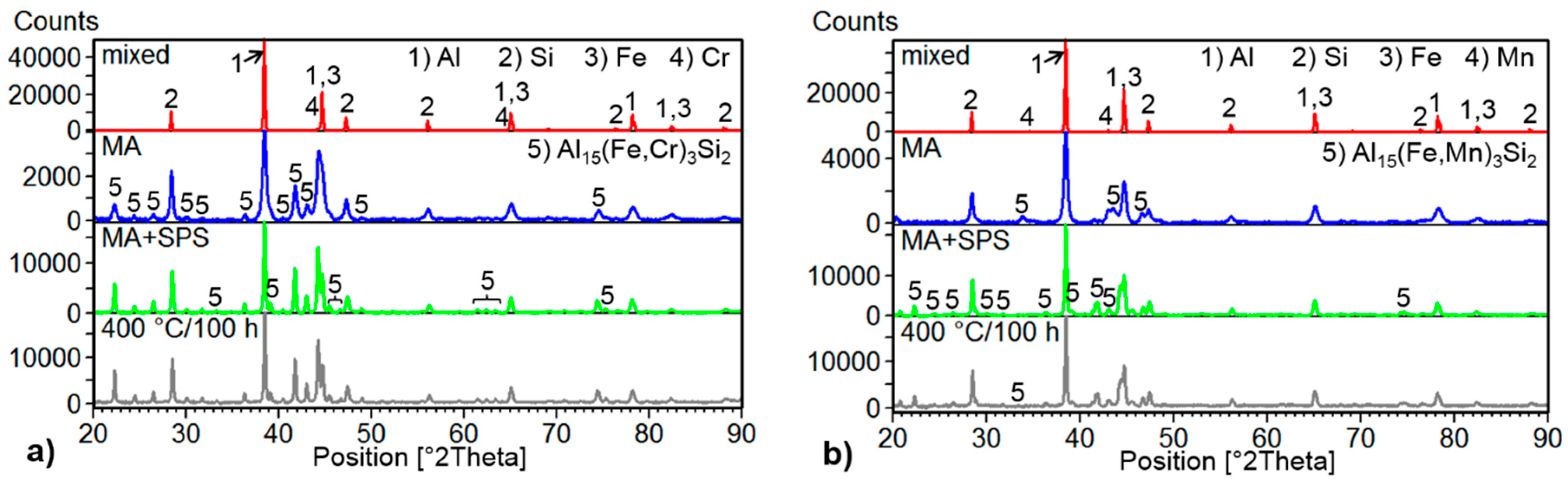

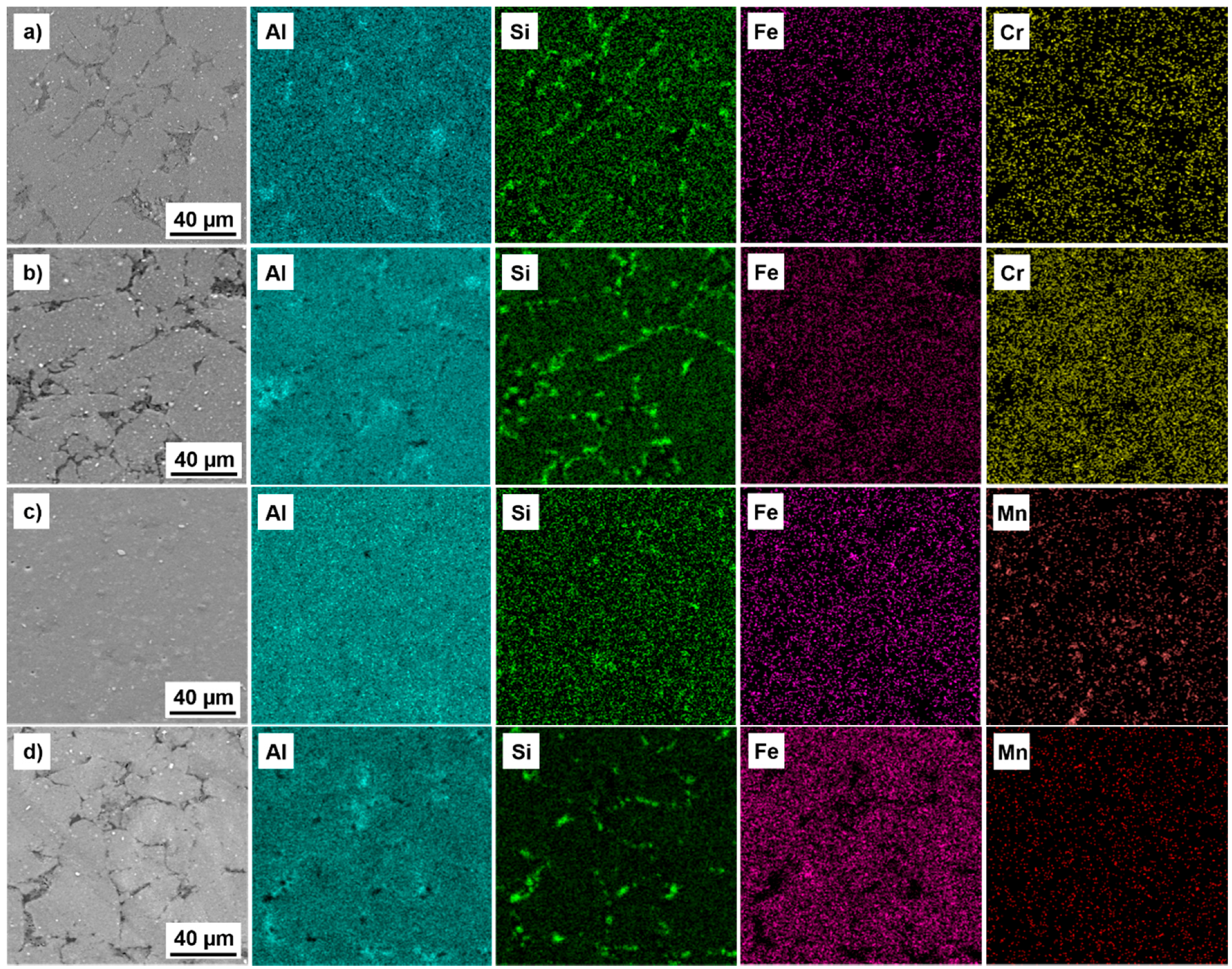

2.1. Microstructure and Phase Compositions

2.2. Mechanical Properties

3. Discussion

3.1. Microstructure

3.2. Mechanical Properties

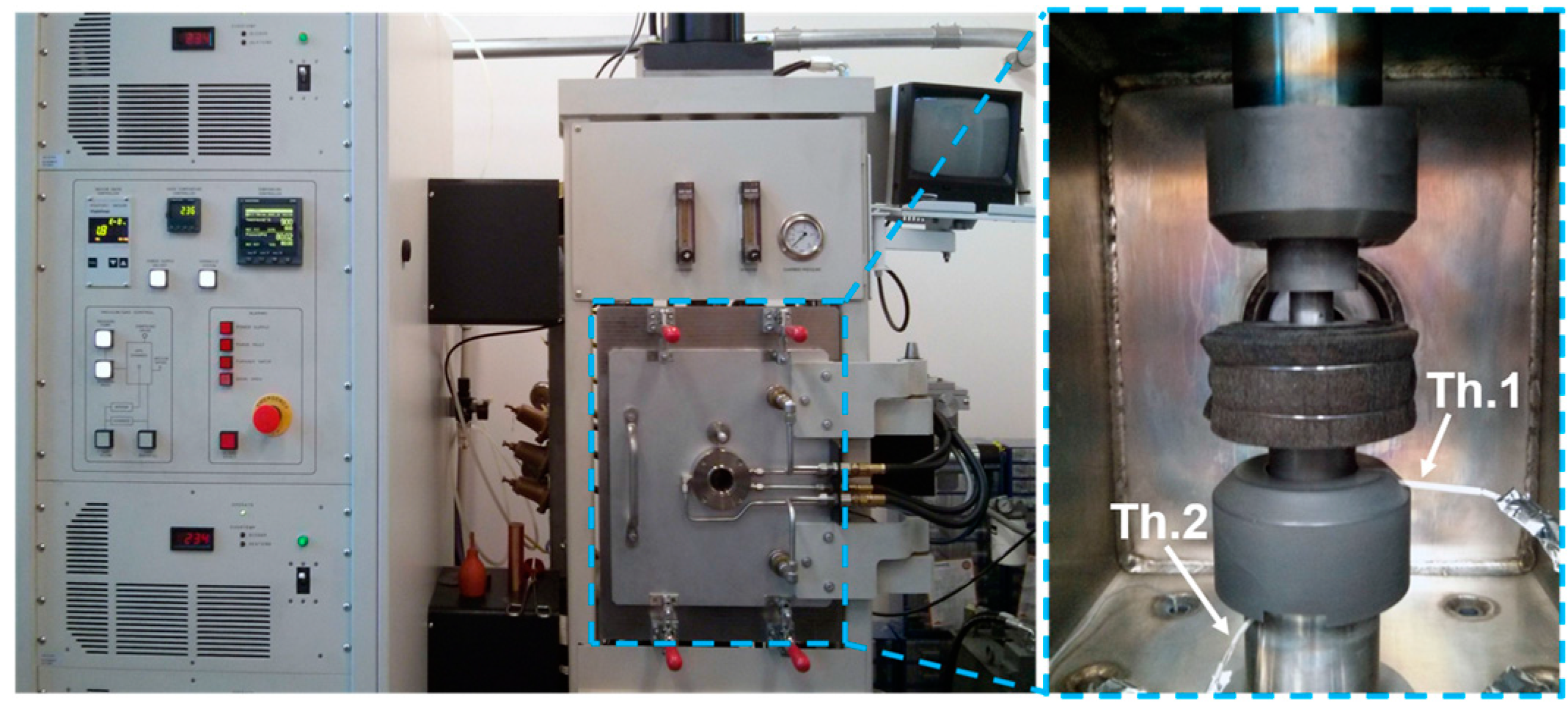

4. Materials and Methods

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lavernia, E.J.; Srivatsan, T.S. The rapid solidification processing of materials: Science, principles, technology, advances, and applications. J. Mater. Sci. 2010, 45, 287–325. [Google Scholar] [CrossRef]

- Chen, J.; Lengsdorf, R.; Henein, H.; Herlach, D.M.; Dahlborg, U.; Calvo-Dahlborg, M. Microstructure evolution in undercooled Al–8 wt %Fe melts: Comparison between terrestrial and parabolic flight conditions. J. Alloys Compd. 2013, 556, 243–251. [Google Scholar] [CrossRef]

- Karaköse, E.; Keskin, M. Structural investigations of mechanical properties of Al based rapidly solidified alloys. Mater. Des. 2011, 32, 4970–4979. [Google Scholar] [CrossRef]

- Kim, T.-S.; Suryanarayana, C.; Chun, B.-S. Effect of alloying elements and degassing pressure on the structure and mechanical properties of rapidly solidified Al–20Si–5Fe–2X (X = Cr, Zr, or Ni) alloys. Mater. Sci. Eng. A 2000, 278, 113–120. [Google Scholar] [CrossRef]

- Louzguine, D.V.; Takeuchi, A.; Inoue, A. New amorphous alloys in Al–Si–Fe–TM (TM = Cr, Mn, V) systems and their crystallization behavior. J. Mater. Sci. Lett. 1998, 17, 1439–1442. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, K.-S.; Wu, H.-C.; Yu, M.-H. Experimental and numerical investigation on pure aluminum by ECAP. Trans. Nonferrous Met. Soc. China 2009, 19, 1303–1311. [Google Scholar] [CrossRef]

- Langdon, T.G. The principles of grain refinement in equal-channel angular pressing. Mater. Sci. Eng. A 2007, 462, 3–11. [Google Scholar] [CrossRef]

- Mani, B.; Jahedi, M.; Paydar, M.H. Consolidation of commercial pure aluminum powder by torsional-equal channel angular pressing (T-ECAP) at room temperature. Powder Technol. 2012, 219, 1–8. [Google Scholar] [CrossRef]

- Balog, M.; Simancik, F.; Bajana, O.; Requena, G. ECAP vs. direct extrusion—Techniques for consolidation of ultra-fine Al particles. Mater. Sci. Eng. A 2009, 504, 1–7. [Google Scholar] [CrossRef]

- Neikov, O.D. Mechanical Alloying. In Handbook of Non-Ferrous Metal Powders; Neikov, O.D., Naboychenko, S.S., Murashova, I.V., Gopienko, V.G., Frishberg, I.V., Lotsko, D.V.S., Eds.; Elsevier: Oxford, UK, 2009; pp. 63–79. [Google Scholar]

- Gu, J.; Gu, S.; Xue, L.; Wu, S.; Yan, Y. Microstructure and mechanical properties of in-situ Al13Fe4/Al composites prepared by mechanical alloying and spark plasma sintering. Mater. Sci. Eng. A 2012, 558, 684–691. [Google Scholar] [CrossRef]

- Neikov, O.D. Nanopowders. In Handbook of Non-Ferrous Metal Powders; Neikov, O.D., Naboychenko, S.S., Murashova, I.V., Gopienko, V.G., Frishberg, I.V., Lotsko, D.V.S., Eds.; Elsevier: Oxford, UK, 2009; pp. 80–101. [Google Scholar]

- Zheng, R.; Yang, H.; Liu, T.; Ameyama, K.; Ma, C. Microstructure and mechanical properties of aluminum alloy matrix composites reinforced with Fe-based metallic glass particles. Mater. Des. 2014, 53, 512–518. [Google Scholar] [CrossRef]

- Cardoso, K.R.; Rodrigues, C.A.D.; Botta F, W.J. Processing of aluminium alloys containing titanium addition by mechanical alloying. Mater. Sci. Eng. A 2004, 1201–1205. [Google Scholar] [CrossRef]

- Ashrafi, H.; Enayati, M.H.; Emadi, R. Nanocrystalline Al/Al12(Fe,V)3Si alloy prepared by mechanical alloying: Synthesis and thermodynamic analysis. Adv. Powder Technol. 2014, 25, 1483–1491. [Google Scholar] [CrossRef]

- Mendis, C.L.; Jhawar, H.P.; Sasaki, T.T.; Oh-ishi, K.; Sivaprasad, K.; Fleury, E.; Hono, K. Mechanical properties and microstructures of Al–1Fe–(0-1)Zr bulk nano-crystalline alloy processed by mechanical alloying and spark plasma sintering. Mater. Sci. Eng. A 2012, 541, 152–158. [Google Scholar] [CrossRef]

- Bidmeshki, C.; Abouei, V.; Saghafian, H.; Shabestari, S.G.; Noghani, M.T. Effect of Mn addition on Fe-rich intermetallics morphology and dry sliding wear investigation of hypereutectic Al-17.5%Si alloys. J. Mater. Res. Technol. 2016, 5, 250–258. [Google Scholar] [CrossRef]

- Zhao, Q.; Qian, Z.; Cui, X.; Wu, Y.; Liu, X. Optimizing microstructures of dilute Al–Fe–Si alloys designed with enhanced electrical conductivity and tensile strength. J. Alloys Compd. 2015, 650, 768–776. [Google Scholar] [CrossRef]

- Cai, Y.; Liang, R.; Hou, L.; Zhang, J. Effect of Cr and Mn on the microstructure of spray-formed Al–25Si–5Fe–3Cu alloy. Mater. Sci. Eng. A 2011, 528, 4248–4254. [Google Scholar] [CrossRef]

- Abouei, V.; Saghafian, H.; Shabestari, S.G.; Zarghami, M. Effect of Fe-rich intermetallics on the wear behavior of eutectic Al–Si piston alloy (LM13). Mater. Des. 2010, 31, 3518–3524. [Google Scholar] [CrossRef]

- Shabestari, S.G.; Parshizfard, E. Effect of semi-solid forming on the microstructure and mechanical properties of the iron containing Al–Si alloys. J. Alloys Compd. 2011, 509, 7973–7978. [Google Scholar] [CrossRef]

- Lin, C.; Wu, S.; Lü, S.; An, P.; Wan, L. Microstructure and mechanical properties of rheo-diecast hypereutectic Al–Si alloy with 2%Fe assisted with ultrasonic vibration process. J. Alloys Compd. 2013, 568, 42–48. [Google Scholar] [CrossRef]

- Koraman, E.; Baydoğan, M.; Sayılgan, S.; Kalkanlı, A. Dry sliding wear behaviour of Al–Fe–Si–V alloys at elevated temperatures. Wear 2015, 322, 101–107. [Google Scholar] [CrossRef]

- Moustafa, M.A. Effect of iron content on the formation of β-Al5FeSi and porosity in Al–Si eutectic alloys. J. Mater. Process. Technol. 2009, 209, 605–610. [Google Scholar] [CrossRef]

- Průša, F.; Vojtěch, D.; Bláhová, M.; Michalcová, A.; Kubatík, T.F.; Čížek, J. Structure and mechanical properties of Al-Si-Fe alloys prepared by short-term mechanical alloying and spark plasma sintering. Mater. Des. 2015, 75, 65–75. [Google Scholar] [CrossRef]

- Eisaabadi B, G.; Davami, P.; Varahram, N.; Kim, S.K. On the effect of hydrogen and Fe on reproducibility of tensile properties in cast Al–Si–Mg alloys. Mater. Sci. Eng. A 2013, 565, 278–284. [Google Scholar] [CrossRef]

- Gorny, A.; Manickaraj, J.; Cai, Z.; Shankar, S. Evolution of Fe based intermetallic phases in Al–Si hypoeutectic casting alloys: Influence of the Si and Fe concentrations, and solidification rate. J. Alloys Compd. 2013, 577, 103–124. [Google Scholar] [CrossRef]

- Rajabi, M.; Vahidi, M.; Simchi, A.; Davami, P. Effect of rapid solidification on the microstructure and mechanical properties of hot-pressed Al–20Si–5Fe alloys. Mater. Charact. 2009, 60, 1370–1381. [Google Scholar] [CrossRef]

- Orozco-González, P.; Castro-Román, M.; Muñiz-Valdez, R.; Luna-Álvarez, S.; Equihua-Guillén, F.; Hernández-Rodríguez, A.; Baltazar-Hernández, V.H.; Alvarado-Hernández, F. Formation and crystal structure of the τ phase in the Al-Fe-Mn-Si system. Mater. Lett. 2016, 180, 277–279. [Google Scholar] [CrossRef]

- Wang, E.R.; Hui, X.D.; Wang, S.S.; Zhao, Y.F.; Chen, G.L. Improved mechanical properties in cast Al–Si alloys by combined alloying of Fe and Cu. Mater. Sci. Eng. A 2010, 527, 7878–7884. [Google Scholar] [CrossRef]

- Seifeddine, S.; Johansson, S.; Svensson, I.L. The influence of cooling rate and manganese content on the β-Al5FeSi phase formation and mechanical properties of Al–Si-based alloys. Mater. Sci. Eng. A 2008, 490, 385–390. [Google Scholar] [CrossRef]

- Průša, F.; Vojtěch, D.; Michalcová, A.; Marek, I. Mechanical properties and thermal stability of Al–Fe–Ni alloys prepared by centrifugal atomisation and hot extrusion. Mater. Sci. Eng. A 2014, 603, 141–149. [Google Scholar] [CrossRef]

- Průša, F.; Vojtěch, D.; Dám, K. Characterization of the Al-13Si-10Fe alloy produced by centrifugal atomization and ultra-high-pressure compaction. Kovove Mater. Met. Mater. 2012, 50, 399–406. [Google Scholar]

- Průša, F.; Vojtech, D.; Bernatiková, A.; Dvorskỳ, D. Mechanical alloying: A way how to improve properties of aluminium alloys. Manuf. Technol. 2015, 15, 1036–1043. [Google Scholar]

- Rajabi, M.; Simchi, A.; Vahidi, M.; Davami, P. Effect of particle size on the microstructure of rapidly solidified Al–20Si–5Fe–2X (X = Cu, Ni, Cr) powder. J. Alloys Compd. 2008, 466, 111–118. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, Z.; Ma, Y.; Jin, Y. Effect of Fe and Mn additions on microstructure and wear properties of spray-deposited Al–20Si alloy. Mater. Lett. 2004, 58, 2442–2446. [Google Scholar] [CrossRef]

- Yang, B.; Wang, F.; Zhang, J.S.; Xiong, B.Q.; Duan, X.J. The effect of Mn on the microstructure of spray-deposited Al–20Si–5Fe–3Cu–1Mg alloy. Scr. Mater. 2001, 45, 509–515. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, J.; Xiong, B.; Zhang, Y. Effect of Fe and Mn additions on microstructure and mechanical properties of spray-deposited Al–20Si–3Cu–1 Mg alloy. Mater. Charact. 2009, 60, 384–388. [Google Scholar] [CrossRef]

- Gale, W.F.; Totemeier, T.C. Smithells Metals Reference Book, 8th ed.; Butterworth-Heinemann: Oxford, UK, 2003. [Google Scholar]

- Yi, J.Z.; Gao, Y.X.; Lee, P.D.; Lindley, T.C. Effect of Fe-content on fatigue crack initiation and propagation in a cast aluminum–silicon alloy (A356–T6). Mater. Sci. Eng. A 2004, 386, 396–407. [Google Scholar] [CrossRef]

- Sasaki, T.T.; Mukai, T.; Hono, K. A high-strength bulk nanocrystalline Al–Fe alloy processed by mechanical alloying and spark plasma sintering. Scr. Mater. 2007, 57, 189–192. [Google Scholar] [CrossRef]

- Hung, P.C.; Sun, P.L.; Yu, C.Y.; Kao, P.W.; Chang, C.P. Inhomogeneous tensile deformation in ultrafine-grained aluminum. Scr. Mater. 2005, 53, 647–652. [Google Scholar] [CrossRef]

| Alloy (wt %) | Stage of Preparation | 2θ (°) | FWHM |

|---|---|---|---|

| Al (111) | Al (111) | ||

| Al-20Si-10Fe-6Cr | as mixed | 38.379 | 0.140 |

| MA | 38.427 | 0.264 | |

| MA + SPS | 38.433 | 0.195 | |

| 400 °C/100 h | 38.458 | 0.194 | |

| Al-20Si-10Fe-6Mn | as mixed | 38.408 | 0.131 |

| MA | 38.449 | 0.286 | |

| MA + SPS | 38.445 | 0.195 | |

| 400 °C/100 h | 38.458 | 0.195 |

| Alloy (Preparation) | Element (at %) | Corresponding Phase | ||||

|---|---|---|---|---|---|---|

| Point No. | Al | Si | Fe | Cr | Mn | |

| Al-20Si-10Fe-6Cr (MA + SPS) | ||||||

| 1 | 96.5 | 0.8 | 1.8 | 0.9 | - | α-Al |

| 2 | 97.2 | 0.9 | 1.2 | 0.7 | - | α-Al |

| 3 | 76.2 | 10.0 | 9.0 | 4.8 | - | Al15(Fe,Cr)3Si2 |

| 4 | 77.5 | 9.1 | 8.7 | 4.7 | - | Al15(Fe,Cr)3Si2 |

| Al-20Si-10Fe-6Mn (MA + SPS) | ||||||

| 1 | 96.5 | 1.4 | 1.3 | - | 0.8 | α-Al |

| 2 | 96.0 | 0.9 | 1.7 | - | 1.4 | α-Al |

| 3 | 72.7 | 11.8 | 12.2 | - | 3.3 | Al15(Fe,Mn)3Si2 |

| 4 | 76.1 | 9.4 | 10.4 | - | 4.1 | Al15(Fe,Mn)3Si2 |

| Alloy | As-Prepared (LT) | Annealed at 400 °C/100 h (LT) | At 400 °C | ||||||

|---|---|---|---|---|---|---|---|---|---|

| HV5 | CS | CYS a | HV5 | CS | CYS a | HV5 b | CSb | CYS | |

| Al-20Si-10Fe-6Cr | 380 ± 7 | 869 | - | 350 ± 10 | 870 | - | - | - | 409 |

| Al-20Si-10Fe-6Mn | 320 ± 6 | 887 | - | 312 ± 7 | 865 | - | - | - | 232 |

| Al-12Si-1Cu-1Mg-1Ni | 121 ± 11 | 680 | 430 | 63 ± 8 | 498 | 180 | - | - | 100 |

| Material (Preparation) | Element (wt %) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ca | Cr | Cu | Fe | Mg | Mn | Ni | Si | Ti | Al | |

| Al-20Si-10Fe-6Cr (MA + SPS) | - | 5.8 | - | 10.4 | - | - | - | 20.3 | - | Bal. |

| Al-20Si-10Fe-6Mn (MA + SPS) | - | 0.3 | - | 10.1 | - | 6.1 | - | 20.2 | - | Bal. |

| Al-12Si-1Cu-1Mg-1Ni (cast, T6 heat-treated) | 0.1 | 0.1 | 1.2 | 0.2 | 1.0 | 0.2 | 0.9 | 11.8 | 0.1 | Bal. |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Průša, F.; Bláhová, M.; Vojtěch, D.; Kučera, V.; Bernatiková, A.; Kubatík, T.F.; Michalcová, A. High-Strength Ultra-Fine-Grained Hypereutectic Al-Si-Fe-X (X = Cr, Mn) Alloys Prepared by Short-Term Mechanical Alloying and Spark Plasma Sintering. Materials 2016, 9, 973. https://doi.org/10.3390/ma9120973

Průša F, Bláhová M, Vojtěch D, Kučera V, Bernatiková A, Kubatík TF, Michalcová A. High-Strength Ultra-Fine-Grained Hypereutectic Al-Si-Fe-X (X = Cr, Mn) Alloys Prepared by Short-Term Mechanical Alloying and Spark Plasma Sintering. Materials. 2016; 9(12):973. https://doi.org/10.3390/ma9120973

Chicago/Turabian StylePrůša, Filip, Markéta Bláhová, Dalibor Vojtěch, Vojtěch Kučera, Adriana Bernatiková, Tomáš František Kubatík, and Alena Michalcová. 2016. "High-Strength Ultra-Fine-Grained Hypereutectic Al-Si-Fe-X (X = Cr, Mn) Alloys Prepared by Short-Term Mechanical Alloying and Spark Plasma Sintering" Materials 9, no. 12: 973. https://doi.org/10.3390/ma9120973