Thermal Shock and Oxidation Behavior of HiPIMS TiAlN Coatings Grown on Ti-48Al-2Cr-2Nb Intermetallic Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

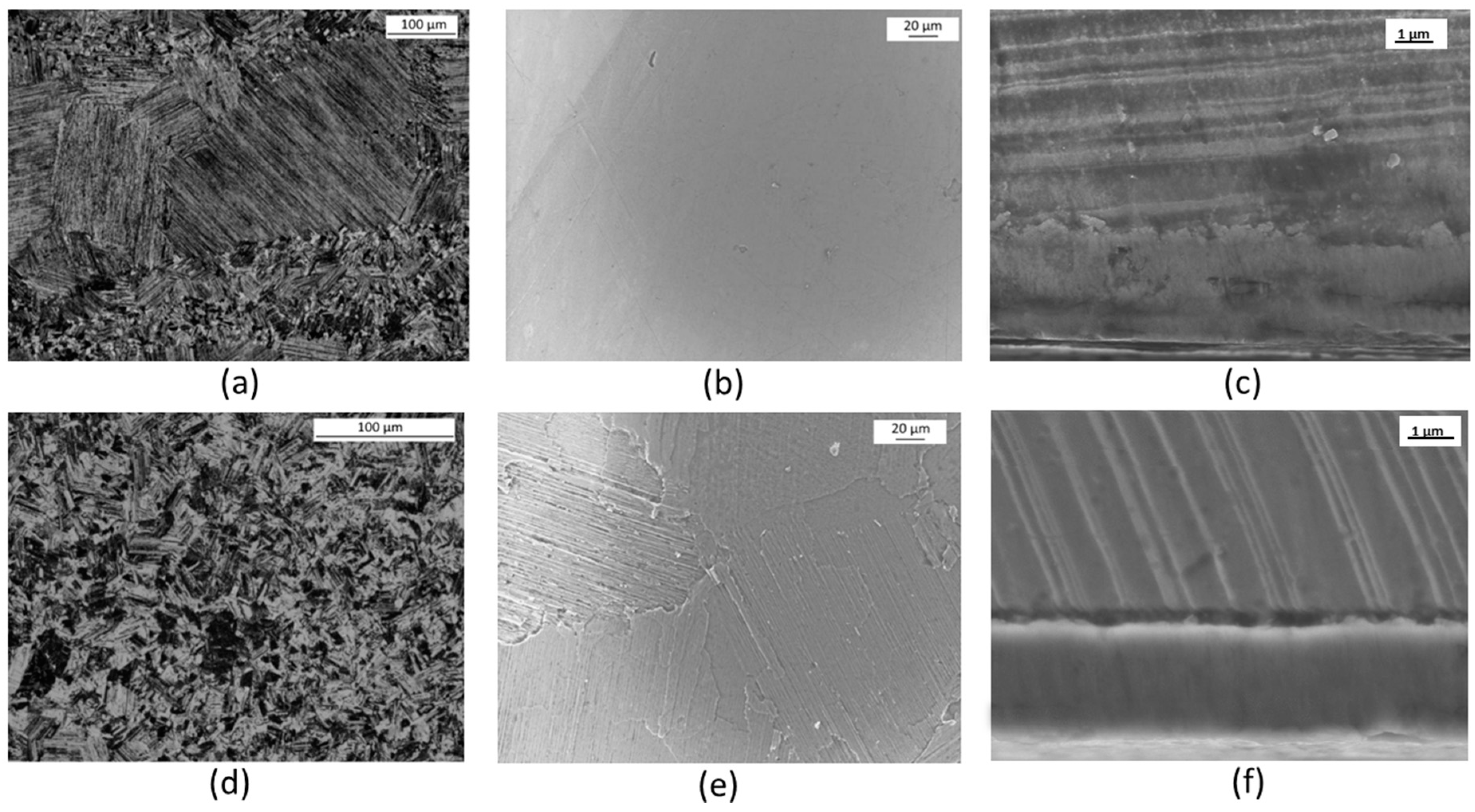

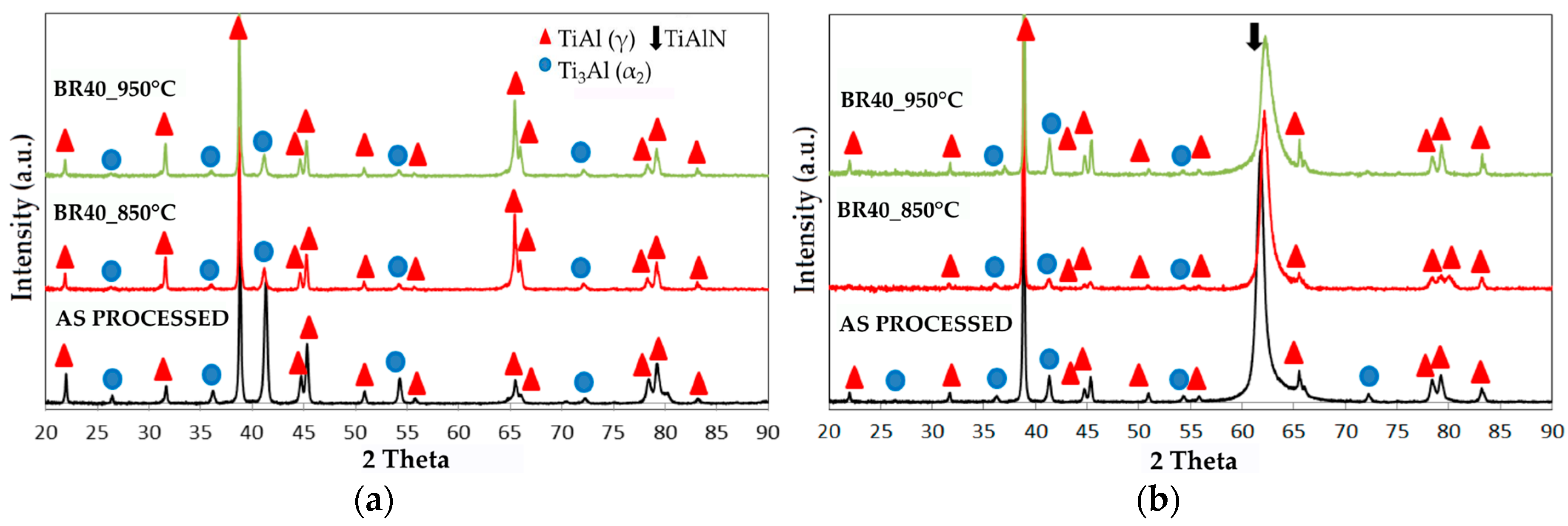

3.1. Microstructure Investigation

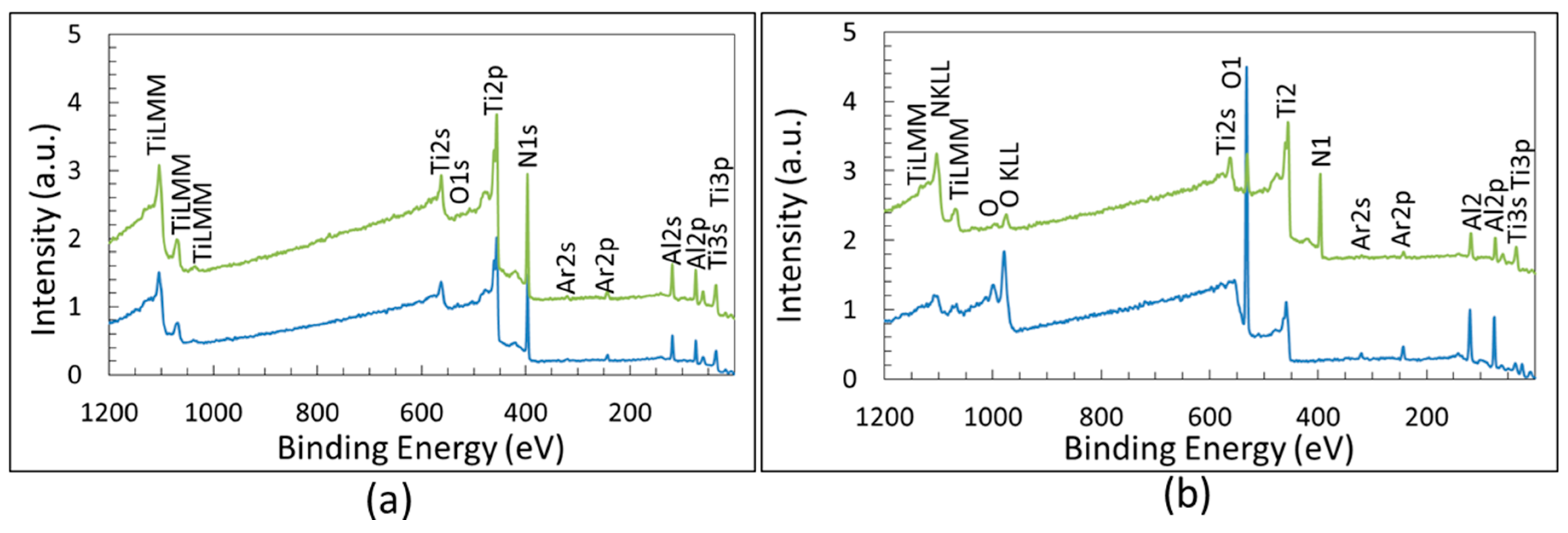

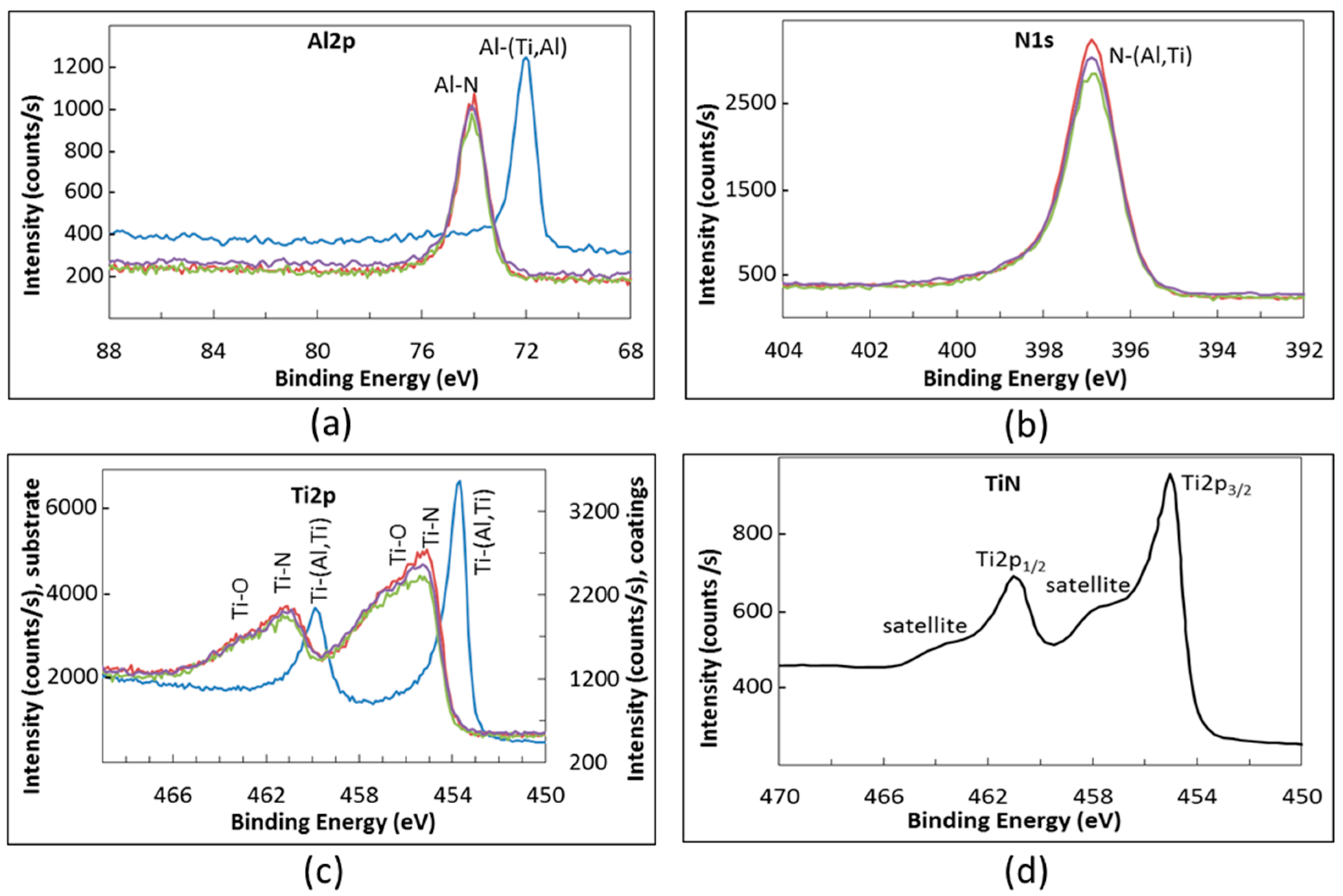

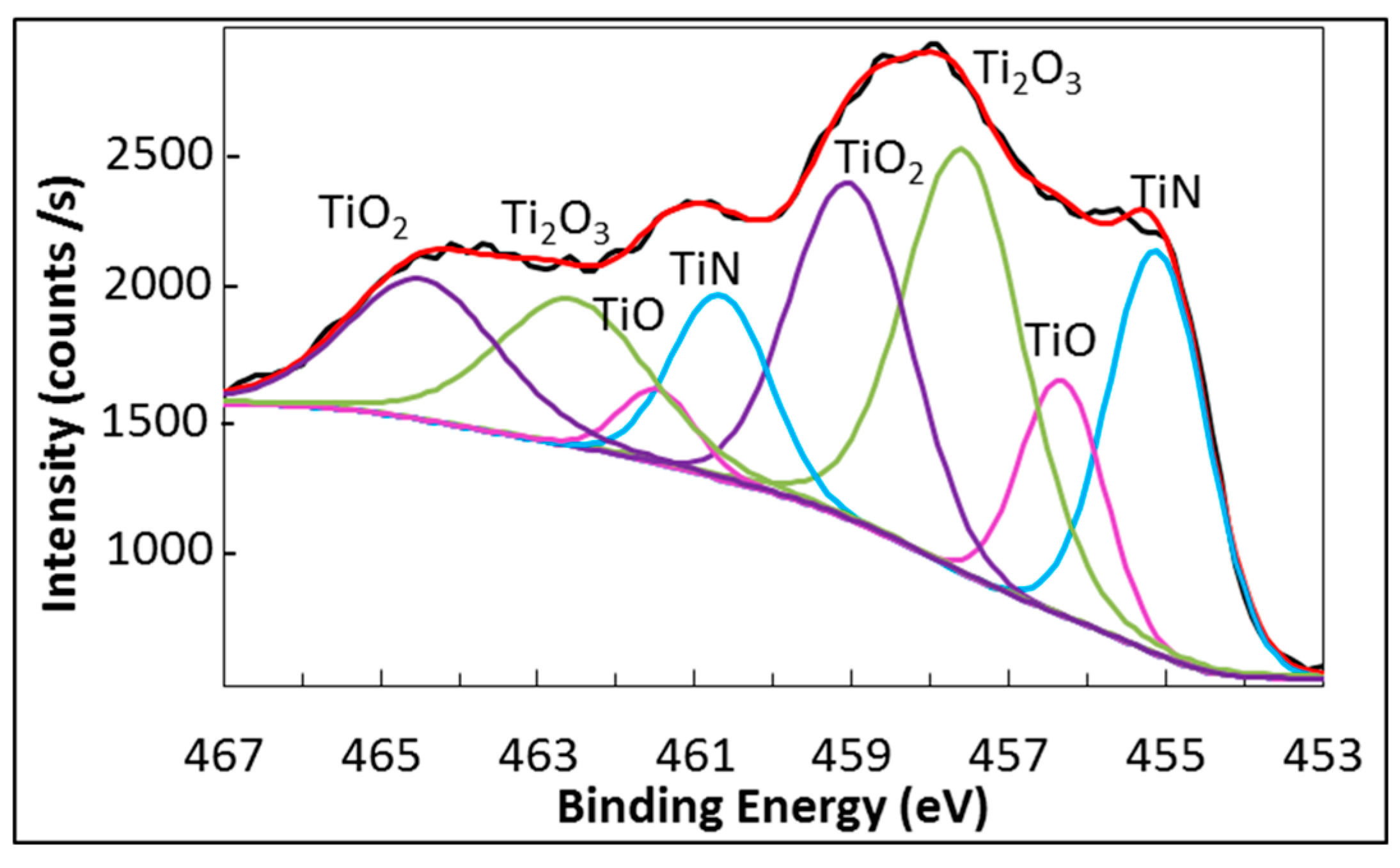

3.2. XPS Chemical Analysis

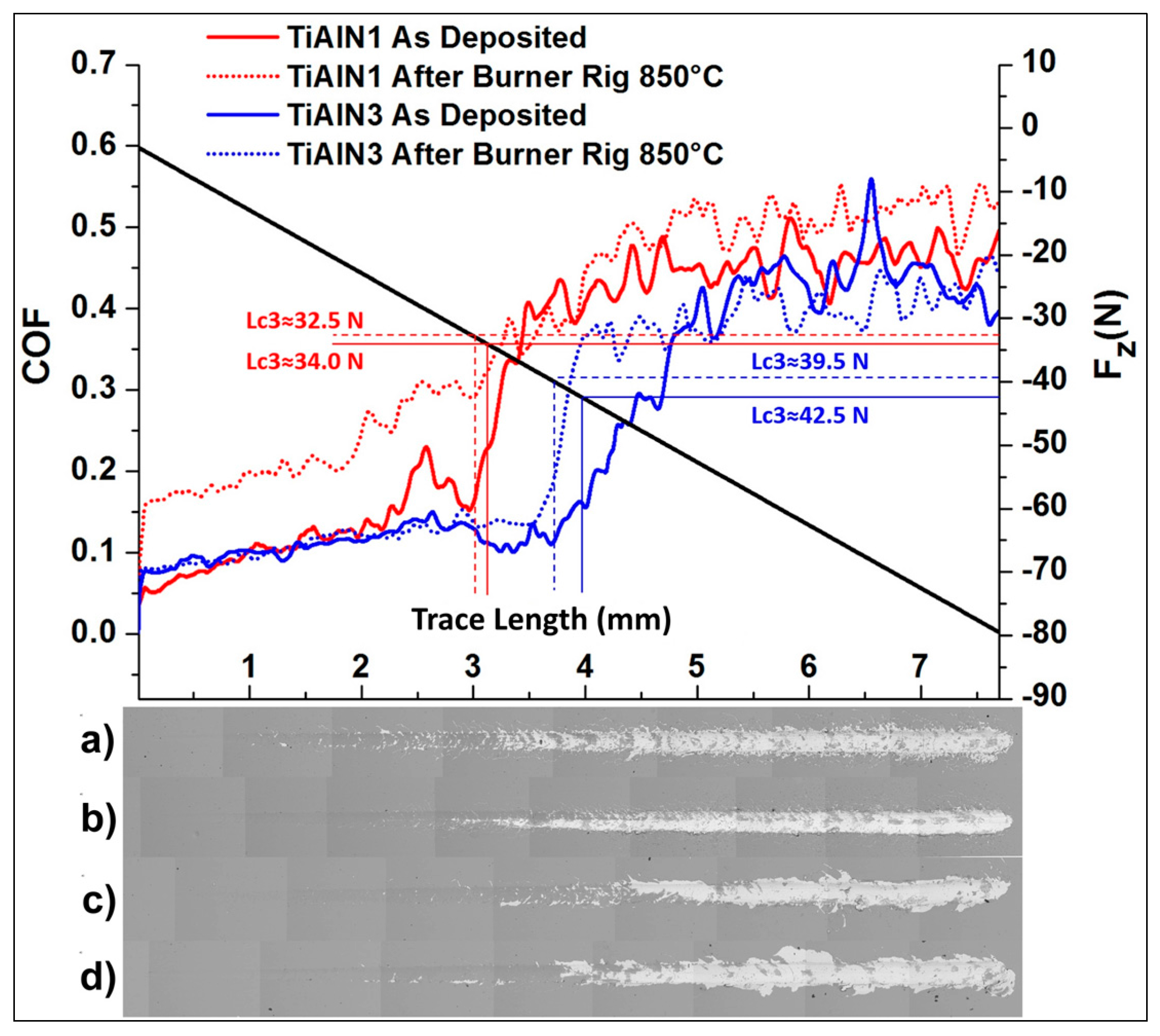

3.3. Scratch Tests and Wear Behavior

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Loria, E.A. Gamma titanium alluminides as prospective structural materials. Intermetallics 2000, 8, 1339–1345. [Google Scholar] [CrossRef]

- Kothari, K.; Radhakrishnan, R.; Werely, N.M. Advances in gamma titanium aluminides and their manufacturing technologies. Prog. Aerosp. Sci. 2012, 55, 1–16. [Google Scholar] [CrossRef]

- Dai, J.; Zhu, J.; Chen, C.; Weng, F. High temperature oxidation behavior and research status of modifications on improving high temperature oxidation resistance of titanium alloys and titanium aluminides: A review. J. Alloys Compd. 2016, 685, 784–798. [Google Scholar] [CrossRef]

- Dimiduk, D.M.; Martin, P.L.; Dutton, R. Accelerated insertion of materials: Gamma alloys pose challenges, but are really not unique. In Proceeding of the 2003 TMS Annual Meeting & Exhibition: 3rd International Symposium on Gamma Titanium Aluminides, San Diego, CA, USA, 2–6 March 2003; pp. 15–22.

- Baur, H.; Wortberg, D.B.; Clemens, H. Titanium Aluminides for Automotive Applications. In Proceeding of the 2003 TMS Annual Meeting & Exhibition: 3rd International Symposium on Gamma Titanium Aluminides, San Diego, CA, USA, 2–6 March 2003; pp. 15–22.

- GE Aviation. The GEnx Commercial Aircraft Engine. Available online: http://www.geae.com/engines/commercial/genx/ (accessed on 13 May 2016).

- Terner, M.; Biamino, S.; Epicoco, P.; Penna, A.; Hedin, O.; Sabbadini, S.; Fino, P.; Pavese, M.; Ackelid, U.; Badini, C.; et al. Electron Beam Melting of high niobium containing TiAl alloy: Feasibility investigation. Steel Res. Int. 2012, 83, 943–949. [Google Scholar] [CrossRef]

- Biamino, S.; Penna, A.; Ackelid, U.; Sabbadini, S.; Tassa, O.; Fino, P.; Pavese, M.; Gennaro, P.; Badini, C. Electron beam melting of Ti-48Al-2Cr-2Nb alloy: Microstructure and mechanical properties investigation. Intermetallics 2011, 19, 776–781. [Google Scholar] [CrossRef]

- Appel, F.; Oering, M.; Wagner, R. Novel design concepts for gamma-base titanium aluminide alloys. Intermetallics 2000, 8, 1283–1312. [Google Scholar] [CrossRef]

- Schwaighofer, E.; Clemens, H.; Mayer, S.; Lindemann, J.; Klose, J.; Smarsly, W.; Guter, V. Microstructural design and mechanical properties of a cast and heat-treated intermetallic multi-phase γ-TiAl based alloy. Intermetallics 2014, 44, 128–140. [Google Scholar] [CrossRef]

- Betwlay, B.P.; Nag, S.; Suzuki, A.; Weimer, M.J. TiAl alloys in commercial aircraft engines. Mater. High Temp. 2016, 33, 549–559. [Google Scholar] [CrossRef]

- Nam, S.W. Single crystal blade for a gas turbine engine: A review of the characteristics and recent research trends for thermal barrier coating. Korean J. Met. Mater. 2015, 53, 833–843. [Google Scholar] [CrossRef]

- Martena, M.; Botto, D.; Fino, P.; Sabbadini, S.; Gola, M.M.; Badini, C. Modelling of TBC system failure: Stress distribution as a function of TGO thickness and thermal expansion mismatch. Eng. Fail. Anal. 2006, 13, 409–426. [Google Scholar] [CrossRef]

- Jeon, S.; Van Tyne, C.J.; Lee, H. Degradation of TiAlN coating by the accelerated life test using pulsed laser ablation. Ceram. Int. 2014, 40, 8677–8685. [Google Scholar] [CrossRef]

- Panjan, P.; Navinsek, B.; Cekada, M.; Zalar, A. Oxidation behavior of TiAlN coating sputtered at low temperature. Vacuum 1999, 53, 127–131. [Google Scholar] [CrossRef]

- Koller, C.M.; Hollerwerger, R.; Rauchbauer, R.; Polcik, P.; Paulitsch, J.; Mayrhofer, P.H. Thermal stability and oxidation resistance of TiAlN/TaAlN multilayer coating. In Proceedings of the 18th Plansee Seminar Conference, Reutte, Austria, 3–7 June 2013.

- Chen, L.; Paulitsch, J.; Du, Y.; Mayrhofer, P.H. Thermal stability and oxidation resistance of Ti–Al–N coatings. Surf. Coat. Technol. 2012, 206, 2954–2960. [Google Scholar] [CrossRef] [PubMed]

- Caliskan, H.; Karaoglanli, A.C. Oxidation behavior of TiAlN/TiN nanolayer hard coating at high temperature. Acta Phys. Polym. A 2014, 125, 456–458. [Google Scholar] [CrossRef]

- Barshilia, H.C.; Yogesh, K.; Rajam, K.S. Deposition of TiAlN coating using reactive bipolar-pulsed direct current unbalanced magneton sputtering. Vacuum 2008, 83, 427–434. [Google Scholar] [CrossRef]

- Nose, M.; Kawabata, T.; Khamseh, S.; Matsuda, K.; Fujii, K.; Ikeno, S.; Chiou, W. Microstructure and properties of TiAlN/a-C nanocomposite coatings prepared by reactive sputtering. Mater. Trans. 2010, 51, 282–287. [Google Scholar] [CrossRef]

- Aperador, W.; Roa-Rodriguez, G.; Mejia, A. Characterization and corrosion behavior of multilayer [TiAlN]n growth on AISI 316LVM steel. Int. J. Electrochem. Sci. 2014, 9, 5025–5034. [Google Scholar]

- Ait-Djafer, A.Z.; Saoula, N.; Aknouche, H.; Guedouar, B.; Madaoui, N. Deposition and characterization of titanium aluminum nitride coating prepared by RF magneton sputtering. Appl. Surf. Sci. 2015, 350, 6–9. [Google Scholar] [CrossRef]

- Ichimura, H.; Kawana, A. High-temperature oxidation of ion-plated TiN and TiAlN films. J. Mater. Res. 1993, 8, 1093–1100. [Google Scholar] [CrossRef]

- Pflumm, R.; Friedle, S.; Schutze, M. Oxidation protection of ϒ-TiAl based alloys—A review. Intermetallics 2015, 56, 1–14. [Google Scholar] [CrossRef]

- Kouznetsov, V.; Macák, K.; Schneider, J.M.; Helmersson, U.; Petrov, I. A novel pulsed magnetron sputter technique utilizing very high target power densities. Surf. Coat. Technol. 1999, 122, 290–293. [Google Scholar] [CrossRef]

- Anders, A. A review comparing cathodic arcs and high power impulse magnetron sputtering (HiPIMS). Surf. Coat. Technol. 2014, 257, 308–325. [Google Scholar] [CrossRef]

- Helmersson, U.; Lattemann, M.; Bohlmark, J.; Ehiasarian, A.P.; Gudmundsson, J.T. Ionized physical vapor deposition (IPVD): A review of technology and applications. Thin Solid Films 2006, 513, 1–24. [Google Scholar] [CrossRef]

- Böhlmark, J. Fundamentals of High Power Impulse Magnetron Sputtering. Ph.D. Thesis, Linköping University, Linköping, Sweden, March 2005. [Google Scholar]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- Gudmundsson, J.T.; Brenning, N.; Lundin, D.; Helmersson, U. High power impulse magnetron sputtering discharge. Vac. Sci. Technol. A 2012, 30, 030801. [Google Scholar] [CrossRef]

- Ehiasarian, A.P.; New, R.; Munz, W.D.; Hultman, L.; Helmersson, U.; Kouznetsov, V. Influence of high power densities on the composition of pulsed magnetron plasmas. Vacuum 2002, 65, 147–154. [Google Scholar] [CrossRef]

- Lemmer, O.; Kölker, W.; Bolz, S.; Schiffers, C. HiPIMS “goes production”, Actual status & outlook. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2012. [Google Scholar]

- Ehiasarian, A.P.; Wen, J.G.; Petrov, I. Interface microstructure engineering by high power impulse magnetron sputtering for the enhancement of adhesion. J. Appl. Phys. 2007, 101, 05431. [Google Scholar] [CrossRef]

- Lattemann, M.; Ehiasarian, A.P.; Bohlmark, J.; Persson, P.Å.O.; Helmersson, U. Investigation of high power impulse magnetron sputtering pretreated interfaces for adhesion enhancement of hard coatings on steel. Surf. Coat. Technol. 2006, 200, 6495–6499. [Google Scholar] [CrossRef]

- Advanced Technical Ceramics—Methods of Test for Ceramic Coatings—Determination of Adhesion and Other Mechanical Failure Modes by a Scratch Test; ISO 1071-3:2005; BSI: London, UK, 2005.

- Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear; ASTM G133-02; ASTM International: West Conshohocken, PA, USA, 2002.

- Kenneth, H.; Matthews, A.; Ronkainen, H. Coatings tribology—Contact mechanisms and surface design. Tribol. Int. 1998, 31, 107–120. [Google Scholar]

- Ikeda, T.; Satoh, H. Phase formation and characterization of hard coatings in the Ti-Al-N system prepared by the cathodic arc ion plating method. Thin Solid Films 1991, 195, 99–110. [Google Scholar] [CrossRef]

- Inamura, S.; Nobugai, K.; Kanamaru, F. The preparation of NaCl-type Ti1-xAlxN solid solution. J. Solid State Chem. 1987, 68, 124–127. [Google Scholar] [CrossRef]

- Ipaz, L.; Aperador, W.; Caicedo, J.; Esteve, J.; Zambrano, G. A Practical Application of X-ray Spectroscopy in Ti-Al-N and Cr-Al-N Thin Films in X-ray Spectroscopy; Sharma, S.K., Ed.; Intech: Rijeka, Croatia, 2012; pp. 21–38. [Google Scholar]

- Ha, S.M.; Park, M.H.; Kim, S.H. Magnetron sputtering of TiAlN films for inkjet printhead resistors. J. Ceram. Process. Res. 2012, 13, s16–s21. [Google Scholar]

- Marco, J.F.; Gancedo, J.R.; Auger, M.A.; Sànchez, O.; Albella, J.M. Chemical stability of TiN, TiAlN and AlN layers in aggressive SO2 environments. Surf. Interface Anal. 2005, 37, 1082–1091. [Google Scholar] [CrossRef]

- Ananthakumar, R.; Subramanian, B.; Kobayashi, A.; Jayachandran, M. Electrochemical corrosion and materials properties of reactively sputtered TiN/TiAlN multilayer coatings. Ceram. Int. 2012, 38, 477–485. [Google Scholar] [CrossRef]

- Chen, J.T.; Wang, J.; Zhang, F.; Zhang, G.A.; Fan, X.Y.; Wu, Z.G.; Yan, P.X. Characterization and temperature controlling property of TiAlN coatings deposited by reactive magnetron co-sputtering. J. Alloys Compd. 2009, 472, 91–96. [Google Scholar] [CrossRef]

- Rizzo, A.; Mirenghi, L.; Massaroa, M.; Galietti, U.; Capodieci, L.; Terzi, R.; Tapfer, L.; Valerini, D. Improved properties of TiAlN coatings through the multilayer structure. Surf. Coat. Technol. 2013, 235, 475–483. [Google Scholar] [CrossRef]

- Biesinger, M.C.; Lau, L.W.M.; Gerson, A.R.; Smart, R.C. Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Sc, Ti, V, Cu and Zn. Appl. Surf. Sci. 2010, 257, 887–898. [Google Scholar] [CrossRef]

- Mizuno, Y.; King, F.K.; Yamauchi, Y.; Homma, T.; Tanaka, A.; Takakuwa, Y.; Momose, T. Temperature dependence of oxide decomposition on titanium surfaces in ultrahigh vacuum. J. Vac. Sci. Technol. A 2002, 20, 1716–1721. [Google Scholar] [CrossRef]

- Lu, G.; Bernasek, S.L.; Schwartz, J. Oxidation of a polycrystalline titanium surface by oxygen and water. Surf. Sci. 2000, 458, 80–90. [Google Scholar] [CrossRef]

- Fu, Y.; Du, H.; Zhang, S.; Huang, W. XPS characterization of surface and interfacial structure of sputtered TiNi films on Si substrate, Mater. Sci. Eng. A 2005, 403, 25–31. [Google Scholar] [CrossRef]

- Maurice, V.; Despert, D.; Zanna, S.; Josso, P.; Bacos, M.-P.; Marcus, P. XPS study of the initial stages of oxidation of α2-Ti3Al and ϒ-TiAl intermetallic alloys. Acta Mater. 2007, 55, 3315–3325. [Google Scholar] [CrossRef]

- Ehiasarian, A.P. High-power impulse magnetron sputtering and its applications. Pure Appl. Chem. 2010, 82, 1247–1258. [Google Scholar] [CrossRef]

- Santana, A.E.; Karimia, A.; Derflinger, V.H.; Schutze, A. Thermal treatment effects on microstructure and mechanical properties of TiAlN thin films. Tribol Lett. 2004, 17, 689–696. [Google Scholar]

- Chinchanikar, S.; Choudhury, S.K. Hard turning using HiPIMS-coated carbide tools: Wear behavior under dry and minimum quantity lubrication (MQL). Measurement 2014, 55, 536–548. [Google Scholar] [CrossRef]

- Shum, P.W.; Tam, W.C.; Li, K.Y.; Zhou, Z.F.; Shen, Y.G. Mechanical and tribological properties of titanium–aluminium–nitride films deposited by reactive close-field unbalanced magnetron sputtering. Wear 2004, 257, 1030–1040. [Google Scholar] [CrossRef]

- Cui, W.F.; Shao, C.J. The improved corrosion resistance and anti-wear performance of Zr–xTi alloys by thermal oxidation treatment. Surf. Coat. Techol. 2015, 283, 101–107. [Google Scholar] [CrossRef]

- Thornton, J.A. The microstructure of sputter-deposited coatings. J. Vac. Sci. Technol. A 1984, 4, 3059–3065. [Google Scholar] [CrossRef]

- Thornton, J.A. Influence of substrate temperature and deposition rate on structure and topography of thick sputtered Cu coatings. J. Vac. Sci. Technol. 1975, 12, 830–835. [Google Scholar] [CrossRef]

| Deposition Steps | Woking Parameters | TiAlN1 | TiAlN2 | TiAlN3 |

|---|---|---|---|---|

| Substrate Pretreatment | Ultrasound cleaning | yes | yes | yes |

| HiPIMS plasma etching (min) | 0 | 60 | 10 | |

| TiAl Interlayer | no | no | yes | |

| Film Deposition Parameters | Mean cathode power (W) | 1000 | ||

| Mean cathode power density (W/cm2) | 12.5 | |||

| Pulse length (μs) | 25 | |||

| Frequency (Hz) | 500 | |||

| Gas | Ar + N2 (50%) | |||

| Pressure (mbar) | 1 × 10−2 | |||

| Substrate bias voltage (V) | −50 | |||

| Duration (min) | 180 | |||

| Sample | O1s (at %) | O Chemical Bonds | Al2p (at %) | Al Chemical Bonds and Species | Ti2p (at %) | Ti chemical Bonds and Species | N1s (at %) | N chemical Bonds and Species | Others (at %) |

|---|---|---|---|---|---|---|---|---|---|

| TiAl alloy | 0.8 | O-(Al,Ti) | 46.8 | Al-M | 43.3 | Ti-M; (Ti-O) | 0 | – | Nb = 4.5 Cr = 4.7 |

| TiAlN1 | 1.7 | O-(Al,Ti) | 23.7 | Al-N; Al-O (AlN; Al2O3) | 22.7 | Ti-N; Ti-O (TiN; TiO) | 50.1 | N-(Al,Ti) (TiAlN) | Ar = bal. |

| TiAlN2 | 0.7 | O-(Al,Ti) | 21.7 | Al-N; (Al-O) (AlN; Al2O3) | 23.9 | Ti-N; (Ti-O) (TiN; TiO) | 52.2 | N-(Al,Ti) (TiAlN) | Ar = bal. |

| TiAlN3 | 0.7 | O-(Al,Ti) | 24.0 | Al-N; (Al-O) (AlN; Al2O3) | 22.9 | Ti-N; (Ti-O) (TiN; TiO) | 50.7 | N-(Al,Ti) (TiAlN) | Ar = bal. |

| TiAl alloy tested at 850 °C | 63.4 | O-Ti; O-Al; (C=O; ads O2) | 17.2 | Al-O (Al2O3) | 15.7 | Ti-O (TiO2; TiO) | – | – | Nb = 0.7 Cr = 1.4 Ar, C = bal. |

| TiAlN1 tested at 850 °C | 52.5 | O-Ti; 0-Al; (ads O2) | 16.7 | Al-O (Al2O3) | 18.4 | Ti-O; Ti-N (TiO2 + Ti2O3; TiN; TiO) | 12.0 | N-(Al,Ti) (TiAlN) | Ar = bal. |

| TiAlN2 tested at 850 °C | 51.7 | O-Ti; 0-Al; (ads O2) | 17.8 | Al-O (Al2O3) | 18.5 | Ti-O; Ti-N (TiO2 + Ti2O3; TiN; TiO) | 12.0 | N-(Al,Ti) (TiAlN) | – |

| TiAlN3 tested at 850 °C | 7.4 | O-Ti; 0-Al | 21.8 | Al-N; Al-O (AlN; Al2O3) | 22.3 | Ti-N; Ti-O (TiN; TiO) | 46.2 | N-(Al,Ti) (TiAlN) | Ar = bal. |

| TiAl alloy tested at 950 °C | 67.6 | O-Ti; O-Al | 13.7 | Al-O (Al2O3) | 17.8 | Ti-O (TiO2 + Ti2O3; TiO) | – | – | – |

| TiAlN1 tested at 950 °C | 62.2 | O-Ti; O-Al | 29.4 | Al-O (Al2O3) | 7.0 | Ti-O; Ti-N (TiO2 + Ti2O3; TiO; TiN) | 1.4 | N-(Al,Ti) (TiAlN) | – |

| TiAlN3 tested at 950 °C | 16.1 | O-Ti; O-Al | 21 | Al-O; Al-N (Al2O3; AlN) | 21.8 | Ti-N; Ti-O (TiN; TiO2 + Ti2O3; TiO) | 41.1 | N-(Al,Ti) (TiAlN) | – |

| Sample | O1s (at %) | O Chemical Bonds | Al2p (at %) | Al Chemical Bonds and Species | Ti2p (at %) | Ti Chemical Bonds and Species | N1s (at %) | N Chemical Bonds and Species |

|---|---|---|---|---|---|---|---|---|

| TiAlN1 as prepared | 62.2 | O-Ti; O-Al | 29.4 | Al-O (Al2O3) | 7.0 | Ti-O; Ti-N (TiO2 + Ti2O3; TiO; TiN) | 1.4 | N-(Al,Ti) (TiAlN) |

| TiAlN1 as tested, after 20 min of surface sputtering | 52.8 | O-Ti; O-Al | 15 | Al-O (Al2O3) | 21 | Ti-O; Ti-N (TiO2 + Ti2O3; TiN; TiO) | 10 | N-(Al,Ti) (TiAlN) |

| TiAlN2 as prepared | 62.3 | O-Ti; O-Al | 31.9 | Al-O (Al2O3) | 4.4 | Ti-O (TiO2 (+Ti2O3); (TiO) | – | – |

| TiAlN2 as tested, after 20 min of surface sputtering | 64.1 | O-Ti; O-Al | 25.2 | Al-O (Al2O3) | 10.7 | Ti-O (TiO2 +Ti2O3); (TiO) | – | – |

| TiAlN3 as prepared | 16.1 | O-Ti; O-Al | 21 | Al-O; Al-N (Al2O3; AlN) | 21.8 | Ti-N; Ti-O (TiN; TiO2 + Ti2O3; TiO) | 41.1 | N-(Al,Ti) (TiAlN) |

| TiAlN3 as tested, after 8 min of surface sputtering | 2.9 | O-Ti; O-Al | 22.7 | Al-N; Al-O (AlN; Al2O3) | 23.5 | Ti-N; Ti-O (TiN; TiO2 + Ti2O3; TiO) | 50.9 | N-(Al,Ti) (TiAlN) |

| Sample | Critical Load Lc3 (N) | Wear Rate mm3/(N∙m) | COF | |||

|---|---|---|---|---|---|---|

| As Deposited | After 40 BR Cycles up to 850 °C | As Deposited | After 40 BR Cycles up to 850 °C | As Deposited | After 40 BR Cycles up to 850 °C | |

| Substrate | – | – | 218 ± 19 | 299 ± 63 | 0.60 | 0.56 |

| TiAlN1 | −34.0 ± 0.5 | −31 ± 1 | 37 ± 3 | 29 ± 6 | 0.95 | 0.58 |

| TiAlN2 | −35 ± 2 | −38 ± 2 | 39 ± 7 | 31 ± 5 | 0.84 | 0.67 |

| TiAlN3 | −42 ± 3 | −38 ± 2 | 37 ± 7 | 34 ± 8 | 0.84 | 0.69 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Badini, C.; Deambrosis, S.M.; Padovano, E.; Fabrizio, M.; Ostrovskaya, O.; Miorin, E.; D’Amico, G.C.; Montagner, F.; Biamino, S.; Zin, V. Thermal Shock and Oxidation Behavior of HiPIMS TiAlN Coatings Grown on Ti-48Al-2Cr-2Nb Intermetallic Alloy. Materials 2016, 9, 961. https://doi.org/10.3390/ma9120961

Badini C, Deambrosis SM, Padovano E, Fabrizio M, Ostrovskaya O, Miorin E, D’Amico GC, Montagner F, Biamino S, Zin V. Thermal Shock and Oxidation Behavior of HiPIMS TiAlN Coatings Grown on Ti-48Al-2Cr-2Nb Intermetallic Alloy. Materials. 2016; 9(12):961. https://doi.org/10.3390/ma9120961

Chicago/Turabian StyleBadini, Claudio, Silvia M. Deambrosis, Elisa Padovano, Monica Fabrizio, Oxana Ostrovskaya, Enrico Miorin, Giuseppe C. D’Amico, Francesco Montagner, Sara Biamino, and Valentina Zin. 2016. "Thermal Shock and Oxidation Behavior of HiPIMS TiAlN Coatings Grown on Ti-48Al-2Cr-2Nb Intermetallic Alloy" Materials 9, no. 12: 961. https://doi.org/10.3390/ma9120961