Patterning the Stiffness of Elastomeric Nanocomposites by Magnetophoretic Control of Cross-linking Impeder Distribution

Abstract

:1. Introduction

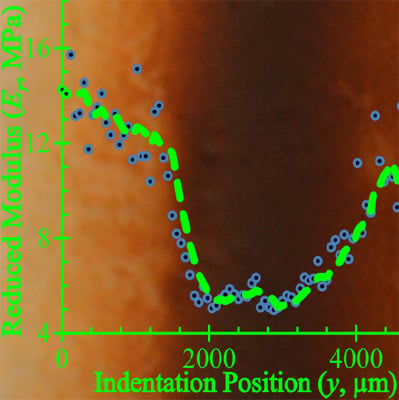

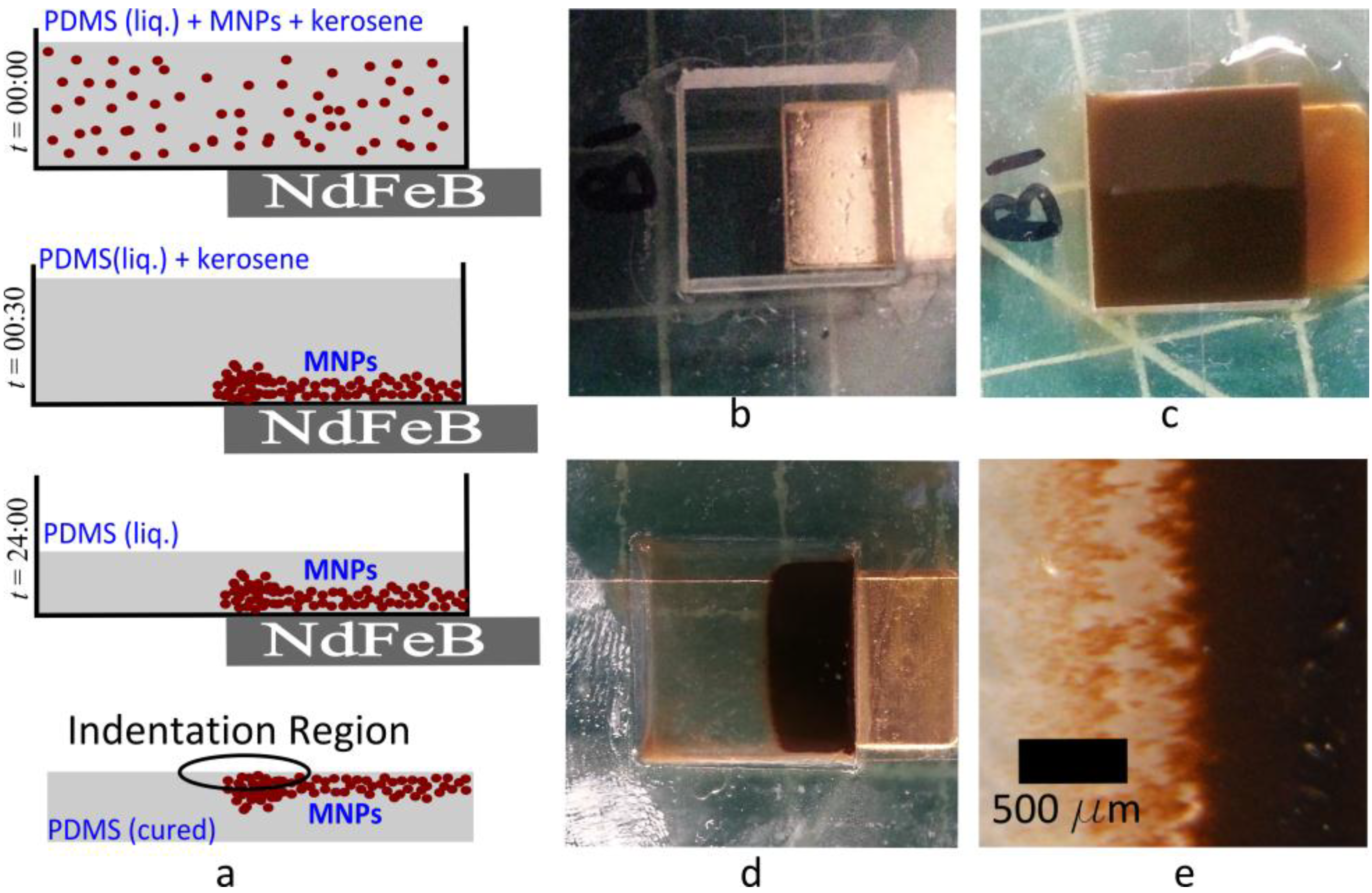

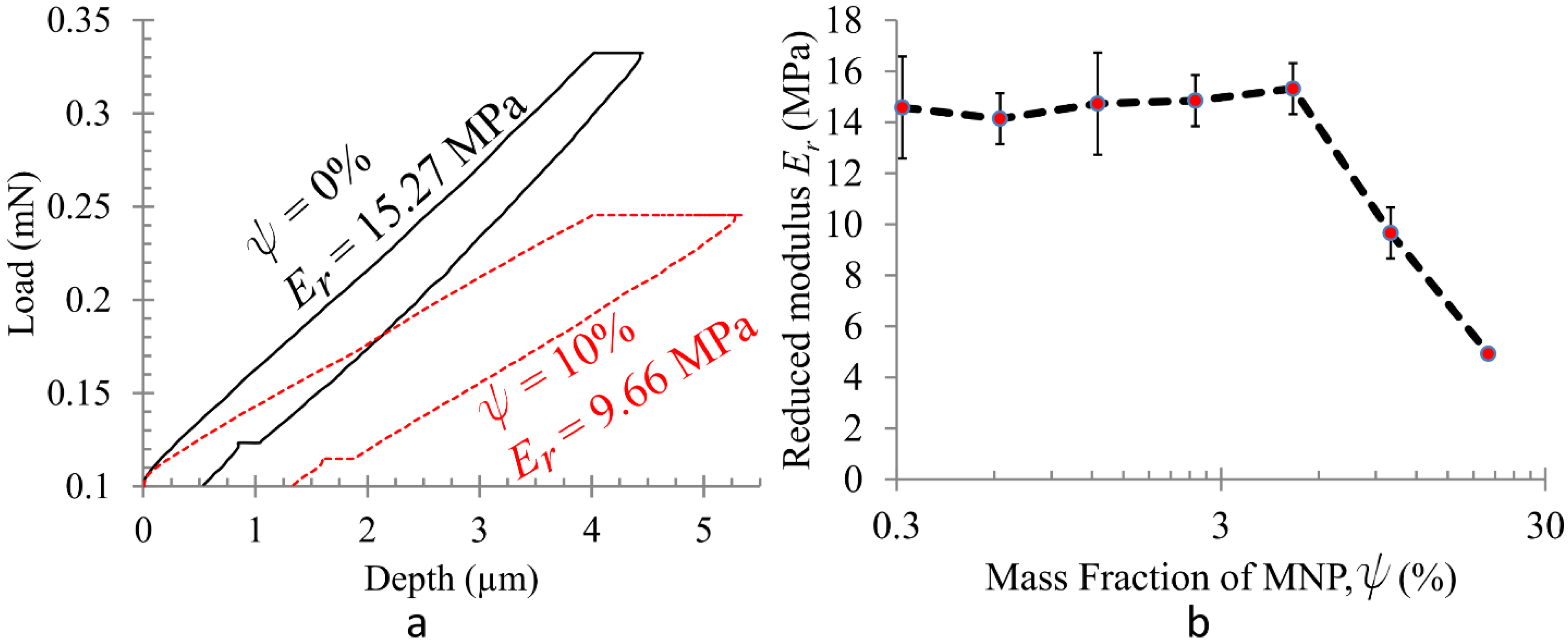

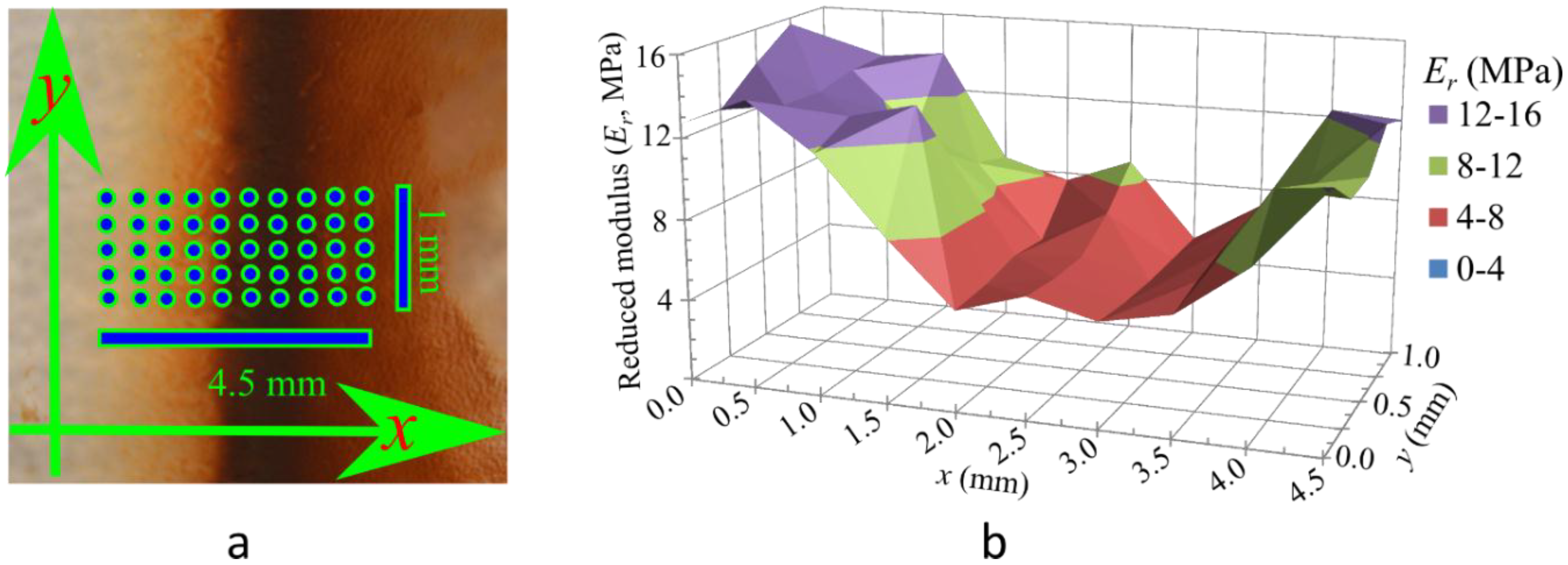

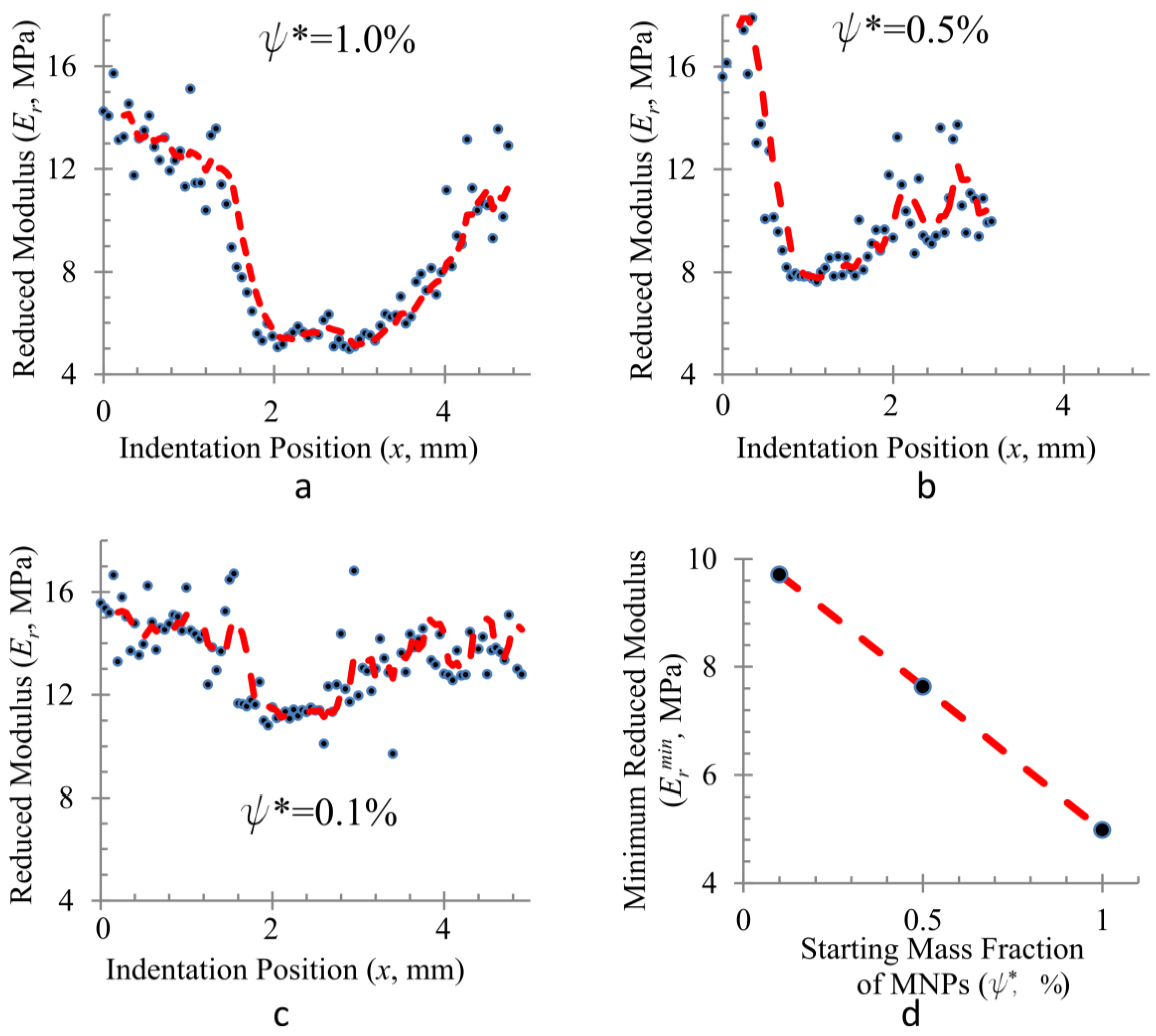

2. Results and Discussion

3. Experimental Section

3.1. Synthesis of Magnetic Nanoparticles and Ferrofluid

3.2. Mold Fabriction

3.3. Preparation of Nanocomposites

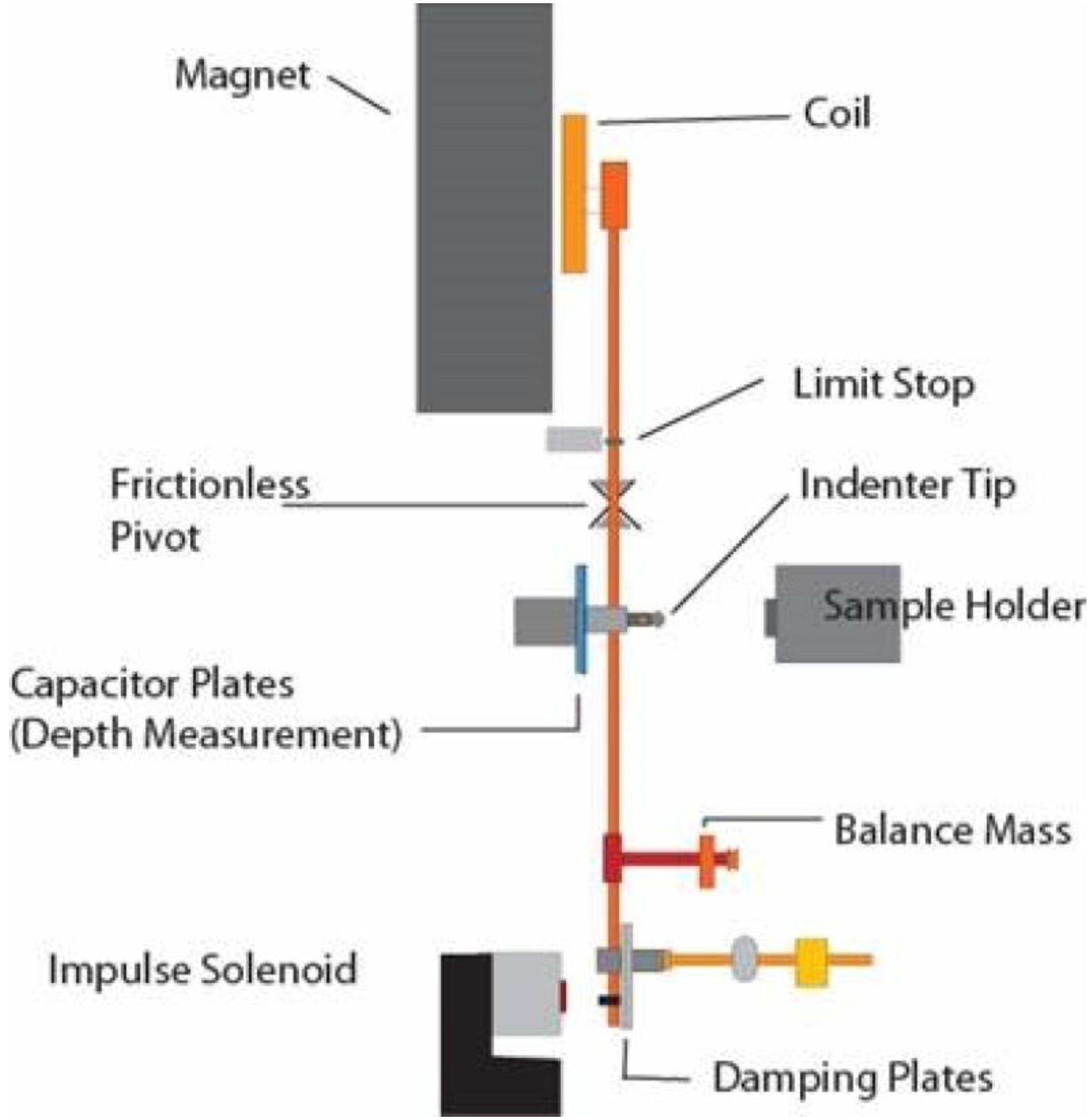

3.4. Nanoindentation

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Suresh, S. Graded materials for resistance to contact deformation and damage. Science 2001, 292, 2447–2451. [Google Scholar] [CrossRef] [PubMed]

- Tai, K.; Dao, M.; Suresh, S.; Palazoglu, A.; Ortiz, C. Nanoscale heterogeneity promotes energy dissipation in bone. Nat. Mater. 2007, 6, 454–462. [Google Scholar] [CrossRef] [PubMed]

- Balooch, G.; Balooch, M.; Nalla, R.K.; Schilling, S.; Filvaroff, E.H.; Marshall, G.W.; Marshall, S.J.; Ritchie, R.O.; Derynck, R.; Alliston, T. Tgf-beta regulates the mechanical properties and composition of bone matrix. Proc. Natl. Acad. Sci. USA 2005, 102, 18813–18818. [Google Scholar] [CrossRef] [PubMed]

- Kieback, B.; Neubrand, A.; Riedel, H. Processing techniques for functionally graded materials. Mater. Sci. Eng. A 2003, 362, 81–106. [Google Scholar] [CrossRef]

- Shen, M.; Bever, M.B. Gradients in polymeric materials. J. Mater. Sci. 1972, 7, 741–746. [Google Scholar] [CrossRef]

- Lee, N.J.; Jang, J. The effect of fibre-content gradient on the mechanical properties of glass-fibre-mat/polypropylene composites. Compos. Sci. Technol. 2000, 60, 209–217. [Google Scholar] [CrossRef]

- Liu, X.Q.; Wang, Y.S.; Zhu, J.H. Epoxy resin/polyurethane functionally graded material prepared by microwave irradiation. J. Appl. Polym. Sci. 2004, 94, 994–999. [Google Scholar] [CrossRef]

- Krumova, M.; Klingshirn, C.; Haupert, F.; Friedrich, K. Microhardness studies on functionally graded polymer composites. Compos. Sci. Technol. 2001, 61, 557–563. [Google Scholar] [CrossRef]

- Rousseau, C.E.; Tippur, H.V. Influence of elastic variations on crack initiation in functionally graded glass-filled epoxy. Eng. Fract. Mech. 2002, 69, 1679–1693. [Google Scholar] [CrossRef]

- Yao, X.F.; Xiong, T.C.; Xu, W.; Yeh, H.Y. Experimental investigations on deformation and fracture behavior of glass sphere filled epoxy functionally graded materials. Appl. Compos. Mater. 2006, 13, 407–420. [Google Scholar] [CrossRef]

- Kirugulige, M.; Tippur, H. Mixed-mode dynamic crack growth in functionally graded glass-filled epoxy. Exp. Mech. 2006, 46, 269–281. [Google Scholar] [CrossRef]

- Yamazaki, K.; Dong, T.; Asakawa, N.; Inoue, Y.; Yazawa, K. Fabrication of compositional-gradient biodegradable polymeric films showing self-bending deformation. Macromol. Rapid Commun. 2009, 30, 435–441. [Google Scholar] [CrossRef] [PubMed]

- Saito, T.; Tanuma, H.; Pan, P.; Dong, T.; Inoue, Y. Gelatin/poly (ethylene oxide) blend films with compositional gradient: Fabrication and characterization. Macromol. Mater. Eng. 2010, 295, 256–262. [Google Scholar] [CrossRef]

- Wen, B.Y.; Li, Q.C.; Hou, S.H.; Wu, G. Preparation and structure study of polypropylene/polyamide-6 gradient materials. J. Appl. Polym. Sci. 2004, 91, 2491–2496. [Google Scholar] [CrossRef]

- Wu, G.; Wen, B.Y.; Hou, S.H. Preparation and structural study of polypropylene-talc gradient materials. Polym. Int. 2004, 53, 749–755. [Google Scholar] [CrossRef]

- Lee, C.S.; Lee, H.; Westervelt, R.M. Microelectromagnets for the control of magnetic nanoparticles. Appl. Phys. Lett. 2001, 79, 3308–3310. [Google Scholar] [CrossRef]

- Erb, R.M.; Son, H.S.; Samanta, B.; Rotello, V.M.; Yellen, B.B. Magnetic assembly of colloidal superstructures with multipole symmetry. Nature 2009, 457, 999–1002. [Google Scholar] [CrossRef] [PubMed]

- Khalil, K.S.; Sagastegui, A.; Li, Y.; Tahir, M.A.; Socolar, J.E.S.; Wiley, B.J.; Yellen, B.B. Binary colloidal structures assembled through ising interactions. Nat. Commun. 2012, 3. [Google Scholar] [CrossRef]

- Henderson, J.; Shi, S.; Cakmaktepe, S.; Crawford, T. Pattern transfer nanomanufacturing using magnetic recording for programmed nanoparticle assembly. Nanotechnology 2012, 23, 185304. [Google Scholar] [CrossRef] [PubMed]

- Erb, R.M.; Sebba, D.S.; Lazarides, A.A.; Yellen, B.B. Magnetic field induced concentration gradients in magnetic nanoparticle suspensions: Theory and experiment. J. Appl. Phys. 2008, 103. [Google Scholar] [CrossRef]

- Hovorka, O.; Yellen, B.; Dan, N.; Friedman, G. Self-consistent model of field gradient driven particle aggregation in magnetic fluids. J. Appl. Phys. 2005, 97. [Google Scholar] [CrossRef]

- Yellen, B.B.; Hovorka, O.; Friedman, G. Arranging matter by magnetic nanoparticle assemblers. Proc. Natl. Acad. Sci. USA 2005, 102, 8860–8864. [Google Scholar] [CrossRef] [PubMed]

- Pankhurst, Q.A.; Connolly, J.; Jones, S.K.; Dobson, J. Applications of magnetic nanoparticles in biomedicine. J. Phys. D Appl. Phys. 2003, 36. [Google Scholar] [CrossRef]

- Pankhurst, Q.A.; Thanh, N.K.T.; Jones, S.K.; Dobson, J. Progress in applications of magnetic nanoparticles in biomedicine. J. Phys. D Appl. Phys. 2009, 42, 224001. [Google Scholar] [CrossRef]

- Bonnemay, L.; Hostachy, S.; Hoffmann, C.; Gautier, J.; Gueroui, Z. Engineering spatial gradients of signaling proteins using magnetic nanoparticles. Nano Lett. 2013, 13, 5147–5152. [Google Scholar] [CrossRef] [PubMed]

- Alexiou, C.; Arnold, W.; Klein, R.J.; Parak, F.G.; Hulin, P.; Bergemann, C.; Erhardt, W.; Wagenpfeil, S.; Luebbe, A.S. Locoregional cancer treatment with magnetic drug targeting. Cancer Res. 2000, 60, 6641–6648. [Google Scholar] [PubMed]

- Stein, J.; Lewis, L.N.; Gao, Y.; Scott, R.A. In situ determination of the active catalyst in hydrosilylation reactions using highly reactive Pt(0) catalyst precursors. J. Am. Chem. Soc. 1999, 121, 3693–3703. [Google Scholar] [CrossRef]

- Stein, J.; Lewis, L.N.; Smith, K.A.; Lettko, K.X. Mechanistic studies of platinum-catalyzed hydrosilylation. J. Inorg. Organomet. Polym. 1991, 1, 325–334. [Google Scholar] [CrossRef]

- Esteves, A.C.C.; Brokken-Zijp, J.; Laven, J.; Huinink, H.P.; Reuvers, N.J.W.; van, M.P.; de With, G. Influence of cross-linker concentration on the cross-linking of PDMS and the network structures formed. Polymer 2009, 50, 3955–3966. [Google Scholar] [CrossRef]

- Stepanov, G.; Alekseeva, E.; Gorbunov, A. Influence of the fillers in a catalytic system based on siel compound. Catal. Ind. 2009, 1, 278–284. [Google Scholar] [CrossRef]

- Fahrni, F.; Prins, M.W.J.; van Ijzendoorn, L.J. Magnetization and actuation of polymeric microstructures with magnetic nanoparticles for application in microfluidics. J. Magn. Magn. Mater. 2009, 321, 1843–1850. [Google Scholar] [CrossRef]

- Pirmoradi, F.; Cheng, L.N.; Chiao, M. A magnetic poly(dimethylesiloxane) composite membrane incorporated with uniformly dispersed, coated iron oxide nanoparticles. J. Micromech. Microeng. 2010, 20. [Google Scholar] [CrossRef]

- Abramchuk, S.; Kramarenko, E.; Grishin, D.; Stepanov, G.; Nikitin, L.V.; Filipcsei, G.; Khokhlov, A.R.; Zrínyi, M. Novel highly elastic magnetic materials for dampers and seals: Part ii. Material behavior in a magnetic field. Polym. Adv. Technol. 2007, 18, 513–518. [Google Scholar] [CrossRef]

- Abramchuk, S.; Kramarenko, E.; Stepanov, G.; Nikitin, L.V.; Filipcsei, G.; Khokhlov, A.R.; Zrínyi, M. Novel highly elastic magnetic materials for dampers and seals: Part i. Preparation and characterization of the elastic materials. Polym. Adv. Technol. 2007, 18, 883–890. [Google Scholar] [CrossRef]

- Ghosh, S.; Puri, I.K. Soft polymer magnetic nanocomposites: Microstructure patterning by magnetophoretic transport and self-assembly. Soft Matter 2013, 9, 2024–2029. [Google Scholar] [CrossRef] [PubMed]

- Fragouli, D.; Buonsanti, R.; Bertoni, G.; Sangregorio, C.; Innocenti, C.; Falqui, A.; Gatteschi, D.; Cozzoli, P.D.; Athanassiou, A.; Cingolani, R. Dynamical formation of spatially localized arrays of aligned nanowires in plastic films with magnetic anisotropy. ACS Nano 2010, 4, 1873–1878. [Google Scholar] [CrossRef] [PubMed]

- Robbes, A.S.; Cousin, F.; Meneau, F.; Dalmas, F.; Boue, F.; Jestin, J. Nanocomposite materials with controlled anisotropic reinforcement triggered by magnetic self-assembly. Macromolecules 2011, 44, 8858–8865. [Google Scholar] [CrossRef]

- Varga, Z.; Filipcsei, G.; Zrínyi, M. Magnetic field sensitive functional elastomers with tuneable elastic modulus. Polymer 2006, 47, 227–233. [Google Scholar] [CrossRef]

- Jestin, J.; Cousin, F.; Dubois, I.; Ménager, C.; Schweins, R.; Oberdisse, J.; Boué, F. Anisotropic reinforcement of nanocomposites tuned by magnetic orientation of the filler network. Adv. Mater. 2008, 20, 2533–2540. [Google Scholar] [CrossRef] [Green Version]

- Fragouli, D.; Das, A.; Innocenti, C.; Guttikonda, Y.; Rahman, S.; Liu, L.; Caramia, V.; Megaridis, C.M.; Athanassiou, A. Polymeric films with electric and magnetic anisotropy due to magnetically assembled functional nanofibers. ACS Appl. Mater. Interfaces 2014, 6, 4535–4541. [Google Scholar] [CrossRef] [PubMed]

- Owen, M.; Clarson, S.; Semlyen, J. Siloxane Polymers; PTR Prentice Hall: Englewood Cliffs, NJ, USA, 1993. [Google Scholar]

- Bokobza, L.; Rapoport, O. Reinforcement of natural rubber. J. Appl. Polym. Sci. 2002, 85, 2301–2316. [Google Scholar] [CrossRef]

- Butter, K.; Bomans, P.H.H.; Frederik, P.M.; Vroege, G.J.; Philipse, A.P. Direct observation of dipolar chains in iron ferrofluids by cryogenic electron microscopy. Nat. Mater. 2003, 2, 88–91. [Google Scholar] [CrossRef] [PubMed]

- Mietta, J.L.; Ruiz, M.M.; Antonel, P.S.; Perez, O.E.; Butera, A.; Jorge, G.; Negri, R.M. Anisotropic magnetoresistance and piezoresistivity in structured Fe3O4-silver particles in pdms elastomers at room temperature. Langmuir 2012, 28, 6985–6996. [Google Scholar] [CrossRef] [PubMed]

- Favier, V.; Cavaille, J.; Canova, G.; Shrivastava, S. Mechanical percolation in cellulose whisker nanocomposites. Polym. Eng. Sci. 1997, 37, 1732–1739. [Google Scholar] [CrossRef]

- Hsu, L.; Weder, C.; Rowan, S.J. Stimuli-responsive, mechanically-adaptive polymer nanocomposites. J. Mater. Chem. 2011, 21, 2812–2822. [Google Scholar] [CrossRef]

- Massart, R. Preparation of aqueous magnetic liquids in alkaline and acidic media. IEEE Trans. Magn. 1981, 17, 1247–1248. [Google Scholar] [CrossRef]

- Massart, R.; Dubois, E.; Cabuil, V.; Hasmonay, E. Preparation and properties of monodisperse magnetic fluids. J. Magn. Magn. Mater. 1995, 149, 1–5. [Google Scholar] [CrossRef]

- Tehrani, M.; Safdari, M.; Al-Haik, M. Nanocharacterization of creep behavior of multiwall carbon nanotubes/epoxy nanocomposite. Int. J. Plast. 2011, 27, 887–901. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Constantinides, G.; Ravi Chandran, K.; Ulm, F.-J.; van Vliet, K. Grid indentation analysis of composite microstructure and mechanics: Principles and validation. Mater. Sci. Eng. A 2006, 430, 189–202. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghosh, S.; Tehrani, M.; Al-Haik, M.S.; Puri, I.K. Patterning the Stiffness of Elastomeric Nanocomposites by Magnetophoretic Control of Cross-linking Impeder Distribution. Materials 2015, 8, 474-485. https://doi.org/10.3390/ma8020474

Ghosh S, Tehrani M, Al-Haik MS, Puri IK. Patterning the Stiffness of Elastomeric Nanocomposites by Magnetophoretic Control of Cross-linking Impeder Distribution. Materials. 2015; 8(2):474-485. https://doi.org/10.3390/ma8020474

Chicago/Turabian StyleGhosh, Suvojit, Mehran Tehrani, Marwan S. Al-Haik, and Ishwar K. Puri. 2015. "Patterning the Stiffness of Elastomeric Nanocomposites by Magnetophoretic Control of Cross-linking Impeder Distribution" Materials 8, no. 2: 474-485. https://doi.org/10.3390/ma8020474