Microwave Annealing for NiSiGe Schottky Junction on SiGe P-Channel

Abstract

:1. Introduction

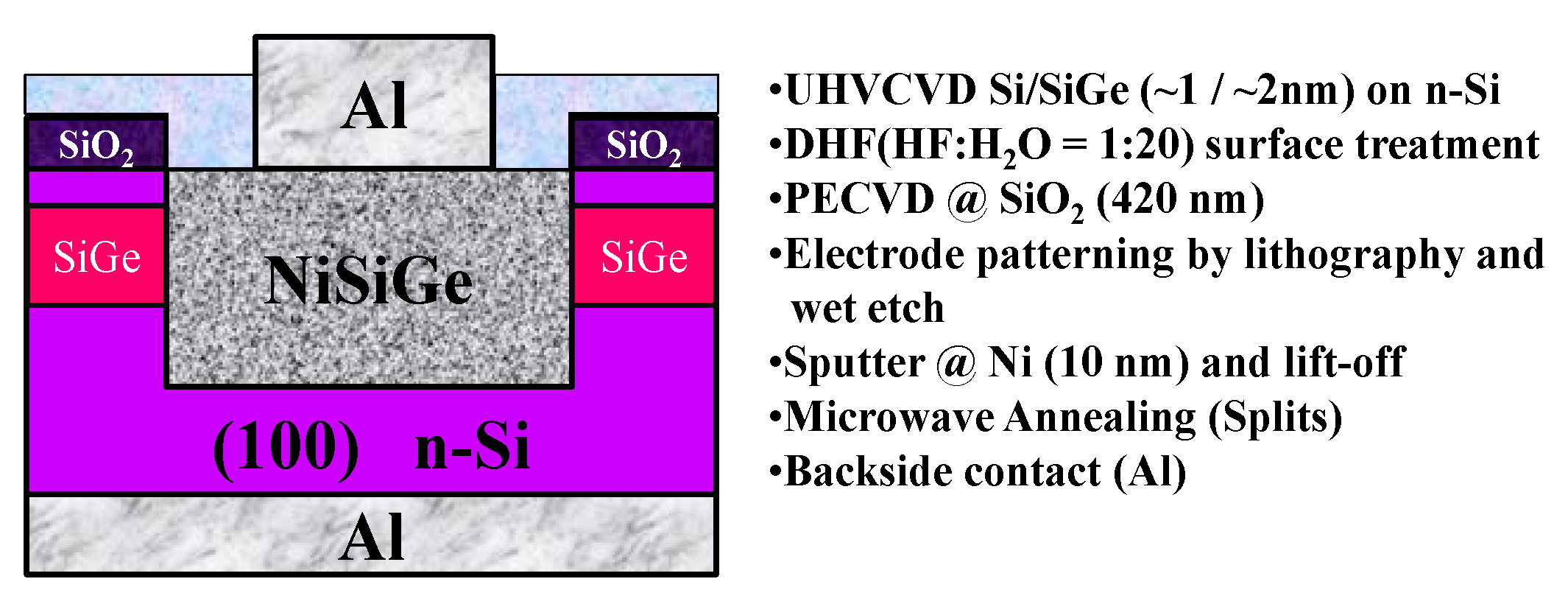

2. Experimental Section

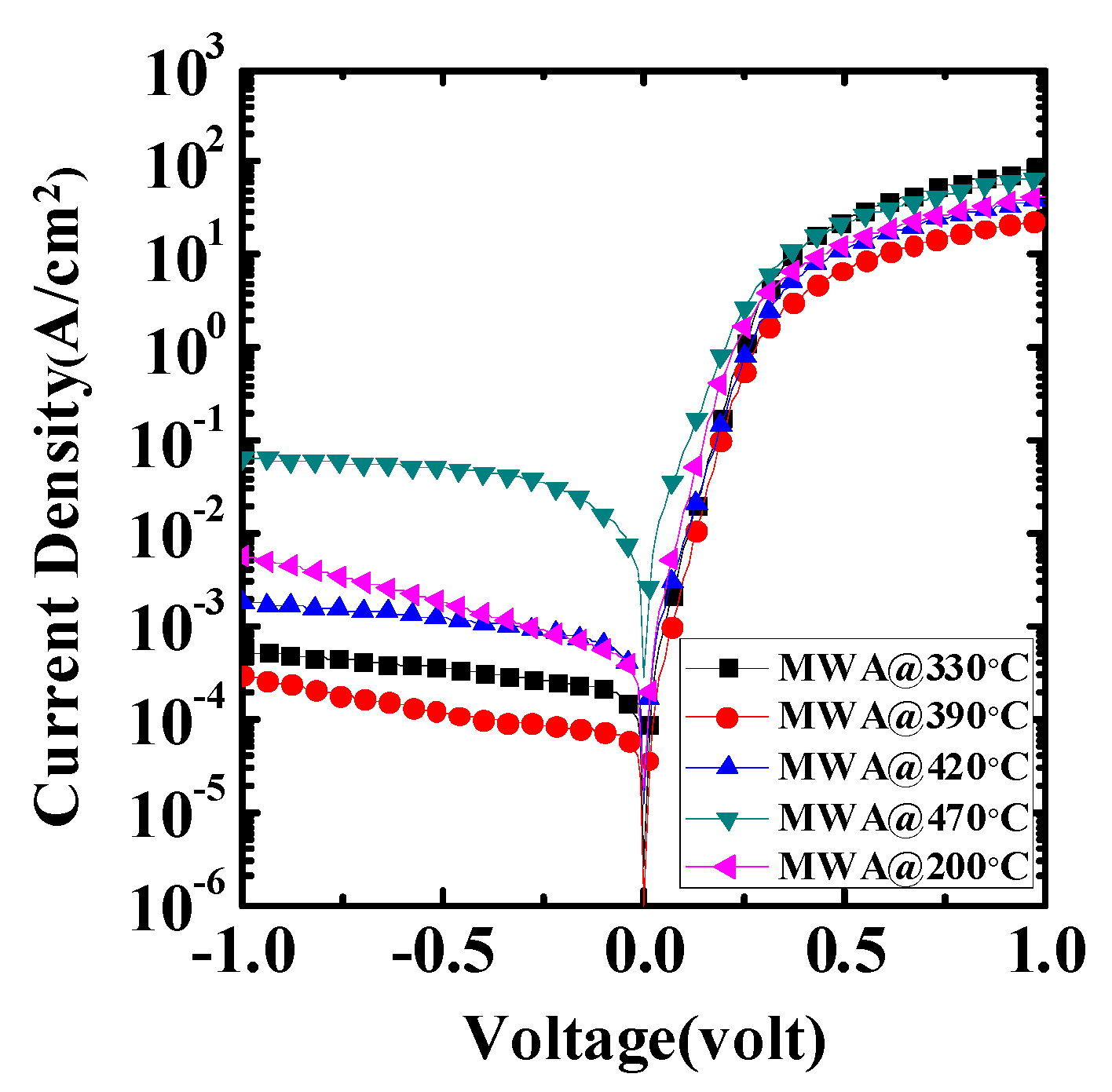

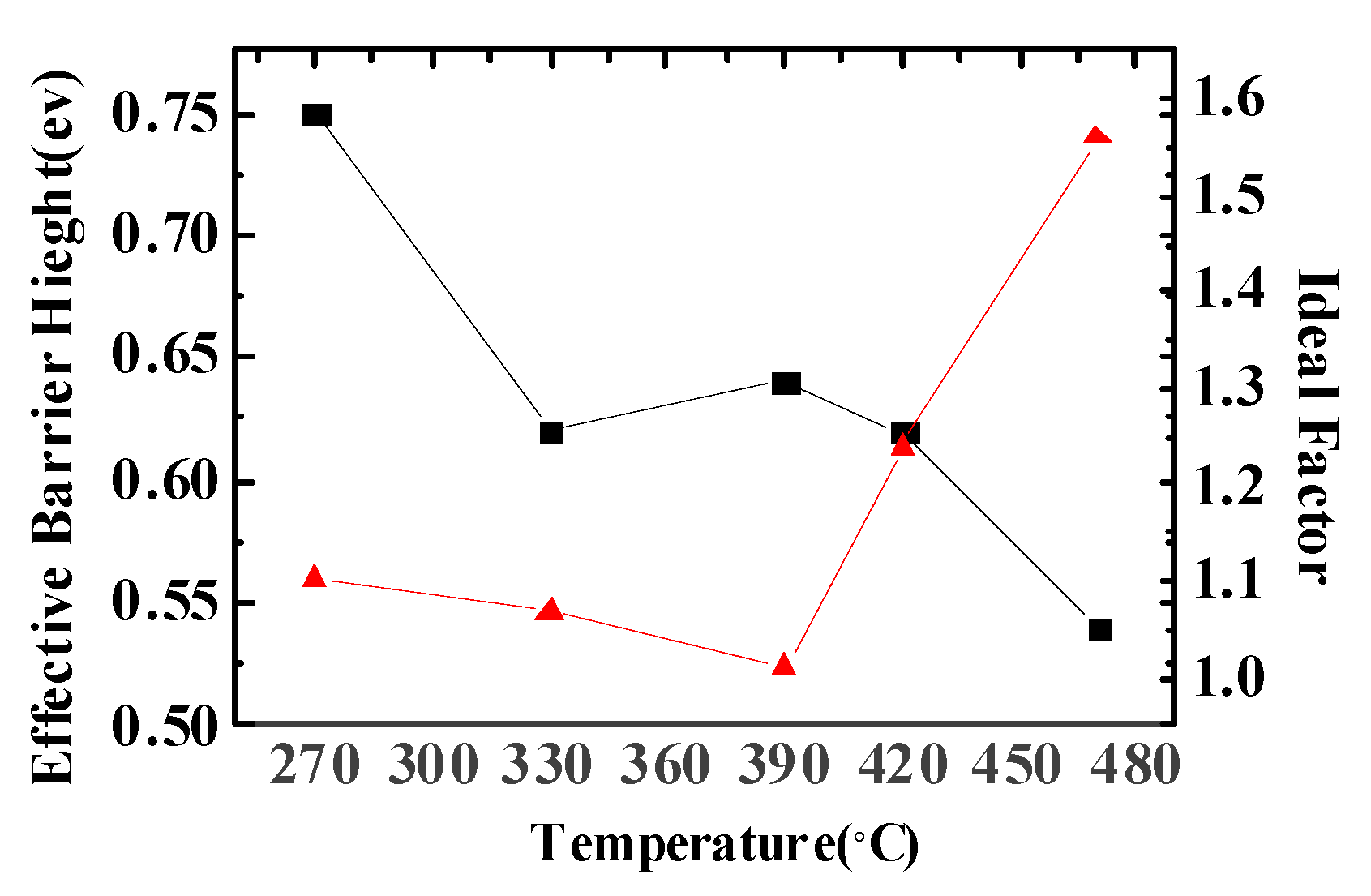

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Datta, M.S.; Dewey, G.; Doczy, M.; Doyle, B.; Jin, B.; Kavalieros, J.; Kotlyar, R.; Metz, M.; Zelick, N.; Chau, R. High Mobility Si/SiGe Strained Channel MOS Transistors with HfO2/TiN Gate Stack. In Proceedings of the IEEE International Electron Devices Meeting, Washington, DC, USA, 8–10 December 2003; p. 23.

- Goley, P.S.; Hudait, M.K. Germanium based field-effect transistors: Challenges and opportunities. Materials 2014, 7, 2301–2339. [Google Scholar] [CrossRef]

- Claeys, C.; Simoen, E. Germanium-Based Technologies: From Materials to Devices, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2007; pp. 1–480. [Google Scholar]

- Delabie, A.; Bellenger, F.; Houssa, M.; Conard, T.; Elshocht, S.V.; Caymax, M.; Heyns, M.; Meuris, M. Effective electrical passivation of Ge(100) for high-k gate dielectric layers using germanium oxide. Appl. Phys. Lett. 2007, 91, 082904–082906. [Google Scholar] [CrossRef]

- Gu, J.J.; Liu, Y.Q.; Xu, M.; Celler, G.K.; Gordon, R.G.; Ye, P.D. High performance atomic-layer-deposited LaLuO3 /Ge-on-insulator p-channel metal-oxide-semiconductor field-effect transistor with thermally grown GeO2 as interfacial passivation layer. Appl. Phys. Lett. 2010, 97, 012106–012108. [Google Scholar] [CrossRef]

- Larson, J.M.; Snyder, J.P. Overview and status of metal s/d schottky-barrier mosfet technology. IEEE Trans. Elec. Dev. 2006, 53, 1048–1058. [Google Scholar] [CrossRef]

- Calvet, L.E.; Luebben, H.; Reed, M.A.; Wang, C.; Snyder, J.P.; Tucker, J.R. Suppression of leakage current in Schottky barrier metal-oxide-semiconductor field-effect transistors. J. Appl. Phys. 2002, 91. [Google Scholar] [CrossRef]

- Koike, M.; Kamimuta, Y.; Tezuka, T. Modulation of NiGe/Ge Schottky barrier height by S and P co-introduction. Appl. Phys. Lett. 2013, 102, 032108–032110. [Google Scholar] [CrossRef]

- Iwai, H.; Ohguro, T.; Ohmi, S.I. NiSi salicide technology for scaled CMOS. Mater. Adv. Met. 2002, 60, 157–169. [Google Scholar] [CrossRef]

- Roy, S.; Midya, K.; Duttagupta, S.P.; Ramakrishnan, D. Nano-scale NiSi and n-type silicon based Schottky barrier diode as a near infra-red detector for room temperature operation. J. Appl. Phys. 2014, 116. [Google Scholar] [CrossRef]

- Zaima, S.; Nakatsuka, O.; Kondo, H.; Sakashita, M.; Sakai, A.; Ogawa, M. Silicide and germanide technology for contacts and metal gates in MOSFET applications. ECS Trans. 2007, 11, 197–205. [Google Scholar]

- Hsu, S.L.; Chien, C.H.; Yang, M.J.; Huang, R.H.; Leu, C.C.; Shen, S.W.; Yang, T.H. Study of thermal stability of nickel monogermanide on single- and polycrystalline germanium substrates. Appl. Phys. Lett. 2005, 86, 251906–251908. [Google Scholar] [CrossRef]

- Kappe, C.O. Controlled microwave heating in modern organic synthesis. Angew. Chem. Int. Ed. 2004, 43, 6250–6285. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.J.; Hsueh, F.K.; Current, M.I.; Wu, C.Y.; Chao, T.S. Susceptor coupling for the uniformity and dopant activation efficiency in implanted Si under fixed-frequency microwave anneal. IEEE Electron. Device Lett. 2012, 33, 248–250. [Google Scholar] [CrossRef]

- Alford, T.L.; Thompson, D.C.; Mayer, J.W.; Theodore, N.D. Dopant activation in ion implanted silicon by microwave annealing. J. Appl. Phys. 2009, 106. [Google Scholar] [CrossRef]

- Sinha, M.; Lee, R.T.P.; Chor, E.F.; Yeo, Y.C. Schottky barrier height modulation of Nickel–dysprosium-alloy germanosilicide contacts for strained P-FinFETs. IEEE Electron. Device Lett. 2009, 30, 1278–1280. [Google Scholar] [CrossRef]

- Sze, S.M. Physics of Semiconductor Devices, 2nd ed.; Wiley: New York, NY, USA, 1981; pp. 256–263. [Google Scholar]

- Dimoulas, A.; Tsipas, P.; Sotiropoulos, A.; Evangelou, E.K. Fermi-level pinning and charge neutrality level in germanium. Appl. Phys. Lett. 2006, 89. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Y.-H.; Tsai, Y.-H.; Hsu, C.-C.; Luo, G.-L.; Lee, Y.-J.; Chien, C.-H. Microwave Annealing for NiSiGe Schottky Junction on SiGe P-Channel. Materials 2015, 8, 7519-7523. https://doi.org/10.3390/ma8115403

Lin Y-H, Tsai Y-H, Hsu C-C, Luo G-L, Lee Y-J, Chien C-H. Microwave Annealing for NiSiGe Schottky Junction on SiGe P-Channel. Materials. 2015; 8(11):7519-7523. https://doi.org/10.3390/ma8115403

Chicago/Turabian StyleLin, Yu-Hsien, Yi-He Tsai, Chung-Chun Hsu, Guang-Li Luo, Yao-Jen Lee, and Chao-Hsin Chien. 2015. "Microwave Annealing for NiSiGe Schottky Junction on SiGe P-Channel" Materials 8, no. 11: 7519-7523. https://doi.org/10.3390/ma8115403

APA StyleLin, Y.-H., Tsai, Y.-H., Hsu, C.-C., Luo, G.-L., Lee, Y.-J., & Chien, C.-H. (2015). Microwave Annealing for NiSiGe Schottky Junction on SiGe P-Channel. Materials, 8(11), 7519-7523. https://doi.org/10.3390/ma8115403