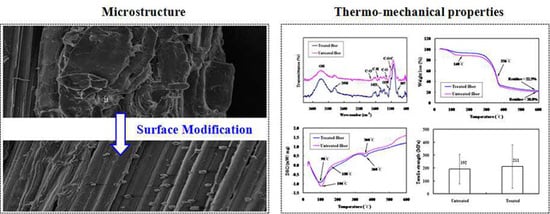

Influence of Surface Modification on the Microstructure and Thermo-Mechanical Properties of Bamboo Fibers

Abstract

:1. Introduction

2. Experimental Section

2.1. Fiber Preparation

2.2. Alkali Treatment

2.3. Measurements

2.3.1. Morphological Characterization

2.3.2. FTIR Spectroscopy

2.3.3. TG and DSC Analysis

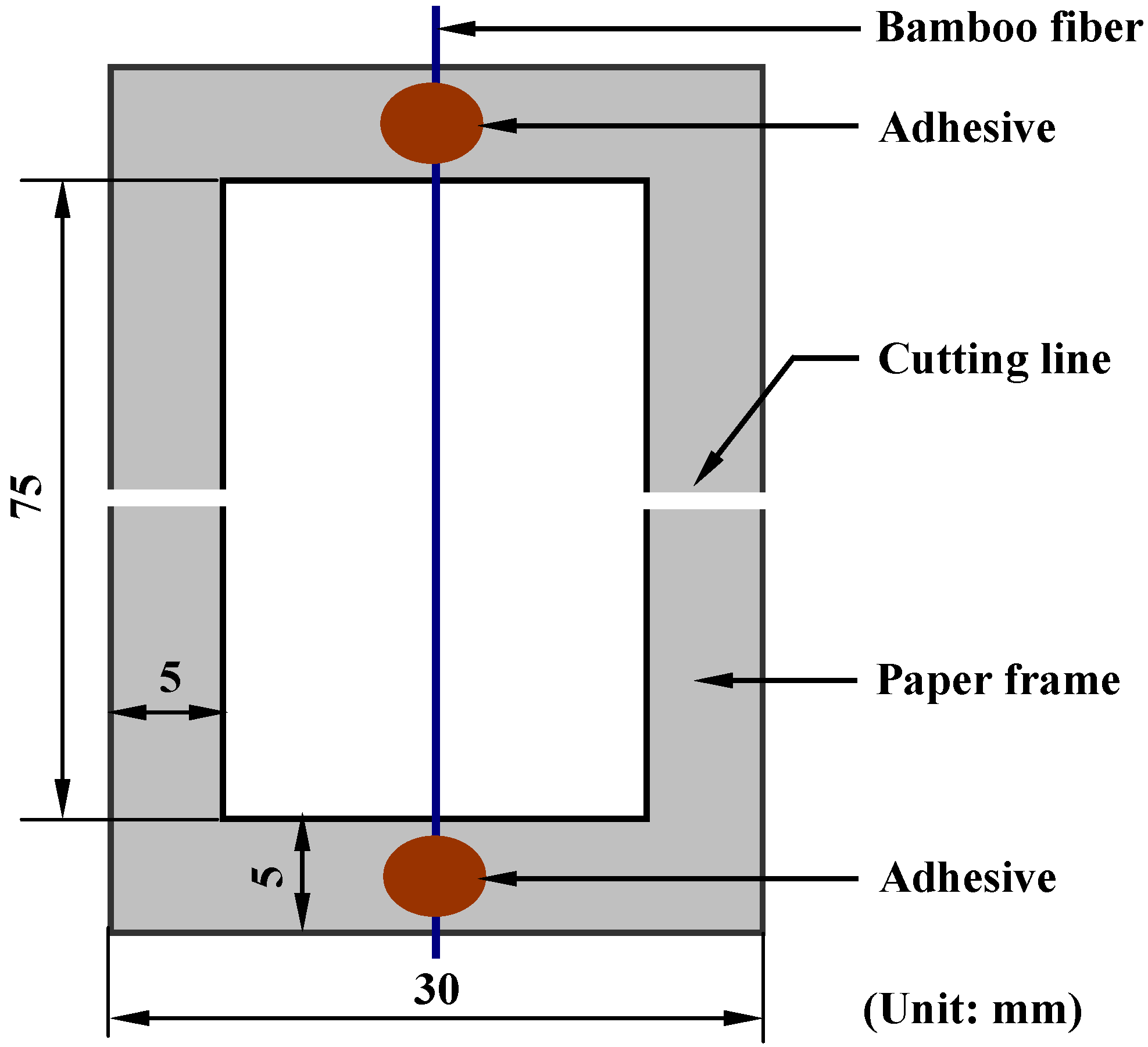

2.3.4. Mechanical Testing

3. Results and Discussion

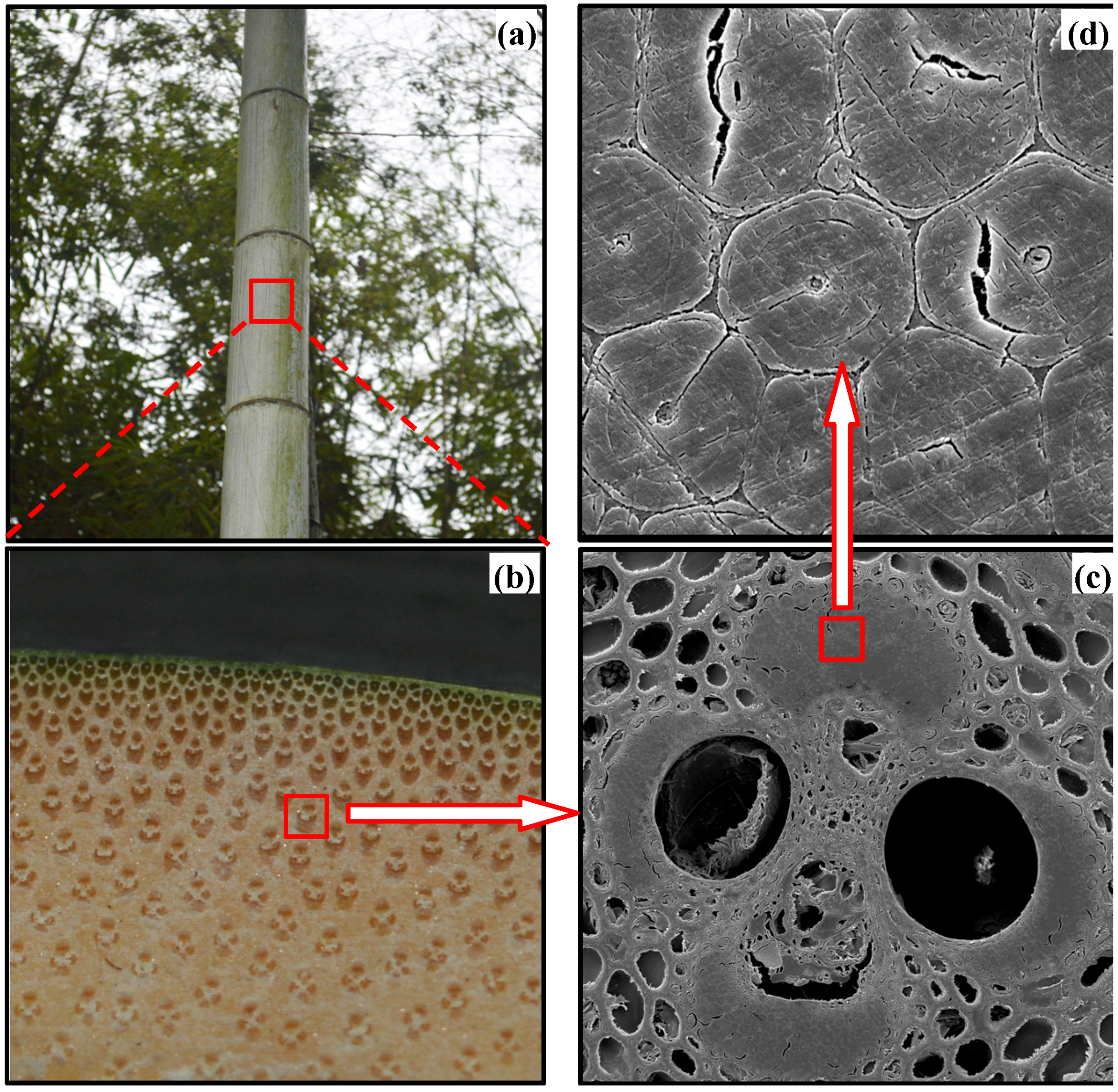

3.1. Structural Characteristics

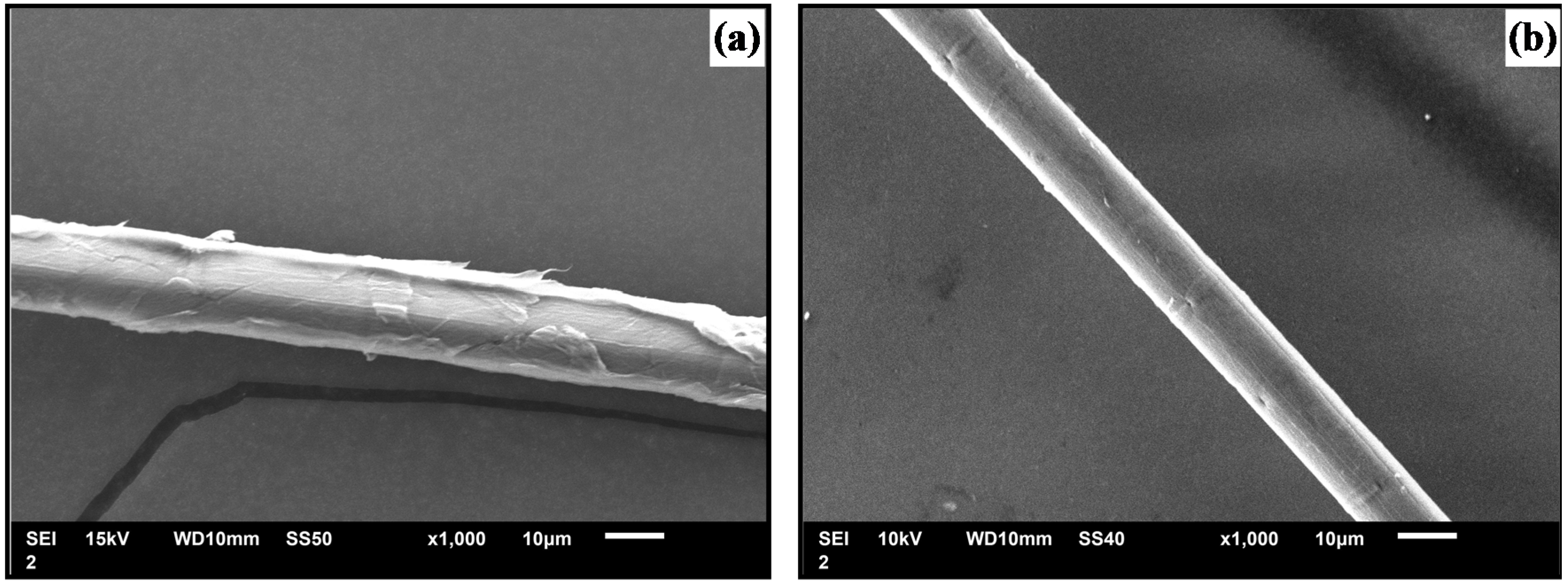

3.2. Surface Profiles

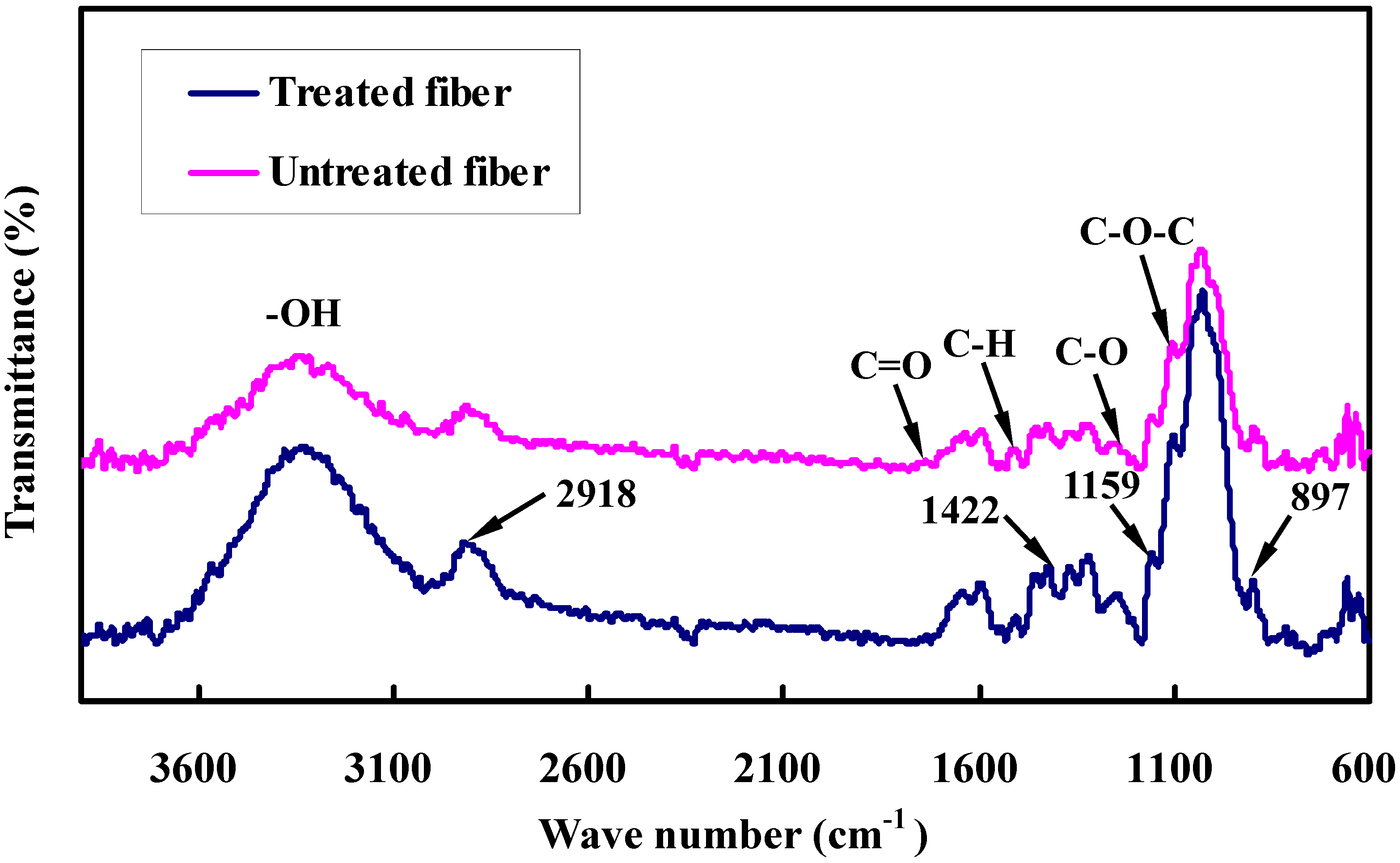

3.3. Infrared Spectroscopic Analysis

| Wavenumber (cm−1) | Possible Assignments | Reference |

|---|---|---|

| 3200–3500 | –OH stretching vibration in cellulose, hemicellulose and lignin | [30] |

| 2918 | C–H stretching vibration in methyl and methylene | [19] |

| 1737 | C=O stretching vibration of hemicellulose and pectin | [17,18] |

| 1513 | C–H stretching vibration of hemicellulose and pectin | [17] |

| 1422, 1159 | Typical absorption peak of cellulose | [31] |

| 1247 | Acetyl groups of lignin | [32] |

| 1104 | C–O–C stretching vibration of cellulose | [17] |

| 1032 | C–O/C–C stretching vibration | [33] |

| 897 | C–OH stretching vibration, which indicates β-glycosidic linkage between the monosaccharides | [34] |

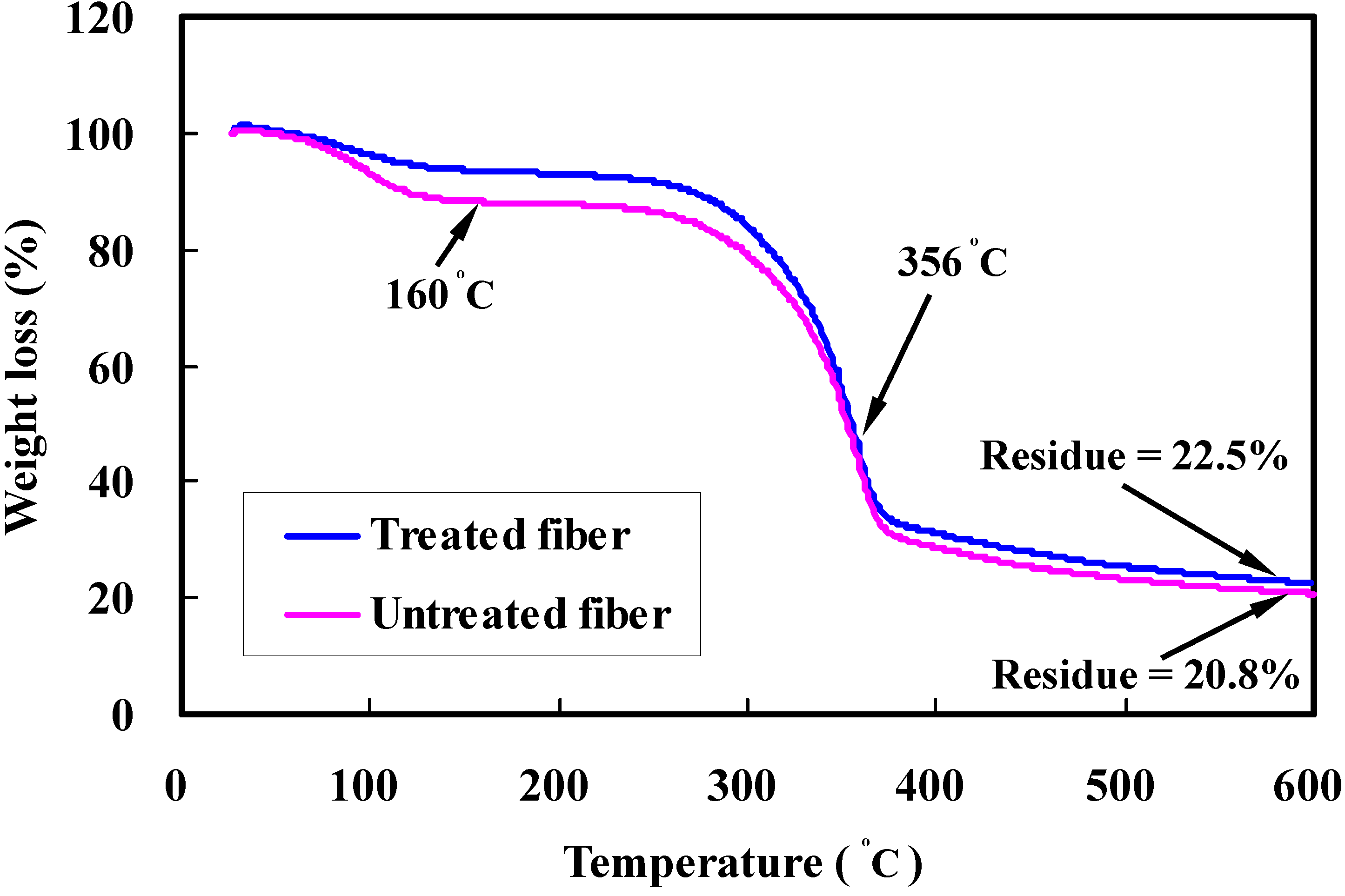

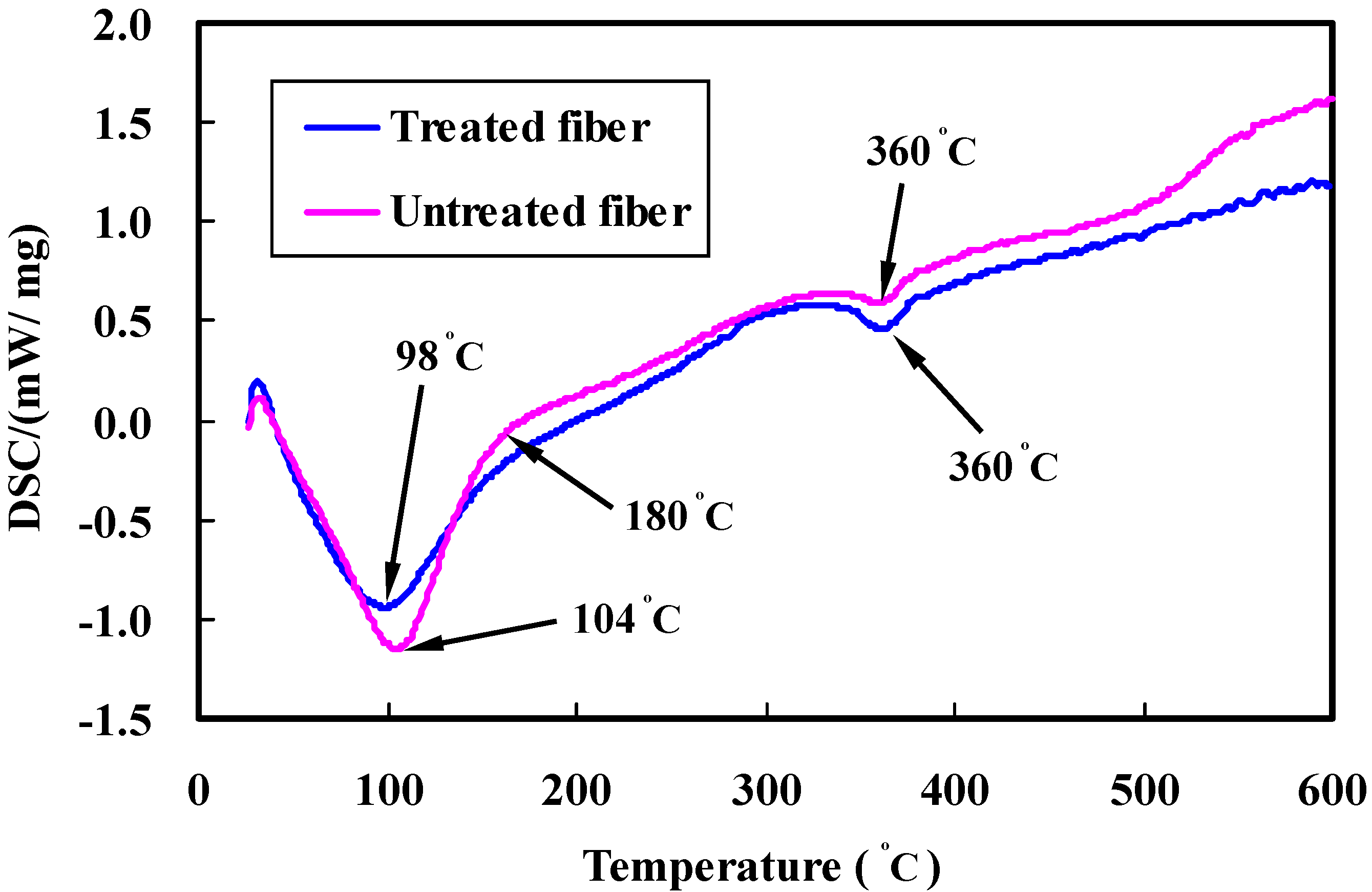

3.4. Thermal Property Analysis

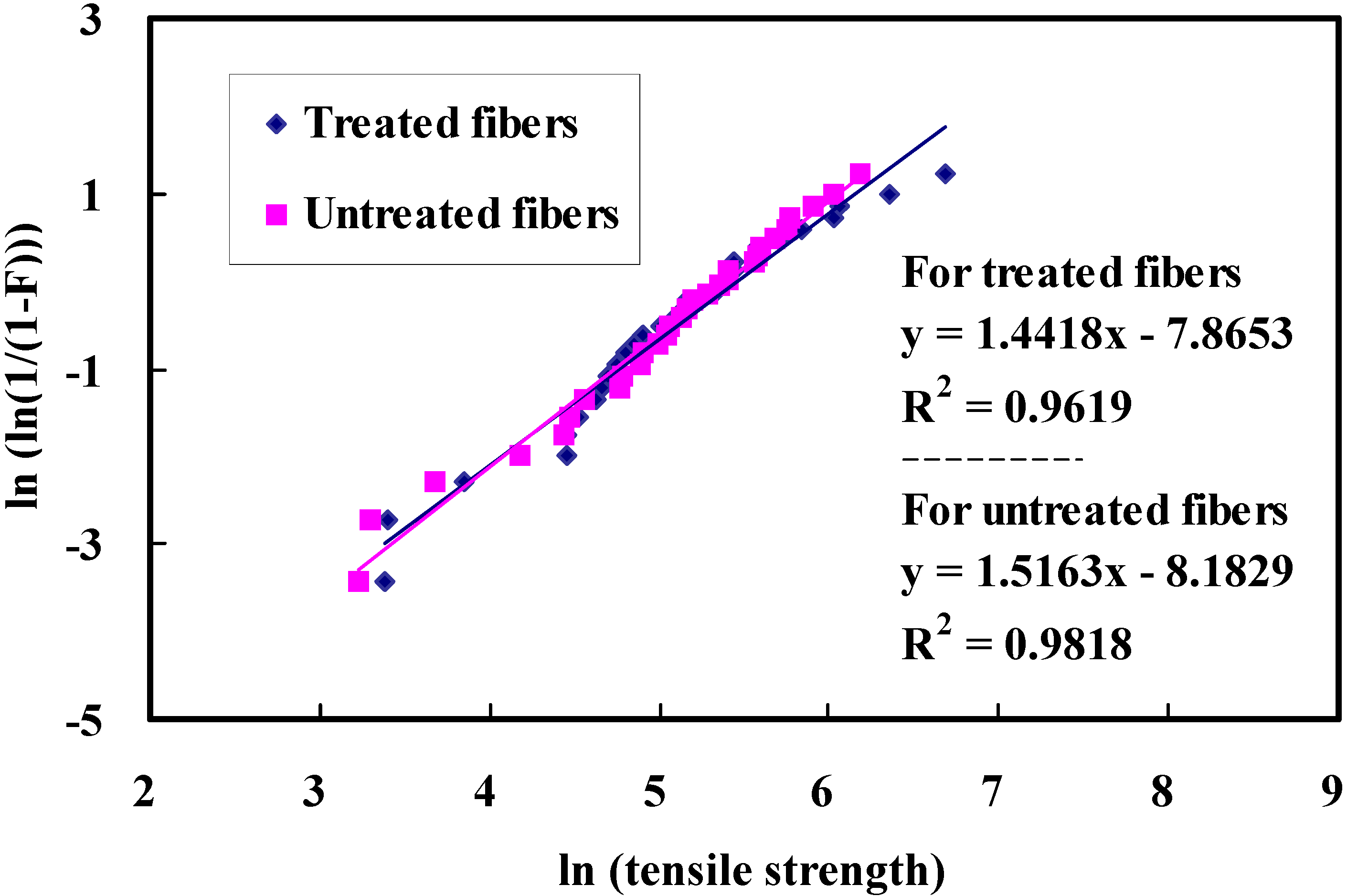

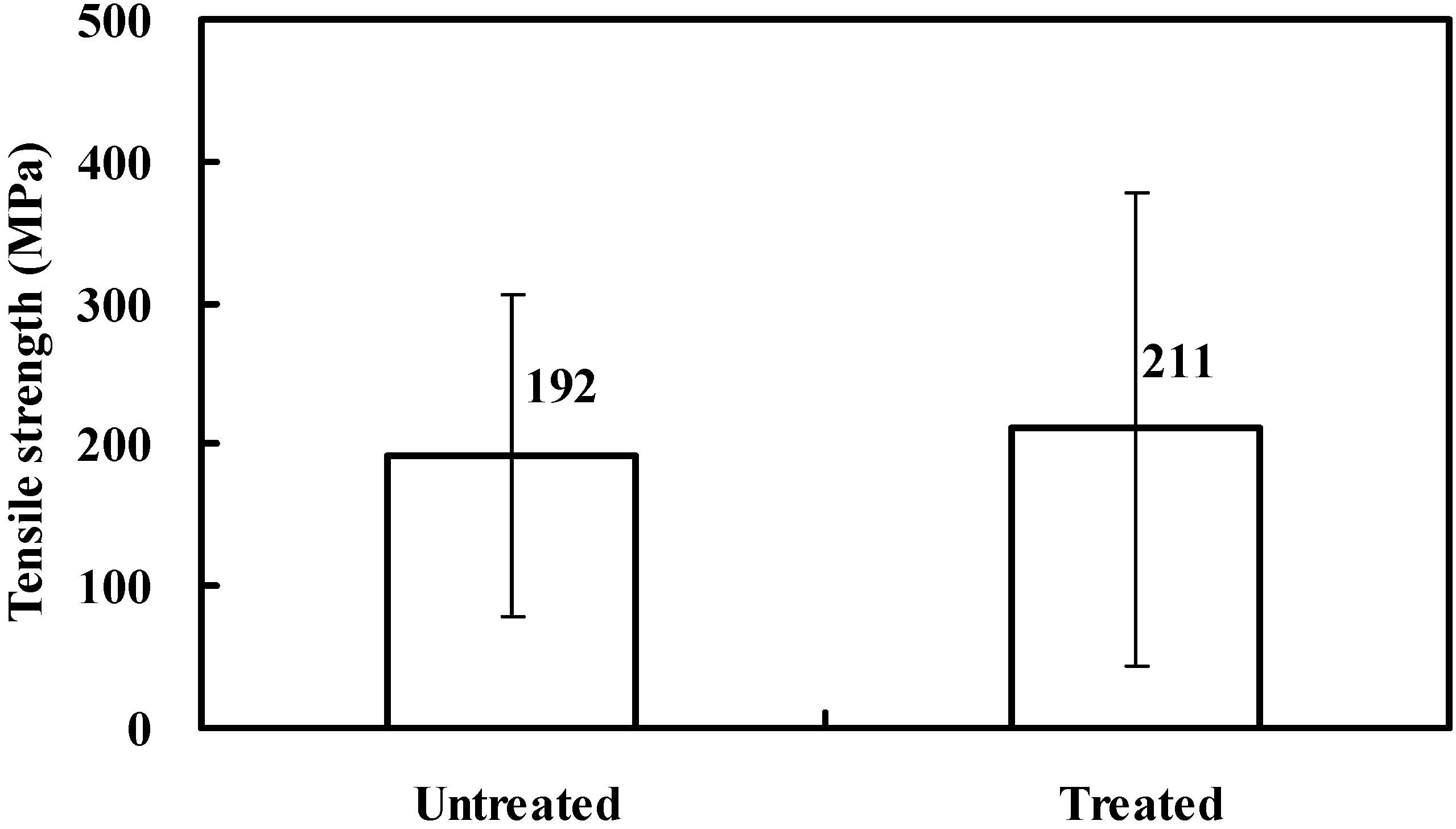

3.5. Tensile Strength

4. Conclusions

- Morphological changes by micrograph observations show that an alkali treatment leads to an increase in fiber surface area available for interlocking adhesion with the matrix resin, resulting in superior interfacial bonding over untreated ones.

- FTIR analysis confirms that removal of hemicellulose and lignin can increase the relative amount of cellulose content in the treated fibers. Furthermore, no new groups are introduced in the cellulose molecules after alkali treatment, as evidenced by spectra measurements.

- TGA-DSC testing reveals that surface treatment can influence chemical structure of bamboo fibers. Treated fibers exhibit higher thermal stability compared to untreated fibers, since the binding materials such as hemicellulose, pectin, and lignin can be diminished from the bamboo fibers by alkali reaction. Experimental results also suggest that hemicellulose is the most reactive constituent and is more easily degraded than the cellulose and lignin. Cellulose exhibits better thermal stability and lignin is degraded in a wide range of temperatures.

- The average fracture strength of treated fiber on the condition of 4 wt % NaOH for 1 h is increased by 10% compared to the untreated fibers. Alkali treatment can reduce the hydrophilicity of bamboo fiber, which might in turn improve the interfacial bonding. However, it is found from the standard deviations that the present concentration has a minor effect on the tensile strength of bamboo fibers.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. A 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Bhat, A.H.; Ireana Yusra, A.F. Green composites from sustainable cellulose nanofibrils: A review. Carbohyd. Polym. 2012, 87, 963–979. [Google Scholar] [CrossRef]

- Manshor, M.R.; Anuar, H.; Nur Aimi, M.N.; Ahmad Fitrie, M.I.; Wan Nazri, W.B.; Sapuan, S.M.; EI-Shekeil, Y.A.; Wahit, M.U. Mechanical, thermal and morphological properties of durian skin fibre reinforced PLA biocomposites. Mater. Des. 2014, 59, 279–286. [Google Scholar] [CrossRef]

- Rao, K.M.M.; Rao, K.M. Extraction and tensile properties of natural fibers: Vakka, date and bamboo. Compos. Struct. 2007, 77, 288–295. [Google Scholar] [CrossRef]

- Ray, A.K.; Das, S.K.; Mondal, S.; Ramachandrarao, P. Microstructural characterization of bamboo. J. Mater. Sci. 2004, 39, 1055–1060. [Google Scholar] [CrossRef]

- Wang, F.; Shao, J.X.; Keer, L.M.; Li, L.; Zhang, J.Q. The effect of elementary fibre variability on bamboo fibre strength. Mater. Des. 2015, 75, 136–142. [Google Scholar] [CrossRef]

- Lo, T.Y.; Cui, H.Z.; Tang, P.W.C.; Leung, H.C. Strength analysis of bamboo by microscopic investigation of bamboo fibre. Construct. Build. Mater. 2008, 22, 1532–1535. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Bhat, I.U.H.; Jawaid, M.; Zaidon, A.; Hermanwan, D.; Hadi, Y.S. Bamboo fibre reinforced biocomposites: A review. Mater. Des. 2012, 42, 353–368. [Google Scholar] [CrossRef]

- Gomes, A.; Matsuo, T.; Goda, K.; Ohgi, J. Development and effect of alkali treatment on tensile properties of curaua fiber green composites. Compos. A 2007, 38, 1811–1820. [Google Scholar] [CrossRef]

- Chen, H.Y.; Miao, M.H.; Ding, X. Influence of moisture absorption on the interfacial strength of bamboo/vinylester composites. Compos. A 2009, 40, 2013–2019. [Google Scholar] [CrossRef]

- Fuentes, C.A.; Tran, L.Q.N.; Dupont-Gillain, C.; Vanderlinden, W.; de Feyter, S.; van Vuure, A.W.; Verpoest, I. Wetting behavior and surface properties of technical bamboo fibers. Colloids Surf. A 2011, 380, 89–99. [Google Scholar] [CrossRef]

- Ngo, T.T.; Lambert, C.A.; Benz, L.; Chau, M.T. Improving the compostability of natural fiber-reinforced thermoset composites with a tertiary oil phase. Polym. Plast. Technol. Eng. 2013, 52, 710–717. [Google Scholar] [CrossRef]

- Ngo, T.T.; Lambert, C.A.; Kohl, J.G. Characterization of compostability and mechanical properties of linseed oil resin composites reinforced with natural fibers. Polym. Plast. Technol. Eng. 2014, 53, 1215–1222. [Google Scholar] [CrossRef]

- Ngo, T.T.; Kohl, J.G.; Paradise, T.; Khalily, A.; Simonson, D.L. Improving mechanical properties of thermoset biocomposites by fiber coating or organic oil addition. Int. J. Polym. Sci. 2015, 2015. [Google Scholar] [CrossRef]

- Zhou, F.; Cheng, G.X.; Jiang, B. Effect of silane treatment on microstructure of sisal fibers. Appl. Surf. Sci. 2014, 292, 806–812. [Google Scholar] [CrossRef]

- Panyasart, K.; Chaiyut, N.; Amornsakchai, T.; Santawitee, O. Effect of surface treatment on the properties of pineapple leaf fibers reinforced polyamide 6 composites. Energy Procedia 2014, 56, 406–413. [Google Scholar] [CrossRef]

- Cai, M.; Takagi, H.; Nakagaito, A.N.; Katoh, M.; Ueki, T.; Waterhouse, G.I.N.; Li, Y. Influence of alkali treatment on internal microstructure and tensile properties of abaca fibers. Ind. Crop. Prod. 2015, 65, 27–35. [Google Scholar] [CrossRef]

- Roy, A.; Chakraborty, S.; Kundu, S.P.; Basak, R.K.; Majumder, S.B.; Adhikari, B. Improvements in mechanical properties of jute fibres through mild alkali treatment as demonstrated by utilisation of the Weibull distribution model. Bioresour. Technol. 2012, 107, 222–228. [Google Scholar] [CrossRef] [PubMed]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Effects of chemical treatments on hemp fibre structure. Appl. Surf. Sci. 2013, 276, 13–23. [Google Scholar] [CrossRef]

- Nitta, Y.; Goda, K.; Noda, J.; Lee, W.-II. Cross-sectional area evaluation and tensile properties of alkali-treated kenaf fibers. Compos. A 2013, 49, 132–138. [Google Scholar] [CrossRef]

- Ma, H.W.; Joo, C.W. Influence of surface treatments on structural and mechanical properties of bamboo fiber-reinforced poly (lactic acid) biocomposites. J. Compos. Mater. 2011, 45, 2455–2463. [Google Scholar] [CrossRef]

- Ma, L.; He, H.; Jiang, C.; Zhou, L.; Luo, Y.F.; Jia, D.M. Effect of alkali treatment on structure and mechanical properties of acrylonitrile-butadiene-styrene/bamboo fiber composites. J. Macromol. Sci. B 2012, 51, 2232–2244. [Google Scholar] [CrossRef]

- ASTM D3822-07 Standard Test Method for Tensile Properties of Single Textile Fibers; American Society of Testing and Materials: West Conshohocken, PA, USA, 2007.

- Trujillo, E.; Osorio, L.; van Vuure, A.W.; Ivens, J.; Verpoest, I. Characterization of Polymer Composite Materials Based on Bamboo Fibres. In Proceedings of the 14th European Conference on Composite Materials, Budapest, Hungary, 7–10 June 2010.

- Liese, W. The Anatomy of Bamboo Culms; International Network for Bamboo and Rattan: Beijing, China, 1998. [Google Scholar]

- Suresh, S. Graded materials for resistance to contact deformation and damage. Science 2001, 292, 2447–2451. [Google Scholar] [CrossRef] [PubMed]

- Ray, D.; Sarkar, B.K. Characterization of alkali-treated jute fibers for physical and mechanical properties. J. Appl. Polym. Sci. 2001, 80, 1013–1020. [Google Scholar] [CrossRef]

- Cao, Y.; Shibata, S.; Fukumoto, I. Mechanical properties of biodegradable composites reinforced with bagasse fibre before and after alkali treatments. Compos. A 2006, 37, 423–429. [Google Scholar] [CrossRef]

- Okubo, K.; Fujii, T.; Yamamoto, Y. Development of bamboo-based polymer composites and their mechanical properties. Compos. A 2004, 35, 377–383. [Google Scholar] [CrossRef]

- Ma, Z.Z.; Pan, G.W.; Xu, H.L.; Huang, Y.L.; Yang, Y.Q. Cellulosic fibers with high aspect ratio from cornhusks via controlled swelling and alkaline penetration. Carbohyd. Polym. 2015, 124, 50–56. [Google Scholar] [CrossRef] [PubMed]

- Baek, B.S.; Park, J.W.; Lee, B.H.; Kim, H.J. Development and application of green composites: using coffee ground and bamboo flour. J. Polym. Environ. 2013, 21, 702–709. [Google Scholar] [CrossRef]

- Sinha, E.; Rout, S.K. Influence of fibre-surface treatment on structural, thermal and mechanical properties of jute. J. Mater. Sci. 2008, 43, 2590–2601. [Google Scholar] [CrossRef]

- Sun, B.L.; Huang, A.M.; Wang, Y.P.; Liu, J.L. Natural bamboo (Neosinocalamus affinis Keng) fiber identification using FT-IR and 2D-IR correlation spectroscopy. J. Nat. Fibers 2015, 12, 1–11. [Google Scholar] [CrossRef]

- O’Sullivan, A.C. Cellulose: the structure slowly unravels. Cellulose 1997, 4, 173–207. [Google Scholar] [CrossRef]

- Choi, H.Y.; Lee, J.S. Effects of surface treatment of ramie fibers in a ramie/poly (lactic acid) composite. Fiber Polym. 2012, 13, 217–223. [Google Scholar] [CrossRef]

- Wang, F.; Shao, J.X. Modified Weibull distribution for analyzing the tensile strength of bamboo fibers. Polymers 2014, 6, 3005–3018. [Google Scholar] [CrossRef]

- Ray, D.; Sarkar, B.K.; Rana, A.K.; Bose, N.R. The mechanical properties of vinylester resin matrix composites reinforced with alkali-treated jute fibres. Compos. A 2001, 32, 119–127. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Wang, F.; Keer, L.M. Influence of Surface Modification on the Microstructure and Thermo-Mechanical Properties of Bamboo Fibers. Materials 2015, 8, 6597-6608. https://doi.org/10.3390/ma8105327

Zhang X, Wang F, Keer LM. Influence of Surface Modification on the Microstructure and Thermo-Mechanical Properties of Bamboo Fibers. Materials. 2015; 8(10):6597-6608. https://doi.org/10.3390/ma8105327

Chicago/Turabian StyleZhang, Xiaoping, Fang Wang, and Leon M. Keer. 2015. "Influence of Surface Modification on the Microstructure and Thermo-Mechanical Properties of Bamboo Fibers" Materials 8, no. 10: 6597-6608. https://doi.org/10.3390/ma8105327