Anodization Mechanism on SiC Nanoparticle Reinforced Al Matrix Composites Produced by Power Metallurgy

Abstract

:1. Introduction

2. Results and Discussion

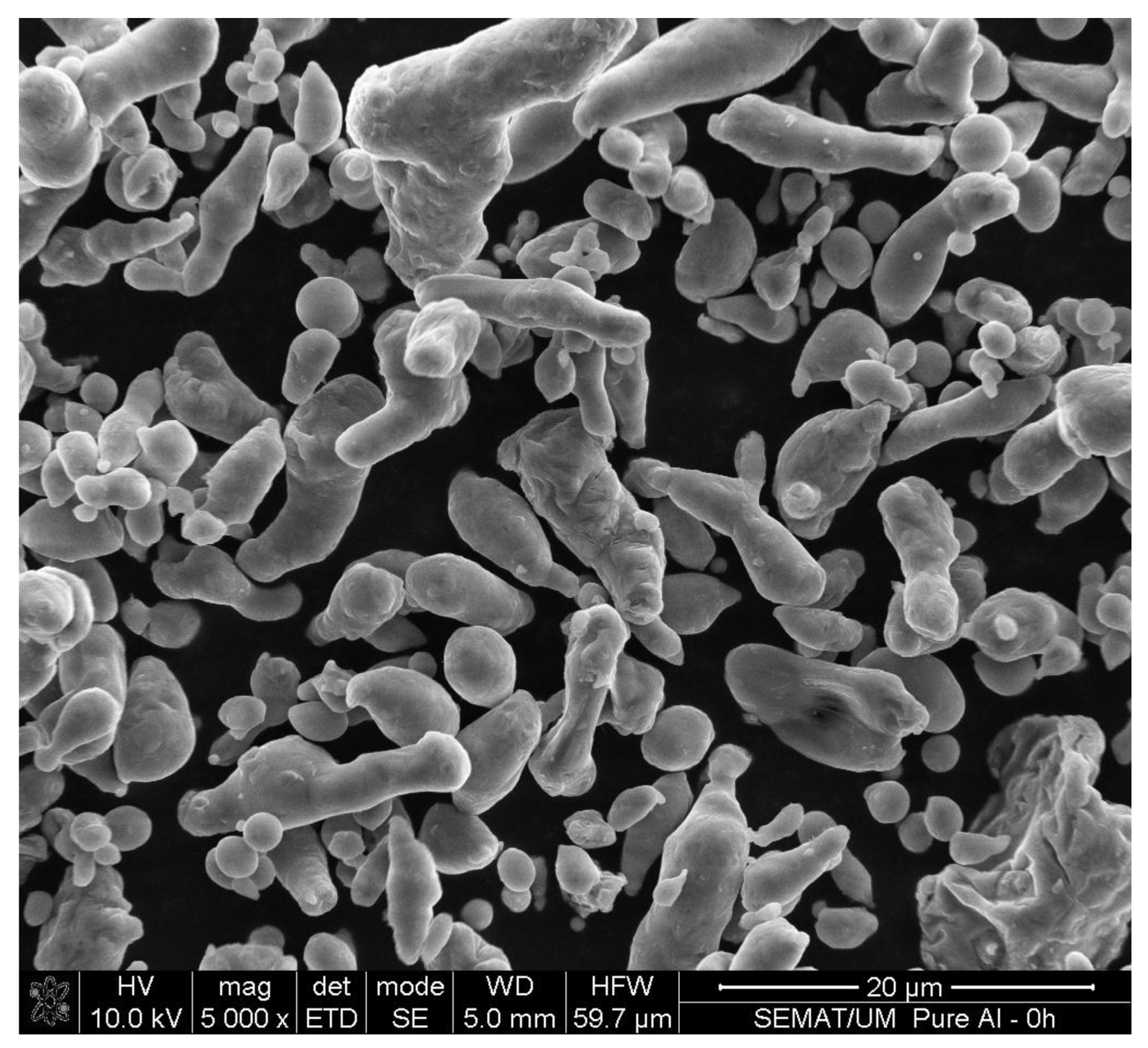

2.1. Raw Materials Characterization

| Powders | Average particles size distribution | ||

|---|---|---|---|

| As-Received Al | 7.70 ± 5.57 µm | ||

| As-Received SiC | 0.07 µm | 0.50 µm | 2.40 µm |

| Material | Al | Si | Fe | Cu | Mn | Cr | |

|---|---|---|---|---|---|---|---|

| As-received Al | 99.60 | 0.13 | 0.18 | 0.01 | >0.01 | >0.01 | |

| 60-min milled | Al | 99.50 | 0.20 | 0.21 | 0.01 | >0.01 | >0.01 |

| Al/1 vol% SiCnp | 98.00 | 1.69 | 0.20 | 0.01 | 0.03 | >0.01 | |

| Al/5 vol% SiCnp | 94.50 | 5.05 | 0.26 | 0.03 | 0.13 | >0.01 | |

| Al/10 vol% SiCnp | 89.80 | 9.66 | 0.31 | 0.02 | 0.14 | 0.02 | |

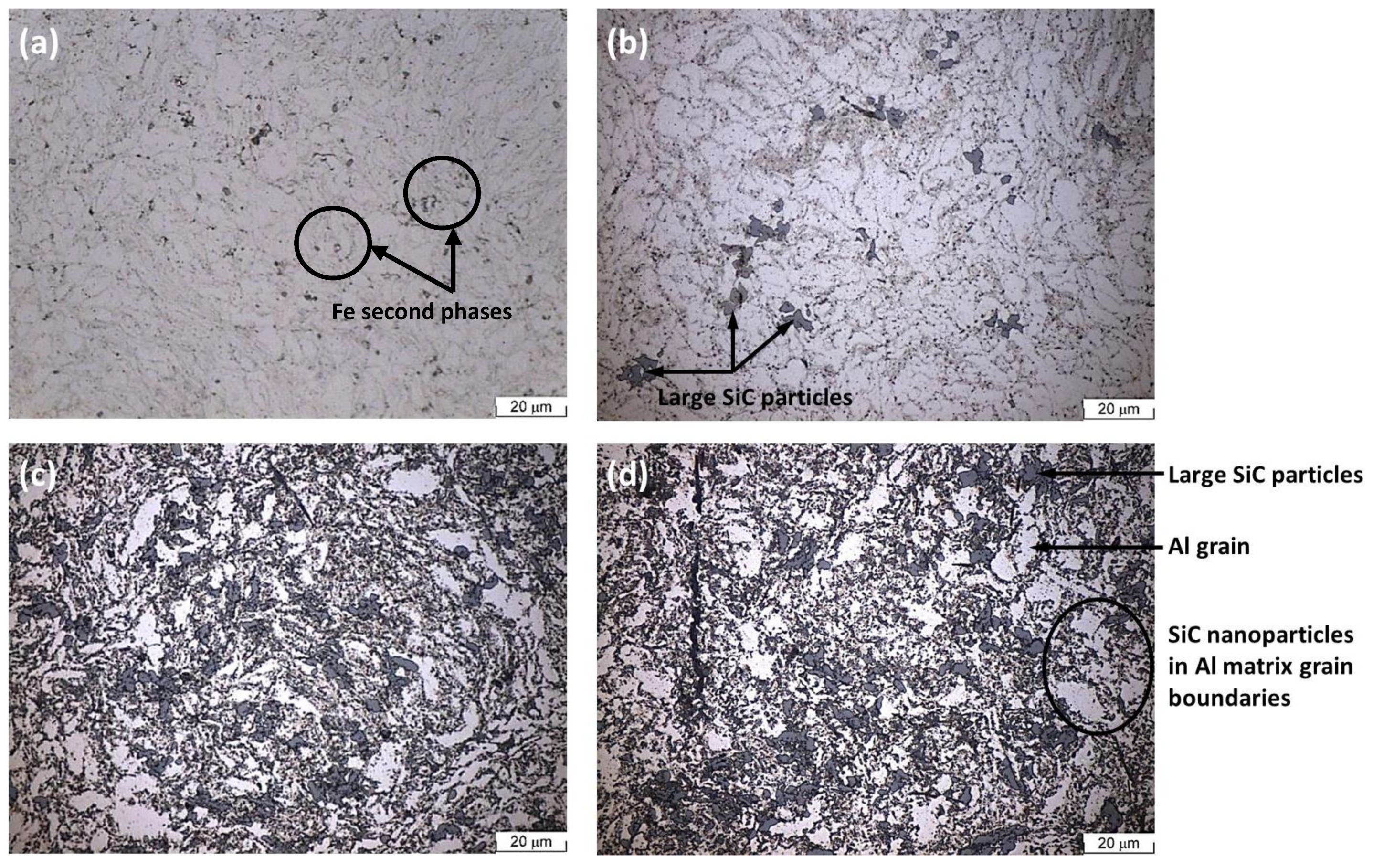

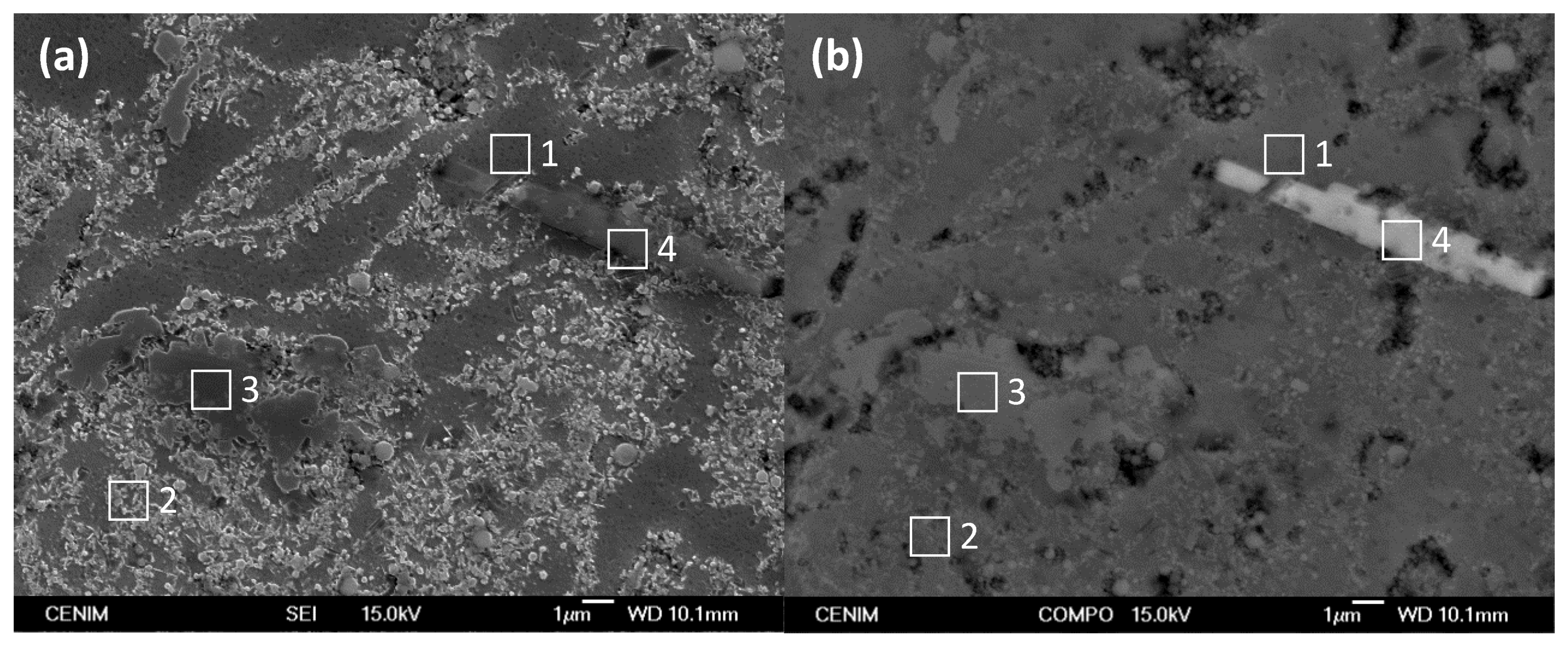

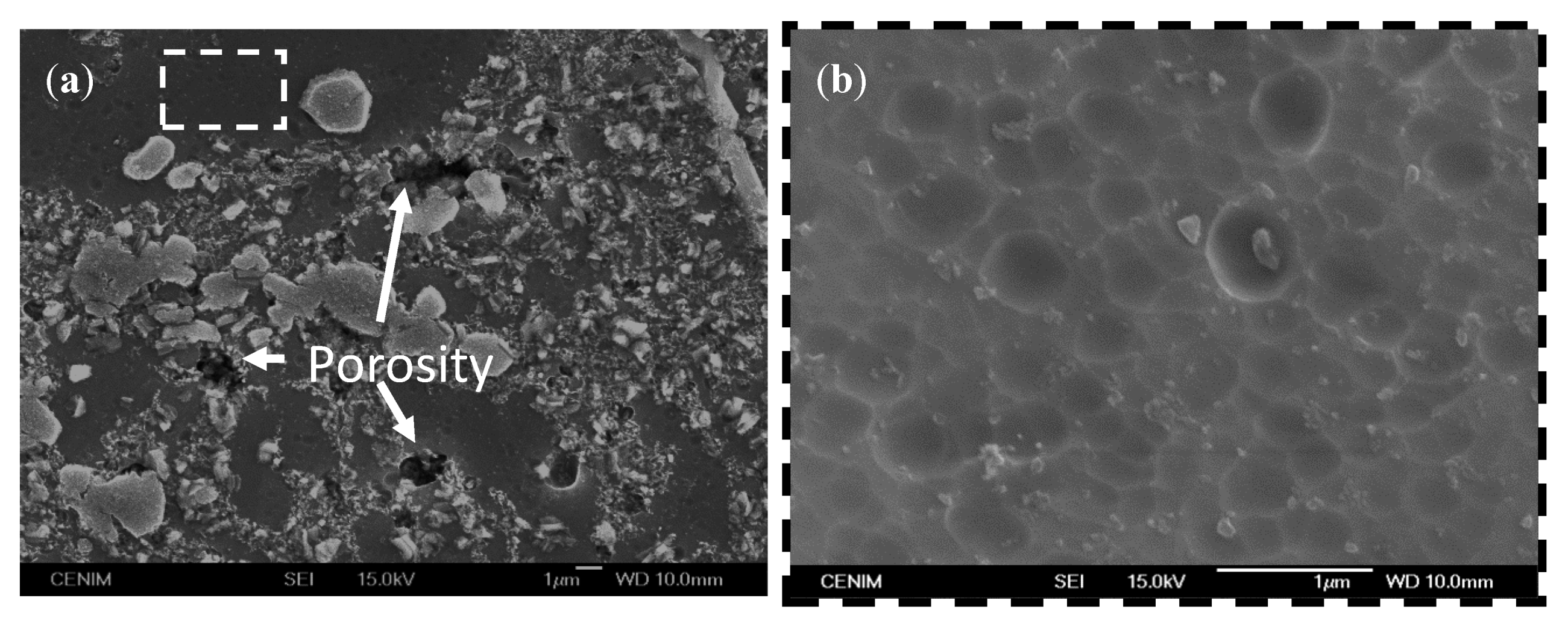

2.2. Microstructure of Al/SiCnp Composites after Sintering

| at% | C | O | Al | Si | Mn | Fe |

|---|---|---|---|---|---|---|

| Spectrum 1 | 2.49 | 3.22 | 92.64 | 1.76 | – | – |

| Spectrum 2 | 20.12 | 10.33 | 52.02 | 17.53 | – | – |

| Spectrum 3 | 8.73 | 7.40 | 32.90 | 50.97 | – | – |

| Spectrum 4 | 8.09 | 13.97 | 56.29 | 12.14 | 0.85 | 8.65 |

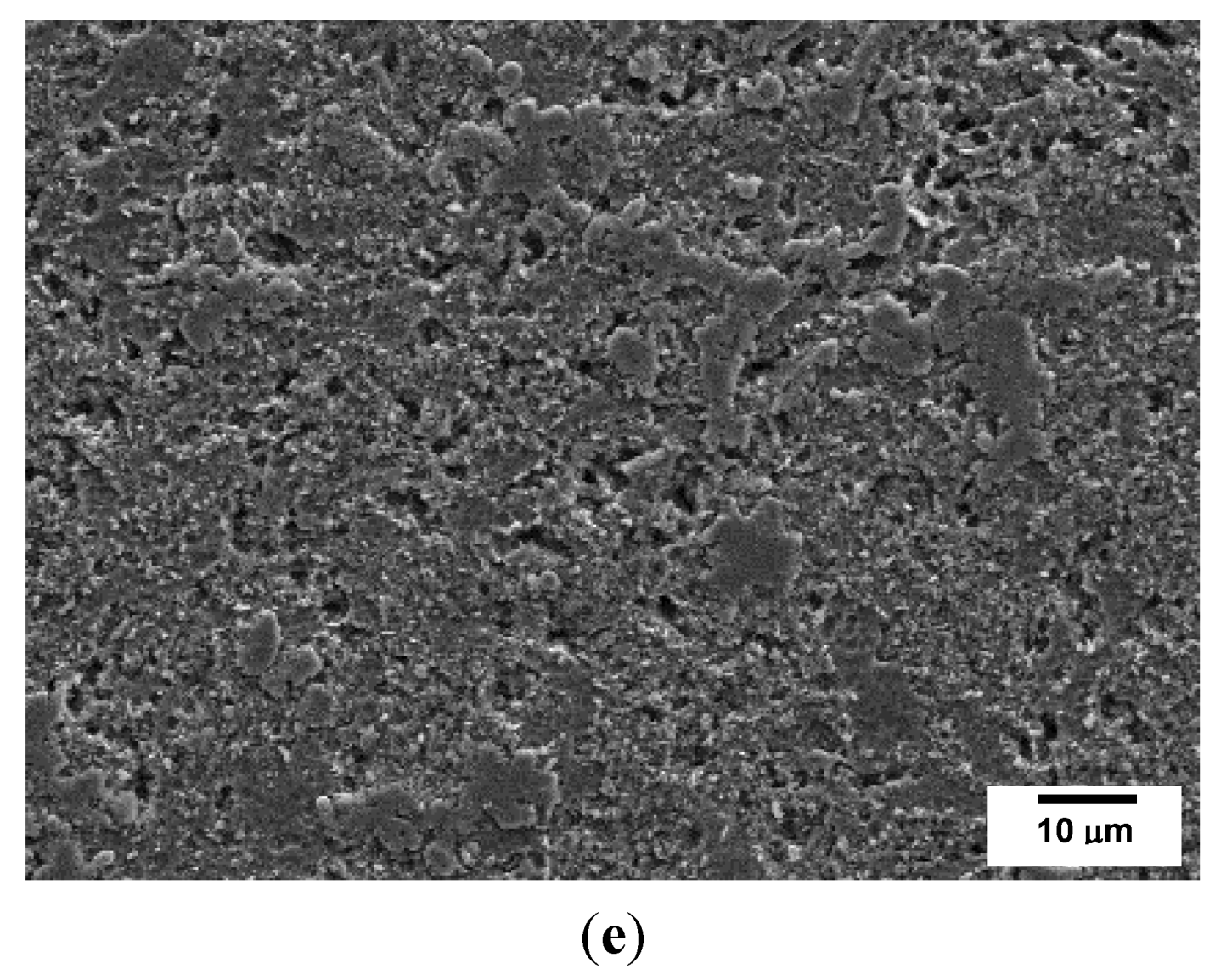

2.3. Surface Modification of Al/SiCnp by Alkaline Etching and De-Smutting

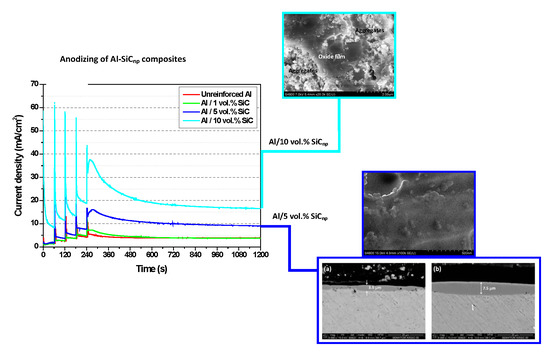

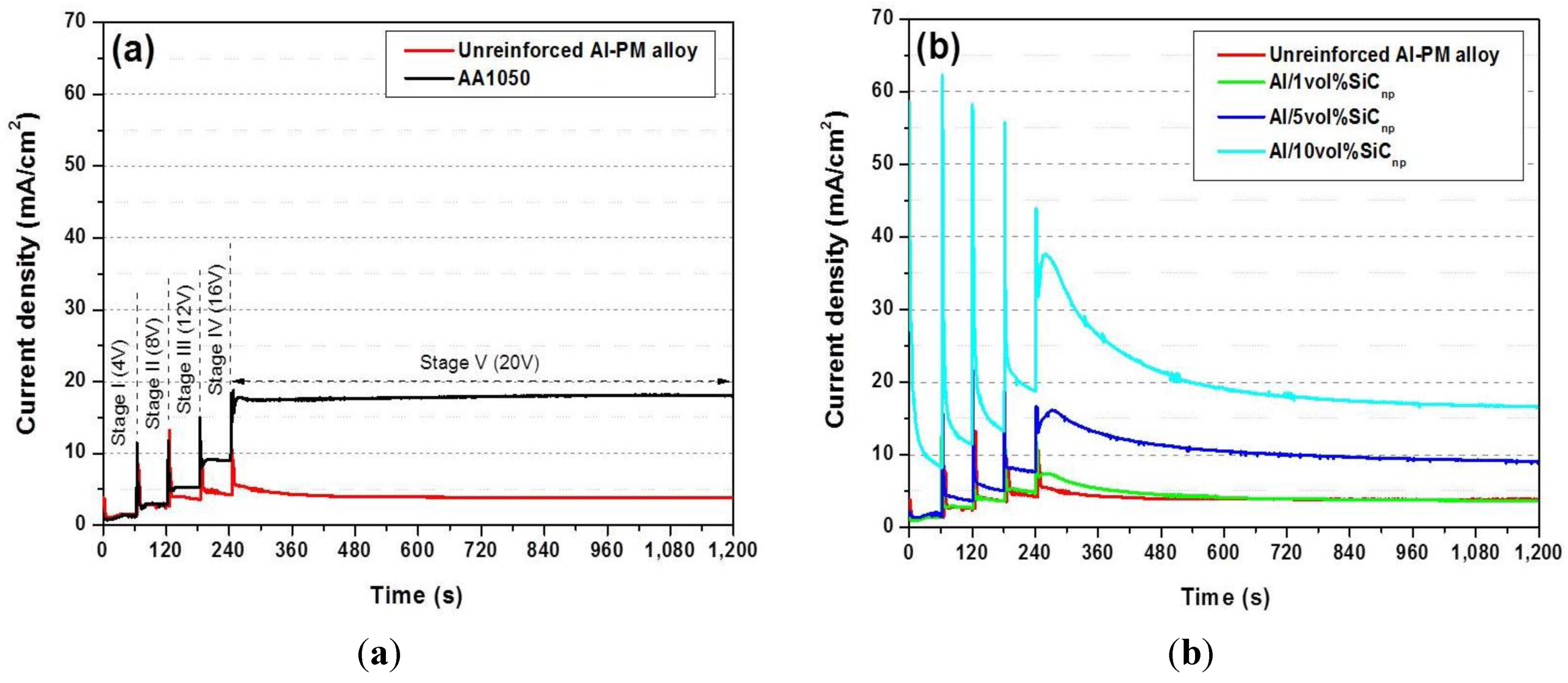

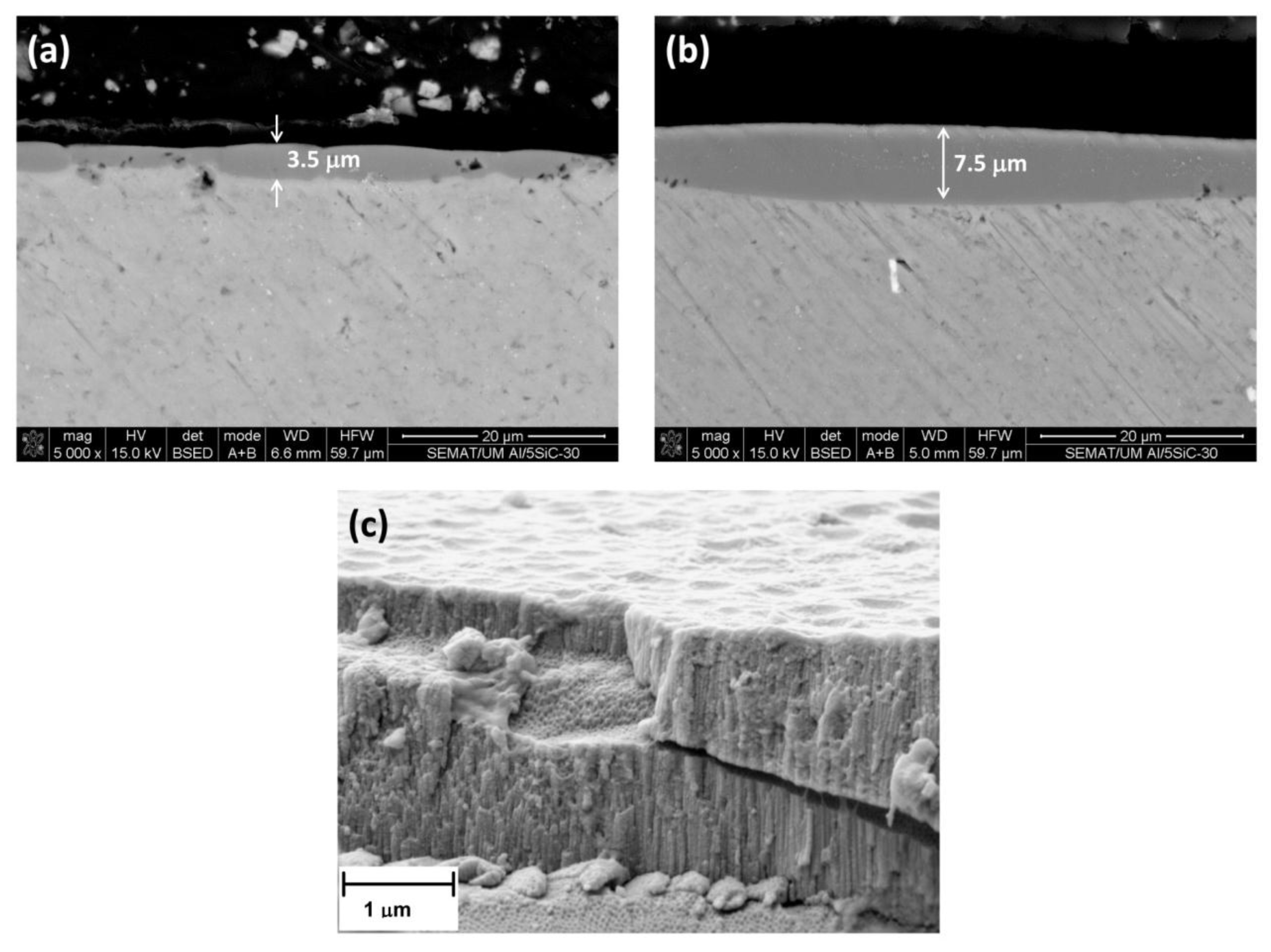

2.4. Anodizing of Al/SiCnp Composites in TSA Bath

3. Experimental Section

3.1. Materials

3.2. Metallographic Preparation and SEM Analysis

3.3. Pretreatment and Anodizing Surface Treatment

4. Conclusions

- Specimens of unreinforced Al-PM alloy and nanosized Al/SiCp composites produced by PM were anodized in tartaric-sulfuric acid at 20 V to study the ability of this surface treatment to fabricate homogeneous anodic films with potential protective properties for the SiCnp-reinforced Al-MMCs.

- The current density versus time response reveals that the SiCnp reinforcement volume fraction influences the anodizing mechanism.

- The increasing content of nanosized SiC particles in Al composites induces a rise of the current density values due to the partial oxidation of the SiCnp. These particles are finally occluded in the film due to the preferential oxidation of the surrounding Al matrix. The presence of gas-filled voids throughout the cross-section of the anodizing film reveals the uniform entrapment of the SiCnp within the anodic film.

- SiC particles in the nanoscale range and with contents of about 1% and 5% decrease the efficiency of the anodizing process and hinder the film formation, but still, a continuous anodic oxide layer covers the surface; conversely, if the content is too high (10%), particles agglomerate, shielding the matrix, and the film is not formed.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chawla, N.; Chawla, K.K. Metal-matrix composites in ground transportation. JOM 2006, 58, 67–70. [Google Scholar] [CrossRef]

- Abdoli, H.; Saebnouri, E.; Sadrnezhaad, S.K.; Ghanbari, M.; Shahrabi, T. Processing and surface properties of Al–AlN composites produced from nanostructured milled powders. J. Alloy. Compd. 2010, 490, 624–630. [Google Scholar] [CrossRef]

- Toptan, F.; Kilicarslan, A.; Karaaslan, A.; Cigdem, M.; Kerti, I. Processing and microstructural characterisation of AA 1070 and AA 6063 matrix B4Cp reinforced composites. Mater. Des. 2010, 31, S87–S91. [Google Scholar] [CrossRef]

- Lee, K.B.; Ahn, J.P.; Kwon, H. Characteristics of AA 6061/BN composite fabricated by pressureless infiltration technique. Metall. Mater. Trans. A 2001, 32A, 1007–1018. [Google Scholar] [CrossRef]

- Ipek, R. Adhesive wear behaviour of B4C and SiC reinforced 4147 Al matrix composites (Al/B4C–Al/SiC). J. Mater. Process. Technol. 2005, 162–163, 71–75. [Google Scholar] [CrossRef]

- Abenojar, J.; Martinez, M.A.; Velasco, F. Effect of the boron content in the aluminium/boron composite. J. Alloy. Compd. 2006, 422, 67–72. [Google Scholar] [CrossRef]

- Abenojar, J.; Velasco, F.; Martinez, M.A. Optimization of processing parameters for the Al + 10%B4C system obtained by mechanical alloying. J. Mater. Process. Technol. 2007, 184, 441–446. [Google Scholar] [CrossRef]

- Kang, Y.C.; Chan, S.L.I. Tensile properties of nanometric Al2O3 particulate-reinforced aluminum matrix composites. Mater. Chem. Phys. 2004, 85, 438–443. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Li, Y.L.; Liang, Y.; Zheng, F.; Bi, J.; Tjong, S.C. Nanometric Si3N4 particulate-reinforced aluminum composite. Mater. Sci. Eng. A 1996, 219, 229–231. [Google Scholar] [CrossRef]

- Hong, S.J.; Kim, H.M.; Huh, D.; Suryanarayana, C.; Chunin, B.S. Effect of clustering on the mechanical properties of SiC particulate-reinforced aluminum alloy 2024 metal matrix composites. Mater. Sci. Eng. A 2003, 347, 198–204. [Google Scholar] [CrossRef]

- Veeresh Kumar, G.B.; Rao, C.S.P.; Selvaraj, N. Studies on mechanical and dry sliding wear of Al6061–SiC composites. Compos. Part B Eng. 2012, 43, 1185–1191. [Google Scholar] [CrossRef]

- Vieira, A.C.; Sequeira, P.D.; Gomes, J.R.; Rocha, L.A. Dry sliding wear of Al alloy/SiCp functionally graded composites: Influence of processing conditions. Wear 2009, 267, 585–592. [Google Scholar] [CrossRef]

- Singh, I.B.; Mondal, D.P.; Singh, M.; Das, S. Influence of SiC particle addition on the corrosion behaviour of 2014 Al-Cu alloy in 3.5% NaCl solution. Corros. Sci. 2009, 51, 234–241. [Google Scholar] [CrossRef]

- Pardo, A.; Merino, M.C.; Merino, S.; Viejo, F.; Carboneras, M.; Arrabal, R. Influence of the reinforcement proportion and matrix composition on pitting corrosion behaviour of cast aluminium matrix composites (A3xx.x/SiCp). Corros. Sci. 2005, 47, 1750–1764. [Google Scholar] [CrossRef]

- Velhinho, A.; Botas, J.D.; Ariza, E.; Gomes, J.R.; Rocha, L.A. Tribocorrosion studies in centrifugally cast Al-matrix SiCp-reinforced functionally graded composites. Mater. Sci. Forum 2004, 455–456, 871–875. [Google Scholar] [CrossRef]

- Vieira, A.C.; Rocha, L.A.; Mischler, S. Influence of SiC reinforcement particles on the tribocorrosion behaviour of Al–SiCp FGMs in 0.05 M NaCl solution. J. Phys. D Appl. Phys. 2011, 44, 185301–185309. [Google Scholar] [CrossRef]

- Torralba, J.M.; Costa, C.E.; Valasco, F. P/M aluminum matrix composites: An overview. J. Mater. Process. Technol. 2003, 133, 203–206. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, R.; Hu, X.; Wang, C.; Huang, Y. Characterization of a powder metallurgy SiC/Cu–Al composite. J. Mater. Process. Technol. 2008, 197, 43–48. [Google Scholar] [CrossRef]

- El-Eskandarany, M.S. Mechanical solid state mixing for synthesizing of SiCp/Al nanocomposites. J. Alloy. Compd. 1998, 279, 263–271. [Google Scholar] [CrossRef]

- Tjong, S.C. Novel nanoparticle-reinforced metal matrix composites with enhanced mechanical properties. Adv. Eng. Mater. 2007, 9, 639–652. [Google Scholar] [CrossRef]

- Rahimian, M.; Ehsani, N.; Parvin, N.; Baharvandi, H.R. The effect of particle size, sintering temperature and sintering time on the properties of Al–Al2O3 composites, made by powder metallurgy. J. Mater. Process. Technol. 2009, 209, 5387–5393. [Google Scholar] [CrossRef]

- Sivasankaran, S.; Sivaprasad, K.; Narayanasamy, R.; Iyer, V.K. Synthesis, structure and sinterability of 6061 AA100−x−x wt.% TiO2 composites prepared by high-energy ball milling. J. Alloy. Compd. 2010, 491, 712–721. [Google Scholar] [CrossRef]

- Shahid, M. Mechanism of film growth during anodizing of Al-alloy-8090/SiC metal matrix composite in sulphuric acid electrolyte. J. Mater. Sci. 1997, 32, 3775–3781. [Google Scholar] [CrossRef]

- He, C.; Liu, C.; Li, F.; Cai, Q.; Shi, Z.; Chen, L.; Bi, J. Corrosion behaviour and protection efficiency of 2024Al and SiCp 2024Al metal matrix composite. J. Mater. Sci. Technol. 2002, 18, 351–353. [Google Scholar] [CrossRef]

- He, C.; Lou, D.; Wang, J.; Cai, Q. Corrosion protection and formation mechanism of anodic coating on SiCp/AL metal martrix composite. Thin Solid Films 2011, 519, 4759–4764. [Google Scholar] [CrossRef]

- Picas, J.A.; Martín, E.; Baile, M.T.; Rupérez, E.; Forn, A. Hard anodizing of aluminium matrix composite A6061/(Al2O3)p for wear and corrosion resistance improvement. Plasma Process. Polym. 2007, 4, S579–S583. [Google Scholar] [CrossRef]

- Wernick, S.; Pinner, R.; Sheasby, P.G. The Surface Treatment and Finishing of Aluminium and Its Alloys, 6th ed.; ASM International Finishing Publications Ltd.: Herts, UK, 2001; Volume 1. [Google Scholar]

- Lin, S.; Greene, H.; Shih, H.; Mansfeld, F. Corrosion protection of Al/SiC metal matrix composites by anodizing. Corrosion 1992, 48, 61–67. [Google Scholar] [CrossRef]

- Hou, J.; Chung, D.D.L. Corrosion protection of aluminum-matrix aluminum nitride and silicon carbide composites by anodization. J. Mater. Sci. 1997, 32, 3113–3121. [Google Scholar] [CrossRef]

- Ocón, P.; García-Rubio, M.; Lavía, A.; García, I. Procedure for Anodising Aluminium or Aluminium Alloys. EP 2055 810A2, 29 October 2007. [Google Scholar]

- Garcia-Rubio, M.; Ocon, P.; Curioni, M.; Thompson, G.E.; Skeldon, P.; Lavia, A.; Garcia, I. Degradation of the corrosion resistance of anodic oxide films through immersion in the anodising electrolyte. Corros. Sci. 2010, 52, 2219–2227. [Google Scholar] [CrossRef]

- Garcia-Rubio, M.; de Lara, M.P.; Ocon, P.; Diekhoff, S.; Beneke, M.; Lavia, A.; Garcia, I. Effect of postreatment on the corrosion behaviour of tartaric-sulphuric anodic films. Electrochim. Acta 2009, 54, 4789–4800. [Google Scholar] [CrossRef]

- Arenas, M.A.; Conde, A.; de Damborenea, J.J. Effect of acid traces on hydrothermal sealing of anodising layers on 2024 aluminium alloy. Electrochim. Acta 2010, 55, 8704–8708. [Google Scholar] [CrossRef]

- He, C.; Zhou, Q.; Liu, J.; Li, F.; Geng, X.; Cai, Q. Effect of size of reinforcement on thickness of anodized coatings on SiC/Al matrix composites. Mater. Lett. 2008, 66, 2441–2443. [Google Scholar] [CrossRef]

- Abenojar, J.; Velasco, F.; Martinez, M.A. Differential thermal analysis of the Al + 20% (Fe–50%B) system. J. Solid State Chem. 2006, 179, 2787–2790. [Google Scholar] [CrossRef]

- Srivastava, V.C.; Ojha, N. Microstructure and electrical conductivity of Al-SiCp composites produced by spray forming process. Bull. Mater. Sci. 2005, 28, 125–130. [Google Scholar] [CrossRef]

- Padmavathi, C.; Upadhyaya, A. Densification, microstructure and properties of supersolidus liquid phase sintered 6711Al-SiC metal matrix composites. Sci. Sinter. 2010, 42, 363–382. [Google Scholar] [CrossRef]

- Bartolomé, M.J.; Lopez, V.; Escudero, E.; Caruana, G.; Gonzalez, J.A. Changes in the specific surface area of porous aluminium oxide films during sealing. Surf. Coat. Technol. 2006, 200, 4530–4537. [Google Scholar] [CrossRef]

- Boisier, G.; Pébère, N.; Druez, C.; Villatine, M.; Suel, S. FESEM and EIS study of sealed AA2024 T3 anodized in sulfuric acid electrolytes: Influence of tartaric acid. J. Electrochem. Soc. 2008, 155, C521–C529. [Google Scholar] [CrossRef]

- Fratila-Apachitei, L.E.; Tichelaar, F.D.; Thompson, G.E.; Terryn, H.; Skeldon, P.; Duszczyk, J.; Katgerman, L. A transmission electron microscopy study of hard anodic oxide layers on AlSi(Cu) alloys. Electrochim. Acta 2004, 49, 3169–3177. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferreira, S.C.; Conde, A.; Arenas, M.A.; Rocha, L.A.; Velhinho, A. Anodization Mechanism on SiC Nanoparticle Reinforced Al Matrix Composites Produced by Power Metallurgy. Materials 2014, 7, 8151-8167. https://doi.org/10.3390/ma7128151

Ferreira SC, Conde A, Arenas MA, Rocha LA, Velhinho A. Anodization Mechanism on SiC Nanoparticle Reinforced Al Matrix Composites Produced by Power Metallurgy. Materials. 2014; 7(12):8151-8167. https://doi.org/10.3390/ma7128151

Chicago/Turabian StyleFerreira, Sonia C., Ana Conde, María A. Arenas, Luis A. Rocha, and Alexandre Velhinho. 2014. "Anodization Mechanism on SiC Nanoparticle Reinforced Al Matrix Composites Produced by Power Metallurgy" Materials 7, no. 12: 8151-8167. https://doi.org/10.3390/ma7128151

APA StyleFerreira, S. C., Conde, A., Arenas, M. A., Rocha, L. A., & Velhinho, A. (2014). Anodization Mechanism on SiC Nanoparticle Reinforced Al Matrix Composites Produced by Power Metallurgy. Materials, 7(12), 8151-8167. https://doi.org/10.3390/ma7128151