Fabrication of Cellulose ZnO Hybrid Nanocomposite and Its Strain Sensing Behavior

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

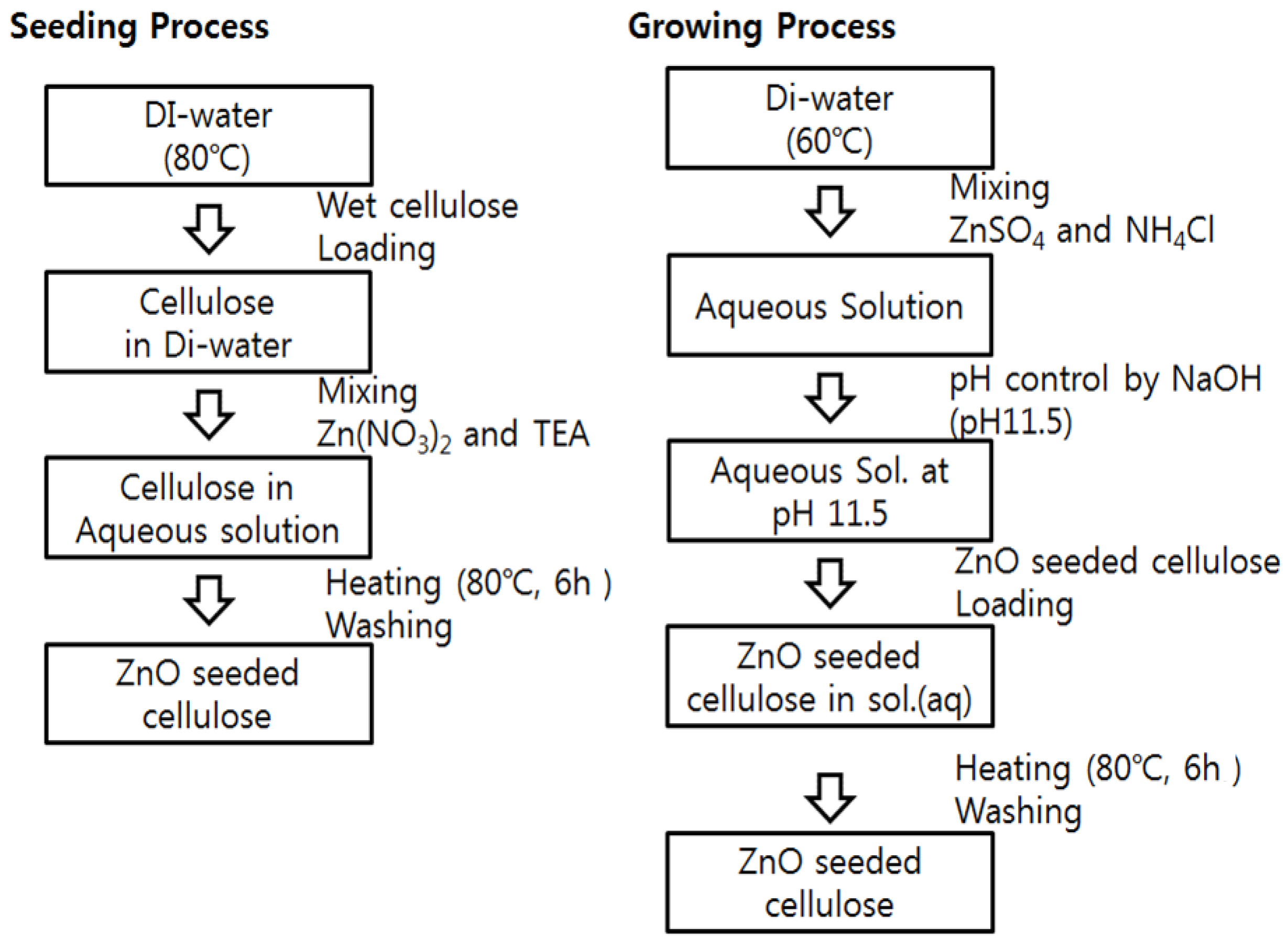

2.2. Fabrication

2.3. Characterization

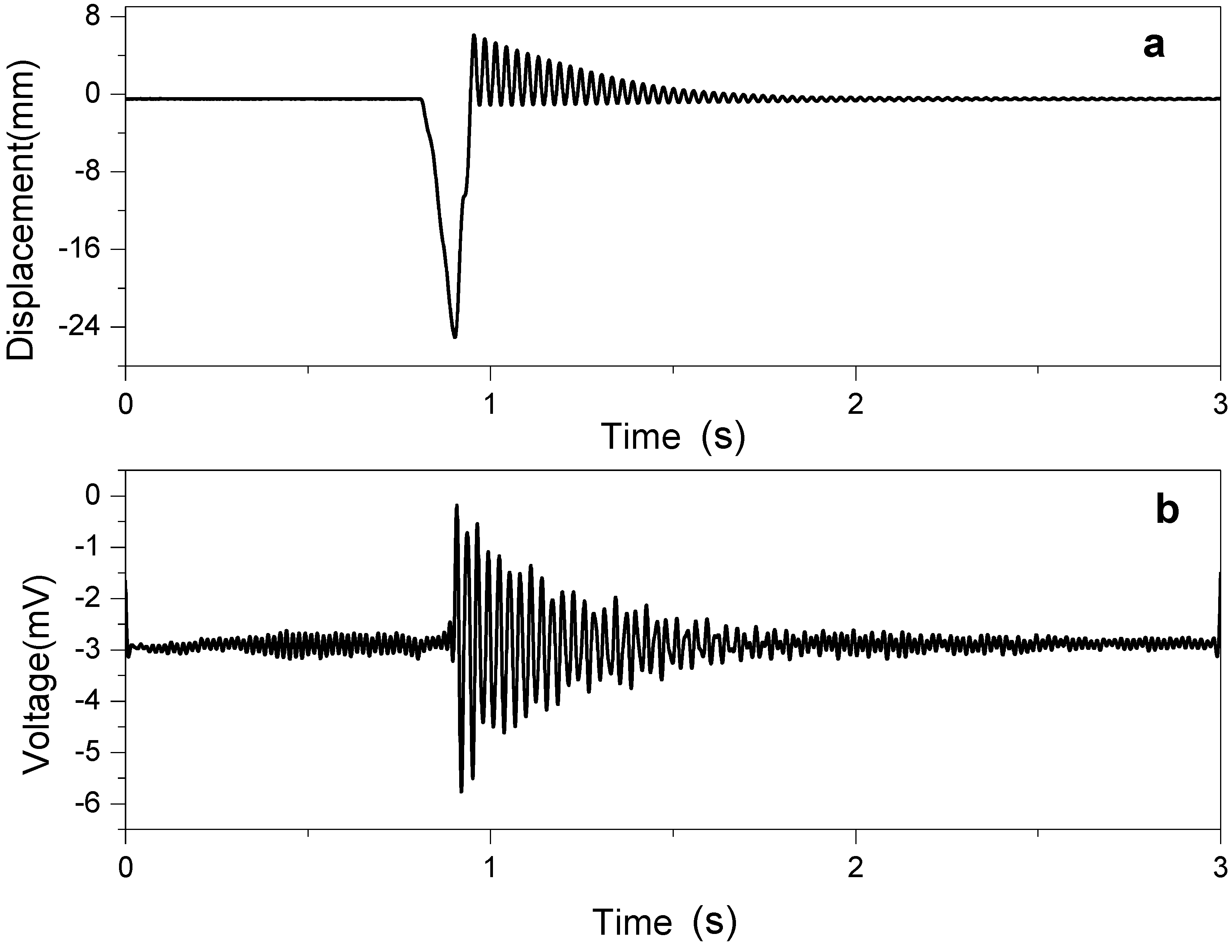

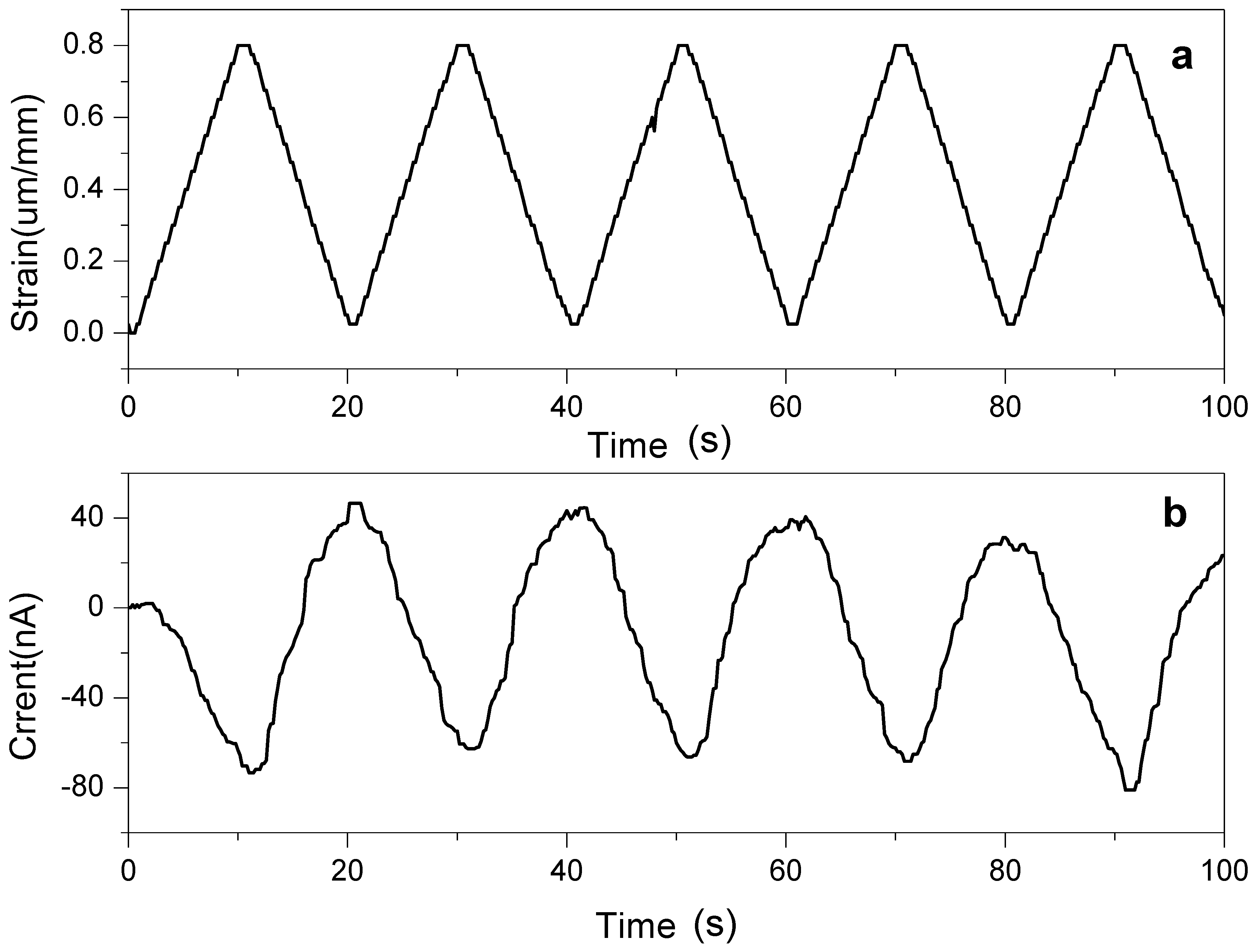

2.4. Strain Sensor Test

3. Results and Discussion

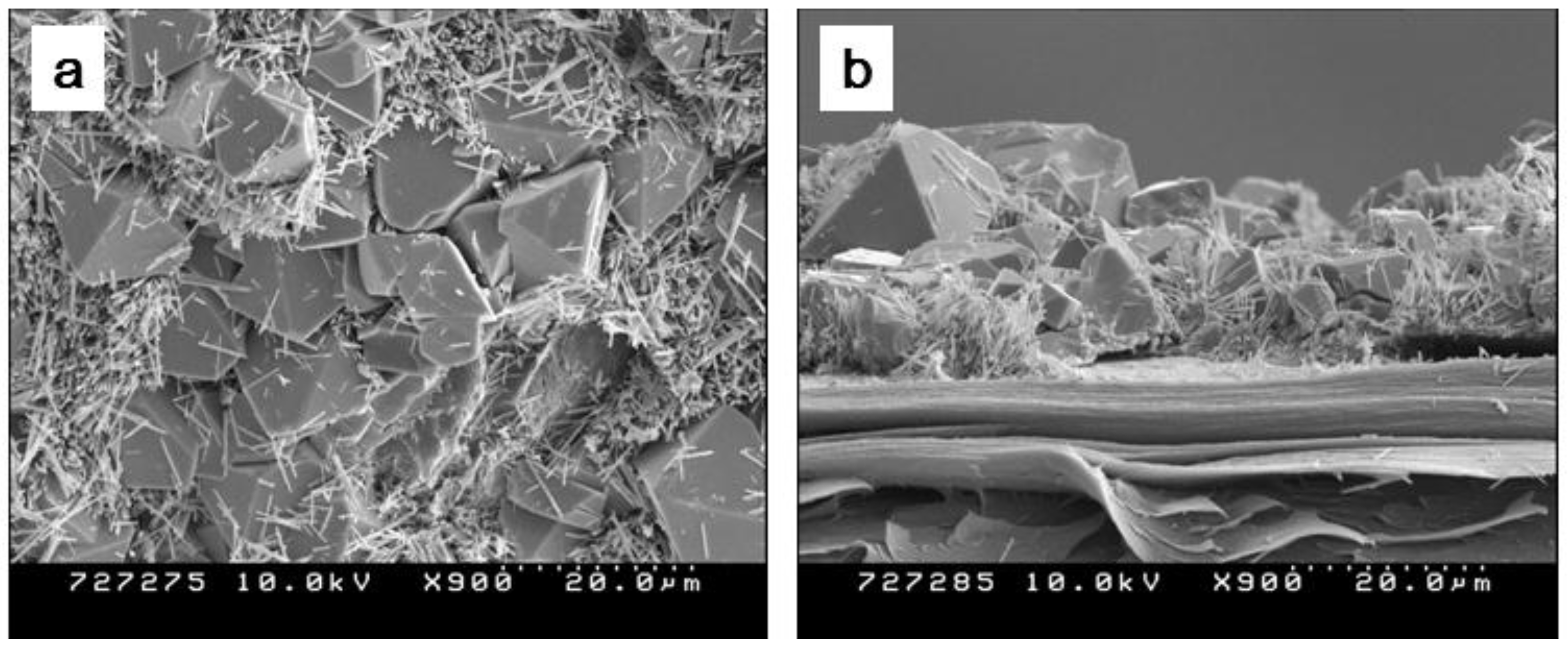

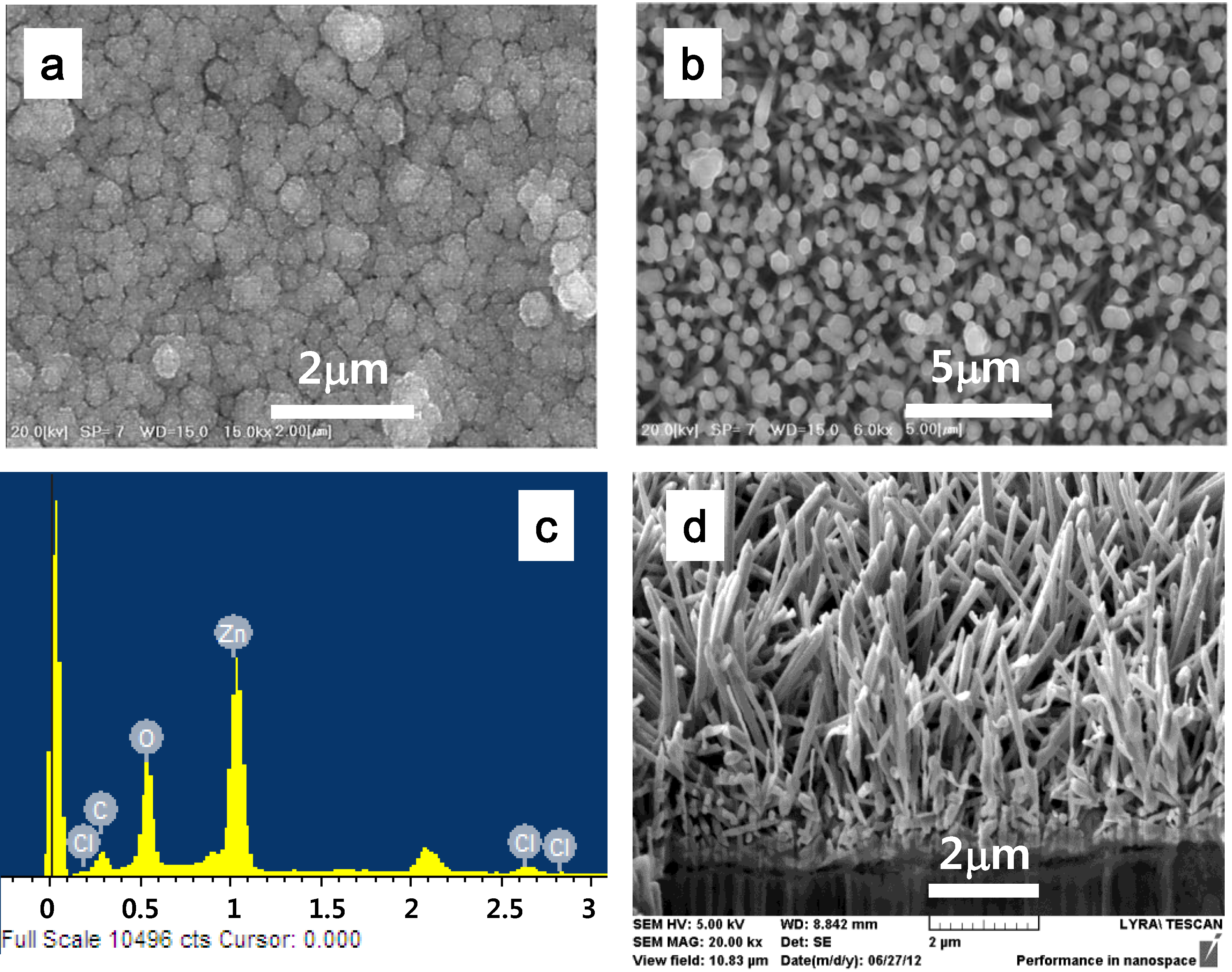

3.1. ZnO Nanorod Growth on Cellulose

3.2. Physical Properties

| Samples | Young’s modulus (GPa) | Piezoelectric charge constant d31 (pC/N) |

|---|---|---|

| Bare cellulose | 5.3 | 6 |

| Aligned cellulose | 7.0 | 30 |

| CEZOHN | 5.0 | 145 |

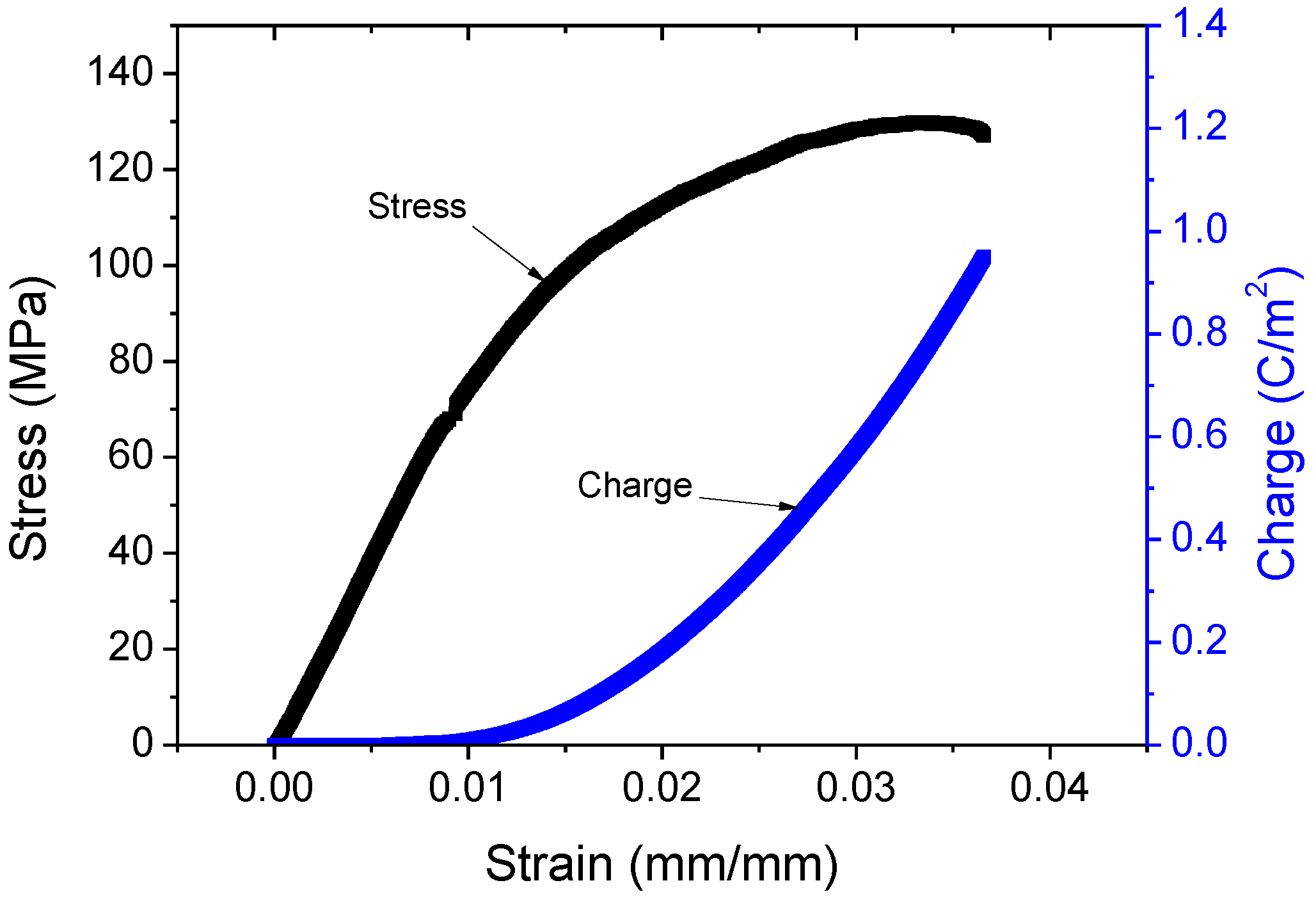

3.3. Strain Sensing

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kim, J.; Yun, S.; Ounaies, Z. Discovery of cellulose as a smart material. Macromolecules 2006, 39, 4202–4206. [Google Scholar] [CrossRef]

- Yun, S.; Jang, S.; Yun, G.-Y.; Kim, J. Electrically aligned cellulose film for electro-active paper and its piezoelectricity. Smart Mater. Struct. 2009, 18, 117001:1–117001:6. [Google Scholar]

- Kim, J.; Yun, G.-Y.; Kim, J.-H.; Lee, J.; Kim, J.-H. Piezoelectric electro active paper (EAPap) speaker. J. Mech. Sci. Technol. 2011, 25, 2763–2768. [Google Scholar] [CrossRef]

- Kim, J.; Yun, S.; Mahadeva, S.K.; Yun, K.; Yang, S.Y.; Maniruzzaman, M. Paper actuators made with cellulose and hybrid materials. Sensors 2010, 10, 1473–1485. [Google Scholar] [PubMed]

- Mun, S.; Chen, Y.; Kim, J. Cellulose-Titanium dioxide-multiwalled carbon nanotube hybrid nanocomposite and its ammonia gas sensing properties at room temperature. Sens. Actuators B Chem. 2012, 171, 1186–1191. [Google Scholar] [CrossRef]

- Chen, Y.; Mun, S.C.; Kim, J. A wide range conductometric pH sensor made with titanium dioxide/multiwall carbon nanotube/cellulose hybrid nanocomposite. IEEE Sens. J. 2013, 13, 4157–4162. [Google Scholar] [CrossRef]

- Mahadeva, S.K.; Kim, J. Conductometric glucose biosensor made with cellulose and tin oxide hybrid nanocomposite. Sens. Actuator B Chem. 2011, 157, 177–182. [Google Scholar] [CrossRef]

- Kim, J.-H.; Yun, S.; Ko, H.-U.; Kim, J. A flexible paper transistor made with aligned single-walled carbon nanotube bonded cellulose composite. Curr. Appl. Phys. 2013, 13, 897–901. [Google Scholar] [CrossRef]

- Lee, J.; Lee, D.; Lim, D.; Yang, K. Structural, electrical and optical properties of ZnO:Al films deposited on flexible organic substrates for solar cell applications. Thin Solid Films 2007, 515, 6094–6098. [Google Scholar] [CrossRef]

- Choi, M.-Y.; Choi, D.; Jin, M.-J.; Kim, I.; Kim, S.-H.; Choi, J.-Y.; Lee, S.Y.; Kim, J.M.; Kim, S.-W. Mechanically powered transparent flexible charge-generating nanodevices with piezoelectric ZnO nanorods. Adv. Mater. 2009, 21, 2185–2189. [Google Scholar] [CrossRef]

- Hao, X.; Ma, J.; Zhang, D.; Yang, T.; Ma, H.; Yang, Y.; Cheng, C.; Huang, J. Thickness dependence of structural, optical and electrical properties of ZnO:Al films prepared on flexible substrates. Appl. Surf. Sci. 2001, 183, 137–142. [Google Scholar] [CrossRef]

- Oprea, O.; Aderonescu, E.; Ficai, D.; Ficai, A.; Oktar, F.; Yetmez, M. ZnO applications and challenges. Curr. Org. Chem. 2014, 18, 192–203. [Google Scholar] [CrossRef]

- Wang, Z.L.; Song, J. Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 2006, 312, 242–246. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Kerr, L.L. Dye sensitized solar cells on paper substrates. Solar Energy Mater. Solar Cells 2011, 95, 2531–2535. [Google Scholar] [CrossRef]

- Gullapalli, H.; Vemuru, V.S.M.; Kumar, A.; Botello-Mendez, A.; Vajtai, R.; Terrones, M.; Nagarajaiah, S.; Ajayan, P.M. Flexible piezoelectric ZnO–paper nanocomposite strain sensor. Small 2010, 6, 1641–1646. [Google Scholar] [CrossRef] [PubMed]

- Ghule, K.; Ghule, A.V.; Chen, B.-J.; Ling, Y.-C. Preparation and characterization of ZnO nanoparticles coated paper and its antibacterial activity study. Green Chem. 2006, 8, 1034–1041. [Google Scholar] [CrossRef]

- Yun, S.; Kim, J.; Lee, K.-S. Evaluation of cellulose electro-active paper made by tape casting and zone stretching methods. Int. J. Precis. Eng. Manuf. 2010, 11, 987–990. [Google Scholar] [CrossRef]

- Qu, X.; Jia, D. Synthesis of octahedral ZnO mesoscale superstructures via thermal decomposing octahedral zinc hydroxide precursors. J. Cryst. Growth 2009, 311, 1223–1228. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ko, H.-U.; Mun, S.; Min, S.-K.; Kim, G.-W.; Kim, J. Fabrication of Cellulose ZnO Hybrid Nanocomposite and Its Strain Sensing Behavior. Materials 2014, 7, 7000-7009. https://doi.org/10.3390/ma7107000

Ko H-U, Mun S, Min S-K, Kim G-W, Kim J. Fabrication of Cellulose ZnO Hybrid Nanocomposite and Its Strain Sensing Behavior. Materials. 2014; 7(10):7000-7009. https://doi.org/10.3390/ma7107000

Chicago/Turabian StyleKo, Hyun-U, Seongcheol Mun, Seung-Ki Min, Gi-Woo Kim, and Jaehwan Kim. 2014. "Fabrication of Cellulose ZnO Hybrid Nanocomposite and Its Strain Sensing Behavior" Materials 7, no. 10: 7000-7009. https://doi.org/10.3390/ma7107000