Progress in Titanium Metal Powder Injection Molding

Abstract

:1. Introduction

- (1)

- Decorative items where mechanical and other properties are not demanding, such as in watch cases;

- (2)

- Mechanical components where mechanical and corrosion properties must exceed that of a stainless steel such as in medical surgical tools;

- (3)

- Life Critical applications where titanium is needed for success such as in biomedical implants.

2. Background

3. Ti-MIM Processing Optimization

| Steps | Key principle | Specific time, temperature, and such |

|---|---|---|

| powder | deagglomerated spheres | gas or plasma atomized |

| typically −325 mesh | 30 to 60 μm median particle size | |

| high tap density | 60% to 62% of pycnometer density | |

| low initial oxygen level | 0.15 wt % maximum | |

| low initial carbon level | 0.04 wt % maximum | |

| binder | majority low molecular polymer | 65% to 75% paraffin wax or polyethylene glycol |

| higher molecular weight backbone | 15% to 25% polypropylene or ethylene vinyl acetate | |

| surfactant, lubricant, plasticizer | 5% stearic acid | |

| mixing | mixing under protective conditions | vacuum or argon cover gas |

| room temperature dry mix all ingredients | at 65 vol % solids loading | |

| heated, high shear mixing | vacuum mix, 30 min at 120 to 185 °C | |

| temperature and solids loading target viscosity | at 500 s−1 of 150 to 250 Pa·s | |

| molding | controlled nozzle temperature | 120 to 180 °C |

| slightly heated mold | 30 °C | |

| injection temperature | 160 °C | |

| injection pressure | 30 MPa | |

| green strength | 10 MPa | |

| debinding | first stage solvent immersion | 60 °C; water for polyethylene glycol, heptane for paraffin wax |

| solvent penetration rate | 2 mm/h | |

| second stage thermal debinding | slow heatargon sweep gas in vacuum | |

| vacuum final step debinding | heat slowly to 450 °C, hold 1 h | |

| presinter heating for strength | hold near 900 °C for 1 h, vacuum | |

| sintering | high temperature sintering | vacuum, refractory metal furnace |

| support or substrate materials | yttria or zirconia trays | |

| peak temperature and time | 1250 °C for 120 to 180 min | |

| sintered density | 95% of theoretical, closed pore condition | |

| densification | hot isostatic pressing | argon without container |

| consolidation conditions | 900 °C, 100 MPa, 60 min | |

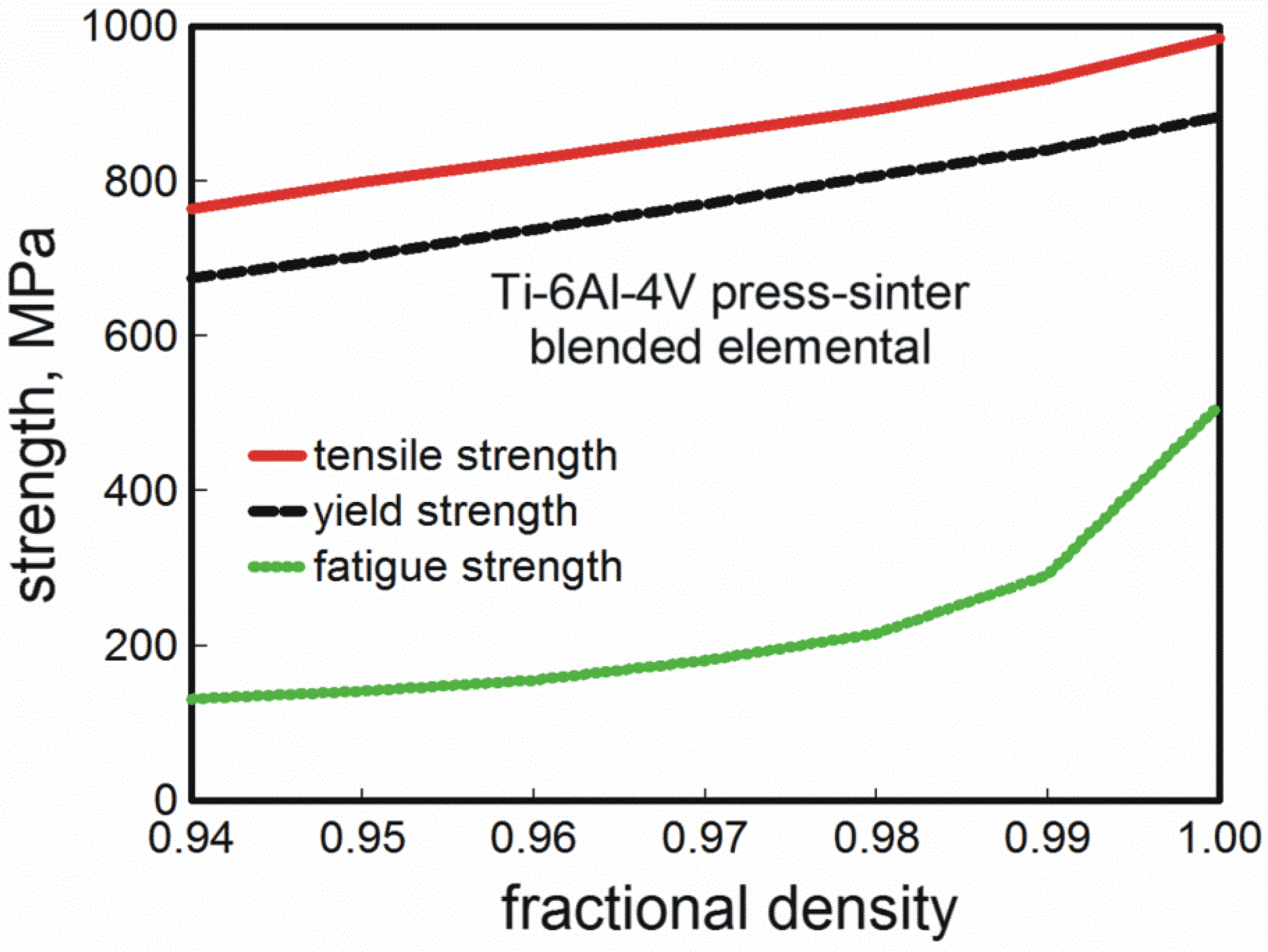

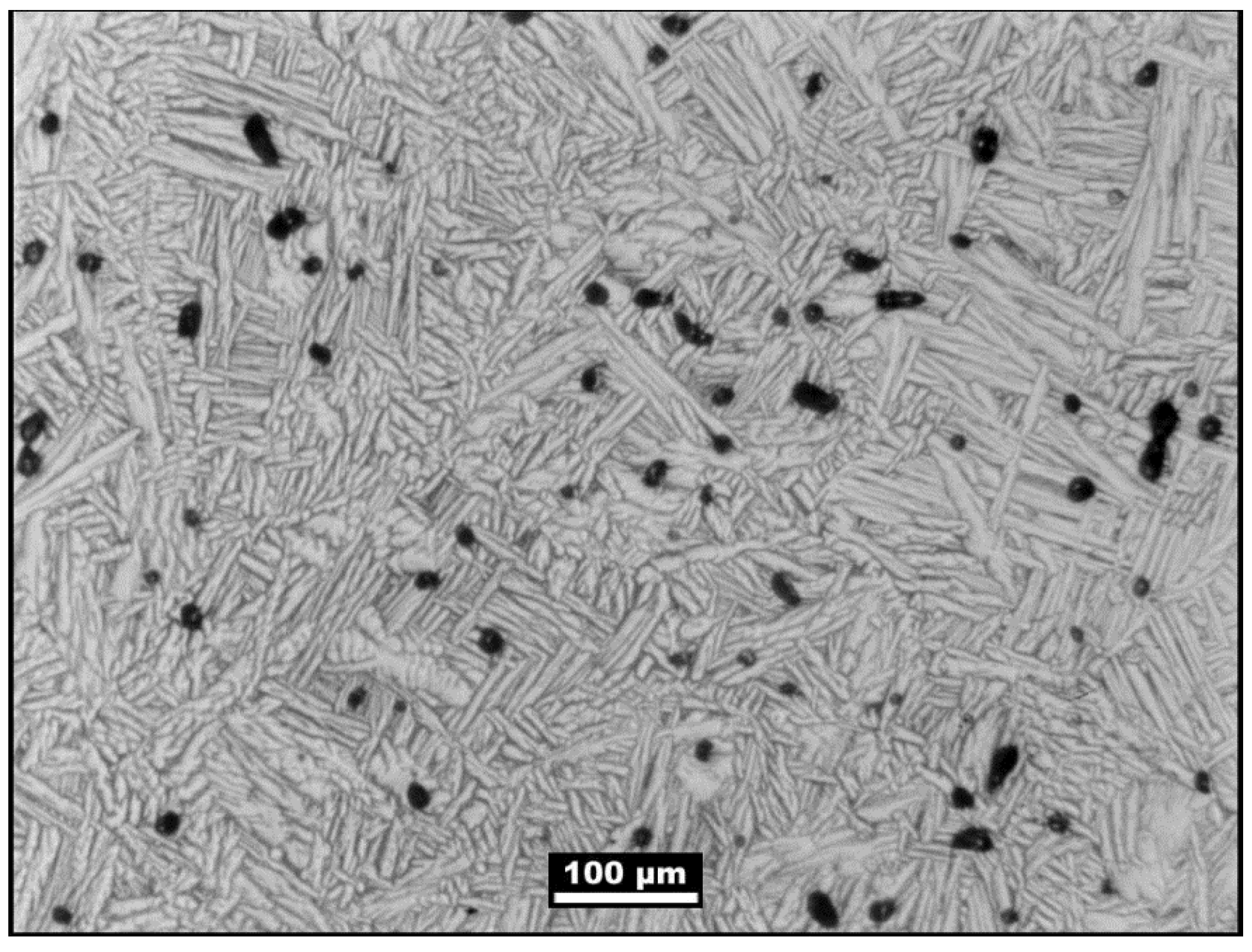

| properties | final density and grain size | 99.5% to 100% |

| grain size | 40 to 100 µm | |

| microstructure | mixed alpha and beta,10 µm platelets | |

| final impurity level | 0.20% to 0.22% oxygen, 0.04% carbon | |

| tensile strength | tensile strength 900 MPa | |

| tensile elongation | 12% | |

| fatigue endurance limit | up to 500 MPa |

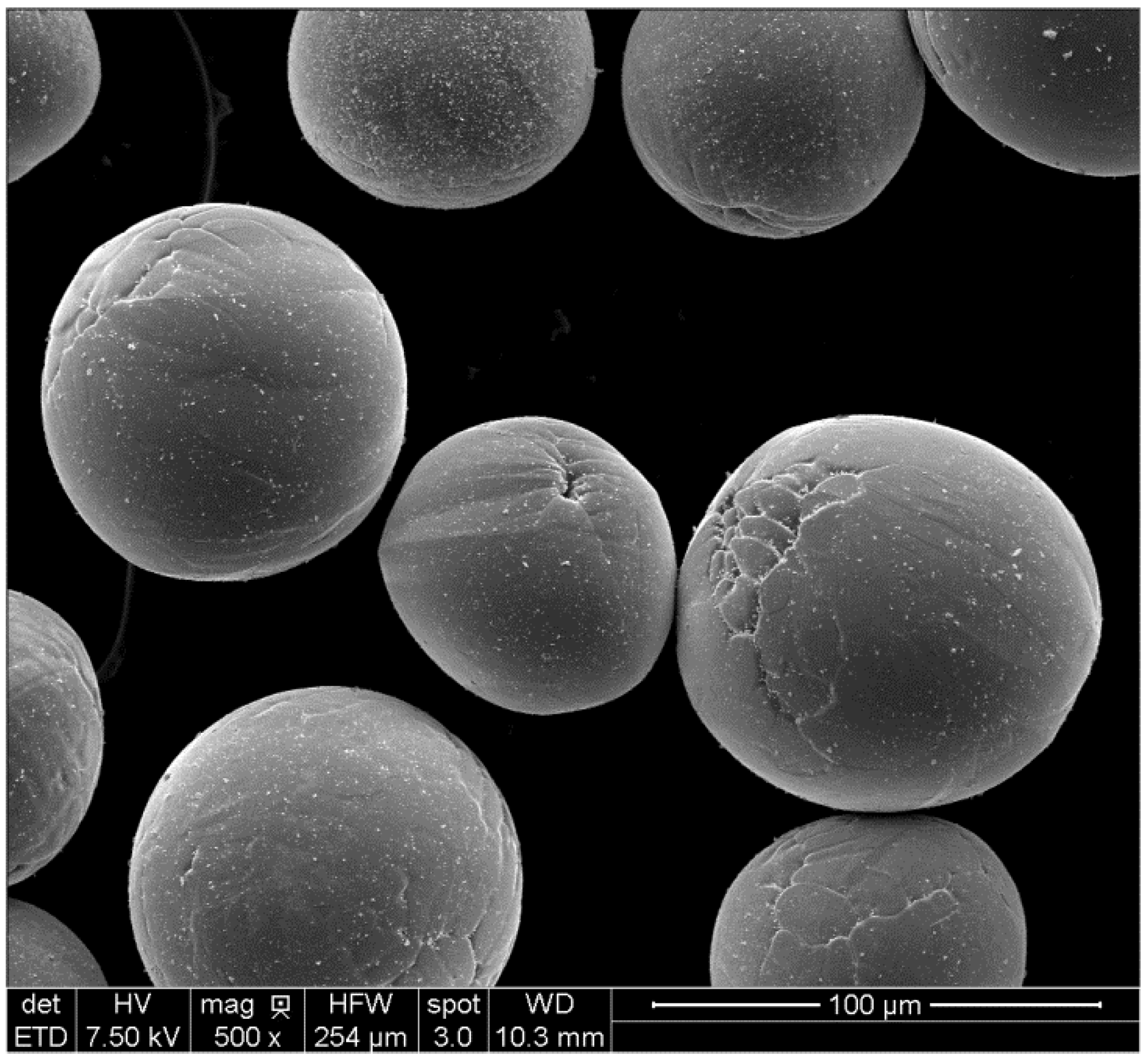

4. Powder Options

- Particle size distribution (quantified by the median particle size);

- Particle shape (quantified by the tap density);

- Interstitial level (quantified by oxygen and carbon levels).

| Powder type | Median size, µm | Tap density, % of pycnometer | Oxygen, wt % | Carbon, wt % |

|---|---|---|---|---|

| sponge fines | 38 | 48 | 0.35 | 0.05 |

| hydride-dehydride | 38 | 38 | 0.25 | 0.04 |

| titanium hydride | 35 | 40 | 0.20 | 0.02 |

| reactive | 30 | 47 | 0.30 | 0.10 |

| gas atomized | 32 | 60 | 0.15 | 0.03 |

| plasma atomized | 60 | 62 | 0.15 | 0.04 |

| rotating electrode | 130 | 72 | 0.15 | 0.02 |

5. Components Design Factors

6. Conclusions

Acknowledgments

Conflicts of Interest

References

- Leyens, C.; Peters, M. Titanium and Titanium Alloys, Fundamentals and Applications; Wiley-VCH: Weinheim, Germany, 2003. [Google Scholar]

- Kaneko, Y.; Ameyama, K.; Saito, K.; Iwasaki, H.; Tokizane, M. Injection molding of titanium powder. J. Jpn. Soc. Powder Powder Metall. 1988, 35, 646–650. [Google Scholar] [CrossRef]

- Ameyama, K.; Kaneko, Y.; Iwasaki, H.; Tokizane, M. Injection molding of titanium powders. In Advances in Powder Metallurgy; MPIF: Princeton, NJ, USA, 1989; Volume 3, pp. 121–126. [Google Scholar]

- Kaneko, Y.; Ameyama, K.; Sakaguchi, S. Application of injection molding to Ti-5 wt % Co and Ti-wt % Al-4 wt % V mixed powders. J. Jpn. Soc. Powder Powder Metall. 1990, 37, 591–596. [Google Scholar]

- Kato, K.; Nozaki, Y.; Matsumoto, A. Properties of sintered TiAl by injection molding. J. Jpn. Soc. Powder Powder Metall. 1992, 39, 875–878. [Google Scholar] [CrossRef]

- Kyogoku, H.; Toda, T.; Shinohara, K. Sintering behavior of titanium compacts with the addition of TiH powder by using injection moldings. J. Jpn. Soc. Powder Powder Metall. 1993, 40, 439–443. [Google Scholar] [CrossRef]

- Kyogoku, H.; Komatsu, S.; Shinohara, K.; Jinushi, H.; Toda, T. Microstructures and mechanical properties of sintered Ti-4% Fe alloy compacts by injection moldings. J. Jpn. Soc. Powder Powder Metall. 1994, 41, 1075–1079. [Google Scholar] [CrossRef]

- Petzoldt, F.; Eifert, H.; Hartwig, T.; Veltl, G. Binder design and process control for high performance MIM materials. In Advances in Powder Metallurgy and Particulate Materials; MPIF: Princeton, NJ, USA, 1995; Volume 6, pp. 3–13. [Google Scholar]

- Kusaka, K.; Kohno, T.; Kondo, T.; Horata, A. Tensile behavior of sintered titanium by MIM process. J. Jpn. Soc. Powder Powder Metall. 1995, 42, 383–387. [Google Scholar]

- Kyogoku, H.; Komatsu, S.; Tsuchitori, I.; Toda, T. Tensile properties of sintered Ti-4% Fe alloy compacts by injection moldings. J. Jpn Soc. Powder Powder Metall. 1995, 42, 1052–1056. [Google Scholar] [CrossRef]

- Kusaka, K.; Kono, T.; Horata, A.; Kondo, T. Tensile behavior of sintered Ti and Ti-6Al-4V alloy by MIM process. In Advances in Powder Metallurgy and Particulate Materials-1996; MPIF: Princeton, NJ, USA, 1996; Volume 19, pp. 127–131. [Google Scholar]

- Deguchi, T.; Ito, M.; Obasta, A.; Koh, Y.; Yamagishi, T.; Oshida, Y. Trial production of titanium orthodontic brackets fabricated by metal injection molding (MIM) with sinterings. J. Dental Res. 1996, 75, 1491–1496. [Google Scholar] [CrossRef]

- German, R.M.; Iacocca, R.G. Powder metallurgy processing. In Physical Metallurgy and Processing of Intermetallic Compound; Stoloff, N.S., Sikka, V.K., Eds.; Chapman and Hall: New York, NY, USA, 1996; pp. 605–654. [Google Scholar]

- Kato, K.; Matsumoto, A.; Ieki, T. Tensile properties at high temperature of sintered TiAl compacts by injection molding. J. Jpn. Soc. Powder Powder Metall. 1997, 44, 1029–1034. [Google Scholar]

- Kono, T.; Horata, A.; Kondo, T. Development of titanium and titanium alloy by metal injection molding process. J. Jpn. Soc. Powder Powder Metall. 1997, 44, 985–992. [Google Scholar] [CrossRef]

- Wohlfromm, H.; Blomacher, M.; Weinand, D.; Langer, E.; Schwarz, M. Novel materials in metal injection moulding. In Powder Injection Moulding, Proceedings of the First European Symposium on Powder Injection Moulding; European Powder Metallurgy Association: Shrewsbury, UK, 1997; pp. 54–61. [Google Scholar]

- Ieki, T.; Katoh, K.; Matsumoto, A.; Masui, T.; Andoh, K. Tensile properties of sintered Ti compacts by metal injection molding process. J. Jpn. Soc. Powder Powder Metall. 1997, 44, 448–452. [Google Scholar] [CrossRef]

- Wohlfromm, H.; Blomacher, M.; Weinand, D. Metal injection molding of titanium and TiAl6V4. In Powder Injection Molding Technologies; German, R.M., Wiesner, H., Cornwall, R.G., Eds.; Innovative Material Solutions: State College, PA, USA, 1998; pp. 339–348. [Google Scholar]

- Kim, Y.; Kim, N.J.; Yoon, T.; Ahn, S. Powder injection molding of Ti-48Al. In Proceedings 1998 PM World Congress, [CD]. Granada, Spain, 18–22 October 1998; European Powder Metallurgy Association: Shrewsbury, UK, 1998. [Google Scholar]

- Eifert, H.; Hartwig, T. State of the art in powder injection molding of titanium. In Advances in Powder Metallurgy and Particulate Materials-1998; MPIF: Princeton, NJ, USA, 1998; Volume 5, pp. 143–150. [Google Scholar]

- German, R.M. Powder injection molding applications to new materials. In Processing and Fabrication of Advanced Materials IV; Khor, A., Srivatsan, T.S., Moore, J.J., Eds.; Institute of Materials: London, UK, 1998; Volume 2, pp. 1363–1375. [Google Scholar]

- Miura, H.; Yokomizo, T.; Sakaguchi, S.; Tokumoto, K.; Nakahara, K. Development of sintered titanium base hard alloy by metal injection molding. J. Jpn. Soc. Powder Powder Metall. 1998, 45, 892–895. [Google Scholar]

- Ito, S.; Ogasawara, N.; Kusano, Y.; Ishiyama, K. Titanium feedstock for rapid catalytic debinding. In Processing and Fabrication of Advanced Materials IV; Khor, A., Srivatsan, T.S., Moore, J.J., Eds.; Institute of Materials: London, UK, 1998; Volume 2, pp. 1433–1441. [Google Scholar]

- Moyer, K.H.; Jones, W.R.; Loughridge, T.; Rodzen, T. The application of metal injection molded metal parts to satisfy specific mechanical and physical properties. In Advances in Powder Metallurgy and Particulate Materials-1998; MPIF: Princeton, NJ, USA, 1998; Volume 5, pp. 85–91. [Google Scholar]

- Van Gestel, I.R. A new production method for high value parts. In Powder Injection Molding Technologies; German, R.M., Wiesner, H., Cornwall, R.G., Eds.; Innovative Material Solutions: State College, PA, USA, 1998; pp. 33–42. [Google Scholar]

- Nakamura, H.; Shimura, T.; Nakabayashi, K. Process for production of Ti sintered compacts using the injection molding method. J. Jpn. Soc. Powder Powder Metallall. 1999, 46, 870–876. [Google Scholar]

- Kim, Y.; Kim, N.J.; Yoon, T.; Ahn, S. Densification behavior of PIMedTiAl parts. J. Jpn. Soc. Powder Powder Metall. 1999, 46, 882–886. [Google Scholar]

- Wang, H.; Lo, S.H.J.; Barry, J.R. Development of high density (99%+) powder injection molded titanium alloys. P/M Sci. Technol. Briefs 1999, 1, 16–18. [Google Scholar]

- Kato, Y. Effect of sintering temperature on density and tensile properties of titanium compacts by metal injection molding. J. Jpn. Soc. Powder Powder Metall. 1999, 46, 865–869. [Google Scholar]

- Maekawa, K.; Takita, M.; Nomura, H. Effect of MIM process conditions on microstructures and mechanical properties of Ti-6Al-4V compacts. J. Jpn. Soc. Powder Powder Metall. 1999, 46, 1053–1057. [Google Scholar] [CrossRef]

- Miura, H.; Itoh, Y.; Uematsu, T.; Asto, K. Advanced PIM process of Ti-6Al-7Nb for materials for medical applications. In Proceedings of the Workshop on Medical Applications for Microminiature Powder Injection Molding, [CD]. Orlando, FL, USA, 2–5 March 2009; German, R.M., Ed.; MPIF: Princeton, NJ, USA, 2009. [Google Scholar]

- Park, S.J.; Wu, Y.; Heaney, D.F.; Zou, X.; Gai, G.; German, R.M. Rheological and thermal debinding behaviors in titanium powder injection molding. Metall. Mater. Trans. 2009, 40, 215–222. [Google Scholar]

- Baril, E.; Lefebvre, L.P.; Thomas, Y.; Ilinca, F. Foam coated MIM gives new edge to titanium implants. Met. Powder Rep. 2008, 63, 46–55. [Google Scholar] [CrossRef]

- Itoh, Y.; Uematsu, T.; Sato, K.; Miura, H.; Niinomi, M. Fabrication of high strength alpha plus beta type titanium alloy compacts by metal injection molding. J. Jpn. Soc. Powder Powder Metall. 2008, 55, 720–724. [Google Scholar]

- Zhao, L.; Qu, Z.; He, X.; Li, S. Sintering of TiAl injection molding. Chin. J. Rare Met. 2008, 32, 180–184. [Google Scholar]

- Osada, T.; Miura, H.; Itoh, Y.; Fujita, M.; Arimoto, N. Optimization of MIM process for Ti-6Al-7Nb alloy powder. J. Jpn. Soc. Powder Powder Metall. 2008, 55, 726–731. [Google Scholar] [CrossRef]

- Kim, Y.C.; Lee, S.; Ahn, S.; Kim, N.J. Application of metal injection molding process to fabrication of bulk parts of TiAl intermetallic. J. Mater. Sci. 2007, 42, 2048–2053. [Google Scholar]

- Itoh, Y.; Miura, H.; Uematsu, T.; Sato, K.; Niinomi, M. Improvement of the properties of Ti-6Al-7Nb alloy by metal injection molding. In Advances in Powder Metallurgy and Particulate Materials-2007; MPIF: Princeton, NJ, USA, 2007; Volume 4, pp. 81–86. [Google Scholar]

- Zou, X.; Wu, Y.; Gai, G.; Heaney, D.F.; Park, S.J.; German, R.M. The effects of spheroidizing treatment on the particle characteristics and feedstock rheologies of HDH Ti powders. Powder Met. Ind. 2006, 16, 1–6. [Google Scholar]

- Sunada, S.; Kawagishi, M.; Majima, K. Corrosion behavior of pure titanium by MIM process under SSRT conditions. J. Jpn. Soc. Powder Powder Metall. 2007, 54, 322–329. [Google Scholar]

- Whittaker, D. Developments in the powder injection moulding of titanium. Powder Inject. Mould. Int. 2007, 1, 27–32. [Google Scholar]

- Li, Y.; Chou, X.M.; Yu, L. Dehydrogenation debinding process of MIM titanium alloys by TiH2 powder. Powder Metall. 2006, 49, 236–239. [Google Scholar]

- Itoh, Y.; Uematsu, T.; Sato, K.; Miura, H.; Niinomi, M. Microstructural modification for injection molded Ti-6Al-4V alloys by addition of Mo powder. J. Jpn. Soc. Powder Powder Metall. 2006, 53, 750–754. [Google Scholar]

- Wu, Y.; Wang, R.; Kwon, Y.S.; Park, S.J.; German, R.M. Injection molding of HDH titanium powder. Int. J. Powder Metall. 2006, 42, 59–66. [Google Scholar]

- Uematsu, T.; Itoh, Y.; Sato, K.; Miura, H. Effects of substrate for sintering on the mechanical properties of injection molded Ti-6Al-4V alloy. J. Jpn. Soc. Powder Powder Metall. 2006, 53, 755–759. [Google Scholar] [CrossRef]

- Miura, H.; Takemasu, T.; Kuwano, Y.; Itoh, Y.; Sato, K. Sintering behavior and mechanical properties of injection molded Ti-6Al-4V alloys. J. Jpn. Soc. Powder Powder Metall. 2006, 53, 815–820. [Google Scholar]

- Weil, K.S.; Nyberg, E.; Simmons, K. A new binder for powder injection molding titanium and other reactive metals. J. Mater. Proc. Technol. 2006, 176, 205–209. [Google Scholar]

- Itoh, Y.; Uematsu, T.; Sato, K.; Miura, H.; Niinomi, M.; Ikeda, M. Sintering behavior and mechanical properties of injection molded Ti-4.3Fe-7.1Cr alloys. J. Jpn. Soc. Powder Powder Metall. 2006, 53, 43–48. [Google Scholar]

- Itoh, Y.; Harikou, Y.; Satoh, K.; Miura, H. Fabrication of near-alpha titanium alloy by metal injection molding. J. Jpn. Soc. Powder Powder Metall. 2005, 52, 43–48. [Google Scholar] [CrossRef]

- Weil, K.S.; Nyberg, E.A.; Simmons, K.L. Use of a naphthalene based binder in injection molding net shape titanium components of controlled porosity. Mater. Trans. 2005, 46, 1525–1531. [Google Scholar] [CrossRef]

- Nyberg, E.; Miller, M.; Simmons, K.; Weil, K. S. Microstructure and mechanical properties of titanium components fabricated by a new powder injection molding technique. Mater. Sci. Eng. 2005, 25, 336–342. [Google Scholar] [CrossRef]

- Miura, H.; Uemura, M.; Kubota, Y. High-temperature properties of injection molded Ti-Al intermetallic compounds. In Advances in Powder Metallurgy and Particulate Materials-2004; MPIF: Princeton, NJ, USA, 2004; Volume 4, pp. 102–105. [Google Scholar]

- Kitajima, A.; Shimizu, T.; Ito, A. Fabrication of bioactive titanium parts by MIM techniques using surface treatment. J. Jpn. Soc. Powder Powder Metall. 2003, 50, 739–744. [Google Scholar] [CrossRef]

- Thian, E.S.; Loh, N.H.; Khor, K.A.; Tor, S.B. Ti-6Al-4V/HA composite feedstock for injection molding. Mater. Lett. 2002, 56, 522–532. [Google Scholar] [CrossRef]

- Guo, S.; Qu, X.; He, X.; Zhou, T.; Duan, B. Powder injection molding of Ti-6Al-4V alloy. J. Mater. Proc. Technol. 2006, 173, 310–314. [Google Scholar]

- Miura, H.; Masuda, T.; Ogasawara, T.; Kankawa, Y. High performance injection molded Ti compacts. J. Jpn. Soc. Powder Powder Metall. 2002, 49, 825–828. [Google Scholar]

- Terauchi, S.; Teraoka, T.; Shinkuma, T.; Sugimoto, T.; Ahida, Y. Development of production technology by metallic powder injection molding for TiAl-Type intermetallic compound with high efficiency. In Proceedings Fifteenth International Plansee Seminar, Reutte, Austria, 28 May–1 June 2001; Rodhammer, P., Wildner, H., Eds.; Plansee Holding: Reutte, Austria, 2001; Volume 1, pp. 610–624. [Google Scholar]

- Xu, Y.; Nomura, H. Corrosion behavior of biomedical titanium alloy Ti-5Al-2.5Fe processed by MIM. J. Jpn. Soc. Powder Powder Metall. 2002, 49, 382–389. [Google Scholar]

- Xu, Y.; Nomura, H.; Takita, M.; Toda, H. Characteristics of metal injection processed Ti-5Al-2.5Fe alloy for implant material. J. Jpn. Soc. Powder Powder Metall. 2001, 48, 316–321. [Google Scholar]

- Wang, L.Y.; Lin, X.L. Sintered titanium compacts by metal injection molding process. In Proceedings of the 2000 Powder Metallurgy World Congress, Japan Society of Powder and Powder Metallurgy, 12–16 November 2000; Kosuge, K., Nagai, H., Eds.; 2000; Volume 1, pp. 320–323. [Google Scholar]

- Shimizu, T.; Kitajima, A.; Kato, K.; Sano, T. Supercritical debinding and its application to PIM of Ti-Al intermetallic compounds. In Proceedings of the 2000 Powder Metallurgy World Congress, Kyoto, Japan, 12–16 November, 2000; Kosuge, K., Nagai, H., Eds.; Japan Society of Powder and Powder Metallurgy: Kyoto, Japan, 2000; Volume 1, pp. 292–295. [Google Scholar]

- Froes, R.H.; German, R.M. Cost reductions prime Ti PIM for growth. Meter. Powder Rep. 2000, 55, 12–21. [Google Scholar]

- Lefebvre, L.P.; Baril, E. Effect of oxygen concentration and distribution on the compression properties on titanium foams. Adv. Eng. Mater. 2008, 10, 868–876. [Google Scholar]

- Takekawa, J.; Sakurai, N. Effect of processing conditions on density, strength and microstructure of Ti-12Mo alloy fabricated by PIM process. J. Jpn. Soc. Powder Powder Metall. 1999, 46, 877–881. [Google Scholar]

- Ergul, E.; Gulsoy, H.O.; Gunay, V. Effect of sintering parameters on mechanical properties of injection moulded Ti-6Al-4V alloys. Powder Metall. 2009, 52, 65–71. [Google Scholar] [CrossRef]

- Cai, Y.X.; Chang, Q.; Ding, Y. Research of injection molding titanium parts. Powder Metall. Technol. 2005, 23, 449–455. [Google Scholar]

- Thomas, Y.; Baril, E.; Ilinca, F.; Hetu, J.F. Development of titanium dental implant by MIM: experiments and simulation. In Advances in Powder Metallurgy and Particulate Materials-2009; MPIF: Princeton, NJ, USA, 2009; Volume 4, pp. 81–93. [Google Scholar]

- Takekawa, J. Metal injection molding of Ti-Mo-Al mixed powders. J. Jpn. Soc. Powder Powder Metall. 1994, 41, 244–247. [Google Scholar]

- Matsumoto, A.; Katoh, K.; Andoh, K. Near net shaping of metal injection molded compacts by pulsed discharge sintering process under pseudo hot isostatic pressing. J. Jpn. Soc. Powder Powder Metall. 1997, 44, 1037–1042. [Google Scholar] [CrossRef]

- Froes, F.H. Powder injection molding (PIM) of titanium alloys—Ripe for expansion. Mater. Tech. 2000, 15, 295–299. [Google Scholar]

- McCabe, T.; Vaidyanathan, C. Material advancement for PIM applications. In Advances in Powder Metallurgy and Particulate Materials-2007; MPIF: Princeton, NJ, USA, 2007; Volume 4, pp. 87–92. [Google Scholar]

- Yoshimitsu, M.; Kayo, I.; Hiroshi, S.; Nakamura, H.; Iji, M.; Masao, T.; Ippei, Y. Single step MIM system with polyacetal binder without debinding process. In Proceedings of the 2000 Powder Metallurgy World Congress, Kyoto, Japan, 12–16 November 2000; Kosuge, K., Nagai, H., Eds.; Japan Society of Powder and Powder Metallurgy: Kyoto, Japan, 2000; pp. 270–273. [Google Scholar]

- Gomes, R.M.; Kowalski, L.; Schaeffer, L.; Duszczyk, J. Injection molding of blended elemental Ti, (6Al-4V) powders. In Proceedings of the 2000 Powder Metallurgy World Congress, Kyoto, Japan, 12–16 November 2000; Kosuge, K., Nagai, H., Eds.; Japan Society of Powder and Powder Metallurgy: Kyoto, Japan, 2000; pp. 324–327. [Google Scholar]

- Williams, B. Challenges for MIM titanium parts. Met. Powder Rep. 2003, 58, 30. [Google Scholar]

- Sun, H.S. The fabrication of Ti injection molded and sintered components. Titan Ind. Prog. 2000, 1, 19–20. [Google Scholar]

- Grohowski, J.A.; Sherman, B.; Strauss, J.T. Processing of titanium by metal injection molding. In Advances in Powder Metallurgy and Particulate Materials-2003; MPIF: Princeton, NJ, USA, 2003; Volume 8, pp. 273–281. [Google Scholar]

- Wang, L.Y. Metal injection molding of blended elemental titanium and zirconium powders. In Advances in Powder Metallurgy and Particulate Materials-2002; MPIF: Princeton, NJ, USA, 2002; Volume 10, pp. 301–314. [Google Scholar]

- Osada, T.; Tanaka, S.; Nishiyabu, K.; Miura, H. Size effects of gas nitriding of injection molded titanium parts. J. Jpn. Soc. Powder Powder Metall. 2006, 53, 745–749. [Google Scholar] [CrossRef]

- El-Kadiri, H.; Wang, L.; Gulsoy, H.O.; Suri, P.; Park, S.J.; Hammi, Y.; German, R.M. Development of a Ti-based alloy: Design and experiment. J. Met. Mater. Min. 2009, 61, 60–66. [Google Scholar]

- Xu, Y.; Nomura, H. Homogenizing analysis for sintering of bio-titanium alloy (Ti-5Al-2.5Fe) in MIM process. J. Jpn. Soc. Powder Powder Metall. 2001, 48, 1089–1096. [Google Scholar]

- Osafume, Y.; Uichida, T.; Nakamura, Y.; Tanaka, Y. Effects of debinding and sintering condition on distortion of sintered compact of injection molded TiAl intermetallic compound. J. Jpn. Soc. Powder Powder Metall. 1994, 41, 506–509. [Google Scholar]

- Kato, K.; Matsumoto, A.; Nozaki, Y.; Ieki, T. Metal injection molding of prealloyed TiAl powders with various Ti/Al ratios. J. Jpn. Soc. Powder Powder Metall. 1995, 42, 1068–1072. [Google Scholar]

- Gerling, R.; Schimansky, F.P. Prospects for metal injection moulding using a gamma titanium aluminide based alloy powder. Mater. Sci. Eng. 2002, 329, 45–49. [Google Scholar]

- Terauchi, S.; Teraoka, T.; Shinkuma, T.; Sugimoto, T. Development of TiAl type intermetallic compounds by metal powder injection molding process. J. Jpn. Soc. Powder Powder Metall. 2000, 47, 1283–1287. [Google Scholar] [CrossRef]

- Ishiyama, S.; Buchkremer, H.P.; Stover, D. The characterization of reinforced TiAl intermetallic with dispersed Cr particles consolidated by HIP. Mater. Trans. 2002, 43, 2331–2336. [Google Scholar] [CrossRef]

- Sago, J.A.; Newkirk, J.W. Metal injection molding of mechanically alloyed powders of advanced P/M alloys. In Advances in Powder Metallurgy and Particulate Materials-1999; MPIF: Princeton, NJ, USA, 1999; Volume 6, pp. 45–57. [Google Scholar]

- Kyogoku, H.; Komatsu, S. Fabrication of TiNi shape memory alloy by powder injection molding. J. Jpn. Soc. Powder Powder Metall. 1999, 46, 1103–1107. [Google Scholar]

- Schuller, E.; Krone, L.; Bram, M.; Buchkremer, H.P.; Stover, D. Metal injection molding of shape memory alloys using prealloyed NiTi powders. J. Mater. Sci. 2005, 40, 4231–4238. [Google Scholar]

- Krone, L.; Mentz, J.; Bram, M.; Buchkremer, H.P.; Stover, D.; Wagner, M.; Eggeler, G.; Christ, D.; Reese, S.; Bogdanski, D.; et al. The potential of powder metallurgy for the fabrication of biomaterials on the basis of nickel-titanium: A case study with a staple showing shape memory behaviour. Adv. Eng. Mater. 2005, 7, 613–619. [Google Scholar]

- Kyogoku, H.; Kawasaki, H.; Komatsu, S. Fabrication of Ti-Ni shape memory alloy by metal injection molding. In Advances in Powder Metallurgy and Particulate Materials 2006; MPIF: Princeton, NJ, USA, 2006; Volume 4, pp. 14–20. [Google Scholar]

- Imgrund, P.; Rota, A.; Schmidt, H. Micro MIM: Making the most of NiTi. Met. Powder Rep. 2008, 63, 21–24. [Google Scholar] [CrossRef]

- Bram, M.; Ahmad-Khanlou, A.; Heckmann, A.; Fuchs, B.; Buchkremer, H.P.; Stover, D. Powder metallurgical fabrication processes for NiTi shape memory alloy parts. Mater. Sci. Eng. 2002, 337, 254–263. [Google Scholar] [CrossRef]

- Imgrund, P.; Petzoldt, F.; Friederici, V. Micro MIM for medical applications. In Proceedings Europe PM 2008, [CD]. Strasbourg, France, 10–11 June 2008; European Powder Metallurgy Association: Shrewsbury, UK, 2008. [Google Scholar]

- Thian, E.S.; Loh, N.H.; Khor, K.A.; Tor, S.B. Microstructures and mechanical properties of powder injection molded Ti-6Al-4V/HA powder. Biomaterials 2002, 23, 2927–2938. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y.; Luo, K.; Chen, Q. TiC0.7N0.3 particulates reinforced titanium matrix composites and components prepared by powder injection molding. Mater. Sci. Eng. Powder Metall. 2005, 10, 344–349. [Google Scholar]

- Ye, H.; Liu, X.Y.; Hong, H. Fabrication of metal matrix composites by metal injection molding—A review. J. Mater. Proc. Technol. 2008, 200, 12–24. [Google Scholar] [CrossRef]

- Abkowitz, S.; Abkowitz, S.M.; Fisher, H.; Schwartz, P.J. Cerme Ti discontinuously reinforced Ti-matrix composites: Manufacturing, properties, and applications. J. Met. Mater. Min. 2004, 56, 37–41. [Google Scholar]

- German, R.M. Powder Injection Molding Design and Applications; Innovative Material Systems: State College, PA, USA, 2003. [Google Scholar]

- German, R.M. Global research and development in powder injection moulding. Powder Inject. Mould. Int. 2007, 1, 33–36. [Google Scholar]

- Kearns, M.; Sandvik Ospery, West Glamorgan, UK. Private communication, 2009.

- Achikita, M. Development of MIM components for automobile and power tools. In Ninth Case Studies on New Product Development; Japan Powder Metallurgy Association: Kyoto, Japan, 2000; pp. 25–34. [Google Scholar]

- Chen, Q.; Cai, Y.T.; Yang, Y.L. Effect of powder size and powder loading on the process of metal injection molding (MIM) for titanium. J. Guangdong Non-Ferrous Met. 1999, 9, 131–135. [Google Scholar]

- German, R.M.; Bose, A. Injection Molding of Metals and Ceramics; MPIF: Princeton, NJ, USA, 1996. [Google Scholar]

- Guo, S.B.; Qu, X.H.; Duan, B.H.; He, X.B.; Qin, M.L. Optimization of titanium alloy injection molding process parameters. Mater. Sci. Eng. 2004, 11, 32–36. [Google Scholar]

- Newkirk, J.W.; Sago, J.A.; Brasel, G.M. Metal injection molding of mechanically alloyed advanced materials. In Advances in Powder Metallurgy and Particulate Materials-1998; MPIF: Princeton, NJ, USA, 1998; Volume 5, pp. 93–105. [Google Scholar]

- Wang, R.F.; Wu, Y.X.; Zhou, X.; Tang, C.A. Debinding and sintering processes for injection molded pure titanium. Powder Met. Technol. 2006, 24, 83–93. [Google Scholar]

- Smarslok, B.; German, R.M. Identification of design parameters in metal powder injection molding. J. Adv. Mater. 2005, 37, 3–11. [Google Scholar]

- Oki, T.; Matsugi, K.; Hatayama, T.; Yanagisawa, O. Microstructure and tensile properties of vacuum sintered/HIPed pure titanium. J. Jpn. Inst. Met. 1995, 59, 746–753. [Google Scholar]

- Conrad, H. Effect of interstitial solutes on the strength and ductility of titanium. Prog. Mater. Sci. 1981, 26, 123–403. [Google Scholar] [CrossRef]

- Ikeda, Y.; Takaki, S. Effects of pores and oxygen content on mechanical properties of a sintered Ti-4 mass % Cr alloy. J. Jpn. Soc. Powder Powder Metall. 1995, 42, 911–917. [Google Scholar]

- Gladden, T. Process for the Manufacture by Sintering of a Titanium Part and a Decorative Article Made Using a Process of This Type. U.S. Patent 5,441,695, 15 August 1995. [Google Scholar]

- Shimizu, T.; Matsuzaki, K.; Ohara, Y. Process of porous titanium using a space holder. J. Jpn. Soc. Powder Powder Metall. 2006, 53, 36–41. [Google Scholar]

- Sakurai, N.; Takekawa, J. Effect of intermediate CIP treatment on density and strength of Ti-12Mo sintered alloy fabricated by MIM process. J. Jpn. Soc. Powder Powder Metall. 2000, 47, 633–657. [Google Scholar] [CrossRef]

- German, R.M. Status of metal powder injection molding of titanium. Int. J. Powder Metall. 2010, 46, 11–17. [Google Scholar]

- Friederici, V.; Bruinink, A.; Imgrund, P.; Seefried, S. Getting the powder mix right for design of bone implants. Met. Powder Rep. 2010, 65, 14–16. [Google Scholar] [CrossRef]

- Miura, H.; Itoh, Y.; Ueamtsu, T.; Sato, K. The influence of density and oxygen content on the mechanical properties of injection molded Ti-6Al-4V alloys. In Advances in Powder Metallurgy and Particulate Materials-2010; MPIF: Princeton, NJ, USA, 2010; Volume 4, pp. 46–53. [Google Scholar]

- Baril, E. Titanium and titanium alloy powder injection moulding—Matching application requirements. Powder Inject. Mould. Int. 2010, 4, 22–32. [Google Scholar]

- German, R.M. Conceptual optimization of titanium powder injection molding. In Advances in Powder Metallurgy and Particulate Materials-2010; Metal Powder Industries Federation: Princeton, NJ, USA, 2010; Volume 4, pp. 67–77. [Google Scholar]

- Scharvogel, M.; Winkelmueller, W. Metal injection molding of titanium for medical and aerospace applications. J. Met. Mater. Min. 2011, 63, 94–96. [Google Scholar]

- Muenya, N.; Manonukl, A. Study of covering conditions for sintering of metal injection moulded commercially pure titanium. J. Met. Mater. Min. 2010, 20, 63–68. [Google Scholar]

- Osada, T.; Miura, H. Nitriding resistance of microminiature powder injection molded titanium. Int. J. Powder Metall. 2010, 46, 39–44. [Google Scholar]

- Ferri, O.M.; Ebel, T.; Bromann, R. Substantial improvement of fatigue behavior MIM using boron microalloying. In Proceedings PM 2010 World Congress, [CD]. Florence, Italy, 10–14 October 2010; European Powder Metallurgy Association: Shrewsbury, UK, 2010. [Google Scholar]

- Thomas, Y.; Baril, E. Benefits of supercritical CO2 debinding for titanium powder injection moulding. In Proceedings PM 2010 World Congress, [CD]. Florence, Italy, 10–14 October 2010; European Powder Metallurgy Association: Shrewsbury, UK, 2010. [Google Scholar]

- Ferri, O.M.; Ebel, T.; Bormann, R. Influence of surface quality and porosity on fatigue behaviour of Ti-6Al-4V components processed by MIM. Mater. Sci. Eng. 2010, 527, 1800–1805. [Google Scholar]

- Aust, E.; Limberg, W.; Gerling, R.; Oger, B.; Ebel, T. Advanced TiAl6Nb7 bone screw implant fabricated by metal injection moulding. Adv. Eng. Mater. 2006, 8, 265–270. [Google Scholar] [CrossRef]

- Ebel, T.; Blawert, C.; Willumeit, R.; Luthringer, B.J.C.; Ferri, O.M.; Feyerabend, F. Ti-6Al-4V-0.5B a modified alloy for implants produced by metal injection moulding. Adv. Eng. Mater. 2011, 13, B440–B453. [Google Scholar]

- Ferri, O.M.; Ebel, T.; Bormann, R. The influence of a small boron addition on the microstructure and mechanical properties of Ti-6Al-4V fabricated by metal injection moulding. Adv. Eng. Mater. 2011, 13, 436–447. [Google Scholar] [CrossRef]

- Demangel, C.; Auzene, D.; Vayssade, M.; Duval, J.L.; Vigneron, P.; Nagel, M.D.; Puippe, J.C. Cytocompatibility of titanium metal injection molding with various anodic oxidation post-treatments. Mater. Sci. Eng. 2013, 32, 1919–1925. [Google Scholar]

- Barbosa, A.P.C.; Bram, M.; Stoever, D.; Buchkremer, H.P. Realization of a titanium spinal implant with a gradient in porosity by 2-component metal injection moulding. Adv. Eng. Mater. 2013, 13, 510–521. [Google Scholar]

- German, R.M. for titanium metal powder injection moulding. In. In Proceedings PM 2010 World Congress, [CD]. Florence, Italy, 10–14 October 2010; European Powder Metallurgy Association: Shrewsbury, UK, 2010. [Google Scholar]

- Arockiasamy, A.; German, R.M.; Heaney, D.F.; Wang, P.T.; King, R.L.; Alcock, B. Effect of additives on sintering response of titanium by powder injection moulding. Powder Metall. 2011, 54, 420–426. [Google Scholar]

- Wen, G.; Cao, P.; Zhang, D. Development and design of binder systems for titanium metal injection molding: An overview. Met. Mater. Trans. 2013, 44, 1530–1547. [Google Scholar] [CrossRef]

- German, R.M. Metal powder injection molding (MIM), key trends and markets. In Handbook of Metal Injection Molding; Heaney, D., Ed.; Woodhead Publishing: London, UK, 2012; pp. 1–25. [Google Scholar]

- Sago, J.A.; Broadley, M.W.; Eckert, J.K. Metal injection molding of alloys for implantable medical devices. Int. J. Powder Metall. 2012, 482, 41–49. [Google Scholar]

- Sago, J.A.; Broadley, M.W.; Eckert, J.K.; Chen, H. Manufacturing of implantable biomedical devices by metal injection molding. In Advances in Powder Metallurgy and Particulate Materials-2010; MPIF: Princeton, NJ, USA, 2010; Volume 4, pp. 89–99. [Google Scholar]

- German, R.M. Infrastructure emergence for metal injection molded titanium medical devices. Int. J. Powder Metall. 2012, 48, 33–48. [Google Scholar]

- Miura, H.; Noda, M.; Kang, H. Dynamic fracture characteristics of injection molded Ti alloy compacts. In Advances in Powder Metallurgy and Particulate Materials-2011; MPIF: Princeton, NJ, USA, 2011; Volume 4, pp. 58–64. [Google Scholar]

- Sidambe, A.T.; Figueroa, L.A.; Hamilton, H.G.C.; Todd, I. Taguchi optimization of MIM titanium sintering. Int. J. Powder Metall. 2011, 47, 21–28. [Google Scholar]

- German, R.M. Metal Injection Molding A Comprehensive MIM Design Guide; Metal Powder Industries Federation: Princeton, NJ, USA, 2011. [Google Scholar]

- Bidaux, J.E.; Closuit, C.; Rodriguez-Arbaizar, M.; Carreno-Morelli, E. Metal injection moulding of Ti-Nb alloys for implant application. Eur. Cells Mater. 2011, 22, 32. [Google Scholar]

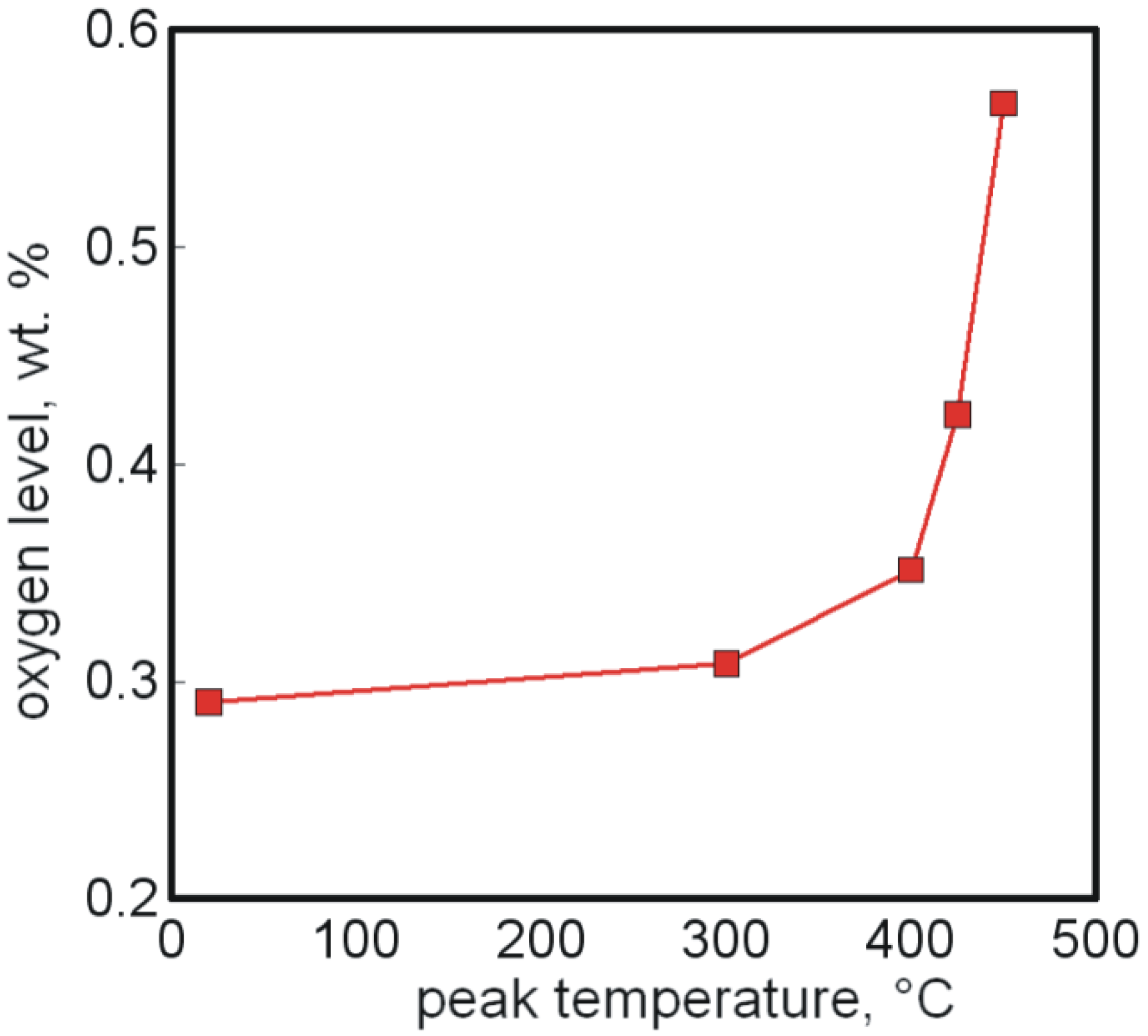

- Baril, E.; Lefebvre, L.P.; Thomas, Y. Interstitial elements in titanium powder metallurgy: Sources and control. Powder Metall. 2011, 54, 183–187. [Google Scholar] [CrossRef]

- Ewart, P.; Ahn, S.; Zhang, D. Mixing titanium MIM feedstock—Homogeneity, debinding, and handling strength. Powder Inject. Mould. Int. 2011, 5, 54–59. [Google Scholar]

- German, R.M. Powder injection moulding in the aerospace industry: Opportunities and challenges. Powder Inject. Mould. Int. 2011, 5, 28–36. [Google Scholar]

- Lenel, F.V. Resistance sintering under pressure. Trans. TMS-AIME 1955, 203, 158–167. [Google Scholar]

- Widmer, R. Coarse powder techniques. In Powder Metallurgy for High-Performance Applications; Burke, J.J, Weiss, V., Eds.; Syracuse University Press: Syracuse, NY, USA, 1972; pp. 69–84. [Google Scholar]

- Smugeresky, J.E.; Dawson, D.B. Effect of powder particle size and hot isostatic pressing temperature on the properties of Ti-6Al-6V-2Sn. In Powder Metallurgy of Titanium Alloys; Froes, F.H., Smugeresky, J.E., Eds.; Metallurgical Society: Warrendale, PA, USA, 1980; pp. 127–138. [Google Scholar]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

German, R.M. Progress in Titanium Metal Powder Injection Molding. Materials 2013, 6, 3641-3662. https://doi.org/10.3390/ma6083641

German RM. Progress in Titanium Metal Powder Injection Molding. Materials. 2013; 6(8):3641-3662. https://doi.org/10.3390/ma6083641

Chicago/Turabian StyleGerman, Randall M. 2013. "Progress in Titanium Metal Powder Injection Molding" Materials 6, no. 8: 3641-3662. https://doi.org/10.3390/ma6083641