1. Introduction

Methods for incorporating fillers within pulp fibers have been the subject of extensive research [

1,

2]. The fillers are selected to serve different papermaking objectives, mainly to enhance the optical and printing properties of paper and, sometimes, to reduce the production costs by partial substitution of fibrous materials [

3,

4]. Due to the shifting trend from a conventional acid to a neutral/alkaline papermaking medium, the use of calcium carbonate as a filler is a reality in the production of writing and printing papers, representing over 90% of filler consumption for these paper grades. The fillers with a high brightness degree allow papermakers to use fiber pulps with lower brightness, which leads to economical bonuses due to the lower price, as well as to a lower ecological impact, by reducing the consumption of chemicals during pulp bleaching [

5,

6]. It has been found that paper with higher filler concentrations can be dried more quickly and the solid content of the paper leaving the pressing section is increased. Additionally, mineral fillers tend to be less expensive than wood pulp fibers by weight, so an increase in filler content reduces the cost of the raw materials [

7].

Conventional filler loading of paper consists in the dosing and uniform distribution of filler particles into fiber suspension, which further are incorporated in paper structure by retention during wet-web formation. One of the main problems of this method is low filler retention into the paper sheet since a large part of the filler particles are passing through the forming wire into the process water. Poor retention means inefficient use of fillers and high loading of wastewater [

8,

9,

10].

Generally, at increased paper loading levels, the limits are set primarily by an accompanying reduction of paper stiffness and insufficient strength properties (tensile strength, tear resistance, internal bond and surface strength). That is why the filler content is limited in the case of paper grades with low basis weight or with high mechanical pulp content, due to an unacceptable decrease of the mechanical resistance indices [

11,

12].

Thus, paper structure should be altered in such a way that desirable paper properties are maintained. Both pigments and cellulose materials need to be used effectively in order to achieve the desired properties at increased levels of filler. New developments such as precipitated fillers and pigments are known to offer new opportunities to improve paper properties [

13,

14,

15].

Literature data [

16,

17,

18,

19,

20,

21] evidence various benefits of the

in-situ loading method, such as: improvements in the optical and strength properties of the paper; decreasing the environmental impact in papermaking by lowering the process of water loading as a result of high filler retention, and by reducing the energy consumption for the pulp stock preparation and waste water treatment. Previous research concerning the solutions for

in-situ loading of the printing paper [

22,

23,

24] lead to developing a method consisting of the direct precipitation of the calcium carbonate into the wall and lumen of pulp fibers.

The present study aims at analyzing the effectiveness of method for in-situ precipitation of calcium carbonate as an additive for printing paper.

2. Experimental

2.1. Materials

The materials used in this study were:

- -

slush pulp made from bleached kraft pulp of resinous and hardwood, refined refined in Valley Hollander at 30° SR (Schopper-Riegler degree);

- -

calcium chloride (for analysis);

- -

sodium hydroxide (for analysis);

- -

carbon dioxide (compressed CO2 cylinder) as chemicals for generation in situ loading by calcium carbonate precipitation.

Chemical reactives were used in order to obtain the following materials:

- -

precipitated calcium carbonate (CCP) [

25,

26] for conventional loading (by direct addition of calcium carbonate to cellulose fiber suspension);

- -

cellulose of resinous with in-situ loading by calcium carbonate precipitation;

- -

cellulose of hardwood with in-situ loading by calcium carbonate precipitation.

2.2. Methods and Procedures

Refining of the pulp fibers was made under standard conditions for the Valley Hollander. The process was controlled by measuring the refining degree of the Schopper-Riegler instrumentation. The final refining degree was established at 30° SR for all series of the experiment. (30° SR)

Direct generation of calcium hydroxide in the pulp suspension and carbonation with carbon dioxide under pressure was based on the following reactions:

The pulp fibers, refining to 30° SR, were dried to 30% consistency and treated under agitation with calcium chloride with concentration and volume known (notated V1c1). Pulp treated with a solution of calcium chloride was dried in order to reach to the consistency of 30%, and filtrate (V2) was analyzed by titration of the calcium ion content. Based on this analysis, we calculated the quantity of calcium retained in the pulp fiber (V1c2). Depending on the quantity of calcium ions retained, the calculated sodium hydroxide was necessary for the formation of calcium hydroxide to be added to the pulp fiber under stirring. For Ca

2+ ions, the reaction underlying its determination by titration with complexone III is:

Calcium complex formed is stable in strongly basic medium (pH > 11), and for detecting the end of the titration, using murexide as the indicator. Ca

2+ content of the sample for analysis, expressed in

gCa

2+/L is calculated with [

27]:

where:

n is the volume of complexone III, used in the titration (mL);

—titer complexone III solution (g/mL);

v—volume of the solution analyzed (mL).

After treating pulp with sodium hydroxide solution, it was dehydrated and centrifuged to a consistency of 15%. Then it was carbonated with carbon dioxide at a pressure of 9 atm in a reactor with stirring for 2 h. Finally, the fiber pulp with in-situ filling is washed in order to remove the extra chemicals unreacted and the calcium carbonate not fixed in the pulp fibers wall and/or lumen.

The calcium carbonate content of the handsheets obtained from both unwashed and washed pulps does not significantly differ from that of filter pads. Practically, the formation of handsheets by water drainage from a diluted suspension (0.3 g/L) on forming wire has a similar effect as the washing process.

Conventional loaded fibers stock was prepared by the dosing and uniform distribution of precipitated calcium carbonate into refined pulp suspension under stirring; the dosage of calcium carbonate was established at 40% after several retention tests to obtaining paper handsheets with the same content of calcium carbonate as those of in-situ loaded fiber pulp (around 9.5%).

The pulp stock was characterized by:

- -

water retention value (WRV-g/g) determined by centrifugation of stock samples (consistency of 10%) under a force of 3000 g, time of 10 min [

28] and reporting the water content to dry material of the sample;

- -

hydrodynamic specific surface area (m

2/g) measured on Brecht apparatus [

10].

Making paper sheets in laboratory and their characteristics: paper sheets were made on the former Rapid-Köthen, at constant grammage of 70 g/m

2 and after conditioning (24 h at 23 °C and 50% UR) they were analyzed regarding:

- -

calcium carbonate content, according with Tappi Standard-T41320 [

29].

- -

opacity and brightness measured with spectrophotometer L&W Elrepho 2000 [

10].

- -

strength properties-breaking length of paper (Lr [Km]), measured with the Instron instrumentationn; burst factor (kPa m

2/g) measure with the Schopper-Dale instrumentation [

30].

- -

air permeability, measured by the DL-WEB apparatus at a 1 Kpa pressure [

30].

X-ray diffraction patterns of calcium carbonate particulates were obtained on a D8 ADVANCE, Bruker-AXS apparatus, equipped with a transmission type goniometer, using nickel-filtered, CuKα radiation (λ = 1.5418 Å) at 36 kV; the goniometer was scanned stepwise every 0.10° from 10° to 60° in the 2θ range; X-ray diffraction was performed only for paper sheets obtained from washed pulps.

The lumen loaded and in-situ synthesized pulp samples were analyzed by Scanning electron microscope (SEM) (VEGA/TESCAN instrument).

2.3. Experimental Program

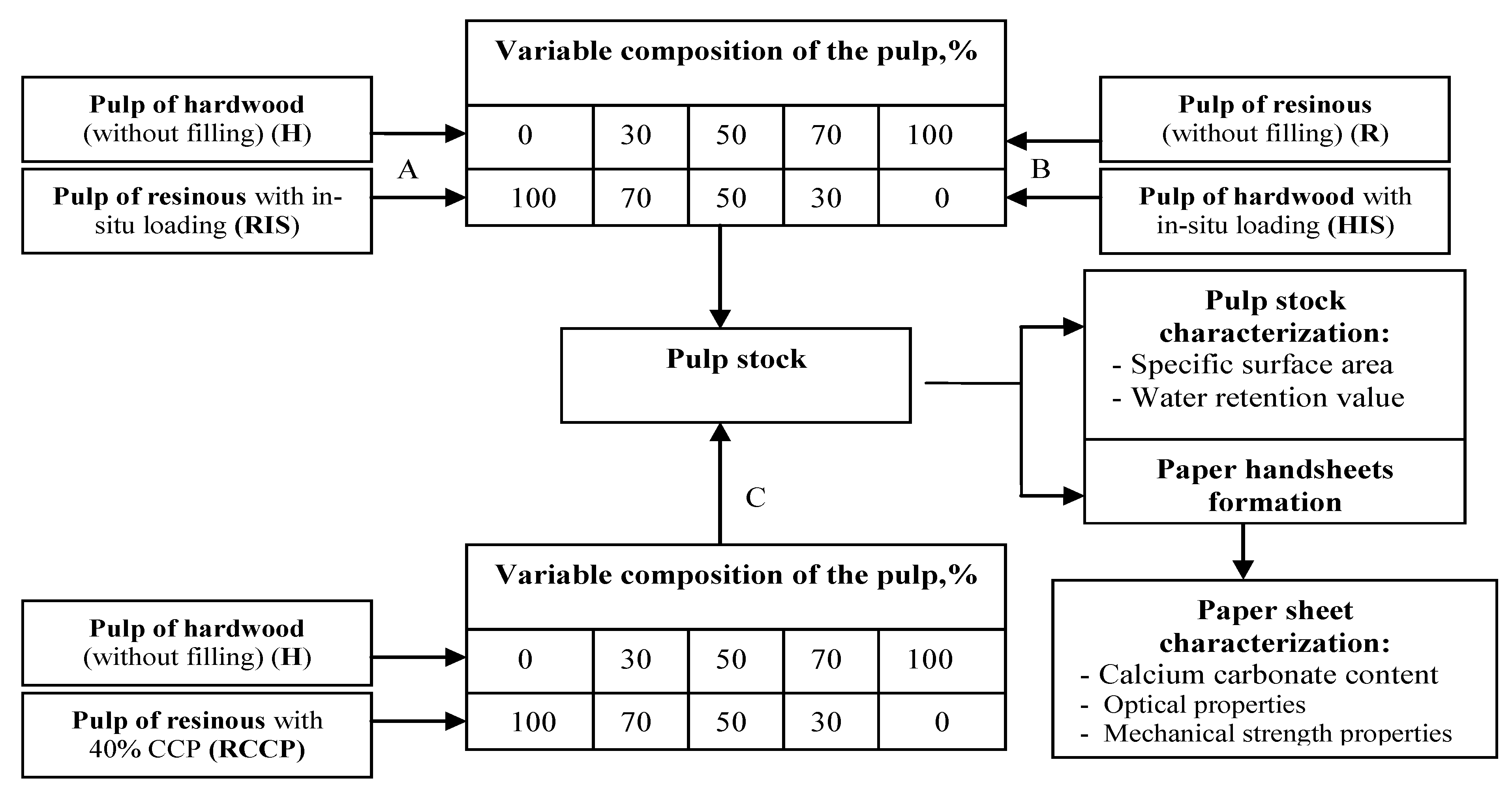

Experimental program (

Figure 1) consists of three series of experiments: A—different pulp compositions: resinous fibers with

in-situ loading/hardwood fibers without filling (RIS/H); B—different pulp compositions: hardwood fibers with

in-situ loading/resinous fibers without filling (HIS/R); C—different pulp compositions: (resinous fibers with constant addition of 40% calcium carbonate precipitated/hardwood fibers) (Reference-RCCP/H).

Figure 1.

Experimental program for the three series of pulp with different composition.

Figure 1.

Experimental program for the three series of pulp with different composition.

3. Results and Discussion

3.1. Characterization of Paper Paste

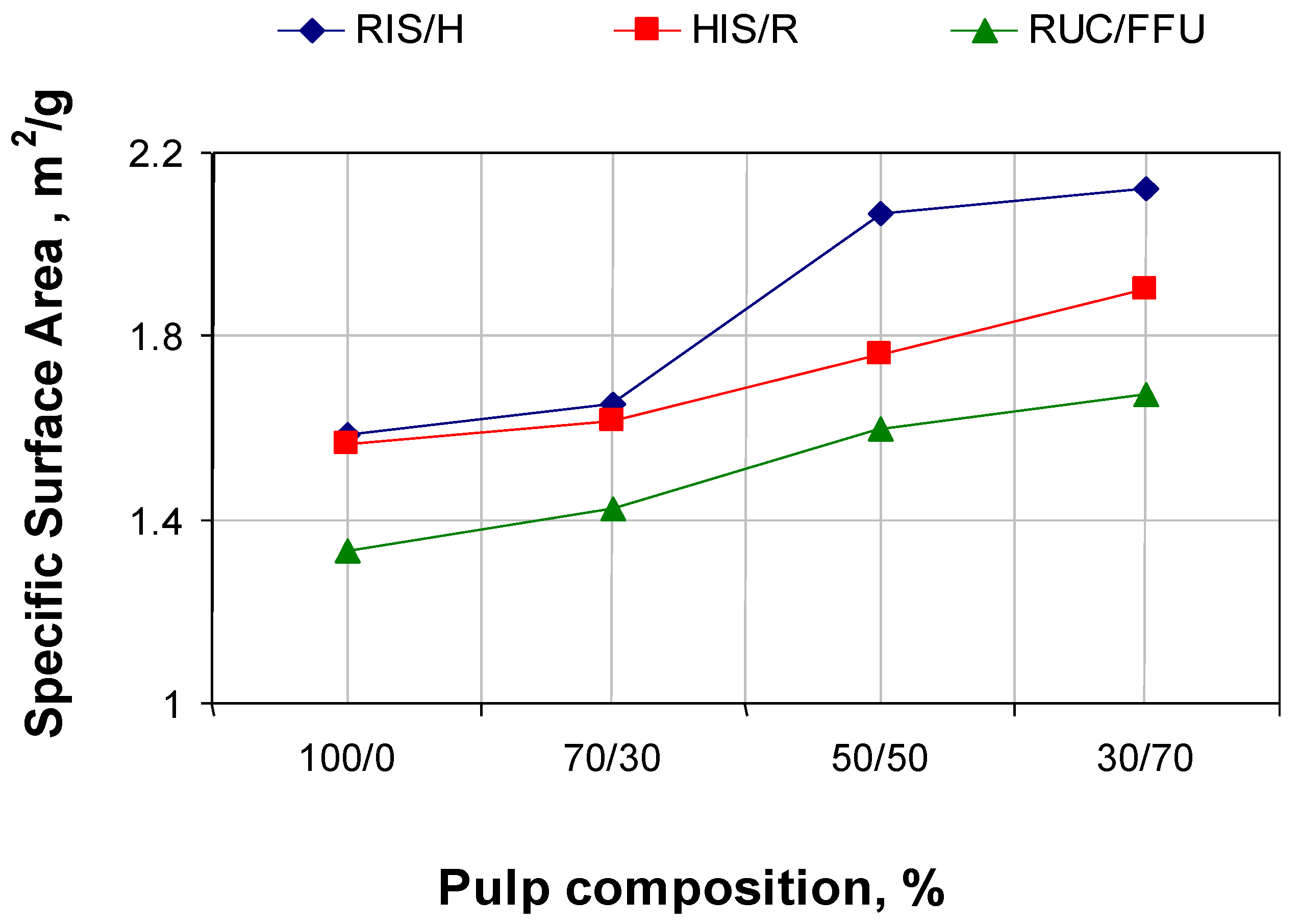

Figure 2 and

Figure 3 show specific surface area (SSA) evolutions and water retention value (WRV) depending on pulp composition for the three series of experiments. The specific surface area of

in-situ loaded fibers’ stock and that of those with loaded fibers increases with the addition of fibers without filling. The biggest increase is made by increasing the addition of hardwood fibers without filling in relation to

in-situ loaded fibers of resinous. The results can be explained by the fact that the hardwood pulp without filling has the biggest specific surface area, also increasing the retention of calcium carbonate precipitated over the resinous pulp surface (see

Figure 4).

Figure 2.

Specific surface area in relation with pulp composition.

Figure 2.

Specific surface area in relation with pulp composition.

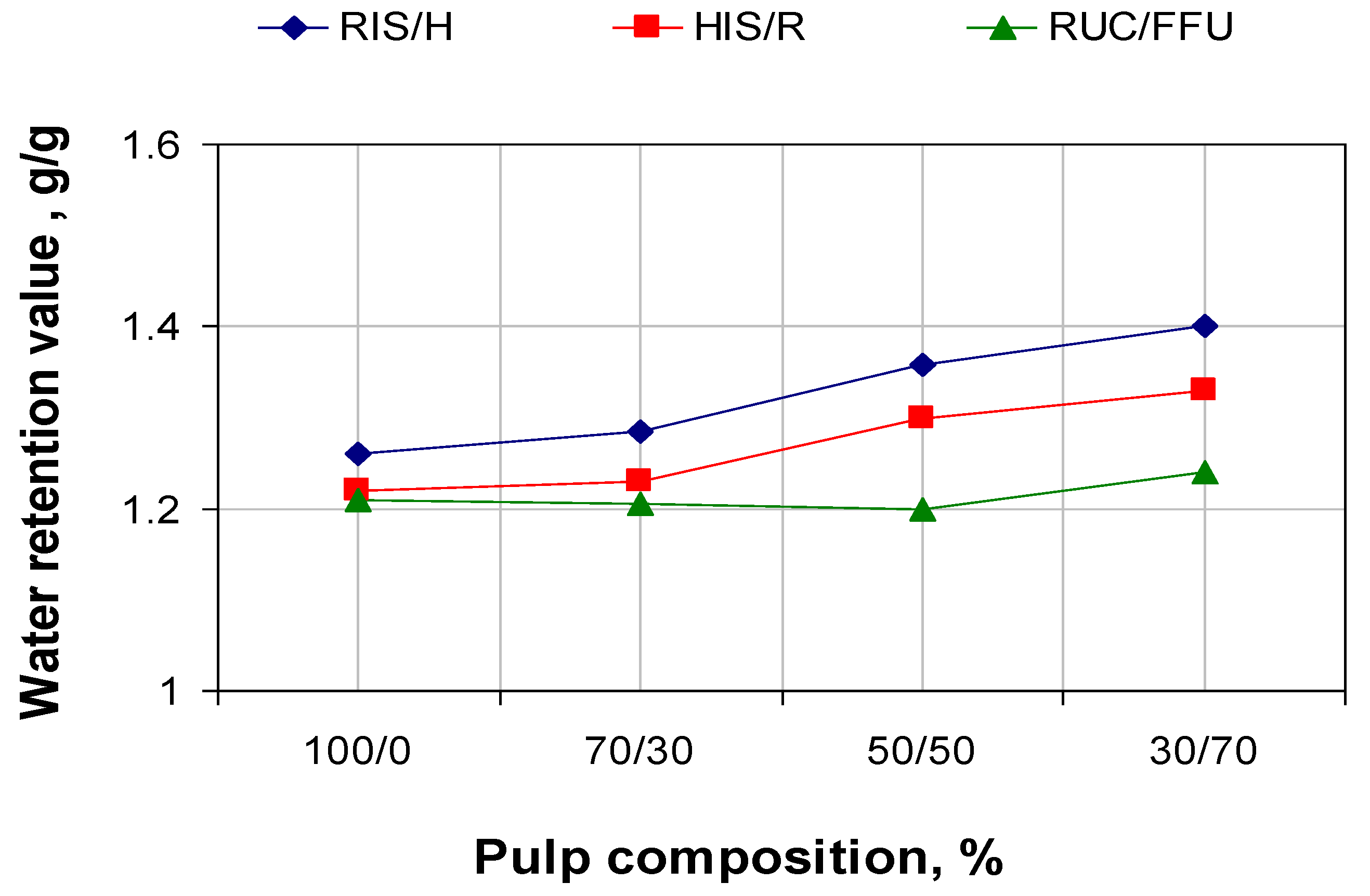

Figure 3.

Water retention value (WRV) in relation with pulp composition.

Figure 3.

Water retention value (WRV) in relation with pulp composition.

Water retention value is always lower for the paper paste with a higher content of in-situ loading fibers, because calcium carbonate shown in a cell’s wall and at fiber surface has a lower affinity for water molecules. As fiber quantity without filling increases, water retention number increases due to reduction in calcium carbonate content.

Figure 4.

CaCO3 content (a) and retention level of CaCO3; (b) in relation with pulp composition.

Figure 4.

CaCO3 content (a) and retention level of CaCO3; (b) in relation with pulp composition.

3.2. Characteristics of Paper Sheets Obtained in Laboratory

Fiber pulp was used for obtaining paper sheets in standard laboratory conditions, which after conditioning were tested for a series of physical-mechanical characteristics. Because physical-mechanical characteristics are influenced by the filling material content and retention mechanism, those will also be discussed depending on those parameters.

3.2.1. Retention of Calcium Carbonate and Structural Properties

Figure 4 shows that, with the no filling addition of pulp, the calcium carbonate content lowers, which is expected because effective addition is reduced at each series of experiments. Starting with the same calcium carbonate content for the first recipe (100/0) we notice that lowering the calcium carbonate content is twice as big for the conventional loading compared with

in-situ loading.

This is explained by lowering the retention level, as is shown in

Figure 3, at the same time as reducing calcium carbonate addition and increasing the content of fine material (pulp of hardwood). Increasing the addition of pulp without filling, compared with the addition of pulp with

in-situ loading, leads in the first place to increase of retention level, and, at higher addition of over 70%, the addition level decreases.

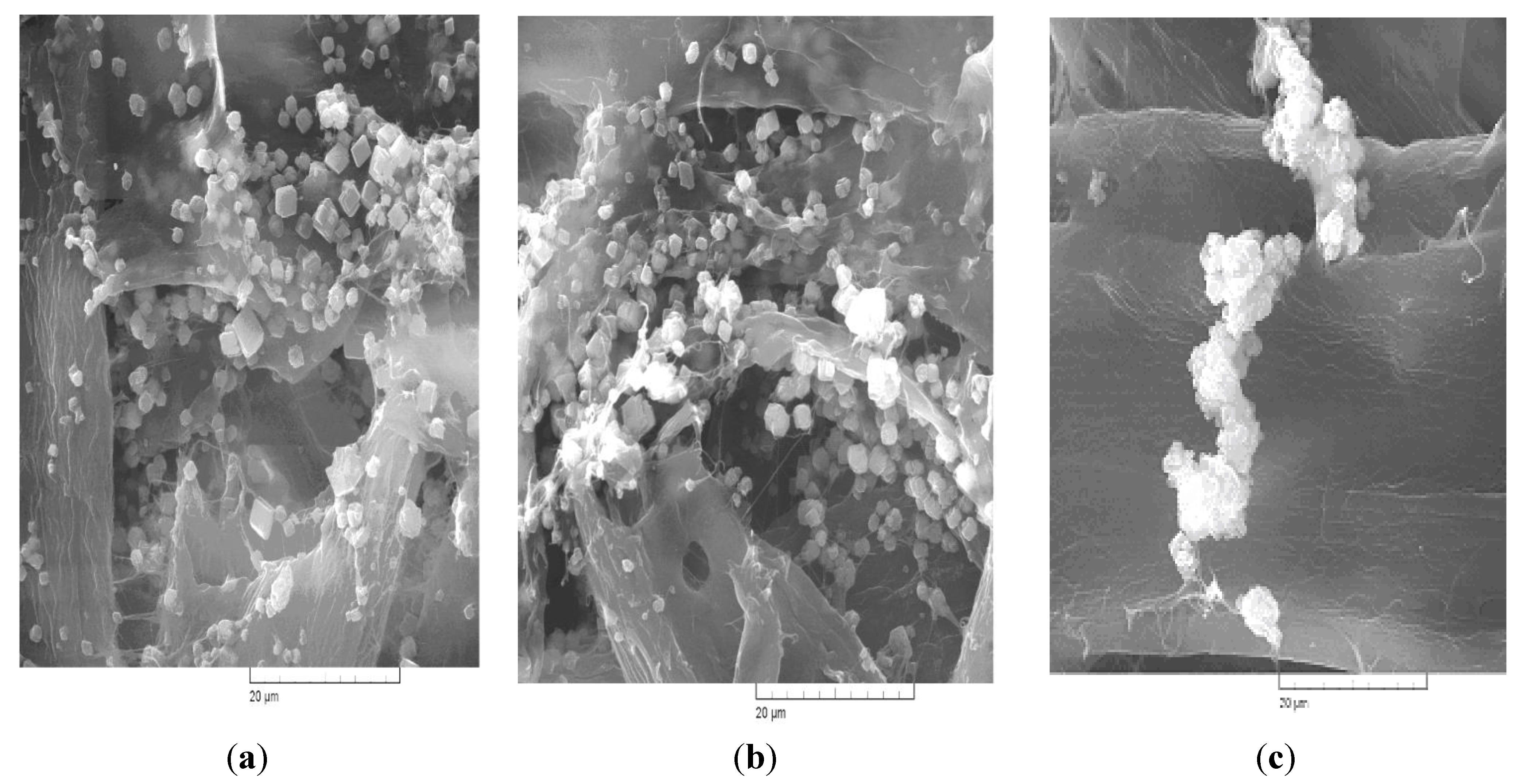

The examination of the SEM images (

Figure 5a–c) evidenced the presence of calcium carbonate crystals within both lumen and fiber wall pores. The results also indicated that the crystallization of CaCO

3 occurs with the formation of calcite microcrystals of specific shape.

Figure 5.

Scanning electron microscope (SEM) images of paper samples, obtained by conventional and respectively, in-situ loading with precipitated calcium carbonate of resinous and hardwood paper. (a) In-situ loading—resinous; (b) in-situ loading—hardwood; (c) conventional loading—resinous.

Figure 5.

Scanning electron microscope (SEM) images of paper samples, obtained by conventional and respectively, in-situ loading with precipitated calcium carbonate of resinous and hardwood paper. (a) In-situ loading—resinous; (b) in-situ loading—hardwood; (c) conventional loading—resinous.

SEM images show that between the two types of pulp with

in-situ loading (RIS and HIS) there are no significant differences regarding the calcium carbonate contents, but values of air permeability (

Figure 6) show significant structural differences.

Resinous pulp with in-situ loading leads to open structures, with higher air permeability than pulp of hardwood, which in turn has higher permeability than pulp of resinous with conventional loading. Evolution of air permeability clearly indicates that in-situ loading fibers could be effectively be used as additive control of porosity of printing paper.

Figure 6.

Evolution of air permeability of paper in relation with paper composition.

Figure 6.

Evolution of air permeability of paper in relation with paper composition.

3.2.2. X-ray Analysis

Precipitated calcium carbonate has been reported to occur usually in three basic polymorphic forms: calcite, vaterite and aragonite, the calcite being the most thermodynamically stable and vaterite the least, under ambient conditions. X-ray diffraction of the CaCO

3 crystals precipitated in the wall and/or lumen of the fibers revealed a typical calcite diffraction pattern. As reported in the literature [

30], calcite (I) is trigonalrhombohedral in shape, R3c, with trigonal axes

a = 4.99 Å and

c = 17.06 Å. The structure has Ca atoms at the origin and in layers, every

c/6 along

c. The planar CO

3 groups are oriented perpendicularly to

c.

Figure 7 shows the X-ray diffraction pattern of the paper sample filled by

in-situ precipitation of calcium carbonate and clearly demonstrates a strong reflection of calcite at 2θ = 29.3°, corresponding to the (104) plane, and at 2θ = 39.4°, corresponding to the (

) plane. In addition to the characteristic peaks of calcite, the X-ray diffractograms present no other characteristic peaks, typical of vaterite or aragonite.

X-ray diffraction analysis was used and to prove the presence of calcium carbonate in the lumen of fibers.

In this respect, the in-situ loaded fibers were washed with an acid solution to remove the particles from the surface pores, the absence of which was evidenced by X-ray diffraction by a characteristic reflection peak of calcite at 29.3° (104), which demonstrates the presence of calcium carbonate into the fiber lumen.

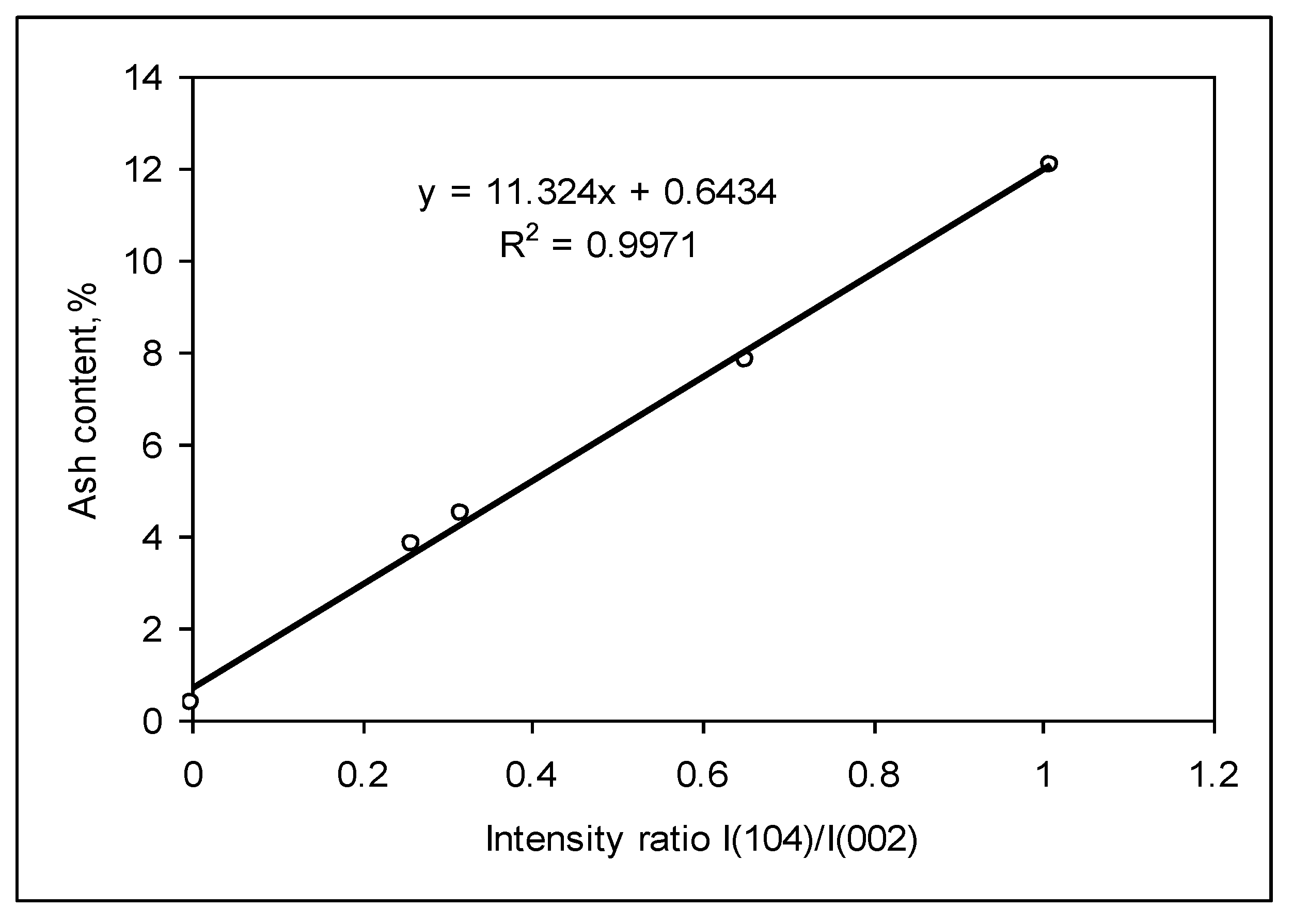

Starting from the above experiment, aimed at localizing the calcium carbonate particles into the fiber lumen, a nondestructive method for evaluating calcium carbonate content of in-situ loading pulp or paper was developed. In this respect, the relationship between the calcium carbonate content and the ratio of the peak heights at 29.3° (104), specific to calcite, and of the peak heights at 22.5° (002), specific to cellulose, was established. Experimental data were obtained by repetitive acid washings of an in-situ loading pulp sample (washed for removing free CaCO3 particles).

Following this, two acid washing steps led to complete dissolution of calcium carbonate from the fiber structure.

Figure 8 (ash content

versus X-ray diffraction intensity ratio) shows a very good correlation (

R2 = 0.9971), that could be used to estimate the calcium carbonate content, based on a standard curve and diffraction intensity ratio measurements.

Figure 7.

X-ray diffraction patterns of paper samples obtained by in-situ loading method.

Figure 7.

X-ray diffraction patterns of paper samples obtained by in-situ loading method.

Figure 8.

Correlation between ratio of I104/I002 diffraction intensity and ash content of paper samples filled in-situ and washed with an acid solution.

Figure 8.

Correlation between ratio of I104/I002 diffraction intensity and ash content of paper samples filled in-situ and washed with an acid solution.

3.2.3. Physical-Mechanical Properties of Paper Samples

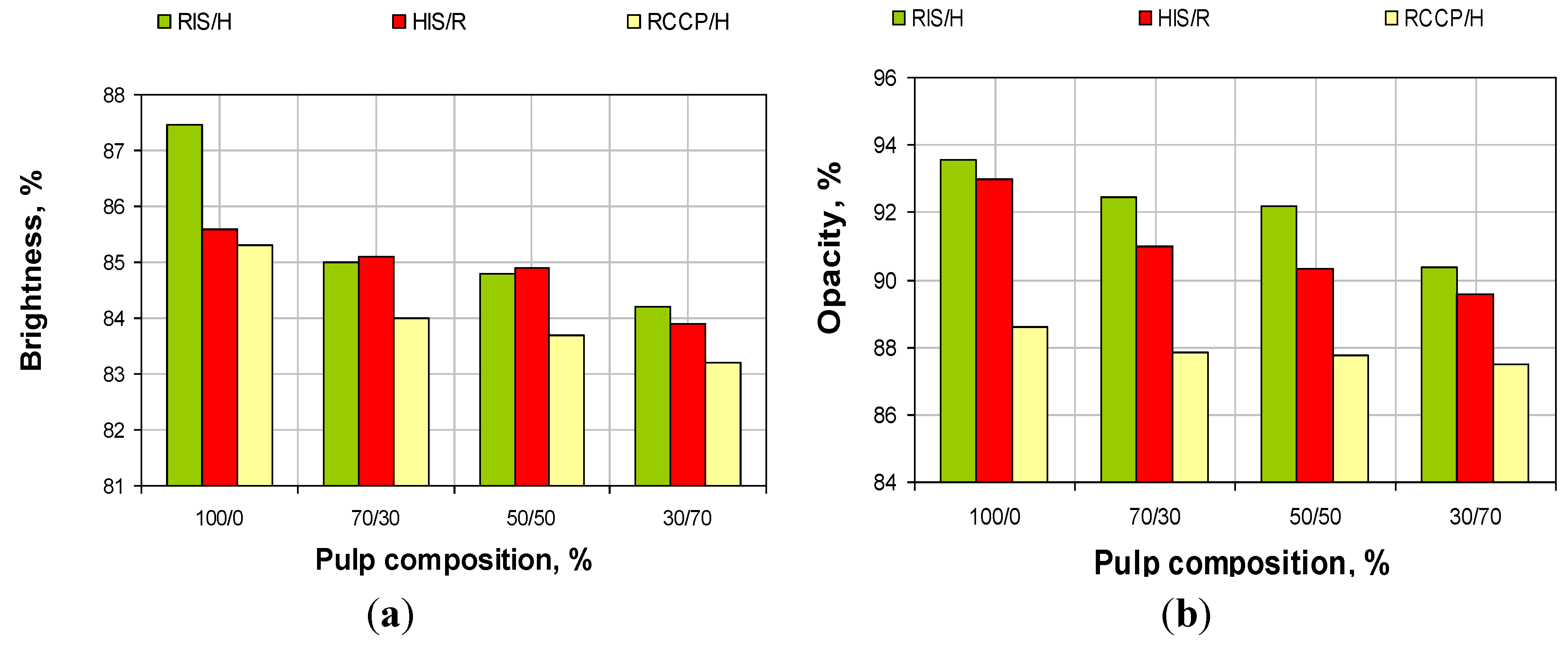

Evolution of brightness and opacity obtained in the three series of experiments is shown in

Figure 9. For about the same content of calcium carbonate in paper (see

Figure 4), paper obtained from 100% resinous pulp with

in-situ loading (RIS) has the brightness of about two percentual units higher than the reference obtained from the resinous with conventional loading. This difference is due to size and distribution of calcium carbonate particles:

in-situ precipitation of determining retention agglomerated calcium carbonate particles in the pores of the cell wall, while conventional loading allows agglomeration of the filler particles and their retention in-between spaces. This also explains different values of opacity. The difference of brightness between pulp and

in-situ loading (RIS, HIS) is due exclusively to the brightness of powder pulp, which is lower for resinous. At the same time, this explanation is also sustained by the fact that differences disappear by increasing the percent of pulp without filling. After addition of pulp of resinous or pulp of hardwood without filling, the brightness and opacity decrease in all three cases, this is due mainly to reduction of calcium carbonate content.

Figure 9.

Evolution of properties in relation with pulp composition (a) brightness and (b) opacity.

Figure 9.

Evolution of properties in relation with pulp composition (a) brightness and (b) opacity.

3.2.4. Mechanical Strength Properties

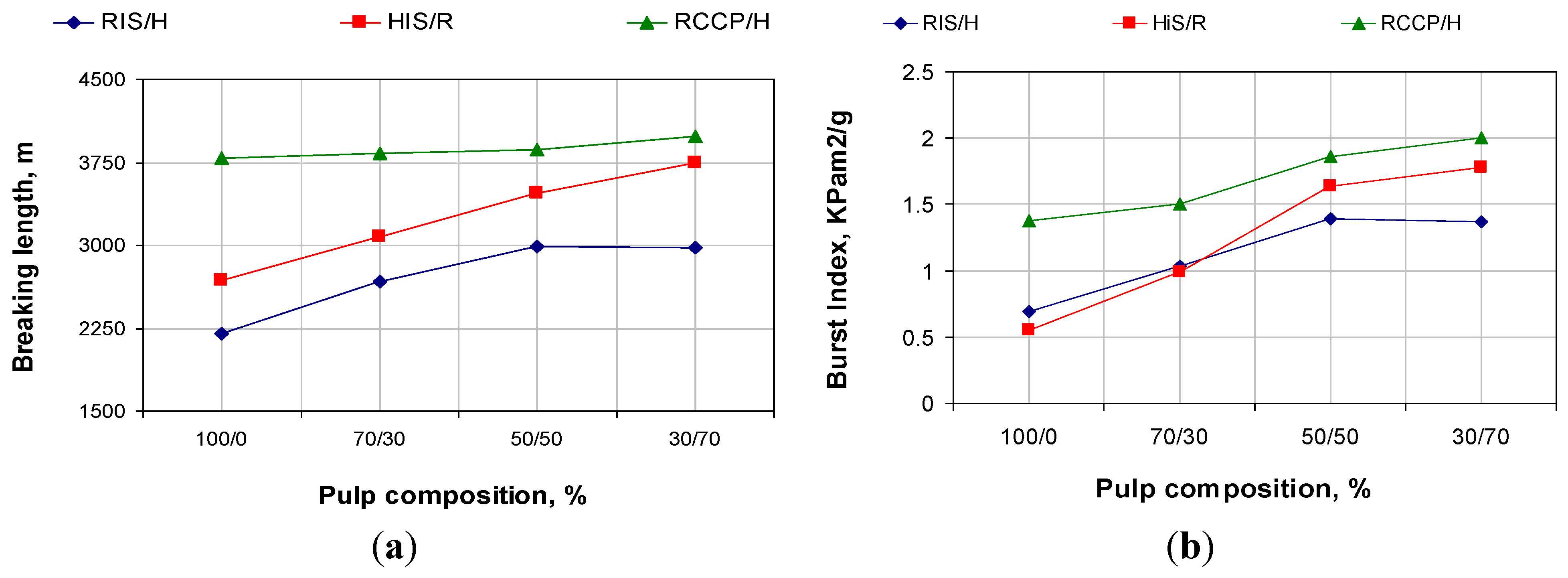

Evolution of strength properties, shown by the breaking length and the burst index, are shown in

Figure 10.

Figure 10.

Evolution of mechanical properties in relation with pulp composition (a) breaking length; (b) burst index.

Figure 10.

Evolution of mechanical properties in relation with pulp composition (a) breaking length; (b) burst index.

We notice that, at about the same calcium carbonate content in the initial paste, the paper obtained with filling of 100% fibers of resinous with

in-situ loading show resistance indices lower then the reference (100% fibers of resinous with conventional loading by direct addition of calcium carbonate to cellulose fiber suspension). For the

in-situ loading, most of the calcium carbonate is precipitate in the cell wall and lumen of pulp fibers, resulting in rigid fibers with surface binding (see

Figure 2, specific surface area). Differences between hardwood pulp with

in-situ loading and resinous pulp with

in-situ loading appear due to initial resistance characteristics of pulp without filling.

The breaking length and the burst index increase by adding pulp without filling. This is mainly due to the decrease of calcium carbonate content. It is also due to the active fiber, which contributes to the increase of specific surface are and the WRV number (see

Figure 2 and

Figure 3).

4. Conclusions

In this study, we investigated the use of hardwood and softwood cellulose fibers treated in the in-situ precipitation of calcium carbonate as an additive in the manufacture of printing papers to replace conventional filling.

Experiments planned for this purpose targeted paper pulp characteristics and paper sheets obtained with various fibers compositions, in which we varied the ratio between resinous and hardwood fibers additions with in-situ loading and adding resinous or hardwood fibers without filling.

Results were analyzed by comparing them with a references series, in which we varied the report between resinous fibers with 40% addition of precipitated calcium carbonate (conventional loading) and hardwood fibers without filling, observing that:

Retention level of calcium carbonate content in paper is greater for in-situ loading, compared with conventional loading, and addition of untreated fibers leads to improvement of retention for in-situ loading and makes it worse for conventional filling.

Compared with conventional loading, at same content of calcium carbonate, fiber addition with in-situ loading (resinous or hardwood) leads to an increase in brightness and especially in paper opacity.

Fibers of in-situ loading lead to higher porosity structures, and adding untreated fibers allows the control of this characteristic because air permeability of paper decreases linearly with the increase of fibers without filling, regardless of whether they are resinous or hardwood.

Compared with conventional loading, at same content of calcium carbonate, mechanical strength properties for in-situ loading are lower because calcium carbonate precipitation in cell wall pores and in fiber’s lumen leads to fibers with lower specific surface area and water retention value. However, strength properties are improved by addition of fibers without filling, so those can be optimized over the other paper characteristics.

The analysis of the X-ray diffraction patterns and SEM images show that the calcium carbonate particulates present a typical calcite diffraction pattern, with precipitation occurring in both the lumen and the wall pores of the cellulose fibers.

The main conclusion is that in-situ loading fibers, no matter if they are resinous or hardwood, can be used as an additive for optimizing printing paper properties, especially the relation between resistance and optical properties.