A Review of Domain Modelling and Domain Imaging Techniques in Ferroelectric Crystals

Abstract

:1. Introduction

2. Domain Modelling in Ferroelectric Crystals

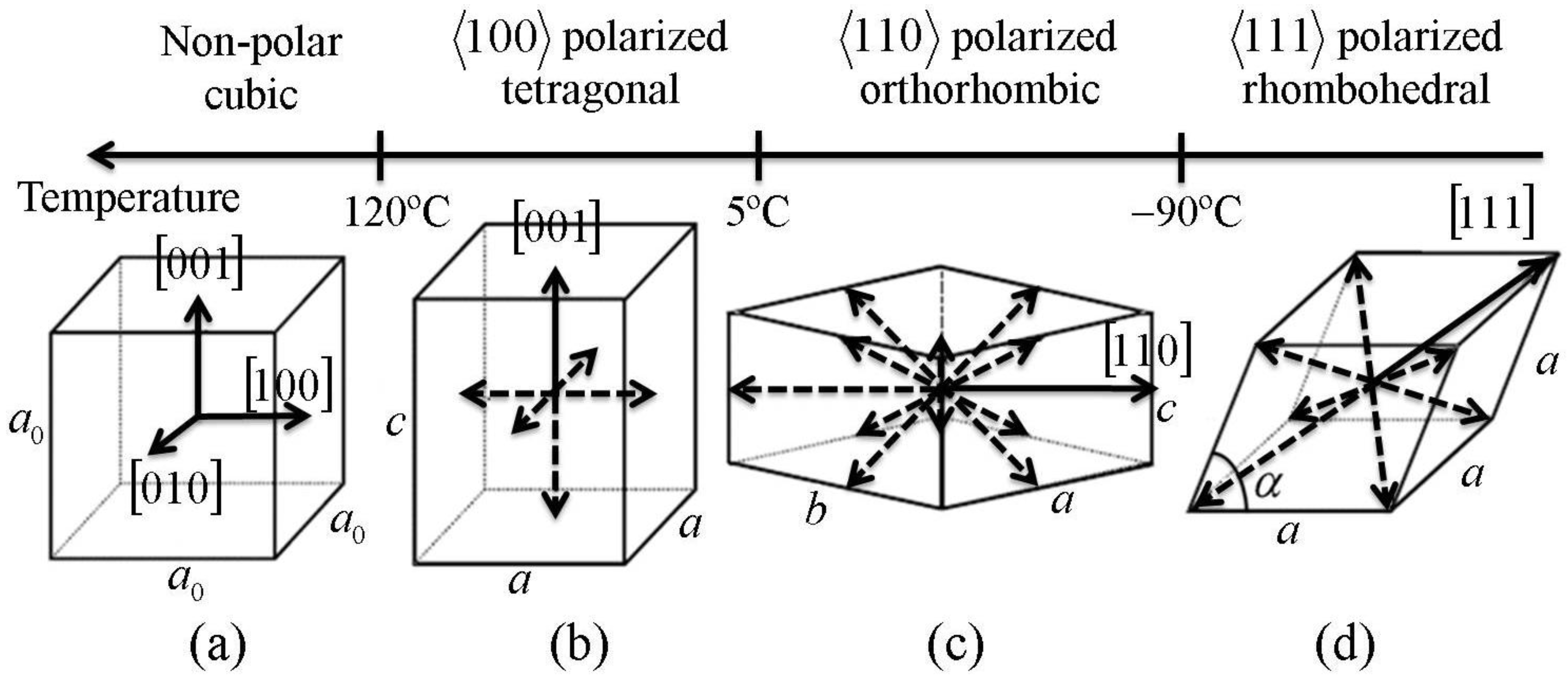

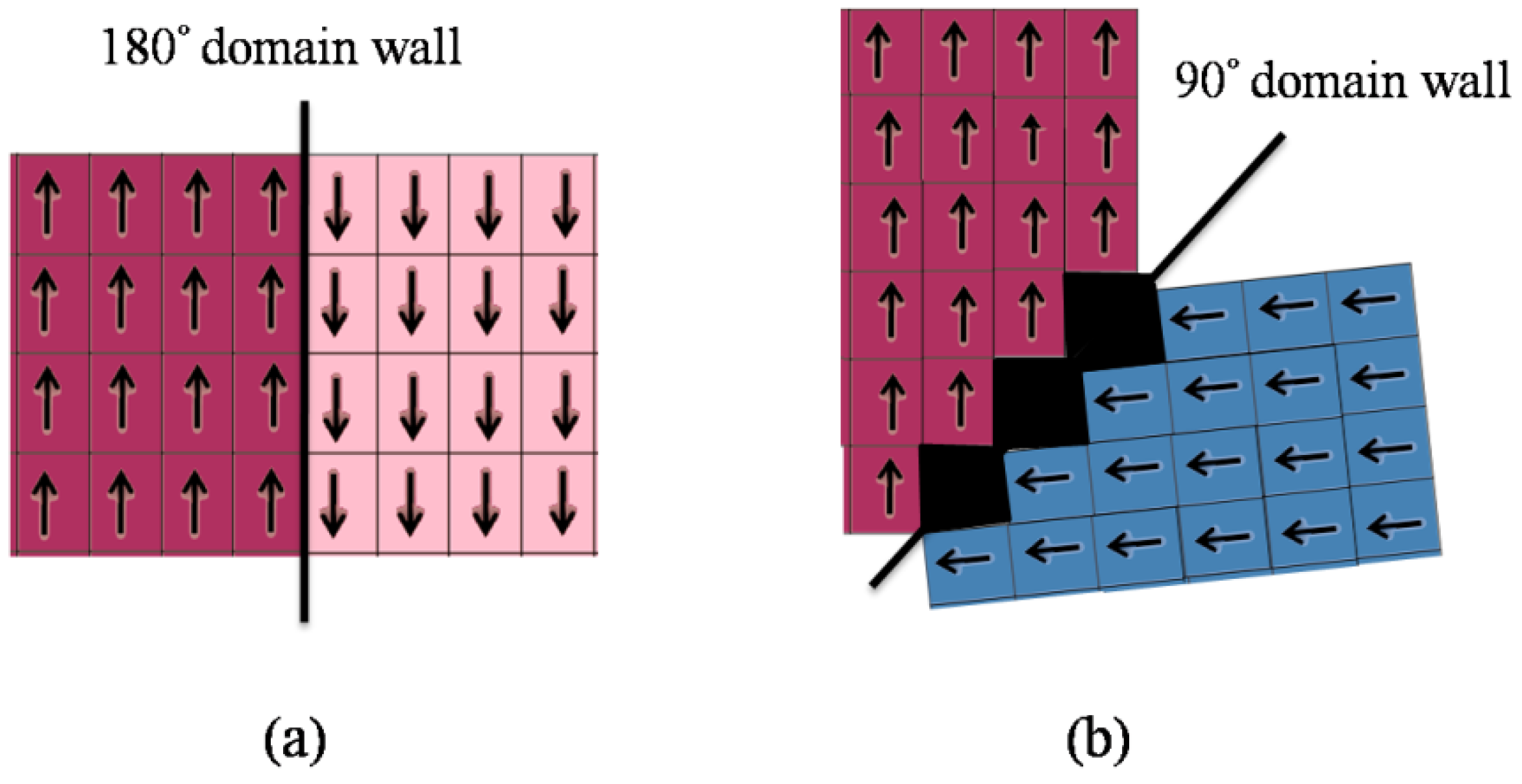

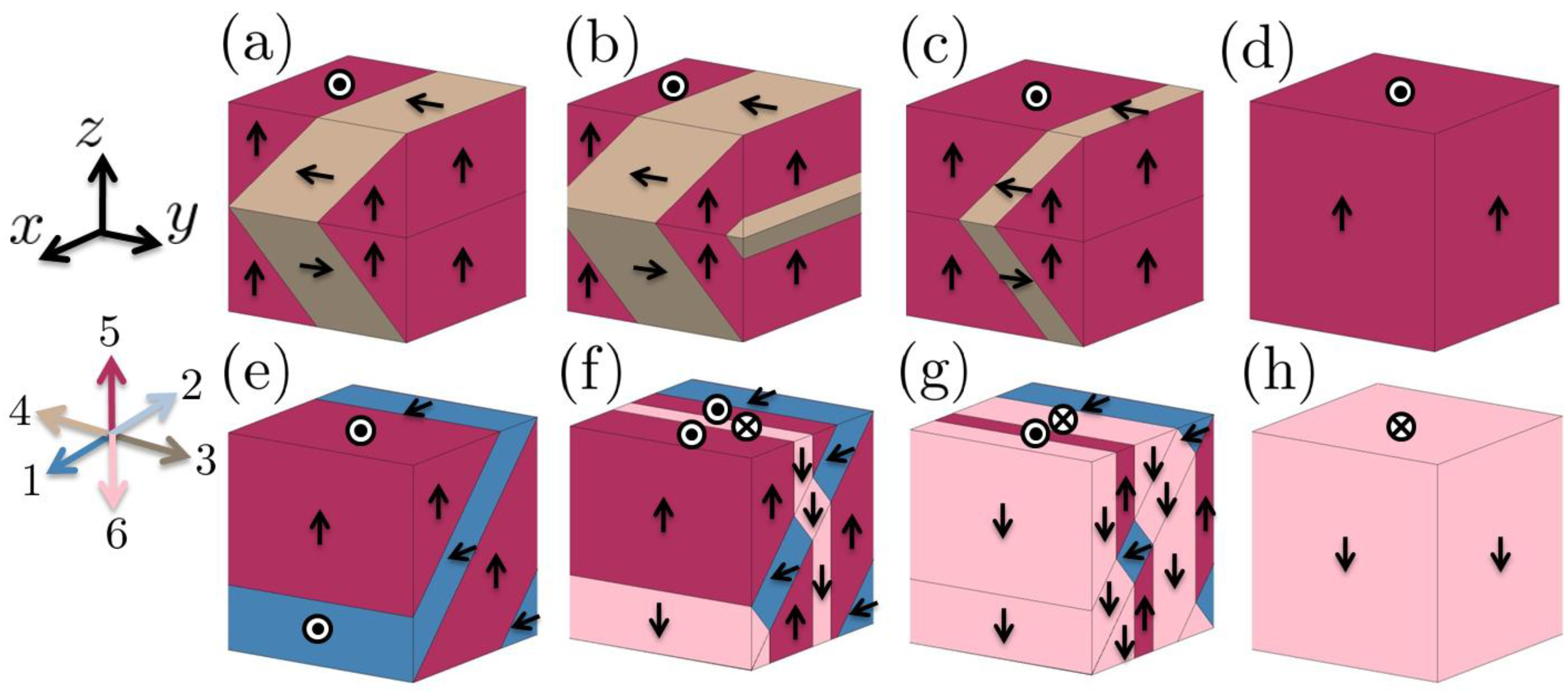

2.1. Crystallography and Ferroelectric Domains

2.2. Micromechanical Switching Models

2.3. Theory of Domain Compatibility

2.4. Domain Evolution Models

2.4.1. Phase Field Models

2.4.2. Sharp Interface Models

2.5. Models for Ferroelectric Films

3. Observation of Domain Structure in Ferroelectric Crystals

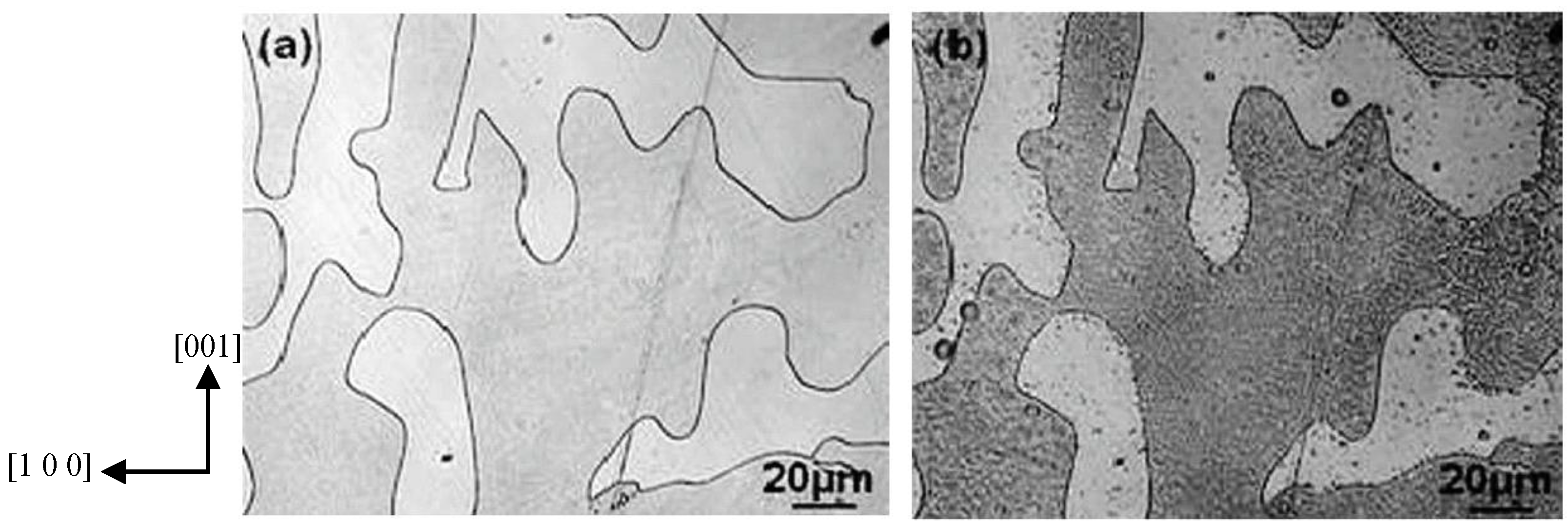

3.1. Surface Treatment Techniques

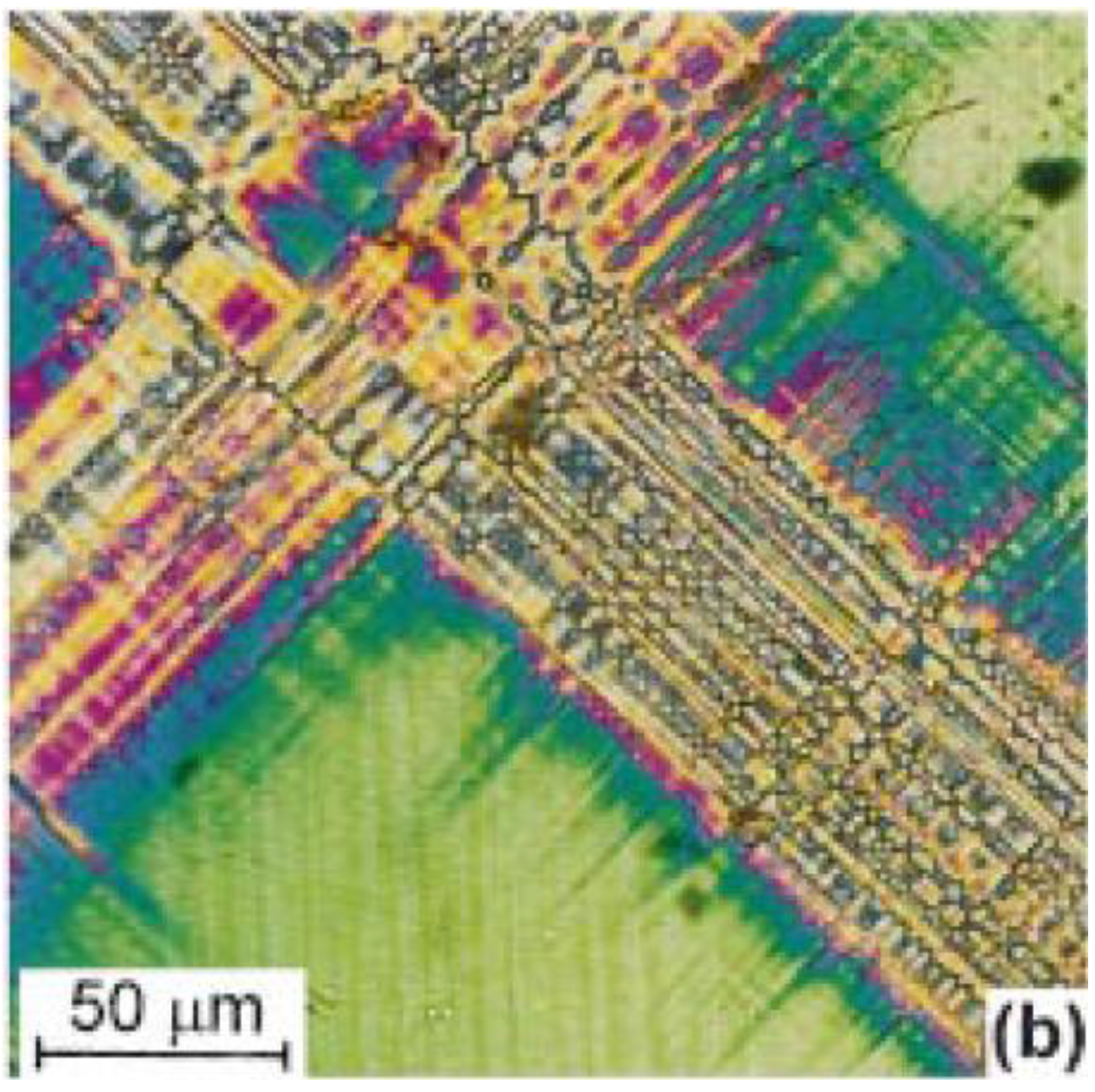

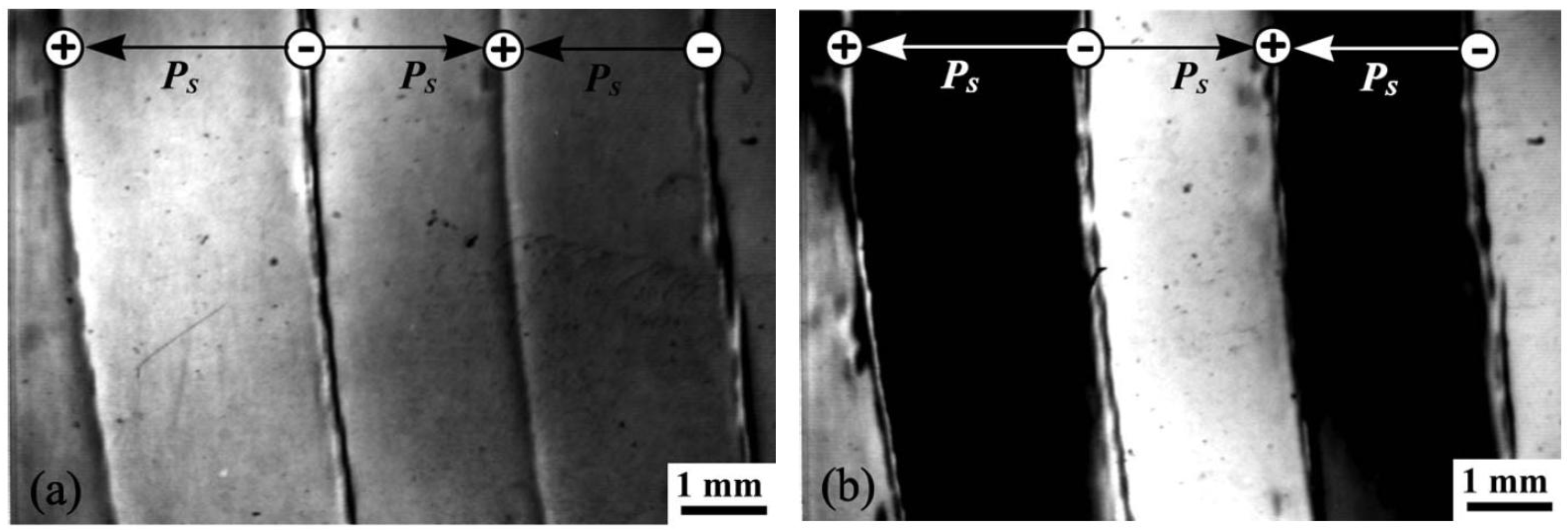

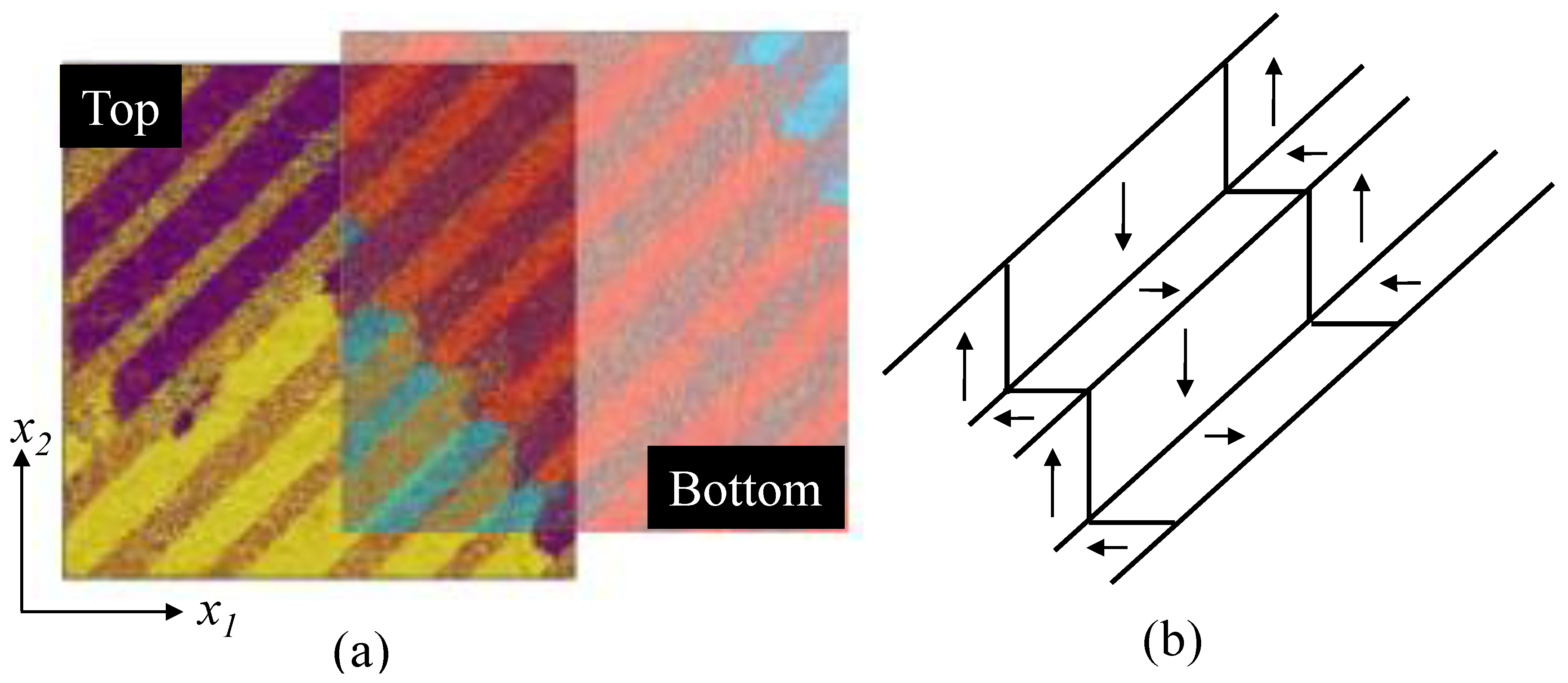

3.2. Optical Techniques

3.3. X-ray Techniques

3.4. Electron Microscopy Techniques

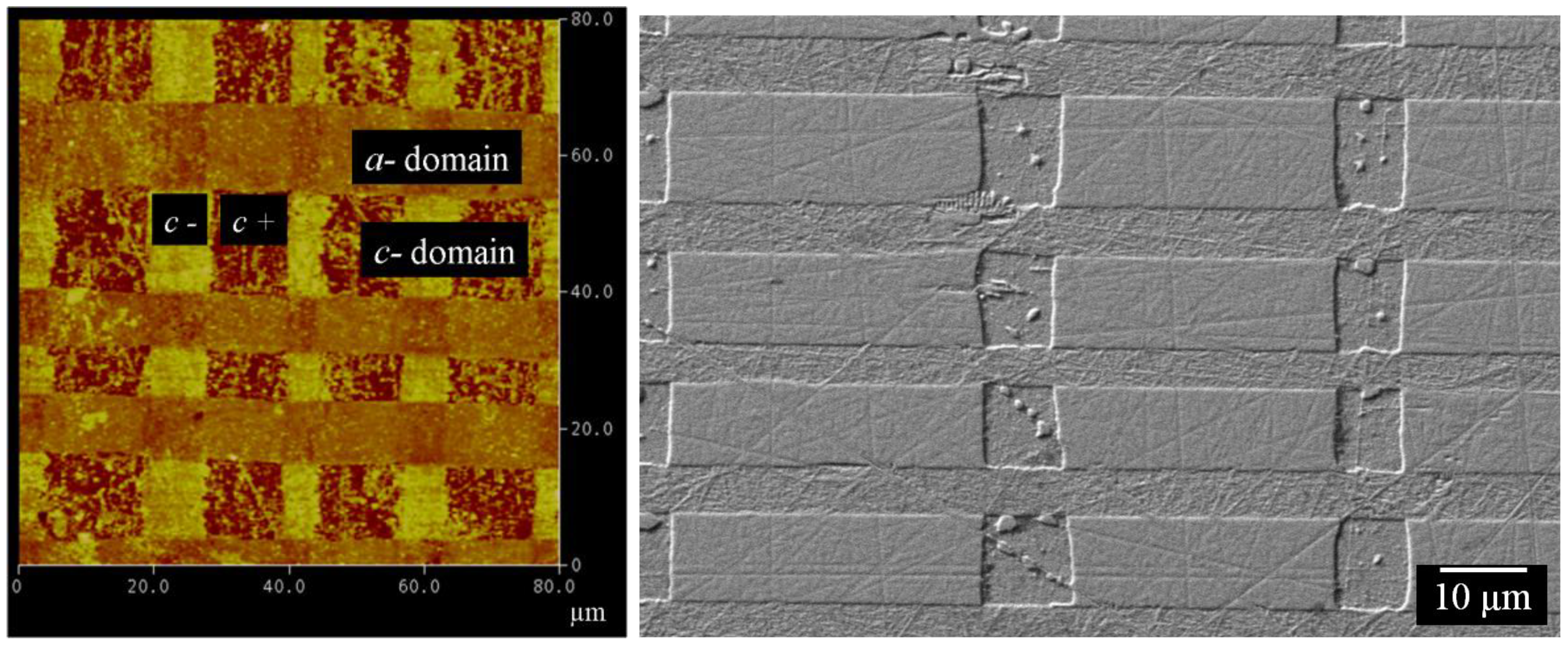

3.5. Scanning Probe Microscopy

3.6. Combined Methods

4. Conclusions

Acknowledgements

References

- Valasek, J. Piezo-electric and allied phenomena in Rochelle salt. Phys. Rev. 1921, 17, 475–481. [Google Scholar] [CrossRef]

- Haertling, G.H. Ferroelectric ceramics: History and technology. J. Am. Ceram. Soc. 1999, 82, 797–818. [Google Scholar] [CrossRef]

- Park, S.E.; Shrout, T.R. Ultrahigh strain and piezoelectric behavior in relaxor based ferroelectric single crystals. J. Appl. Phys. 1997, 82, 1804–1811. [Google Scholar] [CrossRef]

- Saito, Y.; Takao, H.; Tani, T.; Nonoyama, T.; Takatori, K.; Homma, T.; Nagaya, T.; Nakamura, M. Lead-free piezoceramics. Nature 2004, 432, 84–87. [Google Scholar] [CrossRef] [PubMed]

- Cohen, R.E. Theory of ferroelectrics: A vision for the next decade and beyond. J. Phys. Chem. Solids 2000, 61, 139–146. [Google Scholar] [CrossRef]

- Shu, Y.C.; Bhattacharya, K. Domain patterns and macroscopic behaviour of ferroelectric materials. Philos. Mag. B 2001, 81, 2021–2054. [Google Scholar] [CrossRef]

- Arlt, G.; Sasko, P. Domain Configuration and Equilibrium Size of Domains in BaTiO3 Ceramics. J. Appl. Phys. 1980, 51, 4956–4960. [Google Scholar] [CrossRef]

- Huber, J.E. Micromechanical modelling of ferroelectrics. Curr. Opin. Solid State Mater. Sci. 2005, 9, 100–106. [Google Scholar] [CrossRef]

- Hwang, S.C.; Huber, J.E.; McMeeking, R.M.; Fleck, N.A. The simulation of switching in polycrystalline ferroelectric ceramics. J. Appl. Phys. 1998, 84, 1530–1540. [Google Scholar] [CrossRef]

- Lu, W.; Fang, D.N.; Li, C.Q.; Hwang, K.C. Nonlinear electric-mechanical behavior and micromechanics modelling of ferroelectric domain evolution. Acta Mater. 1999, 47, 2913–2926. [Google Scholar] [CrossRef]

- Kessler, H.; Balke, H. On the local and average energy release in polarization switching phenomena. J. Mech. Phys. Solids 2001, 49, 953–978. [Google Scholar] [CrossRef]

- Michelitsch, T.; Kreher, W.S. A simple model for the nonlinear material behavior of ferroelectrics. Acta Mater. 1998, 46, 5085–5094. [Google Scholar] [CrossRef]

- Huber, J.E.; Fleck, N.A.; Landis, C.M.; McMeeking, R.M. A constitutive model for ferroelectric polycrystals. J. Mech. Phys. Solids 1999, 47, 1663–1697. [Google Scholar] [CrossRef]

- Landis, C.M.; McMeeking, R.M. A self-consistent constitutive model for switching in polycrystalline barium titanate. Ferroelectrics 2001, 255, 13–34. [Google Scholar] [CrossRef]

- Rödel, J.; Kreher, W.S. Self-consistent modelling of non-linear effective properties of polycrystalline ferroelectric ceramics. Comput. Mater. Sci. 2000, 19, 123–132. [Google Scholar] [CrossRef]

- Li, F.X.; Fang, D.N. Simulations of domain switching in ferroelectrics by a three-dimensional finite element model. Mech. Mater. 2004, 36, 959–973. [Google Scholar] [CrossRef]

- Anteboth, S.; Bruckner-Foit, A.; Hoffmann, M.J.; Sutter, U.; Schimmel, T.; Muller, M. Electromechanical behaviour of PZT with real domain structure. Comput. Mater. Sci. 2008, 41, 420–429. [Google Scholar] [CrossRef]

- Pathak, A.; McMeeking, R.M. Three-dimensional finite element simulations of ferroelectric polycrystals under electrical and mechanical loading. J. Mech. Phys. Solids 2008, 56, 663–683. [Google Scholar] [CrossRef]

- Haug, A.; Huber, J.E.; Onck, P.R.; Van der Giessen, E. Multi-grain analysis versus self-consistent estimates of ferroelectric polycrystals. J. Mech. Phys. Solids 2007, 55, 648–665. [Google Scholar] [CrossRef]

- Haug, A.; Onck, P.R.; Van der Giessen, E. Development of inter- and intragranular stresses during switching of ferroelectric polycrystals. Int. J. Solids Struct. 2007, 44, 2066–2078. [Google Scholar] [CrossRef]

- Kamlah, M. Ferroelectric and ferroelastic piezoceramics—modeling of electromechanical hysteresis phenomena. Continuum Mech. Therm. 2001, 13, 219–268. [Google Scholar] [CrossRef]

- Landis, C.M. Non-linear constitutive modeling of ferroelectrics. Curr. Opin. Solid State Mater. Sci. 2004, 8, 59–69. [Google Scholar] [CrossRef]

- Bhattacharya, K.; Ravichandran, G. Ferroelectric perovskites for electromechanical actuation. Acta Mater. 2003, 51, 5941–5960. [Google Scholar] [CrossRef]

- Liu, T.; Lynch, C.S. Domain engineered relaxor ferroelectric single crystals. Continuum Mech. Therm. 2006, 18, 119–135. [Google Scholar] [CrossRef]

- Wada, S.; Suzuki, S.; Noma, T.; Suzuki, T.; Osada, M.; Kakihana, M.; Park, S.E.; Cross, L.E.; Shrout, T.R. Enhanced piezoelectric property of barium titanate single crystals with engineered domain configurations. Jpn. J. Appl. Phys. 1999, 38, 5505–5511. [Google Scholar] [CrossRef]

- Bell, A.J. Phenomenologically derived electric field-temperature phase diagrams and piezoelectric coefficients for single crystal barium titanate under fields along different axes. J. Appl. Phys. 2001, 89, 3907–3914. [Google Scholar] [CrossRef]

- Li, J.Y.; Liu, D. On ferroelectric crystals with engineered domain configurations. J Mech Phys Solids 2004, 52, 1719–1742. [Google Scholar] [CrossRef]

- Yin, J.; Cao, W. Observation and analysis of domain configurations in domain engineered PZN-PT single crystals. Ferroelectrics 2001, 251, 93–100. [Google Scholar] [CrossRef]

- Park, S.E.; Wada, S.; Cross, L.E.; Shrout, T.R. Crystallographically engineered BaTiO3 single crystals for high-performance piezoelectrics. J. Appl. Phys. 1999, 86, 2746–2750. [Google Scholar] [CrossRef]

- Zeng, X.; Rajapakse, R.K.N.D. Eshelby tensor for piezoelectric inclusion and application to modeling of domain switching and evolution. Acta Mater. 2003, 51, 4121–4134. [Google Scholar] [CrossRef]

- Molotskii, M. Forward motion of ferroelectric domain walls. Phil. Maga. Lett. 2003, 83, 763–767. [Google Scholar] [CrossRef]

- Su, Y.; Landis, C.M. Continuum thermodynamics of ferroelectric domain evolution: Theory, finite element implementation, and application to domain wall pinning. J. Mech. Phys. Solids 2007, 55, 280–305. [Google Scholar] [CrossRef]

- Tsou, N.T.; Huber, J.E. A Variational Model of Ferroelectric Rank-2 Laminate Domain Structures; Zoubeida, O., Jiangyu, L., Eds.; SPIE: Bellingham, WA, USA, 2010; p. 76440B. [Google Scholar]

- Tsou, N.T.; Huber, J.E. Domain evolution of herringbone structures in ferroelectric single crystals. In Smart Materials, Adaptive Structures and Intelligent Systems; ASME: New York, NY, USA, 2010. [Google Scholar]

- DeSimone, A.; James, R.D. A constrained theory of magnetoelasticity. J. Mech. Phys. Solids. 2002, 50, 283–320. [Google Scholar] [CrossRef]

- Ball, J.M.; James, R.D. Fine phase mixtures as minimizers of energy. Arch. Ration. Mech. Anal. 1987, 100, 13–52. [Google Scholar] [CrossRef]

- Hooton, J.A.; Merz, W.J. Etch patterns and ferroelectric domains in BaTiO3 single crystals. Phys. Rev. 1955, 98, 409–413. [Google Scholar] [CrossRef]

- Arlt, G. Twinning in ferroelectric and ferroelastic ceramics—stress relief. J. Mater. Sci. 1990, 25, 2655–2666. [Google Scholar] [CrossRef]

- Bhattacharya, K. Comparison of the geometrically nonlinear and linear theories of martensitic-transformation. Continuum. Mech. Therm. 1993, 5, 205–242. [Google Scholar] [CrossRef]

- Tsou, N.T.; Huber, J.E. Compatible domain structures and the poling of single crystal ferroelectrics. Mech. Mater. 2010, 42, 740–753. [Google Scholar] [CrossRef]

- Rodel, J. Effective intrinsic linear properties of laminar piezoelectric composites and simple ferroelectric domain structures. Mech. Mater. 2007, 39, 302–325. [Google Scholar] [CrossRef]

- Fousek, J.; Mokry, P. Stress-free domain quadruplets in ferroics. Ferroelectrics 2005, 323, 3–9. [Google Scholar] [CrossRef]

- Savytskii, D.; Bismayer, U. Strain at junctions in multidomain configurations. Phase Transit. 2008, 81, 431–447. [Google Scholar] [CrossRef]

- Meyer, B.; Vanderbilt, D. Ab initio study of ferroelectric domain walls in PbTiO3. Phys. Rev. B 2002, 65, 13–24. [Google Scholar]

- Naumov, I.I.; Bellaiche, L.; Fu, H.X. Unusual phase transitions in ferroelectric nanodisks and nanorods. Nature 2004, 432, 737–740. [Google Scholar] [CrossRef] [PubMed]

- Cohen, R.E.; Krakauer, H. Lattice-dynamics and origin of ferroelectricity in BaTiO3—Linearized-augmented-plane-wave total-energy calculations. Phys. Rev. B 1990, 42, 6416–6423. [Google Scholar] [CrossRef]

- Chen, L.Q. Phase-field models for microstructure evolution. Annu. Rev. Mater. Res. 2002, 32, 113–140. [Google Scholar] [CrossRef]

- Choudhury, S.; Chen, L.Q.; Li, Y.L. Correlation between number of ferroelectric variants and coercive field of lead ziconate titanate single crystals. Appl. Phy.s Lett. 2007, 91, 032902:1–032902:3. [Google Scholar]

- Slutsker, J.; Artemev, A.; Roytburd, A. Phase-field modeling of domain structure of confined nanoferroelectrics. Phys. Rev. Lett. 2008, 100, 087602:1–087602:4. [Google Scholar] [CrossRef]

- Zhang, J.X.; Wu, R.; Choudhury, S.; Li, Y.L.; Hu, S.Y.; Chen, L.Q. Three-dimensional phase-field simulation of domain structures in ferroelectric islands. Appl. Phys. Lett. 2008, 92, 122906:1–122906:3. [Google Scholar]

- Hu, H.L.; Chen, L.Q. Three-dimensional computer simulation of ferroelectric domain formation. J. Am. Ceram Soc. 1998, 81, 492–500. [Google Scholar] [CrossRef]

- Dayal, K.; Bhattacharya, K. A real-space non-local phase-field model of ferroelectric domain patterns in complex geometries. Acta Mater. 2007, 55, 1907–1917. [Google Scholar] [CrossRef]

- Shu, Y.C.; Yen, J.H.; Chen, H.Z.; Li, J.Y.; Li, L.J. Constrained modeling of domain patterns in rhombohedral ferroelectrics. Appl. Phys. Lett. 2008, 92, 052909:1–052909:3. [Google Scholar]

- Schrade, D.; Mueller, R.; Xu, B.; Gross, D. Domain evolution in ferroelectric materials: A continuum phase field model and finite element implementation. Comput. Method. Appl. M 2007, 196, 4365–4374. [Google Scholar] [CrossRef]

- Choudhury, S.; Li, Y.L.; Krill, C.E.; Chen, L.Q. Phase-field simulation of polarization switching and domain evolution in ferroelectric polycrystals. Acta Mater. 2005, 53, 5313–5321. [Google Scholar] [CrossRef]

- Fried, E.; Gurtin, M.E. Continuum theory of thermally-induced phase-transitions based on an order-parameter. Physica D 1993, 68, 326–343. [Google Scholar] [CrossRef]

- Fried, E.; Gurtin, M.E. Dynamic solid-solid transitions with phase characterized by an order-parameter. Physica D 1994, 72, 287–308. [Google Scholar] [CrossRef]

- Cao, W.W.; Cross, L.E. Theory of tetragonal twin structures in ferroelectric perovskites with a 1st-order phase-transition. Phys. Rev. B 1991, 44, 5–12. [Google Scholar] [CrossRef]

- Wang, J.; Shi, S.Q.; Chen, L.Q.; Li, Y.L.; Zhang, T.Y. Phase field simulations of ferroelectric/ferroelastic polarization switching. Acta Mater. 2004, 52, 749–764. [Google Scholar] [CrossRef]

- Zhang, W.; Bhattacharya, K. A computational model of ferroelectric domains. Part I: Model formulation and domain switching. Acta Mater. 2005, 53, 185–198. [Google Scholar] [CrossRef]

- Zhang, W.; Bhattacharya, K. A computational model of ferroelectric domains. Part II: Grain boundaries and defect pinning. Acta Mater. 2005, 53, 199–209. [Google Scholar] [CrossRef]

- Kontsos, A.; Landis, C.M. Computational modeling of domain wall interactions with dislocations in ferroelectric crystals. Int. J. Solids Struct. 2009, 46, 1491–1498. [Google Scholar] [CrossRef]

- Kontsos, A.; Landis, C.M. Phase-field modeling of domain structure energetics and evolution in ferroelectric thin films. J. Appl. Mech. 2010, 77, 041014:1–041014:12. [Google Scholar] [CrossRef]

- Shu, Y.C. Application of energy-minimizing laminates to the modeling of ferroelectric domain and switching. In Finite Plasticity and Visco-Plasticity of Conventional and Emerging Materials; Khan, A.S., Farrokh, B., Eds.; NEAT Press: Jonesboro, AR, USA, 2010; pp. 142–144. [Google Scholar]

- Loge, R.E.; Suo, Z. Nonequilibrium thermodynamics of ferroelectric domain evolution. Acta Mater. 1996, 44, 3429–3438. [Google Scholar] [CrossRef]

- Huber, J.E.; Cocks, A.C.F. A variational model of ferroelectric microstructure. In Proceedings of ASME 2008 Conference on Smart Materials, Adaptive Structures and Intelligent Systems (SMASIS2008), Ellicott, MA, USA, 28–30 October 2008; pp. 225–230.

- Weng, G.J.; Wong, D.T. Thermodynamic driving force in ferroelectric crystals with a rank-2 laminated domain pattern, and a study of enhanced electrostriction. J. Mech. Phys. Solids 2009, 57, 571–597. [Google Scholar] [CrossRef]

- Yen, J.H.; Shu, Y.C.; Shieh, J.; Yeh, J.H. A study of electromechanical switching in ferroelectric single crystals. J. Mech. Phys. Solids 2008, 56, 2117–2135. [Google Scholar] [CrossRef]

- Eshelby, J.D. The elastic energy-momentum tensor. J. Elast. 1975, 5, 321. [Google Scholar] [CrossRef]

- Kessler, H.; Balke, H. A continuum analysis of the driving force of ferroelectric/ferroelastic domain wall motions. J. Mech. Phys. Solids 2006, 54, 113–127. [Google Scholar] [CrossRef]

- Gill, S.P.A.; Cornforth, M.G.; Cocks, A.C.F. Modelling microstructure evolution in engineering materials. Int. J. Plast. 2001, 17, 669–690. [Google Scholar] [CrossRef]

- Burcsu, E.; Ravichandran, G.; Bhattacharya, K. Large electrostrictive actuation of barium titanate single crystals. J. Mech. Phys. Solids 2004, 52, 823–846. [Google Scholar] [CrossRef]

- Setter, N.; Damjanovic, D.; Eng, L.; Fox, G.; Gevorgian, S.; Hong, S.; Kingon, A.; Kohlstedt, H.; Park, N.Y.; Stephenson, G.B.; Stolitchnov, I.; Taganstev, A.K.; Taylor, D.V.; Yamada, T.; Streiffer, S. Ferroelectric thin films: Review of materials, properties, and applications. J. Appl. Phys. 2006, 100, 051606:1–051606:46. [Google Scholar]

- Roytburd, A.L. Thermodynamics of polydomain heterostructures. I. Effect of macrostresses. J. Appl. Phys. 1998, 83, 228–238. [Google Scholar] [CrossRef]

- Hanson, J.N. Fabrication of metallic nanowires on a ferroelectric template via photochemical reaction. Nanotechnology 2006, 17, 4946. [Google Scholar] [CrossRef]

- Li, Y.L.; Hu, S.Y.; Liu, Z.K.; Chen, L.Q. Effect of substrate constraint on the stability and evolution of ferroelectric domain structures in thin films. Acta Mater. 2002, 50, 395–411. [Google Scholar] [CrossRef]

- Choi, K.J.; Biegalski, M.; Li, Y.L.; Sharan, A.; Schubert, J.; Uecker, R.; Reiche, P.; Chen, Y.B.; Pan, X.Q.; Gopalan, V.; Chen, L.Q.; Schlom, D.G.; Eom, C.B. Enhancement of ferroelectricity in strained BaTiO3 thin films. Science 2004, 306, 1005–1009. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharya, K.; James, R.D. A theory of thin films of martensitic materials with applications to microactuators. J. Mech. Phys. Solids 1999, 47, 531–576. [Google Scholar] [CrossRef]

- Koukhar, V.G.; Pertsev, N.A.; Waser, R. In-plane polarization states and their instabilities in polydomain epitaxial ferroelectric thin films. Appl. Phys. Lett. 2001, 78, 530–532. [Google Scholar] [CrossRef]

- Roytburd, A.L. Thermodynamics of polydomain heterostructures. II. Effect of microstresses. J. Appl. Phys. 1998, 83, 239–245. [Google Scholar] [CrossRef]

- Alpay, S.P.; Roytburd, A.L. Thermodynamics of polydomain heterostructures. III. Domain stability map. J. Appl. Phys. 1998, 83, 4714–4723. [Google Scholar] [CrossRef]

- Speck, J.S.; Pompe, W. Domain configurations due to multiple misfit relaxation mechanisms in epitaxial ferroelectric thin films. I. Theory. J. Appl. Phys. 1994, 76, 466–476. [Google Scholar] [CrossRef]

- Pertsev, N.A.; Koukhar, V.G. Polarization instability in polydomain ferroelectric epitaxial thin films and the formation of heterophase structures. Phys. Rev. Lett. 2000, 84, 3722–3725. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.L.; Hu, S.Y.; Liu, Z.K.; Chen, L.Q. Phase-field model of domain structures in ferroelectric thin films. Appl. Phys. Lett. 2001, 78, 3878–3880. [Google Scholar] [CrossRef]

- Huber, J.E. Micromechanical modeling of ferroelectric films. J Mater Res 2006, 21, 557–562. [Google Scholar] [CrossRef]

- Li, Y.L.; Chen, L.Q. Temperature-strain phase diagram for BaTiO3 thin films. Appl. Phys. Lett. 2006, 88, 072905:1–072905:3. [Google Scholar]

- Shu, Y.C.; Yen, J.H. Multivariant model of martensitic microstructure in thin films. Acta Mater. 2008, 56, 3969–3981. [Google Scholar] [CrossRef]

- Tsou, N.T.; Huber, J.E. Theory of compatible domain arrangements in ferroelectric thin films. In Smart Materials, Adaptive Structures and Intelligent Systems; ASME: New York, NY, USA, 2009. [Google Scholar]

- Roytburd, A.L.; Alpay, S.P.; Bendersky, L.A.; Nagarajan, V.; Ramesh, R. Three-domain architecture of stress-free epitaxial ferroelectric films. J. Appl. Phys. 2001, 89, 553–556. [Google Scholar] [CrossRef]

- Roytburd, A.L.; Kim, T.S.; Su, Q.M.; Slutsker, J.; Wuttig, M. Martensitic transformation in constrained films. Acta Mater. 1998, 46, 5095–5107. [Google Scholar] [CrossRef]

- Long-Qing, C. Phase-field method of phase transitions/domain structures in ferroelectric thin films: A review. J. Am. Ceram. Soc. 2008, 91, 1835–1844. [Google Scholar] [CrossRef]

- Pane, I.; Fleck, N.A.; Huber, J.E.; Chu, D.P. Effect of geometry upon the performance of a thin film ferroelectric capacitor. Int. J. Solids Struct. 2008, 45, 2024–2041. [Google Scholar] [CrossRef]

- Pane, I.; Fleck, N.A.; Chu, D.P.; Huber, J.E. The influence of mechanical constraint upon the switching of a ferroelectric memory capacitor. Eur. J. Mech. A-Solid 2009, 28, 195–201. [Google Scholar] [CrossRef]

- Tsou, N.; Huber, J. Compatible domain arrangements and poling ability in oriented ferroelectric films. Continuum Mech. Therm. 2010, 22, 203–219. [Google Scholar] [CrossRef]

- Soergel, E. Visualization of ferroelectric domains in bulk single crystals. Appl. Phys. B 2005, 81, 729–751. [Google Scholar] [CrossRef]

- Tagantsev, A.K.; Cross, L.E.; Fousek, J. Domains in Ferroic Crystals and Thin Films; Springer: Berlin, Germany, 2010. [Google Scholar]

- Hatano, J.; Suda, F.; Futama, H. Improved powder-pattern technique for delineating ferroelectric domains. Jpn. J. Appl. 1973, 12, 1644–1645. [Google Scholar] [CrossRef]

- Ke, C.; Wang, X.; Hu, X.P.; Zhu, S.N.; Qi, M. Nanoparticle decoration of ferroelectric domain patterns in LiNbO3 crystal. J. Appl. Phys. 2007, 101, 064107–064117. [Google Scholar] [CrossRef]

- Furuhata, Y.; Toriyama, K. New liquid-crystal method for revealing ferroelectric domains. Appl. Phys. Lett. 1973, 23, 361–362. [Google Scholar] [CrossRef]

- Tikhomirova, N.A.; Pikin, S.A.; Shuvalov, L.A.; Dontsova, E.I.; Popov, E.S.; Shilnikov, A.V.; Bulatova, L.G. Visualization of static and the dynamics of domain structure in triglycine sulfate by liquid crystals. Ferroelectrics 1980, 29, 145–156. [Google Scholar] [CrossRef]

- Nassau, K.; Levinstein, H.J.; Loiacono, G.M. The domain structure and etching of ferroelectric lithium niobate. Appl. Phys. 1965, 6, 228–229. [Google Scholar]

- Liu, X.; Terabe, K.; Nakamura, M.; Takekawa, S.; Kitamura, K. Nanoscale chemical etching of near-stoichiometric lithium tantalate. J. Appl. Phys. 2005, 97, 064308–064318. [Google Scholar] [CrossRef]

- Müller, M.; Soergel, E.; Buse, K. Visualization of ferroelectric domains with coherent light. Opt. Lett. 2003, 28, 2515–2517. [Google Scholar] [CrossRef] [PubMed]

- Pang, G.K.H.; Baba-Kishi, K.Z. Characterization of butterfly single crystals of BaTiO3 by atomic force, optical and scanning. J. Phys. D: Appl. Phys. 1998, 2846, 2846–2853. [Google Scholar] [CrossRef]

- Potnis, P.R.; Huber, J.E.; Sutter, J.P.; Hofmann, F.; Abbey, B.; Korsunsky, A.M. Mapping of domain structure in Barium Titanate single crystals by synchrotron X-ray topography. Proc. SPIE 2010, 7644A, 1–10. [Google Scholar]

- Merz, W.J. Domain properties of BaTiO3. Phys. Rev. 1952, 7, 421–422. [Google Scholar] [CrossRef]

- Merz, W.J. Domain formation and domain wall motions in ferroelectric BaTiO3 single crystals. Phys. Rev. 1954, 95, 690–698. [Google Scholar] [CrossRef]

- Mulvmill, M.; Uchino, K.; Li, Z.; Cao, W. In-situ observation of the domain configurations during the phase transitions in barium titanate. Phil. Mag. B 1996, 74, 25–36. [Google Scholar] [CrossRef]

- Ye, Z.; Dong, M. Morphotropic domain structures and phase transitions in relaxor-based piezo-/ferroelectric (1−x)Pb(Mg1/3Nb2/3)O3−xPbTiO3 single crystals. J. Appl. Phys. 2000, 87, 2312–2319. [Google Scholar] [CrossRef]

- Tu, C.-S.; Tsai, C.L.; Schmidt, V.H.; Luo, H.; Yin, Z. Dielectric, hypersonic, and domain anomalies of (1−x)Pb(Mg1/3Nb2/3)O3−xPbTiO3 single crystals. J. Appl. Phys. 2001, 89, 7901–7908. [Google Scholar]

- Glazer, A.M.; Lewis, J.G.; Kaminsky, W. An automatic optical imaging system for birefringent media. Proc. Roy. Soc. A: Math. Phys. Eng. 1996, 452, 2751–2765. [Google Scholar] [CrossRef]

- Müller, M.; Soergel, E.; Wengler, M.C.; Buse, K. Light deflection from ferroelectric domain boundaries. Appl. Phys. B: Lasers Opt. 2004, 78, 367–370. [Google Scholar] [CrossRef]

- Müller, M.; Soergel, E.; Buse, K.; Langrock, C.; Fejer, M.M. Investigation of periodically poled lithium niobate crystals by light diffraction. J. Appl. Phys. 2005, 97, 044102–044108. [Google Scholar] [CrossRef]

- Maccormack, S.; Feinberg, J. Revealing 180° domains in ferroelectric crystals by photorefractive beam coupling. Appl. Opt. 1996, 35, 5961–5963. [Google Scholar] [CrossRef] [PubMed]

- Grubsky, V.; Maccormack, S.; Feinberg, J. All-optical three-dimensional mapping of 180° domains hidden in a BaTiO3 crystal. Opt. Lett. 1996, 21, 6–8. [Google Scholar] [CrossRef] [PubMed]

- Kurimura, S.; Uesu, Y. Application of the second harmonic generation microscope to nondestructive observation of periodically poled ferroelectric domains in quasi-phase-matched wavelength converters. J. Appl. Phys. 1997, 81, 369–379. [Google Scholar] [CrossRef]

- Dolino, G. Direct observation of ferroelectric domains in TGS with second-harmonic light. Appl. Phys. Lett. 1973, 22, 123–128. [Google Scholar] [CrossRef]

- Uesu, Y.; Kurimura, S.; Yamamoto, Y. Optical second harmonic images of 90° domain structure in BaTiO3 and periodically inverted antiparallel domains in LiTaO3. Appl. Phys. Lett. 1995, 66, 2165–2175. [Google Scholar] [CrossRef]

- Bozhevolnyi, S.I.; Hvam, Jr.M.; Pedersen, K.; Laurell, F.; Karlsson, H.; Skettrup, T.; Belmonte, M. Second-harmonic imaging of ferroelectric domain walls. Appl. Phys. Lett. 1998, 73, 1814–1824. [Google Scholar] [CrossRef]

- Flörsheimer, M.; Paschotta, R.; Kubitscheck, U. Second-harmonic imaging of ferroelectric domains in LiNbO3 with micron resolution in lateral and axial directions. Appl. Phys. B-Lasers Opt. 1998, 67, 593–599. [Google Scholar] [CrossRef]

- Rosenfeldt, A.; Flörsheimer, M. Nondestructive remote imaging of ferroelectric domain distributions with high three-dimensional resolution. Appl. Phys. B-Lasers Opt. 2001, 73, 523–529. [Google Scholar] [CrossRef]

- Deng, X.; Chen, X. Domain wall characterization in ferroelectrics by using localized nonlinearities. Opt. Express 2010, 18, 15597–15602. [Google Scholar] [CrossRef] [PubMed]

- Niizeki, N.; Hasegawa, M. Direct Observation of Antiparallel 180° Domains in BaTiO3 by X-Ray Anomalous Dispersion Method. J. Phys. Soc. Jpn. 1964, 19, 550–554. [Google Scholar] [CrossRef]

- Park, B.M.; Chung, S.J.; Kim, H.S.; Si, W.; Dudley, M. Synchrotron white-beam X-ray topography of ferroelectric domains in a BaTiO3 single crystal. Phi. Mag. A 1997, 75, 611–620. [Google Scholar] [CrossRef]

- Fogarty, G.; Steiner, B.; Cronin-Golomb, M.; Laor, U.; Garrett, M.H.; Martin, J.; Uhrin, R. Antiparallel ferroelectric domains in photorefractive barium titanate and strontium barium niobate observed by high-resolution X-ray diffraction imaging. J. Opt. Soc. Am. B-Opt. Phys. 1996, 13, 2636–2648. [Google Scholar] [CrossRef]

- Roshchupkin, D.V.; Irzhak, D.V.; Antipov, V.V. Study of LiNbO3 and LiTaO3 ferroelectric domain structures using high-resolution X-ray diffraction under application of external electric field. J. Appl. Phys. 2009, 105, 024112–024117. [Google Scholar] [CrossRef]

- Rogan, R.C.; Tamura, N.; Swift, G.A.; Üstündag, E. Direct measurement of triaxial strain fields around ferroelectric domains using X-ray microdiffraction. Nat. Mater. 2003, 2, 379–381. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Gopalan, V.; Steiner, B. Direct X-ray synchrotron imaging of strains at 180° domain walls in congruent LiNbO3 and LiTaO3 crystals. Appl. Phys. Lett. 2000, 77, 2051–2061. [Google Scholar] [CrossRef]

- Jach, T.; Kim, S.; Gopalan, V.; Durbin, S.; Bright, D. Long-range strains and the effects of applied field at 180° ferroelectric domain walls in lithium niobate. Phys. Rev. B 2004, 69, 1–9. [Google Scholar] [CrossRef]

- Hall, D.A.; Mori, T.; Withers, P.J.; Kungl, H.; Hoffmann, M.J.; Wright, J. Domain switching in rhombohedral PZT ceramics under electrical and mechanical loading. Mater. Sci. Technol. 2008, 24, 927–933. [Google Scholar] [CrossRef]

- Daniels, J.E.; Finlayson, T.R.; Davis, M.; Damjanovic, D.; Studer, A.J.; Hoffman, M.; Jones, J.L. Neutron diffraction study of the polarization reversal mechanism in [111]c-oriented Pb(Zn1/3Nb2/3)O3-xPbTiO3. J. Appl. Phys. 2007, 101, 104108. [Google Scholar] [CrossRef]

- Rogan, R.C.; Üstündag, E.; Clausen, B.R.; Daymond, M.R. Texture and strain analysis of the ferroelastic behavior of Pb(Zr,Ti)O3 by in situ neutron diffraction. J. Appl. Phys. 2003, 93, 4104–4108. [Google Scholar] [CrossRef]

- Jones, J.L.; Slamovich, E.B.; Bowman, K.J. Domain texture distributions in tetragonal lead zirconate titanate by x-ray and neutron diffraction. J. Appl. Phys. 2005, 97, 034113. [Google Scholar] [CrossRef]

- Hall, D.A.; Evans, J.D.S.; Oliver, E.C.; Withers, P.J.; Mori, T. In-situ neutron diffraction study of the rhombohedral to orthorhombic phase transformation in lead zirconate titanate ceramics produced by uniaxial compression. Phil. Mag. Lett. 2007, 87, 41–52. [Google Scholar] [CrossRef]

- Jones, J.L. The use of diffraction in the characterization of piezoelectric materials. J. Electroceram. 2007, 19, 69–81. [Google Scholar] [CrossRef]

- Bihan, R.L. Study of ferroelectric and ferroelastic domain structures by scanning electron microscopy. Ferroelectrics 1989, 97, 19–46. [Google Scholar] [CrossRef]

- Gruner, D.; Shen, Z. Direct Scanning Electron Microscopy Imaging of Ferroelectric Domains After Ion Milling. J. Am. Ceram. Soc. 2010, 93, 48–50. [Google Scholar] [CrossRef]

- Rosenman, G.; Skliar, a.; Lareah, I.; Angert, N.; Tseitlin, M.; Roth, M. Observation of ferroelectric domain structures by secondary-electron microscopy in as-grown KTiOPO4 crystals. Phys. Rev. B-Condens. Matter 1996, 54, 6222–6226. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.; Cao, W. Direct Observation of Ferroelectric Domains in LiTaO3 Using Environmental Scanning Electron Microscopy. Phys. Rev. Lett. 1997, 79, 2558–2561. [Google Scholar] [CrossRef]

- Zhu, S.; Cao, W. Imaging of 180° ferroelectric domains in LiTaO3 by means of scanning electron microscopy. Phys. Status Solid A-Appl. Mat. 1999, 173, 495–502. [Google Scholar] [CrossRef]

- Burnett, T.L.; Comyn, T.P.; Merson, E.; Bell, A.J.; Mingard, K.; Hegarty, T.; Cain, M. Electron backscatter diffraction as a domain analysis technique in BiFeO3-PbTiO3 single crystals. IEEE T. Ultrason. Ferroelectr. 2008, 55, 957–962. [Google Scholar] [CrossRef]

- Farooq, M.U.; Villaurrutia, R.; MacLaren, I.; Burnett, T.L.; Comyn, T.P.; Bell, A.J.; Kungl, H.; Hoffmann, M.J. Electron backscatter diffraction mapping of herringbone domain structures in tetragonal piezoelectrics. J. Appl. Phys. 2008, 104, 024111:1–024111:8. [Google Scholar] [CrossRef]

- Zhang, B.Y.; Jiang, F.M.; Yang, Y.; Yin, Q.R.; Kojima, S. Electron acoustic imaging of BaTiO3 single crystals. J. Appl. Phys. 1996, 80, 1916–1918. [Google Scholar] [CrossRef]

- Bursill, L.A.; Lin, P.J. Microdomains observed at the ferroelectric/paraelectric phase transition of barium titanate. Nature 1984, 311, 550–552. [Google Scholar] [CrossRef]

- Hu, Y.H.; Chan, H.M.; Wen, Z.X.; Harmer, M.P. Scanning Electron Microscopy and Transmission Electron Microscopy Study of Ferroelectric Domains in Doped BaTiO3. J. Am. Ceram. Soc. 1986, 69, 594–602. [Google Scholar] [CrossRef]

- Hilton, A.D.; Randall, C.A.; Barber, D.J.; Shrout, T.R. TEM Studies of Pb (Mg1/3Nb2/3) O3PbTiO3 Ferroelectric Relaxors. Ferroelectrics 1989, 93, 379–386. [Google Scholar] [CrossRef]

- Woodward, D.; Knudsen, J.; Reaney, I. Review of crystal and domain structures in the PbZrxTi(1−x)O3 solid solution. Phys. Rev. B 2005, 72, 1–8. [Google Scholar] [CrossRef]

- Stennett, M.C.; Reaney, I.M.; Miles, G.C.; Woodward, D.I.; West, A.R.; Kirk, C.A.; Levin, I. Dielectric and structural studies of Ba2MTi2Nb3O15 (BMTNO15, M = Bi3+, La3+, Nd3+, Sm3+, Gd3+) tetragonal tungsten bronze-structured ceramics. J. Appl. Phys. 2007, 101, 104114:1–104114:7. [Google Scholar] [CrossRef]

- Floquet, N.; Valot, C.M.; Mesnier, M.T.; Niepce, J.C.; Normand, L.; Thorel, A.; Kilaas, R. Ferroelectric domain walls in BaTiO3: Fingerprints in XRPD diagrapms and quantitative HRTEM image analysis. J. Phys. III France 1997, 7, 1105–1128. [Google Scholar] [CrossRef] [Green Version]

- Tsai, F.; Khiznichenko, V.; Cowley, J. High-resolution electron microscopy of 90° ferroelectric domain boundaries in BaTiO3 and Pb(Zr0.52Ti0.48)O3. Ultramicroscopy 1992, 45, 55–63. [Google Scholar] [CrossRef]

- Foeth, M.; Sfera, A.; Stadelmann, P. Pa A comparison of HREM and weak beam transmission electron microscopy for the quantitative measurement of the thickness of ferroelectric domain walls. Jpn. Soc. Electron Microsc. 1999, 48, 717–723. [Google Scholar] [CrossRef]

- Jia, C.L.; Urban, K.; Mertin, M.; Hoffmann, S.; Waser, R. The structure and formation of nanotwins in BaTiO3 thin films. Phil. Mag. A 1998, 77, 923–939. [Google Scholar] [CrossRef]

- Bonnell, D.A. Scanning Probe Microscopy and Spectroscopy: Theory, Techniques, and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Kalinin, S.V.; Rodriguez, B.J.; Jesse, S.; Karapetian, E.; Mirman, B.; Eliseev, E.A.; Morozovska, A.N. Nanoscale Electromechanics of Ferroelectric and Biological Systems: A New Dimension in Scanning Probe Microscopy. Annu. Rev. Mater. Res. 2007, 37, 189–238. [Google Scholar] [CrossRef]

- Kalinin, S.V.; Morozovska, A.N.; Chen, L.Q.; Rodriguez, B.J. Local polarization dynamics in ferroelectric materials. Rep. Progr. Phys. 2010, 73, 056502–056569. [Google Scholar] [CrossRef]

- Gruverman, a.; Kholkin, a. Nanoscale ferroelectrics: processing, characterization and future trends. Rep. Progr. Phys. 2006, 69, 2443–2474. [Google Scholar] [CrossRef]

- Eng, L.M.; Friedrich, M.; Fousek, J.; Günter, P. Deconvolution of topographic and ferroelectric contrast by noncontact and friction force microscopy. J. Vac. Sci. Technol. B 1996, 14, 1191–1196. [Google Scholar] [CrossRef]

- Nakatani, N. Microscopic structure of cleavage surface of ferroelectric tri-glycine sulfate. Jpn. J. Appl. Phys. 1979, 18, 491–500. [Google Scholar] [CrossRef]

- Lüthi, R.; Haefke, H.; Meyer, K.; Meyer, E.; Howald, L.; Gijntherodt, H. Surface and domain structures scanning force microscopy of ferroelectric crystals studied with scanning force microscopy. J. Appl. Phys. 1993, 74, 7461–7471. [Google Scholar] [CrossRef]

- Munoz-Saldana, J.; Schneider, G.A.; Eng, L.M. Stress induced movement of ferroelastic domain walls in BaTiO3 single crystals evaluated by scanning force microscopy. Surface Sci. 2001, 480, L402–L410. [Google Scholar] [CrossRef]

- Bluhm, H.; Schwarz, U.; Wiesendanger, R. Origin of the ferroelectric domain contrast observed in lateral force microscopy. Phys. Rev. B 1998, 57, 161–169. [Google Scholar] [CrossRef]

- Bluhm, H.; Wadas, A.; Wiesendanger, R.; Roshko, A.; Aust, J.A.; Nam, D. Imaging of domain-inverted gratings in LiNbO3 by electrostatic force microscopy. Appl. Phys. Lett. 1997, 71, 146–156. [Google Scholar] [CrossRef]

- Jungk, T.; Soergel, E. Contrast Mechanism for Visualization of Ferroelectric Domains with Scanning Force Microscopy. Ferroelectrics 2006, 334, 29–34. [Google Scholar] [CrossRef]

- Kalinin, S.; Bonnell, D. Local potential and polarization screening on ferroelectric surfaces. Phys. Rev. B 2001, 63, 1–13. [Google Scholar] [CrossRef]

- Cho, Y.; Kazuta, S.; Matsuura, K. Scanning nonlinear dielectric microscopy with nanometer resolution. Appl. Phys. Lett. 1999, 75, 2833–2838. [Google Scholar] [CrossRef]

- Cho, Y.; Ohara, K. Higher-order nonlinear dielectric microscopy. Appl. Phys. Lett. 2001, 79, 3842–3845. [Google Scholar] [CrossRef]

- Zhao, X.; Dai, J.Y.; Wang, J.; Chan, H.L.W.; Choy, C.L.; Wan, X.M.; Luo, H.S. Domain structure and evolution in (PbMg1/3Nb2/3O3)0.75(PbTiO3)0.25 single crystal studied by temperature-dependent piezoresponse force microscopy. J. Appl. Phys. 2005, 97, 0941071–0941074. [Google Scholar]

- Shvartsman, V.; Kholkin, a. Domain structure of 0.8Pb(Mg1/3Nb2/3)O3-0.2PbTiO3 studied by piezoresponse force microscopy. Phys. Rev. B 2004, 69, 1–5. [Google Scholar] [CrossRef]

- Park, B.M.; Chung, S.J. Optical, Electron Microscopic, and X-ray Topographic Studies of Ferroic Domains in Barium Titanate Crystals Grown from High-Temperature Solution. J. Am. Ceram. Soc. 1994, 77, 3193–3201. [Google Scholar] [CrossRef]

- Burnett, T.L.; Weaver, P.M.; Blackburn, J.F.; Stewart, M.; Cain, M.G. Correlation of electron backscatter diffraction and piezoresponse force microscopy for the nanoscale characterization of ferroelectric domains in polycrystalline lead zirconate titanate. J. Appl. Phys. 2010, 108, 042001:1–042001:7. [Google Scholar] [CrossRef]

- Gupta, P.; Jain, H.; Williams, D.B.; Kalinin, S.V.; Shin, J.; Jesse, S.; Baddorf, A.P. Observation of ferroelectricity in a confined crystallite using electron-backscattered diffraction and piezoresponse force microscopy. Appl. Phys. Lett. 2005, 87, 172903:1–172903:3. [Google Scholar] [CrossRef]

- Garcia, R.E.; Huey, B.D.; Blendell, J.E. Virtual piezoforce microscopy of polycrystalline ferroelectric films. J. Appl. Phys. 2006, 100, 064105:1–064105:10. [Google Scholar]

- Lowe, M.; Hegarty, T.; Mingard, K.; Li, J.; Cain, M. Crystallographic mapping of ferroelectric thin films using piezoresponse force microscopy and electron backscatter diffraction. J. Phys. Confer. Ser. 2008, 126, 012011. [Google Scholar] [CrossRef]

- Yang, B.; Park, N.J.; Seo, B.I.; Oh, Y.H.; Kim, S.J.; Hong, S.K.; Lee, S.S.; Park, Y.J. Nanoscale imaging of grain orientations and ferroelectric domains in (Bi(1-x)Lax)4Ti3O12 films for ferroelectric memories. Appl. Phys. Lett. 2005, 87, 062902. [Google Scholar] [CrossRef]

- Cheng, S.-Y.; Ho, N.-J.; Lu, H.-Y. Micro-indentation-induced domain switching in tetragonal barium titanate. J. Am. Ceram. Soc. 2008, 91, 3721–3727. [Google Scholar] [CrossRef]

- Kuo, H. Y.; Shu, Y. C.; Chen, H. Z.; Hsueh, C. J.; Wang, C. H.; Chu, Y. H. Domain pattern and piezoelectric response across polymorphic phase transition in strained bismuth ferrite films. Appl. Phys. Lett. 2010, 97, 242906. [Google Scholar] [CrossRef]

- Potnis, P.R.; Huber, J.E.; Sutter, J.P. Synchrotron mapping of laminate microstructures in barium titanate single crystals. In Presentedat the 10th European Conference on Applications of Polar Dielectrics (ISAF-ECAPD-10), Edinburgh, UK, 9–12 August 2010.

© 2011 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Potnis, P.R.; Tsou, N.-T.; Huber, J.E. A Review of Domain Modelling and Domain Imaging Techniques in Ferroelectric Crystals. Materials 2011, 4, 417-447. https://doi.org/10.3390/ma4020417

Potnis PR, Tsou N-T, Huber JE. A Review of Domain Modelling and Domain Imaging Techniques in Ferroelectric Crystals. Materials. 2011; 4(2):417-447. https://doi.org/10.3390/ma4020417

Chicago/Turabian StylePotnis, Prashant R., Nien-Ti Tsou, and John E. Huber. 2011. "A Review of Domain Modelling and Domain Imaging Techniques in Ferroelectric Crystals" Materials 4, no. 2: 417-447. https://doi.org/10.3390/ma4020417