Mechanical Properties of Titanium Nitride Nanocomposites Produced by Chemical Precursor Synthesis Followed by High-P,T Treatment

Abstract

:1. Introduction

| Element wt% | C | H | N |

|---|---|---|---|

| a-Ti3N4 precursor | |||

| % Theoretical | - | - | 28.05 |

| % Found 1 | 3.39 | 0.12 | 26.25 |

| % Found 2 | 3.82 | 0.93 | 27.38 |

| % Found 3 | 3.97 | 0.60 | 26.48 |

| % Found 4 | 4.34 | 0.60 | 27.14 |

2. Experimental Procedures

| Sample | T (˚C) | t (h) | Number of measurements | Hardness (GPa) | ||

|---|---|---|---|---|---|---|

| Maximum | Minimum | Mean (1σ) * | ||||

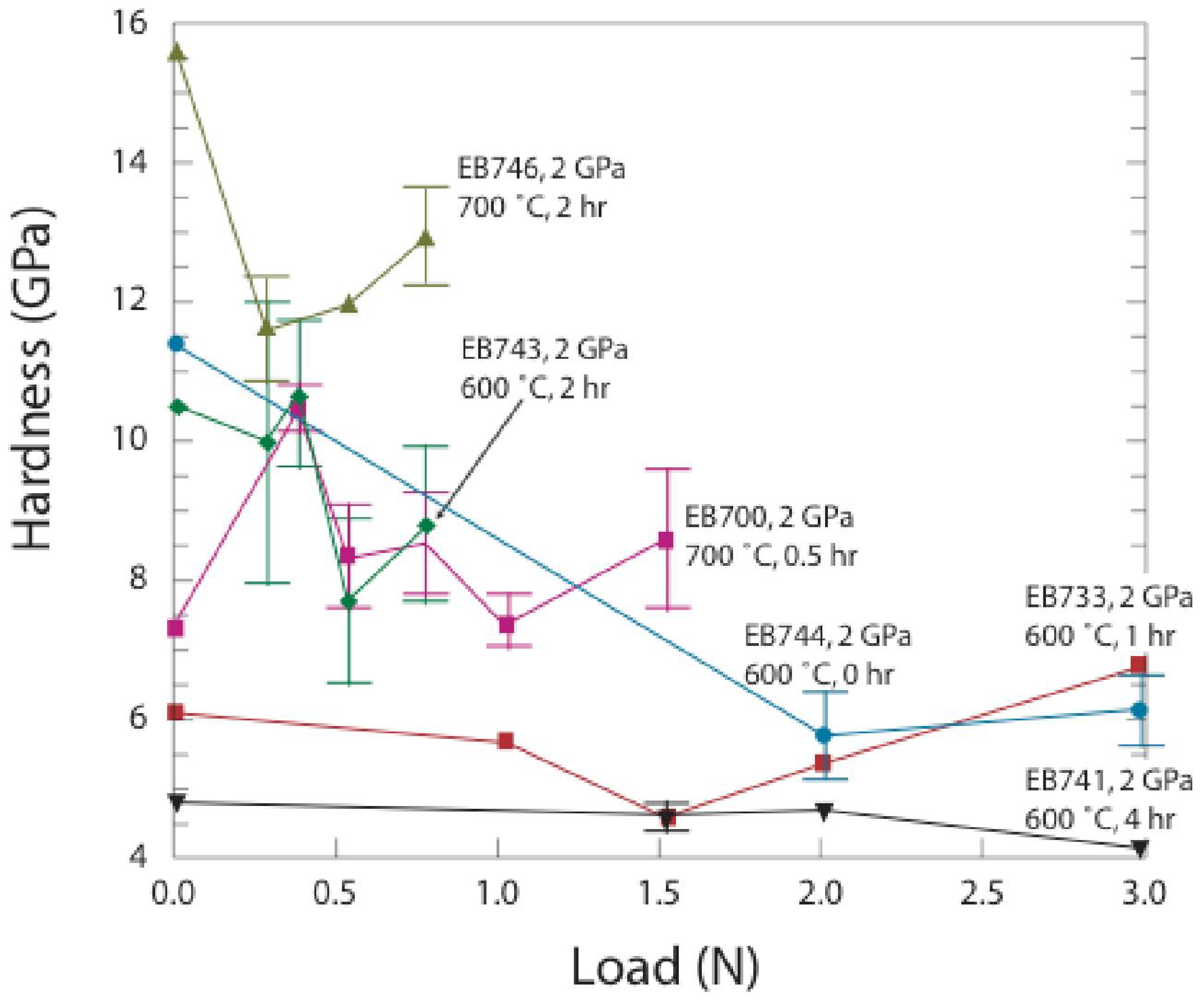

| EB741 | 700 | 4 | 7 | 4.8 | 2.8 | 4.0 (0.7) |

| EB746 | 700 | 2 | 12 | 20.8 | 10.6 | 13.3 (3.1) |

| EB747 | 700 | 1 | 22 | 18.2 | 6.1 | 11.0 (3.0) |

| EB700 | 700 | 0.5 | 22 | 14.0 | 5.2 | 9.4 (2.5) |

| EB732 | 600 | 4 | 7 | 8.3 | 5.8 | 7.2 (0.7) |

| EB743 | 600 | 2 | 17 | 8.0 | 3.9 | 6.2 (1.7) |

| EB733 | 600 | 1 | 4 | 6.8 | 4.6 | 5.6 (0.9) |

| EB734 | 600 | 0.5 | 4 | 6.1 | 4.0 | 4.9 (0.9) |

| EB744 | 600 | 0 | 7 | 7.0 | 5.2 | 6.1 (0.5) |

| EB699 | 500 | 3 | 6 | 12.7 | 6.7 | 8.0 (2.3) |

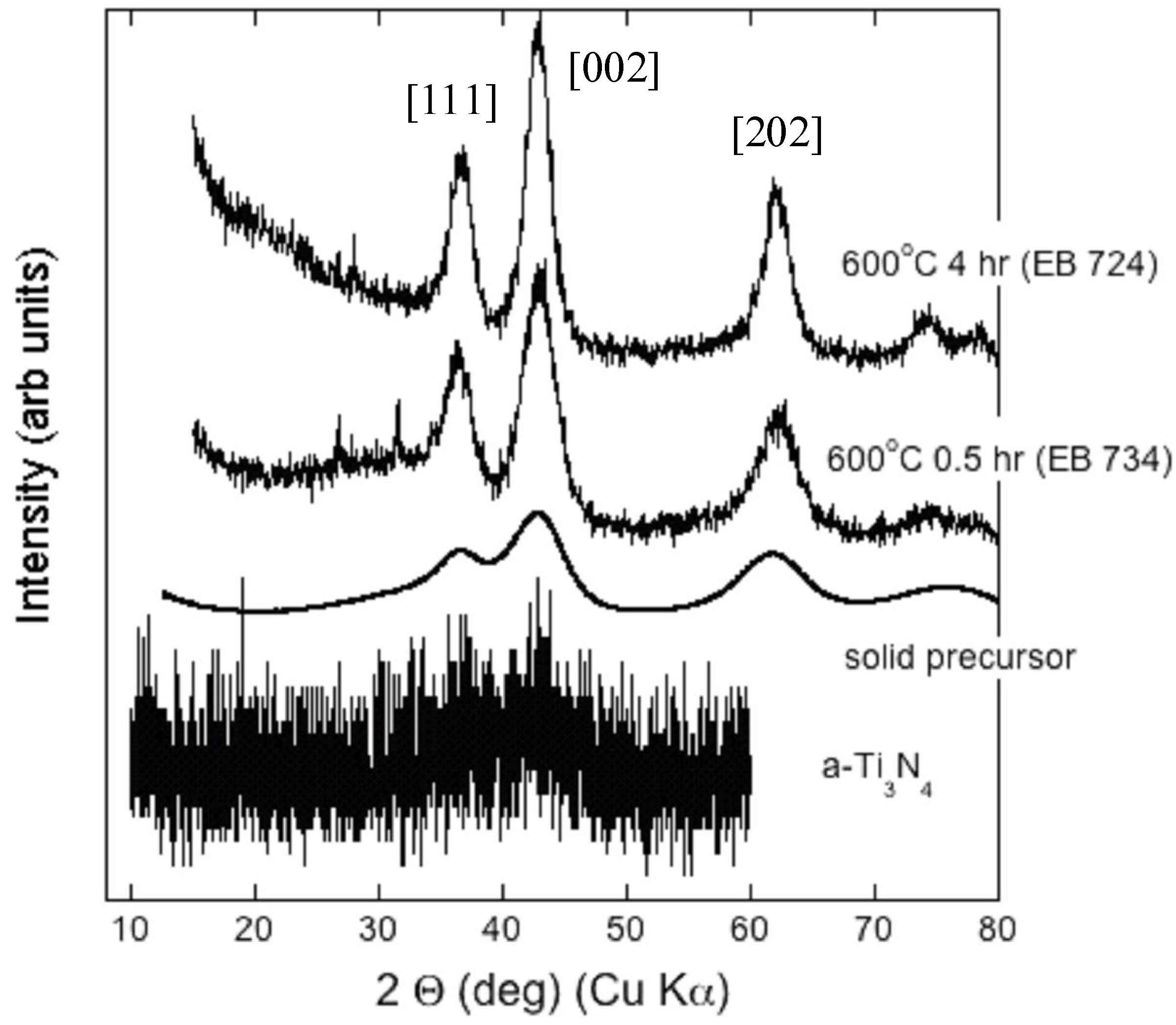

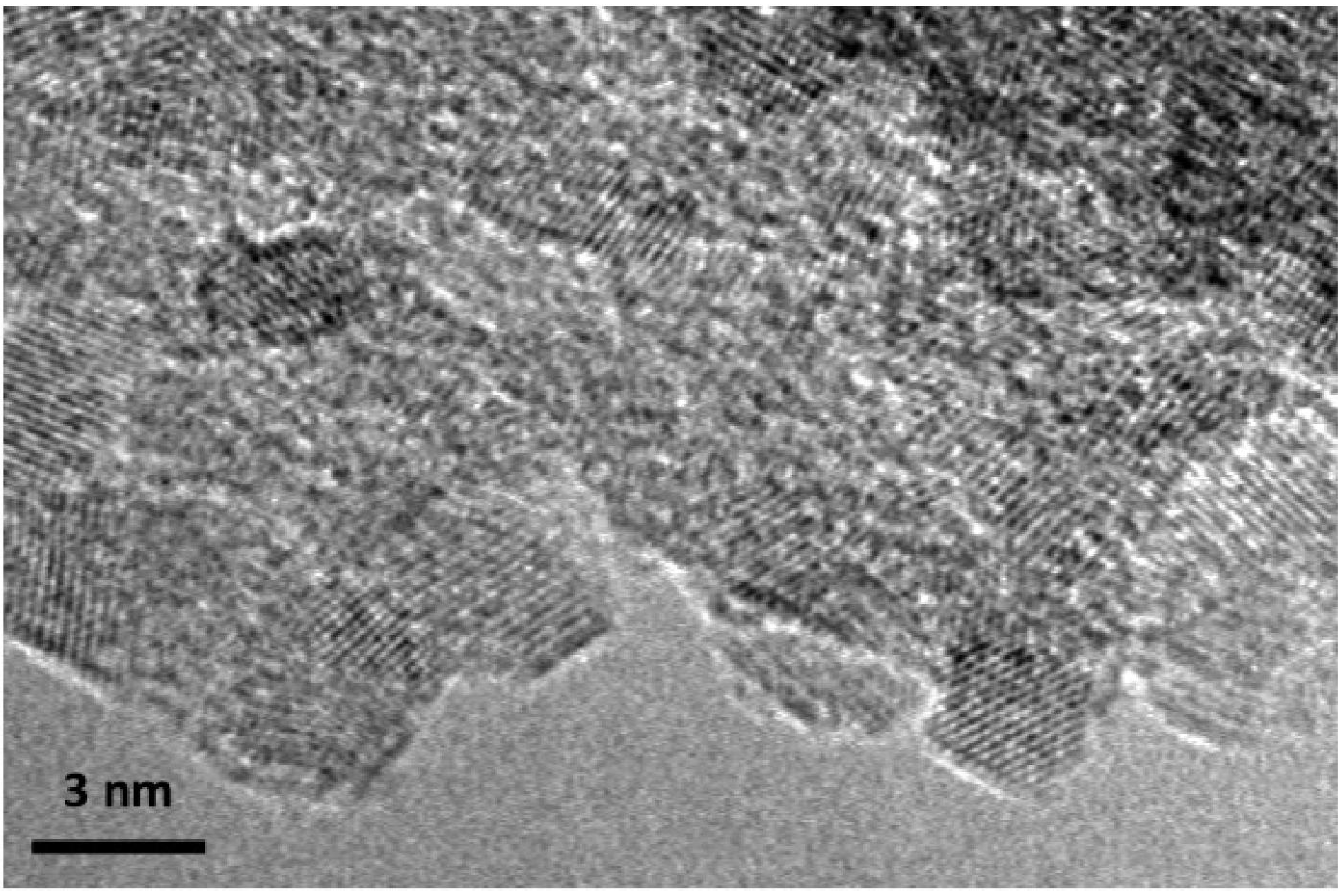

3. Results and Discussion

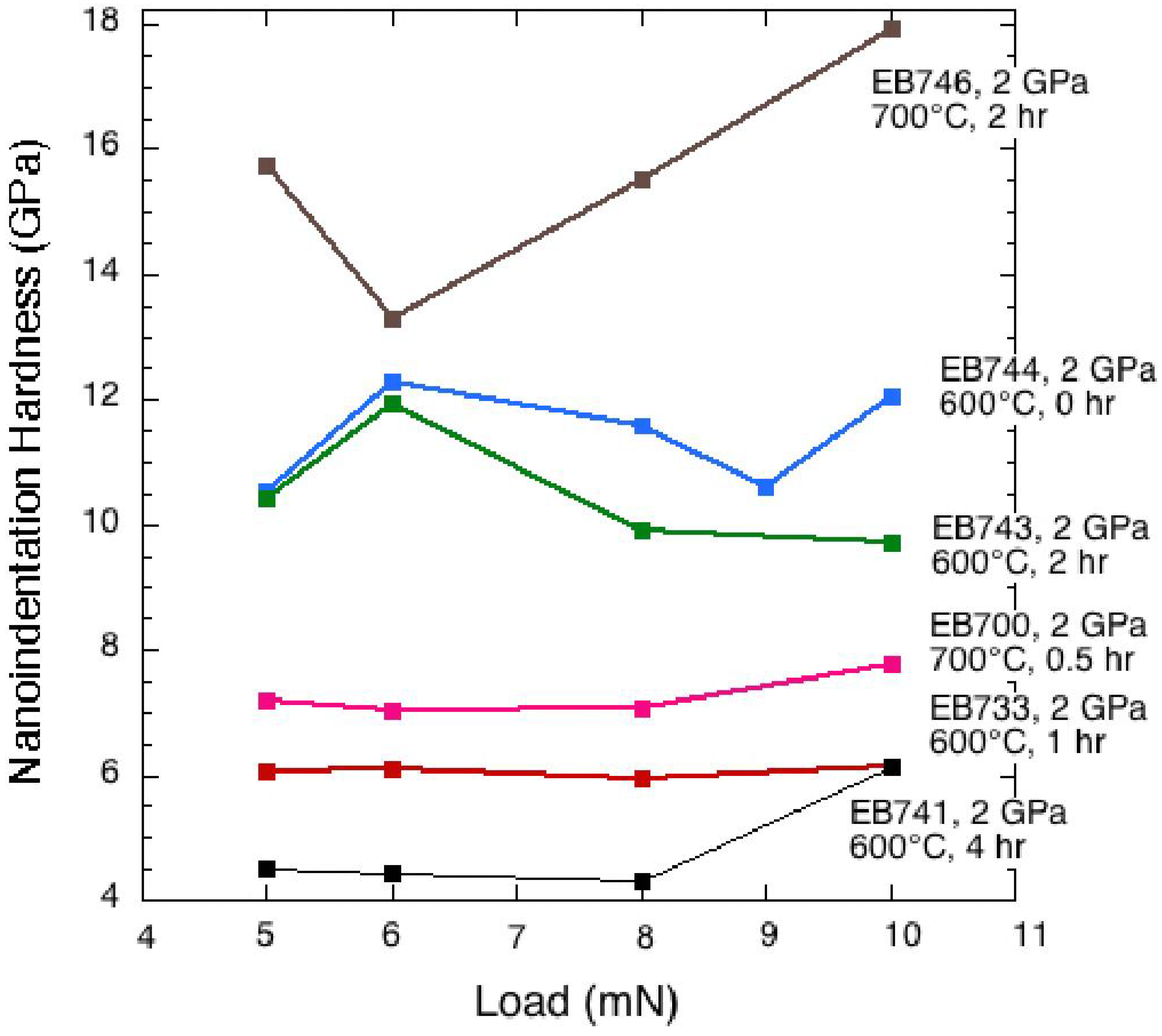

| Sample | T (˚C) | t (h) | Load (mN) | Hardness (GPa) | |

|---|---|---|---|---|---|

| Mean * | |||||

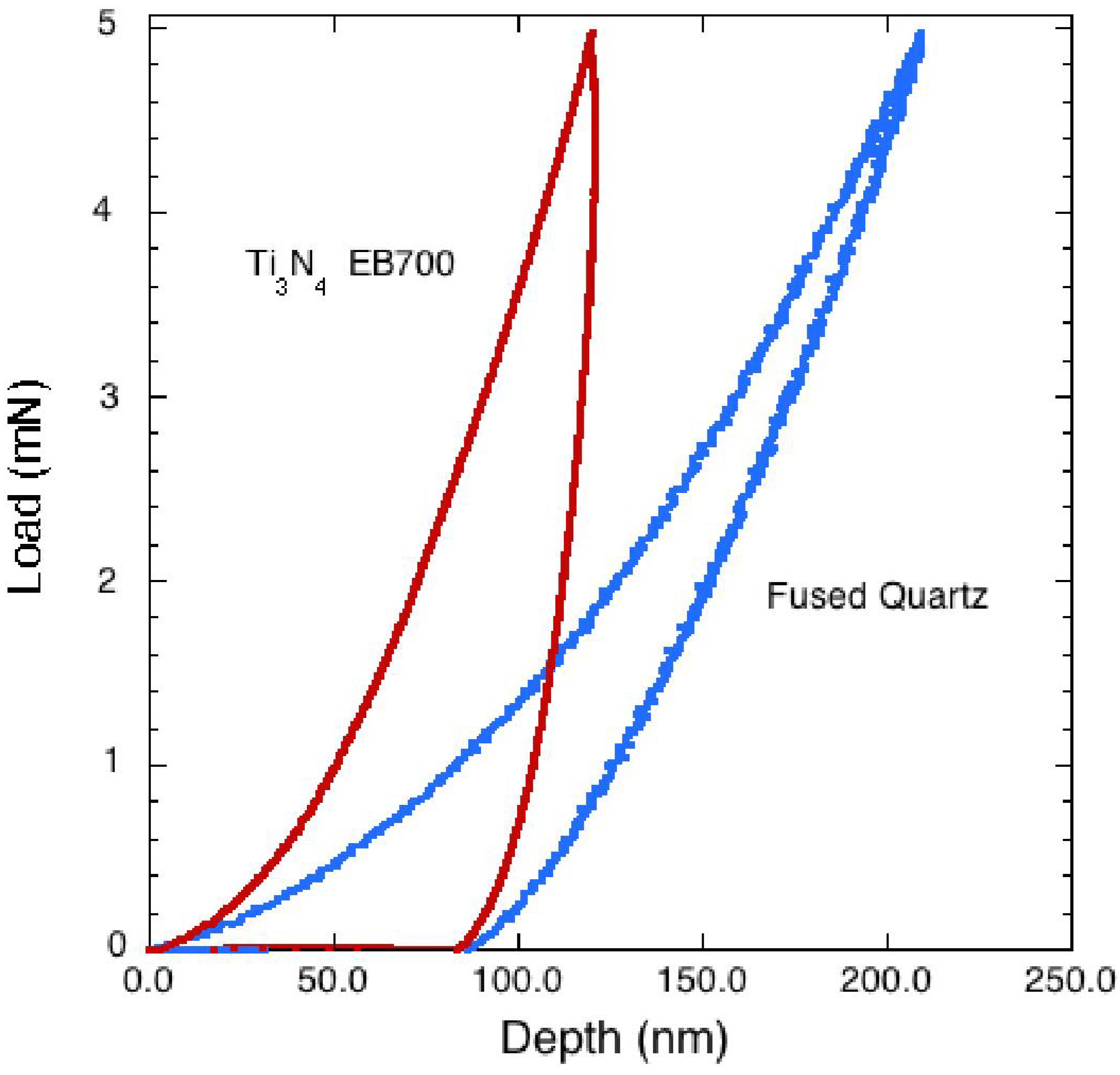

| EB741 | 700 | 4 | 5 | 4.49 | |

| 6 | 4.44 | ||||

| 8 | 4.32 | ||||

| 10 | 6.14 | ||||

| 4.85 (0.86) | |||||

| EB746 | 700 | 2 | 5 | 15.75 | |

| 6 | 13.29 | ||||

| 8 | 15.53 | ||||

| 10 | 17.91 | ||||

| 15.62 (1.89) | |||||

| EB700 | 700 | 0.5 | 5 | 7.19 | |

| 6 | 7.03 | ||||

| 8 | 7.07 | ||||

| 10 | 7.79 | ||||

| 7.27 (0.35) | |||||

| EB732 | 600 | 4 | 5 | 15.28 | |

| 6 | 37.6 | ||||

| 8 | 25.88 | ||||

| 10 | 27.31 | ||||

| 26.52 (9.13) | |||||

| EB743 | 600 | 2 | 5 | 10.42 | |

| 6 | 11.95 | ||||

| 8 | 9.92 | ||||

| 10 | 9.71 | ||||

| 10.50 (1.01) | |||||

| EB733 | 600 | 1 | 5 | 6.08 | |

| 6 | 6.11 | ||||

| 8 | 5.96 | ||||

| 10 | 6.14 | ||||

| 6.07 (0.08) | |||||

| EB744 | 600 | 0 | 5 | 10.52 | |

| 6 | 12.27 | ||||

| 8 | 11.6 | ||||

| 9 | 10.6 | ||||

| 10 | 12.06 | ||||

| 11.41 (0.81) | |||||

| Sample #s | T (°C) | t (h) | E (GPa) | Number of measurements | Klc(1) MPa·m1/2 | Klc(2) MPa·m1/2 | Klc(3) MPa·m1/2 |

|---|---|---|---|---|---|---|---|

| Mean ** | Mean ** | Mean ** | |||||

| EB741 | 700 | 4 | 102.26 | 4 | 0.84 (0.06) | 1.94 (0.69) | 1.69 (0.33) |

| EB700 | 700 | 0.5 | 486.85 | 3 | 1.88 (0.05) | 8.26 (2.23) | 4.39 (0.52) |

| EB733 | 600 | 1 | 119.43 | 4 | 0.89 (0.16) | 1.65 (0.70) | 1.61 (0.51) |

| Sample # | T (°C) | t (h) | Number of measurements | Klc(1) MPa·m1/2 | Klc(2)) MPa·m1/2 | Klc(3) MPa·m1/2 |

|---|---|---|---|---|---|---|

| Mean * | Mean * | Mean * | ||||

| EB741 | 700 | 4 | 19 | 2.58 (0.46) | 7.09 (2.97) | 3.51 (0.68) |

| EB746 | 700 | 2 | 4 | 2.35 (0.41) | 3.99 (0.57) | 3.15 (0.58) |

| EB747 | 700 | 1 | 30 | 2.23 (0.30) | 4.64 (1.07) | 3.03 (0.46) |

| EB700 | 700 | 0.5 | 35 | 2.79 (0.37) | 7.01 (2.14) | 3.84 (0.54) |

| EB732 | 600 | 4 | 3 | 3.55 (0.78) | 10.59 (4.31) | 4.91 (0.96) |

| EB743 | 600 | 2 | 26 | 2.26 (0.22) | 4.92 (0.85) | 3.11 (0.35) |

| EB733 | 600 | 1 | 6 | 2.56 (0.54) | 5.87 (1.37) | 3.47 (0.79) |

| EB734 | 600 | 0.5 | 5 | 2.87 (0.72) | 8.84 (8.84) | 3.92 (0.99) |

| EB744 | 600 | 0 | 7 | 2.83 (0.57) | 6.29 (3.01) | 3.37 (1.04) |

| EB699 | 500 | 3 | 6 | 2.30 (0.29) | 4.82 (1.29) | 3.08 (0.47) |

4. Conclusions

Acknowledgements

References

- Oyoma, S.T. The Chemistry of Transition Metal Nitrides and Carbides; Blackie Academic: Glasgow, UK, 1996. [Google Scholar]

- Riedel, R. Handbook of Hard Ceramic Materials; Wiley VCH: New York, NY, USA, 2000. [Google Scholar]

- Toth, L.E. Transition Metal Carbides and Nitrides; Academic Press: New York, NY, USA, 1971. [Google Scholar]

- Ching, W.Y.; Mo, S.-D.; Ouyang, L.; Tanaka, I.; Yoshiya, M. Prediction of the new spinel phase of Ti3N4 and SiTi2N4 and the metal-insulator transition. Phys. Rev. B 2000, 61, 10609–10614. [Google Scholar]

- Ching, W.Y.; Mo, S.-D.; Tanaka, I.; Yoshiya, M. Prediction of spinel structure and properties of single and double nitrides. Phys. Rev. B 2001, 63, 1–4. [Google Scholar]

- Ching, W.Y.; Xu, Y.-N.; Rulis, P. Structure and properties of spinel Fe3N4 and comparison to zinc blende FeN. Appl. Phys. Lett. 2002, 80, 2904–2906. [Google Scholar] [CrossRef]

- Kroll, P. Advances in computation of temperature-pressure phase diagrams of high-pressure nitrides. Key Eng. Mater. 2009, 403, 77–80. [Google Scholar] [CrossRef]

- Kroll, P.; Schröder, T.; Peters, M. Prediction of novel phases of tantalum(V) nitride and tungsten(VI) nitride that can be synthesized under high pressure and high temperature. Angew. Chem. Int. Ed. 2005, 44, 4249–4254. [Google Scholar] [CrossRef]

- Stampfl, C.; Freeman, A.J. Stable and metastable structures of the multiphase tantalum nitride system. Phys. Rev. B 2005, 71, 1–5. [Google Scholar] [CrossRef]

- Baxter, D.V.; Chisholm, M.H.; Gama, G.J.; DiStasi, V.F.; Hector, A.L.; Parkin, I.P. Molecular routes to metal-carbides, -nitrides, and -oxides. 2. Studies of the ammonolysis of metal dialkylamides and hexamethyldisilylamides. Chem. Mater. 1996, 8, 1222–1228. [Google Scholar]

- Brown, G.M.; Maya, L. Ammonolysis products of the dialkylamides of titanium, zirconium, and niobium as precursors to metal nitrides. J. Am. Ceram. Soc. 1988, 71, 78–82. [Google Scholar] [CrossRef]

- Jackson, A.W.; Hector, A.L.; Shebanova, O.; McMillan, P.F. Amorphous and nanocrystalline titanium nitride and carbonitride materials obtained by solution phase ammonolysis of Ti(NMe2)4. J. Solid State Chem. 2006, 179, 1383–1393. [Google Scholar] [CrossRef]

- Li, J.; Dzivenko, D.; Zerr, A.; Fasel, C.; Zhou, Y.; Riedel, R. Synthesis of nanocrystalline Zr3N4 and Hf3N4 powders from metal dialkylamides. Z. Anorg. Allg. Chem. 2005, 631, 1449–1455. [Google Scholar] [CrossRef]

- Banaszak Holl, M.M.; Wolczanki, P.T.; van Duyne, G.D. Ladder structure of [(tBuCH2)2TaN]5NH3.2C7H8] and its relationship to cubic TaN. J. Am. Chem. Soc. 1990, 112, 7989–7994. [Google Scholar]

- Fricke, M.; Nonninger, R.; Schmidt, H. Production of Si3N4/TiN nanocomposites. Adv. Eng. Mater. 2000, 2, 647–652. [Google Scholar] [CrossRef]

- Phinichka, N.; Chandra, R.; Barber, Z.H. Synthesized nanocomposite TiN/a-SiNx films. J. Metals Mater Miner. 2003, 13, 7–15. [Google Scholar]

- Veprek, S. Superhard nanocomposites: Design concept, properties, present and future industrial applications. Eur. Phys. J. Appl. Phys. 2004, 28, 313–317. [Google Scholar] [CrossRef]

- Kume, S.; Suzuki, K.; Yoshida, H.; Sakakibara, S.; Yamada, Y.; Fukuyi, T.; Akiyama, S.; Yamamoto, M.; Kakagawa, H.; Kanetake, N. Ultrahigh pressure hot isostatic pressing of TiN-coated diamond/TiN/alumina composites under thermodynamically unstable condition for diamonds. Int. J. Refract. Metals Hard Mater. 2001, 19, 17–22. [Google Scholar] [CrossRef]

- Li, S.Z.; Fang, Q.F.; Liu, Q.; Li, Z.S.; Gao, J.; Nesladek, P.; Prochazka, J.; Veprek-Heijman, M.G.J.; Veprek, S. Thermally activated relaxation processes in superhard nc-TiN/a-Si3N4 and nc-(Ti1−xAlx)N/a-Si3N4 nanocomposites studied by means of internal friction measurements. Compos. Sci. Technol. 2005, 65, 735–740. [Google Scholar] [CrossRef]

- QiLiang, H.; Juan, C.; Wei, P.; Jian, C.; Jie, L. In situ processing of TiN/Si3N4, composites by Ti-Si3N4 solid state reaction. Mater. Lett. 1997, 31, 221–225. [Google Scholar] [CrossRef]

- Crowhurst, J.C.; Goncharov, A.F.; Sadigh, B.; Evans, C.L.; Morrall, P.G.; Ferreira, J.L.; Nelson, A.J. Synthesis and characterization of the nitrides of platinum and iridium. Science 2005, 311, 1275–1278. [Google Scholar] [CrossRef]

- Friedrich, A.; Winkler, B.; Bayarjargal, L.; Morgenroth, W.; Arellano, A.E.J.; Milman, V.; Refson, K.; Kunz, M.; Chen, K. Novel rhenium nitrides. Phys. Rev. Lett. 2010, 105, 1–4. [Google Scholar] [CrossRef]

- Kinski, I.; Miehe, G.; Heymann, G.; Theissmann, R.; Riedel, R.; Huppertz, H. High-pressure synthesis of a gallium oxonitride with a spinel-type structure. Z. Naturforsch 2005, 60b, 831–836. [Google Scholar]

- Kinski, I.; Schieba, F.; Riedel, R. Advances in gallium oxonitride ceramics: A new class of materials in the system Ga-O-N. Adv. Eng. Mater. 2005, 7, 921–927. [Google Scholar] [CrossRef]

- Leinenweber, K.; O’Keeffe, M.; Somayazulu, M.; Hubert, H.; McMillan, P.F.; Wolf, G.H. Synthesis and structure refinement of the spinel, γ-Ge3N4. Chem. Eur. J. 1999, 5, 3076–3078. [Google Scholar] [CrossRef]

- Young, A.F.; Sanloup, C.; Gregoryanz, E.; Scandolo, S.; Hemley, R.J.; Mao, H.-K. Synthesis of novel transition metal nitrides IrN2 and OsN2. Phys. Rev. Lett. 2006, 96, 1–4. [Google Scholar] [CrossRef]

- Zerr, A.; Miehe, G.; Riedel, R. Synthesis of cubic zirconium and hafnium nitride having Th3P4 structure. Nat. Mater. 2003, 2, 185–189. [Google Scholar] [CrossRef] [PubMed]

- Zerr, A.; Miehe, G.; Serghiou, G.; Schwarz, M.; Kroke, E.; Riedel, R.; Fuess, H.; Kroll, P.; Boehler, R. Synthesis of cubic silicon nitride. Nat. Mater. 1999, 400, 340–342. [Google Scholar]

- Zerr, A.; Riedel, R.; Sekine, T.; Lowther, J.E.; Ching, W.-Y.; Tanaka, I. Recent advances in new hard high-pressure nitrides. Adv. Mater. 2006, 18, 2933–2948. [Google Scholar] [CrossRef]

- Soignard, E.; Machon, D.; McMillan, P.F.; Dong, J.; Xu, B.; Leinenweber, K. Spinel-structured gallium oxynitride (Ga3O3N): An experimental and theoretical study. Chem. Mater. 2005, 17, 5465–5472. [Google Scholar] [CrossRef]

- Friedrich, A.; Winkler, B.; Bayarjargal, L.; Arellano, A.E.J.; Morgenroth, W.; Biehler, J.; Schröder, F.; Yan, J.; Clark, S.M. In situ observation of the reaction of tantalum with nitrogen in a laser heated diamond anvil cell. J. Alloy Comp. 2010, 502, 5–12. [Google Scholar] [CrossRef]

- Kroll, P. Hafnium nitride with thorium phosphide structure: Physical properties and an assessment of the Hf-N, Zr-N, and Ti-N phase diagrams at high pressures and temperatures. Phys. Rev. Lett. 2003, 90, 1–4. [Google Scholar] [CrossRef]

- McMillan, P.F.; Shebanova, O.; Daisenberger, D.; Quesada Cabrera, R.; Bailey, E.; Hector, A.L.; Lees, V.; Machon, D.; Sella, A.; Wilson, M. Metastable phase transitions and structural transformations in solid-state materials at high pressure. Phase Transit. 2007, 80, 1003–1032. [Google Scholar] [CrossRef]

- Salamat, A. High Pressure Solid State Chemistry of C-N-H and Ti-N Systems. PhD Thesis, University College London, London, UK, 2010. [Google Scholar]

- Kuwahara, H.; Mazaki, N.; Takahashi, M.; Watanabe, T.; Yang, X.; Aizawa, T. Mechanical properties of bulk sintered titanium nitride ceramics. Mater. Sci. Eng. A 2001, 319-321, 687–691. [Google Scholar]

- Lévy, F.; Hones, P.; Schmid, P.E.; Sanjinés, R.; Diserens, M.; Wierner, C. Electronic states and mechanical properties in transition metal nitrides. Surf. Coat. Technol. 1999, 120-121, 284–290. [Google Scholar]

- Chen, X.-J.; Struzhkin, V.V.; Wu, Z.; Somayazulu, M.; Qian, J.; Kung, S.; Christensen, A.N.; Zhao, Y.; Cohen, R.E.; Mao, H.-K.; Hemley, R.J. Hard superconducting nitrides. Proc. Natl. Acad. Sci. USA 2005, 102, 3198–3201. [Google Scholar] [CrossRef] [PubMed]

- Qian, L.; Li, M.; Zhou, Z.; Yang, H.; Shi, X. Comparison of nano-indentation hardness to microhardness. Surf. Coat. Technol. 2005, 195, 264–271. [Google Scholar] [CrossRef]

- Guemmaz, M.; Mosser, A.; Ahuja, R.; Parlebas, J.C. Theoretical and experimental investigations on elastic properties of substoichiometric titanium nitrides: Influence of lattice vacancies. Int. J. Inorg. Mater. 2001, 3, 1319–1321. [Google Scholar] [CrossRef]

- Török, E.; Perry, A.J.; Chollet, L.; Sproul, W.D. Young’s modulus of TiN, TiC, ZrN and HfN. Thin Solid Films 1987, 153, 37–43. [Google Scholar] [CrossRef]

- Anstis, G.R.; Chantikul, P.; Lawn, B.R.; Marshall, D.B. A critical evaluattion of indentation techniques for measuring fracture toughness: I. Direct crack measurements. J. Am. Ceram. Soc. 1981, 64, 533–538. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, T.; Yang, R. A work approach to determine Vickers indentation fracture toughness. J. Am. Ceram. Soc. 2011, 94, 332–335. [Google Scholar] [CrossRef]

- Schiffmann, K.I. Determination of fracture toughness of bulk materials and thin films by nanoindentation: Comparison of different models. Philos. Mag. 2011, 91, 1163–1178. [Google Scholar] [CrossRef]

- Niihara, K. A fracture mechanics analysis of indentation-induced Palmqvist crack in ceramics. J. Mater. Sci. Lett. 1983, 2, 221–223. [Google Scholar] [CrossRef]

- Niihara, K.; Morena, R.; Hasselman, D.P.H. Evaluation of brittle solids by the indentation method with low crack-to-indent ratios. J. Mater. Sci. Lett. 1982, 1, 13–16. [Google Scholar] [CrossRef]

- Sinani, A.B.; Dynkin, N.K.; Lytvinov, L.A.; Konevsky, P.V.; Andreev, E.P. Sapphire hardness in different crystallographic directions. Bull. Russian Acad. Sci. Phys. 2009, 73, 1380–1382. [Google Scholar] [CrossRef]

- Guemmaz, M.; Mosser, A.; Grob, J.J. Ion implantation processing of sub-stoichiometric titanium nitrides and carbonitrides: Chemical, structural and micromechanical investigations. Appl. Phys. A 1997, 64, 407–415. [Google Scholar] [CrossRef]

- Ashley, N.J.; Grimes, R.W.; McClellan, K.J. Accommodation of non-stoichiometry in TiN1−x and ZrN1−x. J. Mater. Sci. 2007, 42, 1884–1889. [Google Scholar] [CrossRef]

- Jhi, S.-H.; Louie, S.G.; Cohen, M.L.; Ihm, J. Vacancy hardening and softening in transition metal carbides and nitrides. Phys. Rev. Lett. 2001, 86, 3348–3351. [Google Scholar] [CrossRef] [PubMed]

- Dridi, Z.; Bouhafs, B.; Ruterana, P.; Aourag, H. First-principles calaulctions of vacancy effects on structural and electronic properties of TiCx and TiNx. J. Phys. Condens. Matter 2002, 14, 10237–10249. [Google Scholar] [CrossRef]

- Chang, Y.A.; Pike, L.M.; Liu, C.T.; Bilbrey, A.R.; Stone, D.S. Correlation of the hardness and vacancy concentration in FeAI. Intermetallics 1993, 1, 107–115. [Google Scholar] [CrossRef]

- Chuprina, V.G. Oxidation of porous nanocrystalline titanium nitride. III. Oxidation mechanism. Powder Metall. Met. Ceram. 2007, 46, 182–188. [Google Scholar] [CrossRef]

- Granier, B.; Chatillon, C.; Allibert, M. Thermodynamic activities in the cubic phase Ti-O-N by high-temperature mass spectrometry. J. Am. Ceram. Soc. 1982, 65, 465–469. [Google Scholar] [CrossRef]

- Voitovich, R.F.; Pugach, E.A. High-temperature oxidation of the nitrides of the groups IV and V transition metals. I. Oxidation of titanium nitride. Powder Metall. Met. Ceram. 1975, 14, 562–566. [Google Scholar] [CrossRef]

- Ovid’ko, I.A. Superplasticity and ductiliy of superstrong nanomaterials. Rev. Adv. Mater. Sci. 2005, 10, 89–104. [Google Scholar]

© 2011 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license ( http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Bailey, E.; Ray, N.M.T.; Hector, A.L.; Crozier, P.; Petuskey, W.T.; McMillan, P.F. Mechanical Properties of Titanium Nitride Nanocomposites Produced by Chemical Precursor Synthesis Followed by High-P,T Treatment. Materials 2011, 4, 1747-1762. https://doi.org/10.3390/ma4101747

Bailey E, Ray NMT, Hector AL, Crozier P, Petuskey WT, McMillan PF. Mechanical Properties of Titanium Nitride Nanocomposites Produced by Chemical Precursor Synthesis Followed by High-P,T Treatment. Materials. 2011; 4(10):1747-1762. https://doi.org/10.3390/ma4101747

Chicago/Turabian StyleBailey, Edward, Nicole M. T. Ray, Andrew L. Hector, Peter Crozier, William T. Petuskey, and Paul F. McMillan. 2011. "Mechanical Properties of Titanium Nitride Nanocomposites Produced by Chemical Precursor Synthesis Followed by High-P,T Treatment" Materials 4, no. 10: 1747-1762. https://doi.org/10.3390/ma4101747