Influence of Annealing Process on Soft Magnetic Properties of Fe-B-C-Si-P Amorphous Alloys

Abstract

:1. Introduction

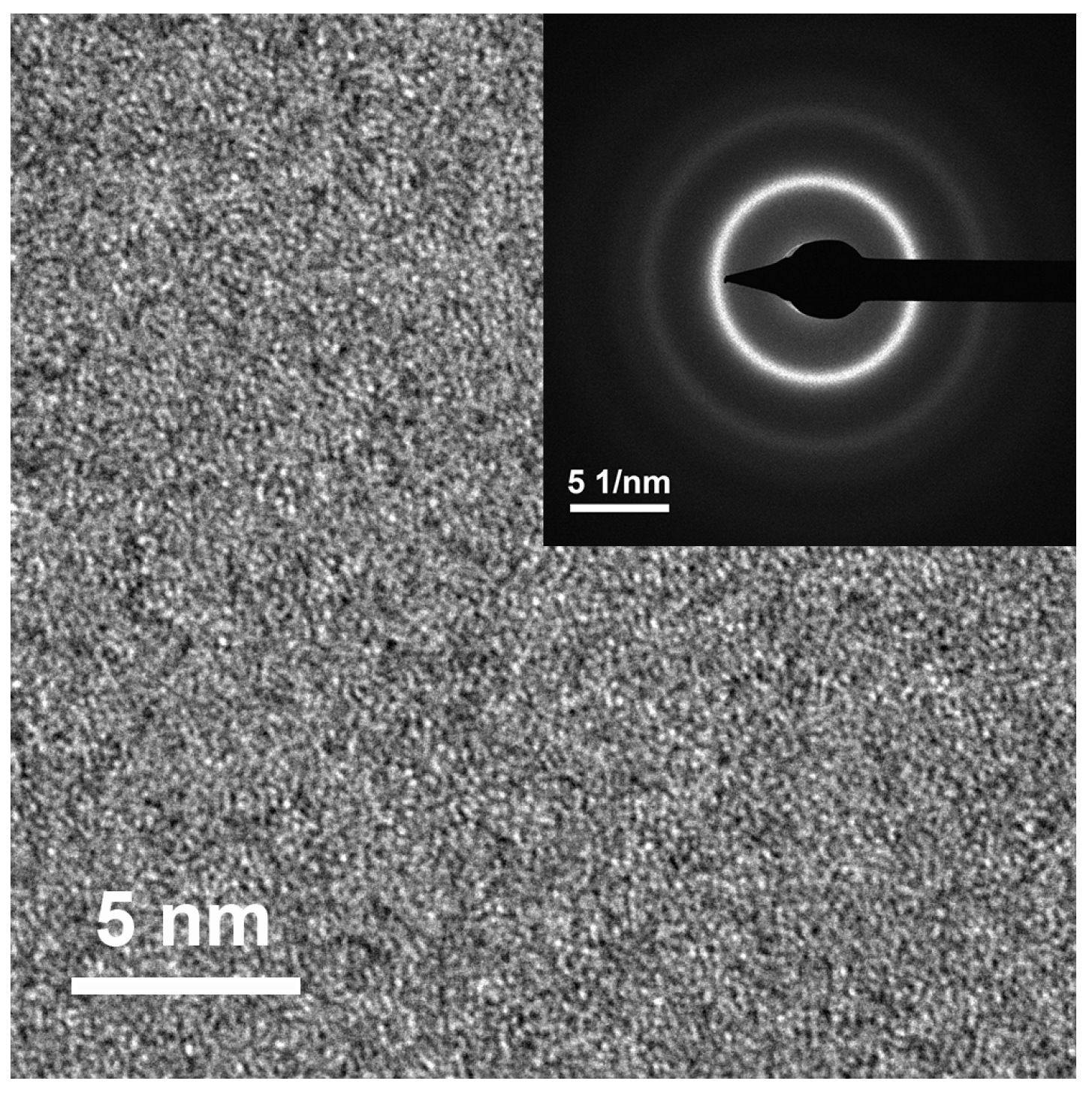

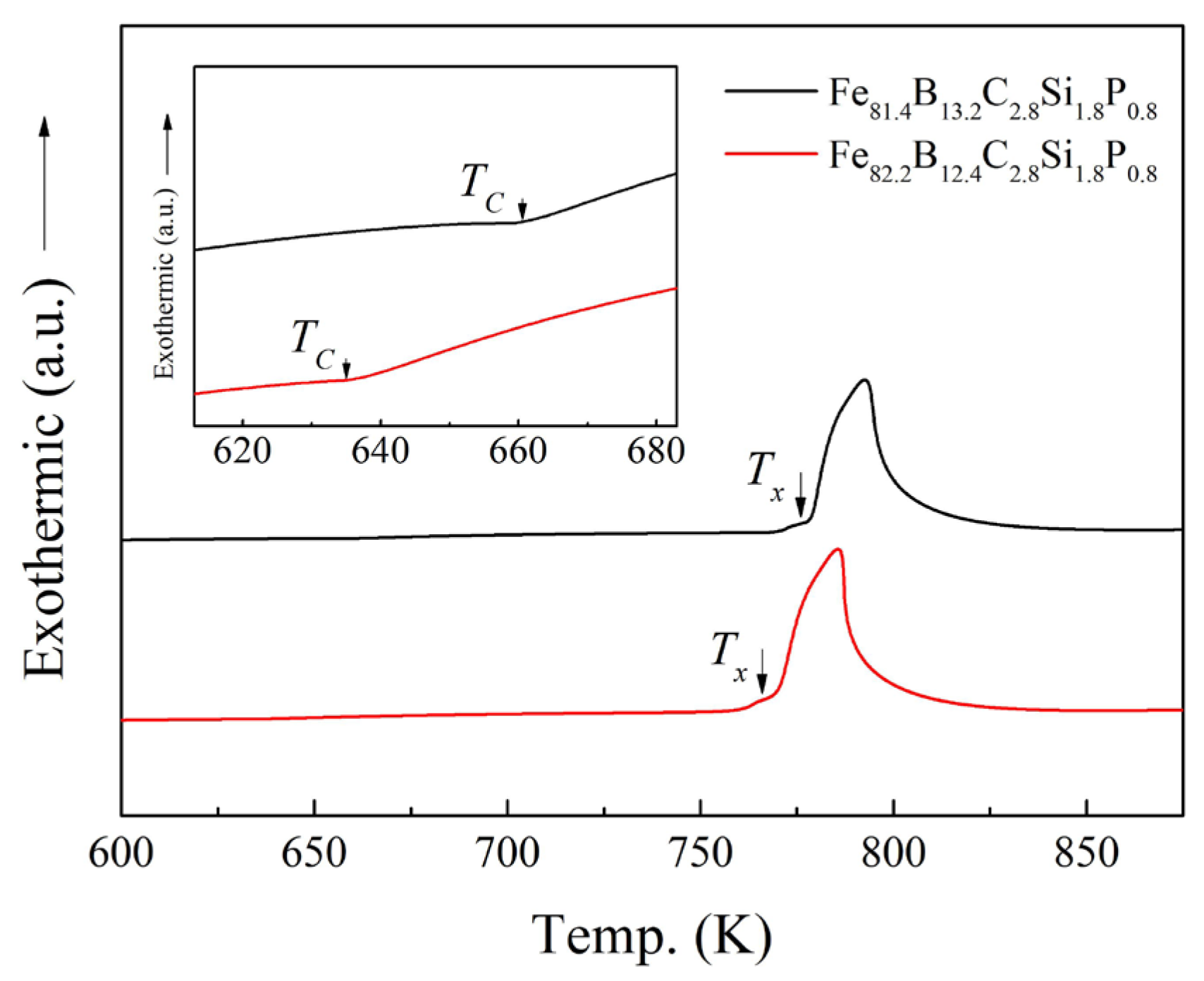

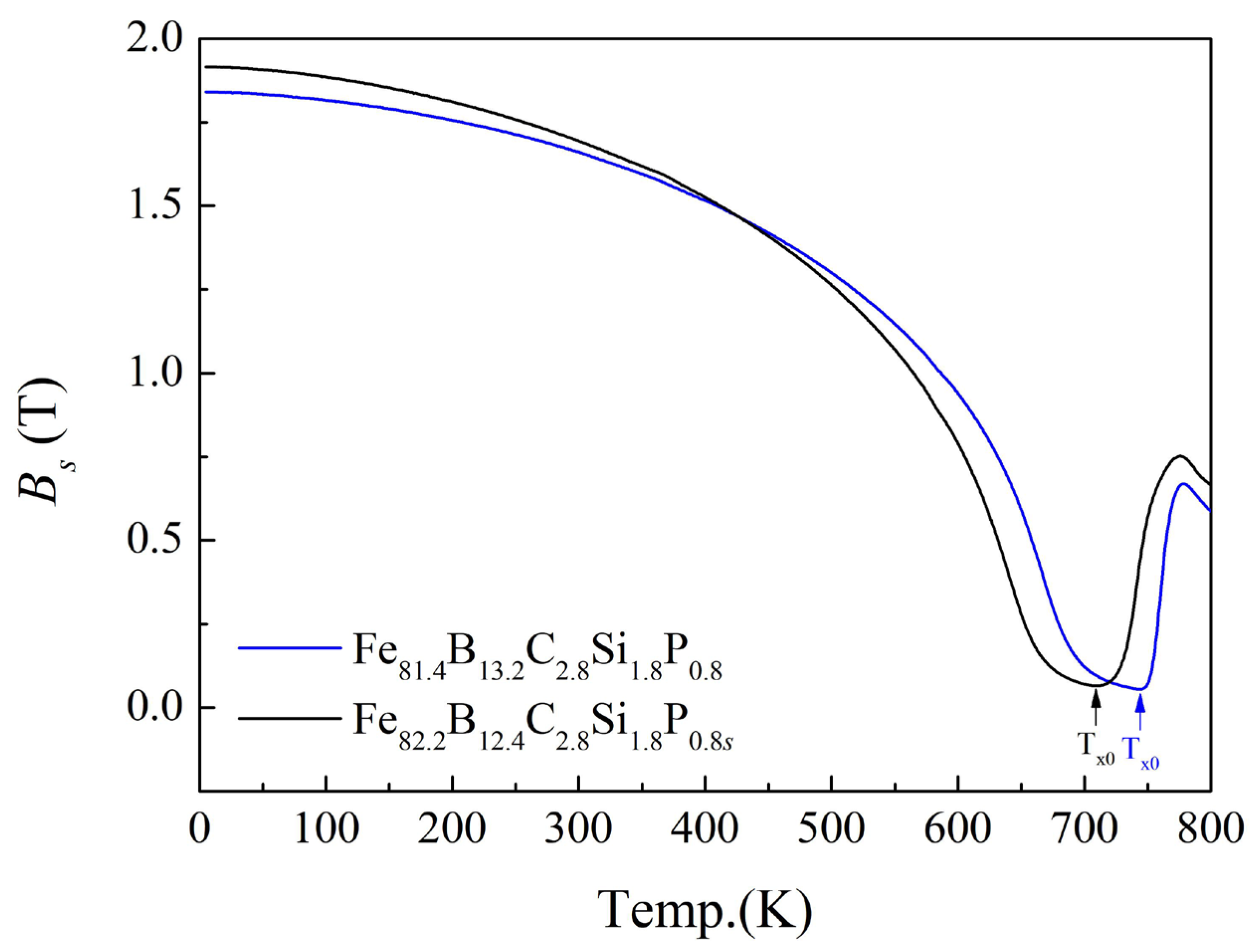

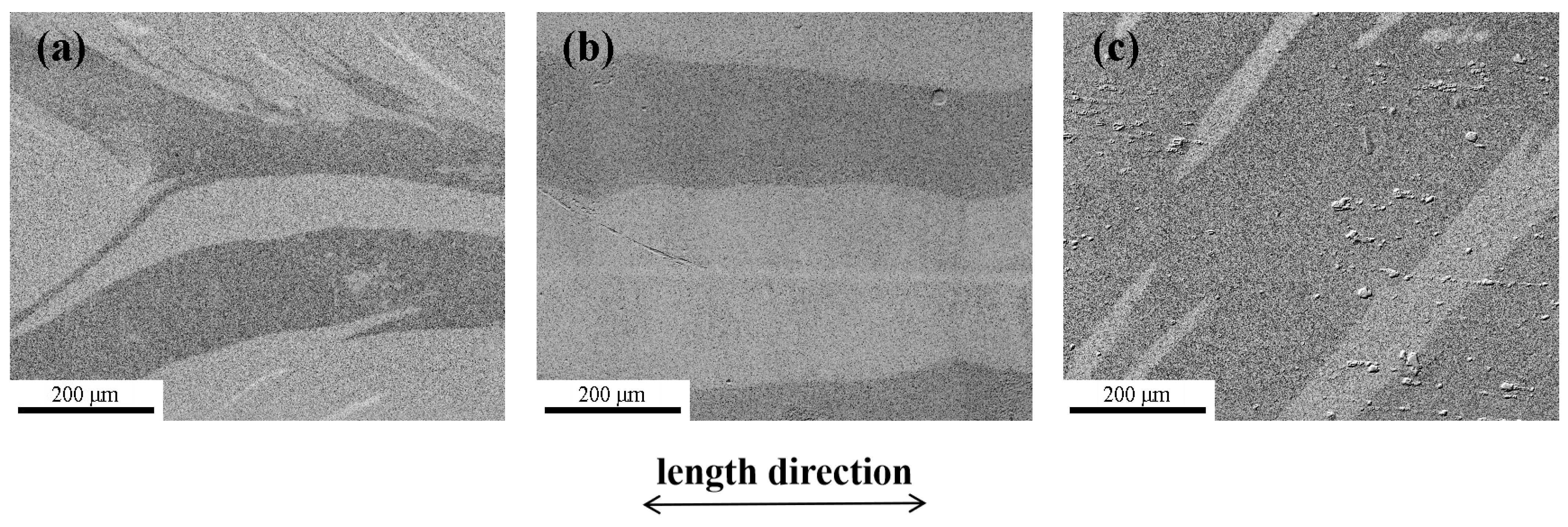

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- (1)

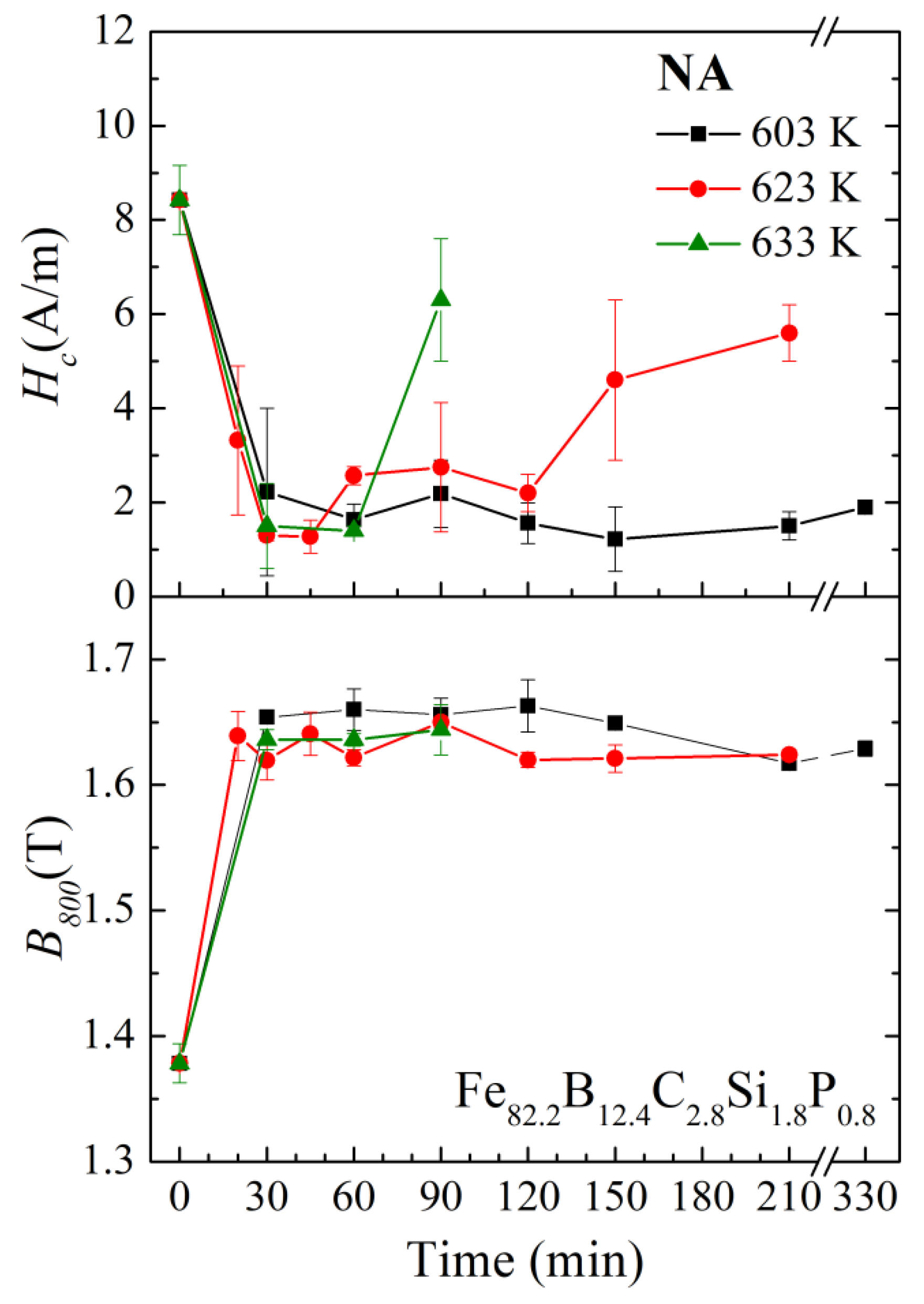

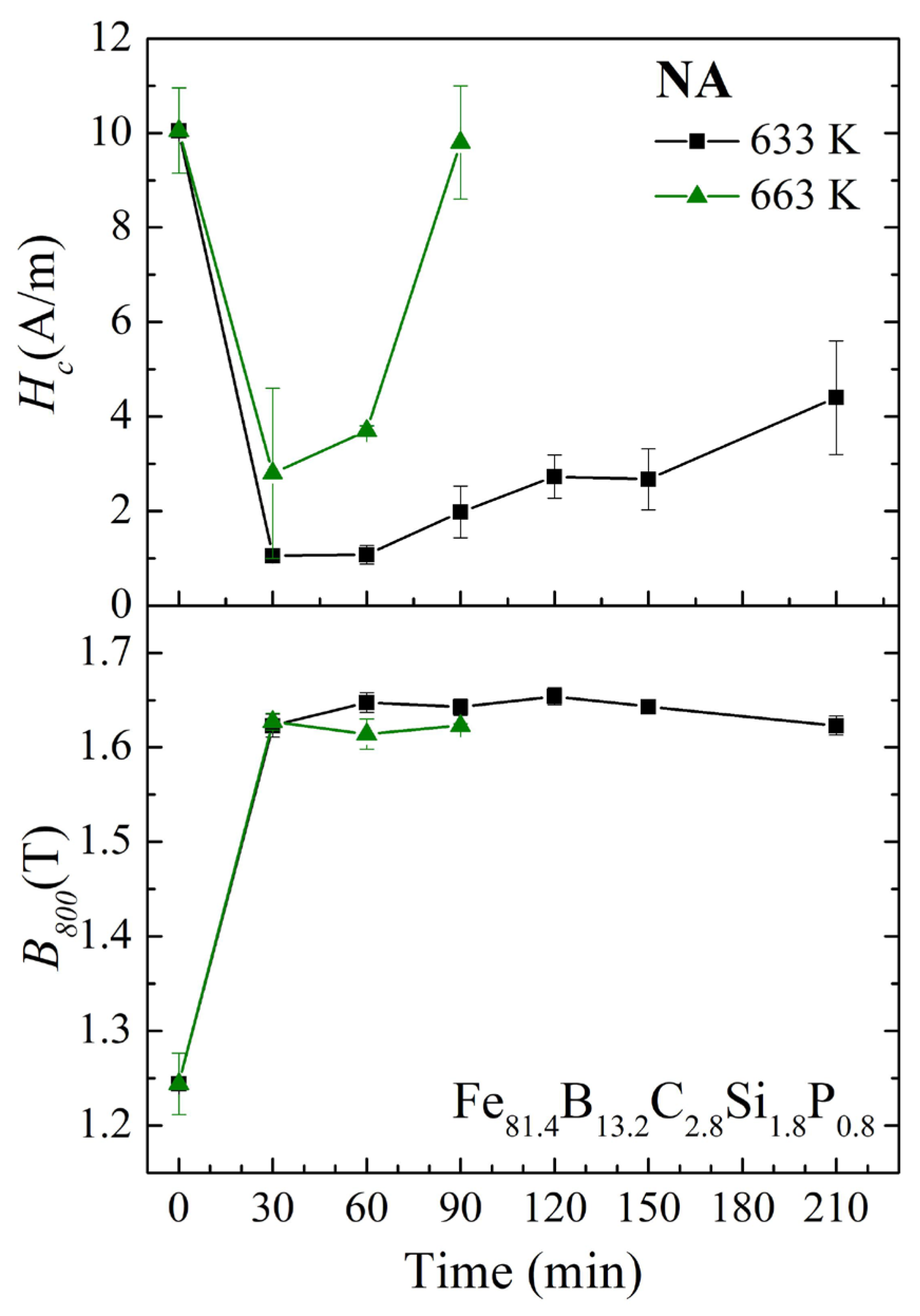

- Fe81.4B13.2C2.8Si1.8P0.8 and Fe82.2B12.4C2.8Si1.8P0.8 amorphous alloys were designed and prepared. This revealed that a lowest and highest temperature, denoted as Ta0 and Tam, respectively, exists for the optimum annealing of the amorphous alloys. The Hc of the Fe81.4 and Fe82.2 amorphous alloys annealed at Ta0–Tam for 90 min was 1.3–2.7 A/m, together with the B800 of 1.64–1.66 T. Ta0 is determined by the variation in the magnetic properties with temperature. Tam is the temperature related to the crystallization of amorphous alloys.

- (2)

- It was found that on the Bs(T)–T curve, there is a temperature Tai at which the dBs/dT begins to decrease rapidly, and Bs(Tai)/Bs(5K) = 45%. When the amorphous alloys were annealed slightly above Tai, the effect of the inner magnetic field generated by spontaneous magnetization on the relaxation behavior became very weak. That is, the temperature Tai could be employed as a characteristic temperature. Slightly above Tai, an optimized annealing temperature Ta0 for the Fe-based amorphous alloys with a relatively low Curie temperature, similar to the studied alloys, could be determined quickly.

- (3)

- When the annealing temperature was selected properly (slightly higher than Tai), the soft magnetic properties of amorphous alloys could remain excellent and stable even if annealed for a very long time. The Hc of the Fe82.2B12.4C2.8Si1.8P0.8 amorphous alloy annealed at Ta1 = 603 K was only 1.9 A/m, while the annealing time was extended to 330 min.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hasegawa, R. Application of amorphous magnetic alloys. Mater. Sci. Eng. A 2004, 375, 90–97. [Google Scholar] [CrossRef]

- Herzer, G. Modern soft magnets: Amorphous and nanocrystalline materials. Acta Mater. 2013, 61, 718–734. [Google Scholar] [CrossRef]

- Milanez, D.H.; Faria, L.I.L.; Leiva, D.R.; Kiminami, C.S.; Botta, W.J. Assessing technological developments in amorphous/glassy metallic alloys using patent indicators. J. Alloys Compd. 2017, 716, 330–335. [Google Scholar] [CrossRef]

- Silveyra, J.M.; Ferrara, E.; Huber, D.L.; Monson, T.C. Soft magnetic materials for a sustainable and electrified world. Science 2018, 362, 418–426. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.L.; Wang, A.D.; Yue, S.Q.; Liu, T.; He, A.N.; Chang, C.T.; Wang, X.M.; Liu, C.T. Significant improvement of soft magnetic properties for Fe(Co) BPSiC amorphous alloys by magnetic field annealing. J. Alloys Compd. 2018, 742, 220–225. [Google Scholar] [CrossRef]

- Kronmuller, H. Micromagnetism and Microstructure of Amorphous-Alloys. J. Appl. Phys. 1981, 52, 1859–1864. [Google Scholar] [CrossRef]

- Kronmuller, H.; Groger, B. Domains, Domain-Walls and the Coercive Field of Amorphous Ferromagnets. J. Phys. 1981, 42, 1285–1292. [Google Scholar] [CrossRef]

- Li, Z.; Yao, K.F.; Liu, T.C.; Li, X.; Wang, S. Effect of Annealing on the Magnetic Properties of FeCoNiCuNbSiB Soft Magnetic Alloys. Front. Mater. 2022, 8, 805609. [Google Scholar] [CrossRef]

- Li, H.; He, A.N.; Wang, A.D.; Xie, L.; Li, Q.; Zhao, C.L.; Zhang, G.Y.; Chen, P.B. Improvement of soft magnetic properties for distinctly high Fe content amorphous alloys via longitudinal magnetic field annealing. J. Magn. Magn. Mater. 2019, 471, 110–115. [Google Scholar] [CrossRef]

- Tejedor, M.; García, J.A.; Carrizo, J.; Elbaile, L.; Santos, J.D. Stress relief and magnetic properties of magnetostrictive Fe79B16Si5 amorphous magnetic ribbons. J. Magn. Magn. Mater. 1999, 202, 485–491. [Google Scholar] [CrossRef]

- Makino, A.; Kubota, T.; Chang, C.; Makabe, M.; Inoue, A. FeSiBP bulk metallic glasses with high magnetization and excellent magnetic softness. J. Magn. Magn. Mater. 2008, 320, 2499–2503. [Google Scholar] [CrossRef]

- Liang, X.F.; He, A.N.; Wang, A.D.; Pang, J.; Wang, C.J.; Chang, C.T.; Qiu, K.Q.; Wang, X.M.; Liu, C.T. Fe content dependence of magnetic properties and bending ductility of FeSiBPC amorphous alloy ribbons. J. Alloys Compd. 2017, 694, 1260–1264. [Google Scholar] [CrossRef]

- Yue, S.; Zhang, H.; Cheng, R.; Wang, A.; Dong, Y.; He, A.; Ni, H.; Liu, C.-T. Magnetic and thermal stabilities of FeSiB eutectic amorphous alloys: Compositional effects. J. Alloys Compd. 2019, 776, 833–838. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, H.; Yue, S.; Wang, A.; He, A.; Cheng, R.; Dong, Y.; Ni, H.; Liu, C.-T. Ultra-low cost and energy-efficient production of FePCSi amorphous alloys with pretreated molten iron from a blast furnace. J. Non-Cryst. Solids 2019, 514, 108–115. [Google Scholar] [CrossRef]

- Tokmakova, E.N.; Vvedenskiy, V.Y. Effect of annealing in unsaturated magnetic field on the magnetic properties of an amorphous alloy Fe77Ni1Si9B13. J. Mater. Sci. Mater. Electron. 2023, 34, 10. [Google Scholar] [CrossRef]

- Hatta, S.; Egami, T.; Graham, C.D. Amorphous Alloys with Improved Room-Temperature Saturation Induction. IEEE Trans. Magn. 1978, 14, 1013–1015. [Google Scholar] [CrossRef]

- Wang, A.D.; Zhao, C.L.; Men, H.; He, A.N.; Chang, C.T.; Wang, X.M.; Li, R.W. Fe-based amorphous alloys for wide ribbon production with high B-s and outstanding amorphous forming ability. J. Alloys Compd. 2015, 630, 209–213. [Google Scholar] [CrossRef]

- Shi, L.X.; Hu, X.Y.; Li, Y.H.; Yuan, G.T.; Yao, K.F. The complementary effects of Fe and metalloids on the saturation magnetization of Fe-based amorphous alloys. Intermetallics 2021, 131, 107116. [Google Scholar] [CrossRef]

- Mitera, M.; Naka, M.; Masumoto, T.; Kazama, N.; Watanabe, K. Effects of Metalloids on Magnetic-Properties of Iron Based Amorphous Alloys. Phys. Status Solidi A 1978, 49, K163–K166. [Google Scholar] [CrossRef]

- Shi, L.X.; Yao, K.F. Composition design for Fe-based soft magnetic amorphous and nanocrystalline alloys with high Fe content. Mater. Des. 2020, 189, 108511. [Google Scholar] [CrossRef]

- Liu, F.J.; Yao, K.F.; Ding, H.Y. Fe-based glassy alloys with high iron content and high saturation magnetization. Intermetallics 2011, 19, 1674–1677. [Google Scholar] [CrossRef]

- Torrens-Serra, J.; Bruna, P.; Rodriguez-Viejo, J.; Roth, S.; Clavaguera-Mora, M.T. Effect of minor additions on the glass forming ability and magnetic properties of Fe-Nb-B based metallic glasses. Intermetallics 2010, 18, 773–780. [Google Scholar] [CrossRef]

- Lashgari, H.R.; Chu, D.; Xie, S.S.; Sun, H.D.; Ferry, M.; Li, S. Composition dependence of the microstructure and soft magnetic properties of Fe-based amorphous/nanocrystalline alloys: A review study. J. Non-Cryst. Solids 2014, 391, 61–82. [Google Scholar] [CrossRef]

- Cullity, B.D.; Graham, C.D. Introduction to Magnetic Materials, 2nd ed.; IEEE/Wiley: Hoboken, NJ, USA, 2009; pp. 115–149. [Google Scholar]

- Shi, L.X.; Qin, X.L.; Yao, K.F. Tailoring soft magnetic properties of Fe-based amorphous alloys through C addition. Prog. Nat. Sci. Mater. Int. 2020, 30, 208–212. [Google Scholar] [CrossRef]

- Graham, C.D.; Egami, T. Magnetic-properties of Amorphous Ribbon. IEEE Trans. Magn. 1979, 15, 1398–1403. [Google Scholar] [CrossRef]

- Suzuki, K.; Herzer, G. Magnetic-field-induced anisotropies and exchange softening in Fe-rich nanocrystalline soft magnetic alloys. Scr. Mater. 2012, 67, 548–553. [Google Scholar] [CrossRef]

- Obi, Y. The Stress Effect on Magnetic Domain Structure of Fe-Co Amorphous Alloys. Appl. Phys. 1979, 18, 119–121. [Google Scholar] [CrossRef]

- Liu, J.P. Nanoscale Magnetic Materials and Applications; Springer: New York, NY, USA, 2009; pp. 275–304. [Google Scholar]

- Azuma, D.; Hasegawa, R.; Saito, S.; Takahashi, M. Effect of residual strain in Fe-based amorphous alloys on field induced magnetic anisotropy and domain structure. J. Appl. Phys. 2013, 113, 17A339. [Google Scholar] [CrossRef]

- Bayri, N.; Kolat, V.S.; Atalay, F.E.; Atalay, S. The effect of furnace annealing and surface crystallization on the anisotropy, ΔE and magnetoimpedance effects in FeCrSiB amorphous wires. J. Phys. D Appl. Phys. 2004, 37, 3067–3072. [Google Scholar] [CrossRef]

- Fecova, L.; Richter, K.; Varga, R. Annealing Effect on Domain Wall Dynamics in Wires with Induced Gradient of Perpendicular Anisotropy. IEEE Trans. Magn. 2022, 58, 4301405. [Google Scholar] [CrossRef]

- Lopatina, E.; Soldatov, I.; Budinsky, V.; Marsilius, M.; Schultz, L.; Herzer, G.; Schäfer, R. Surface crystallization and magnetic properties of Fe84.3Cu0.7Si4B8P3 soft magnetic ribbons. Acta Mater. 2015, 96, 10–17. [Google Scholar] [CrossRef]

| Alloy | Ta0 (K) | Tam (K) | Tai (K) | TC0 (K) | Tx0 (K) | TC (K) | Tx (K) |

|---|---|---|---|---|---|---|---|

| Fe81.4B13.2C2.8Si1.8P0.8 | 623 | 653 | 620 | 667 | 744 | 661 | 776 |

| Fe82.2B12.4C2.8Si1.8P0.8 | 593 | 623 | 589 | 637 | 709 | 635 | 766 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, J.; Wu, Y.; Shi, L.; Wang, R.; Guo, W.; Bu, H.; Shao, Y.; Chen, N.; Yao, K. Influence of Annealing Process on Soft Magnetic Properties of Fe-B-C-Si-P Amorphous Alloys. Materials 2024, 17, 1447. https://doi.org/10.3390/ma17061447

Jia J, Wu Y, Shi L, Wang R, Guo W, Bu H, Shao Y, Chen N, Yao K. Influence of Annealing Process on Soft Magnetic Properties of Fe-B-C-Si-P Amorphous Alloys. Materials. 2024; 17(6):1447. https://doi.org/10.3390/ma17061447

Chicago/Turabian StyleJia, Jili, You Wu, Lingxiang Shi, Ranbin Wang, Wenhui Guo, Hengtong Bu, Yang Shao, Na Chen, and Kefu Yao. 2024. "Influence of Annealing Process on Soft Magnetic Properties of Fe-B-C-Si-P Amorphous Alloys" Materials 17, no. 6: 1447. https://doi.org/10.3390/ma17061447