Carbon Dioxide Uptake Estimation for Spanish Cement-Based Materials

Abstract

:1. Introduction

- In integrated Portland cement plants, i.e., factories with clinker production: Carbon Capture, Utilization, and Storage (CCUS) and biomass waste use as a non-recyclable-waste-derived fuel. Currently, biomass use in Spain accounts for 33% of non-recyclable-waste-derived fuels, whereas in Europe (CEMBUREAU) it accounts for 17%. The global non-recyclable-waste-derived fuels percentage in Spain is 37%, while in Europe (CEMBUREAU) it is 52%. Furthermore, the Spanish carbon neutrality roadmap aims to achieve 70% alternative fuel usage by 2050, of which almost half (about 40%) should be biomass-waste-derived fuels. In Europe (CEMBUREAU), the use of alternative fuels is expected to reach about 90%, with more than 50% being biomass waste.

- In mortar and concrete through their service life: natural carbonation.

- In concrete production (ready-mix concrete or precast concrete): controlled accelerated concrete carbonation permanently stores carbon and increases the concrete compressive strength. This notwithstanding, this process enables the use of cements with a lower content of clinker in the concrete, which leads to a further reduction of carbon dioxide in the built environment. It is well-known that carbonation results in increased compressive strength for CEM I concrete. By contrast, concrete manufactured with blended cements present a lower compressive strength than CEM I concrete.

1.1. Whole-Life Carbon Emissions of Buildings and Civil Constructions

1.2. Carbon Dioxide Uptake by Cement-Based Materials

2. Materials and Methods

2.1. Data Collection

- Annual compilations and collations of data according to official statistics from the Spanish cement sector (Oficemen), beginning in 1990.

- Following a prior request by the authors, in some cases, manufacturers collect and send us data.

2.2. Carbon Dioxide Uptake by Natural Carbonation

2.2.1. Carbonation in the Standardization and Policy Context

2.2.2. Carbonation Modeling

2.2.3. Factors Affecting Carbonation

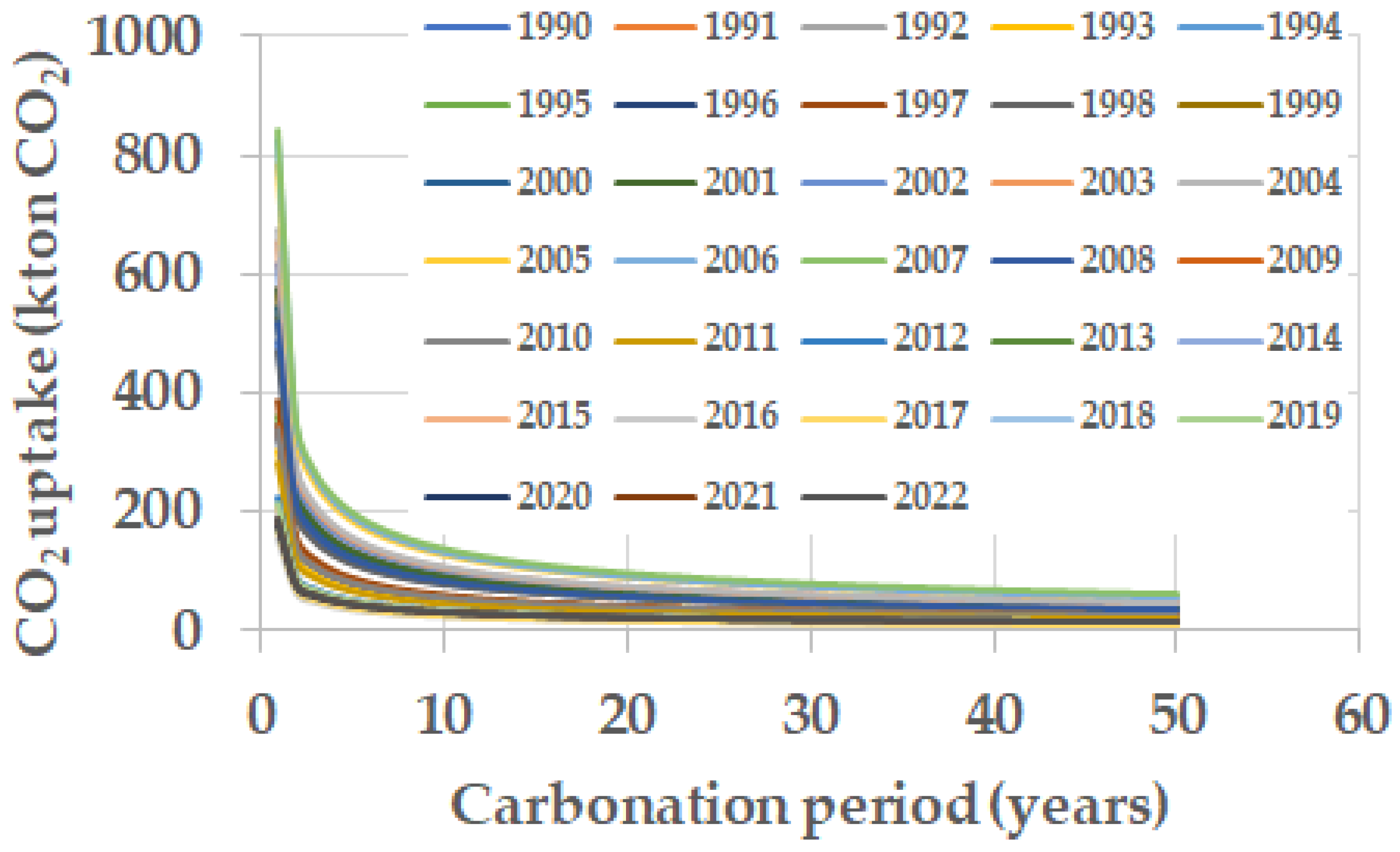

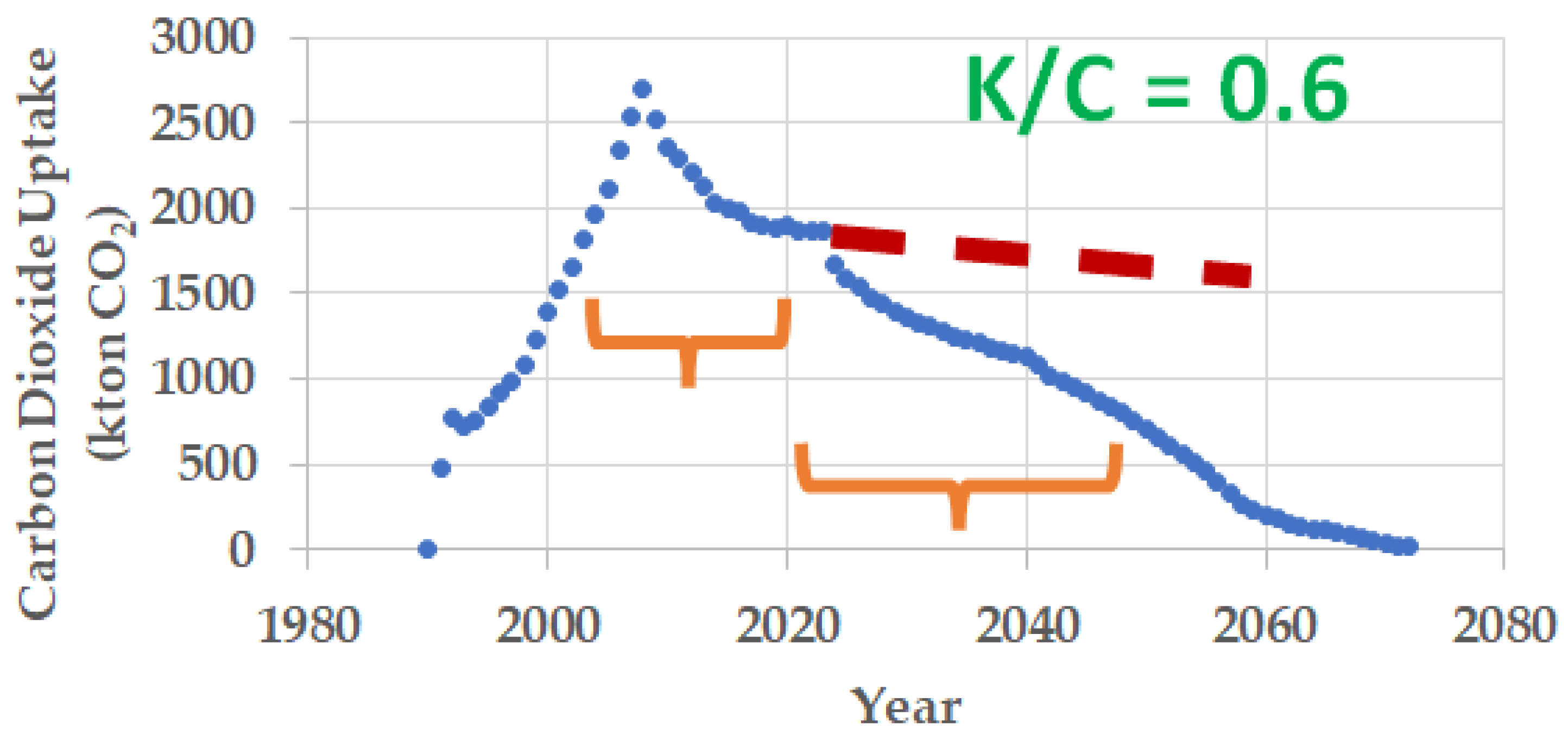

2.3. Carbon Dioxide Uptake Estimation and Hypothesis

- The data used in the CO2 uptake estimation are considered “robust data” since 1990, as they correspond to the verified statistics of the Spanish cement sector. Accordingly, they are “virtually certain” according to the IPCC likelihood scale [48].

- Concrete and mortar to be carbonated have been produced and used in Spain in civil works and building in the years preceding the year concerned.

- The highest growth of the square root of time function is produced during the first years. Therefore, the carbon dioxide uptake estimation has been limited to the first 50 years in this study, considering an average carbonation rate of 3 mm/year0.5.

- It has been considered that 23% of the absorption of carbon dioxide emitted in the decarbonation of the raw materials utilized in the manufacture of Portland cement clinker has taken place in 50 years.

- Due to the high porosity of the mortar, it carbonates at a higher rate, which is why it undergoes special treatment [32].

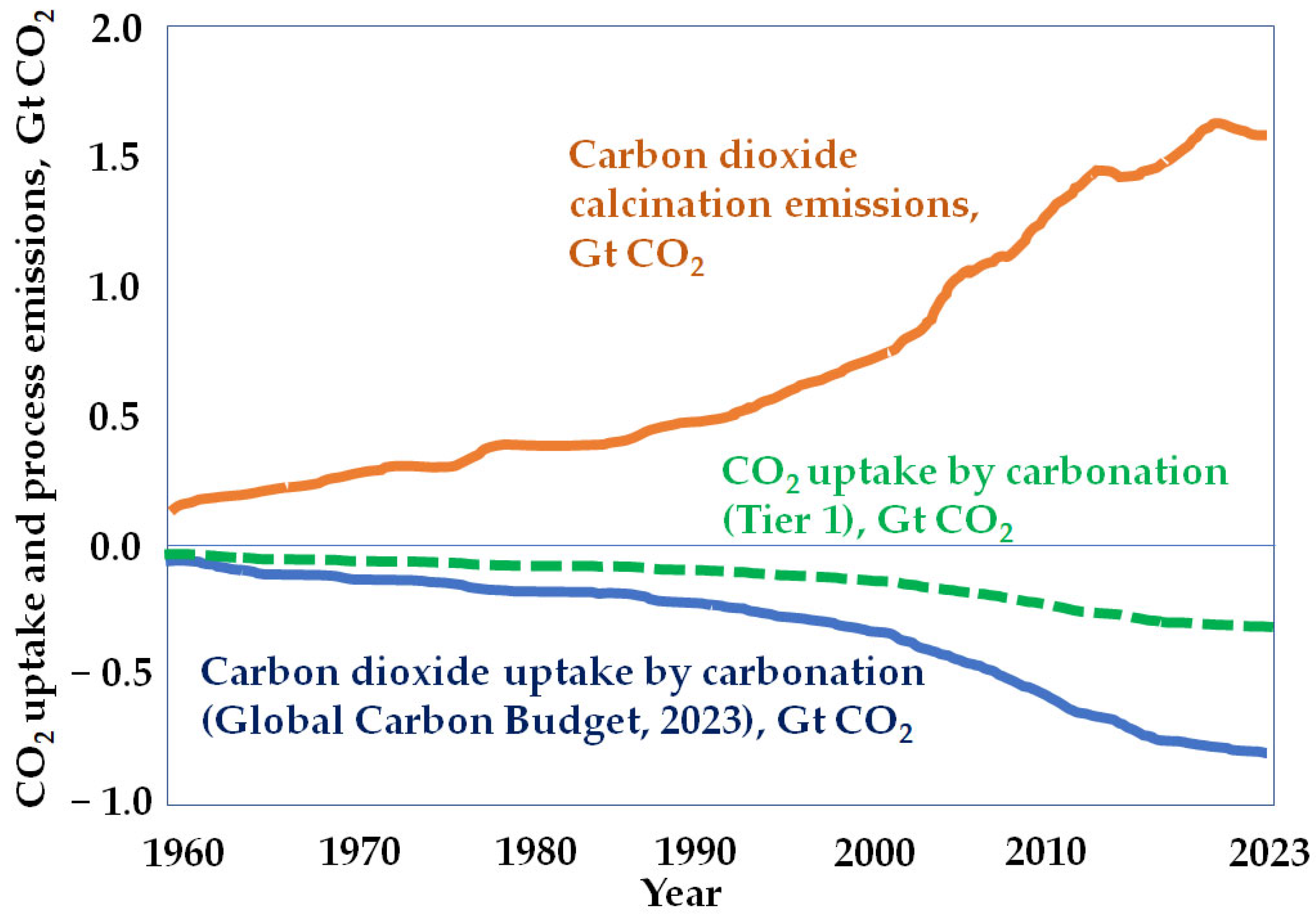

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Commission. The European Green Deal. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions. COM(2019) 640 Final. Brussels, Belgium, 11 December 2019. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:b828d165-1c22-11ea-8c1f-01aa75ed71a1.0002.02/DOC_1&format=PDF (accessed on 18 May 2023).

- European Commission. A New Industrial Strategy for Europe. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions. COM (2020) 102 Final. Brussels, Belgium, 10 March 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52020DC0102 (accessed on 1 September 2023).

- European Commission. Regulation (EU) 2021/1119 of the European Parliament and of the Council of 30 June 2021 Establishing the Framework for Achieving Climate Neutrality and Amending Regulations (EC) No 401/2009 and (EU) 2018/1999 (‘European Climate Law’). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32021R1119 (accessed on 1 September 2023).

- The Global Cement Report™, 14th ed.; Tradeship Publications Ltd.: Surrey, UK; p. 372. Available online: https://www.cemnet.com/Publications/Item/187049/the-global-cement-report-14th-edition.html (accessed on 1 September 2023).

- Wei, J.; Cen, K.; Geng, Y. China’s cement demand and CO2 emissions toward 2030: From the perspective of socioeconomic, technology and population. Environ. Sci. Pollut. Res. Int. 2019, 26, 6409–6423. [Google Scholar] [CrossRef] [PubMed]

- Abigail Speak. AFRY. Thinkpiece: Implications of China’s Proposed 2060 Carbon Neutrality. 29 September 2020. Available online: https://afry.com/sites/default/files/2020-09/afry_management_consulting_-_thinkpiece_-_china_2060_carbon_neutrality_implications_0.pdf (accessed on 1 September 2023).

- Xu, J.-H.; Yi, B.-W.; Fan, Y. A bottom-up optimization model for long-term CO2 emissions reduction pathway in the cement industry: A case study of China. Int. J. Greenh. Gas Control 2016, 44, 199–216. [Google Scholar] [CrossRef]

- Sanjuán, M.Á.; Andrade, C.; Mora, P.; Zaragoza, A. Carbon Dioxide Uptake by Cement-Based Materials: A Spanish Case Study. Appl. Sci. 2020, 10, 339. [Google Scholar] [CrossRef]

- Sanjuán, M.Á.; Zaragoza, A. Chinese standards for cements’ specifications. Cemento-Hormigón 2013, 957, 8–17. (In Spanish) [Google Scholar]

- Gao, T.; Shen, L.; Shen, M.; Liu, L.; Chen, F.; Gao, L. Evolution and projection of CO2 emissions for China’s cement industry from 1980 to 2020. Renew. Sustain. Energy Rev. 2017, 74, 522–537. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Yu, B.; Chen, J.M.; Wei, Y.M. Green transition pathways for cement industry in China. Resour. Conserv. Recycl. 2021, 166, 105355. [Google Scholar] [CrossRef]

- Dinga, C.D.; Wen, Z. China’s green deal: Can China’s cement industry achieve carbon neutral emissions by 2060? Renew. Sustain. Energy Rev. 2022, 155, 111931. [Google Scholar] [CrossRef]

- Sanjuán, M.A. The cement industry’s commitment to reduce CO2 emissions in the context of the COP 21 (Paris 2015). Mater. Construcc. 2016, 66, ed007. [Google Scholar]

- Proposal for a Regulation on an EU Certification for Carbon Removals. European Union (EU): Brussels, Belgium, 30 November 2022. Available online: https://climate.ec.europa.eu/system/files/2022-11/Proposal_for_a_Regulation_establishing_a_Union_certification_framework_for_carbon_removals.pdf (accessed on 1 September 2023).

- European Commission. DG CLIMA—C3. Certification of Carbon Removals—EU Rules. Ref. Ares(2022)869812—07/02/2022. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=PI_COM:Ares(2022)869812 (accessed on 1 September 2023).

- Association of Spanish Cement Producers (Oficemen). The Spanish Cement Industry’s Low-Carbon Roadmap to 2050. Available online: https://www.oficemen.com/ (accessed on 18 May 2023).

- Sanjuán, M.Á.; Argiz, C.; Mora, P.; Zaragoza, A. Carbon Dioxide Uptake in the Roadmap 2050 of the Spanish Cement Industry. Energies 2020, 13, 3452. [Google Scholar] [CrossRef]

- The European Cement Association (CEMBUREAU). European Cement Industry Strives for Carbon Neutral Cement and Concrete Along the Value Chain by 2050, 1st ed.; Cembureau: Brussels, Belgium, 2020; pp. 1–2. [Google Scholar]

- Reiner, D.M.; Hannula, I.; Koljonen, T.; Allen, M.; Lucht, W.; Guillén-Gosálbez, G.; Mac Dowell, N. Europe’s ‘green deal’ and carbon dioxide removal. Nature 2021, 589, 19. [Google Scholar] [CrossRef]

- European Parliament. Report on the Proposal for a Regulation of the European Parliament and of the Council Establishing a Union Certification Framework for Carbon Removals. Report-A9-0329/2023. 3.11.2023—(COM(2022)0672—C9-0399/2022—2022/0394(COD)). Available online: https://www.europarl.europa.eu/doceo/document/A-9-2023-0329_EN.html (accessed on 14 November 2023).

- The Intergovernmental Panel on Climate Change. Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Masson-Delmotte, V., Zhai, P., Pirani, A., Connors, S.L., Péan, C., Berger, S., Caud, N., Chen, Y., Goldfarb, L., Gomis, M.I., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2021; Available online: https://report.ipcc.ch/ar6/wg1/IPCC_AR6_WGI_FullReport.pdf (accessed on 18 May 2023).

- The Intergovernmental Panel on Climate Change. Climate Change 2022: Mitigation of Climate Change. Contribution of Working Group III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Shukla, P.R., Skea, J., Slade, R., Al Khourdajie, A., van Diemen, R., McCollum, D., Pathak, M., Some, S., Vyas, P., Fradera, R., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2022; Available online: https://www.ipcc.ch/report/ar6/wg3/downloads/report/IPCC_AR6_WGIII_FullReport.pdf (accessed on 18 May 2023).

- Task Force on National Greenhouse Gas Inventories (TFI) of The Intergovernmental Panel on Climate Change (IPCC). National Greenhouse Gas Inventories Programme. Technical Support Unit. In 2006 IPCC Guidelines for National Greenhouse Gas. Inventories Volume 3 Industrial Processes and Product Use. Chapter 2 Mineral. Industry Emissions; Eggleston, H.S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; Institute for Global Environmental Strategies (IGES): Hayama, Japan, 2006; pp. 8–19. Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/pdf/3_Volume3/V3_2_Ch2_Mineral_Industry.pdf (accessed on 18 May 2023).

- Task Force on National Greenhouse Gas Inventories (TFI) of The Intergovernmental Panel on Climate Change (IPCC). National Greenhouse Gas Inventories Programme. Technical Support Unit. In 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas. Inventories, 1st ed.; Calvo Buendía, E., Tanabe, K., Kranjc, A., Baasansuren, J., Fukuda, M., Ngarize, S., Osako, A., Pyrozhenko, Y., Shermanau, P., Federici, S., Eds.; Intergovernmental Panel on Climate Change (IPCC): Geneva, Switzerland, 2019; Volume I–V, Available online: https://www.ipcc-nggip.iges.or.jp/public/2019rf/index.html (accessed on 18 May 2023).

- EN 15978:2011; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. European Committee for Standardization (CEN): Brussels, Belgium, 2011.

- Stefaniuk, D.; Hajduczek, M.; Weaver, J.C.; Ulm, F.J.; Masic, A. Cementing CO2 into C-S-H: A step toward concrete carbon neutrality. PNAS Nexus 2023, 2, pgad052. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Ghouleh, Z.; Shao, Y. Review on carbonation curing of cement-based materials. J. CO2 Util. 2017, 21, 119–131. [Google Scholar] [CrossRef]

- Li, Z.; He, Z.; Chen, X. The Performance of Carbonation-Cured Concrete. Materials 2019, 12, 3729. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Chen, Z.; Hu, J. Carbon Sequestration, Mechanical Properties and Carbonation Kinetics of PP-Fiber-Reinforced Cement-Based Composites with CO2-Curing Treatment. Coatings 2022, 12, 1339. [Google Scholar] [CrossRef]

- EN 16757; Sustainability of Construction Works—Environmental Product Declarations—Product Category Rules for Concrete and Concrete Elements. European Committee for Standardization (CEN): Brussels, Belgium, 2022.

- EN 15804:2012+A2:2019/AC:2021; Sustainability of Construction Works—Environmental Product Declaration—Core Rules for the Product Category of Construction Products. European Committee for Standardization (CEN): Brussels, Belgium, 2021.

- IVL; Stripple, H.; Ljungkrantz, C.; Gustafsson, T. CO2 Uptake in Cement-Containing Products. In Background and Calculation Models for IPCC Implementation, 2nd ed.; Report Number: B 2309; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2021; pp. 1–77. Available online: https://www.ivl.se/download/18.34244ba71728fcb3f3f8f9/1622457897161/B2309.pdf (accessed on 15 February 2023).

- Sanjuán, M.Á.; Andrade, C.; Mora, P.; Zaragoza, A. Carbon Dioxide Uptake by Mortars and Concretes Made with Portuguese Cements. Appl. Sci. 2020, 10, 646. [Google Scholar] [CrossRef]

- Sanjuán, M.A.; Estévez, E.; Argiz, C.; del Barrio, D. Effect of curing time on granulated blast-furnace slag cement mortars carbonation. Cem. Concr. Compos. 2018, 90, 257–265. [Google Scholar] [CrossRef]

- Zhang, Q. Mathematical modeling and numerical study of carbonation in porous concrete materials. Appl. Math. Comput. 2016, 281, 16–27. [Google Scholar] [CrossRef]

- Köliö, A.; Niemelä, P.J.; Lahdensivu, J. Evaluation of a carbonation model for existing concrete facades and balconies by consecutive field measurements. Cem. Concr. Compos. 2016, 65, 29–40. [Google Scholar] [CrossRef]

- Isgor, O.B.; Razaqpur, A.G. Finite element modeling of coupled heat transfer, moisture transport and carbonation processes in concrete structures. Cem. Concr. Compos. 2004, 26, 57–73. [Google Scholar] [CrossRef]

- Liang, M.; Lin, S. Mathematical modeling and applications for concrete carbonation. J. Mar. Sci. Technol. 2003, 11, 20–33. [Google Scholar] [CrossRef]

- Muntean, A.; Böhmb, M. A moving-boundary problem for concrete carbonation: Global existence and uniqueness of weak solutions. J. Math. Anal. Appl. 2009, 350, 234–251. [Google Scholar] [CrossRef]

- Leemann, A.; Nygaard, P.; Kaufmann, J.; Loser, R. Relation between carbonation resistance, mix design and exposure of mortar and concrete. Cem. Concr. Compos. 2015, 62, 33–43. [Google Scholar] [CrossRef]

- Crank, J. The Mathematics of Diffusion, 2nd ed.; Oxford University Press: London, UK, 1975. [Google Scholar]

- Goñi, S.; Gaztañaga, M.; Guerrero, A. Role of cement type on carbonation attack. J. Mater. Res. 2002, 17, 1834–1842. [Google Scholar] [CrossRef]

- González, J.A.; Algaba, S.; Andrade, C. Corrosion of reinforcing bars in carbonated concrete. Br. Corrosion J. 1980, 15, 135–139. [Google Scholar] [CrossRef]

- You, X.; Hu, X.; He, P.; Liu, J.; Shi, C. A review on the modelling of carbonation of hardened and fresh cement-based materials. Cem. Concr. Compos. 2022, 125, 104315. [Google Scholar] [CrossRef]

- Andrade, C. Evaluation of the degree of carbonation of concretes in three environments. Constr. Build. Mater. 2020, 230, 116804. [Google Scholar] [CrossRef]

- Bui, H.; Delattre, F.; Levacher, D. Experimental Methods to Evaluate the Carbonation Degree in Concrete—State of the Art Review. Appl. Sci. 2023, 13, 2533. [Google Scholar] [CrossRef]

- Andrade, C.; Sanjuán, M.Á. Updating Carbon Storage Capacity of Spanish Cements. Sustainability 2018, 10, 4806. [Google Scholar] [CrossRef]

- Mach, K.J.; Mastrandrea, M.D.; Freeman, P.T.; Field, C.B. Unleashing expert judgment in assessment. Glob. Environ. Change 2017, 44, 1–14. [Google Scholar] [CrossRef]

- Mastrandrea, M.D.; Field, C.B.; Stocker, T.F.; Edenhofer, O.; Ebi, K.L.; Frame, D.J.; Held, H.; Kriegler, E.; Mach, K.J.; Matschoss, P.R.; et al. 2010: Guidance Note for Lead Authors of the IPCC Fifth Assessment Report on Consistent Treatment of Uncertainties. Intergovernmental Panel on Climate Change (IPCC), 2010; p. 7. Available online: https://www.ipcc.ch/site/assets/uploads/2018/05/uncertainty-guidance-note.pdf (accessed on 15 September 2023).

- Molina, T.; Abadal, E. The Evolution of Communicating the Uncertainty of Climate Change to Policymakers: A Study of IPCC Synthesis Reports. Sustainability 2021, 13, 2466. [Google Scholar] [CrossRef]

- da Silva Rego, J.H.; Sanjuán, M.Á.; Mora, P.; Zaragoza, A.; Visedo, G. Carbon Dioxide Uptake by Brazilian Cement-Based Materials. Appl. Sci. 2023, 13, 10386. [Google Scholar] [CrossRef]

- Kause, A.; Bruine de Bruin, W.; Persson, J.; Thorén, H.; Olsson, L.; Wallin, A.; Dessai, S.; Vareman, N. Confidence levels and likelihood terms in IPCC reports: A survey of experts from different scientific disciplines. Clim. Chang. 2022, 173, 2. [Google Scholar] [CrossRef]

- Friedlingstein, P.; O’Sullivan, M.; Jones, M.W.; Andrew, R.M.; Bakker, D.C.E.; Hauck, J.; Landschützer, P.; Le Quéré, C.; Luijkx, I.T.; Peters, G.P.; et al. Global Carbon Budget 2023. Earth Syst. Sci. Data 2023, 15, 5301–5369. [Google Scholar] [CrossRef]

- Nemet, G.F.; Gidden, M.J.; Greene, J.; Roberts, C.; Lamb, W.F.; Minx, J.C.; Smith, S.M.; Geden, O.; Riahi, K. Near-term deployment of novel carbon removal to facilitate longer-term deployment. Joule 2023, 7, 2653–2659. [Google Scholar] [CrossRef]

- Science Based Targets Initiative’s (SBTi’s). Available online: https://sciencebasedtargets.org/net-zero (accessed on 15 September 2023).

- Fankhauser, S.; Smith, S.M.; Allen, M.; Axelsson, K.; Hale, T.; Hepburn, C.; Kendall, J.M.; Khosla, R.; Lezaun, J.; Mitch-ell-Larson, E.; et al. The meaning of net zero and how to get it right. Nat. Clim. Chang. 2022, 12, 15–21. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanjuán, N.; Mora, P.; Sanjuán, M.Á.; Zaragoza, A. Carbon Dioxide Uptake Estimation for Spanish Cement-Based Materials. Materials 2024, 17, 326. https://doi.org/10.3390/ma17020326

Sanjuán N, Mora P, Sanjuán MÁ, Zaragoza A. Carbon Dioxide Uptake Estimation for Spanish Cement-Based Materials. Materials. 2024; 17(2):326. https://doi.org/10.3390/ma17020326

Chicago/Turabian StyleSanjuán, Natalia, Pedro Mora, Miguel Ángel Sanjuán, and Aniceto Zaragoza. 2024. "Carbon Dioxide Uptake Estimation for Spanish Cement-Based Materials" Materials 17, no. 2: 326. https://doi.org/10.3390/ma17020326