An Experimental Study on the Mechanical Properties and Microstructure of the Cemented Paste Backfill Made by Coal-Based Solid Wastes and Nanocomposite Fibers under Dry–Wet Cycling

Abstract

:1. Introduction

2. Experimental Contents and Methods

2.1. Test Materials and Equipment

2.1.1. Test Materials

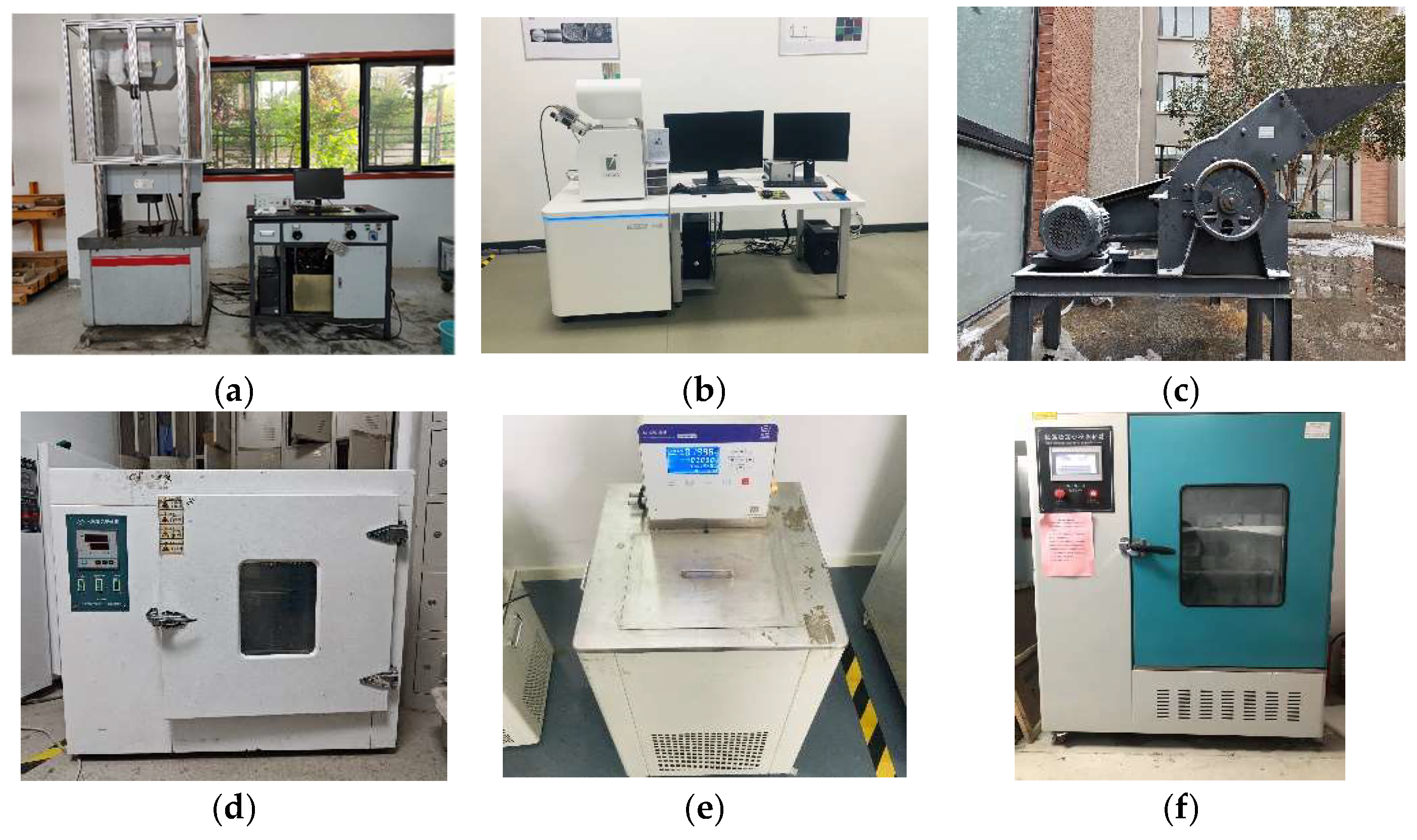

2.1.2. Test Equipment

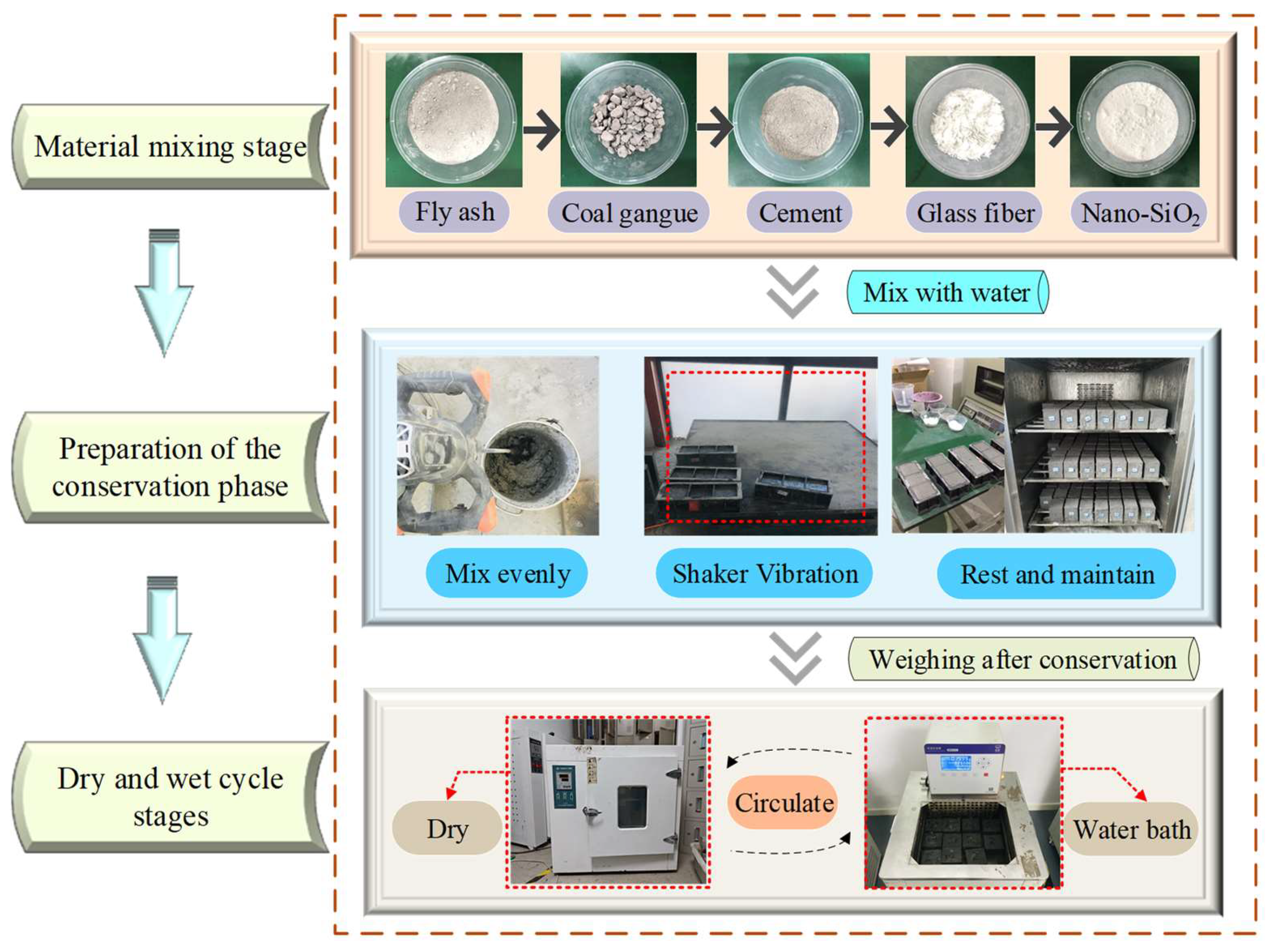

2.2. Testing Schemes

2.3. Specimen Preparation

3. Results and Discussion

3.1. Compressive Strength Test

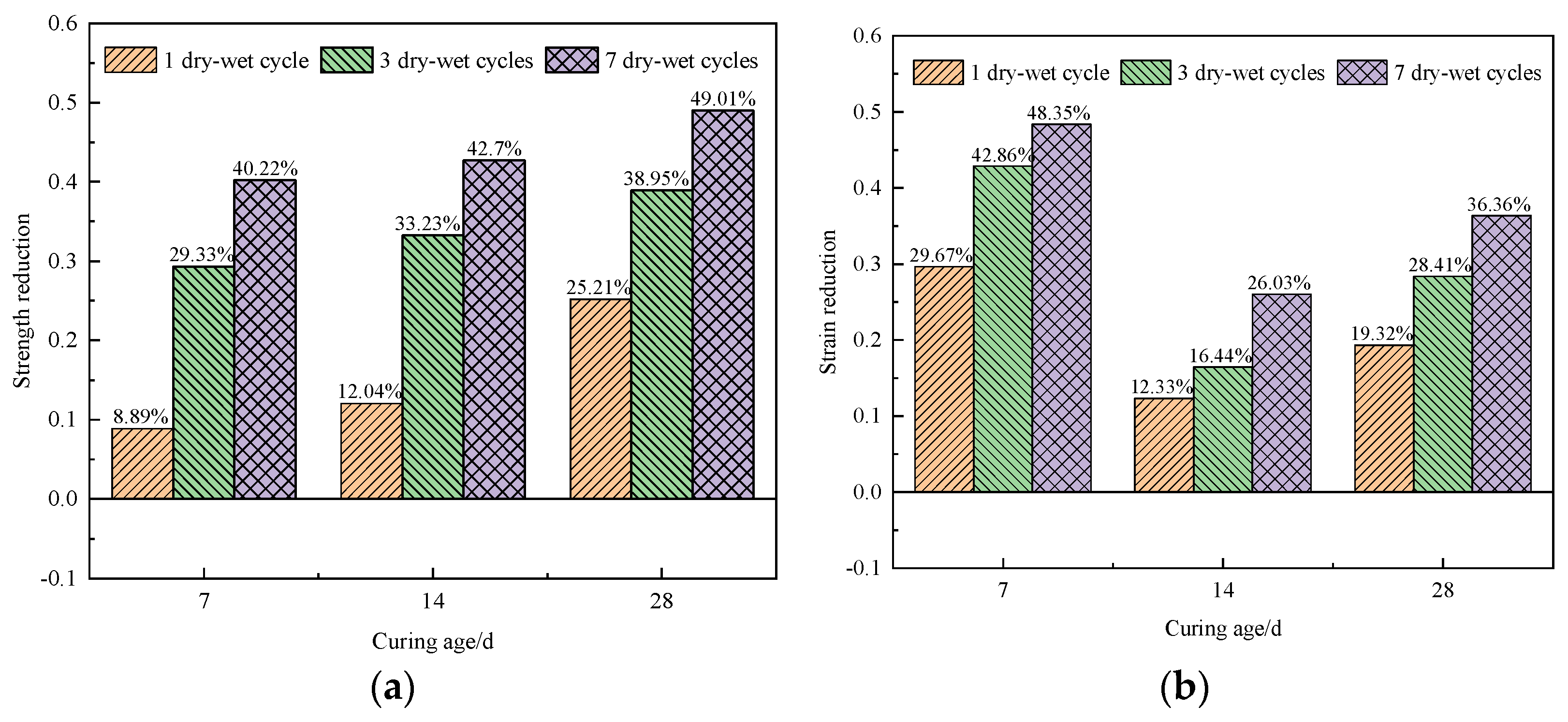

3.1.1. The Effect of Different Dry–Wet Cycles on Compressive Strength

3.1.2. Effect of Curing Age on Compressive Strength of Specimens after Dry–Wet Cycles

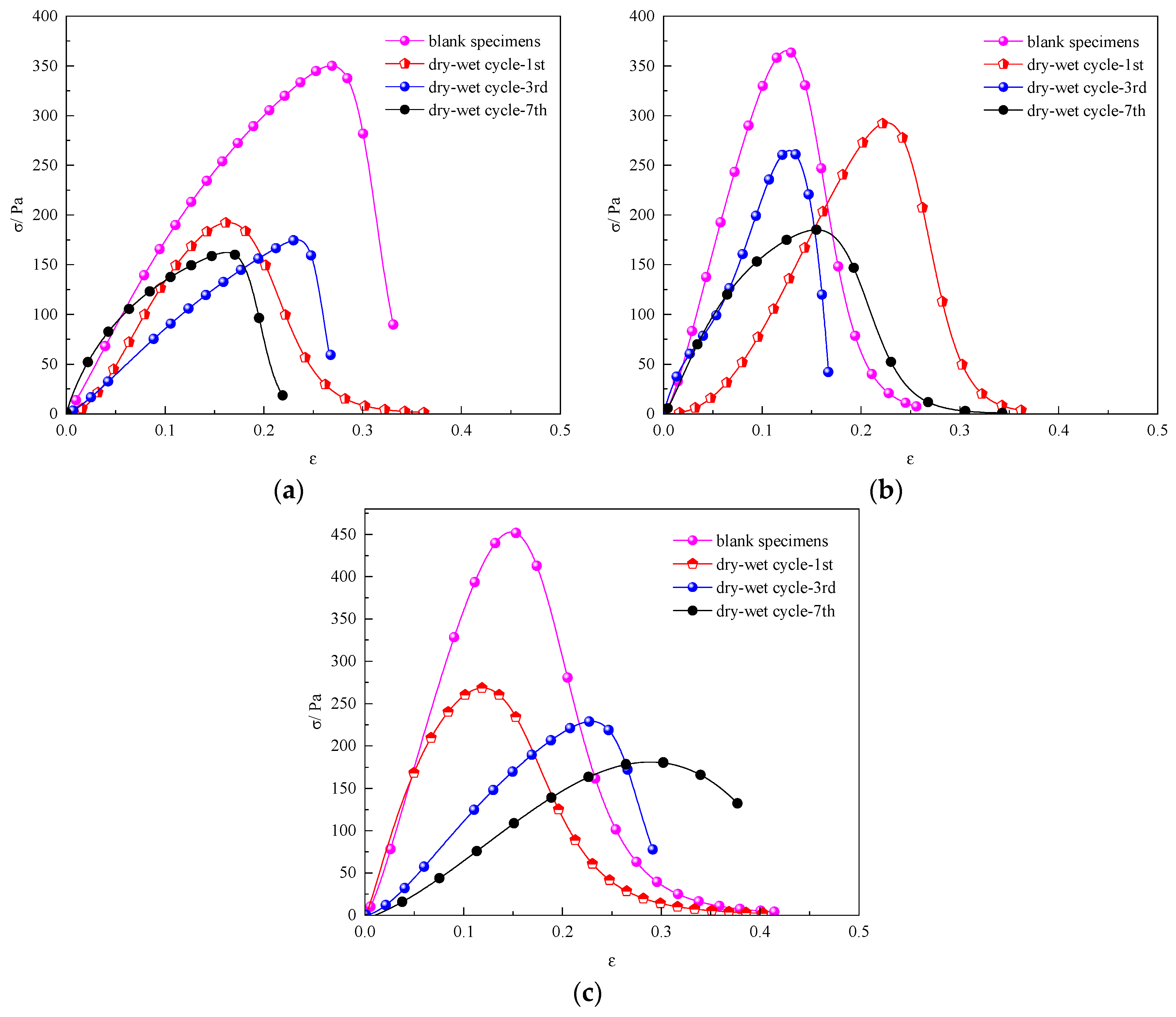

3.2. Tensile Strength Test

3.2.1. The Effect of Different Dry–Wet Cycles on Tensile Strength

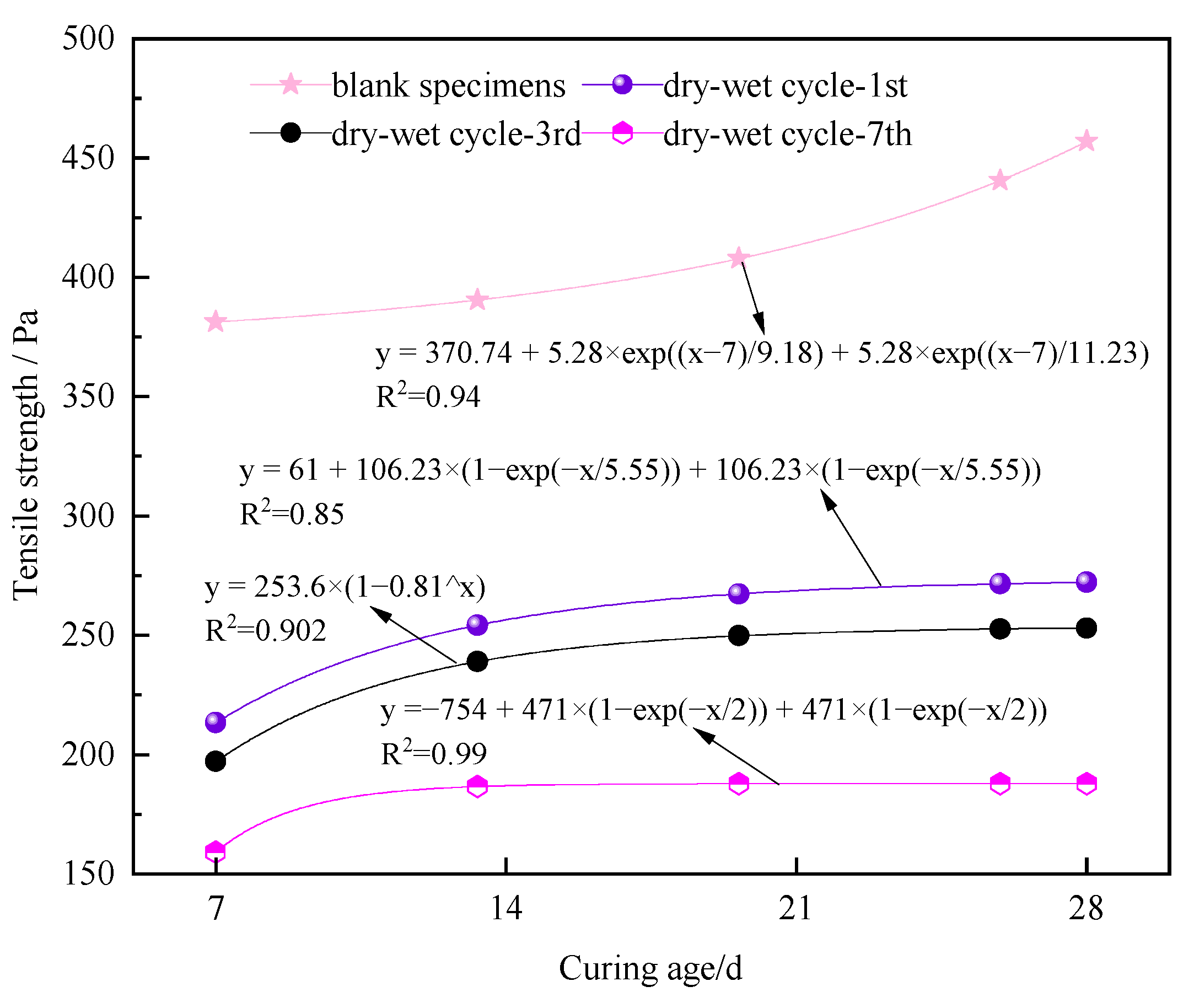

3.2.2. Effect of Curing Age on Tensile Strength of Specimens after Dry–Wet Cycles

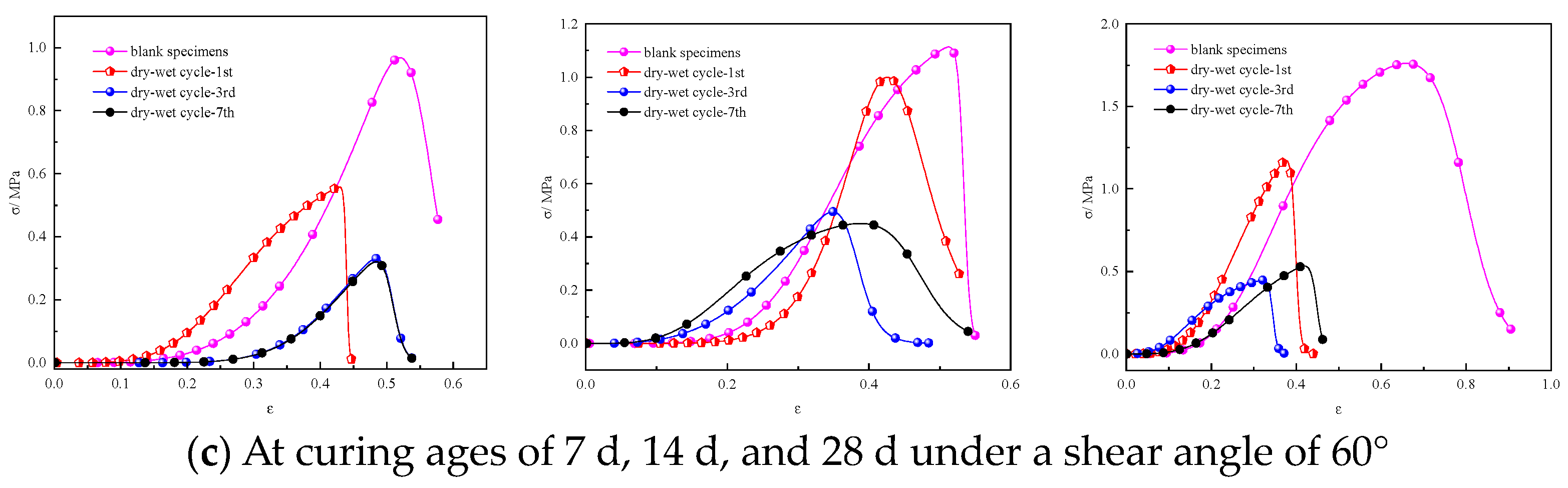

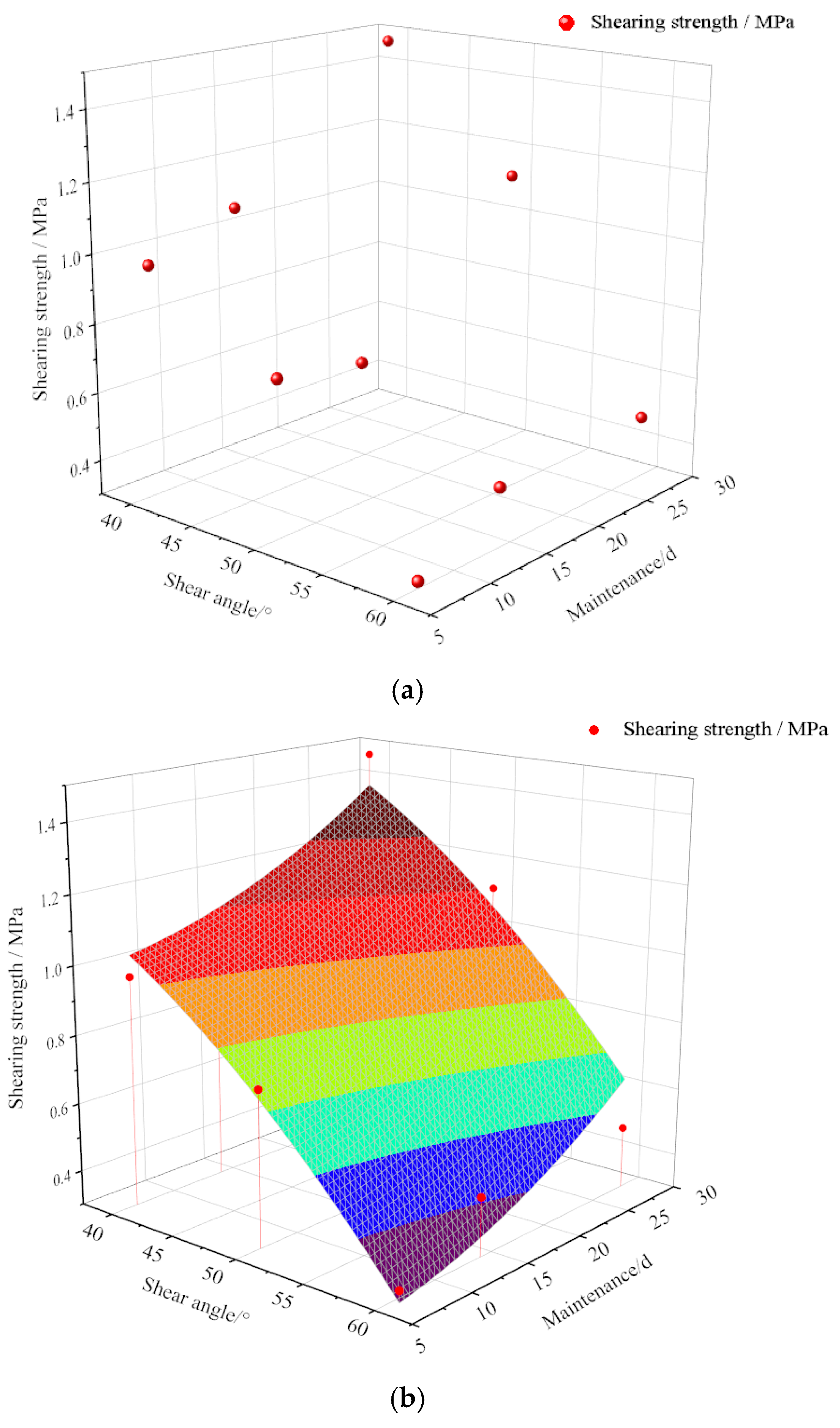

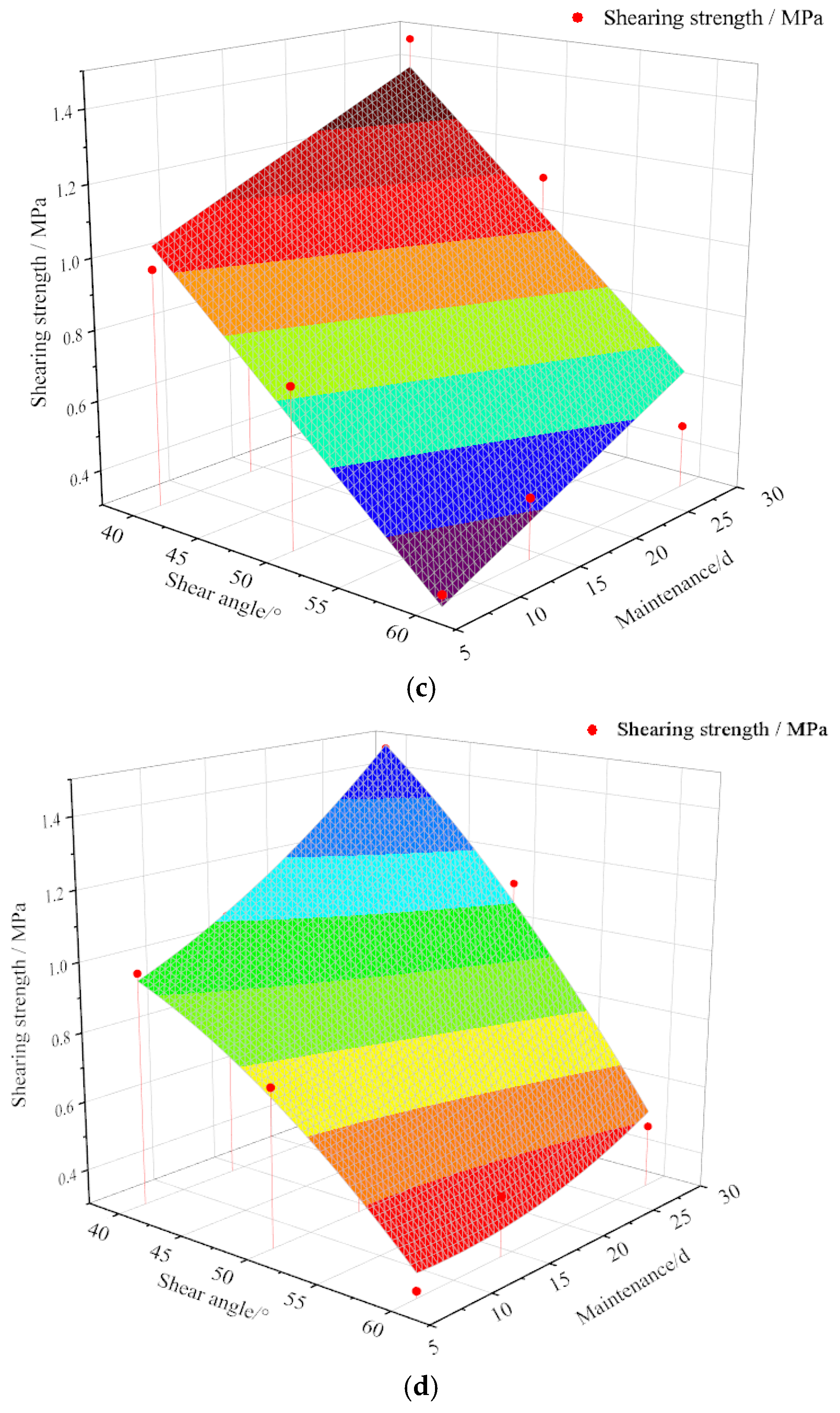

3.3. Shear Strength Tests

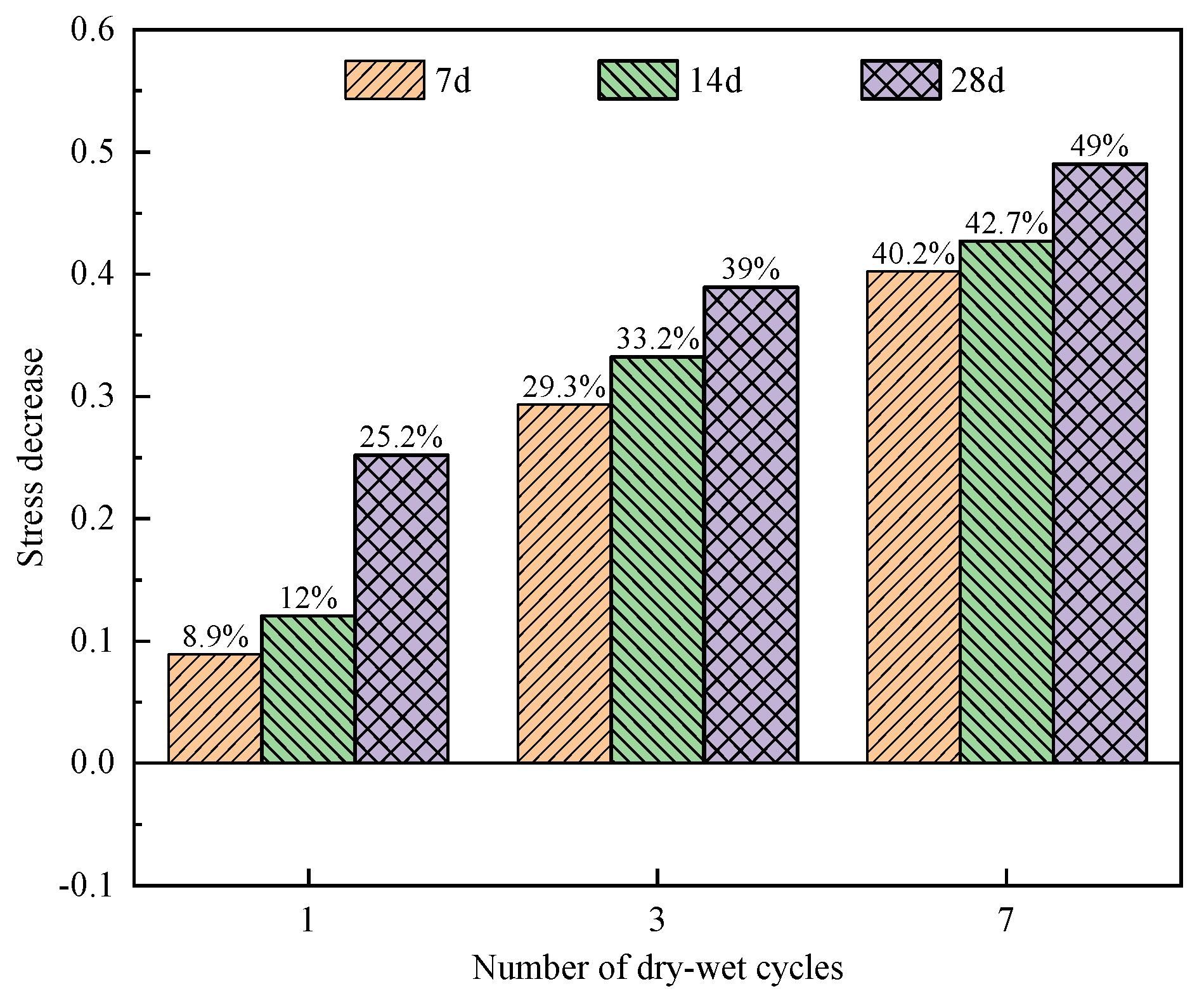

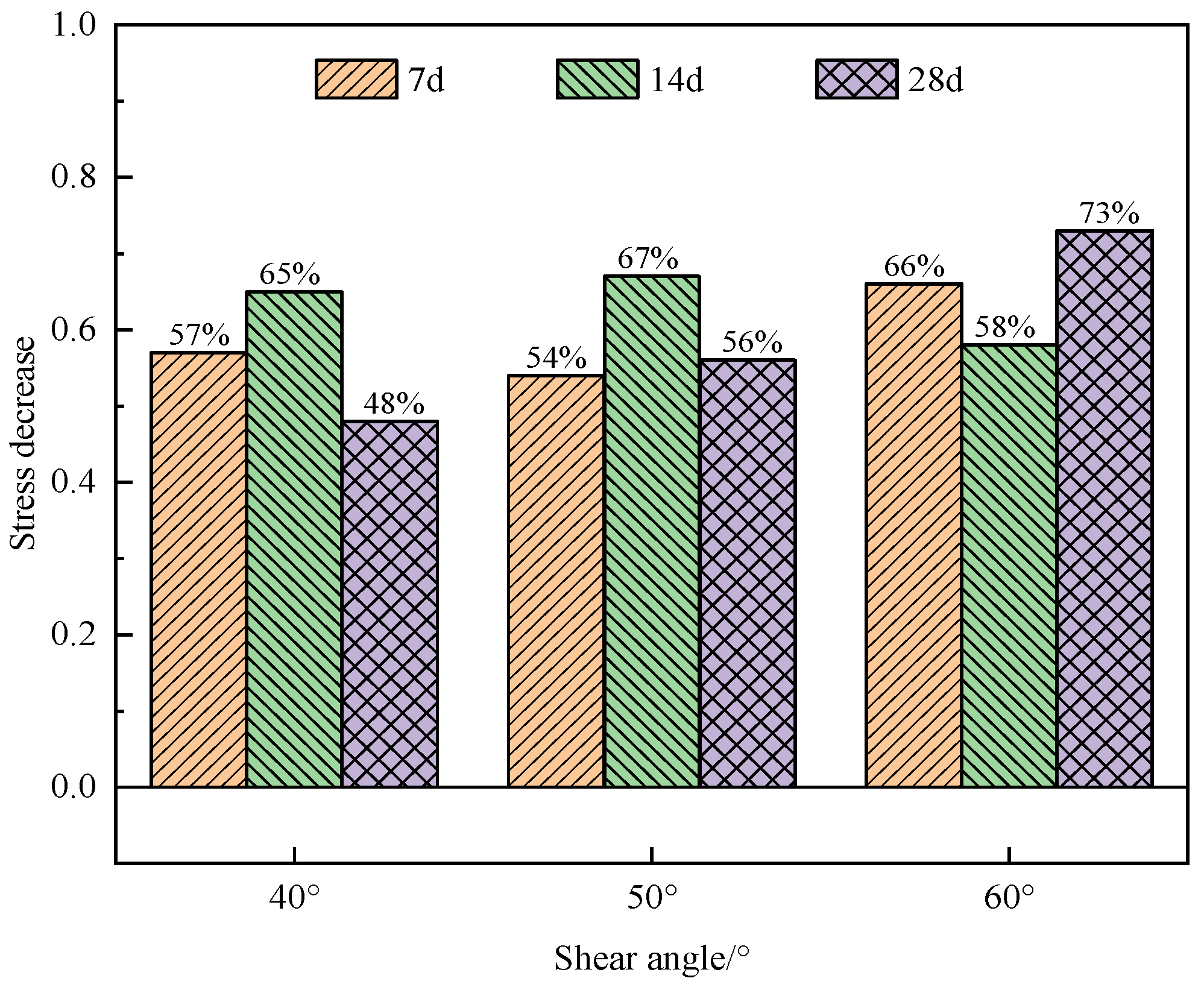

3.3.1. The Effect of Different Dry–Wet Cycles on Shear Strength

3.3.2. Effect of Curing Age on Shear Strength of Specimens after Dry–Wet Cycle

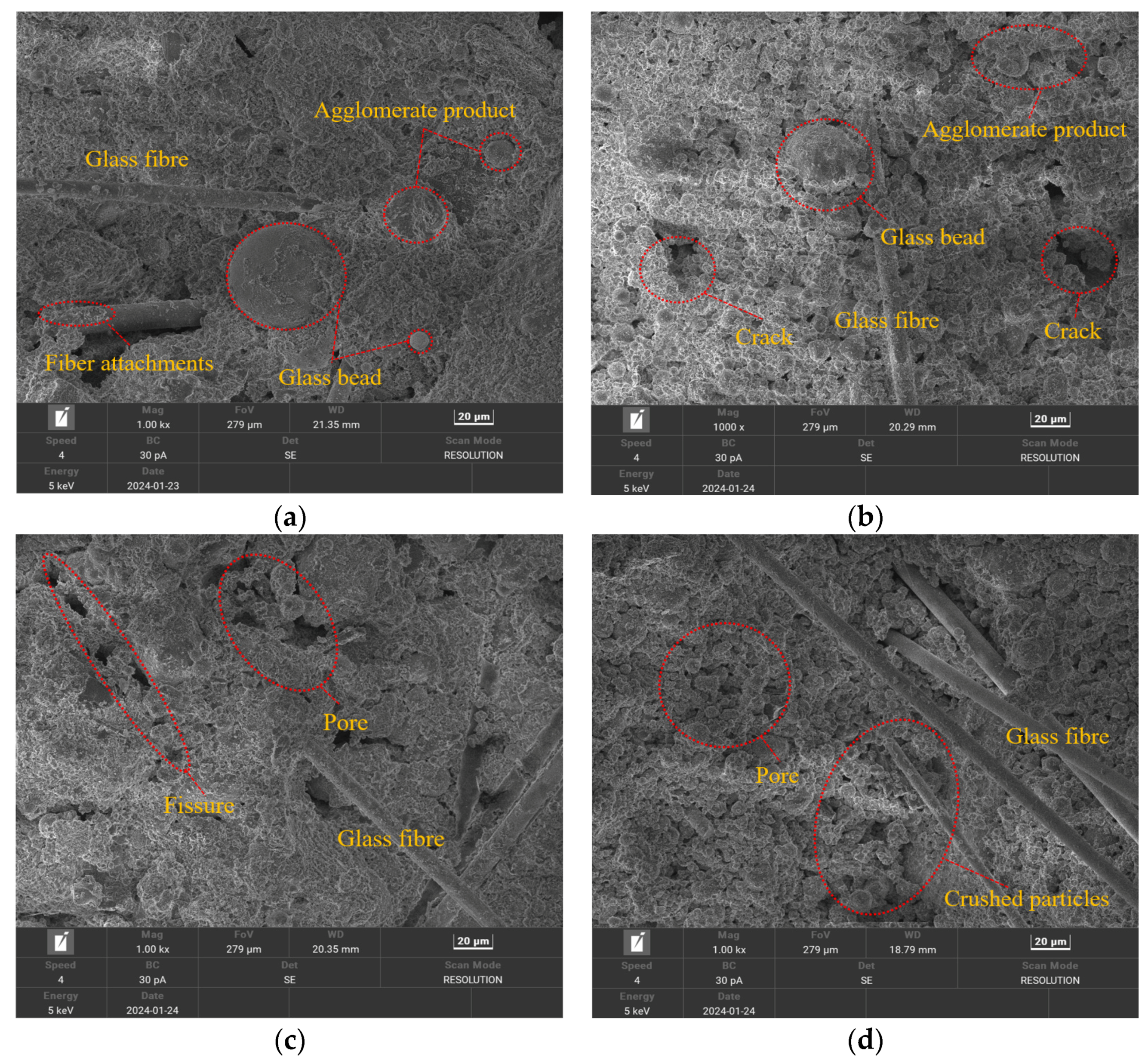

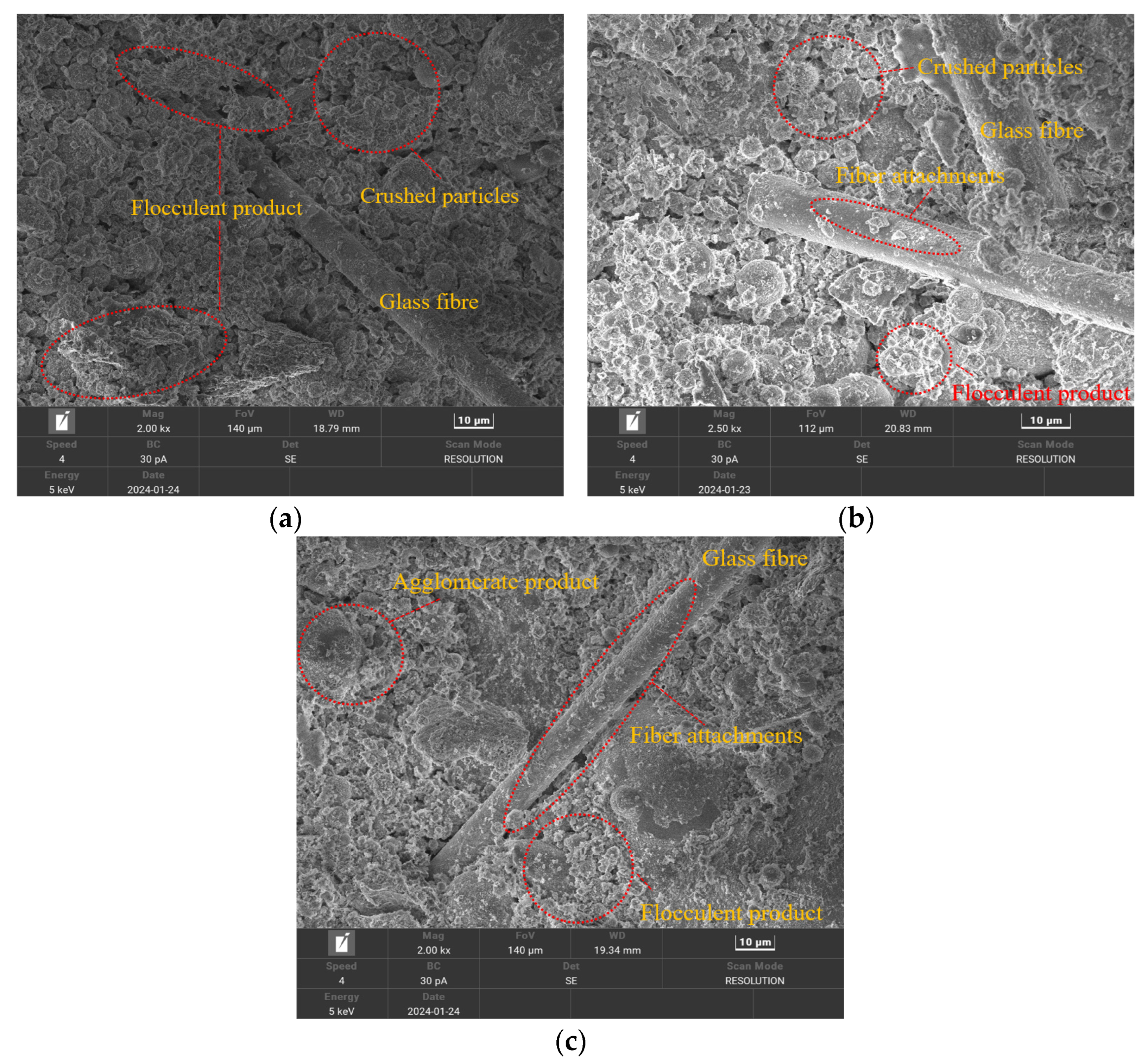

3.4. Analysis of Microstructure

3.4.1. Microscopic Structure of Specimens after Different Dry–Wet Cycles

3.4.2. Microscopic Structure of Specimens at Different Curing Ages

4. Conclusions

- (1)

- With the increase in the number of dry–wet cycles, the peak values regarding the compressive, tensile, and shear strengths of the specimens all decreased. Moreover, during the shear test with a certain number of dry–wet cycles, the larger the shear angle, the more serious impact of the dry–wet cycles on the shear behavior of the specimens was. These results indicate that the mechanical properties of nanocomposite fiber–CPB specimens are greatly affected by the alternation of dry and wet environments within a short time.

- (2)

- With the increase in the curing age, the compressive strength and tensile strength of the specimens after the dry–wet cycling increased exponentially and finally stabilized after 28d of curing. The growth rate of peak stress gradually decreased during the whole process, indicating that with the increase in curing age, the mechanical properties of nanocomposite fiber–CPB are gradually reduced by the dry–wet cycling.

- (3)

- The SEM results show that with the increase in the number of dry–wet cycles, the internal structure of the nanocomposite fiber–CPB material deteriorated gradually; the cracks and pores became more pronounced, leading to greater damage to the internal structural skeleton and an increased susceptibility to surface breakage and spalling.

- (4)

- With the increase in curing age, the hydration products in the nanocomposite fiber–CPB materials became attached to the specimen surface, and the adhesion area gradually increased; at the same time, the number of cracks and holes on the surface decreased, and the failure process of the internal structure gradually decreased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Amrani, M.; Taha, Y.; El Haloui, Y.; Benzaazoua, M.; Hakkou, R. Sustainable Reuse of Coal Mine Waste: Experimental and Economic Assessments for Embankments and Pavement Layer Applications in Morocco. Minerals 2020, 10, 851. [Google Scholar] [CrossRef]

- Zhou, N.; Yao, Y.N.; Song, W.J.; He, Z.W.; Meng, G.H.; Liu, Y. Present situation and prospect of coal gangue treatment technology. J. Min. Saf. Eng. 2020, 37, 136–146. [Google Scholar]

- Du, J.L. Characteristics of coal gangue in Ximing Coal Mine and its significance of resource utilization. China Coal Geol. 2021, 33, 26–30+77. [Google Scholar]

- Gele, J.R.; Zhao, R. Selection of unloading position for automatic waste discharging of truck transport based on EDEM. Coal. Eng. 2021, 53, 91–95. [Google Scholar]

- Fall, M.; Adrien, D.; Célestin, J.C.; Pokharel, M.; Touré, M. Saturated hydraulic conductivity of cemented paste backfill. Miner. Eng. 2009, 22, 1307–1317. [Google Scholar] [CrossRef]

- Fall, M.; Nasir, O. Mechanical Behaviour of the Interface between Cemented Tailings Backfill and Retaining Structures under Shear Loads. Geotech. Geol. Eng. 2010, 28, 779–790. [Google Scholar] [CrossRef]

- Simms, P.; Grabinsky, M.; Zhan, G. Modelling evaporation of paste tailings from the Bulyanhulu mine. Can. Geotech. J. 2007, 44, 1417–1432. [Google Scholar] [CrossRef]

- Ketov, A.; Rudakova, L.; Vaisman, I.; Ketov, I.; Haritonovs, V.; Sahmenko, G. Recycling of rice husks ash for the preparation of resistant, lightweight and environment-friendly fired bricks. Constr. Build. Mater. 2021, 302, 124385. [Google Scholar] [CrossRef]

- Cui, L.; Fall, M. Mechanical and thermal properties of cemented tailings materials at early ages: Influence of initial temperature, curing stress and drainage conditions. Constr. Build. Mater. 2016, 125, 553–563. [Google Scholar] [CrossRef]

- Cui, L.; Fall, M. Multiphysics Model for Consolidation Behavior of Cemented Paste Backfill. Int. J. Géoméch. 2017, 17, 04016077. [Google Scholar] [CrossRef]

- He, Y.; Chen, Q.S.; Qi, C.C.; Zhang, Q.L.; Xiao, C.C. Lithium slag and fly ash-based binder for cemented fine tailings backfill. J. Environ. Manag. 2019, 248, 109282. [Google Scholar] [CrossRef] [PubMed]

- Wang, A.; Cao, S.; Yilmaz, E. Influence of types and contents of nano cellulose materials as reinforcement on stability performance of cementitious tailings backfill. Constr. Build. Mater. 2022, 344, 128179. [Google Scholar] [CrossRef]

- Behera, S.; Mishra, D.; Singh, P.; Mishra, K.; Mandal, S.K.; Ghosh, C.; Kumar, R.; Mandal, P.K. Utilization of mill tailings, fly ash and slag as mine paste backfill material: Review and future perspective. Constr. Build. Mater. 2021, 309, 125120. [Google Scholar] [CrossRef]

- Ouffa, N.; Trauchessec, R.; Benzaazoua, M.; Lecomte, A.; Belem, T. A methodological approach applied to elaborate alkali-activated binders for mine paste backfills. Cem. Concr. Compos. 2022, 127, 104381. [Google Scholar] [CrossRef]

- Aslani, F.; Dehghani, A.; Wang, L. The effect of hollow glass microspheres, carbon nanofibers and activated carbon powder on mechanical and dry shrinkage performance of ultra-lightweight engineered cementitious composites. Constr. Build. Mater. 2021, 280, 122415. [Google Scholar] [CrossRef]

- Ghasabkolaei, N.; Choobbasti, A.J.; Roshan, N.; Ghasemi, S.E. Geotechnical properties of the soils modified with nanomaterials: A comprehensive review. Arch. Civ. Mech. Eng. 2017, 17, 639–650. [Google Scholar] [CrossRef]

- Jha, K.K. An Energy Based Nanomechanical Properties Evaluation Method for Cementitious Materials. Ph.D. Thesis, Florida International University, Miami, FL, USA, 2012. [Google Scholar]

- Farzadnia, N.; Bahmani, S.H.; Asadi, A.; Hosseini, S. Mechanical and microstructural properties of cement pastes with rice husk ash coated with carbon nanofibers using a natural polymer binder. Constr. Build. Mater. 2018, 175, 691–704. [Google Scholar] [CrossRef]

- Fonseca, C.S.; Silva, M.F.; Mendes, R.F.; Hein, P.R.G.; Zangiacomo, A.L.; Savastano, H.; Tonoli, G.H.D. Jute fibers and micro/nanofibrils as reinforcement in extruded fiber-cement composites. Constr. Build. Mater. 2019, 211, 517–527. [Google Scholar] [CrossRef]

- Wang, L.; Lin, X. Mechanical Properties and Micromechanism of Concrete Modified by Carbon Nanofibers. Concr. Cem. Prod. 2020, 1, 51–54. [Google Scholar]

- Qin, R.; Zhou, A.; Yu, Z.; Wang, Q.; Lau, D. Role of carbon nanotube in reinforcing cementitious materials: An experimental and coarse-grained molecular dynamics study. Cem. Concr. Res. 2021, 147, 106517. [Google Scholar] [CrossRef]

- Gao, B.; Cao, S.; Yilmaz, E. Effect of Content and Length of Polypropylene Fibers on Strength and Microstructure of Cementitious Tailings-Waste Rock Fill. Minerals 2023, 13, 142. [Google Scholar] [CrossRef]

- Song, Y.; Zhang, L.; Ren, J.; Chen, J.; Che, Y.; Yang, H.; Bi, R. Study on damage characteristics of weak cementation sandstone under drying-wetting cycles based on nuclear magnetic resonance technique. J. Rock Mech. Eng. 2019, 38, 825–831. [Google Scholar]

- Hale, P.A.; Shakoor, A. A Laboratory Investigation of the Effects of Cyclic Heating and Cooling, Wetting and Drying, and Freezing and Thawing on the Compressive Strength of Selected Sandstones. Environ. Eng. Geosci. 2003, 9, 117–130. [Google Scholar] [CrossRef]

- Duda, M.; Renner, J. The weakening effect of water on the brittle failure strength of sandstone. Geophys. J. Int. 2013, 192, 1091–1108. [Google Scholar] [CrossRef]

- Yao, H.; Zhang, Z.; Zhu, C.; Shi, Y.; Li, Y. Experimental study of mechanical properties of sandstone under cyclic drying and wetting. Rock Soil Mech. 2010, 31, 3704–3708. [Google Scholar]

- Wang, Z.; Liu, X.; Fu, Y.; Zhang, L.; Yuan, W. Erosion analysis of argillaceous sandstone under dry-wet cycle in two pH conditions. Rock Soil Mech. 2016, 37, 3231–3239. [Google Scholar]

- Esfandiari, Z.; Ajdari, M.; Vahedifard, F. Time-Dependent Deformation Characteristics of Unsaturated Sand–Bentonite Mixture under Drying–Wetting Cycles. J. Geotech. Geoenviron. Eng. 2021, 147, 04020172. [Google Scholar] [CrossRef]

- Zhang, F.; Jiang, A.; Yang, X. Shear creep experiments and modeling of granite under dry-wet cycling. Bull. Eng. Geol. Environ. 2021, 80, 5897–5908. [Google Scholar] [CrossRef]

- Guo, J.-J.; Wang, K.; Guo, T.; Yang, Z.-Y.; Zhang, P. Effect of Dry–Wet Ratio on Properties of Concrete Under Sulfate Attack. Materials 2019, 12, 2755. [Google Scholar] [CrossRef]

- Huang, K.; Dai, Z.; Meng, Y.; Yu, F.; Yao, J.; Zhang, W.; Chi, Z.; Chen, S. Mechanical behavior and fracture mechanism of red-bed mudstone under varied dry-wet cycling and prefabricated fracture planes with different loading angles. Theor. Appl. Fract. Mech. 2023, 127, 104094. [Google Scholar] [CrossRef]

- Cai, X.; Zhou, Z.; Tan, L.; Zang, H.; Song, Z. Fracture behavior and damage mechanisms of sandstone subjected to wetting-drying cycles. Eng. Fract. Mech. 2020, 234, 107109. [Google Scholar] [CrossRef]

- Guo, Y.B. Research on Properties of Coal-Based Solid Waste Nanocomposite Fiber Cementitious Materials; China University of Mining and Technology: Beijing, China, 2022. [Google Scholar]

- Cheng, Q.; Wang, H.; Guo, Y.; Du, B.; Yin, Q.; Zhang, L.; Yao, Y.; Zhou, N. Experimental Study on Mechanical Properties of Coal-Based Solid Waste Nanocomposite Fiber Cementitious Backfill Material. Materials 2023, 16, 5314. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.; Zhang, J.; Nan, Z.; Li, M.; He, Z.; Fu, G. Effects of Doping Glass Fibers on the Early Strength of Sand-Based Cemented Paste Backfill for Solid Wastes. Adv. Civ. Eng. 2021, 2021, 5554941. [Google Scholar] [CrossRef]

- Ghafari, E.; Ghahari, S.; Feng, Y.; Severgnini, F.; Lu, N. Effect of Zinc oxide and Al-Zinc oxide nanoparticles on the rheological properties of cement paste. Compos. Part B Eng. 2016, 105, 160–166. [Google Scholar] [CrossRef]

- Liu, X.; Li, Y.; Wang, W.; Zhou, Y.; Cheng, L.; Fan, Z. Research on mechanical properties and strength criterion of carbonaceous shale with pre-existing fissures under drying-wetting cycles. Chin. J. Rock Mech. Eng. 2022, 41, 228–239. [Google Scholar] [CrossRef]

- Zhang, A.; Yang, W.; Ge, Y.; Du, Y.; Liu, P. Effects of nano-SiO2 and nano-Al2O3 on mechanical and durability properties of cement-based materials: A comparative study. J. Build. Eng. 2021, 34, 101936. [Google Scholar] [CrossRef]

- ASTM D4843-88-2016; Standard Test Method for Wetting and Drying Test of Solid Wastes. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Ministry of Housing and Urban Rural Development: Beijing, China, 2019.

- JGJ/T 70-2009; Standard for Test Method of Performance on Building Mortar. Ministry of Housing and Urban-Rural Development: Beijing, China, 2009.

- Zhou, Z.; Cai, X.; Ma, D.; Chen, L.; Wang, S.; Tan, L. Dynamic tensile properties of sandstone subjected to wetting and drying cycles. Constr. Build. Mater. 2018, 182, 215–232. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, P.; Zuo, J.; Liu, C.; Han, Y.; Zhang, Z. Long-term properties and microstructure change of engineered cementitious composites subjected to high sulfate coal mine water in drying-wetting cycles. Mater. Des. 2021, 203, 109610. [Google Scholar] [CrossRef]

- Liu, K.; Gu, T.; Wang, X.; Wang, J. Time-Dependence of the Mechanical Behavior of Loess after Dry-Wet Cycles. Appl. Sci. 2022, 12, 1212. [Google Scholar] [CrossRef]

| Material | Characterization | Parameters | Characterization | Parameters |

|---|---|---|---|---|

| Non-alkali glass fiber | Specification | 6 mm | Fiber density | 2.699 g/cm2 |

| Tensile strength | ≥2000 Mpa | Elongation at break | ≥2.5 | |

| Tensile modulus of elasticity | ≥85 GPa | Acid and alkali resistance | polar altitude | |

| Nano-SiO2 | Specific Surface Area | 240 m2/g | Bulk density | 0.06 g/cm3 |

| Density | 2.2~2.6 g/cm3 | Crystal type | Ball shape | |

| Color | White | Purity | ≥99.99% |

| Serial Number | Instrument/Equipment Name | Manufacturer |

|---|---|---|

| 1 | Electro-hydraulic servo press | Changchun Xinte Testing machine of China (Changchun, China) |

| 2 | SEM | Miero-source Detection (Hangzhou, China) |

| 3 | Jaw crusher | Xuzhou Sideli of China (Xuzhou, China) |

| 4 | Drying oven | Beijing Guangming Medical Equipment of China (Beijing, China) |

| 5 | Thermostatic water tank | Nanjing Xianou Manufacturing Company of China (Nanjing, China) |

| 6 | Standard curing box | Nanjing Jinrui Testing of China (Nanjing, China) |

| Material | Coal Gangune | Fly Ash | Cement | Glass Fiber | Nano-SiO2 |

|---|---|---|---|---|---|

| Percentage | 40% | 50% | 10% | 0.3% | 1% |

| Curing Age | Number of Wet and Dry Cycles | Mechanical Tests | Fine Structure Tests | Quantities | ||

|---|---|---|---|---|---|---|

| 7 d | 0, 1, 3, 7 | Compressive | Tensile | Shear | SEM (10 mm × 10 mm × 5 mm) | 60 |

| 3 | 3 | 9 | 4 | |||

| 14 d | Compressive | Tensile | Shear | SEM (10 mm × 10 mm × 5 mm) | 60 | |

| 3 | 3 | 9 | 4 | |||

| 28 d | Compressive | Tensile | Shear | SEM (10 mm × 10 mm × 5 mm) | 60 | |

| 3 | 3 | 9 | 4 | |||

| Curing Age | Shear Strength/MPa | ||

|---|---|---|---|

| 40° | 50° | 60° | |

| 7 d | 0.97 | 0.75 | 0.32 |

| 14 d | 1.07 | 0.71 | 0.47 |

| 28 d | 1.47 | 1.12 | 0.48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Cheng, Q.; Zhou, N.; Su, H.; Yin, Q.; Du, B.; Zhang, L.; Yao, Y. An Experimental Study on the Mechanical Properties and Microstructure of the Cemented Paste Backfill Made by Coal-Based Solid Wastes and Nanocomposite Fibers under Dry–Wet Cycling. Materials 2024, 17, 2256. https://doi.org/10.3390/ma17102256

Wang H, Cheng Q, Zhou N, Su H, Yin Q, Du B, Zhang L, Yao Y. An Experimental Study on the Mechanical Properties and Microstructure of the Cemented Paste Backfill Made by Coal-Based Solid Wastes and Nanocomposite Fibers under Dry–Wet Cycling. Materials. 2024; 17(10):2256. https://doi.org/10.3390/ma17102256

Chicago/Turabian StyleWang, Haodong, Qiangqiang Cheng, Nan Zhou, Heming Su, Qixiang Yin, Bin Du, Linglei Zhang, and Yue Yao. 2024. "An Experimental Study on the Mechanical Properties and Microstructure of the Cemented Paste Backfill Made by Coal-Based Solid Wastes and Nanocomposite Fibers under Dry–Wet Cycling" Materials 17, no. 10: 2256. https://doi.org/10.3390/ma17102256