Adhesion Properties of Recycled High-Viscosity Asphalt–Aggregate Interface under Dynamic Water Erosion

Abstract

:1. Introduction

2. Materials Preparation and Test Methods

2.1. Materials

2.2. Preparation of Recycled High-Viscosity Modified Asphalt

2.3. Experimental Methods

2.3.1. Adhesion Test

2.3.2. Contact Angle Test

- (1)

- Test methods

- (2)

- Computational modeling

- (3)

- Evaluation indicators

- a.

- Spreading factor

- b.

- Adhesion

- c.

- Flaking work

- d.

- Energy ratio parameters

2.3.3. AFM Test

3. Test Results and Discussion

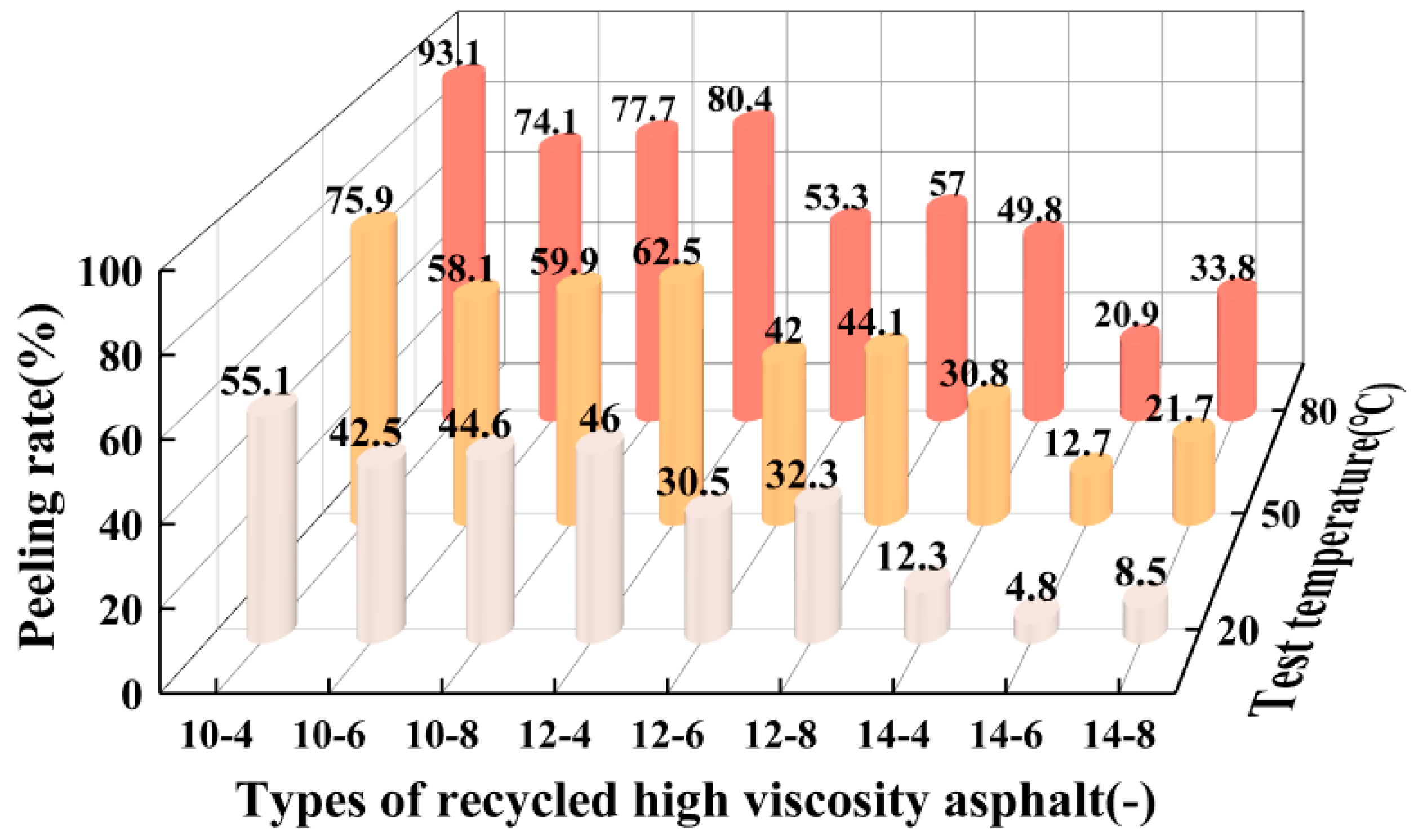

3.1. Study on the Interfacial Spalling Performance of Recycled High-Viscosity Asphalt Aggregate under Dynamic Water Erosion Conditions

3.2. Research on the Adhesion Performance of Regenerated High Viscous Asphalt Based on Surface Energy Principle

3.2.1. Surface Free Energy Measurement

3.2.2. Evaluation of Interfacial Adhesion between Recycled High-Viscosity Asphalt and Aggregate

- (1)

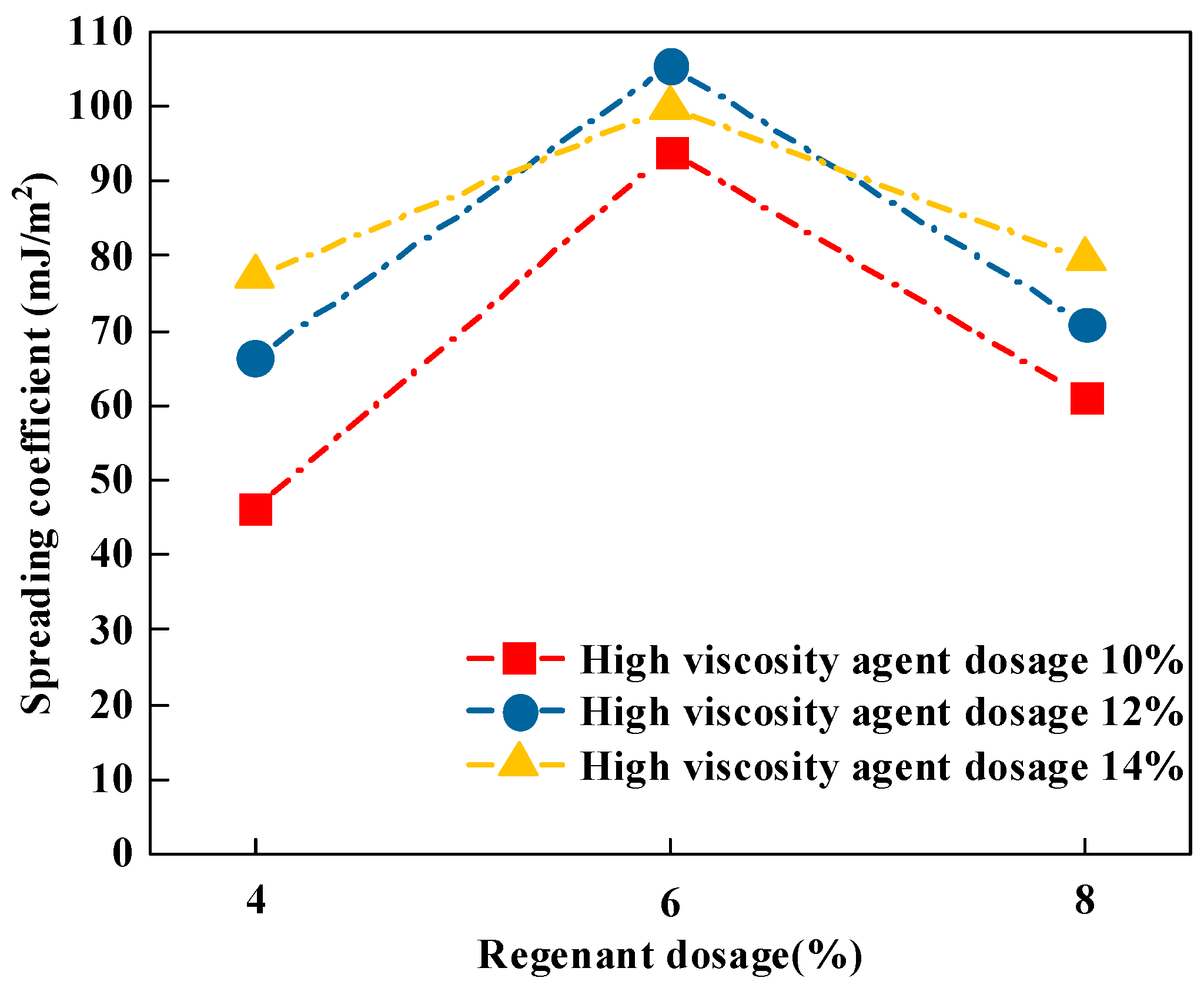

- Spreading factor

- (2)

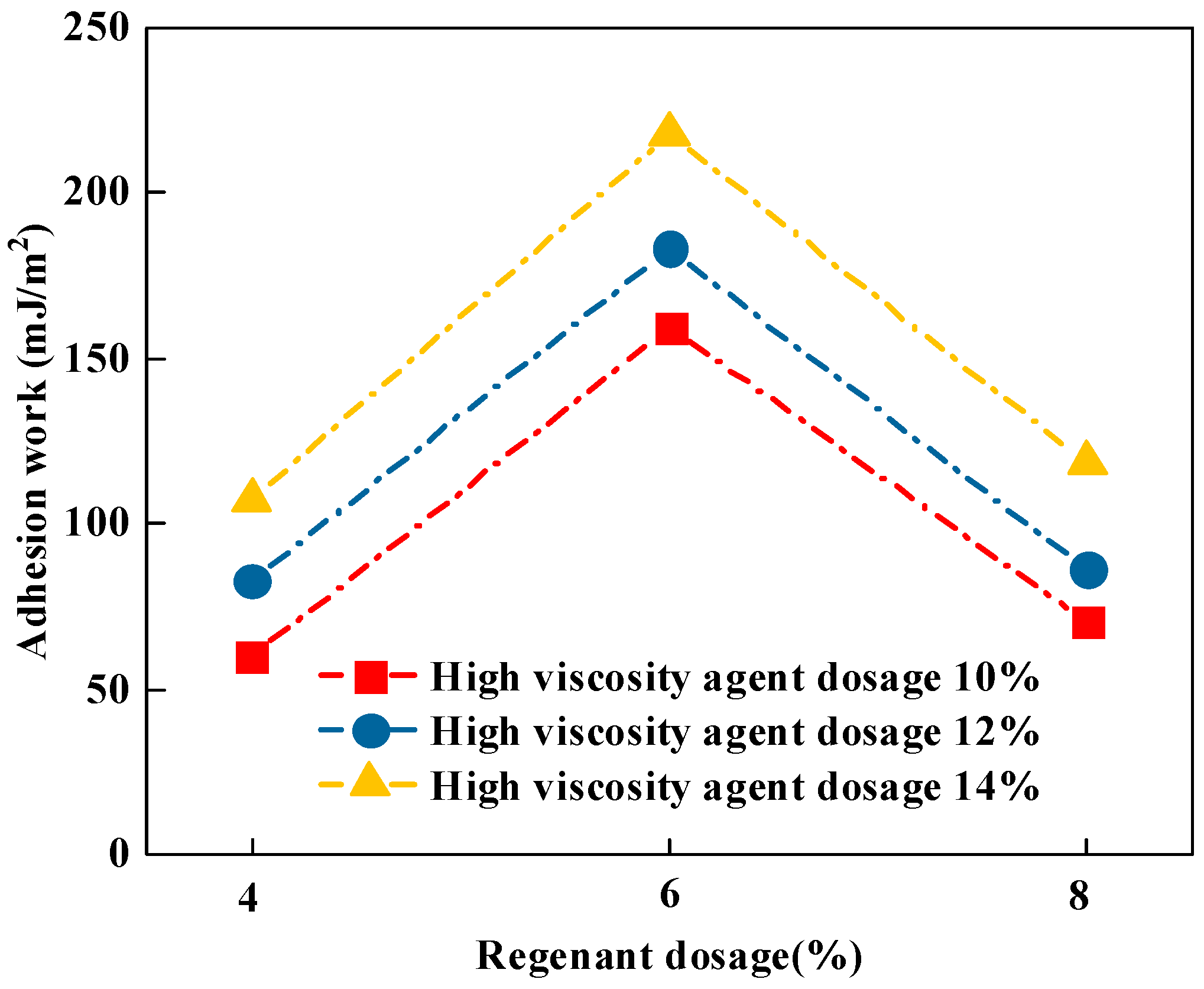

- Adhesion function

- (3)

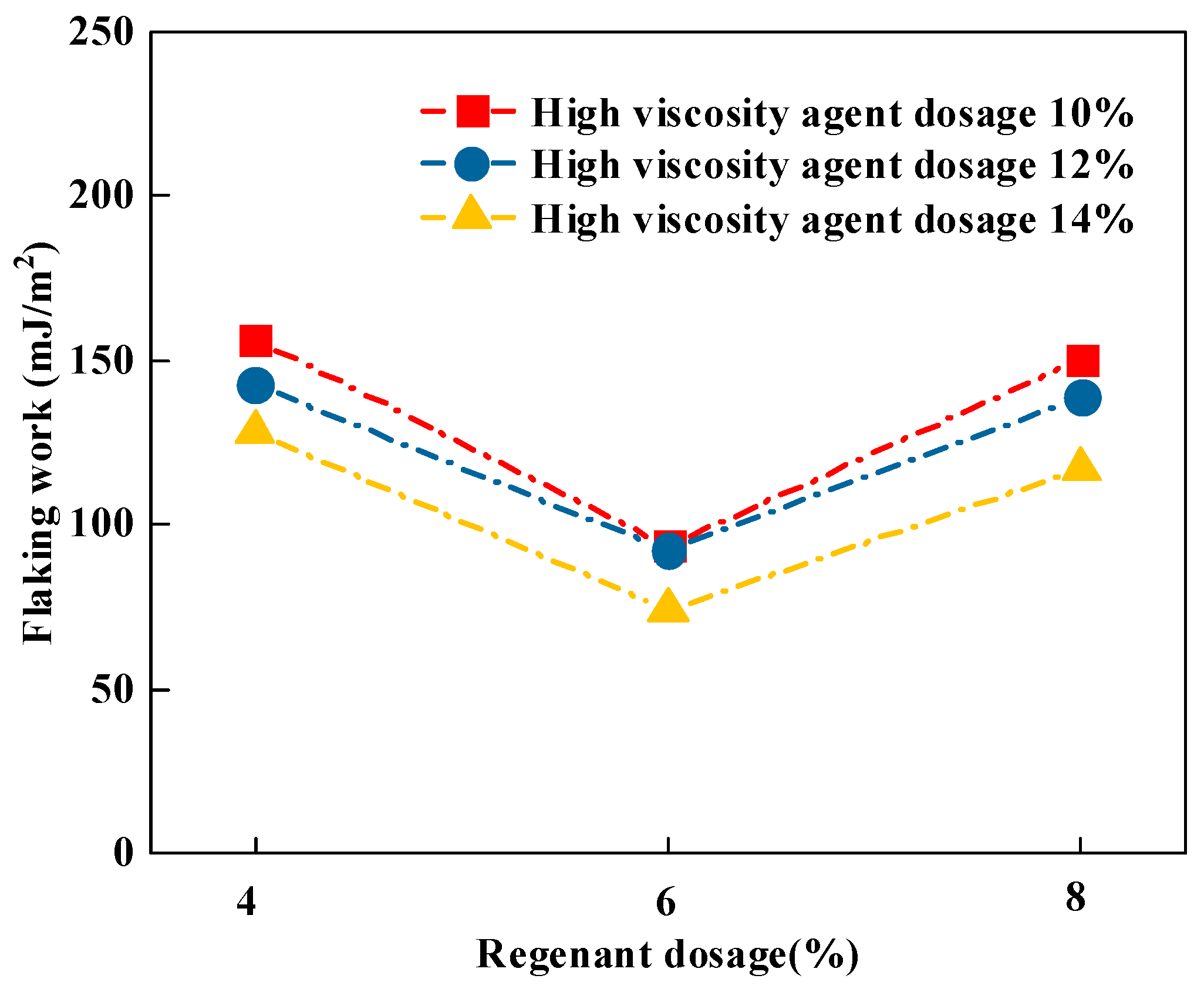

- Flaking work

- (4)

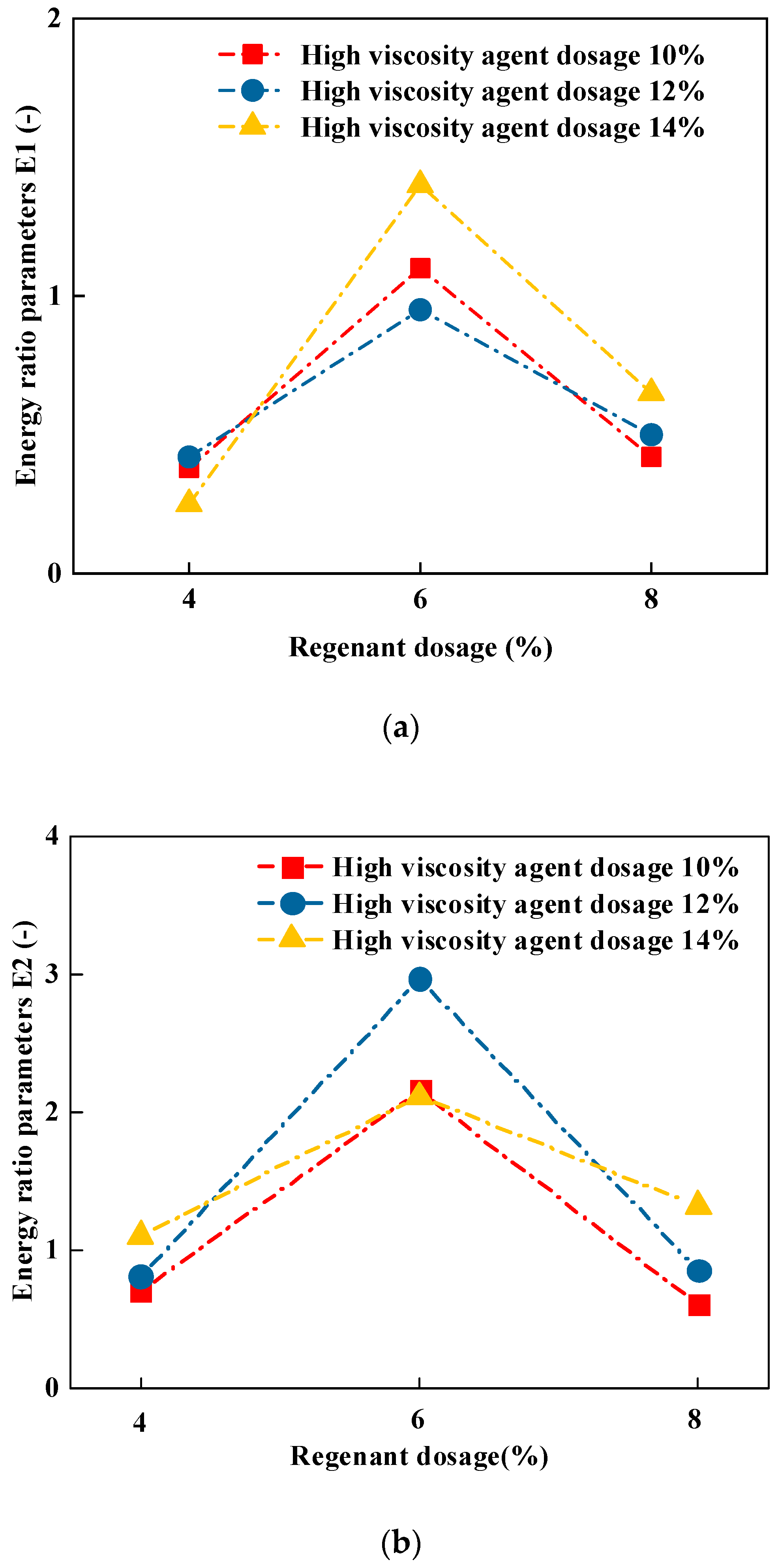

- Energy ratio parameters

3.3. Adhesion Characteristics of Recycled High-Viscosity Asphalt Aggregate Interface Based on AFM

3.3.1. Microscopic Surface Feature Analysis

3.3.2. Roughness

3.3.3. Adhesion

3.4. Significance Analysis

4. Conclusions

- (1)

- In the ultrasonic equipment, simulated dynamic water scour test conditions, different high-viscous agent dosages of aging high-viscous asphalt with the addition of a rejuvenating agent, the rate of spalling on the aggregate surface with the increase in rejuvenating agent dosage decreased first and then increased. A 6% rejuvenating agent dosage of the aging high-viscous asphalt was used with the anti-stripping performance of the best restoration effect. In addition, simulating the adhesion performance test under different weather temperatures, it was found that the higher the temperature, the worse the anti-spalling performance of reclaimed high-viscous asphalt.

- (2)

- Through the contact angle test, it was found that the spreading coefficient and adhesion work of recycled high-viscous asphalt on the surface of the basalt aggregate increased and then decreased with the dosage of the rejuvenating agent under anhydrous conditions, and the spalling work decreased and then increased under aqueous conditions, which is consistent with the conclusion of the kinetic water scour test. By calculating the adhesion performance indexes E1 and E2, it was found that the adhesion performance of recycled high-viscous asphalt increased and then decreased with the increase in the rejuvenating agent under the combined consideration of the state of water and no water, while the influence of high-viscous agent dosage on the adhesion effect was not regular, which could be due to the synergistic effect of the rejuvenating agent and the high-viscous agent in the recovery of adhesion performance of recycled high-viscous asphalt.

- (3)

- The AFM test on different kinds of recycled high-viscosity asphalt “bee-like structure” morphology had some differences with the increase in high-viscosity agent mixing; its “bee-like structure” showed a number of reductions, the area of the trend increased, and there was no obvious change pattern as the amount of regenerant increased. There was no obvious connection between the roughness of recycled high-viscosity asphalt and its adhesion performance, and the pattern of change in adhesion was consistent with the results of the macro-adhesion performance test.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Duan, M.J.; Suo, X.C.; Dong, F.H.; Li, J.H.; Li, G.F. Research on the Control Method for the Reasonable State of Self-Anchored Symmetry Suspension Bridge Stiffening Girders. Symmetry 2022, 14, 935. [Google Scholar] [CrossRef]

- Langa, E.; Buonocore, G.; Squillace, A.; Muiambo, H. Effect of Vegetable Oil on the Properties of Asphalt Binder Modified with High Density Polyethylene. Polymers 2023, 15, 749. [Google Scholar] [CrossRef] [PubMed]

- Mongkol, K.; Chaturabong, P.; Suwannaplai, A. Effect of Bagasse and Coconut Peat Fillers on Asphalt Mixture Workability. Coatings 2020, 10, 1262. [Google Scholar] [CrossRef]

- Shah, P.M.; Mir, M.S. Investigating the influence of carbon nanotube on the performance of asphalt binder. Prog. Rubber Plast. Recycl. Technol. 2021, 37, 422–440. [Google Scholar] [CrossRef]

- Zeiada, W.; Liu, H.Q.; Al-Khateeb, G.G.G.; Shanableh, A.; Samarai, M. Evaluation of test methods for measurement of zero shear viscosity (ZSV) of asphalt binders. Constr. Build. Mater. 2022, 325, 126794. [Google Scholar] [CrossRef]

- Bhat, F.S.; Mir, M.S. Investigating the effects of nano Al2O3 on high and intermediate temperature performance properties of asphalt binder. Road Mater. Pavement Des. 2021, 22, 2604–2625. [Google Scholar] [CrossRef]

- Kiselev, A.; Zhang, H.T.; Liu, Z.Q. The effect of two-phase mixing on the functional and mechanical properties of TPS/SBS-modified porous asphalt concrete. Constr. Build. Mater. 2021, 270, 121841. [Google Scholar] [CrossRef]

- Jiang, J.W.; Leng, Z.; Yang, B.; Lu, G.Y.; Tan, Z.F.; Han, M.Z.; Dong, Z.J. Penetration mechanism of the emulsion-based rejuvenator in damaged porous asphalt mixture: Microstructure characterization and 3D reconstruction. Mater. Des. 2022, 221, 111014. [Google Scholar] [CrossRef]

- Duan, M.J.; Zou, X.X.; Bao, Y.; Li, G.F.; Chen, Y.W.; Li, Z.Z. Experimental investigation of headed studs in steel-ultra-high performance concrete (UHPC) composite sections. Eng. Struct. 2022, 270, 114875. [Google Scholar] [CrossRef]

- Kawakami, A.; Sasaki, I.; Nitta, H.; Yabu, M. Mixture Design for Recycled Porous Asphalt Pavement and Results of Follow-up Survey for Ten Years. Lect. Notes Civ. Eng. 2020, 48, 460–469. [Google Scholar]

- Bozkurt, T.S.; Karakas, A.S. Investigation of Asphalt Pavement to Improve Environmental Noise and Water Sustainability. Sustainability 2022, 14, 14901. [Google Scholar] [CrossRef]

- Duan, M.J.; Zhang, S.Y.; Wang, X.; Dong, F.H. Mechanical Behavior in Perfobond Rib Shear Connector with UHPC-Steel Composite Structure with Coarse Aggregate. KSCE J. Civ. Eng. 2020, 24, 1255–1267. [Google Scholar] [CrossRef]

- Frigio, F.; Pasquini, E.; Partl, M.N.; Canestrari, F. Use of Reclaimed Asphalt in Porous Asphalt Mixtures: Laboratory and Field Evaluations. J. Mater. Civ. Eng. 2015, 27, 04014211. [Google Scholar] [CrossRef]

- Xu, B.; Ding, R.D.; Yang, Z.H.; Sun, Y.R.; Zhang, J.C.; Lu, K.J.; Cao, D.W.; Gao, A.D. Investigation on performance of mineral-oil-based rejuvenating agent for aged high viscosity modified asphalt of porous asphalt pavement. J. Clean. Prod. 2023, 395, 136285. [Google Scholar] [CrossRef]

- Kawakami, A.; Kubo, K.; Sasaki, L.; Kano, T. Study on the Recycling Method for Drainage Asphalt pavement and Evaluation for its Durability. Adv. Mater. Res. 2013, 723, 664–669. [Google Scholar] [CrossRef]

- Zheng, C.F.; Xu, J.P.; Zhang, T.; Tan, G.J. Study on the microscopic damage of porous asphalt mixture under the combined action of hydrodynamic pressure and ice crystal frost heave. Constr. Build. Mater. 2021, 303, 124489. [Google Scholar] [CrossRef]

- Xiong, R.; Chu, C.; Qiao, N.; Wang, L.; Yang, F.; Sheng, Y.P.; Guan, B.W.; Niu, D.Y.; Geng, J.G.; Chen, H.X. Performance evaluation of asphalt mixture exposed to dynamic water and chlorine salt erosion. Constr. Build. Mater. 2019, 201, 121–126. [Google Scholar] [CrossRef]

- Chen, W.X.; Wang, Z.Y.; Guo, W.; Dai, W.T. Measurement and Evaluation for Interbedded Pore Water Pressure of Saturated Asphalt Pavement under Vehicle Loading. Appl. Sci. 2020, 10, 1416. [Google Scholar] [CrossRef]

- Hu, X.D.; Jiang, M.; Bai, T.; Pan, P.; Walubita, L.F. Development and validation of an enhanced test setup for assessing HMA stripping potential under hydrodynamic pressure. Road Mater. Pavement Des. 2020, 21, 2024–2039. [Google Scholar] [CrossRef]

- Guo, M.; Yin, X.; Du, X.L.; Tan, Y.Q. Effect of aging, testing temperature and relative humidity on adhesion between asphalt binder and mineral aggregate. Constr. Build. Mater. 2023, 363, 129775. [Google Scholar] [CrossRef]

- JTG E20-2011; RIOH, Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communications Press: Beijing, China, 2011; Volume JTG E20-2011.

- Jiao, Y.B.; Zhang, Y.; Fu, L.X.; Guo, M.; Zhang, L.D. Influence of crumb rubber and tafpack super on performances of SBS modified porous asphalt mixtures. Road Mater. Pavement Des. 2019, 20, S196–S216. [Google Scholar] [CrossRef]

- Peng, C.; Huang, S.F.; You, Z.P.; Xu, F.; You, L.Y.; Ouyang, H.; Li, T.J.; Guo, C.; Ma, H.C.; Chen, P.X.; et al. Effect of a lignin-based polyurethane on adhesion properties of asphalt binder during UV aging process. Constr. Build. Mater. 2020, 247, 118547. [Google Scholar] [CrossRef]

- Yang, M.; Huang, T.; Lv, S.T.; Zheng, J.L. Effect and mechanism of acidic aggregate surface silane modification on water stability of asphalt mixture. Road Mater. Pavement Des. 2021, 22, 1654–1666. [Google Scholar] [CrossRef]

- Zeng, Z.; Zhang, D.R.; Liu, H.Q. Development of an energy-based framework to determine the surface free energy of asphalt binder: Theoretical models. Mater. Struct. 2021, 54, 241. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, Z.Q.; Zhang, H.J.; Li, W.Y. Analysis of wetting behavior and its influencing factors of rejuvenator/old asphalt interface based on surface wetting theory. Constr. Build. Mater. 2022, 314, 125674. [Google Scholar] [CrossRef]

- Hajj, R.; Bhasin, A. The search for a measure of fatigue cracking in asphalt binders—A review of different approaches. Int. J. Pavement Eng. 2018, 19, 205–219. [Google Scholar] [CrossRef]

- Magazzu, A.; Marcuello, C. Investigation of Soft Matter Nanomechanics by Atomic Force Microscopy and Optical Tweezers: A Comprehensive Review. Nanomaterials 2023, 13, 963. [Google Scholar] [CrossRef]

- Anczykowski, B.; Gotsmann, B.; Fuchs, H.; Cleveland, J.P.; Elings, V.B. How to measure energy dissipation in dynamic mode atomic force microscopy. Appl. Surf. Sci. 1999, 140, 376–382. [Google Scholar] [CrossRef]

- Lostao, A.; Lim, K.; Pallares, M.C.; Ptak, A.; Marcuello, C. Recent advances in sensing the inter-biomolecular interactions at the nanoscale—A comprehensive review of AFM-based force spectroscopy. Int. J. Biol. Macromol. 2023, 238, 124089. [Google Scholar] [CrossRef]

- Sader, J.E.; Larson, I.; Mulvaney, P.; White, L.R. Method for the calibration of atomic force microscope cantilevers. Rev. Sci. Instrum. 1995, 66, 3789–3798. [Google Scholar] [CrossRef]

- Jacobs, G.; Couscheir, K.; Hernando, D.; Moins, B.; Vansteenkiste, S.; Tanghe, T.; Duerinckx, B.; van den Bergh, W. Mechanical performance of asphalt base layers with high RAP content and recycling agents. Road Mater. Pavement Des. 2023, 1–11. [Google Scholar] [CrossRef]

- Ouyang, Q.J.; Xie, Z.W.; Liu, J.H.; Gong, M.H.; Yu, H.Y. Application of Atomic Force Microscopy as Advanced Asphalt Testing Technology: A Comprehensive Review. Polymers 2022, 14, 2851. [Google Scholar] [CrossRef] [PubMed]

- Li, M.C.; Liu, L.P.; Yang, R.K.; Liu, L.X. Investigation of the Influence of Aging on the Nanoscale Adhesion of Asphalt from the Perspective of AFM-IR-Based Chemical Properties. J. Mater. Civ. Eng. 2022, 34, 04022240. [Google Scholar] [CrossRef]

| Evaluation Indicators | Test Results | Technical Requirement |

|---|---|---|

| 25 °C pin man degree (mm) | 69.0 | 60~80 |

| Softening point (°C) | 47.0 | ≥46 |

| 10 °C elongation (cm) | 28.0 | ≥20 |

| Solubility (%) | 99.9 | ≥99.5 |

| Density at 15 °C (g·cm−3) | 1.02 | - |

| Flash Point (°C) | 272 | ≥260 |

| 135 °C rotational viscosity (Pa·s) | 1.30 | ≤3 |

| Film oven aging quality loss (%) | 0.05 | ≤0.8 |

| Film oven aging residual needle penetration ratio (%) | 74.1 | ≥61 |

| Film oven aging 10 °C residual elongation (cm) | 10.0 | ≥6 |

| Type of Asphalt | Needle Penetration (0.1 mm) | Softening Point (°C) | 10 °C Elongation (cm) |

|---|---|---|---|

| R-10-4 | 37.8 | 63.3 | 55.7 |

| R-10-6 | 41.4 | 61.1 | 74.4 |

| R-10-8 | 45.9 | 58.8 | 83.1 |

| R-12-4 | 35.4 | 69.7 | 44.2 |

| R-12-6 | 39.7 | 67.6 | 65.1 |

| R-12-8 | 45.5 | 65.3 | 74.9 |

| R-14-4 | 35.5 | 78.8 | 36.7 |

| R-14-6 | 38.9 | 76.7 | 57.1 |

| R-14-8 | 43.3 | 74.1 | 69.5 |

| Recycled High-Viscosity Asphalt Types | Asphalt Surface Free Energy | Asphalt Dispersion Fraction | Asphalt Polarity Component | Asphalt Polar Acid Fraction | Asphalt Polar Base Fraction |

|---|---|---|---|---|---|

| R-10-4 | 23.95 | 21.96 | 1.99 | 0.23 | 4.32 |

| R-10-6 | 28.85 | 25.84 | 3.01 | 0.49 | 4.65 |

| R-10-8 | 25.84 | 25.14 | 0.70 | 0.05 | 2.52 |

| R-12-4 | 25.29 | 21.51 | 3.77 | 0.50 | 7.14 |

| R-12-6 | 32.67 | 28.02 | 4.65 | 1.02 | 5.30 |

| R-12-8 | 38.19 | 33.89 | 4.30 | 1.47 | 3.13 |

| R-14-4 | 47.02 | 39.26 | 7.76 | 3.54 | 4.25 |

| R-14-6 | 51.01 | 44.53 | 6.47 | 3.44 | 3.05 |

| R-14-8 | 57.60 | 49.66 | 7.93 | 5.21 | 3.02 |

| Aggregates | Aggregates Surface Free Energy | Aggregates Dispersion Fraction | Aggregates Polarity Component | Aggregates Polar Acid Fraction | Aggregates Polar Base Fraction |

|---|---|---|---|---|---|

| Basalt | 233.01 | 56.61 | 176.40 | 15.82 | 491.73 |

| Asphalt Type | Total Number | Total Area (μm2) | Individual Maximum Area (μm2) | Average Area (μm2) | Area Share (%) |

|---|---|---|---|---|---|

| R-10-4 | 58 | 5.381 | 1.228 | 0.118 | 5.4 |

| R-10-6 | 44 | 4.886 | 1.062 | 0.132 | 4.8 |

| R-10-8 | 51 | 5.022 | 1.218 | 0.158 | 5.1 |

| R-12-4 | 50 | 6.878 | 0.568 | 0.118 | 6.8 |

| R-12-6 | 54 | 6.848 | 0.608 | 0.156 | 6.8 |

| R-12-8 | 48 | 6.751 | 0.512 | 0.132 | 6.8 |

| R-14-4 | 46 | 7.522 | 0.880 | 0.150 | 7.6 |

| R-14-6 | 37 | 9.384 | 0.734 | 0.172 | 9.4 |

| R-14-8 | 32 | 8.411 | 0.800 | 0.174 | 8.8 |

| Factor | Sum of Squared Deviations | Degrees of Freedom | Mean Square Error | F-Value | p-Value |

|---|---|---|---|---|---|

| (1) Spreading coefficient | |||||

| Dosage of regeneration agent | 2252 | 2 | 1126 | 25.33 | 0.005 |

| Dosage of high-viscosity agent | 553.8 | 2 | 276.9 | 6.229 | 0.059 |

| (2) Adhesion work | |||||

| Dosage of regeneration agent | 1.979 × 104 | 2 | 9897 | 693.5 | 0.000 |

| Dosage of high-viscosity agent | 3988 | 2 | 1994 | 139.7 | 0.000 |

| (3) Flaking work | |||||

| Dosage of regeneration agent | 5548 | 2 | 2774 | 153.0 | 0.000 |

| Dosage of high-viscosity agent | 1142 | 2 | 571.0 | 31.51 | 0.003 |

| (4) Energy ratio parameter E1 | |||||

| Dosage of regeneration agent | 1.560 | 2 | 0.780 | 4.274 | 0.174 |

| Dosage of high-viscosity agent | 3.552 | 2 | 1.776 | 4.402 | 0.021 |

| (5) Energy ratio parameter E2 | |||||

| Dosage of regeneration agent | 4.568 | 2 | 2.284 | 17.20 | 0.010 |

| Dosage of high-viscosity agent | 0.280 | 2 | 0.140 | 1.054 | 0.428 |

| (6) Surface roughness | |||||

| Dosage of regeneration agent | 0.026 | 2 | 0.013 | 1.072 | 0.423 |

| Dosage of high-viscosity agent | 1.415 | 2 | 0.707 | 57.98 | 0.001 |

| (7) Adhesion force | |||||

| Dosage of regeneration agent | 1001 | 2 | 500.7 | 170.7 | 0.000 |

| Dosage of high-viscosity agent | 1153 | 2 | 576.6 | 196.6 | 0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, K.; Song, S.; Wei, Y.; Li, G.; Guo, F. Adhesion Properties of Recycled High-Viscosity Asphalt–Aggregate Interface under Dynamic Water Erosion. Materials 2023, 16, 6203. https://doi.org/10.3390/ma16186203

Zhao K, Song S, Wei Y, Li G, Guo F. Adhesion Properties of Recycled High-Viscosity Asphalt–Aggregate Interface under Dynamic Water Erosion. Materials. 2023; 16(18):6203. https://doi.org/10.3390/ma16186203

Chicago/Turabian StyleZhao, Kang, Shijie Song, Yang Wei, Guofen Li, and Feng Guo. 2023. "Adhesion Properties of Recycled High-Viscosity Asphalt–Aggregate Interface under Dynamic Water Erosion" Materials 16, no. 18: 6203. https://doi.org/10.3390/ma16186203