Study of the Macro and Micro Characteristics of and Their Relationships in Cemented Backfill Based on SEM

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

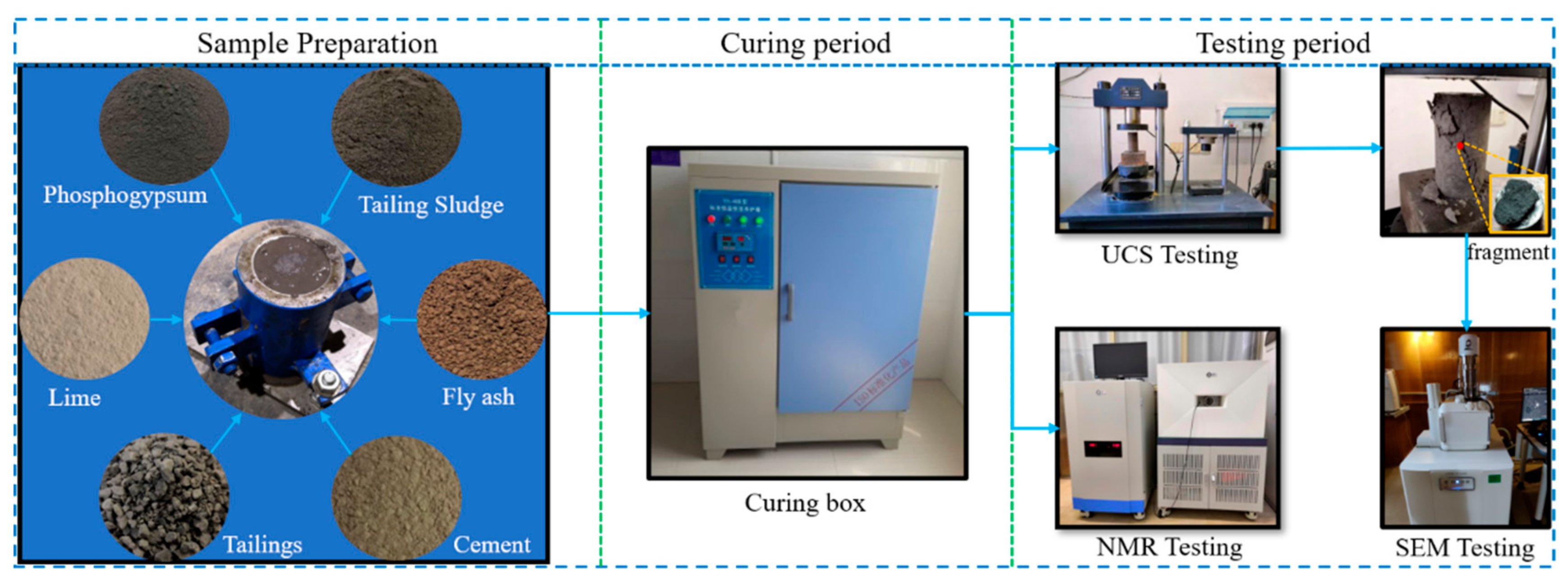

2.2. Experimental Methods

2.2.1. Scheme Design

2.2.2. Sample Testing

- UCS test: The No. 01000405 pressure testing machine made by Changlu, Ji’nan Zhongluchang Testing Machine Co., Ltd., Jinan, China, was used for the UCS test. The loading method was constant force (0.2 kN/s), and the placement position of the sample was at the center of the pressure plate.

- SEM test: A JSM-IT500LV SEM manufactured by JEOL Ltd. was used. Samples were taken at the center of the damaged backfill sample after UCS. Samples, after being sprayed with gold, were observed by SEM.

- NMR test: A MesoMR23-060H NMR instrument made by the Suzhou Niumai Company, Suzhou, China, was used. The test samples were saturated samples. After setting the parameters of the instrument, the samples were then placed in the coil for testing.

3. Result

3.1. UCS Characteristics

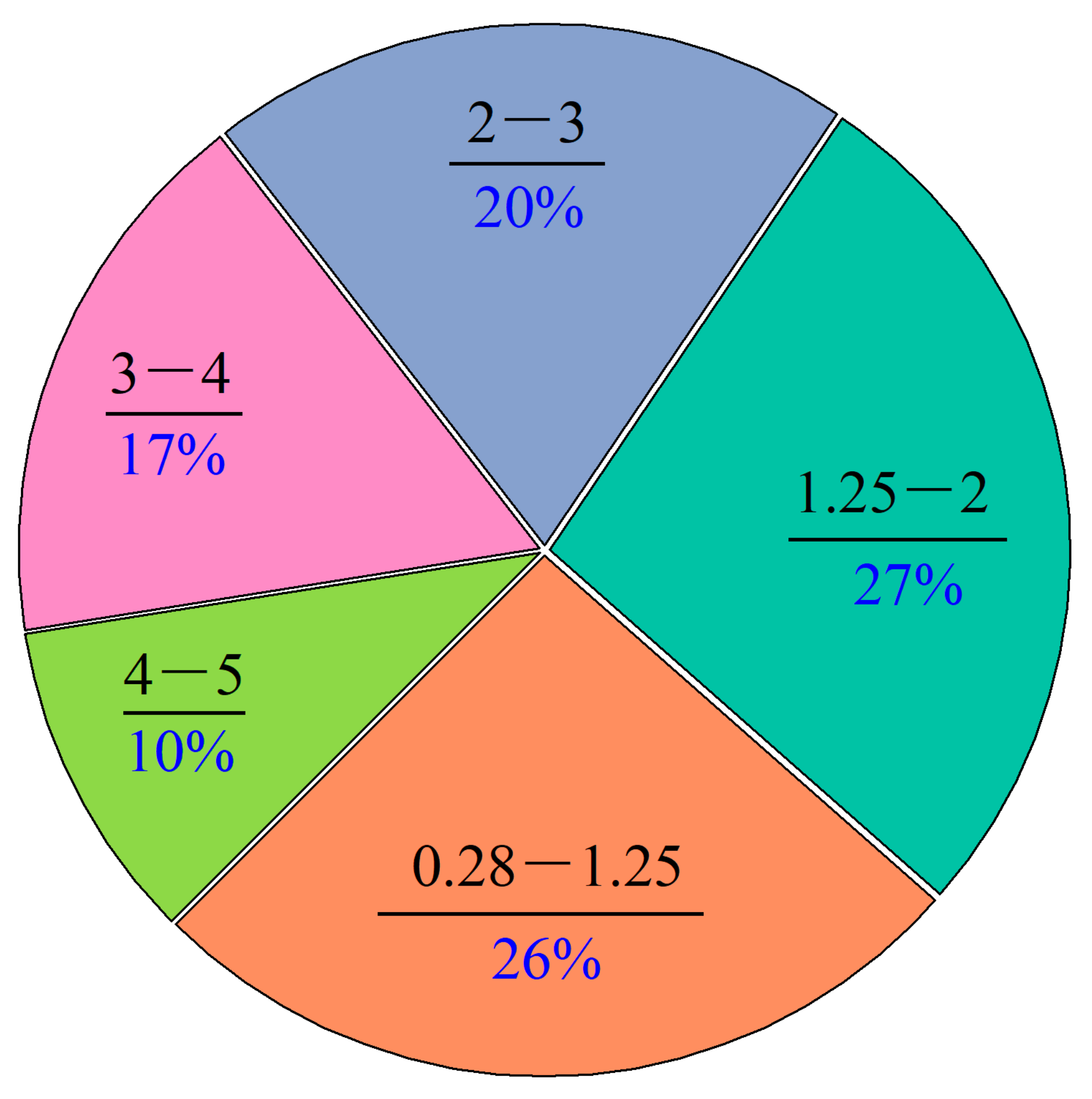

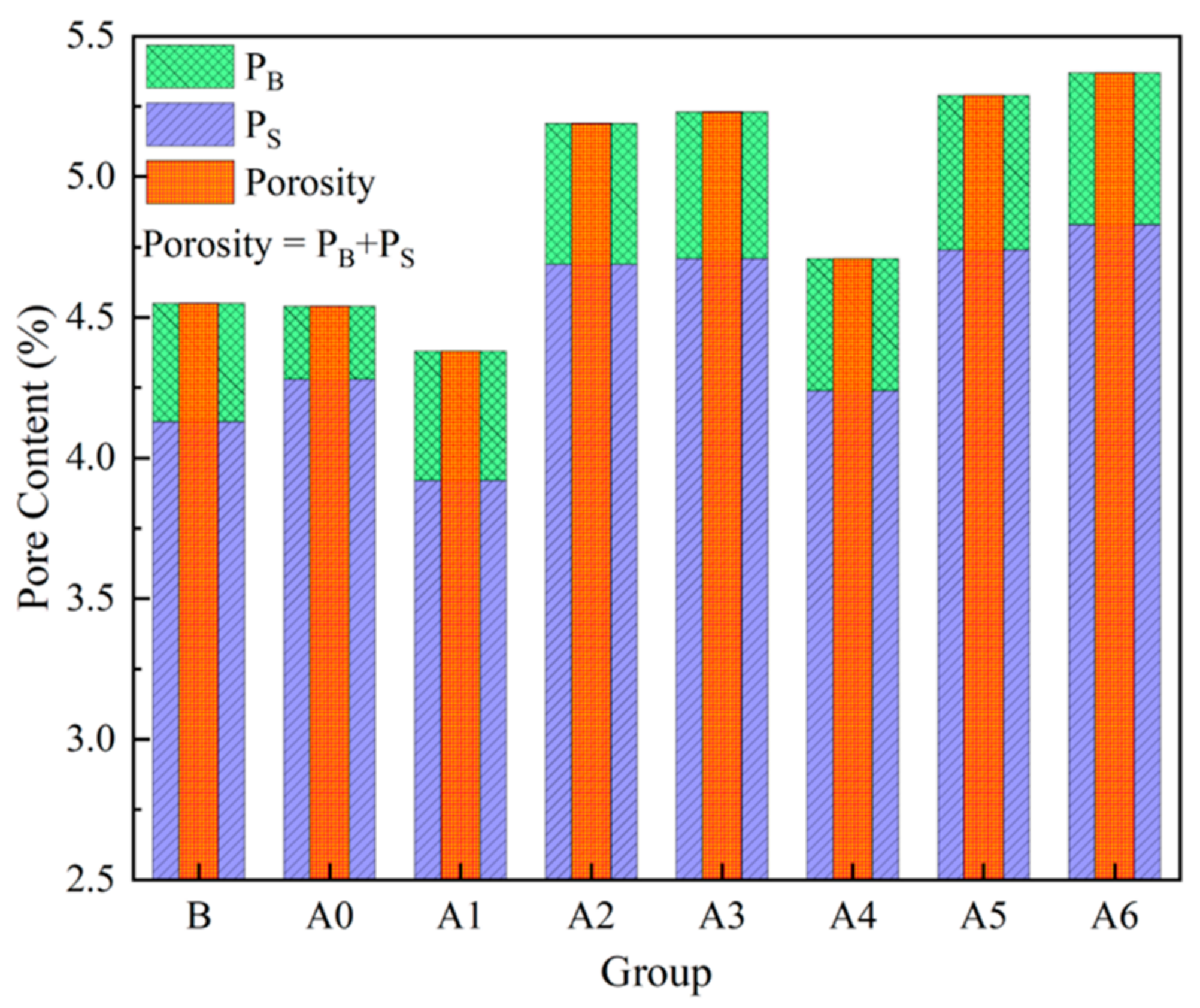

3.2. NMR Characteristics

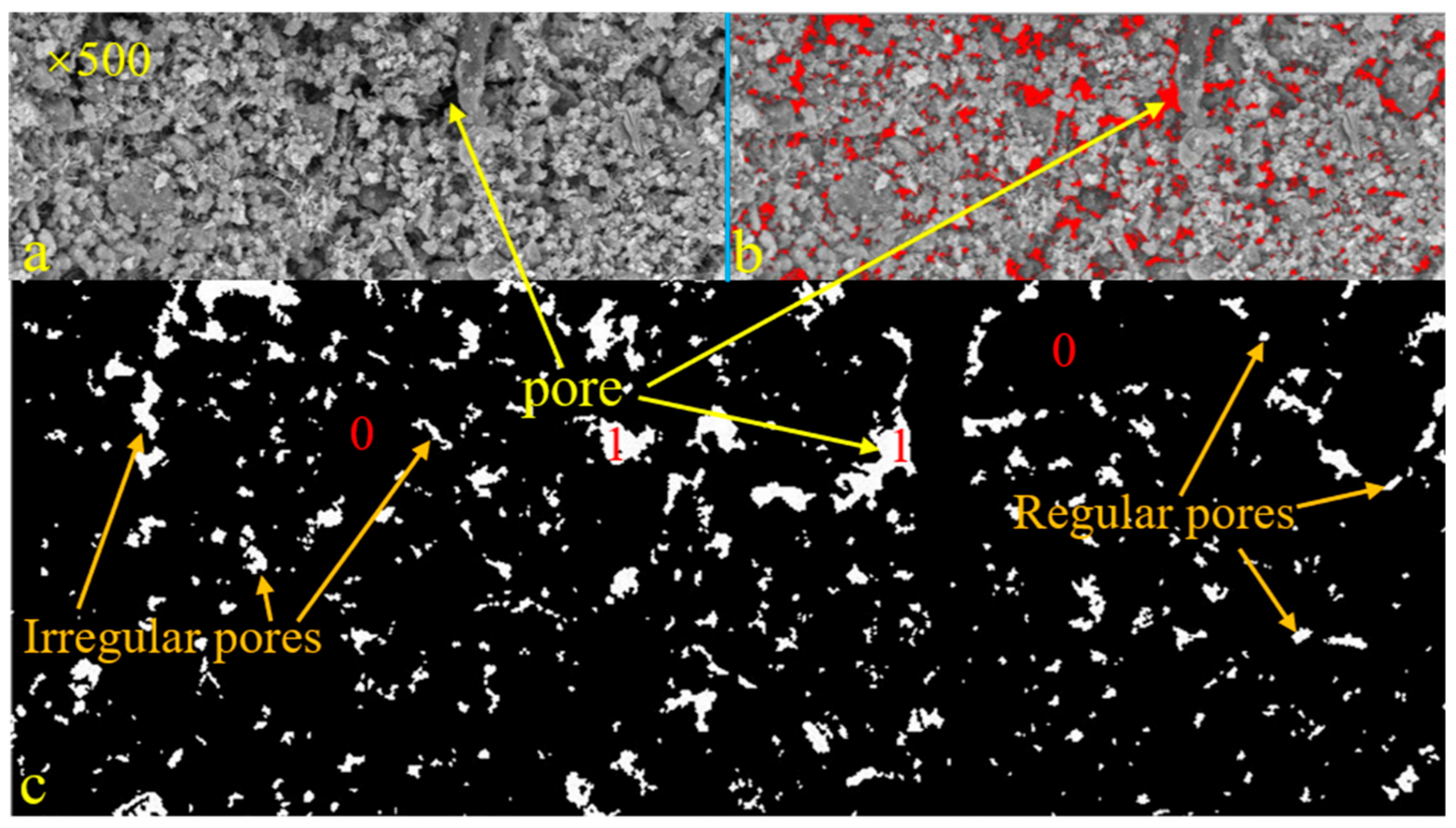

3.3. SEM Characteristics

4. Analysis and Discussion

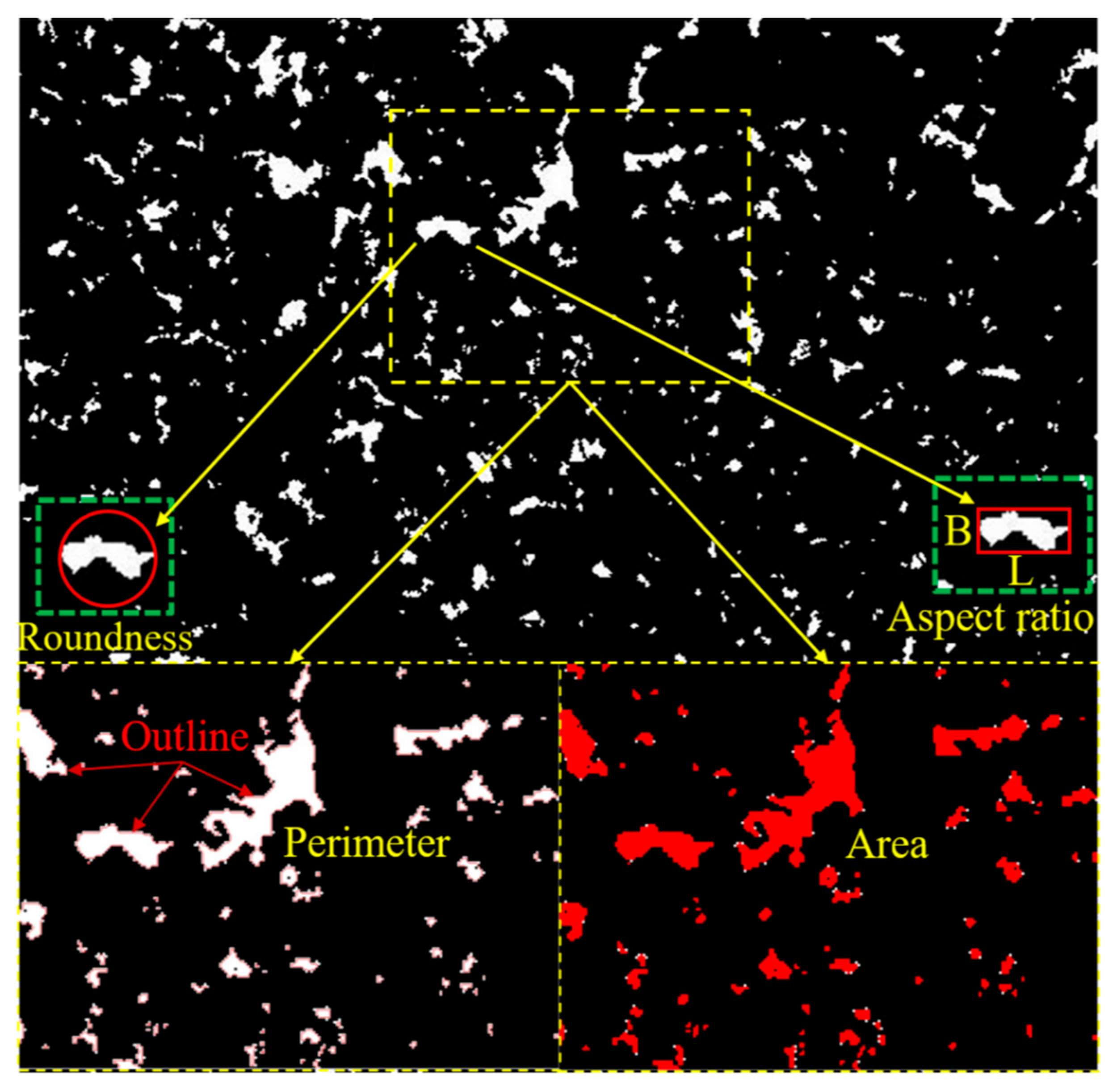

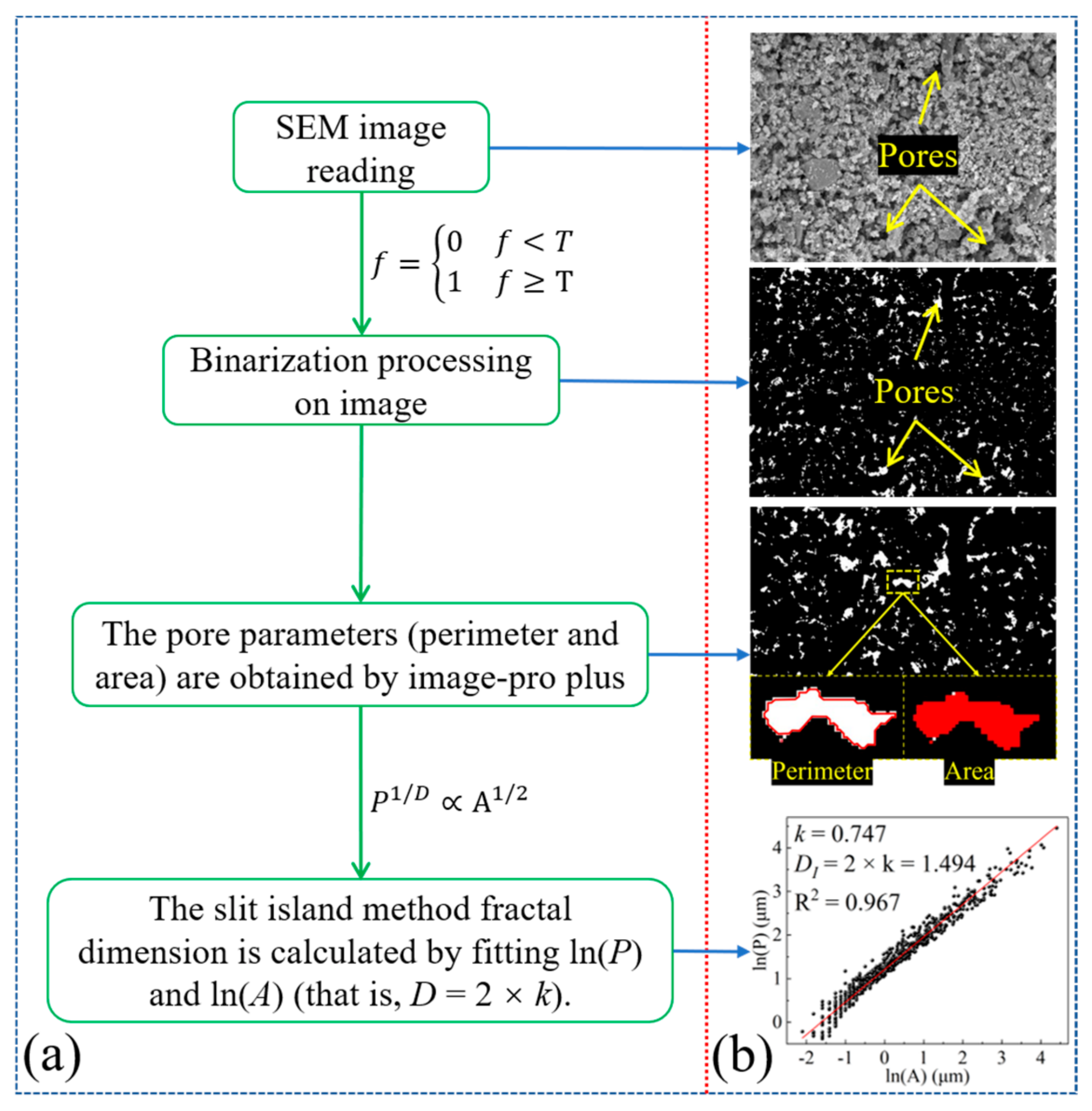

4.1. Extraction of Pore Parameters

4.2. Slit Island Method Fractal Analysis

4.2.1. Slit Island Method

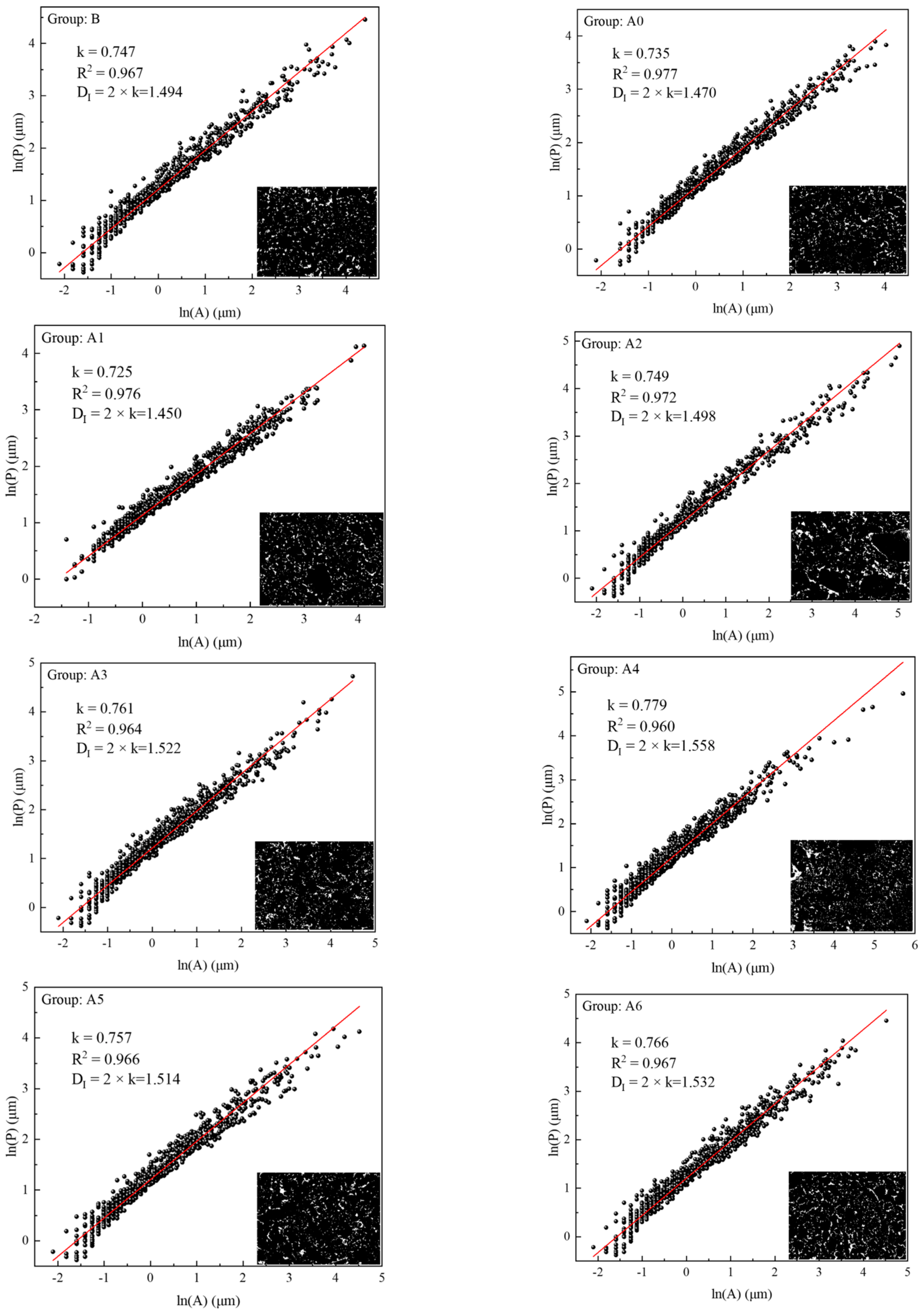

4.2.2. Fractal Features

4.3. Construction of a Functional Relationship Model

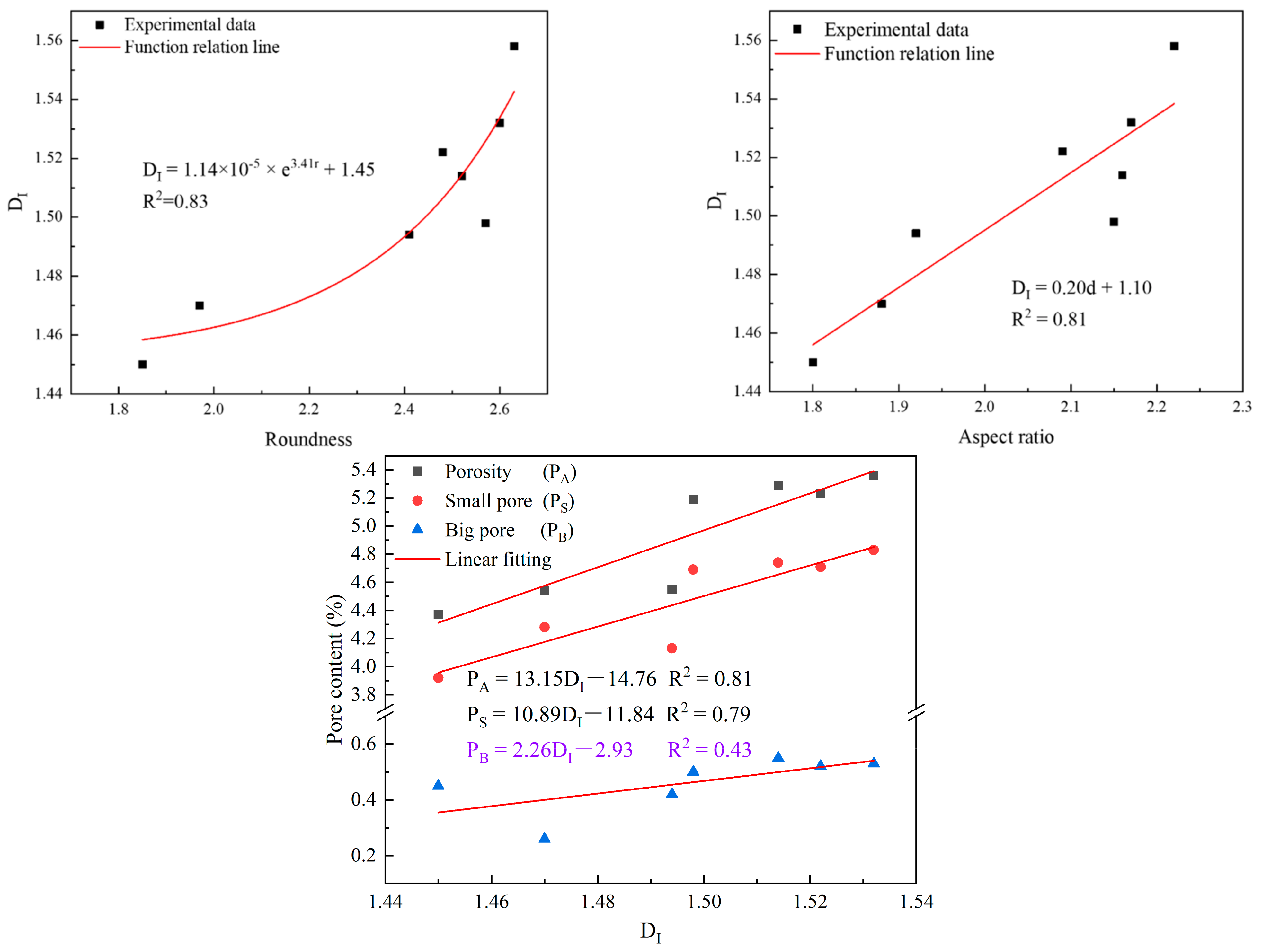

4.3.1. Relationship between the Dimension and Pore Characteristics

4.3.2. Relationship between UCS and Pore Characteristics

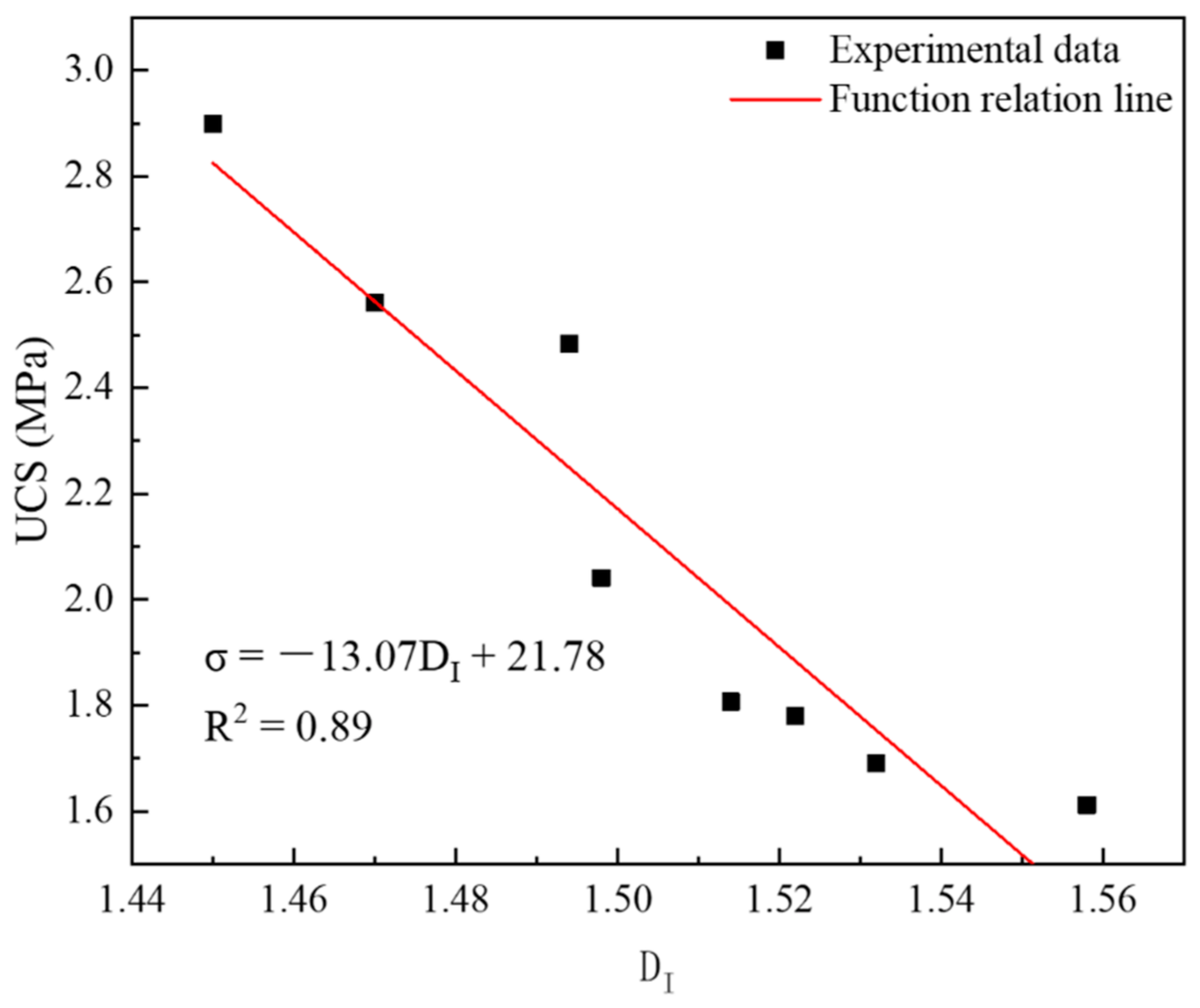

4.3.3. Relationship between UCS and Dimension

5. Conclusions

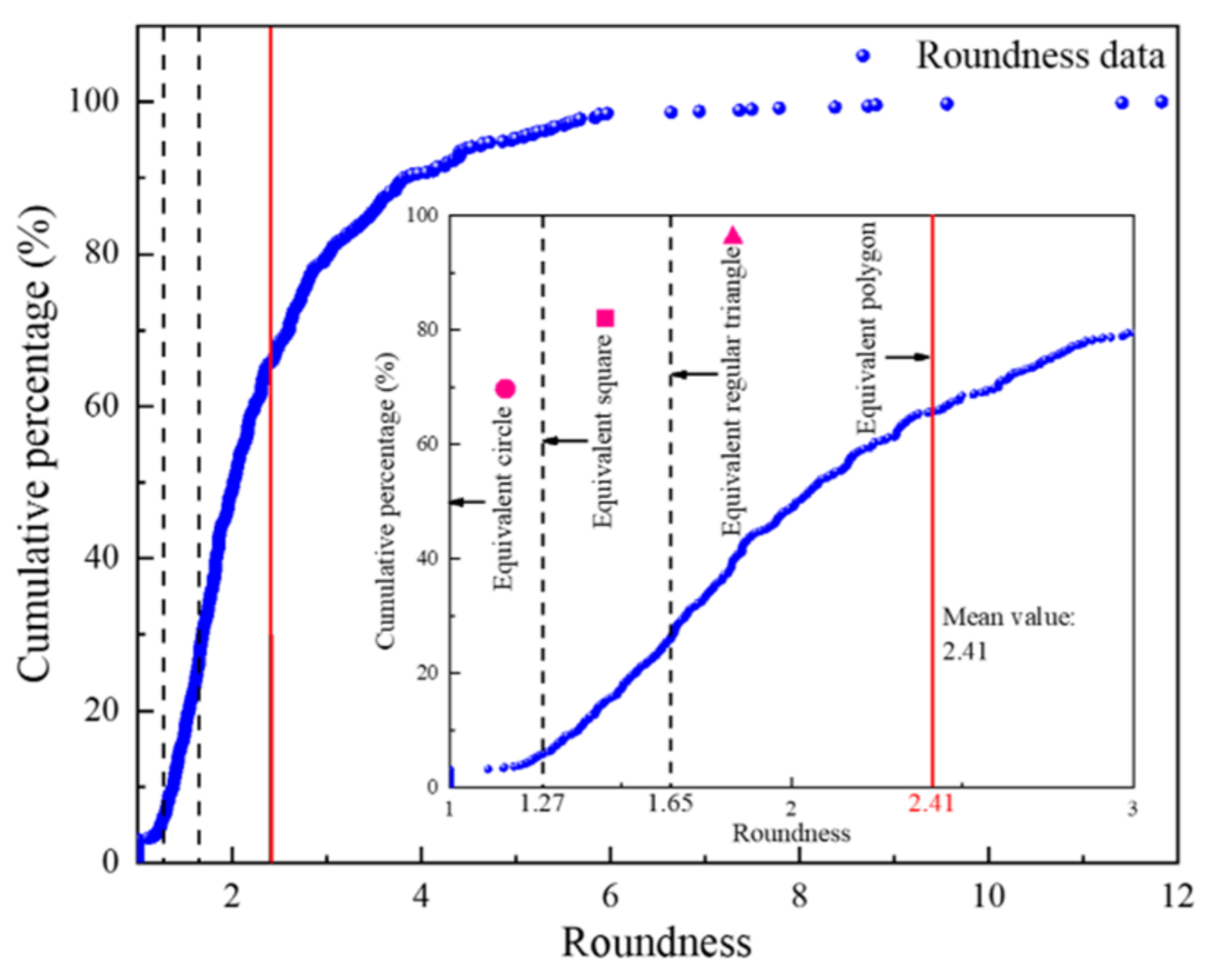

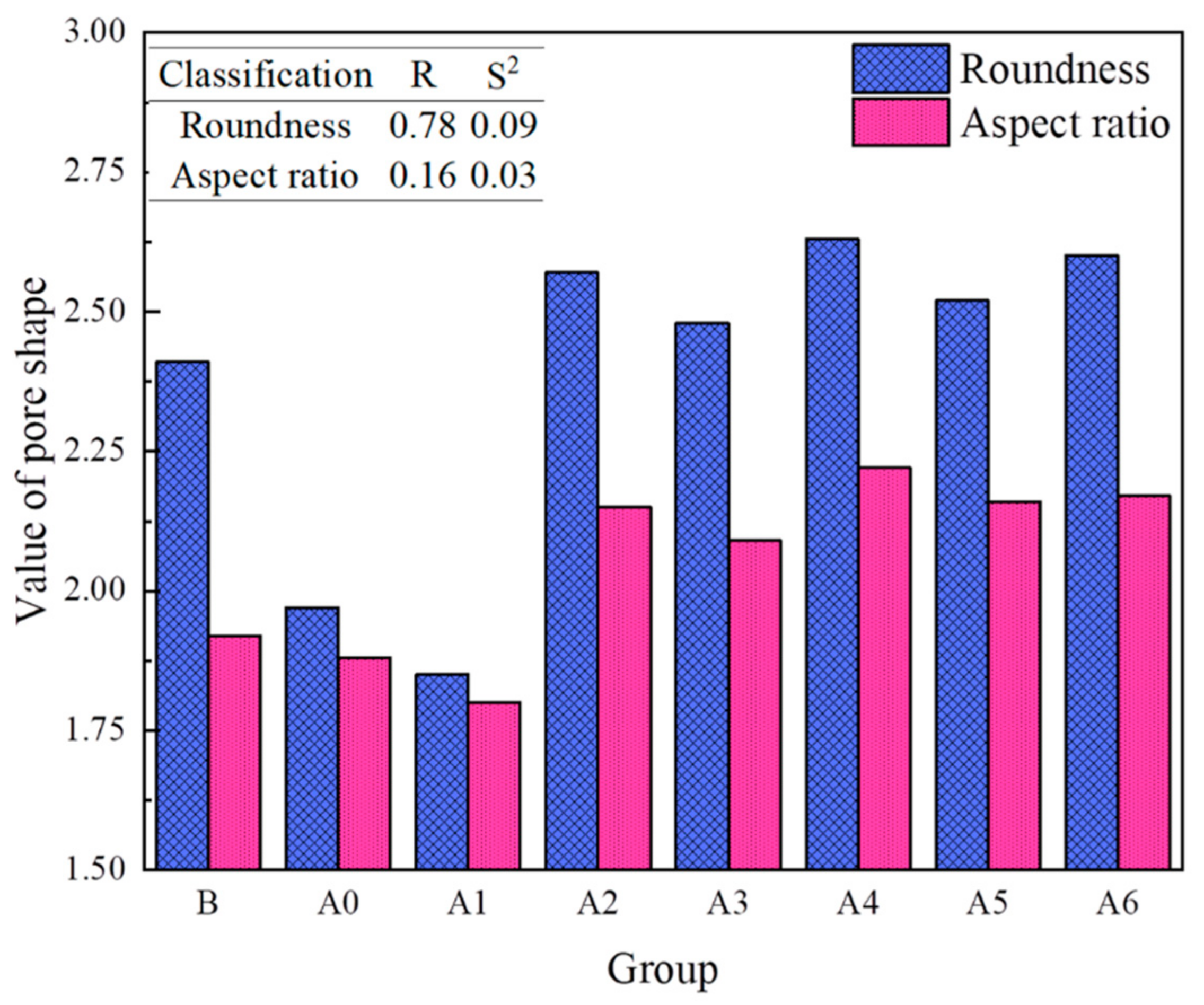

- The pores in the SEM image were complex; this could be seen from the roundness of most of the pore shapes (>80%) being irregular (r > 1.65). However, the whole material showed good fractal characteristics (R2 > 0.96); the fractal dimension ranged from 1.450 to 1.558.

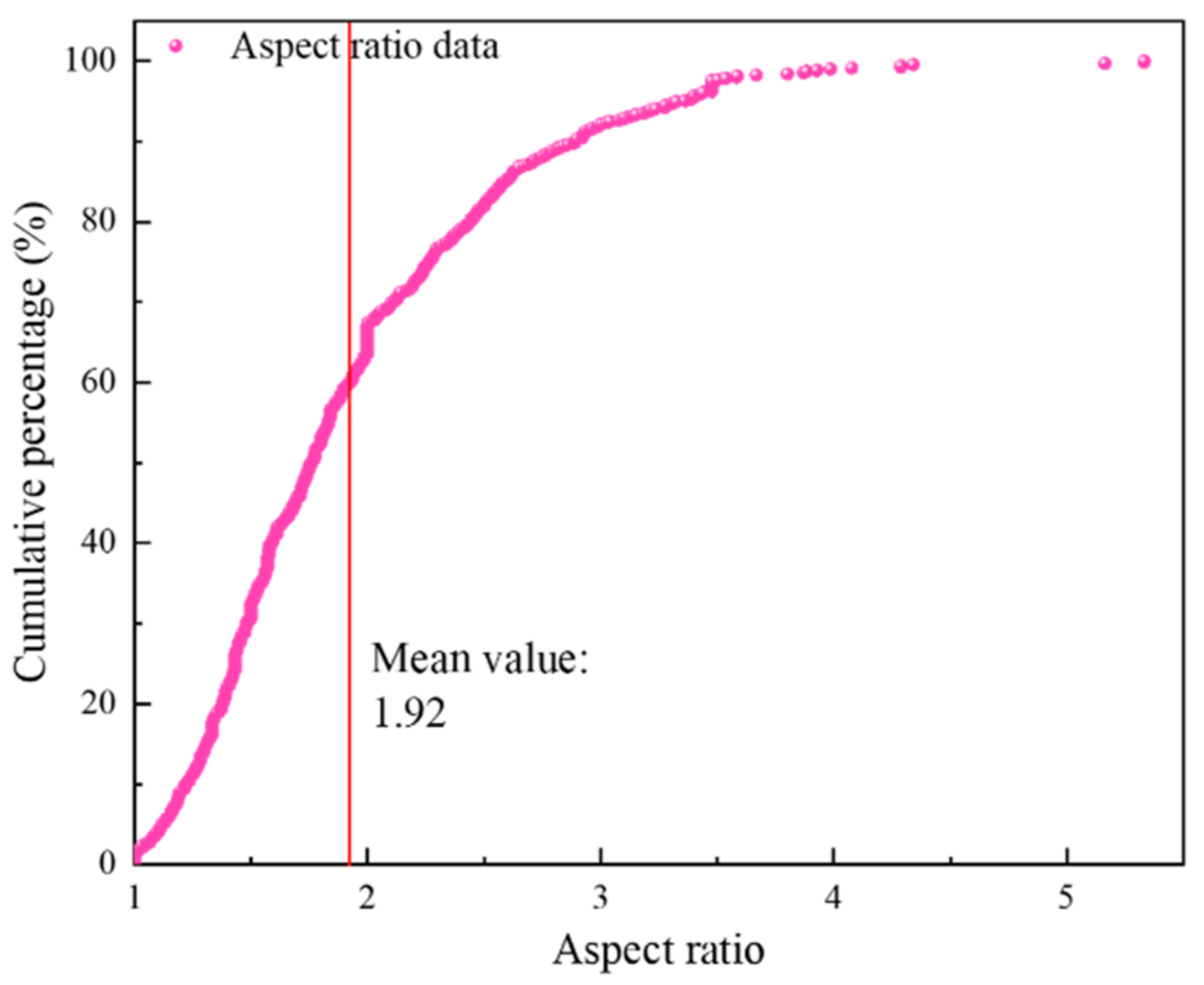

- The complexity of pores is related to both pore shape and pore content. The more irregular the pores are and the larger the pores are, the larger the fractal dimensions of the pores are. That is, the fractal dimension of pores is exponentially, directly proportional to the roundness of the pores (i.e., DI = a*ebr + c), and linearly, directly proportional to the aspect ratio of the pore and pore content (i.e., DI = kx + b, k > 0).

- There are many factors that affect UCS; these include not only the pore content but also the pore shape characteristics. It can be seen from UCS functional relationship model that the UCS had a linear inverse relationship with the roundness, aspect ratio, pore content, and fractal dimension (i.e., σ = kx + b, k < 0).

- The addition of lime should be in moderation. An appropriate amount of lime can increase hydration products, which is beneficial to backfill, but excessive lime is harmful to backfill.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Min, C.D.; Xiong, S.; Shi, Y.; Liu, Z.X.; Lu, X.Y. Early-age compressive strength prediction of cemented phosphogypsum backfill using lab experiments and ensemble learning models. Case Stud. Constr. Mater. 2023, 18, e02107. [Google Scholar] [CrossRef]

- Liu, G.S.; Li, L.; Yao, M.K.; Landry, D.; Malek, F.; Malek, F.; Guo, J. An investigation of the uniaxial compressive strength of a cemented hydraulic backfill made of alluvial sand. Minerals 2017, 7, 4. [Google Scholar] [CrossRef] [Green Version]

- Jin, A.B.; Ju, Y.; Sun, H.; Zhao, Y.; Li, H.; Zhang, Z.; Lu, T. Pore structure and strength deterioration mechanism of phase change energy storage backfill. Rock Soil Mech. 2021, 10, 2623–2633. [Google Scholar]

- Hu, Y.; Li, K.; Zhang, B.; Han, B. Development of cemented paste backfill with superfine tailings: Fluidity, mechanical properties, and Microstructure Characteristics. Materials 2023, 16, 1951. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, Q.; Wen, Z.J.; Zhang, T. Influencing factors on backfill strength and a combined strength prediction model. J. Northeast. Univ. Nat. Sci. 2021, 2, 232–241. [Google Scholar]

- Qiu, H.F.; Zhang, F.S.; Liu, L.; Huan, C.; Hou, D.; Kang, W. Experimental study on acoustic emission characteristics of cemented rock-tailings backfill. Constr. Build. Mater. 2022, 315, 125278. [Google Scholar] [CrossRef]

- Jin, J.X.; Qin, Z.F.; Zuo, S.H.; Feng, J.J.; Sun, Q. The role of rheological additives on fresh and hardened properties of cemented paste backfill. Materials 2022, 15, 3006. [Google Scholar] [CrossRef] [PubMed]

- Kamali, M.; Ghahremaninezhad, A. An investigation into the influence of superabsorbent polymers on the properties of glass powder modified cement pastes. Constr. Build. Mater. 2017, 149, 236–247. [Google Scholar] [CrossRef]

- Zhao, F.W.; Hu, J.H.; Yang, Y.N.; Xiao, H.X.; Ma, F.C. Cross-Scale Study on Lime Modified Phosphogypsum Cemented Backfill by Fractal Theory. Minerals 2022, 12, 403. [Google Scholar] [CrossRef]

- Lv, Q.; Qiu, Q.L.; Zheng, J.; Wang, J. Fractal dimension of concrete incorporating silica fume and its correlations to pore structure, strength and permeability. Constr. Build. Mater. 2019, 228, 116986. [Google Scholar]

- Zhu, Z.D.; Huo, W.W.; Sun, H.; Ma, B.R.; Yang, L. Correlations between unconfined compressive strength, sorptivity and pore structures for geopolymer based on SEM and MIP measurements. J. Build. Eng. 2023, 67, 106011. [Google Scholar] [CrossRef]

- Chen, L.; Yuan, M.; Xu, S.Q.; Wei, S.Y.; Yang, M.M.; Xu, L. Application of digital image technology combined with island method in coal fractal characteristics. J. Saf. Sci. Technol. 2021, 17, 77–83. [Google Scholar]

- Jiang, T.; Xu, W.; Su, Z.Z. Calculation and Analysis of Permeability of Sandstone SEM Image by Small Island Method. J. North China Inst. Sci. Technol. 2018, 15, 54–59. [Google Scholar]

- Yang, X.J.; Wang, J.M.; Zhu, C.; He, M.; Gao, Y. Effect of wetting and drying cycles on microstructure of rock based on SEM. Environ. Earth Sci. 2019, 78, 183. [Google Scholar] [CrossRef]

- Zhong, C.L.; Liu, M.; Zhang, Y.L.; Wang, J.; Liang, D.; Chang, L. Study on mechanical properties of hybrid polypropylene-steel fiber RPC and computational method of fiber content. Materials 2020, 13, 2243. [Google Scholar] [CrossRef]

- Papadopoulos, A.; Bird, N.R.A.; Sacha, J.; Mooney, S.J.; Whitmore, A.P. Fractal Analysis of Pore Roughness in Images of Soil Using the Slit Island Method. Vadose Zone J. 2008, 7, 456–460. [Google Scholar] [CrossRef]

- Mandelbrot, B.B.; Passoja, D.E.; Paullay, A.J. Fractal character of surfaces of metals. Nature 1984, 308, 721–722. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. The Fractal Geometry of Nature; W. H. Freeman and Company: New York, NY, USA, 1983. [Google Scholar]

- Papadopoulos, A.; Mooney, S.J.; Bird, N.R.A. Quantification of the effects of contrasting crops in the development of soil structure: An organic conversion. Soil Use Manag. 2006, 22, 172–179. [Google Scholar] [CrossRef]

- Zhu, Z.B. Fractal Features Research on the Microscopic Pore Structure of Petroleum Reservoir Rocks; Northeast Petroleum University: Daqing, China, 2013. [Google Scholar]

- He, C.Y.; Yuan, W.; Tan, K.F. Study on property of cementitious binder onsisting of phosphogypsum-flyash-lime-cement. New Build. Mater. 2009, 8, 1480–1485. [Google Scholar]

- Chen, X.M.; Gao, J.M.; Zhao, Y.S. Investigation on the hydration of hemihydrate phosphogypsum after post treatment. Constr. Build. Mater. 2019, 229, 116864. [Google Scholar] [CrossRef]

- Ba, T.B.; Xu, Y.Z.; Lu, W.Y.; Liu, Z. Experimental study on the lime neutralizing pretreatment of phosphogypsum. New Build. Mater. 2018, 2, 96–99. [Google Scholar]

- Zhao, F.W.; Hu, J.H.; Yang, D.J.; Kuang, Y.; Xiao, H.; Zheng, M.; Wang, X. Study on the Relationship between Pore Structure and Uniaxial Compressive Strength of Cemented Paste Backfill by Using Air-Entraining Agent. Adv. Civ. Eng. 2021, 2021, 6694744. [Google Scholar] [CrossRef]

- Hu, J.H.; Zhao, F.W.; Kuang, Y.; Yang, D.; Zheng, M.; Zhao, L. Microscopic characteristics of the action of an air entraining agent on cemented paste backfill pores. Alex. Eng. J. 2020, 59, 1583–1593. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, P.; Zhang, H.B. Pore structure of concrete materials. Sci. Technol. Inf. 2007, 36, 139–140. [Google Scholar]

- Liu, L.; Fang, Z.Y.; Qi, C.C.; Zhang, B.; Guo, L.; Song, L. Experimental investigation on the relationship between pore characteristics and unconfined compressive strength of cemented paste backfill. Constr. Build. Mater. 2018, 179, 254–264. [Google Scholar] [CrossRef]

- Wang, X.K.; Li, D.J.; Zhu, Y.T.; Zhang, J.; Yuan, F. Particle shape analysis of clay based on digital image technology. Chin. J. Geotech. Eng. 2020, 42, 168–171. [Google Scholar]

- Wang, S.H.; Li, Z.; Zou, G.L.; Ma, D.K. Fractal characteristics of gradation particles in asphalt mixture image with slit island method. Transp. Comput. 2007, 139, 70–73. [Google Scholar]

- Florio, B.J.; Fawell, P.D.; Small, M. The use of the perimeter-area method to calculate the fractal dimension of aggregates. Powder Technol. 2019, 343, 551–559. [Google Scholar] [CrossRef]

- Fu, W.; Hu, W.S.; Yi, T.S.; Kane, O.I.; Zhang, M.; Huang, X. Fractal dimension analysis of pores in coal reservoir and their impact on petrophysical properties: A case study in the province of Guizhou, SW China. Minerals 2022, 12, 1425. [Google Scholar] [CrossRef]

- Fan, X.Q.; Wang, G.W.; Li, Y.F.; Dai, Q.; Song, L.; Duan, C.; Zhang, C.; Zhang, F. Pore structure evaluation of tight reservoirs in the mixed siliciclastic carbonate sediments using fractal analysis of NMR experiments and logs. Mar. Pet. Geol. 2019, 109, 484–493. [Google Scholar] [CrossRef]

| Sample | Apparent Density/(kg∙m−3) | Packing Density/(kg∙m−3) | Surface Moisture Content/% |

|---|---|---|---|

| Tailings | 2626 | 1464 | 0.120 |

| Tailing sludge | 2653 | 923 | 0.974 |

| Fly ash | 1990 | 650 | 0.049 |

| Phosphogypsum | 1992 | 850 | 8.11 |

| Sample | Mass Fraction/% | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Hydroxyllapatite | Quartz | Hematite | Albite | Plagioclase | Muscovite | Illite | Dolomite | Plaster | Amphibole | Calcite | |

| Tailings | 10.15 | 6.91 | 12.75 | − | - | - | - | 69.65 | 0.2 | - | 0.34 |

| Fly ash | - | 61.55 | 1.46 | 15.99 | - | 20.99 | - | - | - | - | - |

| Phosphogypsum | - | 1.35 | - | - | - | - | 4.05 | - | 94.02 | 0.59 | - |

| Tailing sludge | 60.94 | 2.24 | - | 8.38 | 11.42 | - | 9.76 | 6.30 | 0.34 | - | 0.61 |

| Group | Phosphogypsum Content/% | Lime Content/% | Mass Percentage | Cement Tailings Ratio |

|---|---|---|---|---|

| B | 0 | 0 | 80% | 1:6 |

| A0 | 20 | 0 | ||

| A1 | 20 | 0.2 | ||

| A2 | 20 | 1 | ||

| A3 | 20 | 1.8 | ||

| A4 | 20 | 2.6 | ||

| A5 | 20 | 3.4 | ||

| A6 | 20 | 4.2 |

| Group | B | A0 | A1 | A2 | A3 | A4 | A5 | A6 |

|---|---|---|---|---|---|---|---|---|

| UCS/MPa | 2.48 | 2.56 | 2.90 | 2.04 | 1.78 | 1.61 | 1.81 | 1.69 |

| Change rate/% | 0 | 3.14 | 13.20 | −20.30 | −30.46 | −37.06 | −29.44 | −34.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, F.; Hu, J.; Liu, T.; Zhou, T.; Ren, Q. Study of the Macro and Micro Characteristics of and Their Relationships in Cemented Backfill Based on SEM. Materials 2023, 16, 4772. https://doi.org/10.3390/ma16134772

Zhao F, Hu J, Liu T, Zhou T, Ren Q. Study of the Macro and Micro Characteristics of and Their Relationships in Cemented Backfill Based on SEM. Materials. 2023; 16(13):4772. https://doi.org/10.3390/ma16134772

Chicago/Turabian StyleZhao, Fengwen, Jianhua Hu, Taoying Liu, Tan Zhou, and Qifan Ren. 2023. "Study of the Macro and Micro Characteristics of and Their Relationships in Cemented Backfill Based on SEM" Materials 16, no. 13: 4772. https://doi.org/10.3390/ma16134772