Rehydration Driven Acid Impregnation of Thermally Pretreated Ca-Bentonite—Evolution of the Clay Structure

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. XRD Analysis of Acid Activated Bentonites

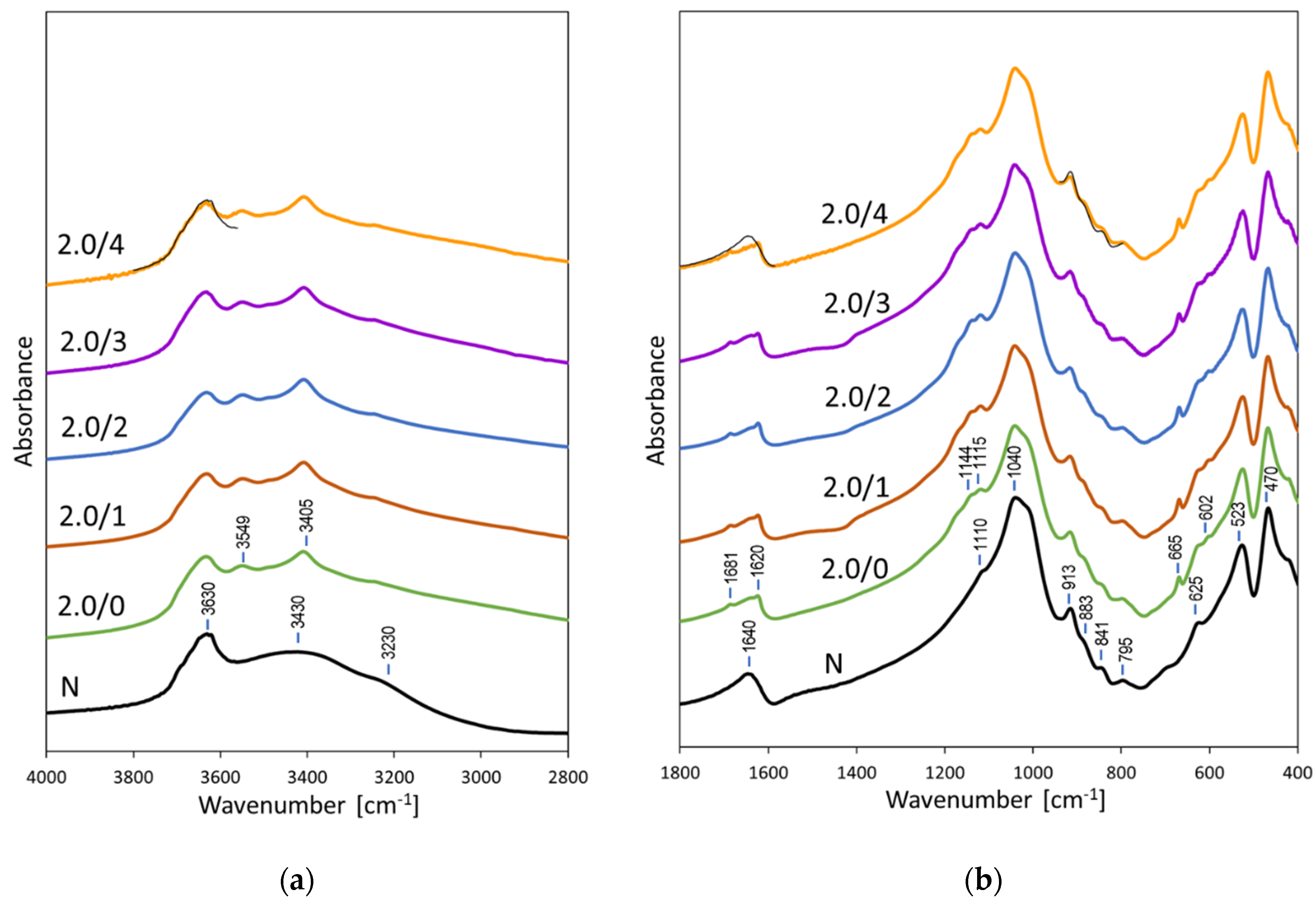

3.2. FTIR Analysis of Acid Activated Bentonites

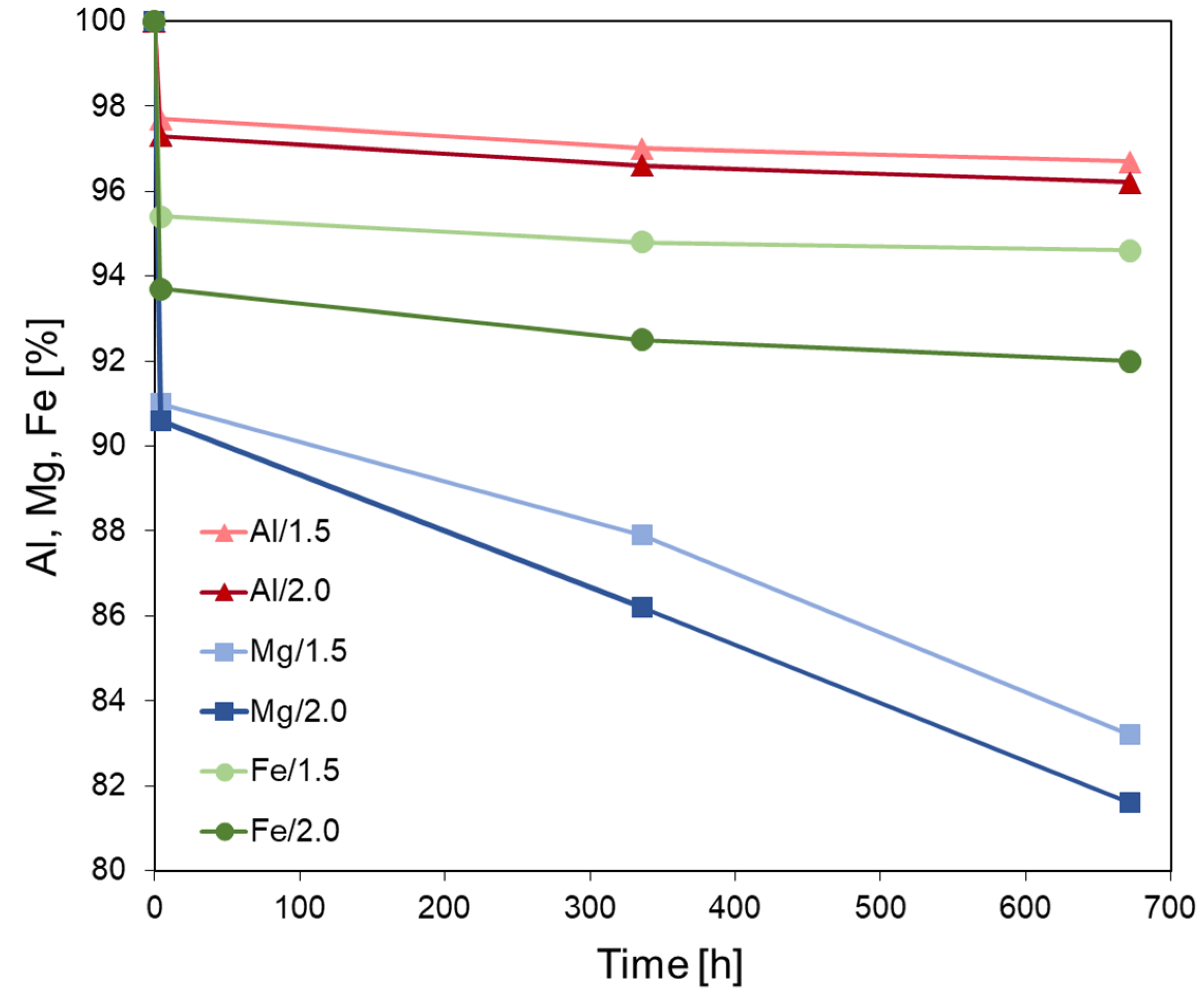

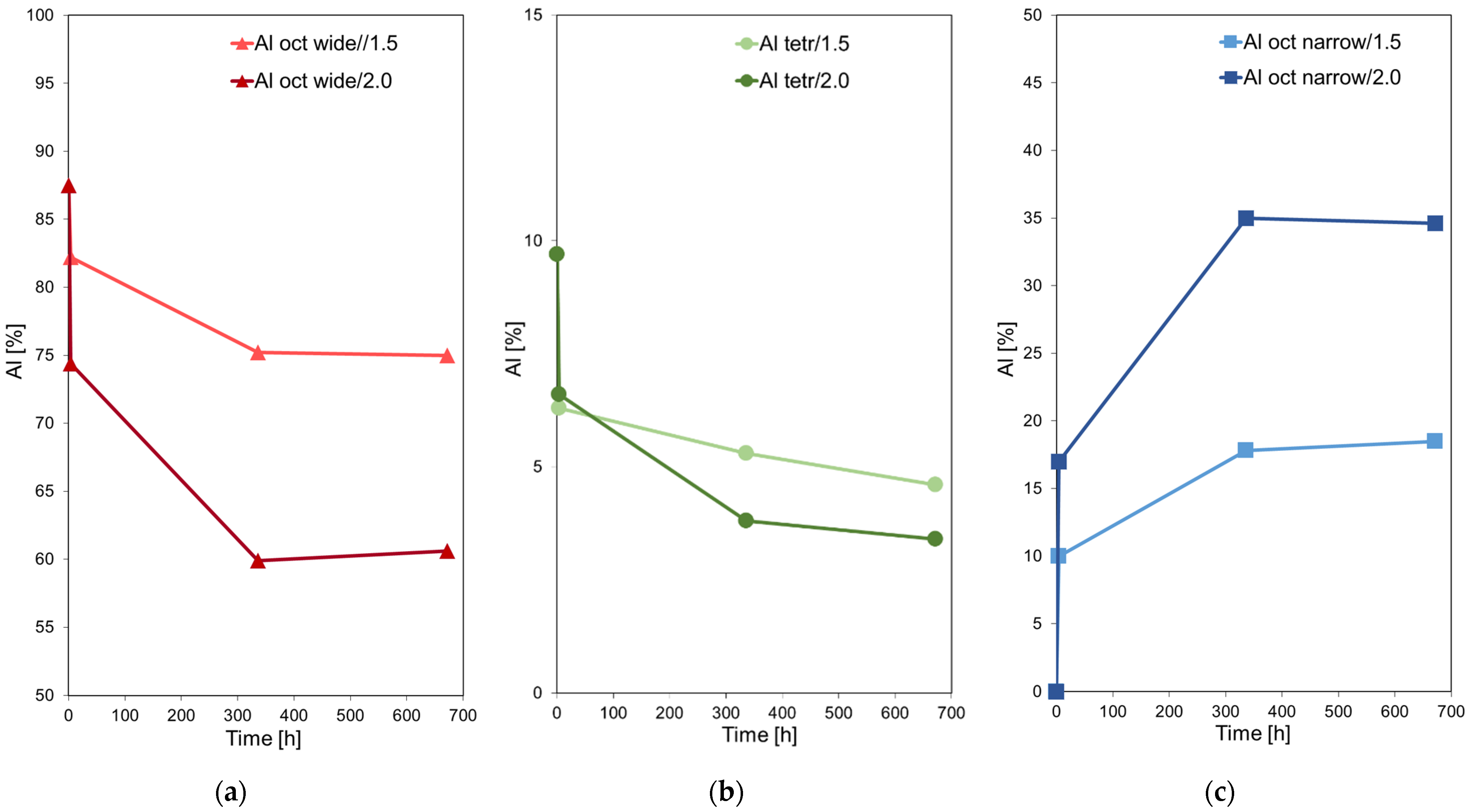

3.3. Quantitative Assessment of Metal Cations Released from the Layers upon Acid Treatment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Jackson, M.L.; Hseung, Y.; Corey, R.B.; Evans, E.J.; Heuvel, R.C.V. Weathering Sequence of Clay-size Minerals in Soils and Sediments. II. Chemical weathering of layer silicates. Soil Sci. Soc. Am. J. 1952, 16, 3–6. [Google Scholar] [CrossRef]

- Vazquez, O.; Monnell, J.D.; Pu, X.; Neufeld, R.D. Major Processes Dominating the Release of Aluminum from Smectite Clays When Leached with Acid Mine Drainage. Environ. Eng. Sci. 2011, 28, 163–169. [Google Scholar] [CrossRef]

- Komadel, P.; Madejová, J. Acid Activation of Clay Minerals. In Handbook of Clay Science. Part A: Fundamentals, 2nd ed.; Bergaya, F., Lagaly, G., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 385–409. [Google Scholar]

- Robertson, R.H.S. Fuller’s Earth: A History of Calcium Montmorillonite; Volturna Press: Hythe, UK, 1986; pp. 266–271. [Google Scholar]

- Chitnis, S.R.; Sharma, M.M. Industrial applications of acid-treated clays as catalysts. React. Funct. Polym. 1997, 32, 93–115. [Google Scholar] [CrossRef]

- Díaz, F.R.V.; Santos, P.D.S. Studies on the acid activation of Brazilian smectitic clays. Química Nova 2001, 24, 345–353. [Google Scholar] [CrossRef]

- Komadel, P. Chemically modified smectites. Clay Miner. 2003, 38, 127–138. [Google Scholar] [CrossRef] [Green Version]

- Murray, H.H. Bentonite Applications. In Applied Clay Mineralogy—Occurrences, Processing and Application of Kaolins, Bentonites, Palygorskite-Sepiolite, and Common Clays; Murray, H.H., Ed.; Elsevier: Amsterdam, The Netherlands, 2006; pp. 111–130. [Google Scholar]

- Carrado, K.A.; Komadel, P. Acid Activation of Bentonites and Polymer-Clay Nanocomposites. Elements 2009, 5, 111–116. [Google Scholar] [CrossRef]

- Hussin, F.; Aroua, M.K.; Daud, W.M.A.W. Textural characteristics, surface chemistry and activation of bleaching earth: A review. Chem. Eng. J. 2011, 170, 90–106. [Google Scholar] [CrossRef]

- McCabe, R.W.; Adams, J.M. Clay Minerals as Catalysts. In Handbook of Clay Science. Part B: Techniques and Applications, 2nd ed.; Bergaya, F., Lagaly, G., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 491–538. [Google Scholar]

- Harvey, C.C.; Lagaly, G. Industrial Applications. In Handbook of Clay Science. Part B: Techniques and Applications, 2nd ed.; Bergaya, F., Lagaly, G., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 451–490. [Google Scholar]

- Komadel, P. Acid activated clays: Materials in continuous demand. Appl. Clay Sci. 2016, 131, 84–99. [Google Scholar] [CrossRef]

- España, V.A.A.; Sarkar, B.; Biswas, B.; Rusmin, R.; Naidu, R. Environmental applications of thermally modified and acid activated clay minerals: Current status of the art. Environ. Technol. Innov. 2019, 13, 383–397. [Google Scholar] [CrossRef]

- Huang, W.J.; Liu, J.H.; She, Q.M.; Zhong, J.Q.; Christidis, G.E.; Zhou, C.H. Recent advances in engineering montmorillonite into catalysts and related catalysis. Catal. Rev. 2021, 1–57. [Google Scholar] [CrossRef]

- Serwicka, E.M. Titania-Clay Mineral Composites for Environmental Catalysis and Photocatalysis. Catalysts 2021, 11, 1087. [Google Scholar] [CrossRef]

- Tkac, I.; Komadel, P.; Müller, D. Acid-Treated Montmorillonites—A Study by 29Si and 27Al MAS NMR. Clay Miner. 1994, 29, 11–19. [Google Scholar] [CrossRef]

- Kumar, P.; Jasra, R.V.; Bhat, T.S.G. Evolution of Porosity and Surface Acidity in Montmorillonite Clay on Acid Activation. Ind. Eng. Chem. Res. 1995, 34, 1440–1448. [Google Scholar] [CrossRef]

- Christidis, G.; Scott, P.; Dunham, A. Acid activation and bleaching capacity of bentonites from the islands of Milos and Chios, Aegean, Greece. Appl. Clay Sci. 1997, 12, 329–347. [Google Scholar] [CrossRef]

- Wang, S.; Guin, J.A. Etherification of dimethylbutene with methanol over clay-based acid catalysts. React. Kinet. Catal. Lett. 2002, 75, 169–175. [Google Scholar] [CrossRef]

- Tyagi, B.; Chudasama, C.D.; Jasra, R.V. Determination of structural modification in acid activated montmorillonite clay by FT-IR spectroscopy. Spectrochim. Acta Part. A Mol. Biomol. Spectrosc. 2006, 64, 273–278. [Google Scholar] [CrossRef]

- Babaki, H.; Salem, A.; Jafarizad, A. Kinetic model for the isothermal activation of bentonite by sulfuric acid. Mater. Chem. Phys. 2008, 108, 263–268. [Google Scholar] [CrossRef]

- Önal, M.; Sarıkaya, Y. Preparation and characterization of acid-activated bentonite powders. Powder Technol. 2007, 172, 14–18. [Google Scholar] [CrossRef]

- Steudel, A.; Batenburg, L.; Fischer, H.; Weidler, P.; Emmerich, K. Alteration of swelling clay minerals by acid activation. Appl. Clay Sci. 2009, 44, 105–115. [Google Scholar] [CrossRef]

- Korichi, S.; Elias, A.; Mefti, A. Characterization of smectite after acid activation with microwave irradiation. Appl. Clay Sci. 2009, 42, 432–438. [Google Scholar] [CrossRef]

- Toor, M.; Jin, B.; Dai, S.; Vimonses, V. Activating natural bentonite as a cost-effective adsorbent for removal of Congo-red in wastewater. J. Ind. Eng. Chem. 2015, 21, 653–661. [Google Scholar] [CrossRef]

- Huang, G.-Q.; Song, Y.-H.; Liu, C.; Yang, J.-M.; Lu, J.; Liu, Z.-T.; Liu, Z.-W. Acid activated montmorillonite for gas-phase catalytic dehydration of monoethanolamine. Appl. Clay Sci. 2019, 168, 116–124. [Google Scholar] [CrossRef]

- Krupskaya, V.; Novikova, L.; Tyupina, E.; Belousov, P.; Dorzhieva, O.; Zakusin, S.; Kim, K.; Roessner, F.; Badetti, E.; Brunelli, A.; et al. The influence of acid modification on the structure of montmorillonites and surface properties of bentonites. Appl. Clay Sci. 2019, 172, 1–10. [Google Scholar] [CrossRef]

- Horri, N.; Sanz-Pérez, E.S.; Arencibia, A.; Sanz, R.; Frini-Srasra, N.; Srasra, E. Effect of acid activation on the CO2 adsorption capacity of montmorillonite. Adsorption 2020, 26, 793–811. [Google Scholar] [CrossRef]

- Nagahashi, E.; Ogata, F.; Saenjum, C.; Nakamura, T.; Kawasaki, N. Preparation and Characterization of Acid-Activated Bentonite with Binary Acid Solution and Its Use in Decreasing Electrical Conductivity of Tap Water. Minerals 2021, 11, 815. [Google Scholar] [CrossRef]

- Kittrick, J.A. Interlayer Forces in Montmorillonite and Vermiculite. Soil Sci. Soc. Am. J. 1969, 33, 217–222. [Google Scholar] [CrossRef]

- Sato, T.; Watanabe, T.; Otsuka, R. Effects of Layer Charge, Charge Location, and Energy Change on Expansion Properties of Dioctahedral Smectites. Clays Clay Miner. 1992, 40, 103–113. [Google Scholar] [CrossRef]

- Laird, D.A. Model for Crystalline Swelling of 2:1 Phyllosilicates. Clays Clay Miner. 1996, 44, 553–559. [Google Scholar] [CrossRef]

- Bahranowski, K.; Klimek, A.; Gaweł, A.; Serwicka, E.M. Rehydration Driven Na-Activation of Bentonite—Evolution of the Clay Structure and Composition. Materials 2021, 14, 7622. [Google Scholar] [CrossRef]

- Górniak, K.; Szydłak, T.; Gaweł, A.; Klimek, A.; Tomczyk, A.; Sulikowski, B.; Olejniczak, Z.; Motyka, J.; Serwicka, E.; Bahranowski, K.; et al. Commercial bentonite from the Kopernica deposit (Tertiary, Slovakia): A petrographic and mineralogical approach. Clay Miner. 2016, 51, 97–122. [Google Scholar] [CrossRef]

- Lang, L.Z.; Xiang, W.; Huang, W.; Cui, D.S.; Schanz, T. An experimental study on oven-drying methods for laboratory determination of water content of a calcium-rich bentonite. Appl. Clay Sci. 2017, 150, 153–162. [Google Scholar] [CrossRef]

- Derkowski, A.; Drits, V.A.; McCarty, D.K. Rehydration of dehydrated-dehydroxylated smectite in a low water vapor environment. Am. Miner. 2012, 97, 110–127. [Google Scholar] [CrossRef]

- Hendershot, W.H.; Lalande, H.; Duquette, M. Ion Exchange and Exchangeable Cations. In Soil Sampling and Methods of Analysis, 2nd ed.; Carter, M.R., Gregorich, E.G., Eds.; CRC Press: Boca Raton, FL, USA, 2008; pp. 225–234. [Google Scholar]

- Ferrage, E. Investigation of the Interlayer Organization of Water and Ions in Smectite from the Combined Use of Diffraction Experiments and Molecular Simulations. A Review of Methodology, Applications, And Perspectives. Clays Clay Miner. 2016, 64, 348–373. [Google Scholar] [CrossRef]

- Ferrage, E.; Tournassat, C.; Rinnert, E.; Lanson, B. Influence of pH on the interlayer cationic composition and hydration state of Ca-montmorillonite: Analytical chemistry, chemical modelling and XRD profile modelling study. Geochim. Cosmochim. Acta 2005, 69, 2797–2812. [Google Scholar] [CrossRef] [Green Version]

- Janek, M.; Komadel, P. Acidity of proton saturated and autotransformed smectites characterized with proton affinity distri-bution. Geol. Carpathica 1999, 50, 373–378. [Google Scholar]

- Rhodes, C.N.; Brown, D.R. Structural characterisation and optimisation of acid-treated montmorillonite and high-porosity silica supports for ZnCl2 alkylation catalysts. J. Chem. Soc. Faraday Trans. 1992, 88, 2269–2274. [Google Scholar] [CrossRef]

- Falaras, P.; Kovanis, I.; Lezou, F.; Seiragakis, G. Cottonseed oil bleaching by acid-activated montmorillonite. Clay Miner. 1999, 34, 221–232. [Google Scholar] [CrossRef]

- Gates, W.; Anderson, J.; Raven, M.; Churchman, G. Mineralogy of a bentonite from Miles, Queensland, Australia and characterisation of its acid activation products. Appl. Clay Sci. 2002, 20, 189–197. [Google Scholar] [CrossRef]

- Temuujin, J.; Jadambaa, T.; Burmaa, G.; Erdenechimeg, S.; Amarsanaa, J.; MacKenzie, K. Characterisation of acid activated montmorillonite clay from Tuulant (Mongolia). Ceram. Int. 2004, 30, 251–255. [Google Scholar] [CrossRef]

- Okada, K.; Arimitsu, N.; Kameshima, Y.; Nakajima, A.; MacKenzie, K. Solid acidity of 2:1 type clay minerals activated by selective leaching. Appl. Clay Sci. 2006, 31, 185–193. [Google Scholar] [CrossRef]

- Breen, C.; Madejová, J.; Komadel, P. Characterisation of moderately acid-treated, size fractionated montmorillonites using IR and MAS NMR spectroscopy and thermal analysis. J. Mater. Chem. 1995, 5, 469–474. [Google Scholar] [CrossRef]

- Vicente-Rodríguez, M.A.; Suarez, M.; Bañares-Muñoz, M.A.; de Dios Lopez-Gonzalez, J. Comparative FT-IR study of the removal of octahedral cations and structural modifications during acid treatment of several silicates. Spectrochim. Acta A 1996, 52, 1685–1694. [Google Scholar] [CrossRef]

- Madejova, J.; Bujdák, J.; Janek, M.; Komadel, P. Comparative FT-IR study of structural modifications during acid treatment of dioctahedral smectites and hectorite. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 1998, 54, 1397–1406. [Google Scholar] [CrossRef]

- Madejová, J.; Gates, W.P.; Petit, S. IR spectra of clay minerals. In Infrared and Raman Spectroscopies of Clay Minerals. Developments in Clay Science; Gates, W.P., Klopproge, J.T., Madejová, J., Bergaya, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; Volume 8, pp. 107–149. [Google Scholar]

- Farmer, V.C. The layer silicates. In Infrared Spectra of Minerals; Farmer, V.C., Ed.; Mineralogical Society: London, UK, 1974; pp. 331–363. [Google Scholar]

- Seidl, V.; Knop, O.; Falk, M. Infrared studies of water in crystalline hydrates: Gypsum, CaSO4•2H2O. Can. J. Chem. 1969, 47, 1361–1368. [Google Scholar] [CrossRef]

- Stoch, L.; Bahranowski, K.; Budek, L.; Fijal, J. Bleaching properties of nonbentonitic clay materials and their modification. Mineral. Pol. 1977, 8, 31–49. [Google Scholar]

- MacKenzie, K.J.D.; Smith, M.E. Multinuclear Solid State NMR of Inorganic Materials, Pergamon Materials Series; Pergamon/Elsevier: Oxford, UK, 2002; Volume 6, pp. 332–371. [Google Scholar]

- Rhodes, C.N.; Brown, D.R. Autotransformation and ageing of acid-treated montmorillonite catalysts: A solid-state 27Al NMR study. J. Chem. Soc. Faraday Trans. 1995, 91, 1031–1035. [Google Scholar] [CrossRef]

- Pentrák, M.; Hronský, V.; Pálková, H.; Uhlík, P.; Komadel, P.; Madejová, J. Alteration of fine fraction of bentonite from Ko-pernica (Slovakia) under acid treatment: A combined XRD, FTIR, MAS NMR and AES study. Appl. Clay Sci. 2018, 163, 204–213. [Google Scholar] [CrossRef]

- Haouas, M.; Taulelle, F.; Martineau, C. Recent advances in application of 27Al NMR spectroscopy to materials science. Prog. Nucl. Magn. Reson. Spectrosc. 2016, 94–95, 11–36. [Google Scholar] [CrossRef]

| Activation Procedure | Purpose | Reference |

|---|---|---|

| Mt + 6 M HCl, acid/clay ratio 200 mL/g, 95 °C, 1–24 h, washed with water and dried at 60 °C. | Study of acid dissolution by 27Al and 29Si MAS NMR | [17] |

| Bent + H2SO4 (0.5–4 M), acid/clay ratio 5 mL/g, 80 °C, 2 h, washed with water. | Study of textural properties and surface acidity | [18] |

| Bent + HCl (0.5–8 M), 70 °C, acid/clay ratio 15 mL/g, 30 min–6 h, washed with water and dried at 100 °C. | Optimization of bleaching properties | [19] |

| Bent + 0.5 M H2SO4, acid/clay ratio 5 mL/g, H2O removed by evaporation, dried at 100 °C, calcined at 300 °C, 2 h. | Catalyst design | [20] |

| Mt + H2SO4 (0.5–5 M), 80 °C, 4 h, washed with water and dried at RT + 6 h at 120 °C. | Study of structural evolution | [21] |

| Bent + H2SO4 (3, 4, or 5 M), acid/clay ratio 10 mL/g, 30–90 °C, 15–120 min. | Study of activation kinetics | [22] |

| Bent + H2SO4 (0–70 wt% of the mixture), acid/clay ratio 20 mL/g, 97 °C, 6 h, washed and dried 4 h at 105 °C. | Study of structural, compositional and textural evolution | [23] |

| Bent + H2SO4 or HCl (1, 5, or 10 M), acid/clay ratio 100 mL/g, 80 °C, 1.5–96 h, washed with water and freeze-dried. | Study of structural evolution and dissolution kinetics | [24] |

| Bent + 2 M HCl, acid/clay ratio 7 mL/g, microwave heated to 100 °C for 1–20 min, washed with water and freeze-dried. | Study of textural properties | [25] |

| Bent + HCl (0.05–0.5 M), acid/clay ratio 0.1 mL/g, 60–100 °C, washed with water, dried 12 h at 55 °C. | Removal of dyes from waste water | [26] |

| Mt + 3.2 M HNO3, acid/clay ratio 49 mL/g, 104 °C, 4–24 h, washed with water, dried and calcined at 450–1150 °C for 4 h. | Catalyst design | [27] |

| Bent + HNO3 (1, 2, 4, or 8 M), 20–90 °C, 1–12 h, washed with water, dried 12–48 h at 60 °C. | Study of properties relevant for radioactive waste barriers | [28] |

| Mt + 3 M HCl, acid/clay ratio 15 mL/g, 95 °C, 1–24 h, washed with water, dried at 80 °C. | CO2 sorption | [29] |

| Bent + 5 M mixtures of H2SO4/HNO3, HNO3/H3PO4, or H3PO4/H2SO4, acid/clay ratio 10 mL/g, RT, 4 h, washed with water, dried at 60 °C. | Control of tap water conductivity | [30] |

| Sample | 29Si MAS NMR Parameter | Tetrahedral Al | Octahedral Al | ||

|---|---|---|---|---|---|

| N | center (ppm) | 67.5 | 54.0 | 2.9 | - |

| intensity contribution (%) | 9.7 | 2.8 | 87.5 | - | |

| 1.5/0 | center (ppm) | 66.0 | 54.7 | 2.9 | 2.1 |

| intensity contribution (%) | 6.3 | 1.5 | 82.2 | 10.0 | |

| 1.5/2 | center (ppm) | 66.2 | 53.5 | 2.9 | 2.1 |

| intensity contribution (%) | 5.3 | 1.7 | 75.2 | 17.8 | |

| 1.5/4 | center (ppm) | 66.1 | 53.6 | 2.9 | 2.1 |

| intensity contribution (%) | 4.6 | 1.9 | 75.0 | 18.5 | |

| 2.0/0 | center (ppm) | 66.9 | 54.5 | 2.9 | 2.1 |

| intensity contribution (%) | 6.6 | 2.0 | 74.4 | 17.0 | |

| 2.0/2 | center (ppm) | 67.2 | 55.5 | 2.9 | 2.1 |

| intensity contribution (%) | 3.8 | 1.3 | 59.9 | 35.0 | |

| 2.0/4 | center (ppm) | 67.2 | 55.6 | 2.9 | 2.1 |

| intensity contribution (%) | 3.4 | 1.4 | 60.6 | 34.6 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bahranowski, K.; Klimek, A.; Gaweł, A.; Olejniczak, Z.; Serwicka, E.M. Rehydration Driven Acid Impregnation of Thermally Pretreated Ca-Bentonite—Evolution of the Clay Structure. Materials 2022, 15, 2067. https://doi.org/10.3390/ma15062067

Bahranowski K, Klimek A, Gaweł A, Olejniczak Z, Serwicka EM. Rehydration Driven Acid Impregnation of Thermally Pretreated Ca-Bentonite—Evolution of the Clay Structure. Materials. 2022; 15(6):2067. https://doi.org/10.3390/ma15062067

Chicago/Turabian StyleBahranowski, Krzysztof, Agnieszka Klimek, Adam Gaweł, Zbigniew Olejniczak, and Ewa M. Serwicka. 2022. "Rehydration Driven Acid Impregnation of Thermally Pretreated Ca-Bentonite—Evolution of the Clay Structure" Materials 15, no. 6: 2067. https://doi.org/10.3390/ma15062067