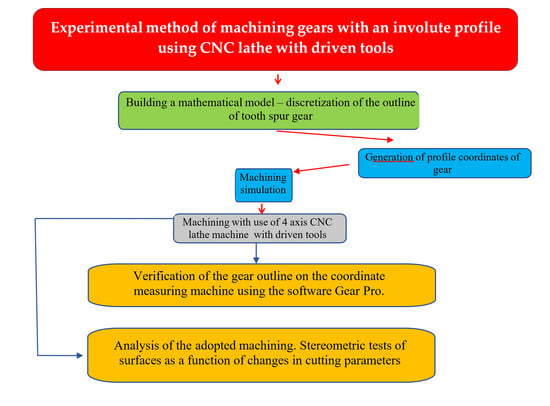

Experimental Method of Machining Gears with an Involute Profile Using CNC Lathe with Driven Tools

Abstract

:1. Introduction

2. Materials and Methods

2.1. Defining the Geometrical Parameters of the Tool Path

- z—number of teeth

- m—module

- c—top clearance

- y—tooth height coefficient

- α—pressure angle

- x—coefficient of profile shift

| -top clearance coefficient | ||

| -top clearance | ||

| -pitch circle diameter | ||

| -addendum | ||

| -dedendum | ||

| -circular pitch | ||

| -addendum circle diameter | ||

| -root circle diameter | ||

| -base circle diameter |

Tooth Profile Modification

2.2. Machining Process

3. Results

3.1. Measurement of Geometrical Compliance of a Gear with the Use of Software Module ZEISS Gear Pro Involute

- Fα—profile deviation, the total overlay of the profile form deviation and the profile slope deviation;

- ffα—form deviation of the profile without consideration of the slope deviation;

- fHα—profile slope deviation of the profile without consideration of the form deviation;

- Fβ—tooth line (lead) deviation, total overlay of the lead form deviation and the lead slope deviation;

- ffβ—form deviation of the lead without consideration of the slope deviation;

- fHβ—lead slope deviation of the outline without consideration of the form deviation.

- Fp—total cumulative pitch deviation, the range of the positional deviation of all the right (left) flanks to the nominal position, with the flanks being analysed independently;

- fp—single pitch deviation, the maximum unsigned positional deviation of all the right (left) flanks to the preceding right (left) flank;

- fu—adjacent pitch difference, the maximum unsigned difference of all the individual single pitch deviations of all the right (left) flanks.

3.2. Measurement of the Structure of the Tooth Surfaces

4. Discussion

5. Conclusions

- Machining with a tool that is not geometrically related to the contour being machined, in our case, as a two-parameter circumference, is an excellent alternative to complicated and expensive hobbing methods.

- This method allows the use of any modifications of the machined tooth profile; moreover, the processing of profiles other than involute with non-standard modules is not a problem in this case.

- This method guarantees very efficient machining and at the same time guarantees the quality of the process. The graph in Figure 11, on the basis of the performed machining simulations, presents the time dependence in the function of feed changes. As can be seen, the feed rate is the biggest factor influencing the efficiency of the entire gear machining process.

- The obtained machining time of less than three minutes for the cutting variant at a feed rate of 1800 mm/min is an excellent result, and the analysis of the quality of the machined surface in this case is also very good.

- The analysed machining process has significant reserves in terms of productivity; the driven tool holder with a maximum rotational speed of 4500 rpm significantly limited the feed rate used in machining.

- The accuracy of the machined profile form deviation in the entire processing did not exceed average value of 10 μm, while assessing the tooth line, the basis average error was 5 μm.

- The measurement of the stereometry of the surface layer showed an even distribution of its structure. The roughness and material ratio indicators showed correct differentiation in relation to the applied changes in machining parameters.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| α | pressure angle |

| angle between the radius of the involute’s initial point and the radius of the considered point of the involute | |

| arc angle in involute function | |

| angle between the ordinate and the leading radius of the point of tangency normal to the outline | |

| angle from the ordinate axis to the point P on pitch circle | |

| angle of the contour for the beginning point A of the tooth involute profile | |

| angle of the contours for the end point B of the tooth involute profile | |

| angle of the contours for the point P on pitch circle | |

| angle of the contours for subsequent points |

References

- Radzevich, P.S. Theory of Gearing: Kinematics, Geometry, and Synthesis; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Litvin, F.L. Development of Gear Technology and Theory of Gearing; NASA Lewis Research Center: Cleveland, OH, USA, 1997. [Google Scholar]

- Brown, J.R. Improved Cutter for Cutting Gear-Wheels. U.S. Patent Application 45,294, 29 November 1864. [Google Scholar]

- Scherbarth, S. Tooth Milling Cutter and Method for Milling the Teeth of Toothed Gear Elements. U.S. Patent Application 9,352,406 B2, 31 May 2016. [Google Scholar]

- Vogel, O.; Nagele, J. Power Skiving Tool for Power Skiving Gear Teeth on a Crown Wheel Workpiece. U.S. Patent Application 2014/0314504 A1, 23 October 2014. [Google Scholar]

- Harmut, M.; Vogel, O. Semi-Completing Gear Skiving Process and Device with Corresponding Skiving Tool for Carrying out a Semi-Completing Skiving Process. EP Patent Application 2 570 217 A1, 15 September 2011. [Google Scholar]

- Sture, S. Cutting Insert and Power Skiving Tool. EP Patent Application 2 965 847 A1, 9 July 2014. [Google Scholar]

- Litvin, F.L.; Feng, P.H.; Lagutin, S.A.; Townsend, D.P.; Sep, T.M. Helical and Spur Gear Drive with Double Crowned Pinion Tooth Surfaces and Conjugated Gear Tooth Surfaces. U.S. Patent Application 6,205,879 B1, 27 March 2001. [Google Scholar]

- Gutmann, P.; Hong, L.J. Toothed Gear Manufactured by Involute Envelope Method. PL/EP Patent Application 2005032 B1, 15 July 2009. [Google Scholar]

- Budzik, G.; Dziubek, T.; Sobolewski, B.; Przeszłowski, Ł. Toothed Gear, Manufacturing Method. PL Patent Application 236610 B1, 12 April 2018. [Google Scholar]

- Bauseler, S. Toothed Gear. PL Patent Application 197335 B1, 16 August 2001. [Google Scholar]

- Kostron, A.; Karowiec, K.; Skrzypiec, A.; Serwotka, R.; Sedlaczek, J. Toothed Gear. PL Patent Application 181581 B1, 12 December 1996. [Google Scholar]

- Batsch, M. Modification Method of Tooth Line of the Gear. PL Patent Application 232725 B1, 21 July 2015. [Google Scholar]

- Boiko, S.L.; Korotkin, V.I.; Veretennikov, V.Y.; Roslivker, E.G.; Fedyakin, R.V.; Chesnkov, V.A.; Yakovlev, A.S.; Kharitonov, J.D.; Fei, V.M.; Galichenko, E.N. Novikov Gearing. U.S. Patent Application 5,022,280, 11 June 1991. [Google Scholar]

- Pengbo, B.; Haizea, G.; Amaia, C.; de Lacalle, L.N.; Barton, M. 5-axis double-flank CNC machining of spiral bevel gears via custom-shaped milling tools—Part I: Modeling and simulation. Prec. Eng. 2020, 64, 204–212. [Google Scholar]

- Shuting, L. Finite element analyses for contact strength and bending strength of a pair of spur gears with machining errors, assembly errors and tooth modifications. Mech. Mach. Theory 2007, 42, 88–114. [Google Scholar]

- Landi, L.; Srecconi, A.; Morettini, G.; Cianetti, F. Analytical procedure for the optimization of plastic gear tooth root. Mech. Mach. Theory 2019, 166, 104496. [Google Scholar] [CrossRef]

- Chavadaki, S.; Kumar, K.C.N.; Rajesh, M.N. Finite element analysis of spur gear to find out the optimum root radius. Mater. Today Proc. 2021, 20, 10672–10675. [Google Scholar] [CrossRef]

- Gnatowski, A.; Gołębski, R.; Sikora, P. Analysis of the Impact of Changes in Thermomechanical Properties of Polymer Materials on the Machining Process of Gears. Polymers 2021, 13, 28. [Google Scholar] [CrossRef] [PubMed]

- Gosselin, C. Multi Axis CnC Manufacturing of Straight and Spiral Bevel Gears. In Advanced Gear Engineering; Mechanisms and Machine Science; Springer: Cham, Switzerland, 2018; Volume 51, pp. 167–204. [Google Scholar]

- Malek, O.; Mielnik, K.; Martens, K.; Jacobs, T.; Bouquet, J.; Auwers, W.; Ten Haaf, P.; Lauwers, B. Lead Time Reduction by High Precision 5-axis Milling of a Prototype Gear. Procedia CIRP 2016, 46, 440–443. [Google Scholar] [CrossRef] [Green Version]

- Kobialka, C. Complete Machining of Gear Blank and Gear Teeth; Technical Paper 10FTM01; American Gear Manufacured Association: Alexandria, VA, USA, 2010. [Google Scholar]

- Gadakh, R.S.; Londhe, P.G.; Shaikh, B.A.; Shaikh, F.S. Gear Manufacturing by using conventional lathe machine. Int. J. Res. Eng. Technol. 2016, 5, 105–110. [Google Scholar]

- Kawasaki, K.; Tsuji, I.; Gunbara, H.; Houjoh, H. Method for remanufacturing large-sized skew gears using CNC machining center. Mech. Mach. Theory 2015, 92, 213–229. [Google Scholar] [CrossRef]

- Yang, L.; Huang, G. The OPC technology research about spiral bevel gear machine tools for machining simulation problems. Proc. Eng. 2011, 15, 1266–1270. [Google Scholar] [CrossRef] [Green Version]

- Chung-Yu, T. Power-skiving tool design method for interference-free involute internal gear cutting. Mech. Mach. Theory 2021, 164, 1–42. [Google Scholar]

- Gołębski, R. Parametric programming of CNC machine tools. In Proceedings of the 4th International Conference on Computing and Solutions in Manufacturing Engineering 2016, Transilvania University of Brașov, Brasov, Romania, 3–4 November 2016; Volume 94. [Google Scholar]

- Gołębski, R.; Boral, P. Study of machining of gears with regular and modified outline using CNC machine tools. Arch. Mater. 2021, 14, 2913. [Google Scholar] [CrossRef] [PubMed]

- Perschmann. Tools Guide Catalogue. Available online: https://www.hoffmann-group.com/GB/en/houk/Mono-machining/Solid-carbide-milling-cutters/GARANT-Master-Alu-solid-carbide-milling-cutter%2C-HPC-HPC-uncoated/p/203208-6 (accessed on 4 November 2021).

- ISO 1328-1:2015; Cylindrical Gears—ISO System of Flank Tolerance Classification—Part 1: Definitions and Allowable Values of Double Flank Radial Composite Deviations; PKN: Warsaw, Poland, 2015.

- ISO 4287:1997; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters; PKN: Warsaw, Poland, 1999.

| Module [mm] | Number of Teeth | Pitch Angle [deg] | Tooth Height Coefficient | Clearance Coefficient [mm] | Face Width [mm] |

|---|---|---|---|---|---|

| 6 | 17 | 20 | 1.0 | 0.20 | 10 |

| Gear Parameter [mm] | Avg. Fα [μm] | Avg. ffα [μm] | Avg. fHα [μm] | Avg. Fβ [μm] | Avg. ffβ [μm] | Avg. fHβ [μm] | fp [μm] | Fp [μm] | fu [μm] |

|---|---|---|---|---|---|---|---|---|---|

| Measurement results | 10 | 11 | 6 | 5 | 7 | 1 | 11 | 31 | 15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gołębski, R. Experimental Method of Machining Gears with an Involute Profile Using CNC Lathe with Driven Tools. Materials 2022, 15, 1077. https://doi.org/10.3390/ma15031077

Gołębski R. Experimental Method of Machining Gears with an Involute Profile Using CNC Lathe with Driven Tools. Materials. 2022; 15(3):1077. https://doi.org/10.3390/ma15031077

Chicago/Turabian StyleGołębski, Rafał. 2022. "Experimental Method of Machining Gears with an Involute Profile Using CNC Lathe with Driven Tools" Materials 15, no. 3: 1077. https://doi.org/10.3390/ma15031077