Influence of Creep Damage on the Fatigue Life of P91 Steel

Abstract

:1. Introduction

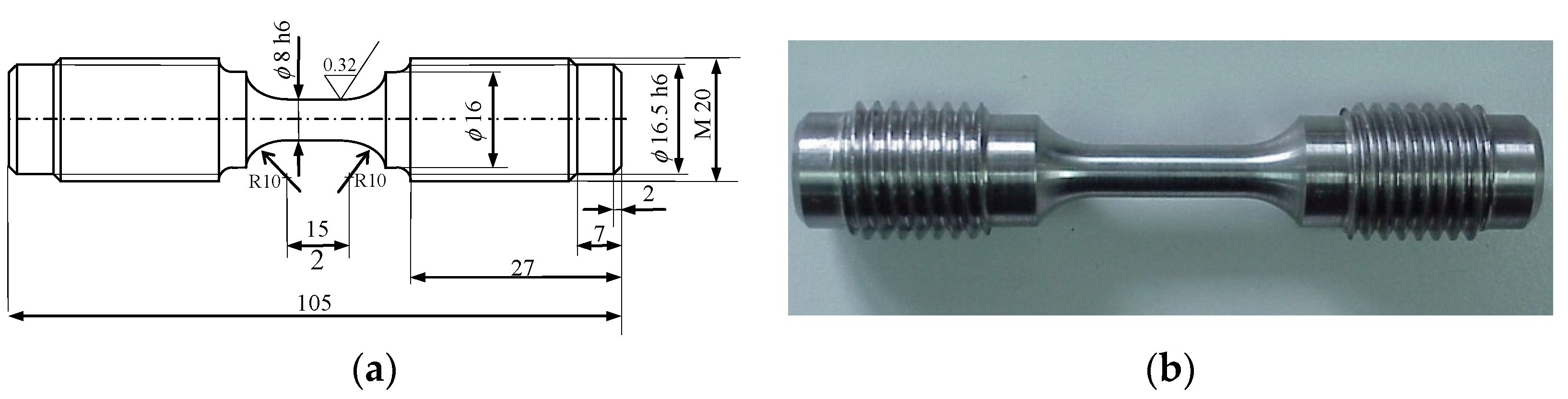

2. Materials and Methods

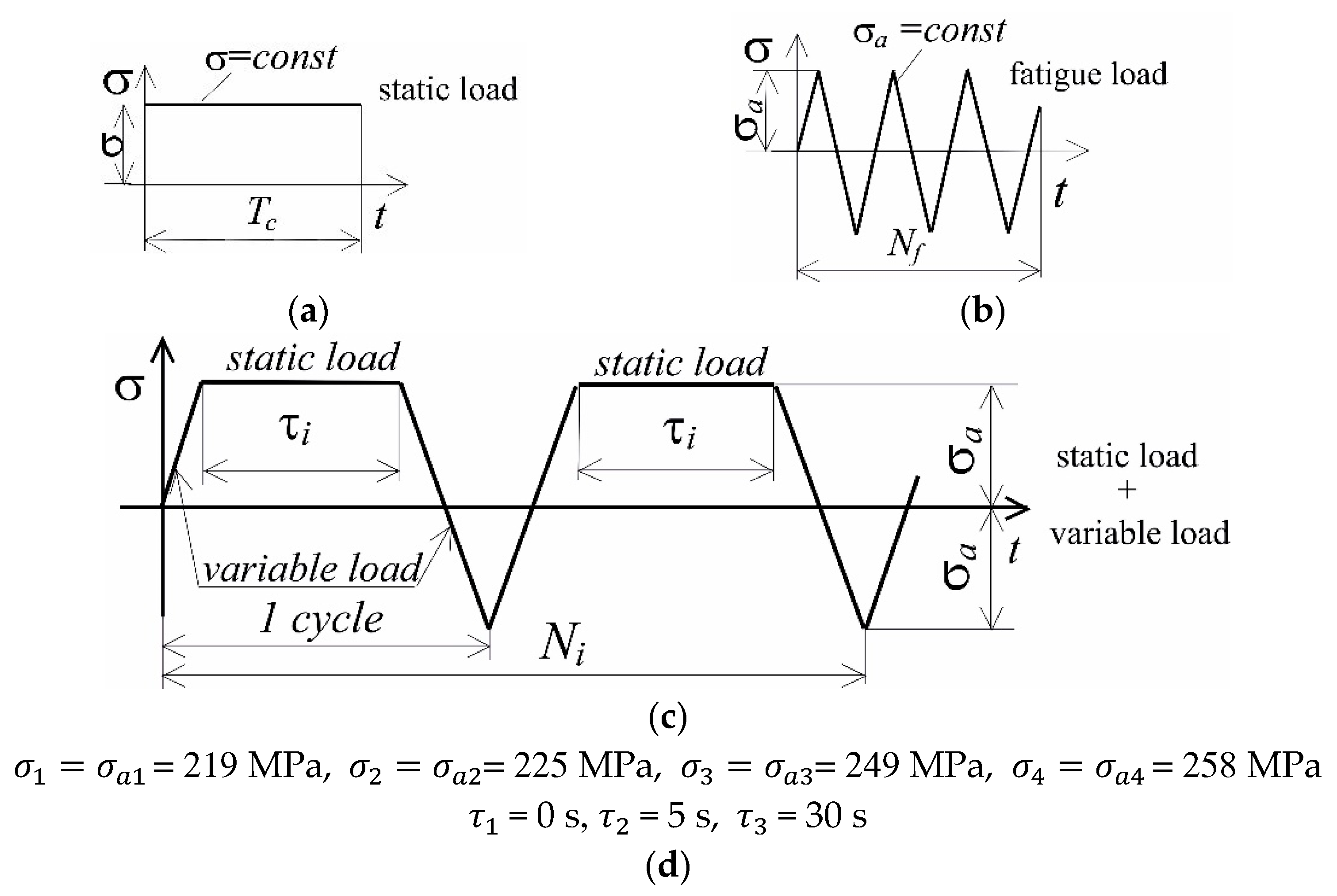

Experimental Testing

3. Results

3.1. Static Tension Test

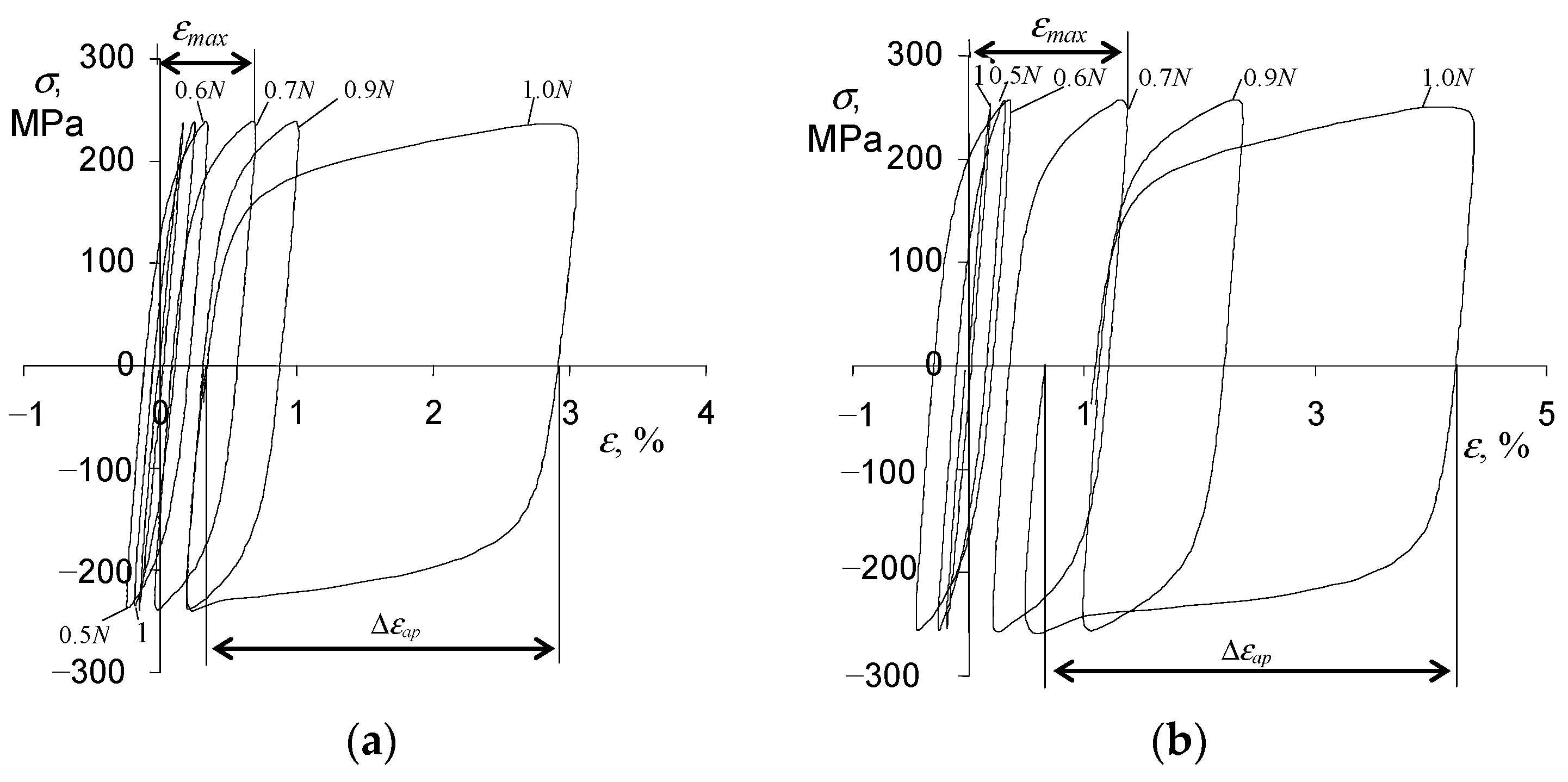

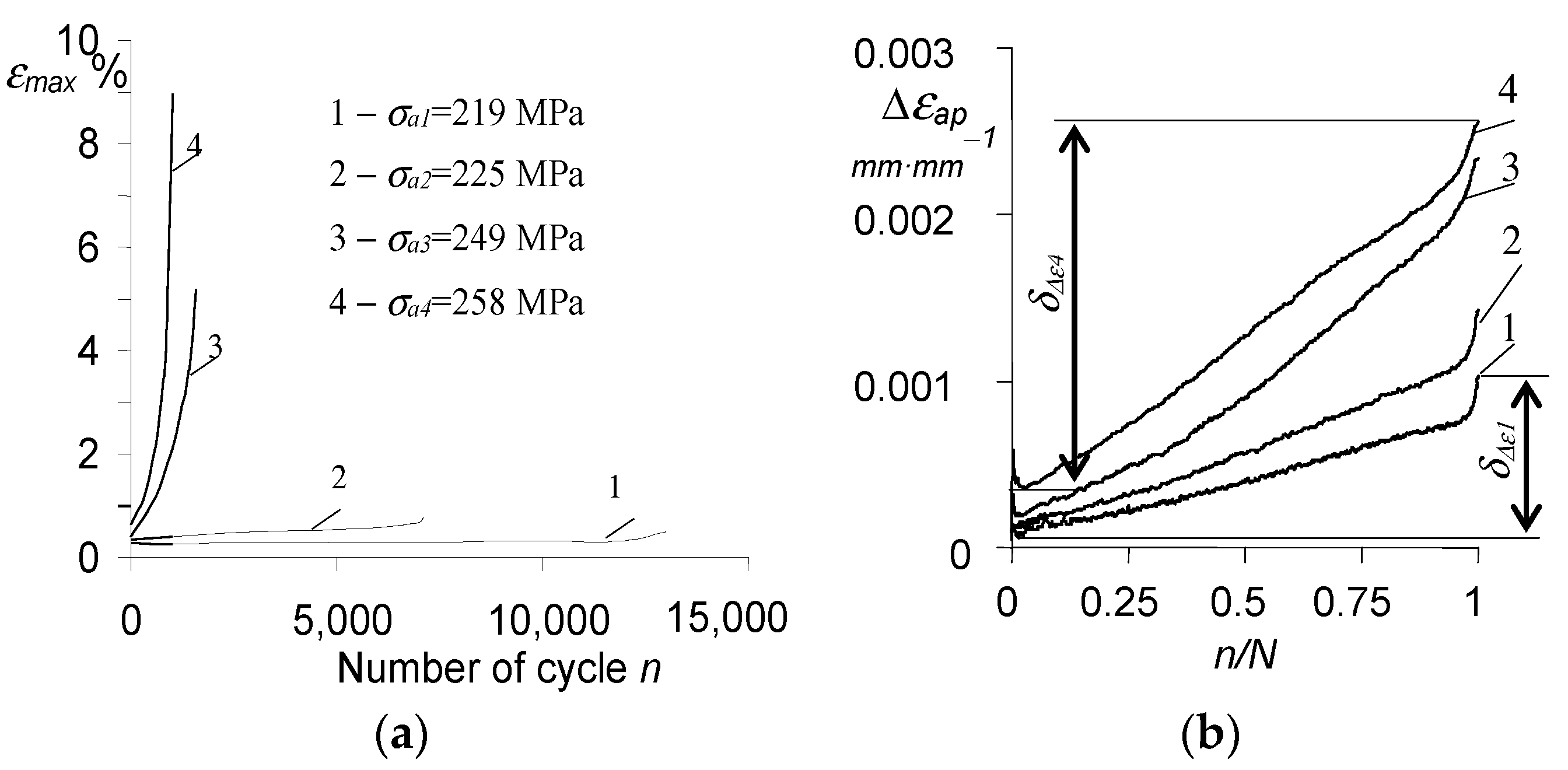

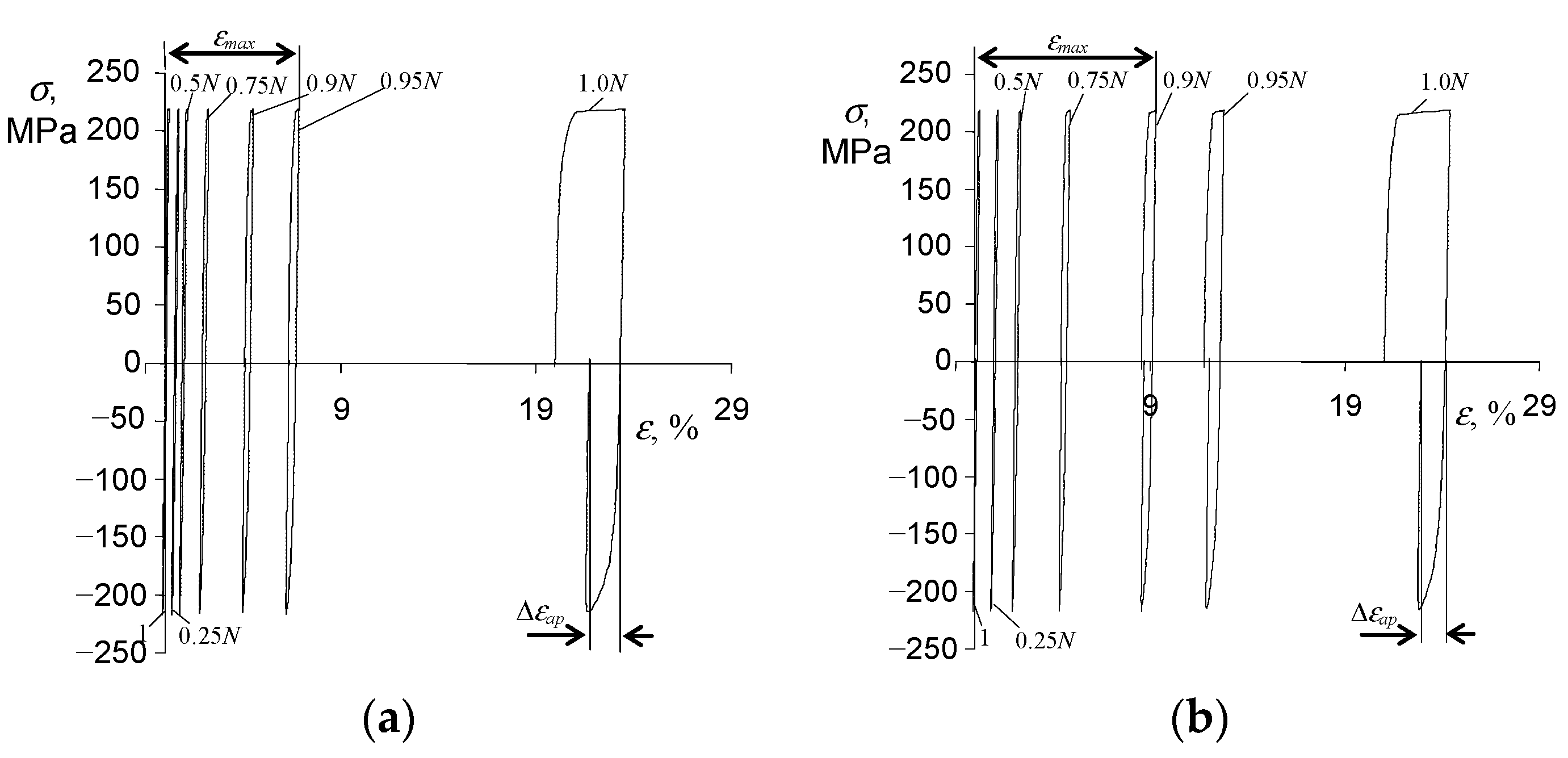

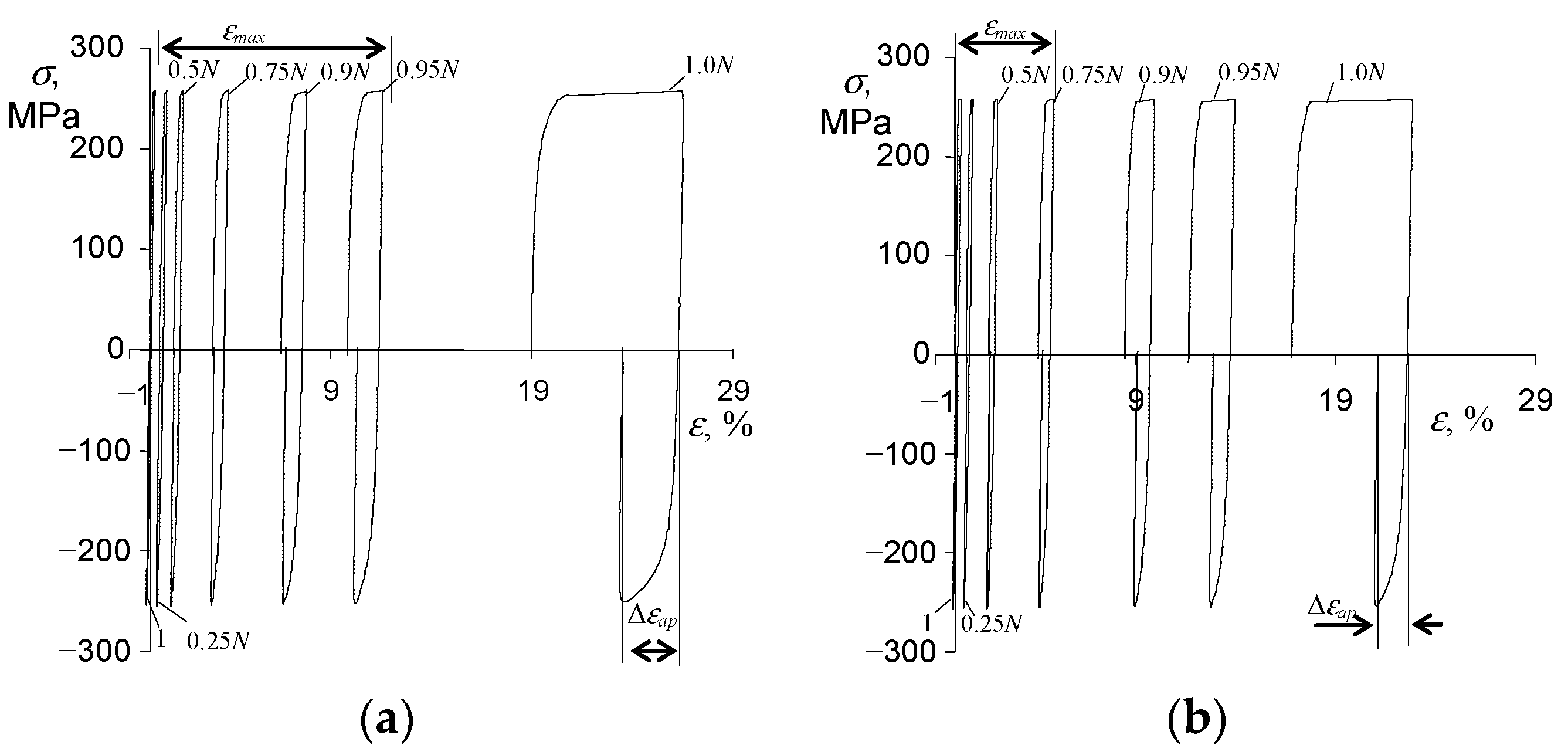

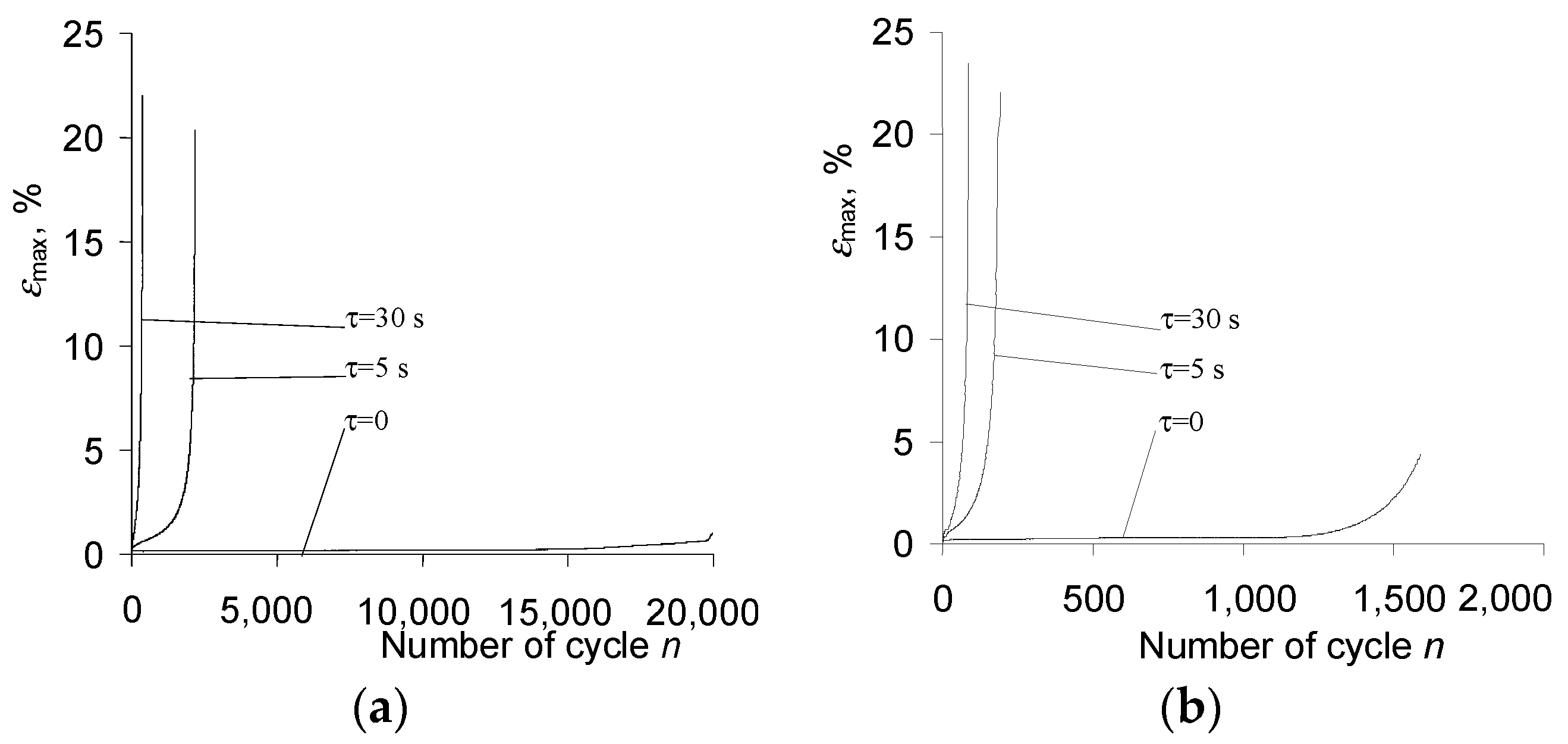

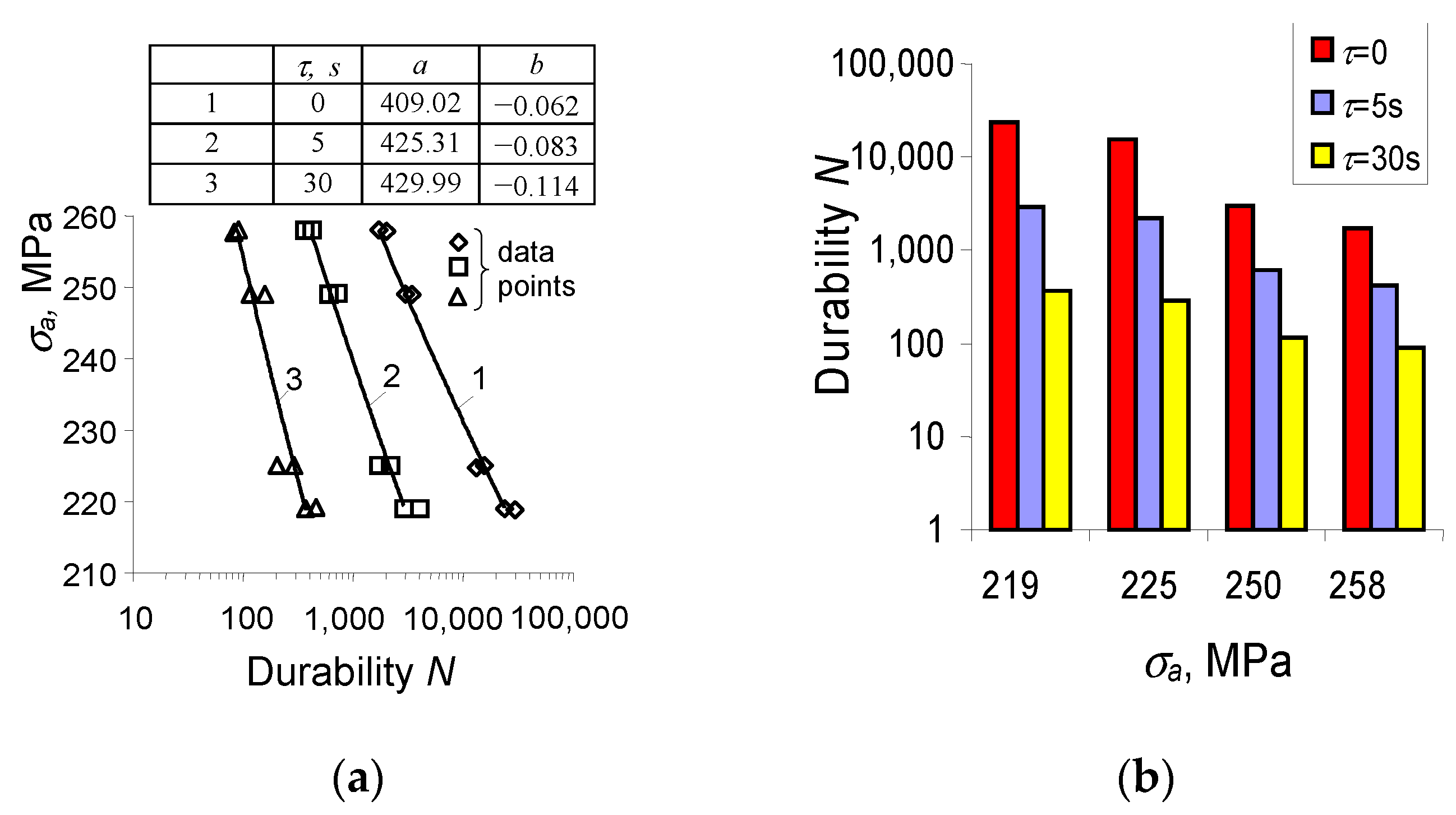

3.2. Fatigue Tests

3.3. Creep Tests

3.4. Fatigue-Creep Tests

3.5. Fractographic Observations

3.6. Durability Assessments

- (1)

- a calculation-based diagram taking into account only the fatigue properties (fatigue);

- (2)

- a calculation-based diagram regarding fatigue and creep (fatigue + creep);

- (3)

- a diagram obtained based on experimental results (experiment).

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mroziński, S.; Piotrowski, M.; Egner, H. Effects of fatigue testing on low-cycle properties of P91 steel. Int. J. Fatigue 2019, 120, 65–72. [Google Scholar] [CrossRef]

- Mroziński, S.; Lis, Z. Comparative Analysis of Methods for Determining Cyclic Properties of Metals, Experimental Mechanics of Solids. Materials Research Forum RLC. Mater. Res. Proc. 2019, 12, 139–145. [Google Scholar]

- Wu, D.-L.; Zhao, P.; Wang, Q.-Q.; Xuan, F.-Z. Cyclic behavior of 9–12% Cr steel under different control modes in low cycle regime: A comparative study. Int. J. Fatigue 2015, 70, 114–122. [Google Scholar] [CrossRef]

- Egner, W.; Sulich, P.; Mroziński, S.; Egner, H. Modelling thermo-mechanical cyclic behavior of P91 steel. Int. J. Plast. 2020, 135, 102820. [Google Scholar] [CrossRef]

- Hu, X.; Zhang, Q.; Jiang, Y.; Rao, G.; Miao, G.; He, W.; Nie, X. The effect of cyclic loading on the creep fatigue life and creep strength of a DS superalloy: Damage mechanism and life modeling. Int. J. Fatigue 2020, 134, 105452. [Google Scholar] [CrossRef]

- Xu, L.; Wang, R.-Z.; Wang, J.; He, L.; Itoh, T.; Miura, H.; Zhang, X.-C.; Tu, S.-T. On multiaxial creep–fatigue considering the non-proportional loading effect: Constitutive modeling, deformation mechanism, and life prediction. Int. J. Plast. 2022, 155, 103337. [Google Scholar] [CrossRef]

- Liu, H.; Yang, X.; Jiang, L.; Lv, S.; Huang, T.; Yang, Y. Fatigue-creep damage interaction model of asphalt mixture under the semi-sine cycle loading. Constr. Build. Mater. 2020, 251, 119070. [Google Scholar] [CrossRef]

- Barat, K.; Sivaprasad, S.; Kar, S.K.; Tarafder, S. A novel rate based methodology for creep fatigue life estimation of superalloys. Int. J. Press. Vessel. Pip. 2020, 182, 104064. [Google Scholar] [CrossRef]

- Igumnov, L.A.; Volkov, I.A. Defining relations of mechanics of damaged media effected by fatigue and creep. Procedia Struct. Integr. 2020, 28, 2086–2098. [Google Scholar] [CrossRef]

- Mroziński, S.; Lis, Z. Research on the influence of creep on low-cycle fatigue life. Energetyka 2019, 11, 760–762(In Polish). [Google Scholar]

- Mroziński, S.; Lis, Z.; Egner, H. Energy Dissipated in Fatigue and Creep Conditions. Materials 2021, 14, 4724. [Google Scholar] [CrossRef] [PubMed]

- Tien, J.K.; Nair, S.V.; Nardone, V.C. Creep fatigue Interactions in Structural Alloys. In Flow and Fracture at Elevated Temperatures; Raj, R., Ed.; ASM Materials Science Seminar: Philadelphia, PA, USA, 1983; Chapter 6; p. 179. [Google Scholar]

- Miner, M. Cumulative Damage in Fatigue. J. Appl. Mech. 1945, 67, A159–A164. [Google Scholar] [CrossRef]

- Zhuang, W.Z.; Swansson, N.S. Thermo-Mechanical Fatigue Life Prediction: A Critical Review; DSTO-TR-0609; DSTO Aeronautical and Maritime Research Laboratory: Victoria, Australia, 1998. [Google Scholar]

- Ahmadzadeh, G.R.; Varvani-Farahani, A. Concurrent ratcheting–fatigue damage analysis of uniaxially loaded A-516 Gr.70 and 42CrMo Steels. Fatigue Fract. Eng. Mater. Struct. 2012, 35, 962–970. [Google Scholar] [CrossRef]

- Chang, L.; Wen, J.B.; Zhou, C.Y.; Zhou, B.B.; Li, J. Uniaxial ratcheting behavior and fatigue life models of commercial pure titanium. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 2024–2039. [Google Scholar] [CrossRef]

- Samuel, K.G.; Rodriguez, P. An empirical relation between strain energy and time in creep deformation. Int. J. Press. Vessel. Pip. 1998, 75, 939–943. [Google Scholar] [CrossRef]

- Payten, W.M.; Dean, D.W.; Snowden, K.U. A strain energy density method for the prediction of creep–fatigue damage in high temperature components. Mater. Sci. Eng. A 2010, 527, 1920–1925. [Google Scholar] [CrossRef]

- Cheng, H.; Chen, G.; Zhang, Z.; Chen, X. Uniaxial ratcheting behaviors of Zircaloy-4 tubes at 400 C. J. Nucl. Mater. 2015, 458, 129–137. [Google Scholar] [CrossRef]

- Song, G.; Hyun, J.; Ha, J. Creep-fatigue prediction of aged 13CrMo44 steel using the tensile plastic strain energy. Eur. Struct. Integr. Soc. 2002, 29, 65–73. [Google Scholar]

- Zheng, X.T.; Xuan, F.Z.; Zhao, P. Ratcheting-creep interaction of advanced 9–12% chromium ferrite steel with anelastic effect. Int. J. Fatigue 2011, 33, 1286–1291. [Google Scholar] [CrossRef]

- Zhao, Z.; Yu, D.; Chen, X. Creep-ratcheting-fatigue life prediction of bainitic 2.25Cr1MoV steel. Procedia Struct. Integr. 2019, 17, 555–561. [Google Scholar] [CrossRef]

- Zhao, Z.; Yu, D.; Chen, G.; Chen, X. Ratcheting fatigue behaviour of bainite 2.25Cr1MoV steel with tensile and compressed hold loading at 455 °C. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1937–1949. [Google Scholar] [CrossRef]

- ASTM E606-92; Standard Practice for Strain—Controlled Fatigue Testing. ASTM: West Conshohocken, PA, USA, 1998.

- Skocki, R. Research on the Influence of Elevated Temperature on the Cyclic Properties of P91 Steel. Ph.D. Thesis, Faculty of Mechanics UST, Bydgoszcz, Poland, 2017. (In Polish). [Google Scholar]

- Mroziński, S.; Lipski, A. The effects of temperature on the strength properties of aluminium alloy 2024-T3. Acta Mech. Autom. 2012, 6, 62–66. [Google Scholar]

- Oh, Y.-J.; Yang, W.-J.; Jung, J.-G.; Choi, W.-D. Thermomechanical fatigue behavior and lifetime prediction of niobium bearing ferritic stainless steels. Int. J. Fatigue 2012, 40, 36–42. [Google Scholar] [CrossRef]

- Brnic, J.; Turkalk, G.; Canadija, M.; Lanc, D. AISI 316Ti (1.4571) steel—Mechanical, creep and fracture properties vs. temperature. J. Constr. Steel Res. 2011, 67, 1948–1952. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr | Mo | Ni |

| 0.197 | 0.442 | 0.489 | 0.017 | 0.005 | 8.82 | 0.971 | 0.307 |

| Al | Co | Cu | Nb | Ti | V | W | |

| 0.012 | 0.017 | 0.036 | 0.074 | 0.004 | 0.201 | 0.02 |

| T, °C | Rp0.2, MPa | Rm, MPa | Z, % | A12.5, % | E, MPa |

|---|---|---|---|---|---|

| 20 | 564 | 716 | 62 | 35 | 209,850 |

| 400 | 463 | 571 | 69 | 44 | 183,220 |

| 600 | 317 | 353 | 72 | 56 | 132,890 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mroziński, S.; Lis, Z.; Egner, H. Influence of Creep Damage on the Fatigue Life of P91 Steel. Materials 2022, 15, 4917. https://doi.org/10.3390/ma15144917

Mroziński S, Lis Z, Egner H. Influence of Creep Damage on the Fatigue Life of P91 Steel. Materials. 2022; 15(14):4917. https://doi.org/10.3390/ma15144917

Chicago/Turabian StyleMroziński, Stanisław, Zbigniew Lis, and Halina Egner. 2022. "Influence of Creep Damage on the Fatigue Life of P91 Steel" Materials 15, no. 14: 4917. https://doi.org/10.3390/ma15144917