Oxidic 2D Materials

Abstract

:1. Introduction

2. 2D Materials

2.1. Non-Oxidic 2D Materials

2.2. Transition Metal Oxides

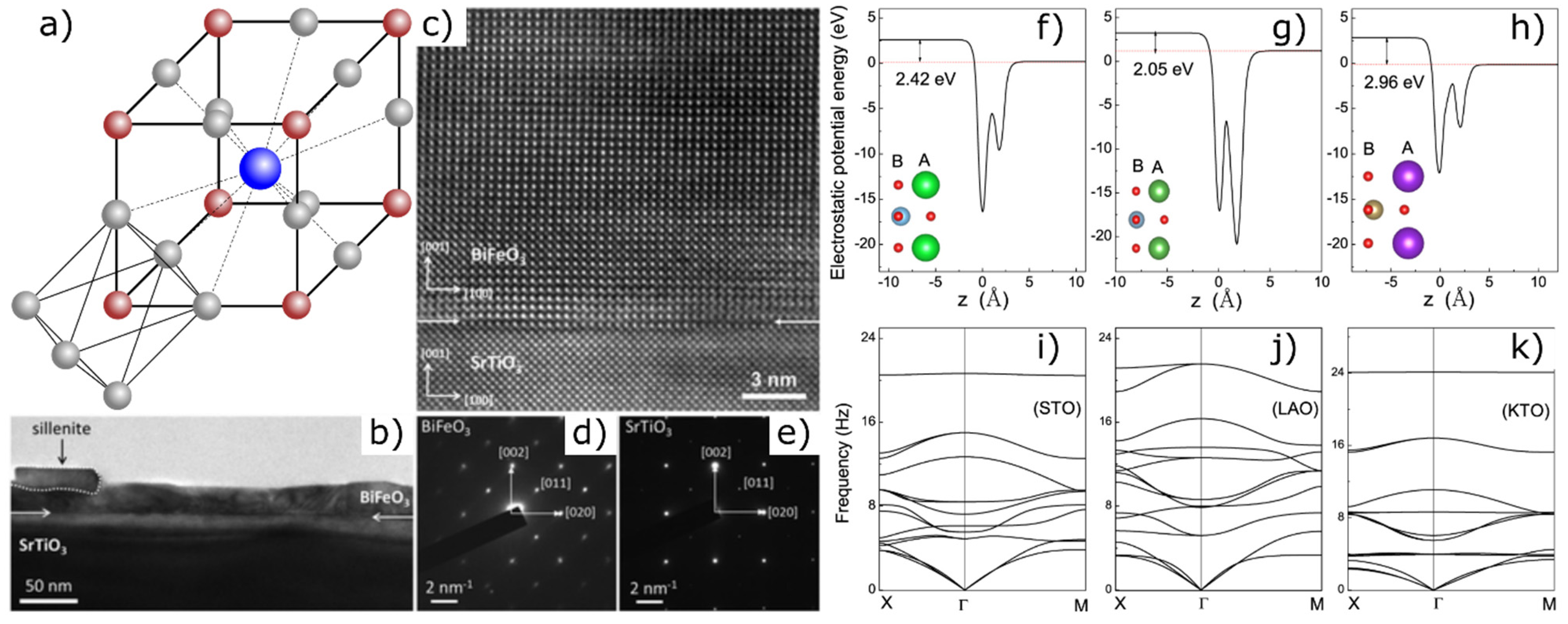

2.2.1. Perovskites

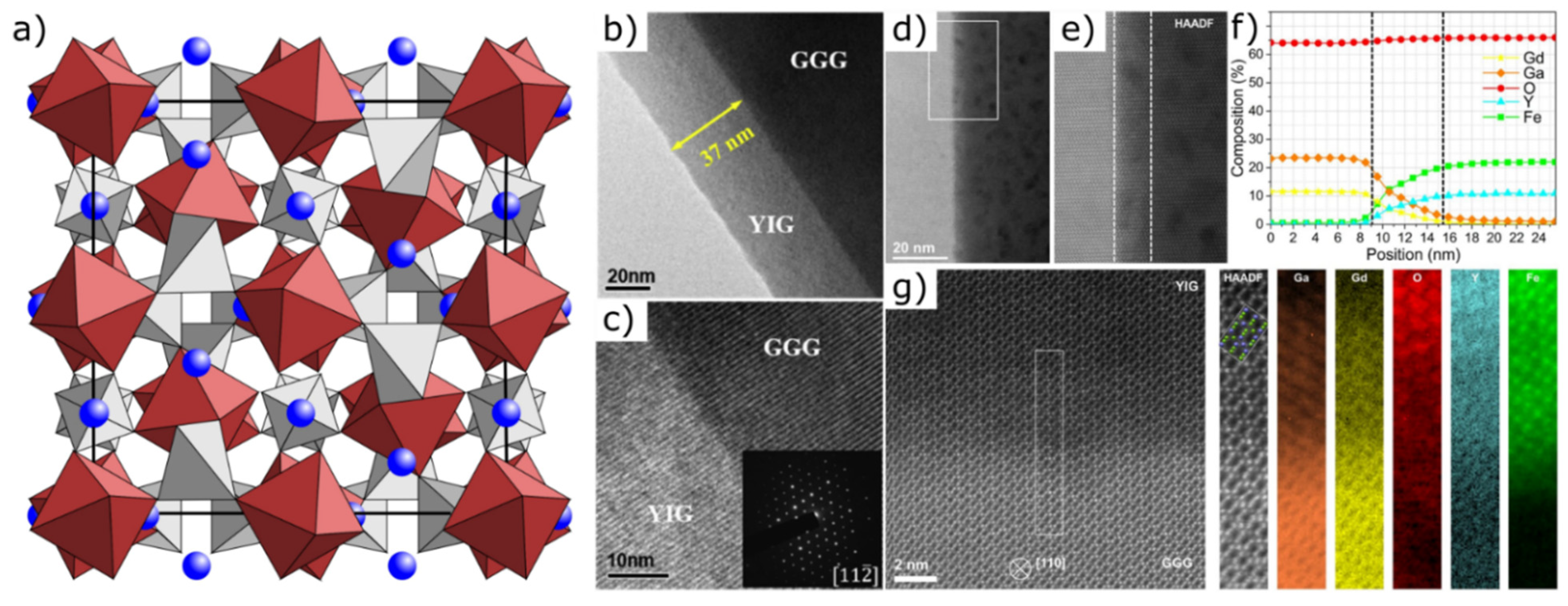

2.2.2. Garnets

2.2.3. Spinels

3. Fabrication Strategies

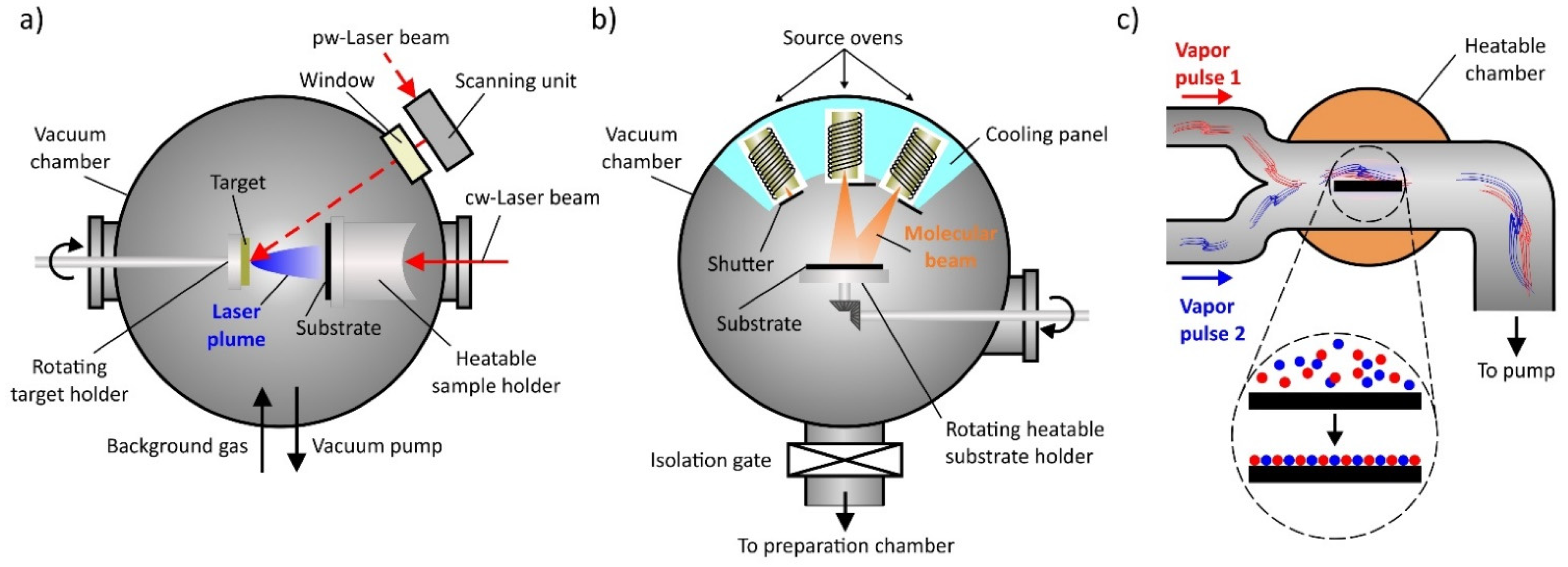

3.1. Growth Techniques

3.1.1. Pulsed Laser Deposition

3.1.2. Molecular Beam Epitaxy

3.1.3. Atomic Layer Deposition

3.2. Transfer

4. Applications

4.1. Free-Standing Monolayers

4.2. Bilayers

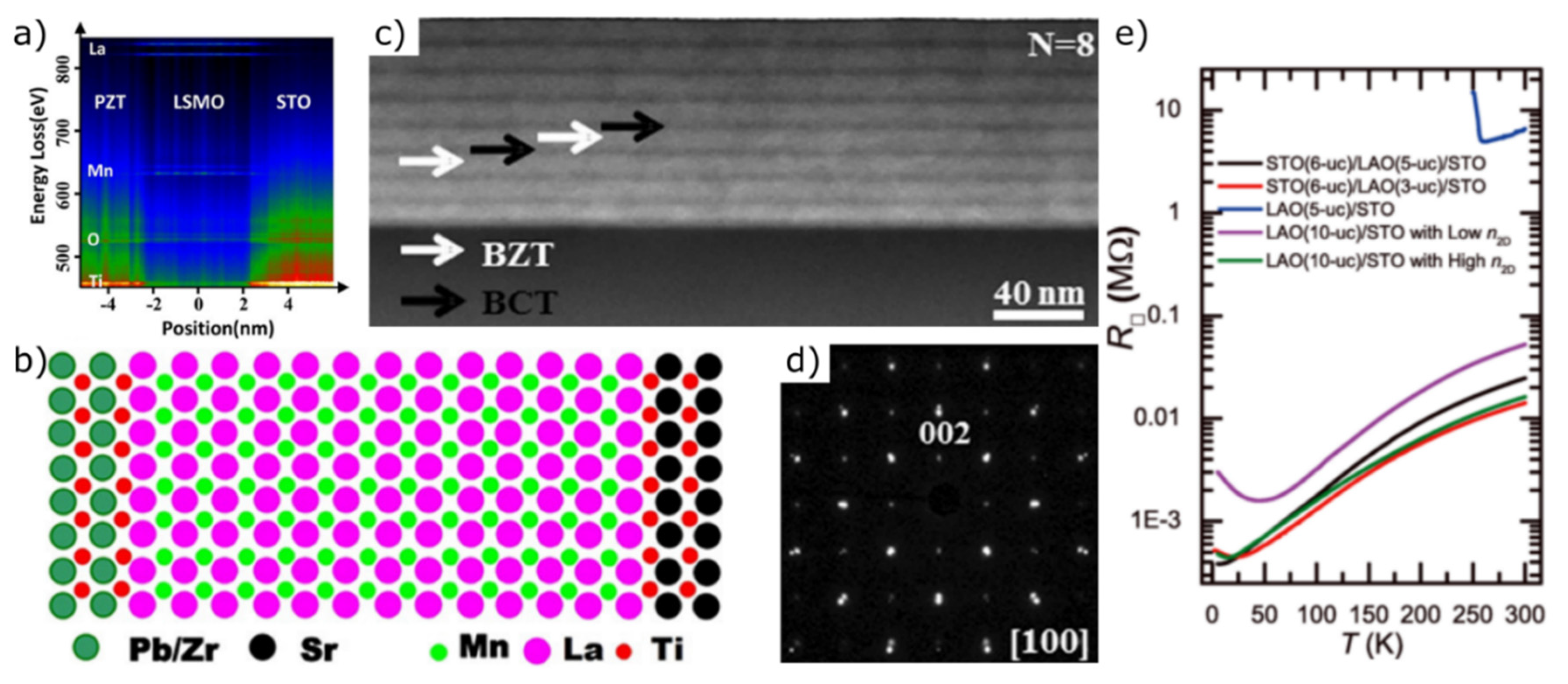

4.3. Multilayers

5. Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, X.X.; Song, P.; Wang, C.C.; Riis-Jensen, A.C.; Fu, W.; Deng, Y.; Wan, D.Y.; Kang, L.X.; Ning, S.C.; Dan, J.D.; et al. Engineering covalently bonded 2D layered materials by self-intercalation. Nature 2020, 581, 171–177. [Google Scholar] [CrossRef] [PubMed]

- Tan, C.L.; Cao, X.H.; Wu, X.J.; He, Q.Y.; Yang, J.; Zhang, X.; Chen, J.Z.; Zhao, W.; Han, S.K.; Nam, G.H.; et al. Recent Advances in Ultrathin Two-Dimensional Nanomaterials. Chem. Rev. 2017, 117, 6225–6331. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, N.; Wang, S.; Zhang, Y. Effect of doping 3d transition metal (Fe, Co, and Ni) on the electronic, magnetic and optical properties of pentagonal ZnO2 monolayer. Phys. E Low-Dimens. Syst. Nanostruct. 2020, 117, 113806. [Google Scholar] [CrossRef]

- Birkholzer, Y.A.; Koster, G. How to make the thinnest possible free-standing sheets of perovskite materials. Nature 2019, 570, 39–40. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bednorz, J.G.; Muller, K.A. Possible high-tc superconductivity in the ba-la-cu-o system. Z. Phys. B-Condens. Matter 1986, 64, 189–193. [Google Scholar] [CrossRef]

- Dagotto, E. Correlated electrons in high-temperature superconductors. Rev. Mod. Phys. 1994, 66, 763–840. [Google Scholar] [CrossRef]

- Ronning, F.; Helm, T.; Hirer, K.R.S.; Bachmann, M.D.; Balicas, L.; Chan, M.K.; Ramshaw, B.J.; McDonald, R.D.; Balakirev, F.F.; Jaime, M.; et al. Electronic in-plane symmetry breaking at field-tuned quantum criticality in CeRhIn5. Nature 2017, 548, 313–317. [Google Scholar] [CrossRef]

- Saito, Y.; Nojima, T.; Iwasa, Y. Highly crystalline 2D superconductors. Nat. Rev. Mater. 2017, 2, 18. [Google Scholar] [CrossRef] [Green Version]

- Reyren, N.; Thiel, S.; Caviglia, A.D.; Kourkoutis, L.F.; Hammerl, G.; Richter, C.; Schneider, C.W.; Kopp, T.; Ruetschi, A.S.; Jaccard, D.; et al. Superconducting interfaces between insulating oxides. Science 2007, 317, 1196–1199. [Google Scholar] [CrossRef]

- Gozar, A.; Logvenov, G.; Kourkoutis, L.F.; Bollinger, A.T.; Giannuzzi, L.A.; Muller, D.A.; Bozovic, I. High-temperature interface superconductivity between metallic and insulating copper oxides. Nature 2008, 455, 782–785. [Google Scholar] [CrossRef]

- Ge, J.F.; Liu, Z.L.; Liu, C.H.; Gao, C.L.; Qian, D.; Xue, Q.K.; Liu, Y.; Jia, J.F. Superconductivity above 100 K in single-layer FeSe films on doped SrTiO3. Nat. Mater. 2015, 14, 285–289. [Google Scholar] [CrossRef] [PubMed]

- Jin, S.; Tiefel, T.H.; McCormack, M.; Fastnacht, R.A.; Ramesh, R.; Chen, L.H. Thousandfold Change in Resistivity in Magnetoresistive La-Ca-Mn-O Films. Science 1994, 264, 413–415. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tokura, Y.; Tomioka, Y. Colossal magnetoresistive manganites. J. Magn. Magn. Mater. 1999, 200, 1–23. [Google Scholar] [CrossRef]

- Imada, M.; Fujimori, A.; Tokura, Y. Metal-insulator transitions. Rev. Mod. Phys. 1998, 70, 1039–1263. [Google Scholar] [CrossRef] [Green Version]

- Ahn, K.H.; Lookman, T.; Bishop, A.R. Strain-induced metal-insulator phase coexistence in perovskite manganites. Nature 2004, 428, 401–404. [Google Scholar] [CrossRef]

- Ramesh, R.; Spaldin, N.A. Multiferroics: Progress and prospects in thin films. Nat. Mater. 2007, 6, 21–29. [Google Scholar] [CrossRef]

- Cheong, S.W.; Mostovoy, M. Multiferroics: A magnetic twist for ferroelectricity. Nat. Mater. 2007, 6, 13–20. [Google Scholar] [CrossRef] [Green Version]

- Tsukazaki, A. A platform for making and transferring oxide films. Nature 2020, 578, 41–42. [Google Scholar] [CrossRef] [Green Version]

- Khuntia, P. Novel magnetism and spin dynamics of strongly correlated electron systems: Microscopic insights. J. Magn. Magn. Mater. 2019, 489, 7. [Google Scholar] [CrossRef]

- Urbaszek, B.; Srivastava, A. Materials in flatland twist and shine. Nature 2019, 567, 39–40. [Google Scholar] [CrossRef]

- Beekman, C. Straining quantum materials even further A nanoscale membrane enables exploration of large tensile strains on complex oxides. Science 2020, 368, 32–33. [Google Scholar] [CrossRef]

- Butler, S.Z.; Hollen, S.M.; Cao, L.Y.; Cui, Y.; Gupta, J.A.; Gutierrez, H.R.; Heinz, T.F.; Hong, S.S.; Huang, J.X.; Ismach, A.F.; et al. Progress, Challenges, and Opportunities in Two-Dimensional Materials Beyond Graphene. ACS Nano 2013, 7, 2898–2926. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Fiori, G.; Bonaccorso, F.; Iannaccone, G.; Palacios, T.; Neumaier, D.; Seabaugh, A.; Banerjee, S.K.; Colombo, L. Electronics based on two-dimensional materials. Nat. Nanotechnol. 2014, 9, 768–779. [Google Scholar] [CrossRef]

- Chhowalla, M.; Jena, D.; Zhang, H. Two-dimensional semiconductors for transistors. Nat. Rev. Mater. 2016, 1, 15. [Google Scholar] [CrossRef]

- Ji, D.X.; Cai, S.H.; Paudel, T.R.; Sun, H.Y.; Zhang, C.C.; Han, L.; Wei, Y.F.; Zang, Y.P.; Gu, M.; Zhang, Y.; et al. Freestanding crystalline oxide perovskites down to the monolayer limit. Nature 2019, 570, 87–90. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [Green Version]

- Radisavljevic, B.; Radenovic, A.; Brivio, J.; Giacometti, V.; Kis, A. Single-layer MoS2 transistors. Nat. Nanotechnol. 2011, 6, 147–150. [Google Scholar] [CrossRef]

- Lopez-Sanchez, O.; Lembke, D.; Kayci, M.; Radenovic, A.; Kis, A. Ultrasensitive photodetectors based on monolayer MoS2. Nat. Nanotechnol. 2013, 8, 497–501. [Google Scholar] [CrossRef]

- Mak, K.F.; He, K.L.; Shan, J.; Heinz, T.F. Control of valley polarization in monolayer MoS2 by optical helicity. Nat. Nanotechnol. 2012, 7, 494–498. [Google Scholar] [CrossRef] [PubMed]

- Spaldin, N.A.; Ramesh, R. Advances in magnetoelectric multiferroics. Nat. Mater. 2019, 18, 203–212. [Google Scholar] [CrossRef]

- Leung, C.M.; Li, J.F.; Viehland, D.; Zhuang, X. A review on applications of magnetoelectric composites: From heterostructural uncooled magnetic sensors, energy harvesters to highly efficient power converters. J. Phys. D-Appl. Phys. 2018, 51, 20. [Google Scholar] [CrossRef]

- Bauer, U.; Przybylski, M.; Kirschner, J.; Beach, G.S.D. Magnetoelectric Charge Trap Memory. Nano Lett. 2012, 12, 1437–1442. [Google Scholar] [CrossRef] [Green Version]

- del Valle, J.; Salev, P.; Tesler, F.; Vargas, N.M.; Kalcheim, Y.; Wang, P.; Trastoy, J.; Lee, M.H.; Kassabian, G.; Ramirez, J.G.; et al. Subthreshold firing in Mott nanodevices. Nature 2019, 569, 388–392. [Google Scholar] [CrossRef]

- Yu, H.; Liu, G.-B.; Tang, J.; Xu, X.; Yao, W. Moiré excitons: From programmable quantum emitter arrays to spin-orbit–coupled artificial lattices. Sci. Adv. 2017, 3, e1701696. [Google Scholar] [CrossRef] [Green Version]

- Hong, S.S.; Yu, J.H.; Lu, D.; Marshall, A.F.; Hikita, Y.; Cui, Y.; Hwang, H.Y. Two-dimensional limit of crystalline order in perovskite membrane films. Sci. Adv. 2017, 3, eaao5173. [Google Scholar] [CrossRef] [Green Version]

- Lu, D.; Baek, D.J.; Hong, S.S.; Kourkoutis, L.F.; Hikita, Y.; Hwang, H.Y. Synthesis of freestanding single-crystal perovskite films and heterostructures by etching of sacrificial water-soluble layers. Nat. Mater. 2016, 15, 1255–1260. [Google Scholar] [CrossRef] [PubMed]

- Kum, H.S.; Lee, H.; Kim, S.; Lindemann, S.; Kong, W.; Qiao, K.; Chen, P.; Irwin, J.; Lee, J.H.; Xie, S.E.; et al. Heterogeneous integration of single-crystalline complex-oxide membranes. Nature 2020, 578, 75–81. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.X.; Liu, J.W.; Feng, J.T.; Zheng, X.; Yang, L.H.; Ge, C.; Jin, K.J.; Wang, Z.M.; Li, R.W. Synthesis of single-crystal La0.67Sr0.33MnO3 freestanding films with different crystal-orientation. APL Mater. 2020, 8, 051105. [Google Scholar] [CrossRef]

- Xu, M.S.; Liang, T.; Shi, M.M.; Chen, H.Z. Graphene-Like Two-Dimensional Materials. Chem. Rev. 2013, 113, 3766–3798. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Katsnelson, M.I.; Grigorieva, I.V.; Dubonos, S.V.; Firsov, A.A. Two-dimensional gas of massless Dirac fermions in graphene. Nature 2005, 438, 197–200. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Fal’ko, V.I.; Colombo, L.; Gellert, P.R.; Schwab, M.G.; Kim, K. A roadmap for graphene. Nature 2012, 490, 192–200. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.D.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Balandin, A.A.; Ghosh, S.; Bao, W.Z.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef]

- Lin, Y.M.; Dimitrakopoulos, C.; Jenkins, K.A.; Farmer, D.B.; Chiu, H.Y.; Grill, A.; Avouris, P. 100-GHz Transistors from Wafer-Scale Epitaxial Graphene. Science 2010, 327, 662. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, M.; Yin, X.B.; Ulin-Avila, E.; Geng, B.S.; Zentgraf, T.; Ju, L.; Wang, F.; Zhang, X. A graphene-based broadband optical modulator. Nature 2011, 474, 64–67. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.S.; Zhao, Y.; Jang, H.; Lee, S.Y.; Kim, J.M.; Ahn, J.H.; Kim, P.; Choi, J.Y.; Hong, B.H. Large-scale pattern growth of graphene films for stretchable transparent electrodes. Nature 2009, 457, 706–710. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.W.; Murali, S.; Stoller, M.D.; Ganesh, K.J.; Cai, W.W.; Ferreira, P.J.; Pirkle, A.; Wallace, R.M.; Cychosz, K.A.; Thommes, M.; et al. Carbon-Based Supercapacitors Produced by Activation of Graphene. Science 2011, 332, 1537–1541. [Google Scholar] [CrossRef] [Green Version]

- Deng, M.; Yang, X.; Silke, M.; Qiu, W.M.; Xu, M.S.; Borghs, G.; Chen, H.Z. Electrochemical deposition of polypyrrole/graphene oxide composite on microelectrodes towards tuning the electrochemical properties of neural probes. Sens. Actuator B-Chem. 2011, 158, 176–184. [Google Scholar] [CrossRef]

- Cao, Y.; Fatemi, V.; Fang, S.; Watanabe, K.; Taniguchi, T.; Kaxiras, E.; Jarillo-Herrero, P. Unconventional superconductivity in magic-angle graphene superlattices. Nature 2018, 556, 43–50. [Google Scholar] [CrossRef]

- Kanetani, K.; Sugawara, K.; Sato, T.; Shimizu, R.; Iwaya, K.; Hitosugi, T.; Takahashi, T. Ca intercalated bilayer graphene as a thinnest limit of superconducting C6Ca. Proc. Natl. Acad. Sci. USA 2012, 109, 19610–19613. [Google Scholar] [CrossRef] [Green Version]

- Wilson, J.A.; Yoffe, A.D. The transition metal dichalcogenides discussion and interpretation of the observed optical, electrical and structural properties. Adv. Phys. 1969, 18, 193–335. [Google Scholar] [CrossRef]

- Duan, X.D.; Wang, C.; Pan, A.L.; Yu, R.Q.; Duan, X.F. Two-dimensional transition metal dichalcogenides as atomically thin semiconductors: Opportunities and challenges. Chem. Soc. Rev. 2015, 44, 8859–8876. [Google Scholar] [CrossRef]

- Golberg, D.; Bando, Y.; Huang, Y.; Terao, T.; Mitome, M.; Tang, C.C.; Zhi, C.Y. Boron Nitride Nanotubes and Nanosheets. ACS Nano 2010, 4, 2979–2993. [Google Scholar] [CrossRef] [PubMed]

- VahidMohammadi, A.; Rosen, J.; Gogotsi, Y. The world of two-dimensional carbides and nitrides (MXenes). Science 2021, 372, eabf1581. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.J.; Liu, C.X.; Qi, X.L.; Dai, X.; Fang, Z.; Zhang, S.C. Topological insulators in Bi2Se3, Bi2Te3 and Sb2Te3 with a single Dirac cone on the surface. Nat. Phys. 2009, 5, 438–442. [Google Scholar] [CrossRef]

- Tang, H.; Liang, D.; Qiu, R.L.J.; Gao, X.P.A. Two-Dimensional Transport--Induced Linear Magneto-Resistance in Topological Insulator Bi2Se3 Nanoribbons. ACS Nano 2011, 5, 7510–7516. [Google Scholar] [CrossRef] [Green Version]

- Osada, M.; Sasaki, T. The rise of 2D dielectrics/ferroelectrics. APL Mater. 2019, 7, 120902. [Google Scholar] [CrossRef] [Green Version]

- Alyoruk, M.M. Piezoelectric properties of monolayer II-VI group oxides by first-principles calculations. Phys. Status Solidi B-Basic Solid State Phys. 2016, 253, 2534–2539. [Google Scholar] [CrossRef]

- Nicolosi, V.; Chhowalla, M.; Kanatzidis, M.G.; Strano, M.S.; Coleman, J.N. Liquid Exfoliation of Layered Materials. Science 2013, 340, 1420. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.H.; Kalantar-Zadeh, K.; Kis, A.; Coleman, J.N.; Strano, M.S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 2012, 7, 699–712. [Google Scholar] [CrossRef]

- Yin, Z.Y.; Li, H.; Jiang, L.; Shi, Y.M.; Sun, Y.H.; Lu, G.; Zhang, Q.; Chen, X.D.; Zhang, H. Single-Layer MoS2 Phototransistors. ACS Nano 2012, 6, 74–80. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, J.X.; Yang, D.; Yin, Z.Y.; Yan, Q.Y.; Zhang, H. Graphene and Graphene-Based Materials for Energy Storage Applications. Small 2014, 10, 3480–3498. [Google Scholar] [CrossRef]

- Cao, X.H.; Tan, C.L.; Zhang, X.; Zhao, W.; Zhang, H. Solution-Processed Two-Dimensional Metal Dichalcogenide-Based Nanomaterials for Energy Storage and Conversion. Adv. Mater. 2016, 28, 6167–6196. [Google Scholar] [CrossRef] [PubMed]

- Peng, X.; Peng, L.L.; Wu, C.Z.; Xie, Y. Two dimensional nanomaterials for flexible supercapacitors. Chem. Soc. Rev. 2014, 43, 3303–3323. [Google Scholar] [CrossRef]

- Schedin, F.; Geim, A.K.; Morozov, S.V.; Hill, E.W.; Blake, P.; Katsnelson, M.I.; Novoselov, K.S. Detection of individual gas molecules adsorbed on graphene. Nat. Mater. 2007, 6, 652–655. [Google Scholar] [CrossRef] [PubMed]

- Fowler, J.D.; Allen, M.J.; Tung, V.C.; Yang, Y.; Kaner, R.B.; Weiller, B.H. Practical Chemical Sensors from Chemically Derived Graphene. ACS Nano 2009, 3, 301–306. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yavari, F.; Koratkar, N. Graphene-Based Chemical Sensors. J. Phys. Chem. Lett. 2012, 3, 1746–1753. [Google Scholar] [CrossRef]

- Wu, S.X.; Zeng, Z.Y.; He, Q.Y.; Wang, Z.J.; Wang, S.J.; Du, Y.P.; Yin, Z.Y.; Sun, X.P.; Chen, W.; Zhang, H. Electrochemically Reduced Single-Layer MoS2 Nanosheets: Characterization, Properties, and Sensing Applications. Small 2012, 8, 2264–2270. [Google Scholar] [CrossRef]

- Hu, Y.L.; Huang, Y.; Tan, C.L.; Zhang, X.; Lu, Q.P.; Sindoro, M.; Huang, X.; Huang, W.; Wang, L.H.; Zhang, H. Two-dimensional transition metal dichalcogenide nanomaterials for biosensing applications. Mater. Chem. Front. 2017, 1, 24–36. [Google Scholar] [CrossRef] [Green Version]

- Hwang, H.Y.; Iwasa, Y.; Kawasaki, M.; Keimer, B.; Nagaosa, N.; Tokura, Y. Emergent phenomena at oxide interfaces. Nat. Mater. 2012, 11, 103–113. [Google Scholar] [CrossRef]

- Ren, Y.F.; Qiao, Z.H.; Niu, Q. Topological phases in two-dimensional materials: A review. Rep. Prog. Phys. 2016, 79, 40. [Google Scholar] [CrossRef] [Green Version]

- Jia, F.; Xu, S.; Zhao, G.; Liu, C.; Ren, W. Structural and electronic properties of two-dimensional freestanding BaTiO3/SrTiO3 heterostructures. Phys. Rev. B 2020, 101, 144106. [Google Scholar] [CrossRef]

- Chen, Y.; Kee, H.Y. Topological phases in iridium oxide superlattices: Quantized anomalous charge or valley Hall insulators. Phys. Rev. B 2014, 90, 10. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.B.; Huang, H.Q.; Haule, K.; Vanderbilt, D. Quantum anomalous Hall phase in (001) double-perovskite monolayers via intersite spin-orbit coupling. Phys. Rev. B 2014, 90, 8. [Google Scholar] [CrossRef] [Green Version]

- Wicklein, S.; Sambri, A.; Amoruso, S.; Wang, X.; Bruzzese, R.; Koehl, A.; Dittmann, R. Pulsed laser ablation of complex oxides: The role of congruent ablation and preferential scattering for the film stoichiometry. Appl. Phys. Lett. 2012, 101, 5. [Google Scholar] [CrossRef] [Green Version]

- Tokura, Y.; Nagaosa, N. Orbital physics in transition-metal oxides. Science 2000, 288, 462–468. [Google Scholar] [CrossRef] [Green Version]

- Sando, D.; Barthelemy, A.; Bibes, M. BiFeO3 epitaxial thin films and devices: Past, present and future. J. Phys.-Condes. Matter 2014, 26, 23. [Google Scholar] [CrossRef]

- Hong, S.S.; Gu, M.Q.; Verma, M.; Harbola, V.; Wang, B.Y.; Lu, D.; Vailionis, A.; Hikita, Y.; Pentcheva, R.; Rondinelli, J.M.; et al. Extreme tensile strain states in La0.7Ca0.3MnO3 membranes. Science 2020, 368, 71–76. [Google Scholar] [CrossRef] [PubMed]

- Spaldin, N.A. Multiferroics: Past, present, and future. MRS Bull. 2017, 42, 385–389. [Google Scholar] [CrossRef] [Green Version]

- Spaldin, N.A.; Fiebig, M. The renaissance of magnetoelectric multiferroics. Science 2005, 309, 391–392. [Google Scholar] [CrossRef]

- Kanhere, P.; Chen, Z. A Review on Visible Light Active Perovskite-Based Photocatalysts. Molecules 2014, 19, 19995–20022. [Google Scholar] [CrossRef] [Green Version]

- Sanchez, F.; Ocal, C.; Fontcuberta, J. Tailored surfaces of perovskite oxide substrates for conducted growth of thin films. Chem. Soc. Rev. 2014, 43, 2272–2285. [Google Scholar] [CrossRef] [Green Version]

- Matsubara, S.; Miura, S.; Miyasaka, Y.; Shohata, N. Preparation of epitaxial ABO3 perovskite-type oxide thin-films on a (100)MgAl2O4/si substrate. J. Appl. Phys. 1989, 66, 5826–5832. [Google Scholar] [CrossRef]

- Shreekala, R.; Rajeswari, M.; Ghosh, K.; Goyal, A.; Gu, J.Y.; Kwon, C.; Trajanovic, Z.; Boettcher, T.; Greene, R.L.; Ramesh, R.; et al. Effect of crystallinity on the magnetoresistance in perovskite manganese oxide thin films. Appl. Phys. Lett. 1997, 71, 282–284. [Google Scholar] [CrossRef]

- Fahey, K.P.; Clemens, B.M.; Wills, L.A. Nonorthogonal twinning in thin-film oxide perovskites. Appl. Phys. Lett. 1995, 67, 2480–2482. [Google Scholar] [CrossRef]

- Goyal, A.; Rajeswari, M.; Shreekala, R.; Lofland, S.E.; Bhagat, S.M.; Boettcher, T.; Kwon, C.; Ramesh, R.; Venkatesan, T. Material characteristics of perovskite manganese oxide thin films for bolometric applications. Appl. Phys. Lett. 1997, 71, 2535–2537. [Google Scholar] [CrossRef]

- Gu, H.S.; Dong, C.; Chen, P.Z.; Bao, D.H.; Kuang, A.X.; Li, X.J. Growth of layered perovskite Bi4Ti3O12 thin films by sol-gel process. J. Cryst. Growth 1998, 186, 403–408. [Google Scholar] [CrossRef]

- Tybell, T.; Ahn, C.H.; Triscone, J.M. Ferroelectricity in thin perovskite films. Appl. Phys. Lett. 1999, 75, 856–858. [Google Scholar] [CrossRef] [Green Version]

- Junquera, J.; Ghosez, P. Critical thickness for ferroelectricity in perovskite ultrathin films. Nature 2003, 422, 506–509. [Google Scholar] [CrossRef]

- Fong, D.D.; Stephenson, G.B.; Streiffer, S.K.; Eastman, J.A.; Auciello, O.; Fuoss, P.H.; Thompson, C. Ferroelectricity in ultrathin perovskite films. Science 2004, 304, 1650–1653. [Google Scholar] [CrossRef]

- Sai, N.; Kolpak, A.M.; Rappe, A.M. Ferroelectricity in ultrathin perovskite films. Phys. Rev. B 2005, 72, 4. [Google Scholar] [CrossRef] [Green Version]

- Yu, Z.; Ramdani, J.; Curless, J.A.; Finder, J.M.; Overgaard, C.D.; Droopad, R.; Eisenbeiser, K.W.; Hallmark, J.A.; Ooms, W.J.; Conner, J.R.; et al. Epitaxial perovskite thin films grown on silicon by molecular beam epitaxy. J. Vac. Sci. Technol. B 2000, 18, 1653–1657. [Google Scholar] [CrossRef]

- Ohnishi, T.; Lippmaa, M.; Yamamoto, T.; Meguro, S.; Koinuma, H. Improved stoichiometry and misfit control in perovskite thin film formation at a critical fluence by pulsed laser deposition. Appl. Phys. Lett. 2005, 87, 3. [Google Scholar] [CrossRef]

- Xu, G.Y.; Hiraka, H.; Shirane, G.; Li, J.F.; Wang, J.L.; Viehland, D. Low symmetry phase in (001) BiFeO3 epitaxial constrained thin films. Appl. Phys. Lett. 2005, 86, 3. [Google Scholar] [CrossRef] [Green Version]

- Xu, G.Y.; Li, J.F.; Viehland, D. Ground state monoclinic (Mb) phase in (110)c BiFeO3 epitaxial thin films. Appl. Phys. Lett. 2006, 89, 3. [Google Scholar] [CrossRef] [Green Version]

- Jang, H.W.; Baek, S.H.; Ortiz, D.; Folkman, C.M.; Das, R.R.; Chu, Y.H.; Shafer, P.; Zhang, J.X.; Choudhury, S.; Vaithyanathan, V.; et al. Strain-induced polarization rotation in epitaxial (001) BiFeO3 thin films. Phys. Rev. Lett. 2008, 101, 4. [Google Scholar] [CrossRef] [Green Version]

- Yan, L.; Cao, H.; Li, J.F.; Viehland, D. Triclinic phase in tilted (001) oriented BiFeO3 epitaxial thin films. Appl. Phys. Lett. 2009, 94, 3. [Google Scholar] [CrossRef]

- Breckenfeld, E.; Wilson, R.; Karthik, J.; Damodaran, A.R.; Cahill, D.G.; Martin, L.W. Effect of Growth Induced (Non)Stoichiometry on the Structure, Dielectric Response, and Thermal Conductivity of SrTiO3 Thin Films. Chem. Mater. 2012, 24, 331–337. [Google Scholar] [CrossRef] [Green Version]

- Akbashev, A.R.; Chen, G.N.; Spanier, J.E. A Facile Route for Producing Single-Crystalline Epitaxial Perovskite Oxide Thin Films. Nano Lett. 2014, 14, 44–49. [Google Scholar] [CrossRef]

- Despont, L.; Koitzsch, C.; Clerc, F.; Garnier, M.G.; Aebi, P.; Lichtensteiger, C.; Triscone, J.M.; Garcia de Abajo, F.J.; Bousquet, E.; Ghosez, P. Direct evidence for ferroelectric polar distortion in ultrathin lead titanate perovskite films. Phys. Rev. B 2006, 73, 6. [Google Scholar] [CrossRef] [Green Version]

- Kwon, D.K.; Lee, M.H. Temperature-Stable High-Energy-Density Capacitors Using Complex Perovskite Thin Films. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 1894–1899. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.H.L.; Du, Y.G.; Papadogianni, A.; Bierwagen, O.; Sallis, S.; Piper, L.F.J.; Bowden, M.E.; Shutthanandan, V.; Sushko, P.V.; Chambers, S.A. Perovskite Sr-Doped LaCrO3 as a New p-Type Transparent Conducting Oxide. Adv. Mater. 2015, 27, 5191–5195. [Google Scholar] [CrossRef] [PubMed]

- Lu, D.; Crossley, S.; Xu, R.J.; Hikita, Y.; Hwang, H.Y. Freestanding Oxide Ferroelectric Tunnel Junction Memories Transferred onto Silicon. Nano Lett. 2019, 19, 3999–4003. [Google Scholar] [CrossRef]

- Xiao, X.B.; Liu, B.G. Freestanding perovskite oxide monolayers as two-dimensional semiconductors. Nanotechnology 2021, 32, 8. [Google Scholar] [CrossRef] [PubMed]

- Gagnidze, T.; Ma, H.; Cancellieri, C.; Bona, G.L.; La Mattina, F. Structural properties of ultrathin SrO film deposited on SrTiO3. Sci. Technol. Adv. Mater. 2019, 20, 456–463. [Google Scholar] [CrossRef] [Green Version]

- Wicklein, S. Defect Engineering of SrTiO3 Thin Films for Resistive Switching Applications. Ph.D. Thesis, Christian-Albrechts-University Kiel, Kiel, Germeny, 2013. [Google Scholar]

- Pai, Y.-Y.; Tylan-Tyler, A.; Irvin, P.; Levy, J. Physics of SrTiO3-based heterostructures and nanostructures: A review. Rep. Prog. Phys. 2018, 81, 036503. [Google Scholar] [CrossRef] [Green Version]

- van Benthem, K.; Elsasser, C.; French, R.H. Bulk electronic structure of SrTiO3: Experiment and theory. J. Appl. Phys. 2001, 90, 6156–6164. [Google Scholar] [CrossRef] [Green Version]

- Vendik, O.G.; Hollmann, E.K.; Kozyrev, A.B.; Prudan, A.M. Ferroelectric tuning of planar and bulk microwave devices. J. Supercond. 1999, 12, 325–338. [Google Scholar] [CrossRef]

- Tagantsev, A.K.; Sherman, V.O.; Astafiev, K.F.; Venkatesh, J.; Setter, N. Ferroelectric materials for microwave tunable applications. J. Electroceram. 2003, 11, 5–66. [Google Scholar] [CrossRef]

- Pertsev, N.A.; Tagantsev, A.K.; Setter, N. Phase transitions and strain-induced ferroelectricity in SrTiO3 epitaxial thin films. Phys. Rev. B 2000, 61, R825–R829. [Google Scholar] [CrossRef]

- Sarantopoulos, A.; Saha, D.; Ong, W.L.; Magen, C.; Malen, J.A.; Rivadulla, F. Reduction of thermal conductivity in ferroelectric SrTiO3 thin films. Phys. Rev. Mater. 2020, 4, 054002. [Google Scholar] [CrossRef]

- Tufte, O.N.; Chapman, P.W. Electron mobility in semiconducting strontium titanate. Phys. Rev. 1967, 155, 796. [Google Scholar] [CrossRef]

- Frederikse, H.P.; Hosler, W.R. Hall mobility in SrTiO3. Phys. Rev. 1967, 161, 822. [Google Scholar] [CrossRef]

- Takahashi, K.S.; Gabay, M.; Jaccard, D.; Shibuya, K.; Ohnishi, T.; Lippmaa, M.; Triscone, J.M. Local switching of two-dimensional superconductivity using the ferroelectric field effect. Nature 2006, 441, 195–198. [Google Scholar] [CrossRef] [PubMed]

- Shibuya, K.; Ohnishi, T.; Uozumi, T.; Sato, T.; Lippmaa, M.; Kawasaki, M.; Nakajima, K.; Chikyow, T.; Koinuma, H. Field-effect modulation of the transport properties of nondoped SrTiO3. Appl. Phys. Lett. 2006, 88, 3. [Google Scholar] [CrossRef]

- Haeni, J.H.; Irvin, P.; Chang, W.; Uecker, R.; Reiche, P.; Li, Y.L.; Choudhury, S.; Tian, W.; Hawley, M.E.; Craigo, B.; et al. Room-temperature ferroelectricity in strained SrTiO3. Nature 2004, 430, 758–761. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Verma, A.; Raghavan, S.; Stemmer, S.; Jena, D. Ferroelectric transition in compressively strained SrTiO3 thin films. Appl. Phys. Lett. 2015, 107, 5. [Google Scholar] [CrossRef] [Green Version]

- Haislmaier, R.C.; Engel-Herbert, R.; Gopalan, V. Stoichiometry as key to ferroelectricity in compressively strained SrTiO3 films. Appl. Phys. Lett. 2016, 109, 5. [Google Scholar] [CrossRef]

- Ahadi, K.; Galletti, L.; Li, Y.; Salmani-Rezaie, S.; Wu, W.; Stemmer, S. Enhancing superconductivity in SrTiO3 films with strain. Sci. Adv. 2019, 5, eaaw0120. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.B.; Shen, S.H.; Guo, L.J.; Mao, S.S. Semiconductor-based Photocatalytic Hydrogen Generation. Chem. Rev. 2010, 110, 6503–6570. [Google Scholar] [CrossRef]

- Konta, R.; Ishii, T.; Kato, H.; Kudo, A. Photocatalytic activities of noble metal ion doped SrTiO3 under visible light irradiation. J. Phys. Chem. B 2004, 108, 8992–8995. [Google Scholar] [CrossRef]

- Calzada, M.L.; Torres, M.; Fuentes-Cobas, L.E.; Mehta, A.; Ricote, J.; Pardo, L. Ferroelectric self-assembled PbTiO3 perovskite nanostructures onto (100)SrTiO3 substrates from a novel microemulsion aided sol-gel preparation method. Nanotechnology 2007, 18, 8. [Google Scholar] [CrossRef]

- Ohta, H.; Sugiura, K.; Koumoto, K. Recent progress in oxide thermoelectric materials: P-type Ca3CO4O9 and n-type SrTiO3. Inorg. Chem. 2008, 47, 8429–8436. [Google Scholar] [CrossRef]

- Su, E.C.; Huang, B.S.; Wey, M.Y. Enhanced optical and electronic properties of a solar light-responsive photocatalyst for efficient hydrogen evolution by SrTiO3/TiO2 nanotube combination. Sol. Energy 2016, 134, 52–63. [Google Scholar] [CrossRef]

- Townsend, T.K.; Browning, N.D.; Osterloh, F.E. Nanoscale Strontium Titanate Photocatalysts for Overall Water Splitting. ACS Nano 2012, 6, 7420–7426. [Google Scholar] [CrossRef]

- Ricinschi, D.; Yun, K.Y.; Okuyama, M. A mechanism for the 150 μC cm−2 polarization of BiFeO3 films based on first-principles calculations and new structural data. J. Phys.-Condes. Matter 2006, 18, L97–L105. [Google Scholar] [CrossRef] [PubMed]

- Bea, H.; Dupe, B.; Fusil, S.; Mattana, R.; Jacquet, E.; Warot-Fonrose, B.; Wilhelm, F.; Rogalev, A.; Petit, S.; Cros, V.; et al. Evidence for Room-Temperature Multiferroicity in a Compound with a Giant Axial Ratio. Phys. Rev. Lett. 2009, 102, 5. [Google Scholar] [CrossRef]

- Zeches, R.J.; Rossell, M.D.; Zhang, J.X.; Hatt, A.J.; He, Q.; Yang, C.H.; Kumar, A.; Wang, C.H.; Melville, A.; Adamo, C.; et al. A Strain-Driven Morphotropic Phase Boundary in BiFeO3. Science 2009, 326, 977–980. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Z.H.; You, L.; Huang, C.W.; Qi, Y.J.; Wang, J.L.; Sritharan, T.; Chen, L. Nanoscale domains in strained epitaxial BiFeO3 thin Films on LaSrAlO4 substrate. Appl. Phys. Lett. 2010, 96, 3. [Google Scholar] [CrossRef] [Green Version]

- Mazumdar, D.; Shelke, V.; Iliev, M.; Jesse, S.; Kumar, A.; Kalinin, S.V.; Baddorf, A.P.; Gupta, A. Nanoscale Switching Characteristics of Nearly Tetragonal BiFeO3 Thin Films. Nano Lett. 2010, 10, 2555–2561. [Google Scholar] [CrossRef] [Green Version]

- Christen, H.M.; Nam, J.H.; Kim, H.S.; Hatt, A.J.; Spaldin, N.A. Stress-induced R-M-A-M-C-T symmetry changes in BiFeO3 films. Phys. Rev. B 2011, 83, 7. [Google Scholar] [CrossRef] [Green Version]

- Qi, X.D.; Wei, M.; Lin, Y.; Jia, Q.X.; Zhi, D.; Dho, J.; Blamire, M.G.; MacManus-Driscoll, J.L. High-resolution x-ray diffraction and transmission electron microscopy of multiferroic BiFeO3 films. Appl. Phys. Lett. 2005, 86, 3. [Google Scholar] [CrossRef]

- Bea, H.; Bibes, M.; Zhu, X.H.; Fusil, S.; Bouzehouane, K.; Petit, S.; Kreisel, J.; Barthelemy, A. Crystallographic, magnetic, and ferroelectric structures of bulklike BiFeO3 thin films. Appl. Phys. Lett. 2008, 93, 3. [Google Scholar] [CrossRef]

- Ryu, S.; Kim, J.Y.; Shin, Y.H.; Park, B.G.; Son, J.Y.; Jang, H.M. Enhanced Magnetization and Modulated Orbital Hybridization in Epitaxially Constrained BiFeO3 Thin Films with Rhombohedral Symmetry. Chem. Mater. 2009, 21, 5050–5057. [Google Scholar] [CrossRef]

- Yang, J.C.; He, Q.; Suresha, S.J.; Kuo, C.Y.; Peng, C.Y.; Haislmaier, R.C.; Motyka, M.A.; Sheng, G.; Adamo, C.; Lin, H.J.; et al. Orthorhombic BiFeO3. Phys. Rev. Lett. 2012, 109, 5. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.H.; Chu, K.; Unal, A.A.; Valencia, S.; Kronast, F.; Kowarik, S.; Seidel, J.; Yang, C.H. Phase separation and electrical switching between two isosymmetric multiferroic phases in tensile strained BiFeO3 thin films. Phys. Rev. B 2014, 89, 6. [Google Scholar] [CrossRef] [Green Version]

- Toupet, H.; Le Marrec, F.; Lichtensteiger, C.; Dkhil, B.; Karkut, M.G. Evidence for a first-order transition from monoclinic alpha to monoclinic beta phase in BiFeO3 thin films. Phys. Rev. B 2010, 81, 4. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.J.; Yao, K.; Yang, P.; Du, Y.H.; He, Q.; Gu, Y.L.; Li, X.L.; Wang, S.S.; Zhou, X.T.; Wang, J. Thickness-dependent twinning evolution and ferroelectric behavior of epitaxial BiFeO3 (001) thin films. Phys. Rev. B 2010, 82, 6. [Google Scholar]

- Chen, Y.Z.; Bovet, N.; Trier, F.; Christensen, D.V.; Qu, F.M.; Andersen, N.H.; Kasama, T.; Zhang, W.; Giraud, R.; Dufouleur, J.; et al. A high-mobility two-dimensional electron gas at the spinel/perovskite interface of gamma-Al2O3/SrTiO3. Nat. Commun. 2013, 4, 6. [Google Scholar] [CrossRef] [PubMed]

- Allibe, J.; Bougot-Robin, K.; Jacquet, E.; Infante, I.C.; Fusil, S.; Carretero, C.; Reverchon, J.L.; Marcilhac, B.; Crete, D.; Mage, J.C.; et al. Optical properties of integrated multiferroic BiFeO3 thin films for microwave applications. Appl. Phys. Lett. 2010, 96, 3. [Google Scholar] [CrossRef]

- Kumar, A.; Rai, R.C.; Podraza, N.J.; Denev, S.; Ramirez, M.; Chu, Y.H.; Martin, L.W.; Ihlefeld, J.; Heeg, T.; Schubert, J.; et al. Linear and nonlinear optical properties of BiFeO3. Appl. Phys. Lett. 2008, 92, 3. [Google Scholar] [CrossRef] [Green Version]

- Ihlefeld, J.F.; Podraza, N.J.; Liu, Z.K.; Rai, R.C.; Xu, X.; Heeg, T.; Chen, Y.B.; Li, J.; Collins, R.W.; Musfeldt, J.L.; et al. Optical band gap of BiFeO3 grown by molecular-beam epitaxy. Appl. Phys. Lett. 2008, 92, 3. [Google Scholar] [CrossRef] [Green Version]

- Hauser, A.J.; Zhang, J.; Mier, L.; Ricciardo, R.A.; Woodward, P.M.; Gustafson, T.L.; Brillson, L.J.; Yang, F.Y. Characterization of electronic structure and defect states of thin epitaxial BiFeO3 films by UV-visible absorption and cathodoluminescence spectroscopies. Appl. Phys. Lett. 2008, 92, 3. [Google Scholar] [CrossRef]

- Zelezny, V.; Chvostova, D.; Pajasova, L.; Vrejoiu, I.; Alexe, M. Optical properties of epitaxial BiFeO3 thin films. Appl. Phys. A-Mater. Sci. Process. 2010, 100, 1217–1220. [Google Scholar] [CrossRef]

- Pan, H.; Zeng, Y.; Shen, Y.; Lin, Y.-H.; Ma, J.; Li, L.; Nan, C.-W. BiFeO3–SrTiO3 thin film as a new lead-free relaxor-ferroelectric capacitor with ultrahigh energy storage performance. J. Mater. Chem. A 2017, 5, 5920–5926. [Google Scholar] [CrossRef]

- Tokura, Y.; Kawasaki, M.; Nagaosa, N. Emergent functions of quantum materials. Nat. Phys. 2017, 13, 1056–1068. [Google Scholar] [CrossRef]

- Spaldin, N.A.; Cheong, S.W.; Ramesh, R. Multiferroics: Past, present, and future. Phys. Today 2010, 63, 38–43. [Google Scholar] [CrossRef] [Green Version]

- Yamada, S.; Abe, N.; Sagayama, H.; Ogawa, K.; Yamagami, T.; Arima, T. Room-Temperature Low-Field Colossal Magnetoresistance in Double-Perovskite Manganite. Phys. Rev. Lett. 2019, 123, 6. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.F.; Tang, J.W.; Ye, J.H. Photoluminescence and photocatalytic properties of SrSnO3 perovskite. Chem. Phys. Lett. 2006, 418, 174–178. [Google Scholar] [CrossRef]

- Lin, W.H.; Cheng, C.; Hu, C.C.; Teng, H.S. NaTaO3 photocatalysts of different crystalline structures for water splitting into H2 and O2. Appl. Phys. Lett. 2006, 89, 3. [Google Scholar] [CrossRef]

- Baek, S.H.; Folkman, C.M.; Park, J.W.; Lee, S.H.; Bark, C.W.; Tybell, T.; Eom, C.B. The Nature of Polarization Fatigue in BiFeO3. Adv. Mater. 2011, 23, 1621–1625. [Google Scholar] [CrossRef] [Green Version]

- Jung, C.U.; Yamada, H.; Kawasaki, M.; Tokura, Y. Magnetic anisotropy control of SrRuO3 films by tunable epitaxial strain. Appl. Phys. Lett. 2004, 84, 2590–2592. [Google Scholar] [CrossRef]

- Liu, L.; Qin, Q.; Lin, W.N.; Li, C.J.; Xie, Q.D.; He, S.K.; Shu, X.Y.; Zhou, C.H.; Lim, Z.; Yu, J.H.; et al. Current-induced magnetization switching in all-oxide heterostructures. Nat. Nanotechnol. 2019, 14, 939–944. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Liu, Z.R.; Yoong, H.Y.; Paudel, T.R.; Xiao, J.X.; Guo, R.; Lin, W.N.; Yang, P.; Wang, J.; Chow, G.M.; et al. Direct observation of room-temperature out-of-plane ferroelectricity and tunneling electroresistance at the two-dimensional limit. Nat. Commun. 2018, 9, 8. [Google Scholar] [CrossRef] [PubMed]

- Kitaeva, V.F.; Zharikov, E.V.; Chistyi, I.L. The Properties of Crystals with Garnet Structure. Phys. Status Solidi A-Appl. Res. 1985, 92, 475–488. [Google Scholar] [CrossRef]

- Dillon, J.F. Optical properties of several ferrimagnetic garnets. J. Appl. Phys. 1958, 29, 539–541. [Google Scholar] [CrossRef]

- Mee, J. Chemical vapor deposition of epitaxial garnet films. IEEE Trans. Magn. 1967, 3, 190–194. [Google Scholar] [CrossRef]

- Krumme, J.P.; Bartels, G.; Espinosa, G.P.; Haberkamp, J.; Tolksdorf, W.; Verweel, J. Thermomagnetic recording in thin garnet layers. Appl. Phys. Lett. 1972, 20, 451–453. [Google Scholar] [CrossRef]

- Wemple, S.H.; Blank, S.L.; Seman, J.A.; Biolsi, W.A. Optical-properties of epitaxial iron-garnet thin-films. Phys. Rev. B 1974, 9, 2134–2144. [Google Scholar] [CrossRef]

- Hansen, P.; Krumme, J.P. Magnetic and Magneto-Optical Properties of Garnet-Films. Thin Solid Film. 1984, 114, 69–107. [Google Scholar] [CrossRef]

- Mitra, A.; Cespedes, O.; Ramasse, Q.; Ali, M.; Marmion, S.; Ward, M.; Brydson, R.M.D.; Kinane, C.J.; Cooper, J.F.K.; Langridge, S.; et al. Interfacial Origin of the Magnetisation Suppression of Thin Film Yttrium Iron Garnet. Sci. Rep. 2017, 7, 8. [Google Scholar] [CrossRef] [PubMed]

- Hill, B.; Schmidt, K.P. Fast switchable magneto-optic memory-display components. Philips J. Res. 1978, 33, 211–225. [Google Scholar]

- Scott, G.B.; Lacklison, D.E. Magneto-optic properties and applications of bismuth substituted iron garnets. IEEE Trans. Magn. 1976, 12, 292–311. [Google Scholar] [CrossRef]

- Lacklison, D.; Scott, G.; Giles, A.; Clarke, J.; Pearson, R.; Page, J. The magnetooptic bubble display. IEEE Trans. Magn. 1977, 13, 973–981. [Google Scholar] [CrossRef]

- Shirasaki, M.; Nakajima, H.; Obokata, T.; Asama, K. Nonmechanical optical switch for single-mode fibers. Appl. Opt. 1982, 21, 4229–4234. [Google Scholar] [CrossRef]

- Ma, R.; Liu, M.; Wang, J.N.; Wang, H. The room temperature deposition of high-quality epitaxial yttrium iron garnet thin film via RF sputtering. J. Alloys Compd. 2017, 708, 213–219. [Google Scholar] [CrossRef]

- Levy, M.; Osgood, R.M.; Kumar, A.; Bakhru, H. Epitaxial liftoff of thin oxide layers: Yttrium iron garnets onto GaAs. Appl. Phys. Lett. 1997, 71, 2617–2619. [Google Scholar] [CrossRef]

- Popova, E.; Keller, N.; Gendron, F.; Guyot, M.; Brianso, M.C.; Dumond, Y.; Tessier, M. Structure and magnetic properties of yttrium-iron-garnet thin films prepared by laser deposition. J. Appl. Phys. 2001, 90, 1422–1428. [Google Scholar] [CrossRef]

- Lin, N.X.; Lin, Y.Z.; Wu, G.J.; Chen, X.; Zhang, Z.Z.; Hu, X.L.; Zhuang, N.F. Growth of high quality Si-based (Gd2Ce)(Fe4Ga)O12 thin film and prospects as a magnetic recording media. J. Alloys Compd. 2021, 875, 7. [Google Scholar] [CrossRef]

- Zanjani, S.M.; Onbasli, M.C. Predicting new iron garnet thin films with perpendicular magnetic anisotropy. J. Magn. Magn. Mater. 2020, 499, 10. [Google Scholar] [CrossRef] [PubMed]

- Gurjar, G.; Sharma, V.; Patnaik, S.; Kuanr, B.K. Control of magnetization dynamics by substrate orientation in YIG thin films. Mater. Res. Express 2021, 8, 10. [Google Scholar] [CrossRef]

- Kotov, V.A.; Nur-E-Alam, M.; Vasiliev, M.; Alameh, K.; Balabanov, D.E.; Burkov, V.I. Enhanced Magneto-Optic Properties in Sputtered Bi- Containing Ferrite Garnet Thin Films Fabricated Using Oxygen Plasma Treatment and Metal Oxide Protective Layers. Materials 2020, 13, 5113. [Google Scholar] [CrossRef]

- Yang, Y.C.; Liu, T.; Bi, L.; Deng, L.J. Recent advances in development of magnetic garnet thin films for applications in spintronics and photonics. J. Alloys Compd. 2021, 860, 33. [Google Scholar] [CrossRef]

- Vasiliev, M.; Nur-E-Alam, M.; Kotov, V.A.; Alameh, K.; Belotelov, V.I.; Burkov, V.I.; Zvezdin, A.K. RF magnetron sputtered (BiDy)3(FeGa)5O12:Bi2O3 composite garnet-oxide materials possessing record magneto-optic quality in the visible spectral region. Opt. Express 2009, 17, 19519–19535. [Google Scholar] [CrossRef] [Green Version]

- Goossens, V.; Wielant, J.; Van Gils, S.; Finsy, R.; Terryn, H. Optical properties of thin iron oxide films on steel. Surf. Interface Anal. 2006, 38, 489–493. [Google Scholar] [CrossRef]

- vanderZaag, P.J.; Fontijn, W.F.J.; Gaspard, P.; Wolf, R.M.; Brabers, V.A.M.; vandeVeerdonk, R.J.M.; vanderHeijden, P.A.A. A study of the magneto-optical Kerr spectra of bulk and ultrathin Fe3O4. J. Appl. Phys. 1996, 79, 5936–5938. [Google Scholar] [CrossRef] [Green Version]

- Verwey, E.J.W.; Heilmann, E.L. Physical properties and cation arrangement of oxides with spinel structures 1. Cation arrangement in spinels. J. Chem. Phys. 1947, 15, 174–180. [Google Scholar] [CrossRef]

- Dalawai, S.P.; Kumar, S.; Aly, M.A.S.; Khan, M.Z.H.; Xing, R.M.; Vasambekar, P.N.; Liu, S.H. A review of spinel-type of ferrite thick film technology: Fabrication and application. J. Mater. Sci.-Mater. Electron. 2019, 30, 7752–7779. [Google Scholar] [CrossRef]

- Walsh, A.; Wei, S.H.; Yan, Y.; Al-Jassim, M.M.; Turner, J.A. Structural, magnetic, and electronic properties of the Co-Fe-Al oxide spinel system: Density-functional theory calculations. Phys. Rev. B 2007, 76, 9. [Google Scholar] [CrossRef]

- Miikkulainen, V.; Ruud, A.; Ostreng, E.; Nilsen, O.; Laitinen, M.; Sajavaara, T.; Fjellvag, H. Atomic Layer Deposition of Spinel Lithium Manganese Oxide by Film-Body-Controlled Lithium Incorporation for Thin-Film Lithium-Ion Batteries. J. Phys. Chem. C 2014, 118, 1258–1268. [Google Scholar] [CrossRef]

- Bonhardt, S.; Kuhnel, K.; Kia, A.M.; Weinreich, W. Formation of highly conformal spinel lithium titanate thin films based on a novel three-step atomic layer deposition process. J. Vac. Sci. Technol. A 2019, 37, 6. [Google Scholar] [CrossRef]

- Hagen, D.J.; Tripathi, T.S.; Karppinen, M. Atomic layer deposition of nickel-cobalt spinel thin films. Dalton Trans. 2017, 46, 4796–4805. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Silwal, P.; Miao, L.; Stern, I.; Zhou, X.L.; Hu, J.; Kim, D.H. Metal insulator transition with ferrimagnetic order in epitaxial thin films of spinel NiCo2O4. Appl. Phys. Lett. 2012, 100, 3. [Google Scholar] [CrossRef]

- Suzuki, Y.; vanDover, R.B.; Gyorgy, E.M.; Phillips, J.M.; Korenivski, V.; Werder, D.J.; Chen, C.H.; Cava, R.J.; Krajewski, J.J.; Peck, W.F.; et al. Structure and magnetic properties of epitaxial spinel ferrite thin films. Appl. Phys. Lett. 1996, 68, 714–716. [Google Scholar] [CrossRef]

- Uhrecky, R.; Bursik, J.; Soroka, M.; Kuzel, R.; Prokleska, J. Use of magnetoplumbite and spinel ferrite seed layers for the growth of oriented Y ferrite thin films. Thin Solid Films 2017, 622, 104–110. [Google Scholar] [CrossRef]

- Luders, U.; Bibes, M.; Bobo, J.F.; Cantoni, M.; Bertacco, R.; Fontcuberta, J. Enhanced magnetic moment and conductive behavior in NiFe2O4 spinel ultrathin films. Phys. Rev. B 2005, 71, 7. [Google Scholar] [CrossRef] [Green Version]

- Coll, M.; Moreno, J.M.M.; Gazquez, J.; Nielsch, K.; Obradors, X.; Puig, T. Low Temperature Stabilization of Nanoscale Epitaxial Spinel Ferrite Thin Films by Atomic Layer Deposition. Adv. Funct. Mater. 2014, 24, 5368–5374. [Google Scholar] [CrossRef]

- Thorat, L.M.; Patil, J.Y.; Nadargi, D.Y.; Ghodake, U.R.; Kambale, R.C.; Suryavanshi, S.S. Ni2+-substituted Mg-Cu-Zn ferrites: A colloidal approach of tuning structural and electromagnetic properties. J. Sol-Gel Sci. Technol. 2018, 86, 731–742. [Google Scholar] [CrossRef]

- Kabbur, S.M.; Ghodake, U.R.; Nadargi, D.Y.; Kambale, R.C.; Suryavanshi, S.S. Effect of Dy3+ substitution on structural and magnetic properties of nanocrystalline Ni-Cu-Zn ferrites. J. Magn. Magn. Mater. 2018, 451, 665–675. [Google Scholar] [CrossRef]

- Valenzuela, R. Novel Applications of Ferrites. Phys. Res. Int. 2012, 2012, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Novoselov, K.S.; Jiang, D.; Schedin, F.; Booth, T.J.; Khotkevich, V.V.; Morozov, S.V.; Geim, A.K. Two-dimensional atomic crystals. Proc. Natl. Acad. Sci. USA 2005, 102, 10451–10453. [Google Scholar] [CrossRef] [Green Version]

- Yi, M.; Shen, Z.G. A review on mechanical exfoliation for the scalable production of graphene. J. Mater. Chem. A 2015, 3, 11700–11715. [Google Scholar] [CrossRef]

- Li, H.; Wu, J.M.T.; Yin, Z.Y.; Zhang, H. Preparation and Applications of Mechanically Exfoliated Single-Layer and Multi layer MoS2 and WSe2 Nanosheets. Acc. Chem. Res. 2014, 47, 1067–1075. [Google Scholar] [CrossRef] [PubMed]

- Arthur, J.R. Molecular beam epitaxy. Surf. Sci. 2002, 500, 189–217. [Google Scholar] [CrossRef]

- Freund, L.B.; Suresh, S. Thin Film Materials: Stress, Defect Formation, and Surface Evolution; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Christen, H.M.; Eres, G. Recent advances in pulsed-laser deposition of complex oxides. J. Phys. Condens. Matter 2008, 20, 264005. [Google Scholar] [CrossRef] [Green Version]

- Koster, G.; Kropman, B.L.; Rijnders, G.; Blank, D.H.A.; Rogalla, H. Quasi-ideal strontium titanate crystal surfaces through formation of strontium hydroxide. Appl. Phys. Lett. 1998, 73, 2920–2922. [Google Scholar] [CrossRef] [Green Version]

- Rijnders, G.; Koster, G.; Leca, V.; Blank, D.H.A.; Rogalla, H. Imposed layer-by-layer growth with pulsed laser interval deposition. Appl. Surf. Sci. 2000, 168, 223–226. [Google Scholar] [CrossRef]

- Tersoff, J.; Vandergon, A.W.D.; Tromp, R.M. Critical island size for layer-by-layer growth. Phys. Rev. Lett. 1994, 72, 266–269. [Google Scholar] [CrossRef]

- Willmott, P.R.; Huber, J.R. Pulsed laser vaporization and deposition. Rev. Mod. Phys. 2000, 72, 315–328. [Google Scholar] [CrossRef]

- Liao, Z.L.; Brahlek, M.; Ok, J.M.; Nuckols, L.; Sharma, Y.; Lu, Q.Y.; Zhang, Y.W.; Lee, H.N. Pulsed-laser epitaxy of topological insulator Bi2Te3 thin films. APL Mater. 2019, 7, 041101. [Google Scholar] [CrossRef] [Green Version]

- Schneider, C.W.; Esposito, M.; Marozau, I.; Conder, K.; Doebeli, M.; Hu, Y.; Mallepell, M.; Wokaun, A.; Lippert, T. The origin of oxygen in oxide thin films: Role of the substrate. Appl. Phys. Lett. 2010, 97, 3. [Google Scholar] [CrossRef]

- Su, D.; Yamada, T.; Gysel, R.; Tagantsev, A.K.; Muralt, P.; Setter, N.; Jiang, N. Growth-mode induced defects in epitaxial SrTiO3 thin films grown on single crystal LaAlO3 by a two-step PLD process. J. Mater. Res. 2011, 26, 770–774. [Google Scholar] [CrossRef] [Green Version]

- Rijnders, G.; Koster, G.; Blank, D.H.A.; Rogalla, H. In-situ growth monitoring during PLD of oxides using RHEED at high oxygen pressure. Mater. Sci. Eng. B-Solid State Mater. Adv. Technol. 1998, 56, 223–227. [Google Scholar] [CrossRef]

- Ohnishi, T.; Shibuya, K.; Yamamoto, T.; Lippmaa, M. Defects and transport in complex oxide thin films. J. Appl. Phys. 2008, 103, 6. [Google Scholar] [CrossRef]

- He, L.; Kou, X.F.; Wang, K.L. Review of 3D topological insulator thin-film growth by molecular beam epitaxy and potential applications. Phys. Status Solidi-Rapid Res. Lett. 2013, 7, 50–63. [Google Scholar] [CrossRef]

- Brooks, C.M.; Kourkoutis, L.F.; Heeg, T.; Schubert, J.; Muller, D.A.; Schlom, D.G. Growth of homoepitaxial SrTiO3 thin films by molecular-beam epitaxy. Appl. Phys. Lett. 2009, 94, 3. [Google Scholar] [CrossRef] [Green Version]

- Yang, G.Z.; Lu, H.B.; Chen, F.; Zhao, T.; Chen, Z.H. Laser molecular beam epitaxy and characterization of perovskite oxide thin films. J. Cryst. Growth 2001, 227, 929–935. [Google Scholar] [CrossRef]

- Leskelä, M.; Ritala, M. Atomic Layer Deposition Chemistry: Recent Developments and Future Challenges. Angew. Chem. Int. Ed. 2003, 42, 5548–5554. [Google Scholar] [CrossRef]

- George, S.M. Atomic Layer Deposition: An Overview. Chem. Rev. 2010, 110, 111–131. [Google Scholar] [CrossRef]

- Leskela, M.; Ritala, M. Atomic layer deposition (ALD): From precursors to thin film structures. Thin Solid Films 2002, 409, 138–146. [Google Scholar] [CrossRef]

- Paivasaari, J.; Niinisto, J.; Myllymaki, P.; Dezelah, C.; Winter, C.H.; Putkonen, M.; Nieminen, M.; Niinisto, L. Atomic layer deposition of rare earth oxides. Top. Appl. Phys. 2007, 106, 15–32. [Google Scholar]

- Johnson, R.W.; Hultqvist, A.; Bent, S.F. A brief review of atomic layer deposition: From fundamentals to applications. Mater. Today 2014, 17, 236–246. [Google Scholar] [CrossRef]

- Parsons, G.N.; George, S.M.; Knez, M. Progress and future directions for atomic layer deposition and ALD-based chemistry. MRS Bull. 2011, 36, 865–871. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.W.; Dong, L.; Zhang, J.Y.; Liu, Y.Q.; Ye, P.D.D.; Gordon, R.G. Heteroepitaxy of La2O3 and La2-xYxO3 on GaAs (111)A by Atomic Layer Deposition: Achieving Low Interface Trap Density. Nano Lett. 2013, 13, 594–599. [Google Scholar] [CrossRef] [Green Version]

- Miikkulainen, V.; Leskela, M.; Ritala, M.; Puurunen, R.L. Crystallinity of inorganic films grown by atomic layer deposition: Overview and general trends. J. Appl. Phys. 2013, 113, 101. [Google Scholar] [CrossRef]

- Zardetto, V.; Williams, B.L.; Perrotta, A.; Di Giacomo, F.; Verheijen, M.A.; Andriessen, R.; Kessels, W.M.M.; Creatore, M. Atomic layer deposition for perovskite solar cells: Research status, opportunities and challenges. Sustain. Energ. Fuels 2017, 1, 30–55. [Google Scholar] [CrossRef]

- Ngo, T.Q.; Posadas, A.; McDaniel, M.D.; Ferrer, D.A.; Bruley, J.; Breslin, C.; Demkov, A.A.; Ekerdt, J.G. Epitaxial growth of LaAlO3 on SrTiO3-buffered Si (001) substrates by atomic layer deposition. J. Cryst. Growth 2013, 363, 150–157. [Google Scholar] [CrossRef]

- Uusi-Esko, K.; Karppinen, M. Extensive Series of Hexagonal and Orthorhombic RMnO3 (R = Y, La, Sm, Tb, Yb, Lu) Thin Films by Atomic Layer Deposition. Chem. Mater. 2011, 23, 1835–1840. [Google Scholar] [CrossRef]

- Kong, W.; Li, H.S.; Qiao, K.; Kim, Y.; Lee, K.; Nie, Y.F.; Lee, D.; Osadchy, T.; Molnar, R.J.; Gaskill, D.K.; et al. Polarity governs atomic interaction through two-dimensional materials. Nat. Mater. 2018, 17, 999–1004. [Google Scholar] [CrossRef]

- Chen, Z.Y.; Wang, B.Y.; Goodge, B.H.; Lu, D.; Hong, S.S.; Li, D.F.; Kourkoutis, L.F.; Hikita, Y.; Hwang, H.Y. Freestanding crystalline YBa2Cu3O7-x heterostructure membranes. Phys. Rev. Mater. 2019, 3, 6. [Google Scholar] [CrossRef]

- Dong, G.H.; Li, S.Z.; Yao, M.T.; Zhou, Z.Y.; Zhang, Y.Q.; Han, X.; Luo, Z.L.; Yao, J.X.; Peng, B.; Hu, Z.Q.; et al. Super-elastic ferroelectric single-crystal membrane with continuous electric dipole rotation. Science 2019, 366, 475–479. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, X.; Xu, X.; Hong, X. Abrupt enhancement of spin-orbit scattering time in ultrathin semimetallic SrIrO3 close to the metal-insulator transition. APL Mater. 2020, 8, 051108. [Google Scholar] [CrossRef]

- Li, D.; Zhao, H.P.; Li, L.H.; Mao, B.D.; Chen, M.; Shen, H.; Shi, W.D.; Jiang, D.L.; Lei, Y. Graphene-Sensitized Perovskite Oxide Monolayer Nanosheets for Efficient Photocatalytic Reaction. Adv. Funct. Mater. 2018, 28, 9. [Google Scholar] [CrossRef]

- Yao, J.; Ye, M.; Sun, Y.; Yuan, Y.; Fan, H.; Zhang, Y.; Chen, C.; Liu, C.; Qu, K.; Zhong, G.; et al. Atomic-Scale insight into the reversibility of polar order in ultrathin epitaxial Nb:SrTiO3/BaTiO3 heterostructure and its implication to resistive switching. Acta Mater. 2020, 188, 23–29. [Google Scholar] [CrossRef]

- Ko, H.; Takei, K.; Kapadia, R.; Chuang, S.; Fang, H.; Leu, P.W.; Ganapathi, K.; Plis, E.; Kim, H.S.; Chen, S.Y.; et al. Ultrathin compound semiconductor on insulator layers for high-performance nanoscale transistors. Nature 2010, 468, 286–289. [Google Scholar] [CrossRef] [Green Version]

- Nomura, K.; Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef] [PubMed]

- Brewer, A.; Cho, K.H.; Saenrang, W.; Baek, S.H.; Frederick, J.C.; Eom, C.B. Uniform sputter deposition of high-quality epitaxial complex oxide thin films. J. Vac. Sci. Technol. A 2017, 35, 6. [Google Scholar] [CrossRef]

- Moran, O.; Hott, R.; Schneider, R.; Halbritter, J. Transport properties of ultrathin SrTiO3 barriers for high-temperature superconductor electronics applications. J. Appl. Phys. 2003, 94, 6717–6723. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Mishchenko, A.; Carvalho, A.; Neto, A.H.C. 2D materials and van der Waals heterostructures. Science 2016, 353, 7. [Google Scholar] [CrossRef] [Green Version]

- Pauli, S.A.; Willmott, P.R. Conducting interfaces between polar and non-polar insulating perovskites. J. Phys.-Condes. Matter 2008, 20, 9. [Google Scholar] [CrossRef]

- Huijben, M.; Brinkman, A.; Koster, G.; Rijnders, G.; Hilgenkamp, H.; Blank, D.H.A. Structure-Property Relation of SrTiO3/LaAlO3 Interfaces. Adv. Mater. 2009, 21, 1665–1677. [Google Scholar] [CrossRef] [Green Version]

- Pentcheva, R.; Pickett, A.E. Electronic phenomena at complex oxide interfaces: Insights from first principles. J. Phys.-Condes. Matter 2010, 22, 14. [Google Scholar] [CrossRef]

- Chen, H.H.; Kolpak, A.M.; Ismail-Beigi, S. Electronic and Magnetic Properties of SrTiO3/LaAlO3 Interfaces from First Principles. Adv. Mater. 2010, 22, 2881–2899. [Google Scholar] [CrossRef]

- Zubko, P.; Gariglio, S.; Gabay, M.; Ghosez, P.; Triscone, J.M. Interface Physics in Complex Oxide Heterostructures. In Annual Review of Condensed Matter Physics; Langer, J.S., Ed.; Annual Reviews: Palo Alto, CA, USA, 2011; Volume 2, pp. 141–165. [Google Scholar]

- Pentcheva, R.; Arras, R.; Otte, K.; Ruiz, V.G.; Pickett, W.E. Termination control of electronic phases in oxide thin films and interfaces: LaAlO3/SrTiO3(001). Philos. Trans. R. Soc. A-Math. Phys. Eng. Sci. 2012, 370, 4904–4926. [Google Scholar] [CrossRef] [Green Version]

- Li, D.F.; Gariglio, S.; Cancellieri, C.; Fete, A.; Stornaiuolo, D.; Triscone, J.M. Fabricating superconducting interfaces between artificially grown LaAlO3 and SrTiO3 thin films. APL Mater. 2014, 2, 8. [Google Scholar] [CrossRef]

- Kornblum, L. Conductive Oxide Interfaces for Field Effect Devices. Adv. Mater. Interfaces 2019, 6, 22. [Google Scholar] [CrossRef]

- Lee, H.; Campbell, N.; Lee, J.; Asel, T.J.; Paudel, T.R.; Zhou, H.; Lee, J.W.; Noesges, B.; Seo, J.; Park, B.; et al. Direct observation of a two-dimensional hole gas at oxide interfaces. Nat. Mater. 2018, 17, 231–236. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.K.; Wu, T.C.; Chen, M.C.; Song, M.Y.; Lee, W.L.; Su, C.P.; Chu, M.W. Influence of SrTiO3 capping layer on the charge transport at the interfaces of SrTiO3/LaAlO3/SrTiO3 (100) heterostructure. Phys. Rev. Mater. 2018, 2, 9. [Google Scholar] [CrossRef]

- Caviglia, A.D.; Gariglio, S.; Reyren, N.; Jaccard, D.; Schneider, T.; Gabay, M.; Thiel, S.; Hammerl, G.; Mannhart, J.; Triscone, J.M. Electric field control of the LaAlO3/SrTiO3 interface ground state. Nature 2008, 456, 624–627. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ohtomo, A.; Hwang, H.Y. A high-mobility electron gas at the LaAlO3/SrTiO3 heterointerface. Nature 2006, 441, 120. [Google Scholar] [CrossRef] [Green Version]

- Thiel, S.; Hammerl, G.; Schmehl, A.; Schneider, C.W.; Mannhart, J. Tunable quasi-two-dimensional electron gases in oxide heterostructures. Science 2006, 313, 1942–1945. [Google Scholar] [CrossRef]

- Ben Shalom, M.; Sachs, M.; Rakhmilevitch, D.; Palevski, A.; Dagan, Y. Tuning Spin-Orbit Coupling and Superconductivity at the SrTiO3/LaAlO3 Interface: A Magnetotransport Study. Phys. Rev. Lett. 2010, 104, 4. [Google Scholar] [CrossRef] [Green Version]

- Dikin, D.A.; Mehta, M.; Bark, C.W.; Folkman, C.M.; Eom, C.B.; Chandrasekhar, V. Coexistence of Superconductivity and Ferromagnetism in Two Dimensions. Phys. Rev. Lett. 2011, 107, 4. [Google Scholar] [CrossRef] [Green Version]

- Zou, K.; Ismail-Beigi, S.; Kisslinger, K.; Shen, X.; Su, D.; Walker, F.J.; Ahn, C.H. LaTiO3/KTaO3 interfaces: A new two-dimensional electron gas system. APL Mater. 2015, 3, 7. [Google Scholar] [CrossRef] [Green Version]

- Song, Q.; Peng, R.; Xu, H.C.; Feng, D.L. The spatial distribution of two dimensional electron gas at the LaTiO3/KTaO3 interface. J. Phys.-Condes. Matter 2017, 29, 5. [Google Scholar] [CrossRef] [PubMed]

- Thompson, J.R.; Boatner, L.A.; Thomson, J.O. Very Low-Temperature Search for Superconductivity in Semiconducting KTaO3. J. Low Temp. Phys. 1982, 47, 467–475. [Google Scholar] [CrossRef]

- Wemple, S.H. Some Transport Properties of Oxygen-Deficient Single-Crystal Potassium Tantalate (KTaO3). Phys. Rev. 1965, 137, A1575. [Google Scholar] [CrossRef]

- Grabowska, E. Selected perovskite oxides: Characterization, preparation and photocatalytic properties-A review. Appl. Catal. B-Environ. 2016, 186, 97–126. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, Z.R.; Sun, Y.Q.; Chen, X.X.; Liu, Y.; Zhang, H.; Li, H.K.; Zhang, M.; Hong, S.Y.; Ren, T.S.; et al. Two-Dimensional Superconductivity at the LaAlO3/KTaO3(110) Heterointerface. Phys. Rev. Lett. 2021, 126, 6. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.L.; Shen, S.C.; You, J.; Li, H.O.; Luo, Z.Z.; Li, C.J.; Qu, G.L.; Xiong, C.M.; Dou, R.F.; He, L.; et al. Two-dimensional superconductivity at (110) LaAlO3/SrTiO3 interfaces. Appl. Phys. Lett. 2014, 105, 5. [Google Scholar] [CrossRef] [Green Version]

- Monteiro, A.; Groenendijk, D.J.; Groen, I.; de Bruijckere, J.; Gaudenzi, R.; van der Zant, H.S.J.; Caviglia, A.D. Two-dimensional superconductivity at the (111) LaAlO3/SrTiO3 interface. Phys. Rev. B 2017, 96, 4. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.J.; Yan, X.; Jin, D.F.; Ma, Y.; Hsiao, H.W.; Lin, Y.L.; Bretz-Sullivan, T.M.; Zhou, X.J.; Pearson, J.; Fisher, B.; et al. Two-dimensional superconductivity and anisotropic transport at KTaO3 (111) interfaces. Science 2021, 371, 716–721. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, Y.; Zhang, H.; Liu, Z.; Tian, H.; Sun, Y.; Zhang, M.; Zhou, Y.; Sun, J.; Xie, Y. Electric field control of superconductivity at the LaAlO3/KTaO3(111) interface. Science 2021, 372, 721. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Luo, G.; Tung, I.C.; Chang, S.H.; Luo, Z.; Malshe, M.; Gadre, M.; Bhattacharya, A.; Nakhmanson, S.M.; Eastman, J.A.; et al. Dynamic layer rearrangement during growth of layered oxide films by molecular beam epitaxy. Nat. Mater. 2014, 13, 879–883. [Google Scholar] [CrossRef]

- Cook, S.; Letchworth-Weaver, K.; Tung, I.C.; Andersen, T.K.; Hong, H.; Marks, L.D.; Fong, D.D. How heteroepitaxy occurs on strontium titanate. Sci. Adv. 2019, 5, 9. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.S.; Seo, S.S.A.; Chisholm, M.F.; Kremer, R.K.; Habermeier, H.U.; Keimer, B.; Lee, H.N. Nonlinear Hall effect and multichannel conduction in LaTiO3/SrTiO3 superlattices. Phys. Rev. B 2010, 82, 4. [Google Scholar] [CrossRef] [Green Version]

- Spurgeon, S.R.; Sushko, P.V.; Chambers, S.A.; Comes, R.B. Dynamic interface rearrangement in LaFeO3/n-SrTiO3 heterojunctions. Phys. Rev. Mater. 2017, 1, 6. [Google Scholar] [CrossRef]

- Comes, R.; Chambers, S. Interface Structure, Band Alignment, and Built-In Potentials at LaFeO3/n-SrTiO3 Heterojunctions. Phys. Rev. Lett. 2016, 117, 5. [Google Scholar] [CrossRef] [Green Version]

- Nakamura, K.; Mashiko, H.; Yoshimatsu, K.; Ohtomo, A. Impact of built-in potential across LaFeO3/SrTiO3 heterojunctions on photocatalytic activity. Appl. Phys. Lett. 2016, 108, 5. [Google Scholar] [CrossRef]

- Nakamura, M.; Kagawa, F.; Tanigaki, T.; Park, H.S.; Matsuda, T.; Shindo, D.; Tokura, Y.; Kawasaki, M. Spontaneous Polarization and Bulk Photovoltaic Effect Driven by Polar Discontinuity in LaFeO3/SrTiO3 Heterojunctions. Phys. Rev. Lett. 2016, 116, 5. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhuo, M.J.; Fu, E.G.; Yan, L.; Wang, Y.Q.; Zhang, Y.Y.; Dickerson, R.M.; Uberuaga, B.P.; Misra, A.; Nastasi, M.; Jia, Q.X. Interface-enhanced defect absorption between epitaxial anatase TiO2 film and single crystal SrTiO3. Scr. Mater. 2011, 65, 807–810. [Google Scholar] [CrossRef]

- Zhuo, M.J.; Uberuaga, B.P.; Yan, L.; Fu, E.G.; Dickerson, R.M.; Wang, Y.Q.; Misra, A.; Nastasi, M.; Jia, Q.X. Radiation damage at the coherent anatase TiO2/SrTiO3 interface under Ne ion irradiation. J. Nucl. Mater. 2012, 429, 1177–1184. [Google Scholar] [CrossRef]

- Dholabhai, P.P.; Aguiar, J.A.; Misra, A.; Uberuaga, B.P. Defect interactions with stepped CeO2/SrTiO3 interfaces: Implications for radiation damage evolution and fast ion conduction. J. Chem. Phys. 2014, 140, 12. [Google Scholar] [CrossRef] [PubMed]

- Aguiar, J.A.; Dholabhai, P.P.; Bi, Z.X.; Jia, Q.X.; Fu, E.G.; Wang, Y.Q.; Aoki, T.; Zhu, J.T.; Misra, A.; Uberuaga, B.P. Linking Interfacial Step Structure and Chemistry with Locally Enhanced Radiation-Induced Amorphization at Oxide Heterointerfaces. Adv. Mater. Interfaces 2014, 1, 8. [Google Scholar] [CrossRef]

- Aguiar, J.A.; Zhuo, M.J.; Bi, Z.X.; Fu, E.G.; Wang, Y.Q.; Dholabhai, P.P.; Misra, A.; Jia, Q.X.; Uberuaga, B.P. Orientation-specific amorphization and intercalated recrystallization at ion-irradiated SrTiO3/MgO interfaces. J. Mater. Res. 2014, 29, 1699–1710. [Google Scholar] [CrossRef]

- Moetakef, P.; Cain, T.A.; Ouellette, D.G.; Zhang, J.Y.; Klenov, D.O.; Janotti, A.; Van de Walle, C.G.; Rajan, S.; Allen, S.J.; Stemmer, S. Electrostatic carrier doping of GdTiO3/SrTiO3 interfaces. Appl. Phys. Lett. 2011, 99, 4. [Google Scholar] [CrossRef] [Green Version]

- Moetakef, P.; Jackson, C.A.; Hwang, J.; Balents, L.; Allen, S.J.; Stemmer, S. Toward an artificial Mott insulator: Correlations in confined high-density electron liquids in SrTiO3. Phys. Rev. B 2012, 86, 4. [Google Scholar] [CrossRef] [Green Version]

- Moetakef, P.; Ouellette, D.G.; Williams, J.R.; Allen, S.J.; Balents, L.; Goldhaber-Gordon, D.; Stemmer, S. Quantum oscillations from a two-dimensional electron gas at a Mott/band insulator interface. Appl. Phys. Lett. 2012, 101, 4. [Google Scholar] [CrossRef] [Green Version]

- Moetakef, P.; Ouellette, D.G.; Zhang, J.Y.; Cain, T.A.; Allen, S.J.; Stemmer, S. Growth and properties of GdTiO3 films prepared by hybrid molecular beam epitaxy. J. Cryst. Growth 2012, 355, 166–170. [Google Scholar] [CrossRef]

- Moetakef, P.; Zhang, J.Y.; Kozhanov, A.; Jalan, B.; Seshadri, R.; Allen, S.J.; Stemmer, S. Transport in ferromagnetic GdTiO3/SrTiO3 heterostructures. Appl. Phys. Lett. 2011, 98, 3. [Google Scholar] [CrossRef] [Green Version]

- Need, R.F.; Isaac, B.J.; Kirby, B.J.; Borchers, J.A.; Stemmer, S.; Wilson, S.D. Interface-Driven Ferromagnetism within the Quantum Wells of a Rare Earth Titanate Superlattice. Phys. Rev. Lett. 2016, 117, 5. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Banerjee, H.; Banerjee, S.; Randeria, M.; Saha-Dasgupta, T. Electronic Structure of Oxide Interfaces: A Comparative Analysis of GdTiO3/SrTiO3 and LaAlO3/SrTiO3 Interfaces. Sci. Rep. 2015, 5, 26. [Google Scholar] [CrossRef]

- Xu, P.; Droubay, T.C.; Jeong, J.S.; Mkhoyan, K.A.; Sushko, P.V.; Chambers, S.A.; Jalan, B. Quasi 2D Ultrahigh Carrier Density in a Complex Oxide Broken-Gap Heterojunction. Adv. Mater. Interfaces 2016, 3, 8. [Google Scholar] [CrossRef]

- Chen, Y.Z.; Trier, F.; Wijnands, T.; Green, R.J.; Gauquelin, N.; Egoavil, R.; Christensen, D.V.; Koster, G.; Huijben, M.; Bovet, N.; et al. Extreme mobility enhancement of two-dimensional electron gases at oxide interfaces by charge-transfer-induced modulation doping. Nat. Mater. 2015, 14, 801–806. [Google Scholar] [CrossRef] [PubMed]

- Schutz, P.; Pfaff, F.; Scheiderer, P.; Chen, Y.Z.; Pryds, N.; Gorgoi, M.; Sing, M.; Claessen, R. Band bending and alignment at the spinel/perovskite gamma-Al2O3/SrTiO3 heterointerface. Phys. Rev. B 2015, 91, 9. [Google Scholar] [CrossRef] [Green Version]

- Li, C.J.; Xue, H.X.; Qu, G.L.; Shen, S.C.; Hong, Y.P.; Wang, X.X.; Liu, M.R.; Jiang, W.M.; Badica, P.; He, L.; et al. Influence of In-Gap States on the Formation of Two-Dimensional Election Gas at ABO3/SrTiO3 Interfaces. Sci. Rep. 2018, 8, 11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hotta, Y.; Susaki, T.; Hwang, H.Y. Polar discontinuity doping of the LaVO3/SrTiO3 interface. Phys. Rev. Lett. 2007, 99, 4. [Google Scholar] [CrossRef] [Green Version]

- Hu, L.; Wei, R.H.; Tang, X.W.; Zhu, S.J.; Zhang, X.K.; Zhu, X.B.; Song, W.H.; Dai, J.M.; Zhang, C.J.; Sun, Y.P. Elucidating the origins of the two-dimensional electron gas in LaVO3/SrTiO3 interfaces. J. Appl. Phys. 2019, 125, 6. [Google Scholar] [CrossRef]

- Jackson, C.A.; Zhang, J.Y.; Freeze, C.R.; Stemmer, S. Quantum critical behaviour in confined SrTiO3 quantum wells embedded in antiferromagnetic SmTiO3. Nat. Commun. 2014, 5, 6. [Google Scholar] [CrossRef] [Green Version]

- O’Sullivan, M.; Hadermann, J.; Dyer, M.S.; Turner, S.; Alaria, J.; Manning, T.D.; Abakumov, A.M.; Claridge, J.B.; Rosseinsky, M.J. Interface control by chemical and dimensional matching in an oxide heterostructure. Nat. Chem. 2016, 8, 347–353. [Google Scholar] [CrossRef]

- Green, M.A.; Ho-Baillie, A.; Snaith, H.J. The emergence of perovskite solar cells. Nat. Photonics 2014, 8, 506–514. [Google Scholar] [CrossRef]

- Peng, B.L.; Zhang, Q.; Li, X.; Sun, T.Y.; Fan, H.Q.; Ke, S.M.; Ye, M.; Wang, Y.; Lu, W.; Niu, H.B.; et al. Large Energy Storage Density and High Thermal Stability in a Highly Textured (111)-Oriented Pb0.8Ba0.2ZrO3 Relaxor Thin Film with the Coexistence of Antiferroelectric and Ferroelectric Phases. ACS Appl. Mater. Interfaces 2015, 7, 13512–13517. [Google Scholar] [CrossRef]

- Xie, Z.K.; Yue, Z.X.; Peng, B.; Zhang, J.; Zhao, C.; Zhang, X.H.; Ruehl, G.; Li, L.T. Large enhancement of the recoverable energy storage density and piezoelectric response in relaxor-ferroelectric capacitors by utilizing the seeding layers engineering. Appl. Phys. Lett. 2015, 106, 5. [Google Scholar] [CrossRef]

- Park, M.H.; Kim, H.J.; Kim, Y.J.; Moon, T.; Kim, K.D.; Hwang, C.S. Effect of the annealing temperature of thin Hf0.3Zr0.7O2 films on their energy storage behavior. Phys. Status Solidi-Rapid Res. Lett. 2014, 8, 857–861. [Google Scholar] [CrossRef]

- Park, M.H.; Kim, H.J.; Kim, Y.J.; Moon, T.; Kim, K.D.; Hwang, C.S. Thin HfxZr1-xO2 Films: A New Lead-Free System for Electrostatic Supercapacitors with Large Energy Storage Density and Robust Thermal Stability. Adv. Energy Mater. 2014, 4, 7. [Google Scholar] [CrossRef]

- Zhao, Y.; Hao, X.H.; Zhang, Q. Energy-Storage Properties and Electrocaloric Effect of Pb(1-3x/2)LaxZr0.85Ti0.15O3 Antiferroelectric Thick Films. ACS Appl. Mater. Interfaces 2014, 6, 11633–11639. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, R.; Li, W.W.; Chen, A.P.; Zhang, W.R.; Yang, J.; Liang, Y.; Tang, R.J.; Wang, H.Y.; Yang, H. Manipulating leakage behavior via distribution of interfaces in oxide thin films. Appl. Phys. Lett. 2014, 105, 4. [Google Scholar] [CrossRef]

- Hsieh, Y.H.; Liou, J.M.; Huang, B.C.; Liang, C.W.; He, Q.; Zhan, Q.; Chiu, Y.P.; Chen, Y.C.; Chu, Y.H. Local Conduction at the BiFeO3-CoFe2O4 Tubular Oxide Interface. Adv. Mater. 2012, 24, 4564–4568. [Google Scholar] [CrossRef] [PubMed]

- Li, W.W.; Zhao, R.; Tang, R.J.; Chen, A.P.; Zhang, W.R.; Lu, X.; Wang, H.Y.; Yang, H. Vertical-Interface-Manipulated Conduction Behavior in Nanocomposite Oxide Thin Films. ACS Appl. Mater. Interfaces 2014, 6, 5356–5361. [Google Scholar] [CrossRef]

- Hunt, B.; Sanchez-Yamagishi, J.D.; Young, A.F.; Yankowitz, M.; LeRoy, B.J.; Watanabe, K.; Taniguchi, T.; Moon, P.; Koshino, M.; Jarillo-Herrero, P.; et al. Massive Dirac Fermions and Hofstadter Butterfly in a van der Waals Heterostructure. Science 2013, 340, 1427–1430. [Google Scholar] [CrossRef] [Green Version]

- Dean, C.R.; Wang, L.; Maher, P.; Forsythe, C.; Ghahari, F.; Gao, Y.; Katoch, J.; Ishigami, M.; Moon, P.; Koshino, M.; et al. Hofstadter’s butterfly and the fractal quantum Hall effect in moire superlattices. Nature 2013, 497, 598–602. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.; DaSilva, A.; Huang, S.; Fallahazad, B.; Larentis, S.; Taniguchi, T.; Watanabe, K.; Leroy, B.J.; MacDonald, A.H.; Tutuc, E. Tunable moire bands and strong correlations in small-twist-angle bilayer graphene. Proc. Natl. Acad. Sci. USA 2017, 114, 3364–3369. [Google Scholar] [CrossRef] [Green Version]

- Tran, K.; Moody, G.; Wu, F.; Lu, X.; Choi, J.; Kim, K.; Rai, A.; Sanchez, D.A.; Quan, J.; Singh, A.; et al. Evidence for moiré excitons in van der Waals heterostructures. Nature 2019, 567, 71–75. [Google Scholar] [CrossRef] [Green Version]

- Meng, Q.P.; Xu, G.Y.; Xin, H.L.; Stach, E.A.; Zhu, Y.M.; Su, D. Quantification of Charge Transfer at the Interfaces of Oxide Thin Films. J. Phys. Chem. A 2019, 123, 4632–4637. [Google Scholar] [CrossRef] [Green Version]

- Sun, Z.X.; Ma, C.R.; Liu, M.; Cui, J.; Lu, L.; Lu, J.B.; Lou, X.J.; Jin, L.; Wang, H.; Jia, C.L. Ultrahigh Energy Storage Performance of Lead-Free Oxide Multilayer Film Capacitors via Interface Engineering. Adv. Mater. 2017, 29, 6. [Google Scholar] [CrossRef]

- Diao, C.; Liu, H.; Lou, G.; Zheng, H.; Yao, Z.; Hao, H.; Cao, M. Structure and electric properties of sandwich-structured SrTiO3/BiFeO3 thin films for energy storage applications. J. Alloys Compd. 2019, 781, 378–384. [Google Scholar] [CrossRef]

- Hu, Z.Q.; Ma, B.H.; Koritala, R.E.; Balachandran, U. Temperature-dependent energy storage properties of antiferroelectric Pb0.96La0.04Zr0.98Ti0.02O3 thin films. Appl. Phys. Lett. 2014, 104, 4. [Google Scholar] [CrossRef]

- Zhao, Y.; Hao, X.H.; Li, M.L. Dielectric properties and energy-storage performance of (Na0.5Bi0.5) TiO3 thick films. J. Alloys Compd. 2014, 601, 112–115. [Google Scholar] [CrossRef]

- Xu, Z.S.; Hao, X.H.; An, S.L. Dielectric properties and energy-storage performance of (Na0.5Bi0.5)TiO3-SrTiO3 thick films derived from polyvinylpyrrolidone-modified chemical solution. J. Alloys Compd. 2015, 639, 387–392. [Google Scholar] [CrossRef]

- Zhang, L.; Hao, X.H. Dielectric properties and energy-storage performances of (1 − x)(Na0.5Bi0.5)TiO3–xSrTiO3 thick films prepared by screen printing technique. J. Alloys Compd. 2014, 586, 674–678. [Google Scholar] [CrossRef]

- Michael, E.K.; Trolier-McKinstry, S. Cubic Pyrochlore Bismuth Zinc Niobate Thin Films for High-Temperature Dielectric Energy Storage. J. Am. Ceram. Soc. 2015, 98, 1223–1229. [Google Scholar] [CrossRef]

- Puli, V.S.; Pradhan, D.K.; Adireddy, S.; Martinez, R.; Silwal, P.; Scott, J.F.; Ramana, C.V.; Chrisey, D.B.; Katiyar, R.S. Nanoscale polarisation switching and leakage currents in (Ba0.955Ca0.045)(Zr0.17Ti0.83)O3 epitaxial thin films. J. Phys. D-Appl. Phys. 2015, 48, 11. [Google Scholar] [CrossRef]

- Ma, B.H.; Kwon, D.K.; Narayanan, M.; Balachandran, U. Dielectric properties and energy storage capability of antiferroelectric Pb0.92La0.08Zr0.95Ti0.05O3 film-on-foil capacitors. J. Mater. Res. 2009, 24, 2993–2996. [Google Scholar] [CrossRef]

- Sun, N.; Wang, Y.; Zhang, L.; Zhang, X.; Hao, X.; Li, M. Effects of thickness on the microstructure and energy-storage performance of PLZT antiferroelectric thick films. J. Adv. Dielectr. 2013, 3, 1350021. [Google Scholar] [CrossRef]

- Ma, B.; Narayanan, M.; Liu, S.; Hu, Z.; Balachandran, U. Development of PLZT film-on-foil capacitors with high energy density. J. Phys. Conf. Ser. 2013, 472, 012004. [Google Scholar] [CrossRef]

- Morten, B.; Decicco, G.; Prudenziati, M. Resonant pressure sensor based on piezoelectric properties of ferroelectric thick-films. Sens. Actuator A-Phys. 1992, 31, 153–158. [Google Scholar] [CrossRef]

- Jaffe, H.; Berlincourt, D.A. Piezoelectric transducer materials. Proc. Inst. Electr. Electron. Eng. 1965, 53, 1372–1386. [Google Scholar] [CrossRef]

- Wang, Z.L.; Song, J.H. Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 2006, 312, 242–246. [Google Scholar] [CrossRef]

- Lopez-Suarez, M.; Pruneda, M.; Abadal, G.; Rurali, R. Piezoelectric monolayers as nonlinear energy harvesters. Nanotechnology 2014, 25, 5. [Google Scholar] [CrossRef] [Green Version]

- Bakaul, S.R.; Serrao, C.R.; Lee, O.; Lu, Z.Y.; Yadav, A.; Carraro, C.; Maboudian, R.; Ramesh, R.; Salahuddin, S. High Speed Epitaxial Perovskite Memory on Flexible Substrates. Adv. Mater. 2017, 29, 6. [Google Scholar] [CrossRef]

- Waduge, W.L.I.; Chen, Y.; Zuo, P.; Jayakodiarachchi, N.; Kuech, T.F.; Babcock, S.E.; Evans, P.G.; Winter, C.H. Solid-Phase Epitaxy of Perovskite High Dielectric PrAlO3 Films Grown by Atomic Layer Deposition for Use in Two-Dimensional Electronics and Memory Devices. ACS Appl. Nano Mater. 2019, 2, 7449–7458. [Google Scholar] [CrossRef]

- Pryds, N.; Toftmann, B.; Bilde-Sorensen, J.B.; Schou, J.; Linderoth, S. Thickness determination of large-area films of yttria-stabilized zirconia produced by pulsed laser deposition. Appl. Surf. Sci. 2006, 252, 4882–4885. [Google Scholar] [CrossRef]

- Blank, D.H.A.; Dekkers, M.; Rijnders, G. Pulsed laser deposition in Twente: From research tool towards industrial deposition. J. Phys. D-Appl. Phys. 2014, 47, 8. [Google Scholar] [CrossRef]

- Gu, X.; Lubyshev, D.; Batzel, J.; Fastenau, J.M.; Liu, W.K.; Pelzel, R.; Magana, J.F.; Ma, Q.; Wang, L.P.; Zhang, P.; et al. Commercial molecular beam epitaxy production of high quality SrTiO3 on large diameter Si substrates. J. Vac. Sci. Technol. B 2009, 27, 1195–1199. [Google Scholar] [CrossRef]

- Reiner, J.W.; Kolpak, A.M.; Segal, Y.; Garrity, K.F.; Ismail-Beigi, S.; Ahn, C.H.; Walker, F.J. Crystalline Oxides on Silicon. Adv. Mater. 2010, 22, 2919–2938. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Engel-Herbert, R. Growth of SrTiO3 on Si(001) by hybrid molecular beam epitaxy. Phys. Status Solidi-Rapid Res. Lett. 2014, 8, 917–923. [Google Scholar] [CrossRef]

- Moreira, I.D.R.; Munoz, D.; Illas, F.; de Graaf, C.; Garcia-Bach, M.A. A relationship between electronic structure effective parameters and T-c in monolayered cuprate superconductors. Chem. Phys. Lett. 2001, 345, 183–188. [Google Scholar] [CrossRef]

- Sonsteby, H.H.; Bratvold, J.E.; Weibye, K.; Fjellvag, H.; Nilsen, O. Phase Control in Thin Films of Layered Cuprates. Chem. Mater. 2018, 30, 1095–1101. [Google Scholar] [CrossRef]

- Hanawaa, M.; Tsukada, I. Tuning of the in-plane strain in cuprate thin films using a solid-solution compound as a buffer layer. Appl. Phys. Lett. 2007, 91, 3. [Google Scholar] [CrossRef]

- Gupta, A.; Chern, M.Y.; Hussey, B.W. Layer-by-layer growth of cuprate thin-films by pulsed-laser deposition. Phys. C 1993, 209, 175–178. [Google Scholar] [CrossRef]

- Pavuna, D.; Abrecht, M.; Cloetta, D.; Xi, X.X.; Margaritondo, G.; Ariosa, D. Systematic studies of (magneto)transport, structural and electronic properties of ultra-thin films of high-T-c cuprates and related layered oxides. Curr. Appl. Phys. 2002, 2, 345–348. [Google Scholar] [CrossRef]

- Logvenov, G.; Gozar, A.; Bozovic, I. High-Temperature Superconductivity in a Single Copper-Oxygen Plane. Science 2009, 326, 699–702. [Google Scholar] [CrossRef] [PubMed]

| Bilayer System | Phenomena and Related Properties | Reference |

|---|---|---|

| Sr2TiO4/SrTiO3 | Dynamic rearrangement during the growth of layered An+1BnO3n+1 oxide systems | [258] |

| LaTiO3/SrTiO3 | Highly active participation of a TiO2 adlayer in dynamic layer rearrangement; magnetotransport properties; formation of a highly mobile conduction channel | [259,260] |

| LaFeO3/SrTiO3 | Dynamic interfacial rearrangement of atomic planes as a function of substrate termination; band alignment affected by interfacial polarity; photocurrent-voltage curves depending on interface termination; spontaneous polarization evoking photovoltaic properties | [261,262,263,264] |

| TiO2/SrTiO3 | Formation of a defect-free zone and an amorphous boundary layer caused by differences in chemical potential and defect mobilities of both phases | [265,266] |

| CeO2/SrTiO3 | Defect trapping by atomic interface steps leading to localized amorphization under ion radiation | [267,268] |

| MgO/SrTiO3 | Orientation-specific amorphization and intercalated recrystallization at ion-irradiated interfaces | [269] |

| GdTiO3/SrTiO3 | Magnetic order; electrical transport and Mott insulation properties, Curie temperature of 30 K; intrinsic electron reconstruction; high concentration of mobile carriers (2DEG); interfacial polar discontinuity | [270,271,272,273,274,275,276] |

| NdTiO3/SrTiO3 | Ultra-high carrier densitiy regime due to additional charge transfer from band alignment | [277] |

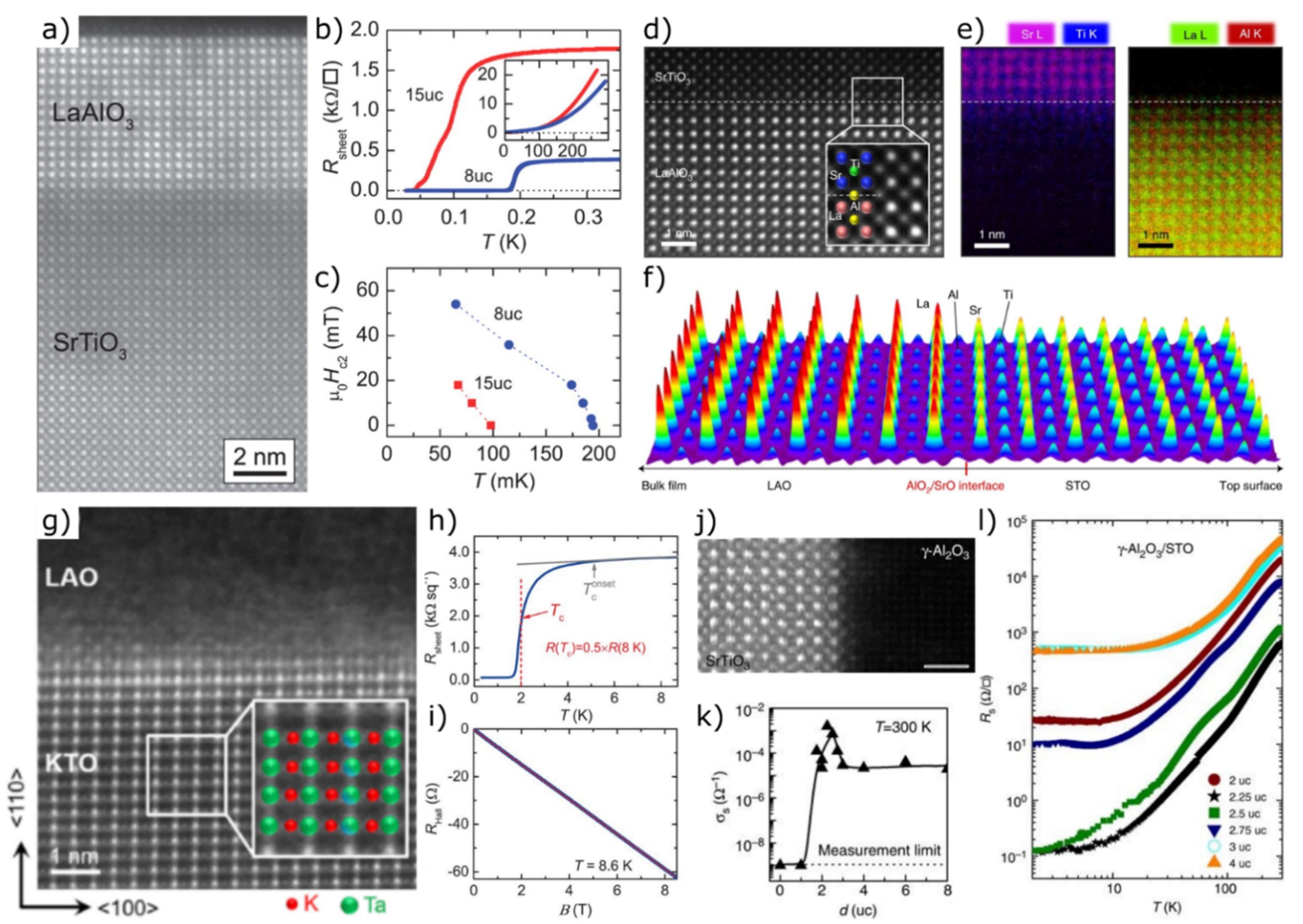

| γ-Al2O3/SrTiO3 | High quality epitaxial heterointerface (Figure 8j), high electron mobility; quantum magnetoresistance oscillations; band bending and alignment, thickness-dependent transport properties (Figure 8k,l) | [141,278,279] |

| LaCrO3/SrTiO3 | Unexpected formation of 2DEG at the initially insulating interface | [280] |

| LaVO3/SrTiO3 | Interface conduction based on electronic reconstructions; thickness-dependent metal-insulator transition; Hall effect at low temperature; growth rate and substrate temperature-dependent structural and electrical interface properties by oxygen substrate-to-film transfer | [281,282] |

| SmTiO3/SrTiO3 | Non-Fermi liquid behaviour; very high film carrier densities | [283] |

| La0.5Zr0.5O1.75/LaAlO3, Nd0.5Zr0.5O1.75/LaAlO3 | Dynamic self-assembly during growth creates coherent interfaces between oxide materials of different crystal structure | [284] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dubnack, O.; Müller, F.A. Oxidic 2D Materials. Materials 2021, 14, 5213. https://doi.org/10.3390/ma14185213

Dubnack O, Müller FA. Oxidic 2D Materials. Materials. 2021; 14(18):5213. https://doi.org/10.3390/ma14185213

Chicago/Turabian StyleDubnack, Oliver, and Frank A. Müller. 2021. "Oxidic 2D Materials" Materials 14, no. 18: 5213. https://doi.org/10.3390/ma14185213