Effects of Insertion of Ag Mid-Layers on Laser Direct Ablation of Transparent Conductive ITO/Ag/ITO Multilayers: Role of Effective Absorption and Focusing of Photothermal Energy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of ITO/Ag/ITO ML and ITO Single Layer (SL) Substrates

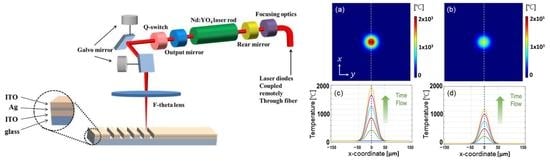

2.2. Laser Direct Ablation Process

2.3. Optical, Electrical, and Elemental Characterizations

2.4. Computational Simulation

3. Results and Discussion

3.1. Experimental Aspects

3.2. Simulation Perspective

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ju, S.; Li, J.F.; Liu, J.; Chen, P.C.; Ha, Y.G.; Ishikawa, F.; Chang, H.; Zhou, C.W.; Facchetti, A.; Janes, D.B.; et al. Transparent active matrix organic light-emitting diode displays driven by nanowire transistor circuitry. Nano Lett. 2008, 8, 997–1004. [Google Scholar] [CrossRef] [PubMed]

- Ellmer, K. Past achievements and future challenges in the development of optically transparent electrodes. Nat. Photonics 2012, 6, 808–816. [Google Scholar] [CrossRef]

- McCarthy, M.A.; Liu, B.; Donoghue, E.P.; Kravchenko, I.; Kim, D.Y.; So, F.; Rinzler, A.G. Low-Voltage, Low-Power, Organic Light-Emitting Transistors for Active Matrix Displays. Science 2011, 332, 570–573. [Google Scholar] [CrossRef] [PubMed]

- Ahn, M.H.; Cho, E.S.; Kwon, S.J. Effect of the duty ratio on the indium tin oxide (ITO) film deposited by in-line pulsed DC magnetron sputtering method for resistive touch panel. Appl. Surf. Sci. 2011, 258, 1242–1248. [Google Scholar] [CrossRef]

- Nishimura, T.; Kim, S.; Chantana, J.; Kawano, Y.; Ishizuka, S.; Minemoto, T. Application of Al-Doped (Zn, Mg)O on pure-sulfide Cu(In, Ga)S-2 solar cells for enhancement of open-circuit voltage. Sol. Energy Mater. Sol. Cells 2019, 202, 110157. [Google Scholar] [CrossRef]

- Ahn, M.H.; Cho, E.S.; Kwon, S.J. Characteristics of ITO-resistive touch film deposited on a PET substrate by in-line DC magnetron sputtering. Vacuum 2014, 101, 221–227. [Google Scholar] [CrossRef]

- Yoon, S.; Lim, J.H.; Yoo, B. Efficient Si/SiOx/ITO Heterojunction Photoanode with an Amorphous and Porous NiOOH Catalyst formed by NiCl2 activation for Water Oxidation. Electrochim. Acta 2017, 237, 37–43. [Google Scholar] [CrossRef]

- Park, S.; Yoon, Y.S. A study on the radiation resistance of CdWO4 thin-film scintillators deposited by using an electron-beam physical vapor deposition method. J. Korean Phys. Soc. 2016, 69, 734–738. [Google Scholar] [CrossRef]

- Chae, S.; Yu, J.; Oh, J.Y.; Lee, T.I. Hybrid poly (3-hexylthiophene) (P3HT) nanomesh/ZnO nanorod p-n junction visible photocatalyst for efficient indoor air purification. Appl. Surf. Sci. 2019, 496, 143641. [Google Scholar] [CrossRef]

- Misra, M.; Hwang, D.K.; Kim, Y.C.; Myoung, J.M.; Lee, T.I. Eco-friendly method of fabricating indium-tin-oxide thin films using pure aqueous sol-gel. Ceram. Int. 2018, 44, 2927–2933. [Google Scholar] [CrossRef]

- Hwang, D.K.; Misra, M.; Lee, Y.E.; Baek, S.D.; Myoung, J.M.; Lee, T. The role of Ar plasma treatment in generating oxygen vacancies in indium tin oxide thin films prepared by the sol-gel process. Appl. Surf. Sci. 2017, 405, 344–349. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, J.W.; Lee, T.I.; Myoung, J.M. Inorganic Nano Light-Emitting Transistor: P-Type Porous Silicon Nanowire/n-Type ZnO Nanofilm. Small 2016, 12, 4222–4228. [Google Scholar] [CrossRef] [PubMed]

- Jung, S.W.; Chae, S.S.; Park, J.H.; Oh, J.Y.; Bhang, S.H.; Baik, H.K.; Lee, T.I. Microscale Soft Patterning for Solution Processable Metal Oxide Thin Film Transistors. ACS Appl. Mater. Interfaces 2016, 8, 7205–7211. [Google Scholar] [CrossRef] [PubMed]

- Choi, K.H.; Kim, J.Y.; Lee, Y.S.; Kim, H.J. ITO/Ag/ITO multilayer films for the application of a very low resistance transparent electrode. Thin Solid Films 1999, 341, 152–155. [Google Scholar] [CrossRef]

- Guillen, C.; Herrero, J. Transparent conductive ITO/Ag/ITO multilayer electrodes deposited by sputtering at room temperature. Opt. Commun. 2009, 282, 574–578. [Google Scholar] [CrossRef]

- Jeong, J.A.; Kim, H.K. Low resistance and highly transparent ITO-Ag-ITO multilayer electrode using surface plasmon resonance of Ag layer for bulk-heterojunction organic solar cells. Sol. Energy Mater. Sol. Cells 2009, 93, 1801–1809. [Google Scholar] [CrossRef]

- Meshram, N.; Loka, C.; Park, K.R.; Lee, K.S. Enhanced transmittance of ITO/Ag(Cr)/ITO (IAI) multi-layered thin films by high temperature annealing. Mater. Lett. 2015, 145, 120–124. [Google Scholar] [CrossRef]

- Lu, H.W.; Huang, C.W.; Kao, P.C.; Chu, S.Y. ITO-free organic light-emitting diodes with MoO3/Al/MoO3 as semitransparent anode fabricated using thermal deposition method. Appl. Surf. Sci. 2015, 347, 116–121. [Google Scholar] [CrossRef]

- Cho, D.Y.; Na, S.I.; Chung, K.B.; Kim, H.K. Embedment of nano-sized Ag layer into Ag-doped In2O3 films for use as highly transparent and conductive anode in organic solar cells. Appl. Surf. Sci. 2015, 347, 88–95. [Google Scholar] [CrossRef]

- Taverne, S.; Caron, B.; Getin, S.; Lartigue, O.; Lopez, C.; Meunier-Della-Gatta, S.; Gorge, V.; Reymermier, M.; Racine, B.; Maindron, T.; et al. Multispectral surface plasmon resonance approach for ultra-thin silver layer characterization: Application to top-emitting OLED cathode. J. Appl. Phys. 2018, 123, 023108. [Google Scholar] [CrossRef] [Green Version]

- Pandey, R.; Wie, C.H.; Lin, X.; Lim, J.W.; Kim, K.K.; Hwang, D.K.; Choi, W.K. Fluorine doped zinc tin oxide multilayer transparent conducting Oxides for organic photovoltaic’s Cells. Sol. Energy Mater. Sol. Cells 2015, 134, 5–14. [Google Scholar] [CrossRef]

- Kim, S.K.; Cho, J.W.; Im, H.S.; Lim, W.C.; Kim, S.K.; Seong, T.Y. Formation of high ultraviolet transparent SrVOx/Ag-based conducting electrode. Ceram. Int. 2020, 46, 19484–19490. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Zhao, J.D.; Wu, H.; Yu, S.W. The enhancement of thermal endurance in doped low emissive ZnO/Ag/ZnO multilayer thin film. J. Alloys Compd. 2020, 832, 154983. [Google Scholar] [CrossRef]

- Chee, K.W.A.; Meng, F.P.; Lai, D.C.; Huang, F. Measurement-based optimization and analysis of α-IGZO/Ag/α-IGZO transparent conducting electrodes fabricated using DC magnetron sputter deposition. Ceram. Int. 2018, 44, 20939–20946. [Google Scholar] [CrossRef]

- Wang, H.L.; Tang, C.M.; Shi, Q.; Wei, M.Y.; Su, Y.F.; Lin, S.S.; Dai, M.J. Influence of Ag incorporation on the structural, optical and electrical properties of ITO/Ag/ITO multilayers for inorganic all-solid-state electrochromic devices. Ceram. Int. 2021, 47, 7666–7673. [Google Scholar] [CrossRef]

- Park, Y.S.; Choi, K.H.; Kim, H.K. Room temperature flexible and transparent ITO/Ag/ITO electrode grown on flexile PES substrate by continuous roll-to-roll sputtering for flexible organic photovoltaics. J. Phys. D Appl. Phys. 2009, 42, 235109. [Google Scholar] [CrossRef]

- Haacke, G. New figure of merit for transparent conductors. J. Appl. Phys. 1976, 47, 4086–4089. [Google Scholar] [CrossRef]

- Christensen, N.E. The Band Structure of Silver and Optical Interband Transitions. Phys. Status Solidi B 1972, 54, 551–563. [Google Scholar] [CrossRef]

- Kim, J.; Lee, K.H.; Kim, S.D.; Lim, J.H.; Myung, N.V. Simple and effective fabrication of Sb2Te3 films embedded with Ag2Te nanoprecipitates for enhanced thermoelectric performance. J. Mater. Chem. A 2018, 6, 349–356. [Google Scholar] [CrossRef]

- Ferrer-Argemi, L.; Yu, Z.Q.; Kim, J.; Myung, N.V.; Lim, J.H.; Lee, J. Silver content dependent thermal conductivity and thermoelectric properties of electrodeposited antimony telluride thin films. Sci. Rep. 2019, 9, 9242. [Google Scholar] [CrossRef] [Green Version]

- Chen, M.F.; Chen, Y.P.; Hsiao, W.T.; Gu, Z.P. Laser direct write patterning technique of indium tin oxide film. Thin Solid Films 2007, 515, 8515–8518. [Google Scholar] [CrossRef]

- Li, Z.H.; Cho, E.S.; Kwon, S.J. A new laser direct etching method of indium tin oxide electrode for application to alternative current plasma display panel. Appl. Surf. Sci. 2009, 255, 9843–9846. [Google Scholar] [CrossRef]

- Li, Z.H.; Cho, E.S.; Kwon, S.J. Laser direct patterning of the T-shaped ITO electrode for high-efficiency alternative current plasma display panels. Appl. Surf. Sci. 2010, 257, 776–780. [Google Scholar] [CrossRef]

- Kim, H.J.; Seo, K.W.; Kim, Y.H.; Choi, J.; Kim, H.K. Direct laser patterning of transparent ITO-Ag-ITO multilayer anodes for organic solar cells. Appl. Surf. Sci. 2015, 328, 215–221. [Google Scholar] [CrossRef]

- Kim, D.H.; Lee, H.S.; Kim, S.C.; Kim, Y.M.; Kim, T.; Kim, J.E.; Suh, K.S. Large-Scale Laser Patterning of Silver Nanowire Network by Using Patterned Optical Mirror Mask. Sci. Adv. Mater. 2016, 8, 1369–1373. [Google Scholar] [CrossRef]

- Hur, J.; Kim, I.T.; Lee, D. Morphology Tuning of Hydrothermally Grown ZnO Nanowires Through Seed Layer Patterning via Laser Direct Writing. J. Nanosci. Nanotechnol. 2017, 17, 7788–7792. [Google Scholar] [CrossRef]

- Rho, Y.; Kang, K.T.; Lee, D. Highly crystalline Ni/NiO hybrid electrodes processed by inkjet printing and laser-induced reductive sintering under ambient conditions. Nanoscale 2016, 8, 8976–8985. [Google Scholar] [CrossRef] [PubMed]

- Nam, V.B.; Shin, J.; Yoon, Y.; Giang, T.T.; Kwon, J.; Suh, Y.D.; Yeo, J.; Hong, S.; Ko, S.H.; Lee, D. Highly Stable Ni-Based Flexible Transparent Conducting Panels Fabricated by Laser Digital Patterning. Adv. Funct. Mater. 2019, 29, 1806895. [Google Scholar] [CrossRef]

- Park, G.; Lee, J.; Kang, S.; Kim, M.; Kang, S.; Choi, W. Design principle of super resolution near-field structure using thermally responsive optical phase change materials for nanolithography applications. Mater. Des. 2016, 102, 45–55. [Google Scholar] [CrossRef]

- Ryu, H.S.; Kim, H.S.; Kim, D.; Lee, S.J.; Choi, W.; Kwon, S.J.; Han, J.H.; Cho, E.S. Understanding of the Mechanism for Laser Ablation-Assisted Patterning of Graphene/ITO Double Layers: Role of Effective Thermal Energy Transfer. Micromachines 2020, 11, 821. [Google Scholar] [CrossRef]

- Allen, E.A.; Scott, G.D.; Thompson, K.T.; Veas, F. Light scattering from aggregated silver and gold films. J. Opt. Soc. Am. 1974, 64, 1190–1193. [Google Scholar] [CrossRef]

- Mishra, A.K.; Mishra, S.K.; Gupta, B.D. SPR based fiber optic sensor for refractive index sensing with enhanced detection accuracy and figure of merit in visible region. Opt. Commun. 2015, 344, 86–91. [Google Scholar] [CrossRef]

- Kapoor, V.; Sharma, N.K.; Sajal, V. Indium tin oxide and silver based fiber optic SPR sensor: An experimental study. Opt. Quantum Electron. 2019, 51, 125. [Google Scholar] [CrossRef]

- Liu, J.M. Simple technique for measurements of pulsed Gaussian-beam spot sizes. Opt. Lett. 1982, 7, 196–198. [Google Scholar] [CrossRef] [PubMed]

- Bonse, J.; Wrobel, J.M.; Kruger, J.; Kautek, W. Ultrashort-pulse laser ablation of indium phosphide in air. Appl. Phys. A 2001, 72, 89–94. [Google Scholar] [CrossRef]

- Crupi, I.; Boscarino, S.; Torrisi, G.; Scapellato, G.; Mirabella, S.; Piccitto, G.; Simone, F.; Terrasi, A. Laser irradiation of ZnO:Al/Ag/ZnO:Al multilayers for electrical isolation in thin film photovoltaics. Nanoscale Res. Lett. 2013, 8, 392. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Takagi, M. Electron-Diffraction Study of Liquid-Solid Transition of Thin Metal Films. J. Phys. Soc. Jpn. 1954, 9, 359–363. [Google Scholar] [CrossRef]

- Lai, S.L.; Guo, J.Y.; Petrova, V.; Ramanath, G.; Allen, L.H. Size-dependent melting properties of small tin particles: Nanocalorimetric measurements. Phys. Rev. Lett. 1996, 77, 99–102. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.X.; Kwon, S.J.; Han, J.H.; Cho, E.S. Laser Direct Patterning of Indium Tin Oxide for Defining a Channel of Thin Film Transistor. J. Nanosci. Nanotechnol. 2013, 13, 7751–7755. [Google Scholar] [CrossRef]

| [Units: at%] | |||||

|---|---|---|---|---|---|

| In | Sn | Ag | O | Si | |

| (1) Remaining region | 33.00 | 4.06 | 2.29 | 35.32 | 18.70 |

| (2) Ablated region | 3.29 | 0 | 0.79 | 50.24 | 31.66 |

| ITO/Ag(0 nm)/ITO | ITO/Ag(6 nm)/ITO | |

|---|---|---|

| Width of electrode (b) [10−4·cm] | 149.09 | 123.96 |

| Thickness of electrode (t) [10−4·cm] | 0.092 | 0.098 |

| Current density at 1 V [104·A/cm2] | 0.29 | 2.98 |

| Resistance per unit length [kΩ/cm] | 6.475 | 0.693 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, Y.; Kim, H.-S.; Lee, H.; Choi, W.; Kwon, S.J.; Han, J.-H.; Cho, E.-S. Effects of Insertion of Ag Mid-Layers on Laser Direct Ablation of Transparent Conductive ITO/Ag/ITO Multilayers: Role of Effective Absorption and Focusing of Photothermal Energy. Materials 2021, 14, 5136. https://doi.org/10.3390/ma14185136

Choi Y, Kim H-S, Lee H, Choi W, Kwon SJ, Han J-H, Cho E-S. Effects of Insertion of Ag Mid-Layers on Laser Direct Ablation of Transparent Conductive ITO/Ag/ITO Multilayers: Role of Effective Absorption and Focusing of Photothermal Energy. Materials. 2021; 14(18):5136. https://doi.org/10.3390/ma14185136

Chicago/Turabian StyleChoi, Younggon, Hong-Seok Kim, Haunmin Lee, Wonjoon Choi, Sang Jik Kwon, Jae-Hee Han, and Eou-Sik Cho. 2021. "Effects of Insertion of Ag Mid-Layers on Laser Direct Ablation of Transparent Conductive ITO/Ag/ITO Multilayers: Role of Effective Absorption and Focusing of Photothermal Energy" Materials 14, no. 18: 5136. https://doi.org/10.3390/ma14185136