Graphene-Based Materials Immobilized within Chitosan: Applications as Adsorbents for the Removal of Aquatic Pollutants

Abstract

:1. Introduction

2. Graphene as an Adsorbent Material

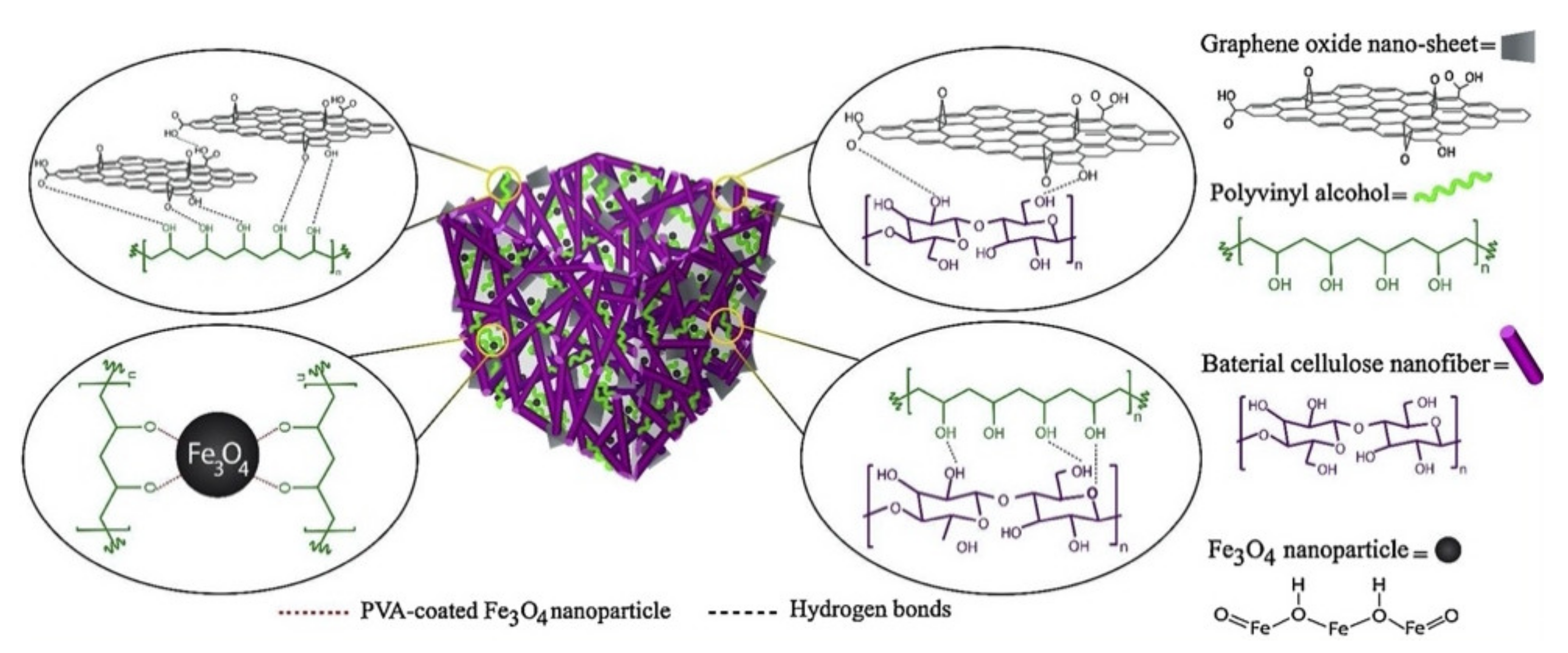

2.1. Adsorption at Graphene Oxide

2.2. Recovery of the GO Adsorbent

2.3. Immobilization of GO within Biopolymers

3. Chitosan as an Immobilization Matrix

4. Graphene/Chitosan Adsorbents

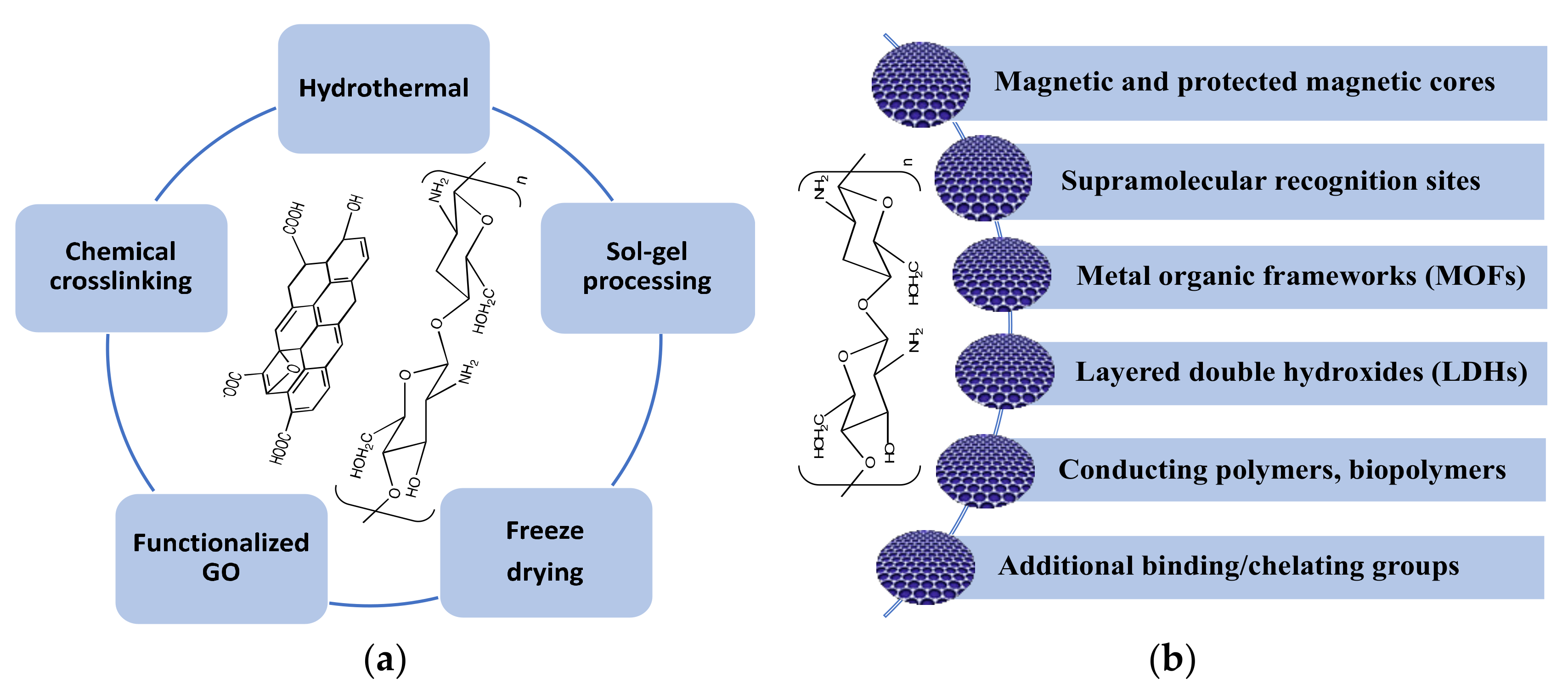

4.1. Formation of Graphene/Chitosan Adsorbents

| Crosslinking Agent | Crosslinking Conditions | Advantages/ Disadvantage | Ref. |

|---|---|---|---|

| Gluteraldehyde | 2% solution (wt %), 1 h at 60 °C | Inexpensive but exhibits toxicity | [148] |

| Gluteraldehyde | 1% solution (wt %), 6 h at 25 °C | [141] | |

| Gluteraldehyde | 2% solution (wt %), 8 h at 30 °C | [154] | |

| Glycidoxypropyltri-methoxysilane (KH-560) | 0.22 g KH-560 with 0.12 g GO, 1.5 g CS at 50 °C | Commonly used coupling agent, some toxicity | [155] |

| Genipin | 1% solution (wt %) added dropwise, 1 h at 25 °C | Negligible toxicity | [150] |

| Borax | 10% solution (wt%) 1 h at 25 °C | Toxic | [151] |

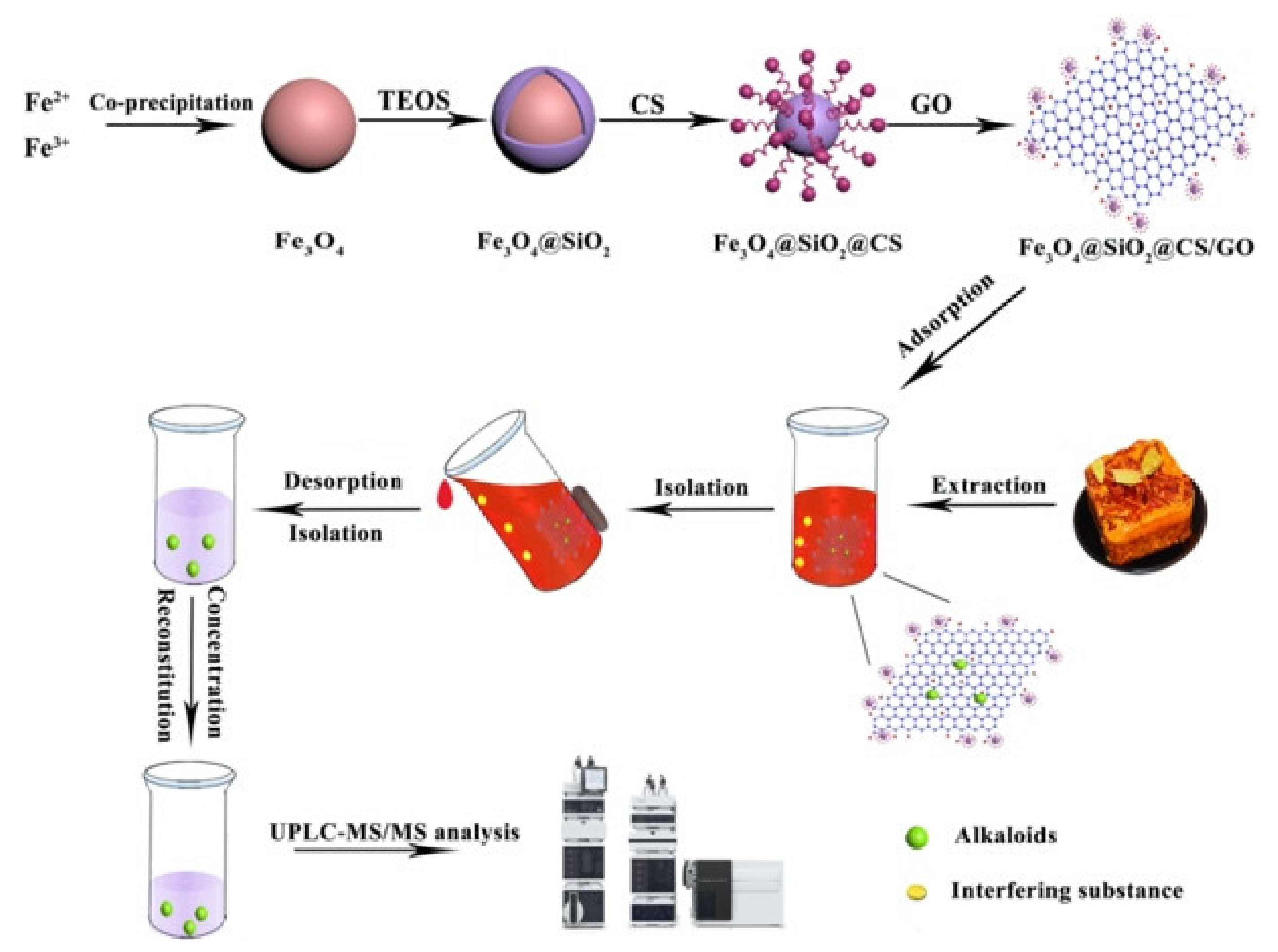

4.2. Magnetic Chitosan/GO

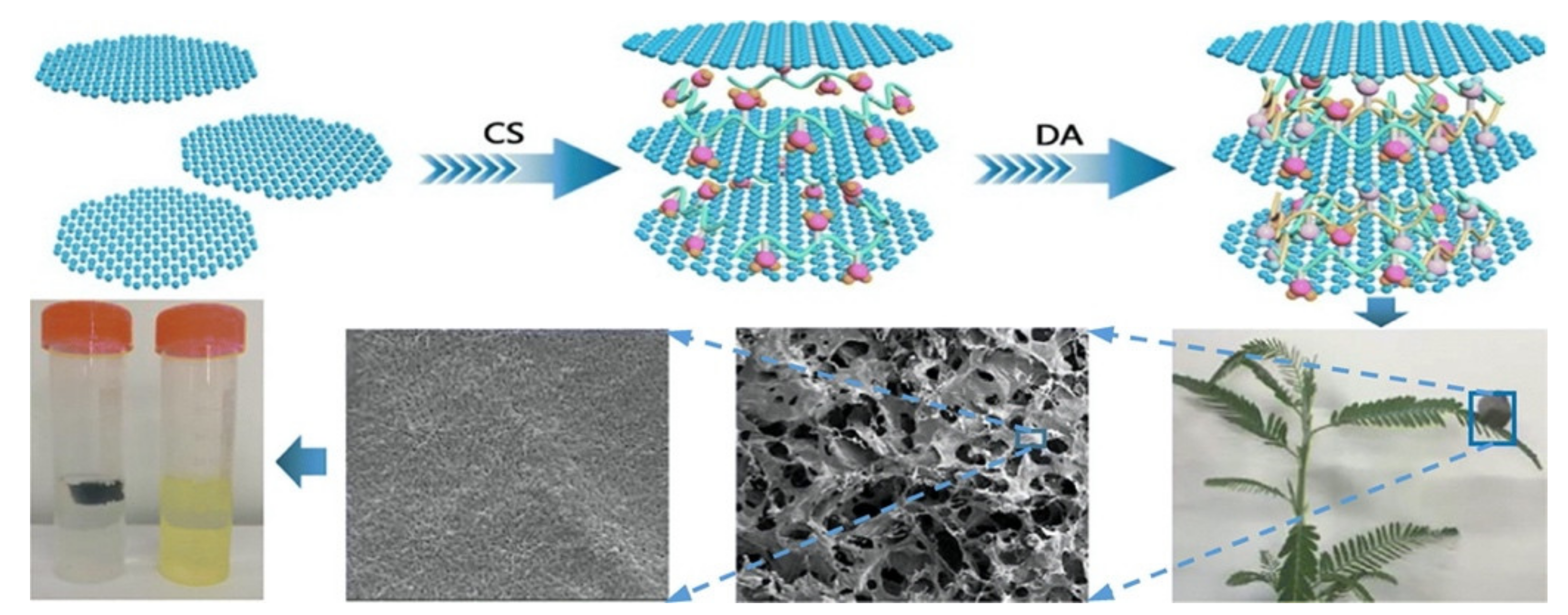

4.3. Chitosan/GO with 3D Architectures

4.4. GO/Chitosan and Additional Chelating Agents

| Chelating Agent | Adsorbent/Adsorption Experiment | Adsorbate | Adsorption qm (mg g−1) | Ref. |

|---|---|---|---|---|

| Ethylenediaminetetraacetic acid (EDTA) | MGO/CS/EDTA Batch, 25 °C, 180 rpm, 0.33 g/L adsorbate, V = 30 mL | Pb(II) Cu(II) As(III) | 206.5 207.3 42.7 | [179] |

| EDTA | GO/CS/EDTA Batch, 25 °C, 160 rpm, 20 mg adsorbent, V = 50 mL | Cr(VI) | 86.2 | [180] |

| EDTA | MGO/CS/EDTA Batch, 33 °C, 0.14 g/L adsorbent, 114 mg/L adsorbate | Rhodamine B | 1085.3 | [213] |

| EDTA | MGO/CS/EDTA Batch, 20 mg adsorbent, V = 15 mL | Pb(II) | 970 | [214] |

| EDTA | MGO/CS/EDTA Batch, 49.2 °C, 40 Hz sonication, 9.5 mg adsorbent, V = 50 mL | Pb(II) | 666.6 | [161] |

| Polydopamine (PDA) | GO/CS/Polyvinyl alcohol (PVA)/PDA Batch, 40 °C, 150 rpm, 50 mg adsorbate | Cu(II) Pb(II) Cd(II) | 210.9 236.2 214.9 | [215] |

| PDA | GO/CS/PDA aerogel Batch, 25 °C, 120 rpm, 0.3 g/L adsorbent | U(VI) | 415.9 | [216] |

| PDA | GO/CS/PDA Batch, 25 °C, 150 rpm, 15 mg adsorbent, V = 20 mL | Cr(VI) | 312.0 | [211] |

| PDA | MWCNT/PDA/GO/CS Batch, 25 °C, 10 mg adsorbent, V = 10 mL | Gd(I) | 150.8 | [217] |

| PDA | GO/CS/PDA Batch, 30 °C, adsorbate 500 mg/L, V = 100 mL | Cu(II) Ni(II) Pb(II) | 170.3 186.8 312.8 | [218] |

| Lignosulfonate (LS) | MGO/LS/CS Batch, 30 °C, 160 rpm, 10 mg adsorbent, V = 20 mL | Methylene blue | 50 | [186] |

| LS | GO/LS/CS Batch, 30 °C, 130 rpm, 0.2 g/L adsorbent, V = 25 mL | Methylene blue | 1023.9 | [143] |

4.5. GO/Chitosan Combined with Other Adsorbent Materials

4.6. GO/CS and Polymer Blending and Hybrids

5. Adsorption and Regeneration Processes

5.1. Adsorption Capacity

5.2. Regeneration Strategies

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brindha, K.; Schneider, M. Impact of urbanization on groundwater quality. In GIS and Geostatistical Techniques for Groundwater Science; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 179–196. ISBN 9780128154137. [Google Scholar]

- Brindha, K.; Paul, R.; Walter, J.; Tan, M.L.; Singh, M.K. Trace metals contamination in groundwater and implications on human health: Comprehensive assessment using hydrogeochemical and geostatistical methods. Environ. Geochem. Health 2020, 42, 3819–3839. [Google Scholar] [CrossRef] [PubMed]

- Anjum, M.; Miandad, R.; Waqas, M.; Gehany, F.; Barakat, M.A. Remediation of wastewater using various nano-materials. Arab. J. Chem. 2016, 12, 4897–4919. [Google Scholar] [CrossRef] [Green Version]

- Casagrande, T.; Lawson, G.; Li, H.; Wei, J.; Adronov, A.; Zhitomirsky, I. Electrodeposition of composite materials containing functionalized carbon nanotubes. Mater. Chem. Phys. 2008, 111, 42–49. [Google Scholar] [CrossRef]

- Hansima, M.A.C.K.; Makehelwala, M.; Jinadasa, K.B.S.N.; Wei, Y.; Nanayakkara, K.G.N.; Herath, A.C.; Weerasooriya, R. Fouling of ion exchange membranes used in the electrodialysis reversal advanced water treatment: A review. Chemosphere 2021, 263, 127951. [Google Scholar] [CrossRef]

- Kar, A.; Bahadur, V. Using excess natural gas for reverse osmosis-based flowback water treatment in US shale fields. Energy 2020, 196, 117145. [Google Scholar] [CrossRef]

- Saffari, R.; Shariatinia, Z.; Jourshabani, M. Synthesis and photocatalytic degradation activities of phosphorus containing ZnO microparticles under visible light irradiation for water treatment applications. Environ. Pollut. 2020, 259, 113902. [Google Scholar] [CrossRef]

- Vidotti, M.; Salvador, R.P.; Torresi, S.I.C.; Antonia, L.H.D. Electrocatalytic oxidation of urea by nanostructured nickel/cobalt hydroxide electrodes. Electrochim. Acta 2008, 53, 4030–4034. [Google Scholar] [CrossRef]

- Yu, T.; Breslin, C.B. Graphene-modified composites and electrodes and their potential applications in the electro-fenton process. Materials 2020, 13, 2254. [Google Scholar] [CrossRef]

- Daniele, C.; Alves, S.; Healy, B.; Pinto, L.A.D.A.; Sant, T.R.; Cadaval, A.; Breslin, C.B. Recent developments in chitosan-based adsorbents for the removal of pollutants from aqueous environments. Molecules 2021, 26, 594. [Google Scholar]

- Subha, R.; Sridevi, O.A.; Anitha, D.; Sudha, D. Treatment methods for the removal of phenol from water—A Review. In Proceedings of the International Conference on Systems, Science, Control, Communication, Engineering and Technology, Coimbatore, India, 10–11 August 2015; pp. 199–203. [Google Scholar]

- Chowdhury, S.; Balasubramanian, R. Recent advances in the use of graphene-family nanoadsorbents for removal of toxic pollutants from wastewater. Adv. Colloid Interface Sci. 2014, 204, 35–56. [Google Scholar] [CrossRef]

- Travlou, N.A.; Kyzas, G.Z.; Lazaridis, N.K.; Deliyanni, E.A. Graphite oxide/chitosan composite for reactive dye removal. Chem. Eng. J. 2013, 217, 256–265. [Google Scholar] [CrossRef]

- Zhang, Q.; Hou, Q.; Huang, G.; Fan, Q. Removal of heavy metals in aquatic environment by graphene oxide composites: A review. Environ. Sci. Pollut. Res. 2020, 27, 190–209. [Google Scholar] [CrossRef]

- Mishra, A.K.; Ramaprabhu, S. Carbon dioxide adsorption in graphene sheets. AIP Adv. 2011, 1. [Google Scholar] [CrossRef]

- Sui, Z.-Y.; Meng, Y.-N.; Xiao, P.-W.; Zhao, Z.-Q.; Wei, Z.-X.; Han, B.-H. Nitrogen-doped graphene aerogels as efficient supercapacitor electrodes and gas adsorbents. ACS Appl. Mater. Interfaces 2015, 7, 1431–1438. [Google Scholar] [CrossRef]

- Liu, F.; Chung, S.; Oh, G.; Seo, T.S. Three-dimensional graphene oxide nanostructure for fast and efficient water-soluble dye removal. ACS Appl. Mater. Interfaces 2012, 4, 922–927. [Google Scholar] [CrossRef]

- Guo, X.; Qu, L.; Tian, M.; Zhu, S.; Zhang, X.; Tang, X.; Sun, K. Chitosan/graphene oxide composite as an effective adsorbent for reactive red dye removal. Water Environ. Res. 2016, 88, 579–588. [Google Scholar] [CrossRef]

- Xing-yu, H.; Yu-kui, T.; Fu-gui, Z.H.U.; Qin-fei, X.I.A.; Miao-miao, T. Graphene oxide-based magnetic boronate-affinity adsorbent for extraction of Horseradish Peroxidase. Chin. J. Anal. Chem. 2020, 48, 20158–20164. [Google Scholar] [CrossRef]

- Sánchez-page, B.; Ana, M.P.; Jim, M.V.; Jesús, J.P.; Gonz, Z.; Fern, L.; Granda, M.; Men, R.; Blasco, J.; Subías, G.; et al. Influence of graphene sheet properties as supports of iridium-based N-heterocyclic carbene hybrid materials for water oxidation electrocatalysis. J. Organomet. Chem. J. 2020, 919, 121334. [Google Scholar] [CrossRef]

- Li, A.; Lin, R.; Lin, C.; He, B.; Zheng, T.; Lu, L.; Cao, Y. An environment-friendly and multi-functional absorbent from chitosan for organic pollutants and heavy metal ion. Carbohydr. Polym. 2016, 148, 272–280. [Google Scholar] [CrossRef]

- Karimi-Maleh, H.; Ayati, A.; Davoodi, R.; Tanhaei, B.; Karimi, F.; Malekmohammadi, S.; Orooji, Y.; Fu, L.; Sillanpää, M. Recent advances in using of chitosan-based adsorbents for removal of pharmaceutical contaminants: A review. J. Clean. Prod. 2021, 291, 125880. [Google Scholar] [CrossRef]

- Yusuf, M.; Elfghi, F.M.; Zaidi, S.A.; Abdullah, E.C.; Khan, M.A. Applications of graphene and its derivatives as an adsorbent for heavy metal and dye removal: A systematic and comprehensive overview. RSC Adv. 2015, 5, 50392–50420. [Google Scholar] [CrossRef]

- Kyzas, G.Z.; Deliyanni, E.A.; Matis, K.A. Graphene oxide and its application as an adsorbent for wastewater treatment. J. Chem. Technol. Biotechnol. 2014, 89, 196–205. [Google Scholar] [CrossRef]

- Peng, W.; Li, H.; Liu, Y.; Song, S. A review on heavy metal ions adsorption from water by graphene oxide and its composites. J. Mol. Liq. 2017, 230, 496–504. [Google Scholar] [CrossRef]

- Duru, İ.; Ege, D.; Kamali, A.R. Graphene oxides for removal of heavy and precious metals from wastewater. J. Mater. Sci. 2016, 51, 6097–6116. [Google Scholar] [CrossRef]

- Liu, X.; Ma, R.; Wang, X.; Ma, Y.; Yang, Y.; Zhuang, L.; Zhang, S.; Jehan, R.; Chen, J.; Wang, X. Graphene oxide-based materials for efficient removal of heavy metal ions from aqueous solution: A review. Environ. Pollut. 2019, 252, 62–73. [Google Scholar] [CrossRef]

- Sherlala, A.I.A.; Raman, A.A.A.; Bello, M.M.; Asghar, A. A review of the applications of organo-functionalized magnetic graphene oxide nanocomposites for heavy metal adsorption. Chemosphere 2018, 193, 1004–1017. [Google Scholar] [CrossRef]

- Lai, K.C.; Lee, L.Y.; Hiew, B.Y.Z.; Thangalazhy-Gopakumar, S.; Gan, S. Environmental application of three-dimensional graphene materials as adsorbents for dyes and heavy metals: Review on ice-templating method and adsorption mechanisms. J. Environ. Sci. 2019, 79, 174–199. [Google Scholar] [CrossRef]

- Lin, Y.; Tian, Y.; Sun, H.; Hagio, T. Progress in modifications of 3D graphene-based adsorbents for environmental applications. Chemosphere 2021, 270. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, B.; Ruan, T.; Chen, Y.; Jin, F.; Peng, L.; Zhou, Y.; Wang, D.; Dou, S. Graphene-based composites for electrochemical energy storage. Energy Storage Mater. 2020, 24, 22–51. [Google Scholar] [CrossRef]

- Tyagi, D.; Wang, H.; Huang, W.; Hu, L.; Tang, Y.; Guo, Z.; Ouyang, Z.; Zhang, H. Recent advances in two-dimensional-material-based sensing technology toward health and environmental monitoring applications. Nanoscale 2020, 12, 3535–3559. [Google Scholar] [CrossRef] [PubMed]

- Shu, R.; Zhang, J.; Guo, C.; Wu, Y.; Wan, Z.; Shi, J.; Liu, Y.; Zheng, M. Facile synthesis of nitrogen-doped reduced graphene oxide/nickel-zinc ferrite composites as high-performance microwave absorbers in the X-band. Chem. Eng. J. 2020, 384. [Google Scholar] [CrossRef]

- Rathi, B.S.; Kumar, P.S.; Show, P.-L. A review on effective removal of emerging contaminants from aquatic systems: Current trends and scope for further research. J. Hazard. Mater. 2021, 409. [Google Scholar] [CrossRef] [PubMed]

- Hussain, M.M.; Wang, J.; Bibi, I.; Shahid, M.; Niazi, N.K.; Iqbal, J.; Mian, I.A.; Shaheen, S.M.; Bashir, S.; Shah, N.S.; et al. Arsenic speciation and biotransformation pathways in the aquatic ecosystem: The significance of algae. J. Hazard. Mater. 2021, 403. [Google Scholar] [CrossRef]

- Rout, P.R.; Zhang, T.C.; Bhunia, P.; Surampalli, R.Y. Treatment technologies for emerging contaminants in wastewater treatment plants: A review. Sci. Total Environ. 2021, 753. [Google Scholar] [CrossRef]

- Somani, P.R.; Somani, S.P.; Umeno, M. Planer nano-graphenes from camphor by CVD. Chem. Phys. Lett. 2006, 430, 56–59. [Google Scholar] [CrossRef]

- Gao, L.; Guest, J.R.; Guisinger, N.P. Epitaxial graphene on Cu(111). Nano Lett. 2010, 10, 3512–3516. [Google Scholar] [CrossRef]

- Dreyer, D.R.; Park, S.; Bielawski, C.W.; Ruoff, R.S. The chemistry of graphene oxide. Chem. Soc. Rev. 2010, 39, 228–240. [Google Scholar] [CrossRef]

- Hummers, W.S.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Eda, G.; Chhowalla, M. Chemically derived graphene oxide: Towards large-area thin-film electronics and optoelectronics. Adv. Mater. 2010, 22, 2392–2415. [Google Scholar] [CrossRef]

- Adeel, M.; Bilal, M.; Rasheed, T.; Sharma, A.; Iqbal, H.M.N. Graphene and graphene oxide: Functionalization and nano-bio-catalytic system for enzyme immobilization and biotechnological perspective. Int. J. Biol. Macromol. 2018, 120, 1430–1440. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J.; Han, L.; Wang, J.; Zhu, L.; Zeng, H. Graphene-based materials for adsorptive removal of pollutants from water and underlying interaction mechanism. Adv. Colloid Interface Sci. 2021, 289. [Google Scholar] [CrossRef]

- Cong, H.-P.; Chen, J.-F.; Yu, S.-H. Graphene-based macroscopic assemblies and architectures: An emerging material system. Chem. Soc. Rev. 2014, 43, 7295–7325. [Google Scholar] [CrossRef]

- Wang, S.; Li, X.; Liu, Y.; Zhang, C.; Tan, X.; Zeng, G.; Song, B.; Jiang, L. Nitrogen-containing amino compounds functionalized graphene oxide: Synthesis, characterization and application for the removal of pollutants from wastewater: A review. J. Hazard. Mater. 2018, 342, 177–191. [Google Scholar] [CrossRef]

- Ai, L.; Zhang, C.; Chen, Z. Removal of methylene blue from aqueous solution by a solvothermal-synthesized graphene/magnetite composite. J. Hazard. Mater. 2011, 192, 1515–1524. [Google Scholar] [CrossRef]

- Cheng, L.; Ji, Y.; Liu, X. Insights into interfacial interaction mechanism of dyes sorption on a novel hydrochar: Experimental and DFT study. Chem. Eng. Sci. 2021, 233. [Google Scholar] [CrossRef]

- Ramesha, G.K.; Vijaya Kumara, A.; Muralidhara, H.B.; Sampath, S. Graphene and graphene oxide as effective adsorbents toward anionic and cationic dyes. J. Colloid Interface Sci. 2011, 361, 270–277. [Google Scholar] [CrossRef]

- Xing, H.T.; Chen, J.H.; Sun, X.; Huang, Y.H.; Su, Z.B.; Hu, S.R.; Weng, W.; Li, S.X.; Guo, H.X.; Wu, W.B.; et al. NH2-rich polymer/graphene oxide use as a novel adsorbent for removal of Cu(II) from aqueous solution. Chem. Eng. J. 2015, 263, 280–289. [Google Scholar] [CrossRef]

- Li, D.; Huang, J.; Huang, L.; Tan, S.; Liu, T. High-performance three-dimensional aerogel based on hydrothermal pomelo peel and reduced graphene oxide as an efficient adsorbent for water/oil separation. Langmuir 2021, 37, 1521–1530. [Google Scholar] [CrossRef]

- Ge, H.; Zou, W. Preparation and characterization of L-glutamic acid-functionalized graphene oxide for adsorption of Pb(II). J. Dispers. Sci. Technol. 2017, 38, 241–247. [Google Scholar] [CrossRef]

- Basadi, N.; Ghanemi, K.; Nikpour, Y. l-Cystine-functionalized graphene oxide nanosheets for effective extraction and preconcentration of mercury ions from environmental waters. Chem. Pap. 2021, 75, 1083–1093. [Google Scholar] [CrossRef]

- Verma, S.; Dutta, R.K. Development of cysteine amide reduced graphene oxide (CARGO) nano-adsorbents for enhanced uranyl ions removal from aqueous medium. J. Environ. Chem. Eng. 2017, 5, 4547–4558. [Google Scholar] [CrossRef]

- Zhang, C.-Z.; Yuan, Y.; Guo, Z. Experimental study on functional graphene oxide containing many primary amino groups fast-adsorbing heavy metal ions and adsorption mechanism. Sep. Sci. Technol. 2018, 53, 1666–1677. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, X.; Wang, Y.; Shan, W.; Lou, Z.; Xiong, Y. A thiourea cross-linked three-dimensional graphene aerogel as a broad-spectrum adsorbent for dye and heavy metal ion removal. New J. Chem. 2020, 44, 16285–16293. [Google Scholar] [CrossRef]

- Janik, P.; Zawisza, B.; Talik, E.; Sitko, R. Selective adsorption and determination of hexavalent chromium ions using graphene oxide modified with amino silanes. Microchim. Acta 2018, 185. [Google Scholar] [CrossRef] [Green Version]

- Suddai, A.; Nuengmatcha, P.; Sricharoen, P.; Limchoowong, N.; Chanthai, S. Feasibility of hard acid-base affinity for the pronounced adsorption capacity of manganese(II) using amino-functionalized graphene oxide. RSC Adv. 2018, 8, 4162–4171. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Liu, L.; Jiang, X.; Yu, J.; Chen, X. Adsorption and removal of malachite green from aqueous solution using magnetic β-cyclodextrin-graphene oxide nanocomposites as adsorbents. Colloids Surf. A Physicochem. Eng. Asp. 2015, 466, 166–173. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y.-G.; Zeng, G.-M.; Hu, X.-J.; Hu, X.; Li, T.-T.; Li, H.-Y.; Wang, Y.-Q.; Jiang, L.-H. Grafting of β-cyclodextrin to magnetic graphene oxide via ethylenediamine and application for Cr(VI) removal. Carbohydr. Polym. 2014, 113, 166–173. [Google Scholar] [CrossRef]

- Liu, X.; Yan, L.; Yin, W.; Zhou, L.; Tian, G.; Shi, J.; Yang, Z.; Xiao, D.; Gu, Z.; Zhao, Y. A magnetic graphene hybrid functionalized with beta-cyclodextrins for fast and efficient removal of organic dyes. J. Mater. Chem. A 2014, 2, 12296–12303. [Google Scholar] [CrossRef]

- Del Valle, E.M.M. Cyclodextrins and their uses: A review. Process Biochem. 2004, 39, 1033–1046. [Google Scholar] [CrossRef]

- Crini, G. Review: A history of cyclodextrins. Chem. Rev. 2014, 114, 10940–10975. [Google Scholar] [CrossRef]

- Challa, R.; Ahuja, A.; Ali, J.; Khar, R.K. Cyclodextrins in drug delivery: An updated review. AAPS PharmSciTech 2005, 6. [Google Scholar] [CrossRef]

- Zhao, Y.; Zheng, X.; Wang, Q.; Zhe, T.; Bai, Y.; Bu, T.; Zhang, M.; Wang, L. Electrochemical behavior of reduced graphene oxide/cyclodextrins sensors for ultrasensitive detection of imidacloprid in brown rice. Food Chem. 2020, 333. [Google Scholar] [CrossRef]

- Healy, B.; Yu, T.; da Silva Alves, D.C.; Okeke, C.; Breslin, C.B. Cyclodextrins as supramolecular recognition systems: Applications in the fabrication of electrochemical sensors. Materials 2021, 14, 1668. [Google Scholar] [CrossRef]

- Crini, G.; Morcellet, M. Synthesis and applications of adsorbents containing cyclodextrins. J. Sep. Sci. 2002, 25, 789–813. [Google Scholar] [CrossRef]

- Nie, Z.-J.; Guo, Q.-F.; Xia, H.; Song, M.-M.; Qiu, Z.-J.; Fan, S.-T.; Chen, Z.-H.; Zhang, S.-X.; Zhang, S.; Li, B.-J. Cyclodextrin self-assembled graphene oxide aerogel microspheres as broad-spectrum adsorbent for removing dyes and organic micropollutants from water. J. Environ. Chem. Eng. 2021, 9. [Google Scholar] [CrossRef]

- Zhong, Y.; He, Y.; Ge, Y.; Song, G. β-Cyclodextrin protected Cu nanoclusters as a novel fluorescence sensor for graphene oxide in environmental water samples. Luminescence 2017, 32, 596–601. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, X.; Liu, X.; Wu, J.; Zhu, X.; Bai, Z.; Yu, Z. Preparation of β-cyclodextrin/graphene oxide and its adsorption properties for methylene blue. Colloids Surf. B Biointerfaces 2021, 200. [Google Scholar] [CrossRef]

- Gupta, V.K.; Agarwal, S.; Sadegh, H.; Ali, G.A.M.; Bharti, A.K.; Hamdy Makhlouf, A.S. Facile route synthesis of novel graphene oxide-β-cyclodextrin nanocomposite and its application as adsorbent for removal of toxic bisphenol A from the aqueous phase. J. Mol. Liq. 2017, 237, 466–472. [Google Scholar] [CrossRef] [Green Version]

- Tan, P.; Hu, Y. Improved synthesis of graphene/β-cyclodextrin composite for highly efficient dye adsorption and removal. J. Mol. Liq. 2017, 242, 181–189. [Google Scholar] [CrossRef]

- Samuel, M.S.; Selvarajan, E.; Subramaniam, K.; Mathimani, T.; Seethappan, S.; Pugazhendhi, A. Synthesized β-cyclodextrin modified graphene oxide (β-CD-GO) composite for adsorption of cadmium and their toxicity profile in cervical cancer (HeLa) cell lines. Process Biochem. 2020, 93, 28–35. [Google Scholar] [CrossRef]

- Tian, H.; Zeng, H.; Zha, F.; Tian, H.; Chang, Y. Synthesis of graphene oxide–supported β-cyclodextrin adsorbent for removal of p-nitrophenol. Water. Air. Soil Pollut. 2020, 231. [Google Scholar] [CrossRef]

- Liu, J.; Liu, G.; Liu, W. Preparation of water-soluble β-cyclodextrin/poly(acrylic acid)/graphene oxide nanocomposites as new adsorbents to remove cationic dyes from aqueous solutions. Chem. Eng. J. 2014, 257, 299–308. [Google Scholar] [CrossRef]

- Jiang, L.; Liu, Y.; Liu, S.; Hu, X.; Zeng, G.; Hu, X.; Liu, S.; Liu, S.; Huang, B.; Li, M. Fabrication of β-cyclodextrin/poly (L-glutamic acid) supported magnetic graphene oxide and its adsorption behavior for 17β-estradiol. Chem. Eng. J. 2017, 308, 597–605. [Google Scholar] [CrossRef]

- Boulanouar, S.; Mezzache, S.; Combès, A.; Pichon, V. Molecularly imprinted polymers for the determination of organophosphorus pesticides in complex samples. Talanta 2018, 176, 465–478. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cheng, L.; Pan, S.; Ding, C.; He, J.; Wang, C. Dispersive solid-phase microextraction with graphene oxide based molecularly imprinted polymers for determining bis(2-ethylhexyl) phthalate in environmental water. J. Chromatogr. A 2017, 1511, 85–91. [Google Scholar] [CrossRef]

- Xu, K.; Wang, X.; Lu, C.; Liu, Y.; Zhang, D.; Cheng, J. Toxicity of three carbon-based nanomaterials to earthworms: Effect of morphology on biomarkers, cytotoxicity, and metabolomics. Sci. Total Environ. 2021, 777. [Google Scholar] [CrossRef]

- Malhotra, N.; Villaflores, O.B.; Audira, G.; Siregar, P.; Lee, J.-S.; Ger, T.-R.; Hsiao, C.-D. Toxicity studies on graphene-based nanomaterials in aquatic organisms: Current understanding. Molecules 2020, 25, 3618. [Google Scholar] [CrossRef]

- Dasmahapatra, A.K.; Dasari, T.P.S.; Tchounwou, P.B. Graphene-Based Nanomaterials Toxicity in Fish. Rev. Environ. Contam. Toxicol. 2019, 247, 1–58. [Google Scholar]

- Martínez-Álvarez, I.; Le Menach, K.; Devier, M.-H.; Barbarin, I.; Tomovska, R.; Cajaraville, M.P.; Budzinski, H.; Orbea, A. Uptake and effects of graphene oxide nanomaterials alone and in combination with polycyclic aromatic hydrocarbons in zebrafish. Sci. Total Environ. 2021, 775. [Google Scholar] [CrossRef]

- Shi, Y.-C.; Wang, A.-J.; Wu, X.-L.; Chen, J.-R.; Feng, J.-J. Green-assembly of three-dimensional porous graphene hydrogels for efficient removal of organic dyes. J. Colloid Interface Sci. 2016, 484, 254–262. [Google Scholar] [CrossRef]

- Weng, D.; Song, L.; Li, W.; Yan, J.; Chen, L.; Liu, Y. Review on synthesis of three-dimensional graphene skeletons and their absorption performance for oily wastewater. Environ. Sci. Pollut. Res. 2021, 28, 16–34. [Google Scholar] [CrossRef]

- Arabkhani, P.; Asfaram, A. Development of a novel three-dimensional magnetic polymer aerogel as an efficient adsorbent for malachite green removal. J. Hazard. Mater. 2020, 384. [Google Scholar] [CrossRef]

- Kabiri, S.; Tran, D.N.H.; Cole, M.A.; Losic, D. Functionalized three-dimensional (3D) graphene composite for high efficiency removal of mercury. Environ. Sci. Water Res. Technol. 2016, 2, 390–402. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhu, X.; Chen, B. Stable graphene oxide/poly(ethyleneimine) 3D aerogel with tunable surface charge for high performance selective removal of ionic dyes from water. Chem. Eng. J. 2018, 334, 1119–1127. [Google Scholar] [CrossRef]

- Rashidi Nodeh, H.; Sereshti, H.; Gaikani, H.; Kamboh, M.A.; Afsharsaveh, Z. Magnetic graphene coated inorganic-organic hybrid nanocomposite for enhanced preconcentration of selected pesticides in tomato and grape. J. Chromatogr. A 2017, 1509, 26–34. [Google Scholar] [CrossRef]

- Geng, Z.; Lin, Y.; Yu, X.; Shen, Q.; Ma, L.; Li, Z.; Pan, N.; Wang, X. Highly efficient dye adsorption and removal: A functional hybrid of reduced graphene oxide-Fe3O4 nanoparticles as an easily regenerative adsorbent. J. Mater. Chem. 2012, 22, 3527–3535. [Google Scholar] [CrossRef]

- Deng, J.-H.; Zhang, X.-R.; Zeng, G.-M.; Gong, J.-L.; Niu, Q.-Y.; Liang, J. Simultaneous removal of Cd(II) and ionic dyes from aqueous solution using magnetic graphene oxide nanocomposite as an adsorbent. Chem. Eng. J. 2013, 226, 189–200. [Google Scholar] [CrossRef]

- Gul, K.; Sohni, S.; Waqar, M.; Ahmad, F.; Norulaini, N.A.N.; AK, M.O. Functionalization of magnetic chitosan with graphene oxide for removal of cationic and anionic dyes from aqueous solution. Carbohydr. Polym. 2016, 152, 520–531. [Google Scholar] [CrossRef]

- Kharissova, O.V.; Dias, H.V.R.; Kharisov, B.I. Magnetic adsorbents based on micro- and nano-structured materials. RSC Adv. 2015, 5, 6695–6719. [Google Scholar] [CrossRef]

- Sahraei, R.; Sekhavat Pour, Z.; Ghaemy, M. Novel magnetic bio-sorbent hydrogel beads based on modified gum tragacanth/graphene oxide: Removal of heavy metals and dyes from water. J. Clean. Prod. 2017, 142, 2973–2984. [Google Scholar] [CrossRef]

- Li, J.; Ma, J.; Chen, S.; Huang, Y.; He, J. Adsorption of lysozyme by alginate/graphene oxide composite beads with enhanced stability and mechanical property. Mater. Sci. Eng. C 2018, 89, 25–32. [Google Scholar] [CrossRef]

- Szymańska, E.; Winnicka, K. Stability of chitosan—A challenge for pharmaceutical and biomedical applications. Mar. Drugs 2015, 13, 1819–1846. [Google Scholar] [CrossRef]

- Wu, Z.; Huang, W.; Shan, X.; Li, Z. Preparation of a porous graphene oxide/alkali lignin aerogel composite and its adsorption properties for methylene blue. Int. J. Biol. Macromol. 2020, 143, 325–333. [Google Scholar] [CrossRef]

- Kyzasa, G.Z.; Deliyannib, E.A.; Bikiarisb, D.N.; Mitropoulos, A.C. Graphene composites as dye adsorbents: Review. Chem. Eng. Res. Des. 2017, 129, 75–88. [Google Scholar] [CrossRef]

- Dotto, G.L.; Pinto, L.A.A. General considerations about chitosan. In Frontiers in Biomaterials; Bentham Science: Sharjah, United Arab Emirates, 2017; pp. 3–33. [Google Scholar]

- Rodrigues, D.A.S.; Moura, J.M.; Dotto, G.L.; Cadaval, T.R.S.; Pinto, L.A.A. Preparation, characterization and dye adsorption/reuse of chitosan-vanadate films. J. Polym. Environ. 2018, 26, 2917–2924. [Google Scholar] [CrossRef]

- Alves, D.C.S.; Coseglio, B.B.; Pinto, L.A.A.; Cadaval, T.R.S. Development of Spirulina/chitosan foam adsorbent for phenol adsorption. J. Mol. Liq. 2020, 309, 113256. [Google Scholar] [CrossRef]

- Gerhardt, R.; Farias, B.S.; Moura, J.M.; De Almeida, L.S.; Adriano, R.; Dias, D.; Cadaval, T.R.S.; Pinto, L.A.A. Development of chitosan/Spirulina sp. blend films as biosorbents for Cr6+ and Pb2+ removal. Int. J. Biol. Macromol. 2020, 155, 142–152. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Wang, X.; Zhang, X.; Yang, Y.; Duan, J. A high-efficiency and plane-enhanced chitosan film for cefotaxime adsorption compared with chitosan particles in water. Chem. Eng. J. 2020. [Google Scholar] [CrossRef]

- Firozjaee, T.T.; Mehrdadi, N.; Baghdadi, M.; Nabi Bidhendi, G.R.N. The removal of diazinon from aqueous solution by chitosan/carbon nanotube adsorbent. Desalin. Water Treat. 2017, 79, 291–300. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Li, C.; Bao, C.; Jia, Q.; Xiao, P.; Liu, X.; Zhang, Q. Preparation and characterization of chitosan/graphene oxide composites for the adsorption of Au(III) and Pd(II). Talanta 2012, 93, 350–357. [Google Scholar] [CrossRef]

- Jiménez-Gómez, C.P.; Cecilia, J.A. Chitosan: A Natural Biopolymer with a Wide and Varied Range of Applications. Molecules 2020, 25, 3981. [Google Scholar] [CrossRef]

- Affonso, L.N.; Marques, J.L.; Lima, V.V.C.; Gonçalves, J.O.; Barbosa, S.C.; Primel, E.G.; Burgo, T.A.L.; Dotto, G.L.; Pinto, L.A.A.; Cadaval, T.R.S. Removal of fluoride from fertilizer industry effluent using carbon nanotubes stabilized in chitosan sponge. J. Hazard. Mater. 2020, 388. [Google Scholar] [CrossRef]

- Gonçalves, J.O.; Santos, J.P.; Rios, E.C.; Crispim, M.M.; Dotto, G.L.; Pinto, L.A.A. Development of chitosan based hybrid hydrogels for dyes removal from aqueous binary system. J. Mol. Liq. 2017, 225, 265–270. [Google Scholar] [CrossRef]

- Crini, G.; Badot, P.M. Application of chitosan, a natural aminopolysaccharide, for dye removal from aqueous solutions by adsorption processes using batch studies: A review of recent literature. Prog. Polym. Sci. 2008, 33, 399–447. [Google Scholar] [CrossRef]

- Akpan, E.I.; Gbenebor, O.P.; Adeosun, S.O.; Cletus, O. Solubility, degree of acetylation, and distribution of acetyl groups in chitosan. In Handbook of Chitin and Chitosan; Elsevier: Amsterdam, The Netherlands, 2020; pp. 131–164. ISBN 9780128179703. [Google Scholar]

- Zhou, H.Y.; Guang, X.; Kong, M.; Sheng, C.; Su, D.; Kennedy, J.F. Effect of molecular weight and degree of chitosan deacetylation on the preparation and characteristics of chitosan thermosensitive hydrogel as a delivery system. Carbohydrate 2008, 73, 265–273. [Google Scholar] [CrossRef]

- Nunthanid, J.; Puttipipatkhachorn, S.; Yamamoto, K.; Peck, G.E. Physical properties and molecular behavior of chitosan films. Drug Dev. Ind. Pharm. 2001, 27, 143–157. [Google Scholar] [CrossRef]

- Bof, M.J.; Bordadgaray, V.C.; Locaso, D.E.; García, M.A. Chitosan molecular weight effect on starch-composite film properties. Food Hydrocoll. 2015, 51, 281–294. [Google Scholar] [CrossRef]

- Habiba, U.; Chin, T.; Siddique, T.A.; Salleh, A.; Chin, B.; Afifi, A.M. Effect of degree of deacetylation of chitosan on adsorption capacity and reusability of chitosan / polyvinyl alcohol / TiO2 nano composite. Int. J. Biol. Macromol. 2017, 104, 1133–1142. [Google Scholar] [CrossRef]

- Moura, J.M.; Farias, B.S.; Rodrigues, D.A.S. Preparation of chitosan with different characteristics and its application for bofilms production. J. Polym. Environ. 2015, 23, 470–477. [Google Scholar] [CrossRef]

- Tavares, L.; Emanuel, E.; Flores, E.; Rodrigues, R.C.; Hertz, P.F. Effect of deacetylation degree of chitosan on rheological properties and physical chemical characteristics of genipin-crosslinked chitosan beads. Food Hydrocoll. 2020, 106. [Google Scholar] [CrossRef]

- Gupta, K.C.; Jabrail, F.H. Effects of degree of deacetylation and cross-linking on physical characteristics, swelling and release behavior of chitosan microspheres. Carbohydr. Polym. 2006, 66, 43–54. [Google Scholar] [CrossRef]

- Gonçalves, J.O.; Duarte, D.A.; Dotto, G.L.; Pinto, L.A.A. Use of chitosan with different deacetylation degrees for the adsorption of food dyes in a binary system. Clean Soil Air Water 2013, 9, 767–774. [Google Scholar] [CrossRef]

- Piccin, J.S.; Vieira, M.L.G.; Gonçalves, J.O.; Dotto, G.L.; Pinto, L.A.A. Adsorption of FD & C Red No. 40 by chitosan: Isotherms analysis. J. Food Eng. 2009, 95, 16–20. [Google Scholar] [CrossRef]

- Zhu, H.; Fu, Y.; Jiang, R.; Yao, J.; Liu, L.; Chen, Y.; Xiao, L.; Zeng, G. Preparation, characterization and adsorption properties of chitosan modified magnetic graphitized multi-walled carbon nanotubes for highly effective removal of a carcinogenic dye from aqueous solution. Appl. Surf. Sci. 2013, 285, 865–873. [Google Scholar] [CrossRef]

- Iamsamai, C.; Hannongbua, S.; Ruktanonchai, U. The effect of the degree of deacetylation of chitosan on its dispersion of carbon nanotubes. Carbon 2010, 48, 25–30. [Google Scholar] [CrossRef]

- Gonçalves, J.O.; Esquerdo, V.M.; Cadaval, T.R.S.; Pinto, L.A.A. Chitosan-based hydrogels. In Sustainable Agriculture Reviews 36; Springer: Aix-en-Provence, France, 2019; pp. 49–123. ISBN 9783540228608. [Google Scholar]

- Pillai, C.K.S.; Paul, W.; Sharma, C.P. Chitin and chitosan polymers: Chemistry, solubility and fiber formation. Prog. Polym. Sci. 2009, 34, 641–678. [Google Scholar] [CrossRef]

- Kubota, N.; Eguchi, Y. Facile preparation of water-soluble N-acetylated chitosan and molecular weight dependence of its water-solubility. Polym. J. 1997, 29, 123–127. [Google Scholar] [CrossRef] [Green Version]

- Chang, S.H.; Lin, H.T.V.; Wu, G.J.; Tsai, G.J. pH Effects on solubility, zeta potential, and correlation between antibacterial activity and molecular weight of chitosan. Carbohydr. Polym. 2015, 134, 74–81. [Google Scholar] [CrossRef]

- Rinaudo, M.; Pavlov, G.; Desbrières, J. Solubilization of chitosan in strong acid medium. Int. J. Polym. Anal. Charact. 1999, 5, 267–276. [Google Scholar] [CrossRef]

- Lu, S.; Song, X.; Cao, D.; Chen, Y.; Yao, K. Preparation of water-soluble chitosan. J. Appl. Polym. Sci. 2004, 91, 3497–3503. [Google Scholar] [CrossRef]

- Esquerdo, V.M.; Cadaval, T.R.S.; Dotto, G.L.; Pinto, L.A.A. Chitosan scaffold as an alternative adsorbent for the removal of hazardous food dyes from aqueous solutions. J. Colloid Interface Sci. 2014, 424, 7–15. [Google Scholar] [CrossRef] [Green Version]

- Zhang, D.; Wang, L.; Zeng, H.; Yan, P.; Nie, J.; Sharma, V.K. A three-dimensional macroporous network structured chitosan / cellulose biocomposite sponge for rapid and selective removal of mercury (II) ions from aqueous solution. Chem. Eng. J. 2019, 363, 192–202. [Google Scholar] [CrossRef]

- Sirajudheen, P.; Karthikeyan, P.; Ramkumar, K.; Meenakshi, S. Effective removal of organic pollutants by adsorption onto chitosan supported graphene oxide-hydroxyapatite composite: A novel reusable adsorbent. J. Mol. Liq. 2020, 318. [Google Scholar] [CrossRef]

- Zhang, H.; Dang, Q.; Liu, C.; Cha, D.; Yu, Z.; Zhu, W.; Fan, B. Uptake of Pb(II) and Cd(II) on chitosan microsphere surface successively grafted by methyl acrylate and diethylenetriamine. ACS Appl. Mater. Interfaces 2017, 9, 11144–11155. [Google Scholar] [CrossRef]

- Dragan, E.S.; Dinu, M.V. Advances in porous chitosan-based composite hydrogels: Synthesis and applications Ecaterina. React. Funct. Polym. 2019, 146, 104372. [Google Scholar] [CrossRef]

- Pakdel, P.M.; Peighambardoust, S.J. Review on recent progress in chitosan-based hydrogels for wastewater treatment application. Carbohydr. Polym. 2018, 201, 264–279. [Google Scholar] [CrossRef]

- Saheed, O.I.; Oh, D.W.; Suah, M.B.F. Chitosan modifications for adsorption of pollutants—A review. J. Hazard. Mater. 2021, 408, 124889. [Google Scholar] [CrossRef]

- Lai, K.C.; Lee, L.Y.; Hiew, B.Y.Z.; Yang, T.C.-K.; Pan, G.-T.; Thangalazhy-Gopakumar, S.; Gan, S. Utilisation of eco-friendly and low cost 3D graphene-based composite for treatment of aqueous Reactive Black 5 dye: Characterisation, adsorption mechanism and recyclability studies. J. Taiwan Inst. Chem. Eng. 2020, 114, 57–66. [Google Scholar] [CrossRef]

- Yang, A.; Yang, P.; Huang, C.P. Preparation of graphene oxide–chitosan composite and adsorption performance for uranium. J. Radioanal. Nucl. Chem. 2017, 313, 371–378. [Google Scholar] [CrossRef]

- Kamal, S.; Khan, F.; Kausar, H.; Khan, M.S.; Ahmad, A.; Ishraque Ahmad, S.; Asim, M.; Alshitari, W.; Nami, S.A.A. Synthesis, characterization, morphology, and adsorption studies of ternary nanocomposite comprising graphene oxide, chitosan, and polypyrrole. Polym. Compos. 2020, 41, 3758–3767. [Google Scholar] [CrossRef]

- Mohseni Kafshgari, M.; Tahermansouri, H. Development of a graphene oxide/chitosan nanocomposite for the removal of picric acid from aqueous solutions: Study of sorption parameters. Colloids Surf. B Biointerfaces 2017, 160, 671–681. [Google Scholar] [CrossRef] [PubMed]

- Rinaudo, M. Chitin and chitosan: Properties and applications. Prog. Polym. Sci. 2006, 31, 603–632. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, L.; Bai, H.; Li, L. Graphene oxide-chitosan composite hydrogels as broad-spectrum adsorbents for water purification. J. Mater. Chem. A 2013, 1, 1992–2001. [Google Scholar] [CrossRef]

- Wu, K.; Liu, X.; Li, Z.; Jiao, Y.; Zhou, C. Fabrication of chitosan/graphene oxide composite aerogel microspheres with high bilirubin removal performance. Mater. Sci. Eng. C 2020, 106. [Google Scholar] [CrossRef]

- Luo, J.; Fan, C.; Xiao, Z.; Sun, T.; Zhou, X. Novel graphene oxide/carboxymethyl chitosan aerogels via vacuum-assisted self-assembly for heavy metal adsorption capacity. Colloids Surf. A Physicochem. Eng. Asp. 2019, 578. [Google Scholar] [CrossRef]

- Zhang, M.; Ma, G.; Zhang, L.; Chen, H.; Zhu, L.; Wang, C.; Liu, X. Chitosan-reduced graphene oxide composites with 3D structures as effective reverse dispersed solid phase extraction adsorbents for pesticides analysis. Analyst 2019, 144, 5164–5171. [Google Scholar] [CrossRef]

- Yang, X.; Tu, Y.; Li, L.; Shang, S.; Tao, X.-M. Well-dispersed chitosan/graphene oxide nanocomposites. ACS Appl. Mater. Interfaces 2010, 2, 1707–1713. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, M.; Jiang, H.; Shi, J.; Li, F.; Xia, Y.; Zhang, G.; Li, H. Bio-inspired layered chitosan/graphene oxide nanocomposite hydrogels with high strength and pH-driven shape memory effect. Carbohydr. Polym. 2017, 177, 116–125. [Google Scholar] [CrossRef]

- Wang, Y.; Xia, G.; Wu, C.; Sun, J.; Song, R.; Huang, W. Porous chitosan doped with graphene oxide as highly effective adsorbent for methyl orange and amido black 10B. Carbohydr. Polym. 2015, 115, 686–693. [Google Scholar] [CrossRef]

- Yan, M.; Huang, W.; Li, Z. Chitosan cross-linked graphene oxide/lignosulfonate composite aerogel for enhanced adsorption of methylene blue in water. Int. J. Biol. Macromol. 2019, 136, 927–935. [Google Scholar] [CrossRef]

- Han Lyn, F.; Tan, C.P.; Zawawi, R.M.; Nur Hanani, Z.A. Enhancing the mechanical and barrier properties of chitosan/graphene oxide composite films using trisodium citrate and sodium tripolyphosphate crosslinkers. J. Appl. Polym. Sci. 2021, 138. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, X.; Zhu, J.; Bai, J.; Gao, L.; Liu, S.; Jiao, T. Facile preparation of self-assembled chitosan-based composite hydrogels with enhanced adsorption performances. Colloids Surf. A Physicochem. Eng. Asp. 2020, 598. [Google Scholar] [CrossRef]

- Vlasceanu, G.M.; Crica, L.E.; Pandele, A.M.; Ionita, M. Graphene oxide reinforcing genipin crosslinked chitosan-gelatin blend films. Coatings 2020, 10, 189. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Liu, R.; Li, M.; Yu, F.; He, C. Removal of pharmaceuticals by novel magnetic genipin-crosslinked chitosan/graphene oxide-SO3H composite. Carbohydr. Polym. 2019, 220, 141–148. [Google Scholar] [CrossRef]

- Yan, N.; Capezzuto, F.; Lavorgna, M.; Buonocore, G.G.; Tescione, F.; Xia, H.; Ambrosio, L. Borate cross-linked graphene oxide-chitosan as robust and high gas barrier films. Nanoscale 2016, 8, 10783–10791. [Google Scholar] [CrossRef] [Green Version]

- Ruan, J.; Wang, X.; Yu, Z.; Wang, Z.; Xie, Q.; Zhang, D.; Huang, Y.; Zhou, H.; Bi, X.; Xiao, C.; et al. Enhanced Physiochemical and Mechanical Performance of Chitosan-Grafted Graphene Oxide for Superior Osteoinductivity. Adv. Funct. Mater. 2016, 26, 1085–1097. [Google Scholar] [CrossRef]

- Salzano de Luna, M.; Ascione, C.; Santillo, C.; Verdolotti, L.; Lavorgna, M.; Buonocore, G.G.; Castaldo, R.; Filippone, G.; Xia, H.; Ambrosio, L. Optimization of dye adsorption capacity and mechanical strength of chitosan aerogels through crosslinking strategy and graphene oxide addition. Carbohydr. Polym. 2019, 211, 195–203. [Google Scholar] [CrossRef]

- Sharma, P.; Singh, A.K.; Shahi, V.K. Selective Adsorption of Pb(II) from aqueous medium by cross-linked chitosan-functionalized graphene oxide adsorbent. ACS Sustain. Chem. Eng. 2019, 7, 1427–1436. [Google Scholar] [CrossRef]

- Kong, D.; He, L.; Li, H.; Zhang, F.; Song, Z. Preparation and characterization of graphene oxide/chitosan composite aerogel with high adsorption performance for Cr(VI) by a new crosslinking route. Colloids Surf. A Physicochem. Eng. Asp. 2021, 625. [Google Scholar] [CrossRef]

- Sreeprasad, T.S.; Maliyekkal, S.M.; Lisha, K.P.; Pradeep, T. Reduced graphene oxide-metal/metal oxide composites: Facile synthesis and application in water purification. J. Hazard. Mater. 2011, 186, 921–931. [Google Scholar] [CrossRef]

- Yang, K.; Hu, L.; Ma, X.; Ye, S.; Cheng, L.; Shi, X.; Li, C.; Li, Y.; Liu, Z. Multimodal imaging guided photothermal therapy using functionalized graphene nanosheets anchored with magnetic nanoparticles. Adv. Mater. 2012, 24, 1868–1872. [Google Scholar] [CrossRef]

- Rebekah, A.; Bharath, G.; Naushad, M.; Viswanathan, C.; Ponpandian, N. Magnetic graphene/chitosan nanocomposite: A promising nano-adsorbent for the removal of 2-naphthol from aqueous solution and their kinetic studies. Int. J. Biol. Macromol. 2020, 159, 530–538. [Google Scholar] [CrossRef]

- Singh, N.; Riyajuddin, S.; Ghosh, K.; Mehta, S.K.; Dan, A. Chitosan-graphene oxide hydrogels with embedded magnetic iron oxide nanoparticles for dye removal. ACS Appl. Nano Mater. 2019, 2, 7379–7392. [Google Scholar] [CrossRef]

- Xu, L.; Suo, H.; Wang, J.; Cheng, F.; Liu, H.; Qiu, H. Magnetic graphene oxide decorated with chitosan and Au nanoparticles: Synthesis, characterization and application for detection of trace rhodamine B. Anal. Methods 2019, 11, 3837–3843. [Google Scholar] [CrossRef]

- Foroughi, M.; Azqhandi, M.H.A. A biological-based adsorbent for a non-biodegradable pollutant: Modeling and optimization of Pb (II) remediation using GO-CS-Fe3O4-EDTA nanocomposite. J. Mol. Liq. 2020, 318. [Google Scholar] [CrossRef]

- Sarkar, A.K.; Bediako, J.K.; Choi, J.-W.; Yun, Y.-S. Functionalized magnetic biopolymeric graphene oxide with outstanding performance in water purification. NPG Asia Mater. 2019, 11. [Google Scholar] [CrossRef]

- Anush, S.M.; Chandan, H.R.; Gayathri, B.H.; Asma; Manju, N.; Vishalakshi, B.; Kalluraya, B. Graphene oxide functionalized chitosan-magnetite nanocomposite for removal of Cu(II) and Cr(VI) from waste water. Int. J. Biol. Macromol. 2020, 164, 4391–4402. [Google Scholar] [CrossRef] [PubMed]

- Tran, H.V.; Hoang, L.T.; Huynh, C.D. An investigation on kinetic and thermodynamic parameters of methylene blue adsorption onto graphene-based nanocomposite. Chem. Phys. 2020, 535. [Google Scholar] [CrossRef]

- Tasmia; Shah, J.; Jan, M.R. Microextraction of selected endocrine disrupting phenolic compounds using magnetic chitosan biopolymer graphene oxide nanocomposite. J. Polym. Environ. 2020, 28, 1673–1683. [Google Scholar] [CrossRef]

- Shafaati, M.; Miralinaghi, M.; Shirazi, R.H.S.M.; Moniri, E. The use of chitosan/Fe3O4 grafted graphene oxide for effective adsorption of rifampicin from water samples. Res. Chem. Intermed. 2020. [Google Scholar] [CrossRef]

- Jiang, X.; Pan, W.; Chen, M.; Yuan, Y.; Zhao, L. The fabrication of a thiol-modified chitosan magnetic graphene oxide nanocomposite and its adsorption performance towards the illegal drug clenbuterol in pork samples. Dalt. Trans. 2020, 49, 6097–6107. [Google Scholar] [CrossRef]

- Tang, T.; Cao, S.; Xi, C.; Li, X.; Zhang, L.; Wang, G.; Chen, Z. Chitosan functionalized magnetic graphene oxide nanocomposite for the sensitive and effective determination of alkaloids in hotpot. Int. J. Biol. Macromol. 2020, 146, 343–352. [Google Scholar] [CrossRef]

- Wu, Z.; Deng, W.; Zhou, W.; Luo, J. Novel magnetic polysaccharide/graphene oxide @Fe3O4 gel beads for adsorbing heavy metal ions. Carbohydr. Polym. 2019, 216, 119–128. [Google Scholar] [CrossRef]

- Le, T.T.N.; Le, V.T.; Dao, M.U.; Nguyen, Q.V.; Vu, T.T.; Nguyen, M.H.; Tran, D.L.; Le, H.S. Preparation of magnetic graphene oxide/chitosan composite beads for effective removal of heavy metals and dyes from aqueous solutions. Chem. Eng. Commun. 2019, 206, 1337–1352. [Google Scholar] [CrossRef]

- Jiang, X.; Pan, W.; Xiong, Z.; Zhang, Y.; Zhao, L. Facile synthesis of layer-by-layer decorated graphene oxide based magnetic nanocomposites for β-agonists/dyes adsorption removal and bacterial inactivation in wastewater. J. Alloys Compd. 2021, 870. [Google Scholar] [CrossRef]

- Rebekah, A.; Navadeepthy, D.; Bharath, G.; Viswanathan, C.; Ponpandian, N. Removal of 1-napthylamine using magnetic graphene and magnetic graphene oxide functionalized with Chitosan. Environ. Nanotechnol. Monit. Manag. 2021, 15. [Google Scholar] [CrossRef]

- Fan, L.; Luo, C.; Li, X.; Lu, F.; Qiu, H.; Sun, M. Fabrication of novel magnetic chitosan grafted with graphene oxide to enhance adsorption properties for methyl blue. J. Hazard. Mater. 2012, 215–216, 272–279. [Google Scholar] [CrossRef]

- Debnath, S.; Maity, A.; Pillay, K. Magnetic chitosan-GO nanocomposite: Synthesis, characterization and batch adsorber design for Cr(VI) removal. J. Environ. Chem. Eng. 2014, 2, 963–973. [Google Scholar] [CrossRef]

- Samuel, M.S.; Shah, S.S.; Bhattacharya, J.; Subramaniam, K.; Pradeep Singh, N.D. Adsorption of Pb(II) from aqueous solution using a magnetic chitosan/graphene oxide composite and its toxicity studies. Int. J. Biol. Macromol. 2018, 115, 1142–1150. [Google Scholar] [CrossRef]

- Wang, F.; Yang, B.; Wang, H.; Song, Q.; Tan, F.; Cao, Y. Removal of ciprofloxacin from aqueous solution by a magnetic chitosan grafted graphene oxide composite. J. Mol. Liq. 2016, 222, 188–194. [Google Scholar] [CrossRef]

- Fan, L.; Luo, C.; Sun, M.; Qiu, H.; Li, X. Synthesis of magnetic β-cyclodextrin-chitosan/graphene oxide as nanoadsorbent and its application in dye adsorption and removal. Colloids Surf. B Biointerfaces 2013, 103, 601–607. [Google Scholar] [CrossRef] [PubMed]

- Sherlala, A.I.A.; Raman, A.A.A.; Bello, M.M.; Buthiyappan, A. Adsorption of arsenic using chitosan magnetic graphene oxide nanocomposite. J. Environ. Manage. 2019, 246, 547–556. [Google Scholar] [CrossRef] [PubMed]

- Shahzad, A.; Miran, W.; Rasool, K.; Nawaz, M.; Jang, J.; Lim, S.-R.; Lee, D.S. Heavy metals removal by EDTA-functionalized chitosan graphene oxide nanocomposites. RSC Adv. 2017, 7, 9764–9771. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Luo, H.; Liu, P.; Fang, W.; Geng, J. A novel modified graphene oxide/chitosan composite used as an adsorbent for Cr(VI) in aqueous solutions. Int. J. Biol. Macromol. 2016, 87, 586–596. [Google Scholar] [CrossRef]

- Li, L.; Fan, L.; Sun, M.; Qiu, H.; Li, X.; Duan, H.; Luo, C. Adsorbent for chromium removal based on graphene oxide functionalized with magnetic cyclodextrin-chitosan. Colloids Surf. B Biointerfaces 2013, 107, 76–83. [Google Scholar] [CrossRef]

- Li, L.; Fan, L.; Sun, M.; Qiu, H.; Li, X.; Duan, H.; Luo, C. Adsorbent for hydroquinone removal based on graphene oxide functionalized with magnetic cyclodextrin-chitosan. Int. J. Biol. Macromol. 2013, 58, 169–175. [Google Scholar] [CrossRef]

- Wang, Y.; Li, L.; Luo, C.; Wang, X.; Duan, H. Removal of Pb2+ from water environment using a novel magnetic chitosan/graphene oxide imprinted Pb2+. Int. J. Biol. Macromol. 2016, 86, 505–511. [Google Scholar] [CrossRef]

- Kong, D.; Wang, N.; Qiao, N.; Wang, Q.; Wang, Z.; Zhou, Z.; Ren, Z. Facile preparation of ion-imprinted chitosan microspheres enwrapping Fe3O4 and graphene oxide by inverse suspension cross-linking for highly selective removal of copper(II). ACS Sustain. Chem. Eng. 2017, 5, 7401–7409. [Google Scholar] [CrossRef]

- Jamali, M.; Akbari, A. Facile fabrication of magnetic chitosan hydrogel beads and modified by interfacial polymerization method and study of adsorption of cationic/anionic dyes from aqueous solution. J. Environ. Chem. Eng. 2021, 9. [Google Scholar] [CrossRef]

- Subedi, N.; Lähde, A.; Abu-Danso, E.; Iqbal, J.; Bhatnagar, A. A comparative study of magnetic chitosan (Chi@Fe3O4) and graphene oxide modified magnetic chitosan (Chi@Fe3O4GO) nanocomposites for efficient removal of Cr(VI) from water. Int. J. Biol. Macromol. 2019, 137, 948–959. [Google Scholar] [CrossRef]

- Wu, X.-L.; Xiao, P.; Zhong, S.; Fang, K.; Lin, H.; Chen, J. Magnetic ZnFe2O4@chitosan encapsulated in graphene oxide for adsorptive removal of organic dye. RSC Adv. 2017, 7, 28145–28151. [Google Scholar] [CrossRef] [Green Version]

- Zeng, W.; Liu, Y.-G.; Hu, X.-J.; Liu, S.-B.; Zeng, G.-M.; Zheng, B.-H.; Jiang, L.-H.; Guo, F.-Y.; Ding, Y.; Xu, Y. Decontamination of methylene blue from aqueous solution by magnetic chitosan lignosulfonate grafted with graphene oxide: Effects of environmental conditions and surfactant. RSC Adv. 2016, 6, 19298–19307. [Google Scholar] [CrossRef]

- Hosseinzadeh, H.; Ramin, S. Effective removal of copper from aqueous solutions by modified magnetic chitosan/graphene oxide nanocomposites. Int. J. Biol. Macromol. 2018, 113, 859–868. [Google Scholar] [CrossRef]

- Asadabadi, S.; Merati, Z. A tailored magnetic composite synthesized by graphene oxide, chitosan and aminopolycarboxylic acid for diminishing dye contaminant. Cellulose 2021, 28, 2327–2351. [Google Scholar] [CrossRef]

- Tang, T.; Cao, S.; Xi, C.; Chen, Z. Multifunctional magnetic chitosan-graphene oxide-ionic liquid ternary nanohybrid: An efficient adsorbent of alkaloids. Carbohydr. Polym. 2021, 255. [Google Scholar] [CrossRef]

- Taher, F.A.; Kamal, F.H.; Badawy, N.A.; Shrshr, A.E. Hierarchical magnetic/chitosan/graphene oxide 3D nanostructure as highly effective adsorbent. Mater. Res. Bull. 2018, 97, 361–368. [Google Scholar] [CrossRef]

- Gong, Y.; Su, J.; Li, M.; Zhu, A.; Liu, G.; Liu, P. Fabrication and adsorption optimization of novel magnetic core-shell chitosan/graphene oxide/β-cyclodextrin composite materials for bisphenols in aqueous solutions. Materials 2020, 13, 5408. [Google Scholar] [CrossRef]

- Fan, L.; Luo, C.; Sun, M.; Qiu, H. Synthesis of graphene oxide decorated with magnetic cyclodextrin for fast chromium removal. J. Mater. Chem. 2012, 22, 24577–24583. [Google Scholar] [CrossRef]

- Wang, D.; Liu, L.; Jiang, X.; Yu, J.; Chen, X.; Chen, X. Adsorbent for p-phenylenediamine adsorption and removal based on graphene oxide functionalized with magnetic cyclodextrin. Appl. Surf. Sci. 2015, 329, 197–205. [Google Scholar] [CrossRef]

- Sun, Z.; Fang, S.; Hu, Y.H. 3D graphene materials: From understanding to design and synthesis control. Chem. Rev. 2020, 120, 10336–10453. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Chen, Y. Three-dimensional graphene networks: Synthesis, properties and applications. Natl. Sci. Rev. 2015, 2, 40–53. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Huang, S.; Zhao, X.; Zhang, Y. Fabrication of three-dimensional porous β-cyclodextrin/chitosan functionalized graphene oxide hydrogel for methylene blue removal from aqueous solution. Colloids Surf. A Physicochem. Eng. Asp. 2018, 539, 1–10. [Google Scholar] [CrossRef]

- Yu, P.; Wang, H.-Q.; Bao, R.-Y.; Liu, Z.; Yang, W.; Xie, B.-H.; Yang, M.-B. Self-assembled sponge-like chitosan/reduced graphene oxide/montmorillonite composite hydrogels without cross-linking of chitosan for effective Cr(VI) sorption. ACS Sustain. Chem. Eng. 2017, 5, 1557–1566. [Google Scholar] [CrossRef]

- Nasiri, R.; Arsalani, N.; Panahian, Y. One-pot synthesis of novel magnetic three-dimensional graphene/chitosan/nickel ferrite nanocomposite for lead ions removal from aqueous solution: RSM modelling design. J. Clean. Prod. 2018, 201, 507–515. [Google Scholar] [CrossRef]

- Zhou, G.; Wang, K.P.; Liu, H.W.; Wang, L.; Xiao, X.F.; Dou, D.D.; Fan, Y.B. Three-dimensional polylactic acid@graphene oxide/chitosan sponge bionic filter: Highly efficient adsorption of crystal violet dye. Int. J. Biol. Macromol. 2018, 113, 792–803. [Google Scholar] [CrossRef]

- Yu, R.; Shi, Y.; Yang, D.; Liu, Y.; Qu, J.; Yu, Z.-Z. Graphene oxide/chitosan aerogel microspheres with honeycomb-cobweb and radially oriented microchannel structures for broad-spectrum and rapid adsorption of water contaminants. ACS Appl. Mater. Interfaces 2017, 9, 21809–21819. [Google Scholar] [CrossRef]

- Kovtun, A.; Campodoni, E.; Favaretto, L.; Zambianchi, M.; Salatino, A.; Amalfitano, S.; Navacchia, M.L.; Casentini, B.; Palermo, V.; Sandri, M.; et al. Multifunctional graphene oxide/biopolymer composite aerogels for microcontaminants removal from drinking water. Chemosphere 2020, 259. [Google Scholar] [CrossRef]

- Zhang, D.; Li, N.; Cao, S.; Liu, X.; Qiao, M.; Zhang, P.; Zhao, Q.; Song, L.; Huang, X. A layered chitosan/grapheneoxide sponge as reusable adsorbent for removal of heavy metal ions. Chem. Res. Chin. Univ. 2019, 35, 463–470. [Google Scholar] [CrossRef]

- Yu, B.; Xu, J.; Liu, J.-H.; Yang, S.-T.; Luo, J.; Zhou, Q.; Wan, J.; Liao, R.; Wang, H.; Liu, Y. Adsorption behavior of copper ions on graphene oxide-chitosan aerogel. J. Environ. Chem. Eng. 2013, 1, 1044–1050. [Google Scholar] [CrossRef]

- Mei, J.; Zhang, H.; Mo, S.; Zhang, Y.; Li, Z.; Ou, H. Prominent adsorption of Cr(VI) with graphene oxide aerogel twined with creeper-like polymer based on chitosan oligosaccharide. Carbohydr. Polym. 2020, 247. [Google Scholar] [CrossRef]

- Zhao, L.; Dong, P.; Xie, J.; Li, J.; Wu, L.; Yang, S.-T.; Luo, J. Porous graphene oxide-chitosan aerogel for tetracycline removal. Mater. Res. Express 2014, 1. [Google Scholar] [CrossRef]

- Javadi, E.; Baghdadi, M.; Taghavi, L.; Ahmad Panahi, H. Removal of 4-nonylphenol from surface water and municipal wastewater effluent using three-dimensional graphene oxide–chitosan aerogel beads. Int. J. Environ. Res. 2020, 14, 513–526. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, S.; Feng, X.; Yu, J.; Jiang, X. Self-assembly of sponge-like kaolin/chitosan/reduced graphene oxide composite hydrogels for adsorption of Cr(VI) and AYR. Environ. Sci. Pollut. Res. 2019, 26, 28898–28908. [Google Scholar] [CrossRef]

- Bernsmann, F.; Ball, V.; Addiego, F.; Ponche, A.; Michel, M.; Gracio, J.J.D.A.; Toniazzo, V.; Ruch, D. Dopamine-melanin film deposition depends on the used oxidant and buffer solution. Langmuir 2011, 27, 2819–2825. [Google Scholar] [CrossRef]

- Li, L.; Wei, Z.; Liu, X.; Yang, Y.; Deng, C.; Yu, Z.; Guo, Z.; Shi, J.; Zhu, C.; Guo, W.; et al. Biomaterials cross-linked graphene oxide composite aerogel with a macro–nanoporous network structure for efficient Cr (VI) removal. Int. J. Biol. Macromol. 2020, 156, 1337–1346. [Google Scholar] [CrossRef]

- Cao, N.; Lyu, Q.; Li, J.; Wang, Y.; Yang, B.; Szunerits, S.; Boukherroub, R. Facile synthesis of fluorinated polydopamine/chitosan/reduced graphene oxide composite aerogel for efficient oil/water separation. Chem. Eng. J. 2017, 326, 17–28. [Google Scholar] [CrossRef]

- Nekouei Marnani, N.; Shahbazi, A. A novel environmental-friendly nanobiocomposite synthesis by EDTA and chitosan functionalized magnetic graphene oxide for high removal of Rhodamine B: Adsorption mechanism and separation property. Chemosphere 2019, 218, 715–725. [Google Scholar] [CrossRef]

- Croitoru, A.-M.; Ficai, A.; Ficai, D.; Trusca, R.; Dolete, G.; Andronescu, E.; Turculet, S.C. Chitosan/graphene oxide nanocomposite membranes as adsorbents with applications in water purification. Materials 2020, 13, 1687. [Google Scholar] [CrossRef] [Green Version]

- Li, T.; Liu, X.; Li, L.; Wang, Y.; Ma, P.; Chen, M.; Dong, W. Polydopamine-functionalized graphene oxide compounded with polyvinyl alcohol/chitosan hydrogels on the recyclable adsorption of cu(II), Pb(II) and cd(II) from aqueous solution. J. Polym. Res. 2019, 26. [Google Scholar] [CrossRef]

- Liao, Y.; Wang, M.; Chen, D. Preparation of polydopamine-modified graphene oxide/chitosan aerogel for uranium(VI) adsorption. Ind. Eng. Chem. Res. 2018, 57, 8472–8483. [Google Scholar] [CrossRef]

- Zhang, Y.; Bian, T.; Jiang, R.; Zhang, Y.; Zheng, X.; Li, Z. Bionic chitosan-carbon imprinted aerogel for high selective recovery of Gd(III) from end-of-life rare earth productions. J. Hazard. Mater. 2021, 407. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Fan, C.; Zhou, X. Functionalized graphene oxide/carboxymethyl chitosan composite aerogels with strong compressive strength for water purification. J. Appl. Polym. Sci. 2021, 138. [Google Scholar] [CrossRef]

- Samuel, M.S.; Subramaniyan, V.; Bhattacharya, J.; Parthiban, C.; Chand, S.; Singh, N.D.P. A GO-CS@MOF [Zn(BDC)(DMF)] material for the adsorption of chromium(VI) ions from aqueous solution. Compos. Part B Eng. 2018, 152, 116–125. [Google Scholar] [CrossRef]

- Samuel, M.S.; Suman, S.; Venkateshkannan; Selvarajan, E.; Mathimani, T.; Pugazhendhi, A. Immobilization of Cu3(btc)2 on graphene oxide-chitosan hybrid composite for the adsorption and photocatalytic degradation of methylene blue. J. Photochem. Photobiol. B Biol. 2020, 204. [Google Scholar] [CrossRef]

- Chang, R.; Ma, S.; Guo, X.; Xu, J.; Zhong, C.; Huang, R.; Ma, J. Hierarchically assembled graphene oxide composite membrane with self-healing and high-efficiency water purification performance. ACS Appl. Mater. Interfaces 2019, 11, 46251–46260. [Google Scholar] [CrossRef]

- Ma, L.; Wang, Q.; Islam, S.M.; Liu, Y.; Ma, S.; Kanatzidis, M.G. Highly selective and efficient removal of heavy metals by layered double hydroxide intercalated with the MoS42- Ion. J. Am. Chem. Soc. 2016, 138, 2858–2866. [Google Scholar] [CrossRef]

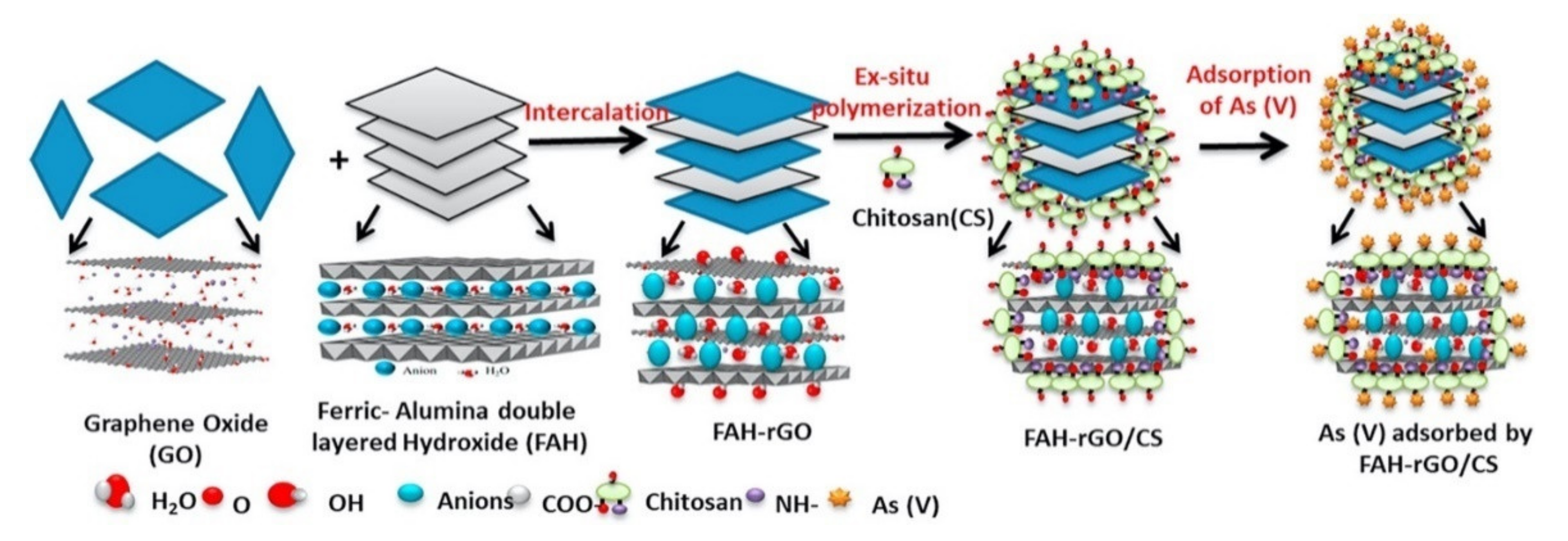

- Priya, V.N.; Rajkumar, M.; Magesh, G.; Mobika, J.; Sibi, S.P.L. Chitosan assisted Fe-Al double layered hydroxide/reduced graphene oxide composites for As(V) removal. Mater. Chem. Phys. 2020, 251. [Google Scholar] [CrossRef]

- Sanmugam, A.; Vikraman, D.; Park, H.J.; Kim, H.-S. One-pot facile methodology to synthesize chitosan-ZnO-graphene oxide hybrid composites for better dye adsorption and antibacterial activity. Nanomaterials 2017, 7, 363. [Google Scholar] [CrossRef] [Green Version]

- Guo, X.; Yang, H.; Liu, Q.; Liu, J.; Chen, R.; Zhang, H.; Yu, J.; Zhang, M.; Li, R.; Wang, J. A chitosan-graphene oxide/ZIF foam with anti-biofouling ability for uranium recovery from seawater. Chem. Eng. J. 2020, 382. [Google Scholar] [CrossRef]

- Das, L.; Das, P.; Bhowal, A.; Bhattachariee, C. Synthesis of hybrid hydrogel nano-polymer composite using graphene oxide, chitosan and PVA and its application in waste water treatment. Environ. Technol. Innov. 2020, 18, 100664. [Google Scholar] [CrossRef]

- Tang, H.; Liu, Y.; Li, B.; Zhu, L.; Tang, Y. Preparation of chitosan graft polyacrylic acid/graphite oxide composite and the study of its adsorption properties of cationic dyes. Polym. Sci. Ser. A 2020, 62, 272–283. [Google Scholar] [CrossRef]

- Zhao, L.; Yang, S.; Yilihamu, A.; Ma, Q.; Shi, M.; Ouyang, B.; Zhang, Q.; Guan, X.; Yang, S.-T. Adsorptive decontamination of Cu2+-contaminated water and soil by carboxylated graphene oxide/chitosan/cellulose composite beads. Environ. Res. 2019, 179. [Google Scholar] [CrossRef]

- Mittal, H.; Al Alili, A.; Morajkar, P.P.; Alhassan, S.M. GO crosslinked hydrogel nanocomposites of chitosan/carboxymethyl cellulose—A versatile adsorbent for the treatment of dyes contaminated wastewater. Int. J. Biol. Macromol. 2021, 167, 1248–1261. [Google Scholar] [CrossRef]

- Li, C.; Yan, Y.; Zhang, Q.; Zhang, Z.; Huang, L.; Zhang, J.; Xiong, Y.; Tan, S. Adsorption of Cd2+ and Ni2+ from aqueous single-metal solutions on gaphene oxide-chitosan-poly(vinyl alcohol) hydrogels. Langmuir 2019, 35, 4481–4490. [Google Scholar] [CrossRef]

- Huo, J.; Yu, G.; Wang, J. Adsorptive removal of Sr(II) from aqueous solution by polyvinyl alcohol/graphene oxide aerogel. Chemosphere 2021, 278, 130492. [Google Scholar] [CrossRef]

- Li, L.; Wang, Z.; Ma, P.; Bai, H.; Dong, W.; Chen, M. Preparation of polyvinyl alcohol/chitosan hydrogel compounded with graphene oxide to enhance the adsorption properties for Cu(II) in aqueous solution. J. Polym. Res. 2015, 22. [Google Scholar] [CrossRef]

- Liu, Y.; Nie, P.; Yu, F. Enhanced adsorption of sulfonamides by a novel carboxymethyl cellulose and chitosan-based composite with sulfonated graphene oxide. Bioresour. Technol. 2021, 320, 124373. [Google Scholar] [CrossRef]

- Salahuddin, N.; EL-Daly, H.; El Sharkawy, R.G.; Nasr, B.T. Synthesis and efficacy of PPy/CS/GO nanocomposites for adsorption of ponceau 4R dye. Polymer 2018, 146, 291–303. [Google Scholar] [CrossRef]

- Klongklaew, P.; Naksena, T.; Kanatharana, P.; Bunkoed, O. A hierarchically porous composite monolith polypyrrole/octadecyl silica/graphene oxide/chitosan cryogel sorbent for the extraction and pre-concentration of carbamate pesticides in fruit juices. Anal. Bioanal. Chem. 2018, 410, 7185–7193. [Google Scholar] [CrossRef]

- Salahuddin, N.A.; EL-Daly, H.A.; El Sharkawy, R.G.; Nasr, B.T. Nano-hybrid based on polypyrrole/chitosan/grapheneoxide magnetite decoration for dual function in water remediation and its application to form fashionable colored product. Adv. Powder Technol. 2020, 31, 1587–1596. [Google Scholar] [CrossRef]

- Lai, K.C.; Hiew, B.Y.Z.; Lee, L.Y.; Gan, S.; Thangalazhy-Gopakumar, S.; Chiu, W.S.; Khiew, P.S. Ice-templated graphene oxide/chitosan aerogel as an effective adsorbent for sequestration of metanil yellow dye. Bioresour. Technol. 2019, 274, 134–144. [Google Scholar] [CrossRef]

- Li, X.; Zhou, H.; Wu, W.; Wei, S.; Xu, Y.; Kuang, Y. Studies of heavy metal ion adsorption on chitosan/sulfydryl-functionalized graphene oxide composites. J. Colloid Interface Sci. 2015, 448, 389–397. [Google Scholar] [CrossRef]

- Samuel, M.S.; Shah, S.S.; Subramaniyan, V.; Qureshi, T.; Bhattacharya, J.; Pradeep Singh, N.D. Preparation of graphene oxide/chitosan/ferrite nanocomposite for chromium(VI) removal from aqueous solution. Int. J. Biol. Macromol. 2018, 119, 540–547. [Google Scholar] [CrossRef]

- Ouyang, A.; Wang, C.; Wu, S.; Shi, E.; Zhao, W.; Cao, A.; Wu, D. Highly porous core-shell structured graphene-chitosan beads. ACS Appl. Mater. Interfaces 2015, 7, 14439–14445. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Wang, H.; Xia, G.; Huang, W.; Song, R. Microporous spongy chitosan monoliths doped with graphene oxide as highly effective adsorbent for methyl orange and copper nitrate (Cu(NO3)2) ions. J. Colloid Interface Sci. 2014, 416, 243–251. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, Z.; Guo, W.; Zhu, C.; Zou, Y. Simple fabrication of chitosan/graphene nanoplates composite spheres for efficient adsorption of acid dyes from aqueous solution. Int. J. Biol. Macromol. 2018, 112, 1048–1054. [Google Scholar] [CrossRef]

- Sharififard, H.; Shahraki, Z.H.; Rezvanpanah, E.; Rad, S.H. A novel natural chitosan/activated carbon/iron bio-nanocomposite: Sonochemical synthesis, characterization, and application for cadmium removal in batch and continuous adsorption process. Bioresour. Technol. 2018, 270, 562–569. [Google Scholar] [CrossRef]

- Zhao, R.; Li, Y.; Ji, J.; Wang, Q.; Li, G.; Wu, T.; Zhang, B. Efficient removal of phenol and p-nitrophenol using nitrogen-doped reduced graphene oxide. Colloids Surf. A Physicochem. Eng. Asp. 2021, 611. [Google Scholar] [CrossRef]

| Adsorbent | Adsorbate | Adsorption qm (mg g−1) | Ref. |

|---|---|---|---|

| β-CD/GO | Bisphenol A | 373.4 | [72] |

| β-CD/GO | Methyl blue | 580.4 | [73] |

| Methyl orange | 328.2 | ||

| Basic fuchsin | 425.8 | ||

| β-CD/GO | Cd(II) | 196.0 | [74] |

| β-CD/GO | p-Nitrophenol | 117.28 | [75] |

| β-CD/poly(acrylic acid)/GO) | Methylene blue | 247.99 | [76] |

| Safranine T | 175.49 | ||

| β-CD/poly (L-glutamic acid) magnetic/GO | 17β-estradiol | 298.9 | [77] |

| Synthetic Step | Advantages/Disadvantages |

|---|---|

| Sol gel | Simple, other reagents can be easily added/mixing of GO and chitosan gives rise to an increase in solution viscosity, which can give rise to inhomogeneity in the final GO/CS hydrogel. |

| Hydrothermal | No need for crosslinking agents/some cost considerations with the relatively high temperatures in the vicinity of 120 °C. |

| Crosslinking Agents | Increase in mechanical properties/reduces the number of chelating sites that are required to bind and trap the pollutants and can be toxic. |

| Functionalised GO | Modifiable oxygenated functional groups of GO are ideal for functionalised, rich chemistry, can be used to crosslink single graphene sheets/synthesis can be time consuming. |

| Freeze drying | Scaffolds with defined pore size, highly suited to enhanced adsorption/freeze drying can be slow. |

| Adsorbent | Adsorbate | Adsorption Conditions | Adsorption qm (mg g−1) | Ref. |

|---|---|---|---|---|

| MGO/CS | Rifampicin | Batch mode, 55 °C, 200 rpm, 10 mg adsorbent, 20 mg/L adsorbate | 102.11 | [166] |

| MGO/CS | As(III) | Batch, 25 °C, 250 rpm, 10 mg/L adsorbate, V = 100 mL | 45 | [178] |

| MGO/CS | Methylene blue Eriochrome black T | Batch, 26 °C, 130 rpm, 50 mg adsorbent, 100 mg/L adsorbate, V = 50 mL | 289 292 | [183] |

| MGO/CS | Cr(VI) | Batch, 21 °C, 500 mg adsorbent, 40 mg/L adsorbate, V = 10 mL | 100.51 | [184] |

| GO/CS/ZnFe2O4 | Basic fuchsin | Batch, 25 °C, 50 mg adsorbent, 50 mg/L adsorbate, V = 25 mL | 335.57 | [185] |

| Methacrylic acid functionalized-MGO/CS | Methylene blue | Batch, 25 °C, 120 rpm, 10 mg adsorbent, 100 mg/L adsorbate, V = 20 mL | 2478 | [162] |

| MGO/CS/ Lignosulfonate | Methylene blue | Batch, 30 °C, 160 rpm, 10 mg adsorbent, V = 20 mL | 253.53 | [186] |

| MGO/CS/ Ethylenediamine | Cu(II) | Batch, 25 °C, 300 rpm, 10 mg adsorbent, 100 mg/L adsorbate, V = 50 mL | 217.4 | [187] |

| MGO/CS/SiO2 | Dopamine Clenbuterol Orciprenaline Methylene blue Crystal violet | Batch, 20 °C, 180 rpm, 10 mg adsorbent, V = 100 mL | 127.34 109.56 150.21 300.42 347.35 | [171] |

| MGO/CS/SiO2 | methyl violet | Batch, 52 °C, 150 rpm, 10 mg adsorbent, 10 mg/L adsorbate, V = 5 mL | 243.8 | [188] |

| MGO/CS/SiO2/ ionic liquid | Morphine Codeine Ephedrine Amphetamine Benzoylecgonine | Batch, 25 °C, 150 rpm, 15 mg adsorbent, 10 mg/L adsorbate, V = 5 mL | 7.2 8.4 9.2 5.8 11.2 | [189] |

| 3D-MGO/CS | Disperse blue 367 | Batch, 25 °C, 150 rpm, 150 mg adsorbent, 60 mg/L adsorbate | 298.27 | [190] |

| β-CD-MGO/CS | Bisphenol A Bisphenol F | Batch, 30 °C, 200 rpm, 20 mg adsorbent, 20 mg/L adsorbate, V = 50 mL | 326.8 328.3 | [191] |

| β-CD–MGO/CS | Hydroquinone | Batch mode, 180 rpm, 100 mg adsorbent, V = 100 mL | 148 | [182] |

| β-CD–MGO/CS | Cr(VI) | Batch, 180 rpm, 100 mg adsorbent, 50 mg/L adsorbate, V = 100 mL | 67.66 | [181] |

| β-CD–MGO/CS | Cr(VI) | Batch, 150 rpm, 100 mg adsorbent, 100 mg/L adsorbate, V = 100 mL | 120 | [192] |

| β-CD–MGO/CS | Malachite green | Batch, 25 °C, 150 rpm, 5 mg adsorbent, V = 20 mL | 740.74 | [60] |

| β-CD–MGO/CS | p-Phenylene-diamine | Batch, 45 °C, 5 mg adsorbent, 100 mg/L adsorbate, V = 20 mL | 1102.58 | [193] |

| β-CD–MGO/CS | Methylene blue | Batch, 25 °C, 180 rpm, 10 mg adsorbent, V = 25 mL | 43.34 | [177] |

| Blended Polymer | Adsorbent/Adsorption Experiment | Adsorbate | Adsorption qm (mg g−1) | Ref. |

|---|---|---|---|---|

| PVA (poly(vinyl alcohol)) | GO/CS/PVA Batch, 30 °C, 160 rpm, 20 mg adsorbent, V = 40 mL | Cd(II) Ni(II) | 172.11 70.37 | [230] |

| PVA | GO/CS/PVA Batch, 140 rpm, 6 g/L adsorbent | Congo red dye | 12.38 | [226] |

| PVA | GO/CS/PVA Batch, 22.16 mg/L adsorbate, 0.5 g/L adsorbent | Sr(II) | 17.48 | [231] |

| PVA | GO/CS/PVA Batch, 30 °C, 150 rpm, 50 mg adsorbent, V = 100 mL | Cu(II) | 162 | [232] |

| PAA (polyacrylic acid) | GO/CS/PAA Batch, 25 °C, 0.2 g adsorbent, V = 150 mL | Rhodamine 6G Methyl violet Methyl orange | 224.6 169.2 195.6 | [227] |

| PAA | GO/CS/PAA/Fe3O4 Batch, 25 °C, 300 rpm, 10 mg adsorbent, V = 50 mL | Cu(II) | 217.4 | [187] |

| PLA (polylactic acid) | GO/CS/PLA Batch, 110 rpm, 25–45 °C, 30 mg adsorbent, V = 30 mL | Crystal violet | 45 | [201] |

| CMC (carboxymethyl cellulose) | GO/CMC/CS Batch, 25 °C, 200 rpm, 5 mg adsorbent, V = 20 mL | Sulfameth- oxazole Sulfapyridine | 312.2 161.8 | [233] |

| CMC | GO/CS/CMC Batch, 25 °C, 0.4–0.6 g/L adsorbent | MB MO | 655.98 404.52 | [229] |

| C Cellulose) | GO/CS/C Batch, 30 °C, 200 rpm, 5 mg adsorbent, V = 8 mL | Cu(II) | 22.40 | [228] |

| SA (sodium alginate) | GO/SA/CS/FeO Batch, 30 °C, 50 mg adsorbent | Cu(II) Cd(II) Pb(II) | 55.96 86.28 189.04 | [169] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alves, D.C.d.S.; Healy, B.; Yu, T.; Breslin, C.B. Graphene-Based Materials Immobilized within Chitosan: Applications as Adsorbents for the Removal of Aquatic Pollutants. Materials 2021, 14, 3655. https://doi.org/10.3390/ma14133655

Alves DCdS, Healy B, Yu T, Breslin CB. Graphene-Based Materials Immobilized within Chitosan: Applications as Adsorbents for the Removal of Aquatic Pollutants. Materials. 2021; 14(13):3655. https://doi.org/10.3390/ma14133655

Chicago/Turabian StyleAlves, Daniele C. da Silva, Bronach Healy, Tian Yu, and Carmel B. Breslin. 2021. "Graphene-Based Materials Immobilized within Chitosan: Applications as Adsorbents for the Removal of Aquatic Pollutants" Materials 14, no. 13: 3655. https://doi.org/10.3390/ma14133655