An Overview on the Rheology, Mechanical Properties, Durability, 3D Printing, and Microstructural Performance of Nanomaterials in Cementitious Composites

Abstract

:1. Introduction

1.1. Nanomaterials in Cementitious Composites

1.2. Fresh Properties of Cementitious Material

1.3. Durability Performance

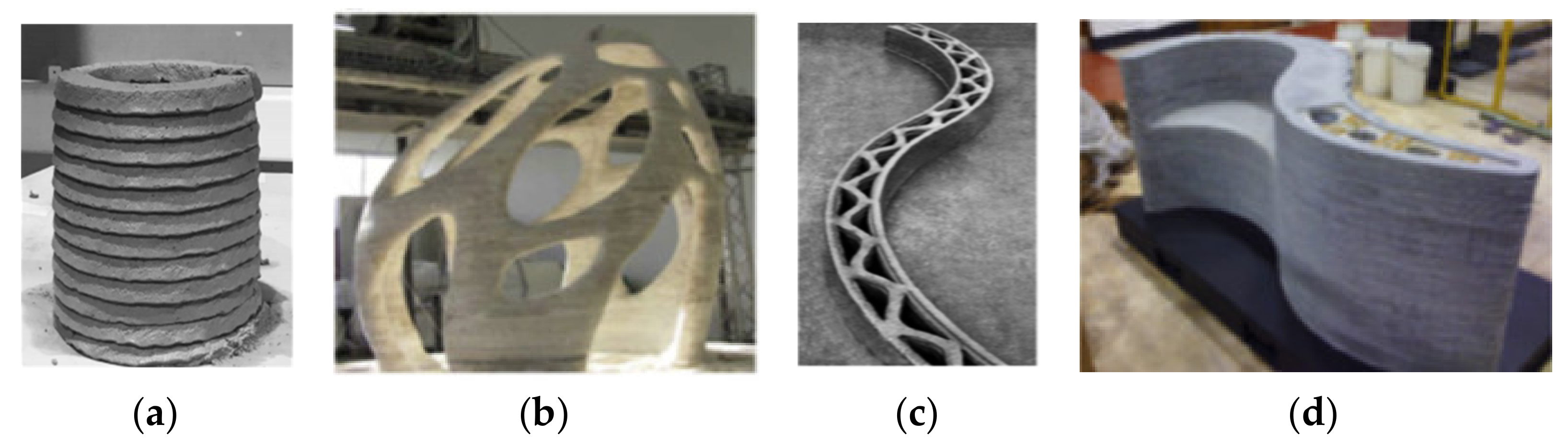

1.4. 3D Printing Materials

2. Significance of This Study

3. Rheology and Slump

4. Mechanical Properties

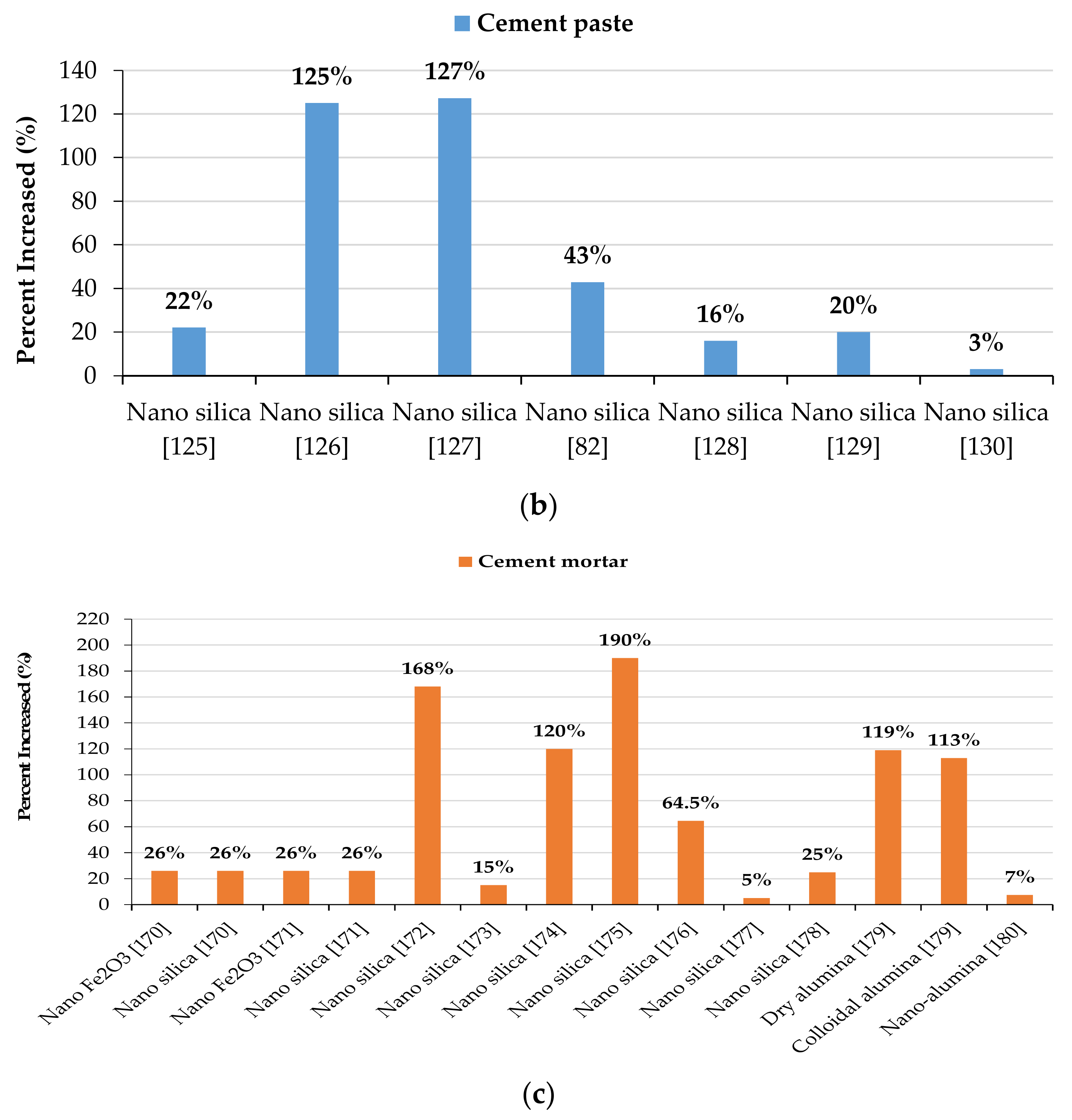

4.1. Compressive Strength

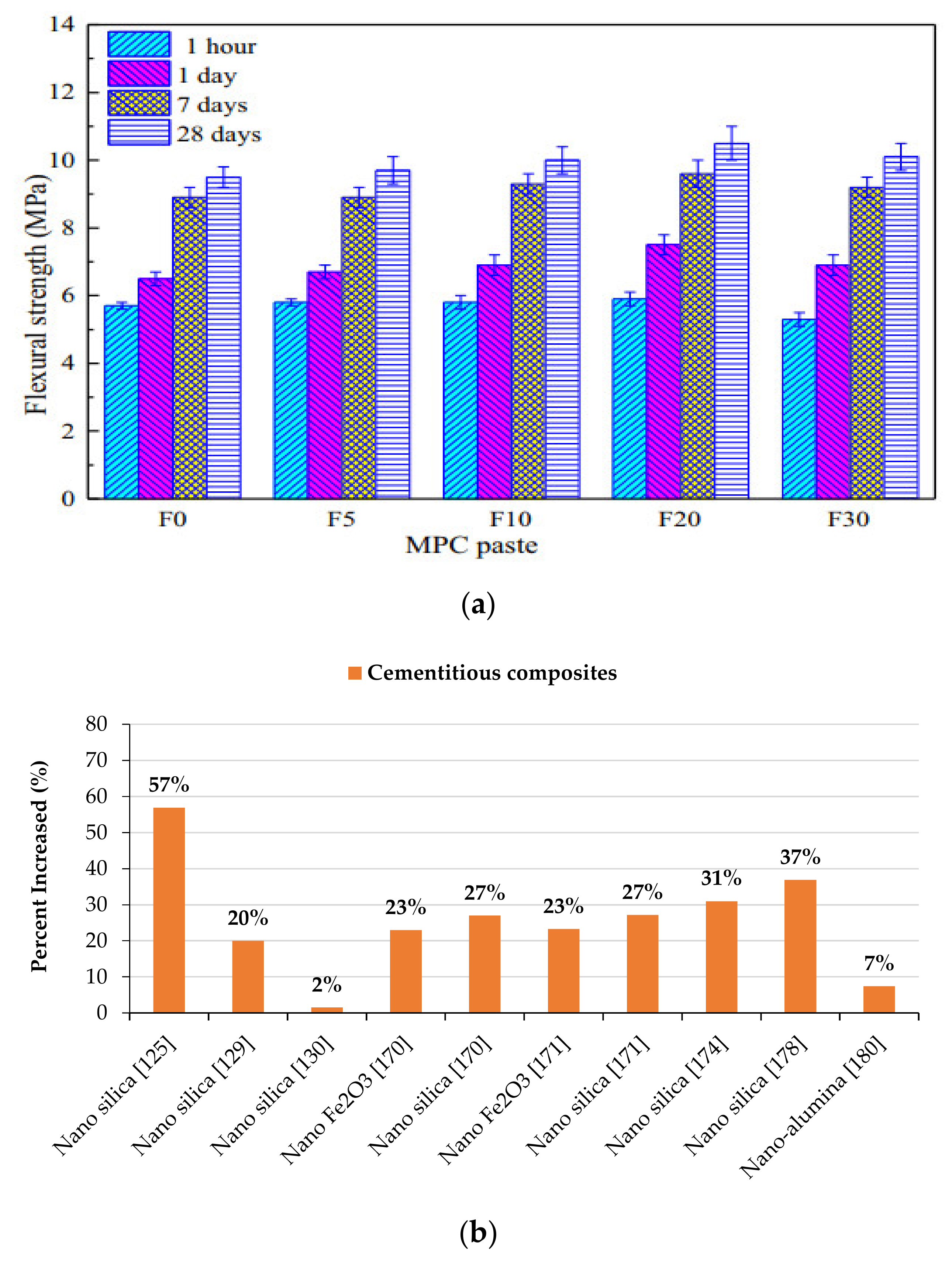

4.2. Flexural Strength

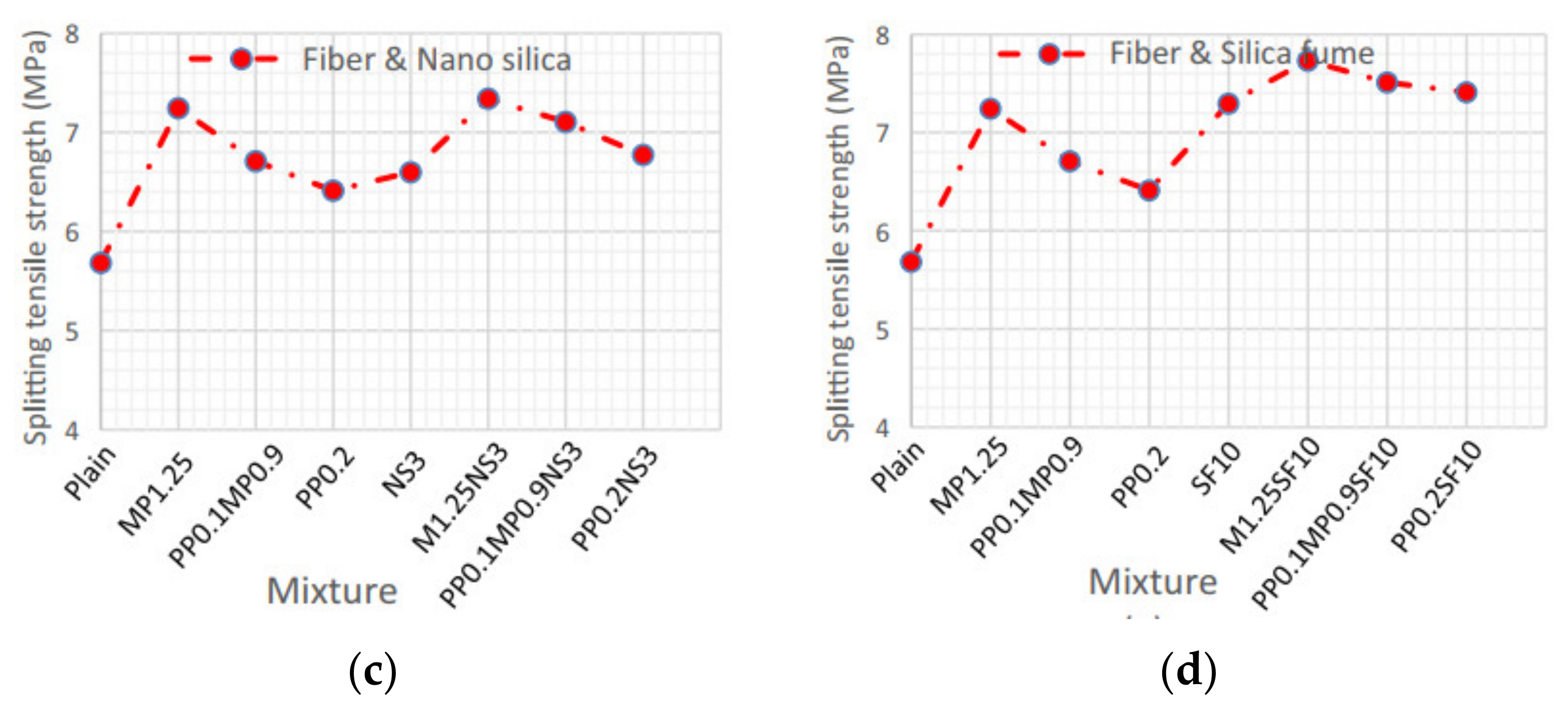

4.3. Tensile Strength

5. Durability Performance

5.1. Shrinkage

5.2. Pores

5.3. Porosity

6. 3D Printing of Cementitious Composites

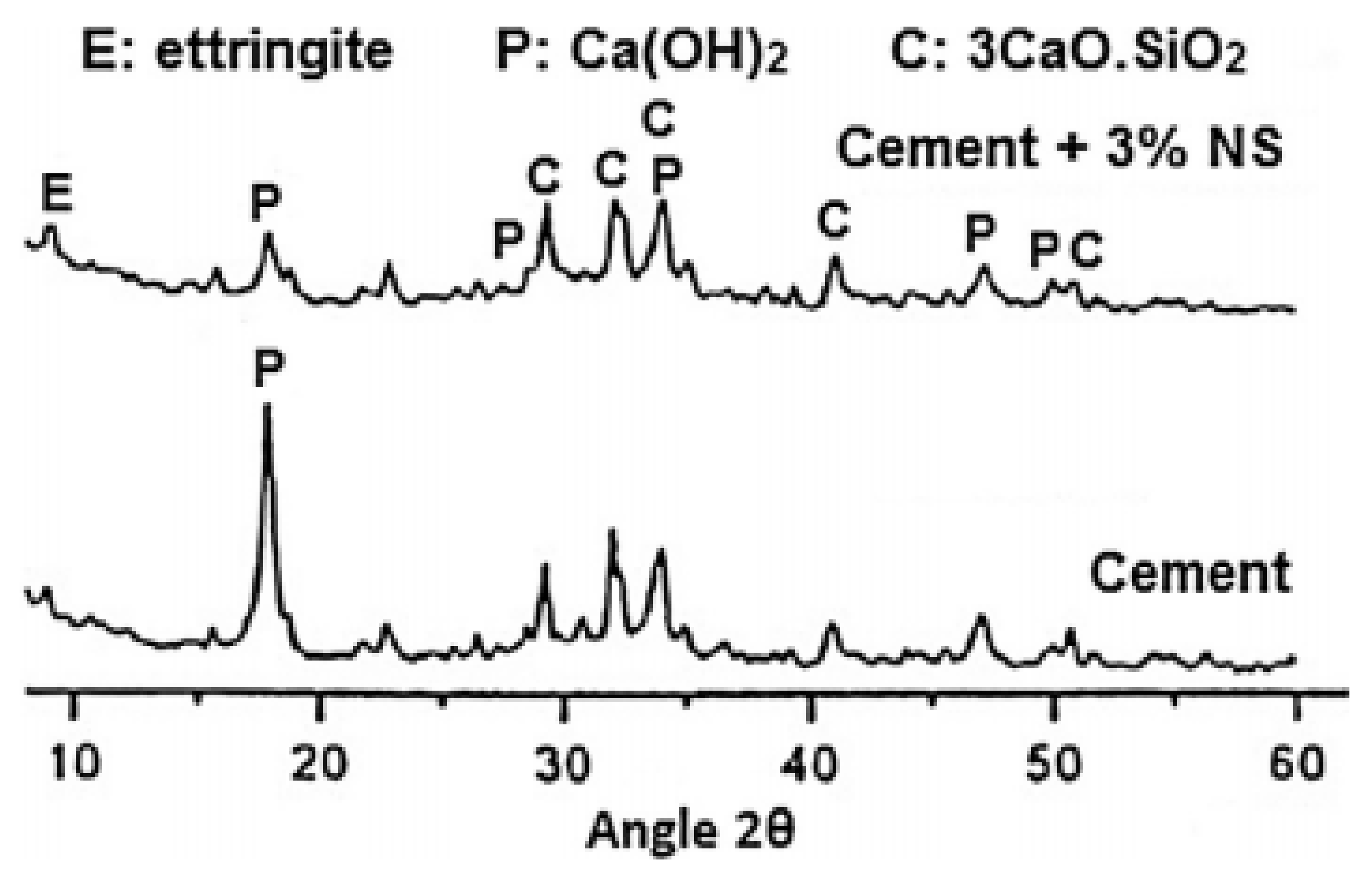

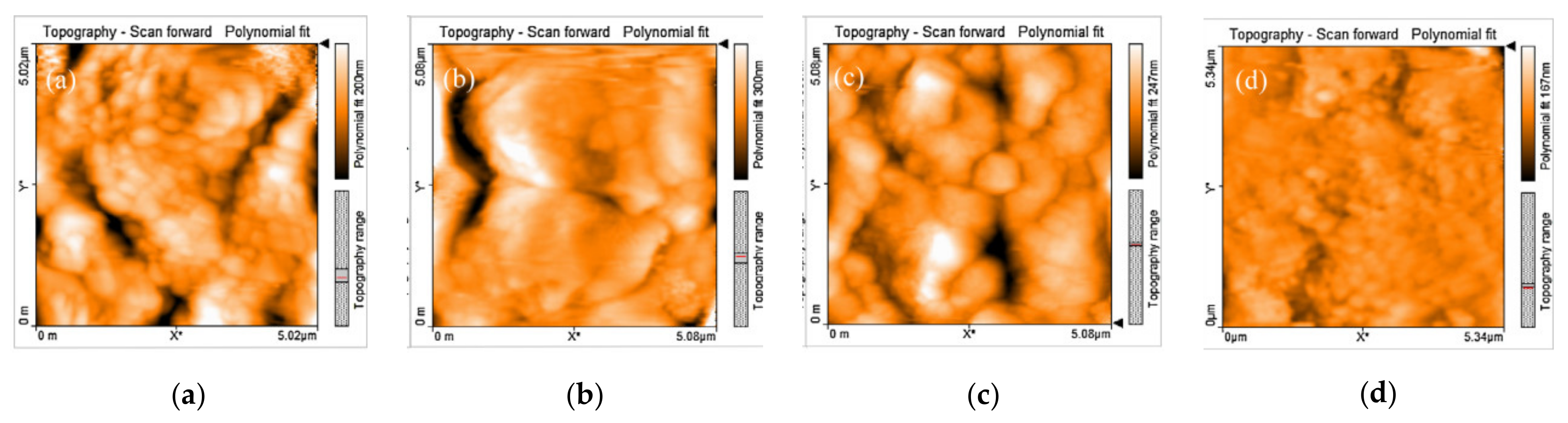

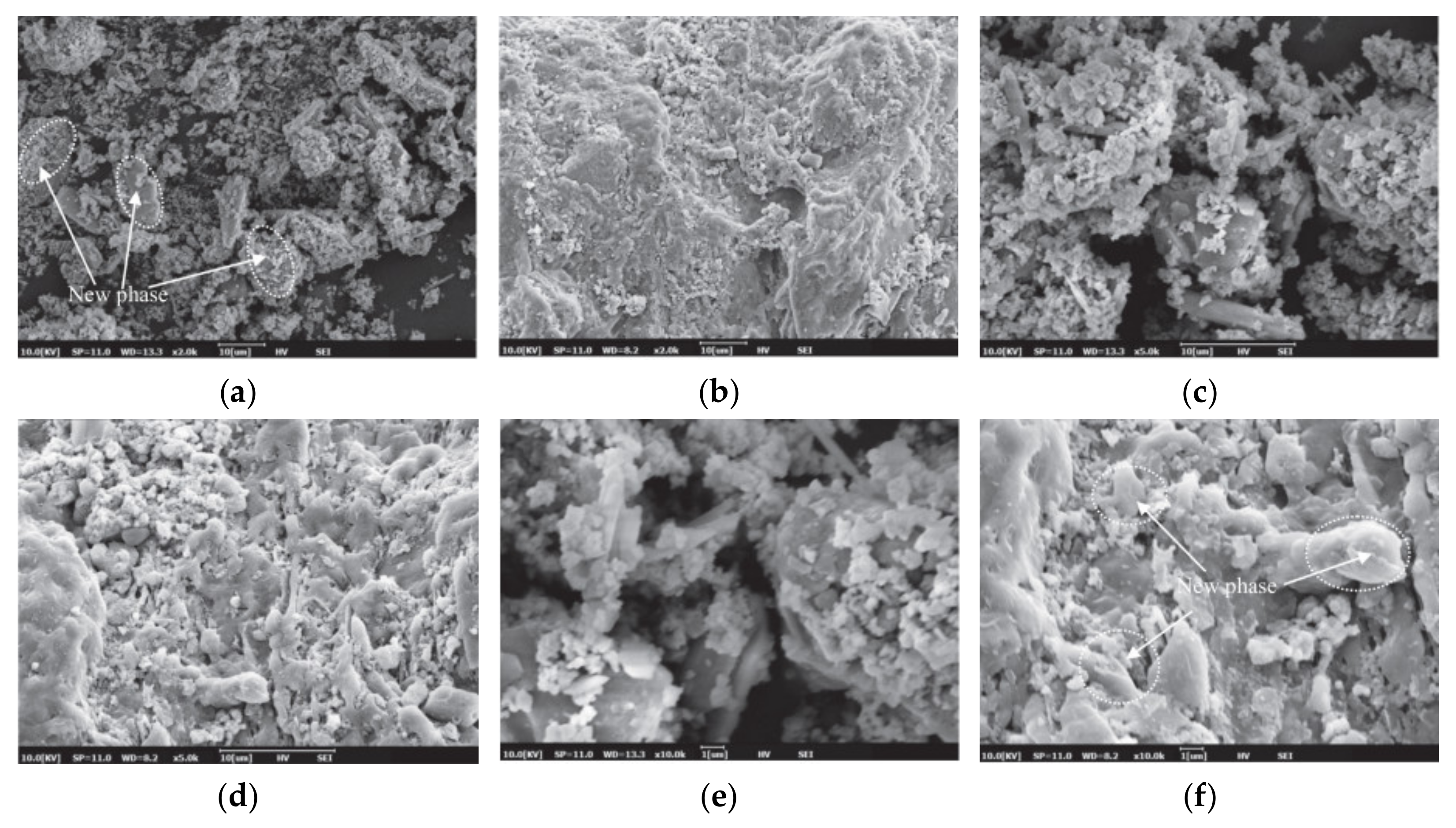

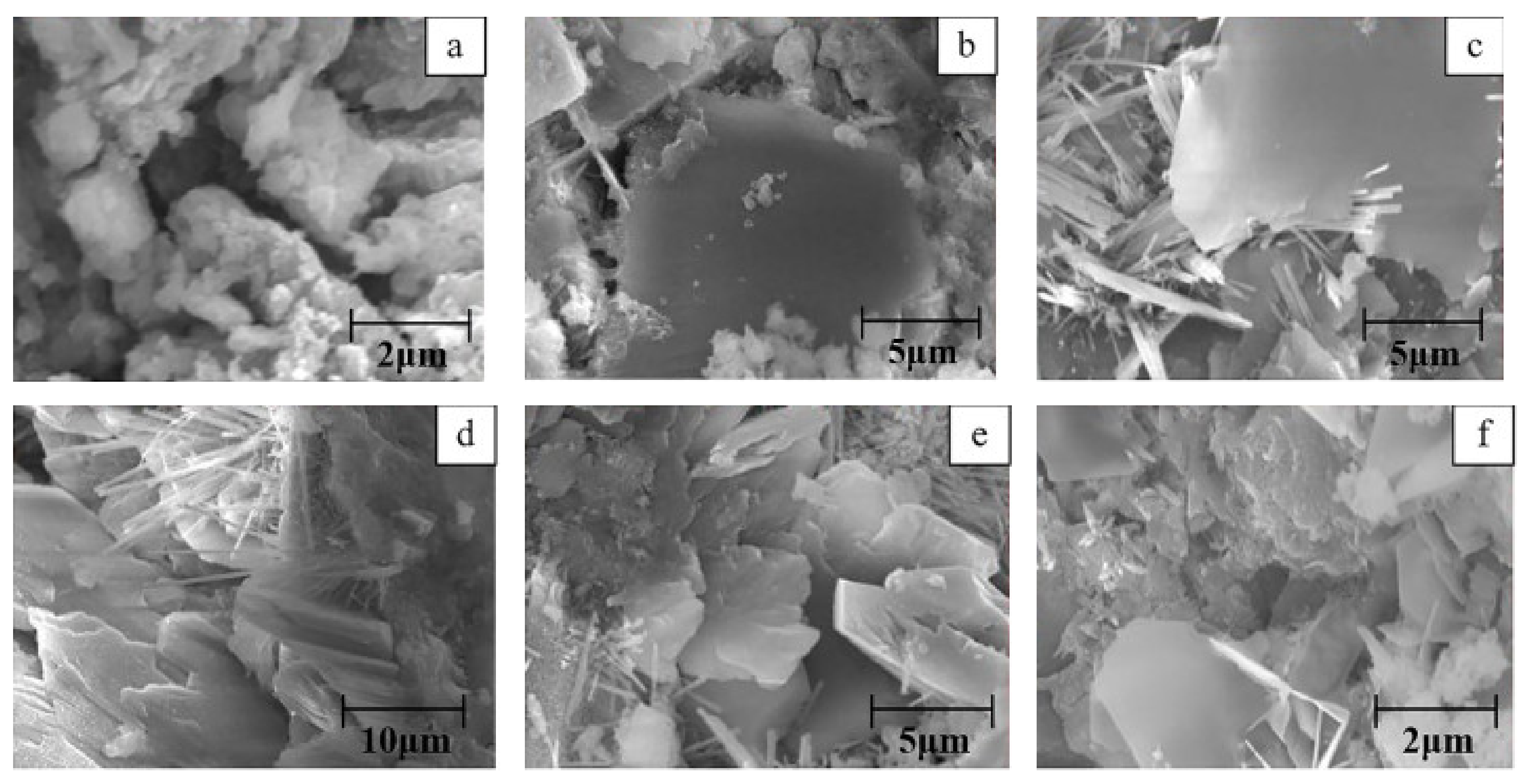

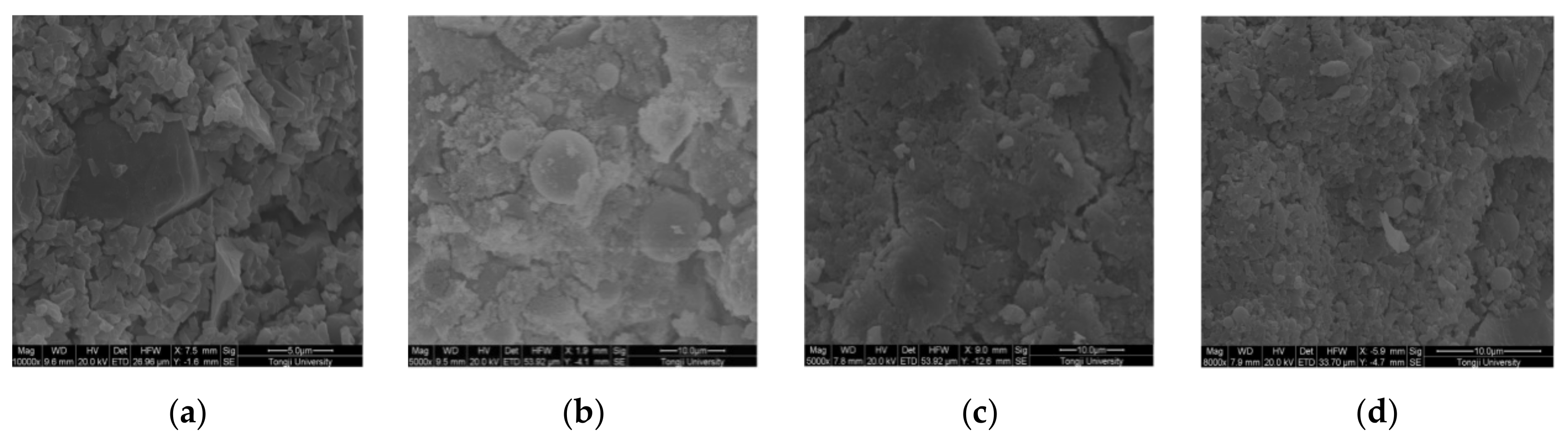

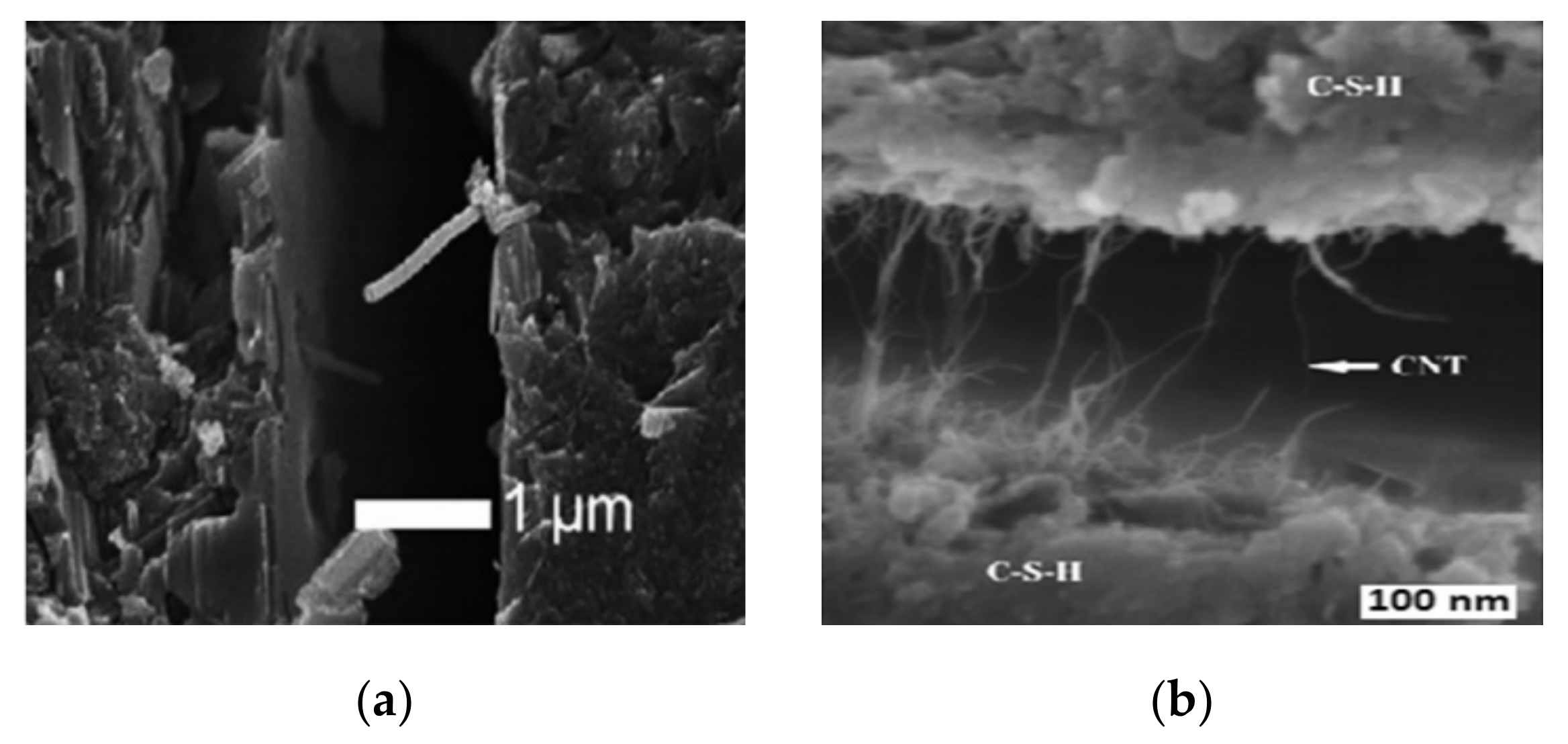

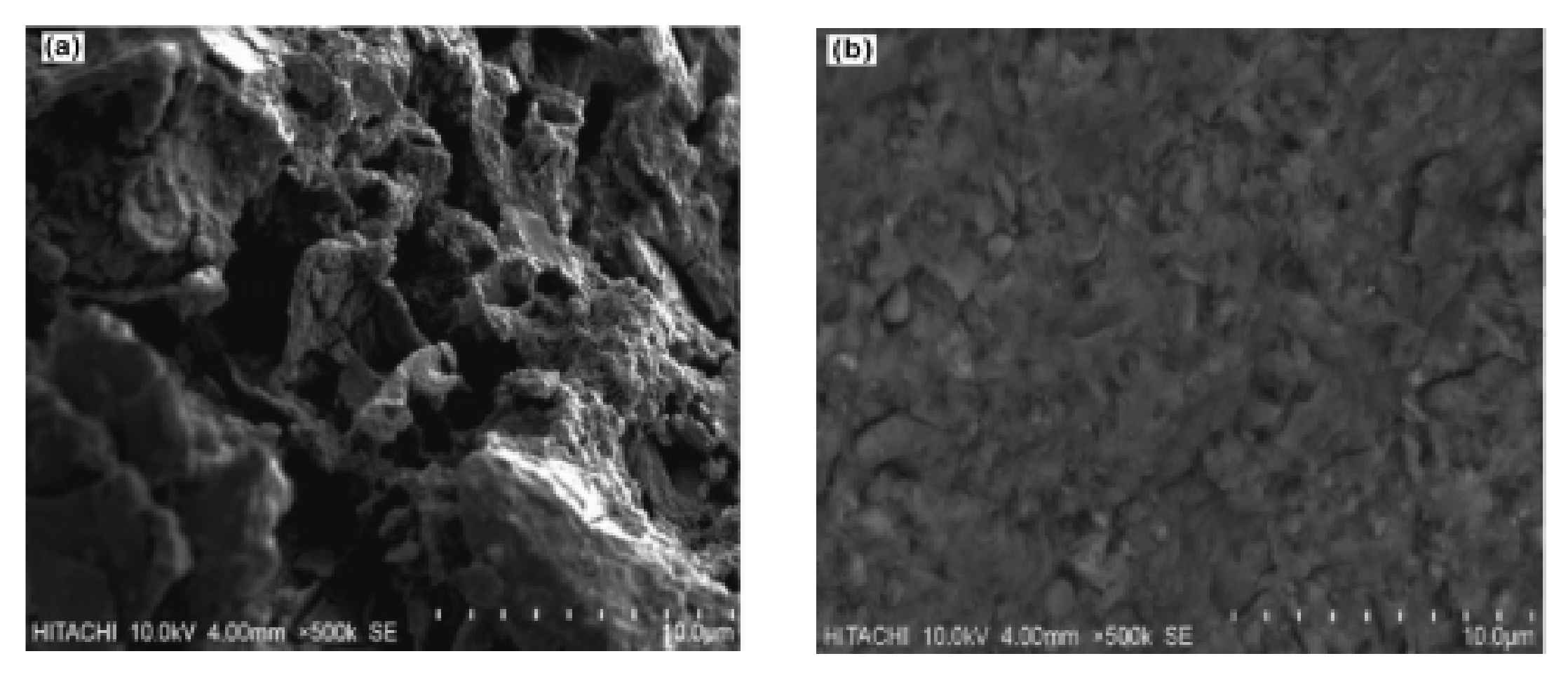

7. Microstructural Properties of Nanomaterials in Composites

8. Conclusions and Future Recommendations

8.1. Conclusions

8.2. Future Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rastogi, S.; Sharma, G.; Kandasubramanian, B. Nanomaterials and the Environment. In The ELSI Handbook of Nanotechnology; Wiley: Hoboken, NJ, USA, 2020; pp. 1–23. [Google Scholar]

- Pierrehumbert, R. There is no Plan B for dealing with the climate crisis. Bull. Atom. Sci. 2019, 75, 215–221. [Google Scholar] [CrossRef] [Green Version]

- Buzea, C.; Pacheco, I. Toxicity of nanoparticles. In Nanotechnology in Eco-Efficient Construction; Elsevier BV: Amsterdam, The Netherlands, 2019; pp. 705–754. [Google Scholar]

- Pacheco-Torgal, F.; Diamanti, M.V.; Nazari, A.; Goran-Granqvist, C.; Pruna, A.; Amirkhanian, S. Nanotechnology in Eco-Efficient Construction: Materials, Processes and Applications; Woodhead Publishing: Cambridge, UK, 2018. [Google Scholar]

- Norhasri, M.M.; Hamidah, M.; Fadzil, A.M. Applications of using nano material in concrete: A review. Constr. Build. Mater. 2017, 133, 91–97. [Google Scholar] [CrossRef]

- Safiuddin; Gonzalez, M.; Cao, J.; Tighe, S.L. State-of-the-art report on use of nano-materials in concrete. Int. J. Pavement Eng. 2014, 15, 940–949. [Google Scholar] [CrossRef]

- Glenn, J. Nanotechnology in Concrete: Critical Review and Statistical Analysis; Florida Atlantic University: Boca Raton, FL, USA, 2013. [Google Scholar]

- Skinner, L.B.; Chae, S.R.; Benmore, C.J.; Wenk, H.R.; Monteiro, P.J.M. Nanostructure of Calcium Silicate Hydrates in Cements. Phys. Rev. Lett. 2010, 104, 195502. [Google Scholar] [CrossRef] [PubMed]

- Nazar, S.; Yang, J.; Thomas, B.S.; Azim, I.; Rehman, S.K.U. Rheological properties of cementitious composites with and without nano-materials: A comprehensive review. J. Clean. Prod. 2020, 272, 122701. [Google Scholar] [CrossRef]

- Kumar, D.P.; Amit, S.; Chand, M.S.R. Influence of various nano-size materials on fresh and hardened state of fast setting high early strength concrete [FSHESC]: A state-of-the-art review. Constr. Build. Mater. 2021, 277, 122299. [Google Scholar] [CrossRef]

- Balaguru, P.; Chong, K. Nanotechnology and concrete: Research opportunities. In Proceedings of the ACI Session on Nanotechnology of Concrete: Recent Developments and Future Perspectives, Denver, CO, USA, 7 November 2006; pp. 15–28. [Google Scholar]

- Norhasri, M.M.; Hamidah, M.; Fadzil, A.M. Inclusion of nano metaclayed as additive in ultra high performance concrete (UHPC). Constr. Build. Mater. 2019, 201, 590–598. [Google Scholar] [CrossRef]

- Amin, M.; Abu El-Hassan, K. Effect of using different types of nano materials on mechanical properties of high strength concrete. Constr. Build. Mater. 2015, 80, 116–124. [Google Scholar] [CrossRef]

- Dopko, M. Fiber Reinforced Concrete: Tailoring Composite Properties with Discrete Fibers. Master’s Thesis, Iowa State University, Ames, IA, USA, 2018. [Google Scholar]

- Land, G.; Stephan, D. Preparation and Application of Nanoscaled C-S-H as an Accelerator for Cement Hydration. In Nanotechnology in Construction; J.B. Metzler: Germany, Stuttgart, 2015; pp. 117–122. [Google Scholar]

- Adesina, A. Nanomaterials in cementitious composites: Review of durability performance. J. Build. Pathol. Rehab. 2020, 5, 1–9. [Google Scholar] [CrossRef]

- Peyvandi, A.; Soroushian, P.; Balachandra, A.M.; Sobolev, K. Enhancement of the durability characteristics of concrete nanocomposite pipes with modified graphite nanoplatelets. Constr. Build. Mater. 2013, 47, 111–117. [Google Scholar] [CrossRef]

- Péra, J.; Husson, S.; Guilhot, B. Influence of finely ground limestone on cement hydration. Cem. Concr. Compos. 1999, 21, 99–105. [Google Scholar] [CrossRef] [Green Version]

- Behnood, A.; Ziari, H. Effects of silica fume addition and water to cement ratio on the properties of high-strength concrete after exposure to high temperatures. Cem. Concr. Compos. 2008, 30, 106–112. [Google Scholar] [CrossRef]

- Hashimoto, K.; Irie, H.; Fujishima, A. TiO2Photocatalysis: A Historical Overview and Future Prospects. Jpn. J. Appl. Phys. 2005, 44, 8269–8285. [Google Scholar] [CrossRef]

- Farzadnia, N.; Ali, A.A.A.; Demirboga, R. Characterization of high strength mortars with nano alumina at elevated temperatures. Cem. Concr. Res. 2013, 54, 43–54. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Ou, J. Self-Sensing Concrete in Smart Structures; Butterworth-Heinemann: Oxford, UK, 2014. [Google Scholar]

- Diab, M.; Elyamany, H.E.; Elmoaty, M.A.; Sreh, M.M. Effect of nanomaterials additives on performance of concrete resistance against magnesium sulfate and acids. Constr. Build. Mater. 2019, 210, 210–231. [Google Scholar] [CrossRef]

- Cifuentes, H.; Ríos, J.D.; Álvarez, E.J.G. Effect of mix design on the size-independent fracture energy of normal-and high-strength self-compacting concrete. Mater. Constr. 2018, 68, 1–11. [Google Scholar] [CrossRef]

- Min, T.-B.; Cho, I.-S.; Park, W.-J.; Choi, H.-K.; Lee, H.-S. Experimental study on the development of compressive strength of early concrete age using calcium-based hardening accelerator and high early strength cement. Constr. Build. Mater. 2014, 64, 208–214. [Google Scholar] [CrossRef]

- Bentz, P. Activation energies of high-volume fly ash ternary blends: Hydration and setting. Cem. Concr. Compos. 2014, 53, 214–223. [Google Scholar] [CrossRef]

- Jiang, Z.; Qian, C.; Chen, Q. Experimental investigation on the volume stability of magnesium phosphate cement with different types of mineral admixtures. Constr. Build. Mater. 2017, 157, 10–17. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, B.; Qin, Z.; Pen, D.; Haque, M.A. Experimental research on properties and microstructures of magnesium-iron phosphate cement. Constr. Build. Mater. 2020, 257, 119570. [Google Scholar] [CrossRef]

- Guan, Y.; Sun, R.; Won, M.C.; Ge, Z.; Gao, Y. Experimental study and field application of calcium sulfoaluminate cement for rapid repair of concrete pavements. Front. Struct. Civ. Eng. 2017, 11, 338–345. [Google Scholar] [CrossRef]

- Silvestre, N.; De Brito, J. Review on concrete nanotechnology. Eur. J. Environ. Civ. Eng. 2016, 20, 455–485. [Google Scholar] [CrossRef]

- Martínez-Mera, M.; Espinosa-Pesqueira, M.; Pérez-Hernández, R.; Arenas-Alatorre, J. Synthesis of magnetite (Fe3O4) nano-particles without surfactants at room temperature. Mater. Lett. 2007, 61, 4447–4451. [Google Scholar] [CrossRef]

- Lavergne, F.; Belhadi, R.; Carriat, J.; Ben Fraj, A. Effect of nano-silica particles on the hydration, the rheology and the strength development of a blended cement paste. Cem. Concr. Compos. 2019, 95, 42–55. [Google Scholar] [CrossRef] [Green Version]

- Reches, Y. Nanoparticles as concrete additives: Review and perspectives. Constr. Build. Mater. 2018, 175, 483–495. [Google Scholar] [CrossRef]

- Senff, L.; Hotza, D.; Lucas, S.; Ferreira, V.; Labrincha, J.A. Effect of nano-SiO2 and nano-TiO2 addition on the rheological behavior and the hardened properties of cement mortars. Mater. Sci. Eng. A 2012, 532, 354–361. [Google Scholar] [CrossRef]

- Balapour, M.; Joshaghani, A.; Althoey, F. Nano-SiO2 contribution to mechanical, durability, fresh and microstructural characteristics of concrete: A review. Constr. Build. Mater. 2018, 181, 27–41. [Google Scholar] [CrossRef]

- Kuo, W.-T.; Lin, K.-L.; Chang, W.-C.; Luo, H.-L. Effects of nano-materials on properties of waterworks sludge ash cement paste. J. Ind. Eng. Chem. 2006, 12, 702–709. [Google Scholar]

- Björnström, A.; Martinelli, A.; Matic, A.; Börjesson, L.; Panas, I. Accelerating effects of colloidal nano-silica for beneficial cal-cium–silicate–hydrate formation in cement. Chem. Phys. Lett. 2004, 392, 242–248. [Google Scholar] [CrossRef]

- Liu, J.; Li, Q.; Xu, S. Influence of nanoparticles on fluidity and mechanical properties of cement mortar. Constr. Build. Mater. 2015, 101, 892–901. [Google Scholar] [CrossRef]

- Chen, J.; Kou, S.-C.; Poon, C.-S. Hydration and properties of nano-TiO2 blended cement composites. Cem. Concr. Compos. 2012, 34, 642–649. [Google Scholar] [CrossRef]

- Jalal, M.; Fathi, M.; Farzad, M. Effects of fly ash and TiO2 nanoparticles on rheological, mechanical, microstructural and thermal properties of high strength self compacting concrete. Mech. Mater. 2013, 61, 11–27. [Google Scholar] [CrossRef]

- Nehdi, M. Clay in cement-based materials: Critical overview of state-of-the-art. Constr. Build. Mater. 2014, 51, 372–382. [Google Scholar] [CrossRef]

- Kawashima, S.; Kim, J.H.; Corr, D.J.; Shah, S.P. Study of the mechanisms underlying the fresh-state response of ce-mentitious materials modified with nanoclays. Constr. Build. Mater. 2012, 36, 749–757. [Google Scholar] [CrossRef] [Green Version]

- Voigt, T.; Mbele, J.-J.; Wang, K.; Shah, S.P. Using Fly Ash, Clay, and Fibers for Simultaneous Improvement of Concrete Green Strength and Consolidatability for Slip-Form Pavement. J. Mater. Civ. Eng. 2010, 22, 196–206. [Google Scholar] [CrossRef]

- Pekmezci, B.Y.; Voigt, T.; Wang, K.; Shah, S.P. Low compaction energy concrete for improved slipform casting of concrete pavements. ACI Mater. J. 2007, 104, 251. [Google Scholar]

- Kim, J.H.; Beacraft, M.; Shah, S.P. Effect of mineral admixtures on formwork pressure of self-consolidating concrete. Cem. Concr. Compos. 2010, 32, 665–671. [Google Scholar] [CrossRef]

- Chen, J.; Liang, C.; Li, B.; Wang, E.; Li, G.; Hou, X. The effect of nano-γAl2O3 additive on early hydration of calcium alu-minate cement. Constr. Build. Mater. 2018, 158, 755–760. [Google Scholar] [CrossRef]

- Li, W.; Li, X.; Chen, S.J.; Long, G.; Liu, Y.M.; Duan, W.H. Effects of Nanoalumina and Graphene Oxide on Early-Age Hydration and Mechanical Properties of Cement Paste. J. Mater. Civ. Eng. 2017, 29, 04017087. [Google Scholar] [CrossRef]

- Luo, H.-L.; Lin, D.-F.; Shieh, S.-I.; You, Y.-F. Micro-observations of different types of nano-Al 2 O 3 on the hydration of cement paste with sludge ash replacement. Environ. Technol. 2014, 36, 1–10. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Rehman, S.K.; Ibrahim, Z.; Jameel, M.; Memon, S.A.; Javed, M.F.; Aslam, M.; Mehmood, K.; Nazar, S. Assessment of rheological and piezore-sistive properties of graphene based cement composites. Int. J. Concr. Struct. Mater. 2018, 12, 1–23. [Google Scholar] [CrossRef]

- Sixuan, H. Multifunctional Graphite Nanoplatelets (GNP) Reinforced Cementitious Composites. Master’s Thesis, National University of Singapore, Singapore, 2012. [Google Scholar]

- Wu, Y.-Y.; Que, L.; Cui, Z.; Lambert, P. Physical Properties of Concrete Containing Graphene Oxide Nanosheets. Materials 2019, 12, 1707. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lv, S.; Ma, Y.; Qiu, C.; Sun, T.; Liu, J.; Zhou, Q. Effect of graphene oxide nanosheets of microstructure and mechanical properties of cement composites. Constr. Build. Mater. 2013, 49, 121–127. [Google Scholar] [CrossRef]

- Du, H.; Pang, S.D. Enhancement of barrier properties of cement mortar with graphene nanoplatelet. Cem. Concr. Res. 2015, 76, 10–19. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.M.; Li, W.; Li, C.Y.; Sanjayan, J.G.; Duan, W.H.; Li, Z. Effects of graphene oxide agglomerates on workability, hydration, microstructure and compressive strength of cement paste. Constr. Build. Mater. 2017, 145, 402–410. [Google Scholar] [CrossRef]

- Lin, C.; Wei, W.; Hu, Y.H. Catalytic behavior of graphene oxide for cement hydration process. J. Phys. Chem. Solids 2016, 89, 128–133. [Google Scholar] [CrossRef]

- Wang, C.; Yang, C.; Liu, F.; Wan, C.; Pu, X. Preparation of Ultra-High Performance Concrete with common technology and materials. Cem. Concr. Compos. 2012, 34, 538–544. [Google Scholar] [CrossRef]

- Bentz, P.; Turpin, R. Potential applications of phase change materials in concrete technology. Cem. Cocnr. Compos. 2007, 29, 527–532. [Google Scholar] [CrossRef] [Green Version]

- Nili, M.; Ehsani, A. Investigating the effect of the cement paste and transition zone on strength development of concrete containing nanosilica and silica fume. Mater. Des. 2015, 75, 174–183. [Google Scholar] [CrossRef]

- Salvador, R.P.; Cavalaro, S.H.; Segura, I.; Figueiredo, A.D.; Pérez, J. Early age hydration of cement pastes with alkaline and alkali-free accelerators for sprayed concrete. Constr. Build. Mater. 2016, 111, 386–398. [Google Scholar] [CrossRef]

- Chithra, S.; Kumar, S.S.; Chinnaraju, K. The effect of Colloidal Nano-silica on workability, mechanical and durability properties of High Performance Concrete with Copper slag as partial fine aggregate. Constr. Build. Mater. 2016, 113, 794–804. [Google Scholar] [CrossRef]

- Hou, P.; Kawashima, S.; Kong, D.; Corr, D.J.; Qian, J.; Shah, S.P. Modification effects of colloidal nanoSiO2 on cement hy-dration and its gel property. Compos. Part. B Eng. 2013, 45, 440–448. [Google Scholar] [CrossRef] [Green Version]

- De Paula, J.N.; Calixto, J.M.; Ladeira, L.O.; Ludvig, P.; Souza, T.C.C.; Rocha, J.M.; de Melo, A.A.V. Mechanical and rheological behavior of oil-well cement slurries produced with clinker containing carbon nanotubes. J. Pet. Sci. Eng. 2014, 122, 274–279. [Google Scholar] [CrossRef]

- Makar, J.; Margeson, J.; Luh, J. Carbon nanotube/cement composites-early results and potential applications. In Proceedings of the 3rd International Conference on Construction Materials: Performance, Innovations and Structural Implications, Vancouver, BC, Canada, 22 August 2005; pp. 1–10. [Google Scholar]

- Santra, A.K.; Boul, P.J.; Pang, X. Influence of Nanomaterials in Oilwell Cement Hydration and Mechanical Properties. Soc. Pet. Eng. SPE 2012. [Google Scholar] [CrossRef]

- Siddique, R.; Mehta, A. Effect of carbon nanotubes on properties of cement mortars. Constr. Build. Mater. 2014, 50, 116–129. [Google Scholar] [CrossRef]

- Makar, J.M.; Chan, G.W. Growth of Cement Hydration Products on Single-Walled Carbon Nanotubes. J. Am. Ceram. Soc. 2009, 92, 1303–1310. [Google Scholar] [CrossRef]

- Roussel, N. A thixotropy model for fresh fluid concretes: Theory, validation and applications. Cem. Concr. Res. 2006, 36, 1797–1806. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Q.; An, X.; Liu, Y.; Li, H. Effect of constituents on rheological properties of fresh concrete—A review. Cem. Concr. Compos. 2017, 83, 146–159. [Google Scholar] [CrossRef]

- Ferraris, C.F. Measurement of the rheological properties of high performance concrete: State of the art report. J. Res. Natl. Inst. Stand. Technol. 1999, 104, 461–478. [Google Scholar] [CrossRef]

- Tattersall, H.; Banfill, P.F. The Rheology of Fresh Concrete; Pitman Books Limited: London, UK, 1983. [Google Scholar]

- Tattersall, H. Workability and Quality Control of Concrete; CRC Press: Boca Raton, FL, USA, 1991. [Google Scholar]

- Chappuis, J.; Banfill, P. Rheology of Fresh Cement and Concrete by PFG Banfill); University Press: Cambridge, UK, 1991; Volume 3. [Google Scholar]

- Ferraris, C.F.; Gaidis, J.M. Connection between the rheology of concrete and rheology of cement paste. Mater. J. 1992, 89, 388–393. [Google Scholar]

- Billberg, P.H.; Roussel, N.; Amziane, S.; Beitzel, M.; Charitou, G.; Freund, B.; Gardner, J.N.; Grampeix, G.; Graubner, C.-A.; Keller, L.; et al. Field validation of models for predicting lateral form pressure exerted by SCC. Cem. Concr. Compos. 2014, 54, 70–79. [Google Scholar] [CrossRef]

- Yen, T.; Tang, C.-W.; Chang, C.-S.; Chen, K.-H. Flow behaviour of high strength high-performance concrete. Cem. Concr. Compos. 1999, 21, 413–424. [Google Scholar] [CrossRef]

- Roussel, N. Rheology of fresh concrete: From measurements to predictions of casting processes. Mater. Struct. 2007, 40, 1001–1012. [Google Scholar] [CrossRef]

- Perrot, A.; Pierre, A.; Vitaloni, S.; Picandet, V. Prediction of lateral form pressure exerted by concrete at low casting rates. Mater. Struct. 2014, 48, 2315–2322. [Google Scholar] [CrossRef]

- Feys, D.; Verhoeven, R.; De Schutter, G. Evaluation of Time Independent Rheological Models Applicable to Fresh Self-Compacting Concrete. Appl. Rheol. 2007, 17, 56244–56251. [Google Scholar] [CrossRef]

- Ferraris, C.F. Concrete rheology: Knowledge and challenges. In Proceedings of the 2nd International RILEM Symposium on Advances in Concrete through Science and Engineering, Quebec, QC, Canada, 11–13 September 2006. [Google Scholar]

- Hu, J. A Study of Effects of Aggregate on Concrete Rheology. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2018. [Google Scholar]

- Shih, J.-Y.; Chang, T.-P.; Hsiao, T.-C. Effect of nanosilica on characterization of Portland cement composite. Mater. Sci. Eng. A 2006, 424, 266–274. [Google Scholar] [CrossRef]

- Lee, S.-J.; Won, J.-P. Shrinkage characteristics of structural nano-synthetic fibre-reinforced cementitious composites. Compos. Struct. 2016, 157, 236–243. [Google Scholar] [CrossRef]

- Felekoğlu, B.; Tosun, K.; Baradan, B. Effects of fibre type and matrix structure on the mechanical performance of self-compacting micro-concrete composites. Cem. Concr. Res. 2009, 39, 1023–1032. [Google Scholar] [CrossRef]

- Quercia, G.; Hüsken, G.; Brouwers, H. Water demand of amorphous nano silica and its impact on the workability of cement paste. Cem. Concr. Res. 2012, 42, 344–357. [Google Scholar] [CrossRef] [Green Version]

- Givi, A.N.; Rashid, S.A.; Aziz, F.N.A.; Salleh, M.A.M. The effects of lime solution on the properties of SiO2 nanoparticles binary blended concrete. Compos. Part B Eng. 2011, 42, 562–569. [Google Scholar] [CrossRef]

- Givi, N.; Rashid, S.A.; Aziz, F.N.A.; Salleh, M.A.M. Influence of 15 and 80 nano-SiO2 particles addition on mechanical and physical properties of ternary blended concrete incorporating rice husk ash. J. Exp. Nanosci. 2013, 8, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Sari, M.; Prat, E.; Labastire, J.-F. High strength self-compacting concrete Original solutions associating organic and inorganic admixtures. Cem. Concr. Res. 1999, 29, 813–818. [Google Scholar] [CrossRef]

- Mahapatra, K.; Barai, S.V. Hybrid fiber reinforced self compacting concrete with fly ash and colloidal nano silica: A sys-tematic study. Constr. Build. Mater. 2018, 160, 828–838. [Google Scholar] [CrossRef]

- Khoshakhlagh, A.; Nazari, A.; Khalaj, G. Effects of Fe2O3 Nanoparticles on Water Permeability and Strength Assessments of High Strength Self-Compacting Concrete. J. Mater. Sci. Technol. 2012, 28, 73–82. [Google Scholar] [CrossRef]

- Ji, T. Preliminary study on the water permeability and microstructure of concrete incorporating nano-SiO2. Cem. Concr. Res. 2005, 35, 1943–1947. [Google Scholar] [CrossRef]

- Tibbits, S.; McKnelly, C.; Olguin, C.; Dikovsky, D.; Hirsch, S. 4D Printing and Universal Transformation; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Panda, B.; Tan, M.J.; Gibson, I.; Chua, C.K. The disruptive evolution of 3D printing. In Proceedings of the 2nd International Conference on Progress in Additive Manufacturing, Singapore, 16–19 May 2016; pp. 152–157. [Google Scholar]

- Bandyopadhyay, A.; Heer, B. Additive manufacturing of multi-material structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Lee, J.-Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Ding, Z.; Yuan, C.; Peng, X.; Wang, T.; Qi, H.J.; Dunn, M.L. Direct 4D printing via active composite materials. Sci. Adv. 2017, 3, e1602890. [Google Scholar] [CrossRef] [Green Version]

- Le, T.; Austin, S.; Lim, S.; Buswell, R.; Law, R.; Gibb, A.; Thorpe, T. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef] [Green Version]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.; Thorpe, T. Developments in construction-scale additive manu-facturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef] [Green Version]

- Di Bella, C.; Duchi, S.; O’Connell, C.D.; Blanchard, R.; Augustine, C.; Yue, Z.; Thompson, F.; Richards, C.; Beirne, S.; Onofrillo, C.; et al. In situ handheld three-dimensional bioprinting for cartilage regeneration. J. Tissue Eng. Regen. Med. 2018, 12, 611–621. [Google Scholar] [CrossRef]

- Han, Y.L.; Hu, J.; Genin, G.M.; Lu, T.J.; Xu, F. BioPen: Direct writing of functional materials at the point of care. Sci. Rep. 2015, 4, 4872. [Google Scholar] [CrossRef] [Green Version]

- Quanji, Z.; Lomboy, G.R.; Wang, K. Influence of nano-sized highly purified magnesium alumino silicate clay on thixotropic behavior of fresh cement pastes. Constr. Build. Mater. 2014, 69, 295–300. [Google Scholar] [CrossRef]

- Kazemian, A.; Yuan, X.; Cochran, E.; Khoshnevis, B. Cementitious materials for construction-scale 3D printing: Laboratory testing of fresh printing mixture. Constr. Build. Mater. 2017, 145, 639–647. [Google Scholar] [CrossRef]

- Rubio, M.; Sonebi, M.; Amziane, S. 3D printing of fibre cement-based materials: Fresh and rheological performances. Acad. J. Civ. Eng. 2017, 35, 480–488. [Google Scholar]

- Panda, B.; Ruan, S.; Unluer, C.; Tan, M.J. Improving the 3D printability of high volume fly ash mixtures via the use of nano attapulgite clay. Compos. Part B Eng. 2019, 165, 75–83. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; She, W.; Yang, L.; Liu, G.; Yang, Y. Rheological and harden properties of the high-thixotropy 3D printing concrete. Constr. Build. Mater. 2019, 201, 278–285. [Google Scholar] [CrossRef]

- Panda, B.; Singh, G.B.; Unluer, C.; Tan, M.J. Synthesis and characterization of one-part geopolymers for extrusion based 3D concrete printing. J. Clean. Prod. 2019, 220, 610–619. [Google Scholar] [CrossRef]

- Wallevik, H.; Wallevik, J.E. Rheology as a tool in concrete science: The use of rheographs and workability boxes. Cem. Concr. Res. 2011, 41, 1279–1288. [Google Scholar] [CrossRef]

- Zhang, R.; Cheng, X.; Hou, P.; Ye, Z. Influences of nano-TiO2 on the properties of cement-based materials: Hydration and drying shrinkage. Constr. Build. Mater. 2015, 81, 35–41. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S.; Riahi, S.; Shamekhi, S.F.; Khademno, A. Influence of Al2O3 nanoparticles on the compressive strength and workability of blended concrete. J. Am. Sci. 2010, 6, 6–9. [Google Scholar]

- Nazari, A.; Riahi, S.; Riahi, S.; Shamekhi, S.F.; Khademno, A. Benefits of Fe2O3 nanoparticles in concrete mixing matrix. J. Am. Sci. 2010, 6, 102–106. [Google Scholar]

- Nazari, A.A.; Riahi, S. The effects of TiO2 nanoparticles on physical, thermal and mechanical properties of concrete using ground granulated blast furnace slag as binder. Mater. Sci. Eng. A 2011, 528, 2085–2092. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. Improvement compressive strength of concrete in different curing media by Al2O3 nanoparticles. Mater. Sci. Eng. A 2011, 528, 1183–1191. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. RETRACTED: Al2O3 nanoparticles in concrete and different curing media. Energy Build. 2011, 43, 1480–1488. [Google Scholar] [CrossRef]

- Rashad, M. A synopsis about the effect of nano-Al2O3, nano-Fe2O3, nano-Fe3O4 and nano-clay on some properties of ce-mentitious materials–A short guide for Civil Engineer. Mater. Des. 2013, 52, 143–157. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.; Lv, C.-X.; Cui, X.-Y.; Li, S.-Y.; Wang, X. Rheological behavior of fresh cement pastes with a graphene oxide additive. New Carbon Mater. 2016, 31, 574–584. [Google Scholar] [CrossRef]

- Shang, Y.; Zhang, D.; Yang, C.; Liu, Y.; Liu, Y. Effect of graphene oxide on the rheological properties of cement pastes. Constr. Build. Mater. 2015, 96, 20–28. [Google Scholar] [CrossRef]

- Gong, K.; Pan, Z.; Korayem, A.H.; Qiu, L.; Li, D.; Collins, F.; Wang, C.M.; Duan, W.H. Reinforcing Effects of Graphene Oxide on Portland Cement Paste. J. Mater. Civ. Eng. 2015, 27, 4014010. [Google Scholar] [CrossRef]

- Middelkoop, V.; Slater, T.; Florea, M.; Neațu, F.; Danaci, S.; Onyenkeadi, V.; Boonen, K.; Saha, B.; Baragau, I.-A.; Kellici, S. Next frontiers in cleaner synthesis: 3D printed graphene-supported CeZrLa mixed-oxide nanocatalyst for CO2 utilisation and direct propylene carbonate production. J. Clean. Prod. 2019, 214, 606–614. [Google Scholar] [CrossRef]

- Bai, J.; Allaoui, A. Effect of the length and the aggregate size of MWNTs on the improvement efficiency of the mechanical and electrical properties of nanocomposites—Experimental investigation. Compos. Part. A Appl. Sci. Manuf. 2003, 34, 689–694. [Google Scholar] [CrossRef]

- Zou, B.; Chen, S.J.; Korayem, A.H.; Collins, F.; Wang, C.; Duan, W.H. Effect of ultrasonication energy on engineering properties of carbon nanotube reinforced cement pastes. Carbon 2015, 85, 212–220. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Grasley, Z.; Tyson, B.; Al-Rub, R.A. Carbon nano filaments in cementitious materials: Some issues on dispersion and interfacial bond. ACI Spec. Publ. 2009, 267, 21–34. [Google Scholar]

- Leonavičius, D.; Pundienė, I.; Girskas, G.; Pranckevičienė, J.; Kligys, M.; Kairytė, A. The effect of multi-walled carbon nanotubes on the rheological properties and hydration process of cement pastes. Constr. Build. Mater. 2018, 189, 947–954. [Google Scholar] [CrossRef]

- Kim, H.; Park, I.; Lee, H. Improved piezoresistive sensitivity and stability of CNT/cement mortar composites with low water–binder ratio. Compos. Struct. 2014, 116, 713–719. [Google Scholar] [CrossRef]

- Rashad, M. A comprehensive overview about the effect of nano-SiO2 on some properties of traditional cementitious materials and alkali-activated fly ash. Constr. Build. Mater. 2014, 52, 437–464. [Google Scholar] [CrossRef]

- Qing, Y.; Zenan, Z.; Li, S.; Rongshen, C. A comparative study on the pozzolanic activity between nano-SiO2 and silica fume. J. Wuhan Univ.Technol. Mater. Sci. Ed. 2006, 21, 153–157. [Google Scholar] [CrossRef]

- Qing, Y.; Zenan, Z.; Deyu, K.; Rongshen, C. Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar] [CrossRef]

- Stefanidou, M.; Papayianni, I. Influence of nano-SiO2 on the Portland cement pastes. Compos. Part. B Eng. 2012, 43, 2706–2710. [Google Scholar] [CrossRef]

- Berra, M.; Carassiti, F.; Mangialardi, T.; Paolini, A.; Sebastiani, M. Effects of nanosilica addition on workability and com-pressive strength of Portland cement pastes. Constr. Build. Mater. 2012, 35, 666–675. [Google Scholar] [CrossRef]

- Gaitero, J.; Campillo, I.; Guerrero, A. Reduction of the calcium leaching rate of cement paste by addition of silica nano-particles. Cem. Concr. Res. 2008, 38, 1112–1118. [Google Scholar] [CrossRef] [Green Version]

- Pourjavadi, A.; Fakoorpoor, S.M.; Hosseini, P.; Khaloo, A. Interactions between superabsorbent polymers and cement-based composites incorporating colloidal silica nanoparticles. Cem. Concr. Compos. 2013, 37, 196–204. [Google Scholar] [CrossRef]

- Shebl, S.S.; Allie, L.; Morsy, M.S.; Aglan, H.A. Mechanical behavior of activated nano silicate filled cement binders. J. Mater. Sci. 2009, 44, 1600–1606. [Google Scholar] [CrossRef]

- Thuadaij, N.; Nuntiya, A. Synthesis and characterization of nanosilica from rice husk ash prepared by precipitation method. J. Nat. Sci. Spec. Issue Nanotechnol. 2008, 7, 59–65. [Google Scholar]

- Shen, D.; Shi, X.; Zhu, S.; Duan, X.; Zhang, J. Relationship between tensile Young’s modulus and strength of fly ash high strength concrete at early age. Constr. Build. Mater. 2016, 123, 317–326. [Google Scholar] [CrossRef]

- Haque, M.A.; Chen, B. Research progresses on magnesium phosphate cement: A review. Constr. Build. Mater. 2019, 211, 885–898. [Google Scholar] [CrossRef]

- Sofi, M.; van Deventer, J.; Mendis, P.; Lukey, G. Engineering properties of inorganic polymer concretes (IPCs). Cem. Concr. Res. 2007, 37, 251–257. [Google Scholar] [CrossRef]

- Khaloo, A.; Mobini, M.H.; Hosseini, P. Influence of different types of nano-SiO2 particles on properties of high-performance concrete. Constr. Build. Mater. 2016, 113, 188–201. [Google Scholar] [CrossRef]

- Supit, W.M.; Shaikh, F.U.A. Durability properties of high volume fly ash concrete containing nano-silica. Mater. Struct. 2015, 48, 2431–2445. [Google Scholar] [CrossRef]

- Xiao, H.; Zhang, F.; Liu, R.; Zhang, R.; Liu, Z.; Liu, H. Effects of pozzolanic and non-pozzolanic nanomaterials on ce-ment-based materials. Constr. Build. Mater. 2019, 213, 1–9. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H. Development of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC): Towards an efficient utilization of binders and fibres. Constr. Build. Mater. 2015, 79, 273–282. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.-H.; Islam, J. Use of nano-silica to reduce setting time and increase early strength of concretes with high volumes of fly ash or slag. Constr. Build. Mater. 2012, 29, 573–580. [Google Scholar] [CrossRef]

- Salemi, N.; Behfarnia, K. Effect of nano-particles on durability of fiber-reinforced concrete pavement. Constr. Build. Mater. 2013, 48, 934–941. [Google Scholar] [CrossRef]

- Li, W.; Huang, Z.; Cao, F.; Sun, Z.; Shah, S.P. Effects of nano-silica and nano-limestone on flowability and mechanical properties of ultra-high-performance concrete matrix. Constr. Build. Mater. 2015, 95, 366–374. [Google Scholar] [CrossRef]

- Ghasemzadeh, F.; Sajedi, S.; Shekarchi, M.; Layssi, H.; Hallaji, M. Performance evaluation of different repair concretes pro-posed for an existing deteriorated jetty structure. J. Perform. Constr. Facil. 2014, 28, 04014013. [Google Scholar] [CrossRef]

- Ghafoori, N.; Maler, M.O.; Najimi, M.; Hasnat, A. Properties of high early-strength Type V cement concrete for rapid repair. Proc. MATEC Web Conf. EDP Sci. 2019, 289, 02003. [Google Scholar] [CrossRef]

- Jalal, M.; Mansouri, E.; Sharifipour, M.; Pouladkhan, A.R. Mechanical, rheological, durability and microstructural prop-erties of high performance self-compacting concrete containing SiO2 micro and nanoparticles. Mater. Des. 2012, 34, 389–400. [Google Scholar] [CrossRef]

- Bahadori, H.; Hosseini, P. Reduction of cement consumption by the aid of silica nano-particles (investigation on concrete properties). J. Civ. Eng. Manag. 2012, 18, 416–425. [Google Scholar] [CrossRef]

- Bastos, G.; Patiño-Barbeito, F.; Patiño-Cambeiro, F.; Armesto, J. Nano-inclusions applied in cement-matrix composites: A review. Materials 2016, 9, 1015. [Google Scholar] [CrossRef] [PubMed]

- Mohseni, E.; Tsavdaridis, K.D. Effect of nano-alumina on pore structure and durability of Class F Fly ash self-compacting mortar. Am. J. Eng. Appl. Sci. 2016, 9, 323–333. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. Computer-aided design of the effects of Fe2O3 nanoparticles on split tensile strength and water per-meability of high strength concrete. Mater. Des. 2011, 32, 3966–3979. [Google Scholar] [CrossRef]

- Facconi, L.; Minelli, F.; Plizzari, G.; Pasetto, A.; Marco, P.S. Precast Fibre-Reinforced Self-Compacting Concrete Slabs. Fibre Reinforced Concrete: From Design to Structural Applications-FRC. Available online: https://www.researchgate.net/profile/Luca-Facconi/publication/280063988_Precast_fiber_reinforced_self_compacting_concrete_slabs/links/5c07df6d4585157ac1aa8afe/Precast-fiber-reinforced-self-compacting-concrete-slabs.pdf (accessed on 12 April 2021).

- Cibilakshmi, G.; Jegan, J. A DOE approach to optimize the strength properties of concrete incorporated with different ratios of PVA fibre and nano-Fe2O3. Adv. Compos. Lett. 2020, 29. [Google Scholar] [CrossRef] [Green Version]

- Bragança, M.; Portella, K.F.; Bonato, M.M.; Alberti, E.; Marino, C.E.B. Performance of Portland cement concretes with 1% nano-Fe3O4 addition: Electrochemical stability under chloride and sulfate environments. Constr. Build. Mater. 2016, 117, 152–162. [Google Scholar] [CrossRef]

- Zhang, W.; Yin, C.; Ma, F.; Huang, Z. Mechanical Properties and Carbonation Durability of Engineered Cementitious Composites Reinforced by Polypropylene and Hydrophilic Polyvinyl Alcohol Fibers. Materials 2018, 11, 1147. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Chen, L.; Liu, A.; Wang, X. Effect of nano-CaCO3 on properties of cement paste. Energy Procedia 2012, 16, 991–996. [Google Scholar] [CrossRef] [Green Version]

- Sikora, P.; Horszczaruk, E.; Cendrowski, K.; Mijowska, E. The influence of nano-Fe3O4 on the microstructure and me-chanical properties of cementitious composites. Nanoscale Res. Lett. 2016, 11, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Morsy, M.; Alsayed, S.; Aqel, M. Effect of nano-clay on mechanical properties and microstructure of ordinary Portland cement mortar. Int. J. Civ. Environ. Eng. IJCEE-IJENS 2010, 10, 23–27. [Google Scholar]

- De Belie, N.; Soutsos, M.; Gruyaert, E. Properties of Fresh and Hardened Concrete Containing Supplementary Cementitious Materials; Springer: Berlin/Heidelberg, Germany, 2018; Volume 25. [Google Scholar]

- Wang, X.-Y.; Lee, H.-S. Modeling the hydration of concrete incorporating fly ash or slag. Cem. Concr. Res. 2010, 40, 984–996. [Google Scholar] [CrossRef]

- Zhang, P.; Wan, J.; Wang, K.; Li, Q. Influence of nano-SiO2 on properties of fresh and hardened high performance concrete: A state-of-the-art review. Constr. Build. Mater. 2017, 148, 648–658. [Google Scholar] [CrossRef]

- Kim, Y.; Hanif, A.; Usman, M.; Munir, M.J.; Kazmi, S.M.S.; Kim, S. Slag waste incorporation in high early strength concrete as cement replacement: Environmental impact and influence on hydration & durability attributes. J. Clean. Prod. 2018, 172, 3056–3065. [Google Scholar] [CrossRef]

- Şahmaran, M.; Al-Emam, M.; Yıldırım, G.; Şimşek, Y.E.; Erdem, T.K.; Lachemi, M. High-early-strength ductile cementitious composites with characteristics of low early-age shrinkage for repair of infrastructures. Mater. Struct. 2013, 48, 1389–1403. [Google Scholar] [CrossRef] [Green Version]

- Shen, D.; Wang, X.; Cheng, D.; Zhang, J.; Jiang, G. Effect of internal curing with super absorbent polymers on autogenous shrinkage of concrete at early age. Constr. Build. Mater. 2016, 106, 512–522. [Google Scholar] [CrossRef]

- Rad, T.A.; Tanzadeh, J.; Pourdada, A. Laboratory evaluation of self-compacting fiber-reinforced concrete modified with hybrid of nanomaterials. Constr. Build. Mater. 2020, 232, 117211. [Google Scholar] [CrossRef]

- Lee, C.; Lee, S.; Nguyen, N. Modeling of Compressive Strength Development of High-Early-Strength-Concrete at Different Curing Temperatures. Int. J. Concr. Struct. Mater. 2016, 10, 205–219. [Google Scholar] [CrossRef] [Green Version]

- Hu, Z.; Teng, Y.; Wang, Q.; Wu, L. Dielectric properties of CaCu2.9Zn0.1Ti4O12 ceramics by addition of Al2O3 nanoparticles. J. Mater. Sci. Mater. Electron. 2018, 29, 9245–9250. [Google Scholar] [CrossRef]

- Xu, L.; Meng, T.; Huang, M.Z. Effects of nano-CaCO3 on the compressive strength and microstructure of high strength concrete in different curing temperature. Appl. Mech. Mater. 2012, 121, 126–131. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Mukherjee, S.; Nikraz, H. Effects of nano-Al2O3 on early-age microstructural properties of cement paste. Constr. Build. Mater. 2014, 52, 189–193. [Google Scholar] [CrossRef]

- Riding, K.; Silva, D.A.; Scrivener, K. Early age strength enhancement of blended cement systems by CaCl2 and dietha-nol-isopropanolamine. Cem. Concr. Res. 2010, 40, 935–946. [Google Scholar] [CrossRef] [Green Version]

- Seifan, M.; Mendoza, S.; Berenjian, A. Mechanical properties and durability performance of fly ash based mortar containing nano- and micro-silica additives. Constr. Build. Mater. 2020, 252, 119121. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.-G.; Yuan, J.; Ou, J. Microstructure of cement mortar with nano-particles. Compos. Part. B Eng. 2004, 35, 185–189. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.-G.; Ou, J.-P. A study on mechanical and pressure-sensitive properties of cement mortar with nanophase materials. Cem. Concr. Res. 2004, 34, 435–438. [Google Scholar] [CrossRef]

- Jo, B.-W.; Kim, C.-H.; Tae, G.-H.; Park, J.-B. Characteristics of cement mortar with nano-SiO2 particles. Constr. Build. Mater. 2007, 21, 1351–1355. [Google Scholar] [CrossRef]

- Ltifi, M.; Guefrech, A.; Mounanga, P.; Khelidj, A. Experimental study of the effect of addition of nano-silica on the behaviour of cement mortars Mounir. Procedia Eng. 2011, 10, 900–905. [Google Scholar] [CrossRef] [Green Version]

- Sadrmomtazi, A.; Fasihi, A.; Balalaei, F.; Haghi, A. Investigation of mechanical and physical properties of mortars containing silica fume and nano-SiO. In Proceedings of the Third International Conference on Concrete and Development, Tehran, Iran, 27 April 2009; pp. 27–29. [Google Scholar]

- Ibrahim, R.K.; Hamid, R.; Taha, M. Fire resistance of high-volume fly ash mortars with nanosilica addition. Constr. Build. Mater. 2012, 36, 779–786. [Google Scholar] [CrossRef]

- Kontoleontos, F.; Tsakiridis, P.; Marinos, A.; Kaloidas, V.; Katsioti, M. Influence of colloidal nanosilica on ultrafine cement hydration: Physicochemical and microstructural characterization. Constr. Build. Mater. 2012, 35, 347–360. [Google Scholar] [CrossRef]

- Lin, D.; Lin, K.; Chang, W.; Luo, H.; Cai, M. Improvements of nano-SiO2 on sludge/fly ash mortar. Waste Manag. 2008, 28, 1081–1087. [Google Scholar] [CrossRef] [PubMed]

- Boshehrian, A.; Hosseini, P. Effect of nano-SiO2 particles on properties of cement mortar applicable for ferrocement elements. Concr. Res. Lett. 2011, 2, 167–180. [Google Scholar]

- Campillo, I.; Guerrero, A.; Dolado, J.; Porro, A.; Ibáñez, J.; Goñi, S. Improvement of initial mechanical strength by nanoalumina in belite cements. Mater. Lett. 2007, 61, 1889–1892. [Google Scholar] [CrossRef]

- Li, Z.; Wang, H.; He, S.; Lu, Y.; Wang, M. Investigations on the preparation and mechanical properties of the nano-alumina reinforced cement composite. Mater. Lett. 2006, 60, 356–359. [Google Scholar] [CrossRef]

- Fallah, S.; Nematzadeh, M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr. Build. Mater. 2017, 132, 170–187. [Google Scholar] [CrossRef]

- Bautista-Gutierrez, K.P.; Herrera-May, A.L.; Santamaría-López, J.M.; Honorato-Moreno, A.; Zamora-Castro, S.A. Recent Progress in Nanomaterials for Modern Concrete Infrastructure: Advantages and Challenges. Materials 2019, 12, 3548. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Madandoust, R.; Mohseni, E.; Mousavi, S.Y.; Namnevis, M. An experimental investigation on the durability of self-compacting mortar containing nano-SiO2, nano-Fe2O3 and nano-CuO. Constr. Build. Mater. 2015, 86, 44–50. [Google Scholar] [CrossRef]

- Gopinath, S.; Mouli, P.; Murthy, A.; Iyer, N.; Maheswaran, S. Effect of Nano Silica on Mechanical Properties and Durability of Normal Strength Concrete. Arch. Civ. Eng. 2012, 58, 433–444. [Google Scholar] [CrossRef]

- Tobbala, D. Effect of Nano-ferrite addition on mechanical properties and gamma ray attenuation coefficient of steel fiber rein-forced heavy weight concrete. Constr. Build. Mater. 2019, 207, 48–58. [Google Scholar] [CrossRef]

- Chen, D.-H.; Lin, H.-H.; Sun, R. Field performance evaluations of partial-depth repairs. Constr. Build. Mater. 2011, 25, 1369–1378. [Google Scholar] [CrossRef]

- Zou, B.; Huang, C.Z.; Wang, J.; Liu, B.Q. Effect of Nano-Scale TiN on the Mechanical Properties and Microstructure of Si3N4 Based Ceramic Tool Materials. Key Eng. Mater. 2006, 315-316, 154–158. [Google Scholar] [CrossRef]

- Wang, X.H.; Xu, C.H.; Yi, M.D.; Zhang, H.F. Effects of nano-ZrO2 on the microstructure and mechanical properties of Ti (C, N)-based cermet die materials. Adv. Mater. Res. 2011, 154, 1319–1323. [Google Scholar] [CrossRef]

- Wang, L.; Meng, L.J. Influence of Carbon Nano-fiber on Mechanical Property of PALC. Appl. Mech. Mater. 2014, 35, 785–787. [Google Scholar] [CrossRef]

- Al Ghabban, A.; Al Zubaidi, A.B.; Jafar, M.; Fakhri, Z. Effect of Nano SiO2 and Nano CaCO3 on The Mechanical Properties, Durability and flowability of Concrete. Proc. IOP Conf. Ser. Mater. Sci. Eng. IOP Publ. 2018, 454, 012016. [Google Scholar] [CrossRef]

- Saba, N.; Paridah, M.; Abdan, K.; Ibrahim, N.; Saba, N.; Paridah, M.; Abdan, K.; Ibrahim, N. Effect of oil palm nano filler on mechanical and morphological properties of kenaf reinforced epoxy composites. Constr. Build. Mater. 2016, 123, 15–26. [Google Scholar] [CrossRef]

- Thind, S.; Singh, J.; Saini, J.; Bhunia, H. Mechanical and Wear Properties of Hybrid. Epoxy Nanocomposites; NISCAIR-CSIR: New Delhi, India, 2015. [Google Scholar]

- Lv, S.; Liu, J.; Sun, T.; Ma, Y.; Zhou, Q. Effect of GO nanosheets on shapes of cement hydration crystals And their formation process. Constr. Build. Mater. 2014, 64, 231–239. [Google Scholar] [CrossRef]

- Pan, Z.; He, L.; Qiu, L.; Korayem, A.H.; Li, G.; Zhu, J.W.; Collins, F.; Li, D.; Duan, W.H.; Wang, M.C. Mechanical properties and microstructure of a graphene oxide–cement composite. Cem. Concr. Compos. 2015, 58, 140–147. [Google Scholar] [CrossRef]

- Khorasani, M.T.; Joorabloo, A.; Moghaddam, A.; Shamsi, H.; MansooriMoghadam, Z. Incorporation of ZnO nanoparticles into heparinised polyvinyl alcohol/chitosan hydrogels for wound dressing application. Int. J. Biol. Macromol. 2018, 114, 1203–1215. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Lv, R.; Ma, X.; Zou, M.; Wang, W.; Yan, L.; Ding, T.; Ye, X.; Liu, D. Lysozyme immobilization on the calcium alginate film under sonication: Development of an antimicrobial film. Food Hydrocoll. 2018, 83, 1–8. [Google Scholar] [CrossRef]

- Wang, L.; Yu, I.K.; Tsang, D.C.; Yu, K.; Li, S.; Poon, C.S.; Dai, J.-G. Upcycling wood waste into fibre-reinforced magnesium phosphate cement particleboards. Constr. Build. Mater. 2018, 159, 54–63. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.; Wan, S. Effects of different nanomaterials on hardening and performance of ultra-high strength concrete (UHSC). Cem. Concr. Compos. 2016, 70, 24–34. [Google Scholar] [CrossRef] [Green Version]

- Fang, Y.; Chen, B.; Oderji, S.Y. Experimental research on magnesium phosphate cement mortar reinforced by glass fiber. Constr. Build. Mater. 2018, 188, 729–736. [Google Scholar] [CrossRef]

- Chen, Z. Effect of Polypropylene Fiber on Shrinkage Properties of Cement-stabilized Macadam. Mod. Appl. Sci. 2009, 3, p71. [Google Scholar] [CrossRef] [Green Version]

- Meng, W.; Khayat, K.H. Effect of graphite nanoplatelets and carbon nanofibers on rheology, hydration, shrinkage, me-chanical properties, microstructure of UHPC. Cem. Concr. Res. 2018, 105, 64–71. [Google Scholar] [CrossRef]

- Alonge, O.R.; Ramli, M.B.; Lawalson, T.J. Properties of hybrid cementitious composite with metakaolin, nanosilica and epoxy. Constr. Build. Mater. 2017, 155, 740–750. [Google Scholar] [CrossRef]

- Salvador, R.P.; Cavalaro, S.H.; Cincotto, M.A.; De Figueiredo, A.D. Parameters controlling early age hydration of cement pastes containing accelerators for sprayed concrete. Cem. Concr. Res. 2016, 89, 230–248. [Google Scholar] [CrossRef]

- Nguyen, D.H.; Dao, V.T.; Lura, P. Tensile properties of concrete at very early ages. Constr. Build. Mater. 2017, 134, 563–573. [Google Scholar] [CrossRef]

- Liu, X.; Fang, T.; Zuo, J. Effect of Nano-Materials on Autogenous Shrinkage Properties of Cement Based Materials. Symmetry 2019, 11, 1144. [Google Scholar] [CrossRef] [Green Version]

- Haruehansapong, S.; Pulngern, T.; Chucheepsakul, S. Effect of nanosilica particle size on the water permeability, abrasion resistance, drying shrinkage, and repair work properties of cement mortar containing nano-SiO2. Adv. Mater. Sci. Eng. 2017, 2017. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Du, X.; Zhao, X.; Zhou, Z.; Cheng, X. Durability and Interfacial Properties of Concrete with Nanosilica-Modified Mortar Cover. J. Mater. Civ. Eng. 2019, 31, 04019073. [Google Scholar] [CrossRef]

- Hakamy, A.; Shaikh, F.; Low, M.I. Characteristics of hemp fabric reinforced nanoclay–cement nanocomposites. Cem. Concr. Compos. 2014, 50, 27–35. [Google Scholar] [CrossRef]

- Zhang, M.-H.; Li, H. Pore structure and chloride permeability of concrete containing nano-particles for pavement. Constr. Build. Mater. 2011, 25, 608–616. [Google Scholar] [CrossRef]

- Igarashi, S.-I.; Watanabe, A.; Kawamura, M. Evaluation of capillary pore size characteristics in high-strength concrete at early ages. Cem. Concr. Res. 2005, 35, 513–519. [Google Scholar] [CrossRef] [Green Version]

- Shamsai, A.; Peroti, S.; Rahmani, K.; Rahemi, L. Effect of water-cement ratio on abrasive strength, porosity and permeability of nano-silica concrete. World Appl. Sci. J. 2012, 17, 929–933. [Google Scholar]

- Ji, Y.; Sun, Z.; Chen, C.; Pel, L.; Barakat, A. Setting characteristics, mechanical properties and microstructure of cement pastes containing accelerators mixed with superabsorbent polymers (SAPs): An NMR study combined with additional meth-ods. Materials 2019, 12, 315. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mohseni, E.; Khotbehsara, M.M.; Naseri, F.; Monazami, M.; Sarker, P. Polypropylene fiber reinforced cement mortars con-taining rice husk ash and nano-alumina. Constr. Build. Mater. 2016, 111, 429–439. [Google Scholar] [CrossRef]

- Tobón, J.; Payá, J.; Borrachero, M.; Restrepo, O. Mineralogical evolution of Portland cement blended with silica nanoparticles and its effect on mechanical strength. Constr. Build. Mater. 2012, 36, 736–742. [Google Scholar] [CrossRef]

- Liu, H.; Yu, Y.; Liu, H.; Jin, J.; Liu, S. Hybrid effects of nano-silica and graphene oxide on mechanical properties and hy-dration products of oil well cement. Constr. Build. Mater. 2018, 191, 311–319. [Google Scholar] [CrossRef]

- Albar, A.; Chougan, M.; Kheetan, M.J.A.; Swash, M.R.; Ghaffar, S.H. Effective extrusion-based 3D printing system design for cementitious-based materials. Results Eng. 2020, 6, 100135. [Google Scholar] [CrossRef]

- Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Bos, F.; Perrot, A.; da Silva, W.L.; Nerella, V.; Fataei, S.; Wolfs, R.; Sonebi, M.; Roussel, N. Extrusion-based additive manufacturing with cement-based materials—Production steps, processes, and their underlying physics: A review. Cem. Concr. Res. 2020, 132, 106037. [Google Scholar] [CrossRef]

- Sikora, P.; Chougan, M.; Cuevas, K.; Liebscher, M.; Mechtcherine, V.; Ghaffar, S.H.; Liard, M.; Lootens, D.; Krivenko, P.; Sanytsky, M.; et al. The effects of nano- and micro-sized additives on 3D printable cementitious and alkali-activated composites: A review. Appl. Nanosci. 2021, 1–19. [Google Scholar] [CrossRef]

- Jolin, M.; Burns, D.; Bissonnette, B.; Gagnon, F.; Bolduc, L.-S. Understanding the pumpability of concrete. In Proceedings of the 2009 Engineering Conferences International, Quebec City, QC, Canada, 7–10 June 2009. [Google Scholar]

- Khan, M. Mix suitable for concrete 3D printing: A review. In Proceedings of the Materials Today; Elsevier BV: Amsterdam, The Netherlands, 2020; Volume 32, pp. 831–837. [Google Scholar]

- Mechtcherine, V.; Nerella, V.N.; Kasten, K. Testing pumpability of concrete using Sliding Pipe Rheometer. Constr. Build. Mater. 2014, 53, 312–323. [Google Scholar] [CrossRef]

- Secrieru, E.; Fataei, S.; Schröfl, C.; Mechtcherine, V. Study on concrete pumpability combining different laboratory tools and linkage to rheology. Constr. Build. Mater. 2017, 144, 451–461. [Google Scholar] [CrossRef]

- Malaeb, Z.; AlSakka, F.; Hamzeh, F. 3D concrete printing: Machine design, mix proportioning, and mix comparison be-tween different machine setups. In 3D Concrete Printing Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 115–136. [Google Scholar]

- Figueiredo, S.C.; Rodríguez, C.R.; Ahmed, Z.Y.; Bos, D.; Xu, Y.; Salet, T.M.; Çopuroğlu, O.; Schlangen, E.; Bos, F.P. An approach to develop printable strain hardening cementitious composites. Mater. Des. 2019, 169, 107651. [Google Scholar] [CrossRef]

- Alghamdi, H.; Nair, S.A.; Neithalath, N. Insights into material design, extrusion rheology, and properties of 3D-printable alkali-activated fly ash-based binders. Mater. Des. 2019, 167, 107634. [Google Scholar] [CrossRef]

- Chen, Y.; Figueiredo, S.C.; Li, Z.; Chang, Z.; Jansen, K.; Çopuroğlu, O.; Schlangen, E. Improving printability of limestone-calcined clay-based cementitious materials by using viscosity-modifying admixture. Cem. Concr. Res. 2020, 132, 106040. [Google Scholar] [CrossRef]

- Jo, H.; Jo, B.W.; Cho, W.; Kim, J.-H. Development of a 3D Printer for Concrete Structures: Laboratory Testing of Ce-mentitious Materials. Int. J. Concr. Struct. Mater. 2020, 14, 1–11. [Google Scholar] [CrossRef]

- Papachristoforou, M.; Mitsopoulos, V.; Stefanidou, M. Evaluation of workability parameters in 3D printing concrete. Procedia Struct. Integr. 2018, 10, 155–162. [Google Scholar] [CrossRef]

- Buswell, R.; De Silva, W.L.; Jones, S.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Wangler, T.; Roussel, N.; Bos, F.P.; Salet, T.A.; Flatt, R.J. Digital Concrete: A Review. Cem. Concr. Res. 2019, 123, 105780. [Google Scholar] [CrossRef]

- Federowicz, K.; Kaszynska, M.; Zieliński, A.; Hoffmann, M. Effect of Curing Methods on Shrinkage Development in 3D-Printed Concrete. Materials 2020, 13, 2590. [Google Scholar] [CrossRef]

- Kaszynska, M.; Zielinski, A. Effect of lightweight aggregate on minimizing autogenous shrinkage in Self-Consolidating Concrete. Procedia Eng. 2015, 108, 608–615. [Google Scholar] [CrossRef] [Green Version]

- Nerella, V.N.; Hempel, S.; Mechtcherine, V. Effects of layer-interface properties on mechanical performance of concrete elements produced by extrusion-based 3D-printing. Constr. Build. Mater. 2019, 205, 586–601. [Google Scholar] [CrossRef]

- Van Der Putten, J.; Deprez, M.; Cnudde, V.; De Schutter, G.; Van Tittelboom, K. Microstructural Characterization of 3D Printed Cementitious Materials. Materials 2019, 12, 2993. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, H.; Kim, J.-H.J.; Moon, J.-H.; Kim, W.-W.; Seo, E.-A. Correlation between pore characteristics and tensile bond strength of additive manufactured mortar using X-ray computed tomography. Constr. Build. Mater. 2019, 226, 712–720. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.; Lim, S.; Buswell, R.A.; Gibb, A.G.F.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. 2012, 45, 1221–1232. [Google Scholar] [CrossRef] [Green Version]

- Chougan, M.; Ghaffar, S.H.; Jahanzat, M.; Albar, A.; Mujaddedi, N.; Swash, R. The influence of nano-additives in strengthening mechanical performance of 3D printed multi-binder geopolymer composites. Constr. Build. Mater. 2020, 250, 118928. [Google Scholar] [CrossRef]

- Rahul, A.; Santhanam, M.; Meena, H.; Ghani, Z. 3D printable concrete: Mixture design and test methods. Cem. Concr. Compos. 2019, 97, 13–23. [Google Scholar] [CrossRef]

- Reales, O.A.M.; Duda, P.; Silva, E.C.; Paiva, M.D.; Filho, R.D.T. Nanosilica particles as structural buildup agents for 3D printing with Portland cement pastes. Constr. Build. Mater. 2019, 219, 91–100. [Google Scholar] [CrossRef]

- Gao, X.; Kawashima, S.; Liu, X.; Shah, S.P. Influence of clays on the shrinkage and cracking tendency of SCC. Cem. Concr. Compos. 2012, 34, 478–485. [Google Scholar] [CrossRef] [Green Version]

- Qian, Y.; Ma, S.; Kawashima, S.; De Schutter, G. Rheological characterization of the viscoelastic solid-like properties of fresh cement pastes with nanoclay addition. Theor. Appl. Fract. Mech. 2019, 103, 102262. [Google Scholar] [CrossRef]

- Sonebi, M.; García-Taengua, E.; Hossain, K.; Khatib, J.; Lachemi, M. Effect of nanosilica addition on the fresh properties and shrinkage of mortars with fly ash and superplasticizer. Constr. Build. Mater. 2015, 84, 269–276. [Google Scholar] [CrossRef]

- Kruger, J.; Zeranka, S.; van Zijl, G. An ab initio approach for thixotropy characterisation of (nanoparticle-infused) 3D printable concrete. Constr. Build. Mater. 2019, 224, 372–386. [Google Scholar] [CrossRef]

- Challagulla, V.; Rohatgi, V.; Sharma, D.; Kumar, R. Recent developments of nanomaterial applications in additive man-ufacturing: A brief review. Curr. Opin.Chem. Eng. 2020, 28, 75–82. [Google Scholar] [CrossRef]

- Ma, G.; Wang, L.; Ju, Y. State-of-the-art of 3D printing technology of cementitious material—An emerging technique for construction. Sci. China Ser. E Technol. Sci. 2017, 61, 475–495. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Corker, J.; Fan, M. Additive manufacturing technology and its implementation in construction as an eco-innovative solution. Autom. Constr. 2018, 93, 1–11. [Google Scholar] [CrossRef]

- Zuo, J.; Yao, W.; Xu, J.; Chen, Y.; Liu, X. Effects of Carbon Nanotube-Carbon Fiber Cementitious Conductive Anode for Cathodic Protection of Reinforced Concrete. J. Test. Evaluat. 2017, 45, 1777–1786. [Google Scholar] [CrossRef]

- Mokhtar, M.; Abo-El-Enein, S.; Hassaan, M.; Morsy, M.; Khalil, M. Mechanical performance, pore structure and micro-structural characteristics of graphene oxide nano platelets reinforced cement. Constr. Build. Mater. 2017, 138, 333–339. [Google Scholar] [CrossRef]

- Han, B.; Sun, S.; Ding, S.; Zhang, L.; Yu, X.; Ou, J. Review of nanocarbon-engineered multifunctional cementitious composites. Compos. Part. A Appl. Sci. Manuf. 2015, 70, 69–81. [Google Scholar] [CrossRef]

- Najigivi, A.; Khaloo, A.; Zad, A.I.; Rashid, S.A. Investigating the effects of using different types of SiO2 nanoparticles on the mechanical properties of binary blended concrete. Compos. Part. B Eng. 2013, 54, 52–58. [Google Scholar] [CrossRef]

- Panda, B.; Unluer, C.; Tan, M.J. Extrusion and rheology characterization of geopolymer nanocomposites used in 3D printing. Compos. Part. B Eng. 2019, 176, 107290. [Google Scholar] [CrossRef]

- Panda, B.; Mohamed, N.A.N.; Paul, S.C.; Singh, G.B.; Tan, M.J.; Šavija, B. The effect of material fresh properties and process parameters on buildability and interlayer adhesion of 3D printed concrete. Materials 2019, 12, 2149. [Google Scholar] [CrossRef] [Green Version]

| References | Type | Effect |

|---|---|---|

| Peyvandi, et al. [17] | Carbon Nanotubes (CNTs) | Reduction in permeability and resistivity to an aggressive environment |

| Pera, et al. [18] | Nano calcium carbonate (NCC) | Refinement of pores and quicker hydration reaction |

| Behnood and Ziari [19] | Nano-silica (NS) | Improved durability and less permeable |

| Hashimoto, et al. [20] | Nano clay (NC) | Higher pore refinement and thermal properties |

| Hashimoto, et al. [20] | Nano titanium (NTI) | Higher photo-catalytic activity, self-disinfection, and self-cleaning |

| Farzadnia, et al. [21] | Nano alumina (NA) | Minimum permeability and pore refinement |

| Han, et al. [22] | Nano magnetite (NMT) | Better mechanical properties, self-sensing, refinement of pores |

| Diab, et al. [23] | Nano metakaolin (NMK) | Lowering the permeability |

| Reference | Wang, et al. [57] | Bentz and Turpin [58] | Nili and Ehsani [59] | Salvador, et al. [60] | Nili and Ehsani [59] | Chithra, et al. [61] | Hou, et al. [62] |

|---|---|---|---|---|---|---|---|

| Details of the NM’s | NS | NCS | NA | NC | N-Fe2O3 | N-Fe3O4 | N-MgO |

| State | Powder | Liquid | Powder | Powder | Powder | Powder | Powder |

| Range of the average size of particles (nm) | 15 | 8.5–9.0 | 12–18 | 3 | 13–17 | 100 | 100 |

| Color | White | White | White | Pale White | Brown | Dark Brown | White |

| Density (gram/cm3) | 2.2–2.6 | 1.21 | 0.1 | 2.29 | 0.15 | 4.8 | 3.58 |

| Formula (chemical) | SiO2 | SiO2 | Al2O3 | Al2Si 2O5 (O-H)4 | Fe2O3 | Fe3O4 | MgO |

| Optimized %age | 3 | 3 | 1 | 1.9 | 1 | 2 | 7.5 |

| Nano Content (%) | 0 and 3 | 0, 1, 2, and 3 | 0, 1, 2, 3, and 5 | 0, 0.5, 1, 2, and 5 | 0, 0.2, 0.4, 0.6, and 0.8 | 0, 0.8, and 3.8 | 0 and 0.6 | 0 and 0.5 | 0, 2, 5, and 10 | 0, 2, 4, 6, and 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Effect | It improved compressive and flexural strength. The optimum content is 3% by weight. | Increased compressive strength. The optimum content is 2%, followed by 1%, by weight. | Enhanced compressive and bond strength. Optimum content is 5%, followed by 3%, by mass. | Better compressive strength. The optimum content is 0.5%, followed by 2%, by weight. | Higher compressive strength. The optimum content is 0.6%, followed by 0.4%, by weight of cement. | Increase in the compressive strength. | Improvement in compressive strength. | Enhancement in the strengths. | Increase in the indirect tensile strength. The optimum content is 2% by weight of cement. | Increment in the compressive strength. The optimum content is 10%, followed by 6%, by the weight of the cement. |

| Authors | Qing, et al. [125] | Kuo, et al. [36] | Qing, et al. [126] | Stefanidou and Papayianni [127] | Shih, et al. [82] | Berra, et al. [128] | Gaitero, et al. [129] | Pourjavadi, et al. [130] | Shebl, et al. [131] | Thuadaij and Nuntiya [132] |

| Sample | Plain Cement | GO Cement | NS Cement | Hybrid Cement |

|---|---|---|---|---|

| MIV (mL/g) | 0.220 | 0.207 | 0.196 | 0.171 |

| Average diameter of pore (nm) | 19.5 | 18 | 17.1 | 16.2 |

| Porosity (%) | 32.38 | 32.04 | 30.01 | 24.12 |

| Surface to volume ratio (mL/g) | 46.374 | 44.475 | 44.233 | 42.880 |

| Type of NM | NC | NS | Graphene-Based Materials |

|---|---|---|---|

| Specification | Highly purified attapulgite NC | - | Nano graphite platelets (NGPs) |

| Highly purified magnesium alumino-silicate clay | - | ||

| Nano attapulgite clay | - | ||

| Hydrophilic bentonite NC | - | ||

| Quantities | 0-0.1-0.3-0.5% by mass of binder (MB) | 0.5%–1% by mass of solid | 0.1%–0.5% by MB |

| 0%–3% by mass of cement (MS) | 0.5-2-3.5% by MS | ||

| 0.1%–0.5% by MB | 1, 2, 3% by MS | ||

| 0.5%–1% by mass of solid | - | ||

| Optimum | 0.5% by MB | - | 1.0% by MB |

| 0.5%–1% by MS | 3.5% by MS | ||

| 0.5% by MB | 1% by MS | ||

| Effect | Boost in cohesion and static yield strength | Boost in the velocity of the structural build-up of the paste | Effective rheology modification agent with increased mechanical performance |

| Facilitates re-flocculation and improves the thixotropic properties of the mixture | Decreased plastic shrinkage | ||

| Boosts static yield stress without affecting apparent viscosity | Boost in the re-flocculation rate | ||

| Thickening effect, increment in the static yield strength | - | ||

| References | Qian, et al. [242], Quanji, et al. [101], Panda, et al. [104], Reales, et al. [240] | Reales, et al. [240], Sonebi, et al. [243], Kruger, et al. [244] | Chougan, et al. [238] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, H.; Li, X. An Overview on the Rheology, Mechanical Properties, Durability, 3D Printing, and Microstructural Performance of Nanomaterials in Cementitious Composites. Materials 2021, 14, 2950. https://doi.org/10.3390/ma14112950

Song H, Li X. An Overview on the Rheology, Mechanical Properties, Durability, 3D Printing, and Microstructural Performance of Nanomaterials in Cementitious Composites. Materials. 2021; 14(11):2950. https://doi.org/10.3390/ma14112950

Chicago/Turabian StyleSong, Hongwei, and Xinle Li. 2021. "An Overview on the Rheology, Mechanical Properties, Durability, 3D Printing, and Microstructural Performance of Nanomaterials in Cementitious Composites" Materials 14, no. 11: 2950. https://doi.org/10.3390/ma14112950