Carbon Nanomaterials for Enhancing the Thermal, Physical and Rheological Properties of Asphalt Binders

Abstract

:1. Introduction

2. Scope of Work and Objectives

3. Materials and Methods

3.1. Matrix Asphalt

3.2. Graphene and Carbon Nanotubes

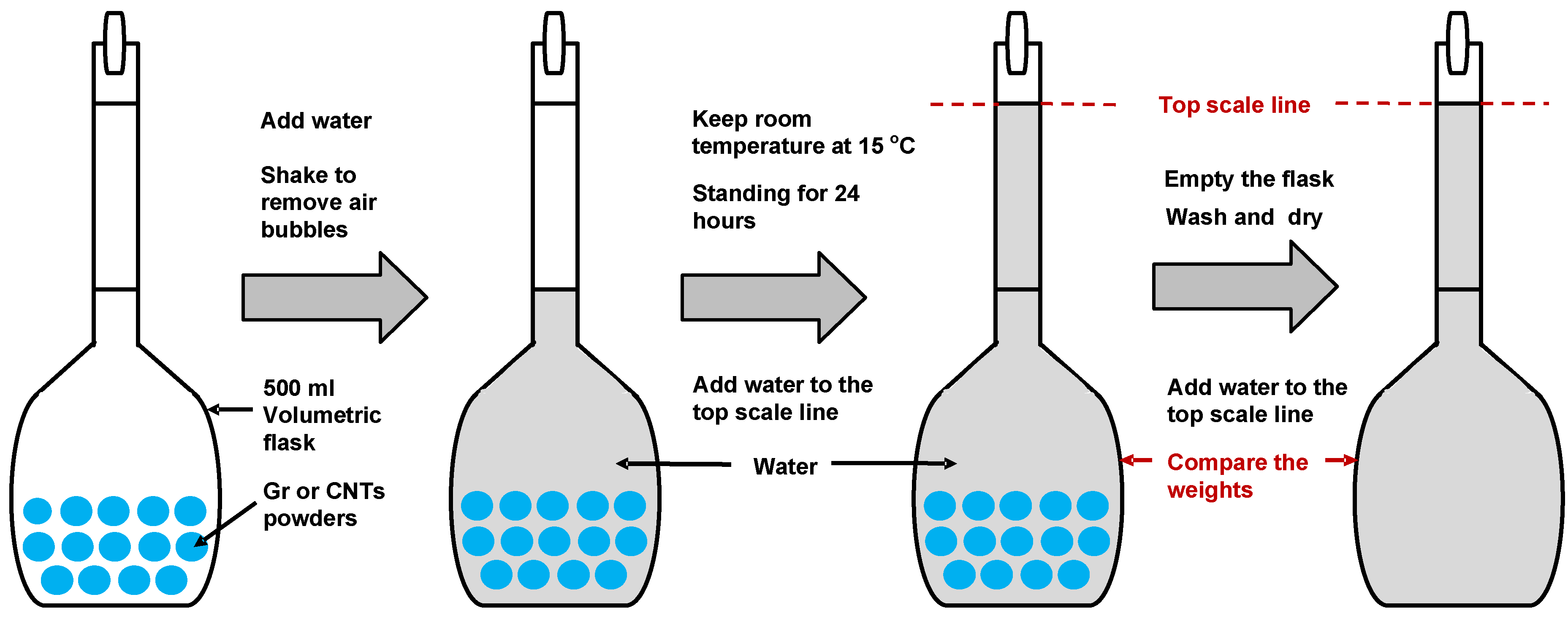

3.2.1. Physical Parameters

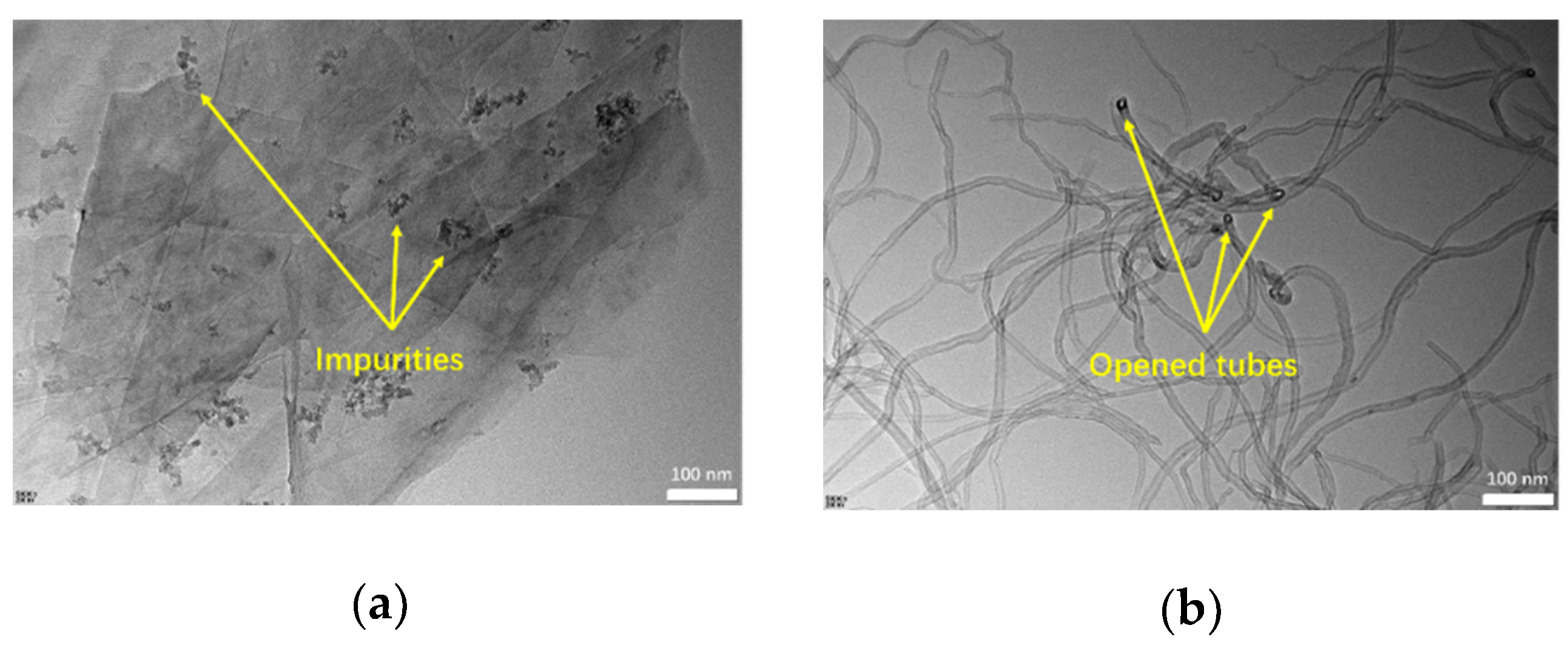

3.2.2. SEM and HRTEM Observations

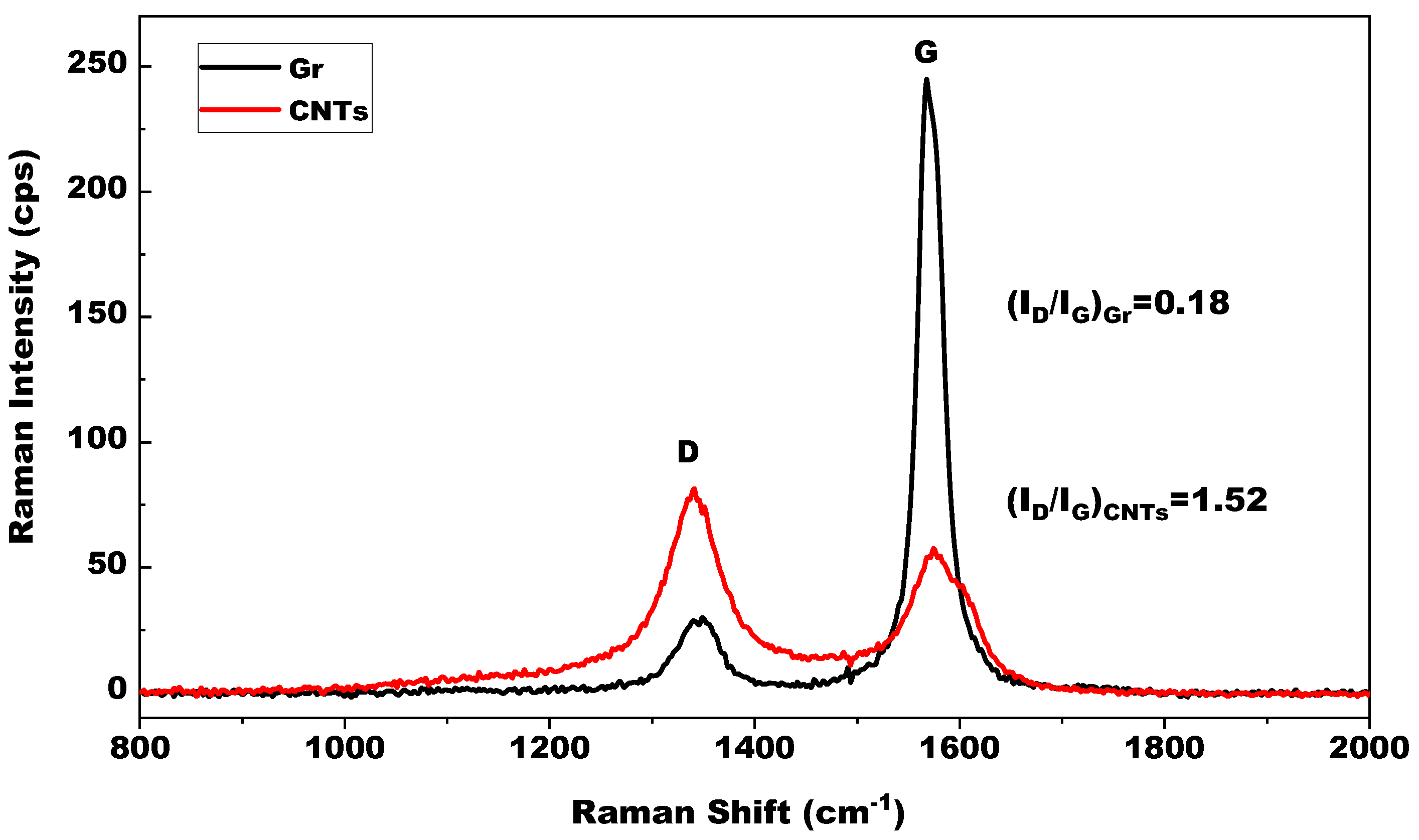

3.2.3. Raman Scattering

3.3. Gr and CNTs Modified Asphalt Binders

3.3.1. Preparation Samples

3.3.2. HRTEM Observations

3.4. Thermal Properties Tests

3.5. Physical Properties Tests

3.6. Rheological Properties Tests

3.6.1. Brookfield Viscosity Tests

3.6.2. Dynamic Shear Rheometer (DSR) Tests

3.7. Modification Mechanism Tests

3.7.1. Fourier Transform Infrared Spectroscopy (FTIR) Characterizations

3.7.2. SARA Fraction Tests

4. Results and Discussion

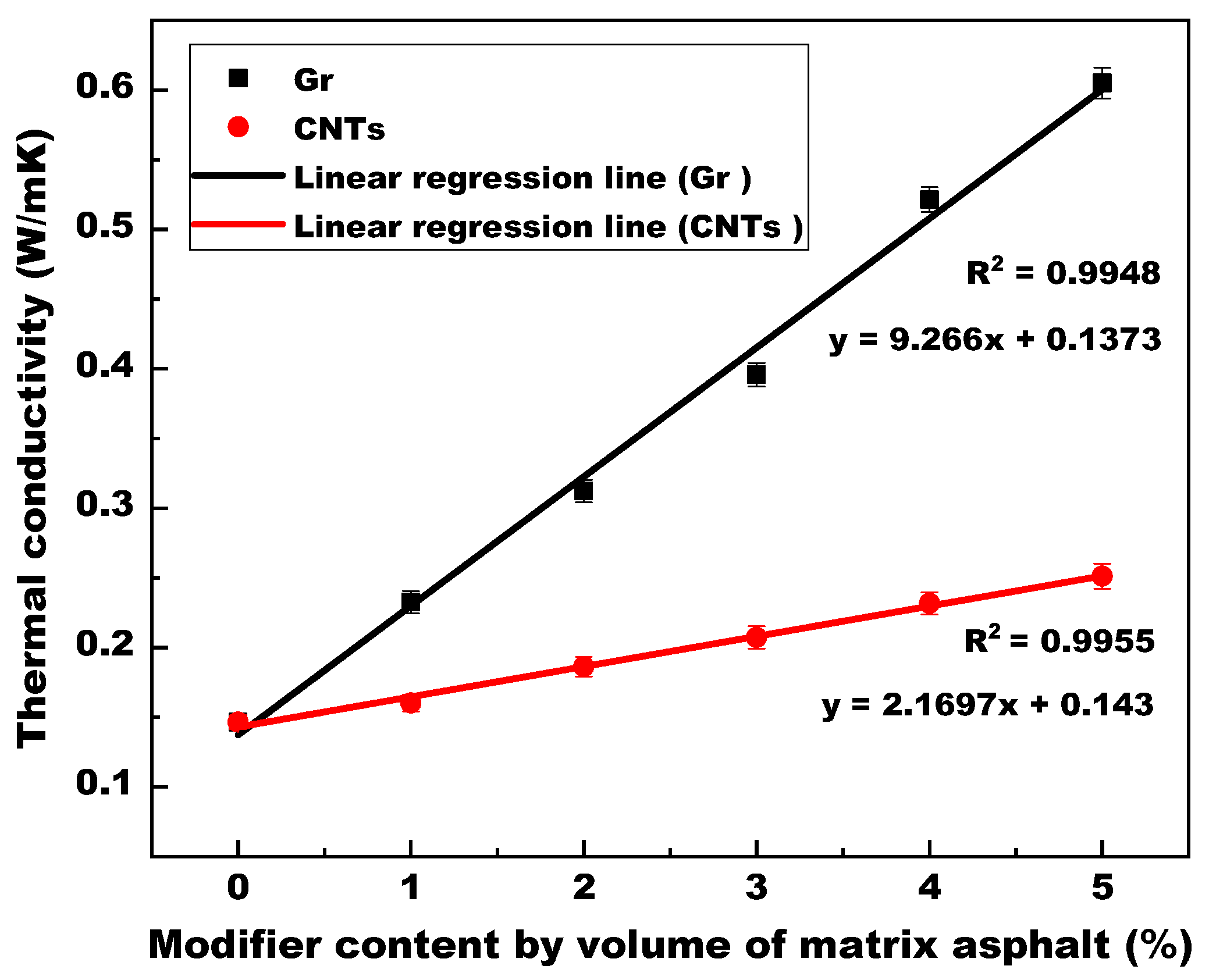

4.1. Thermal Properties of Asphalt Binders

4.1.1. Thermal Conductivity

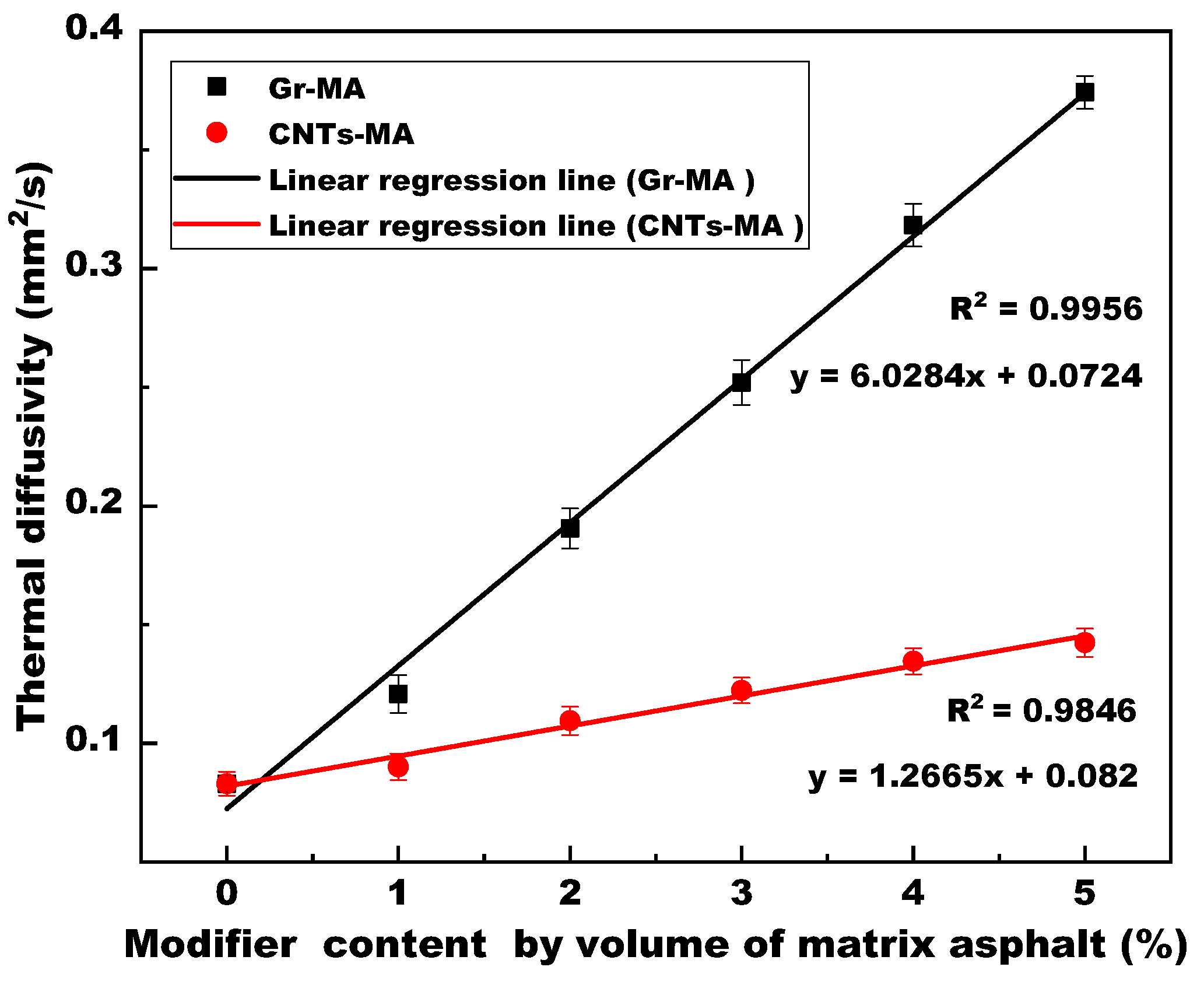

4.1.2. Thermal Diffusivity

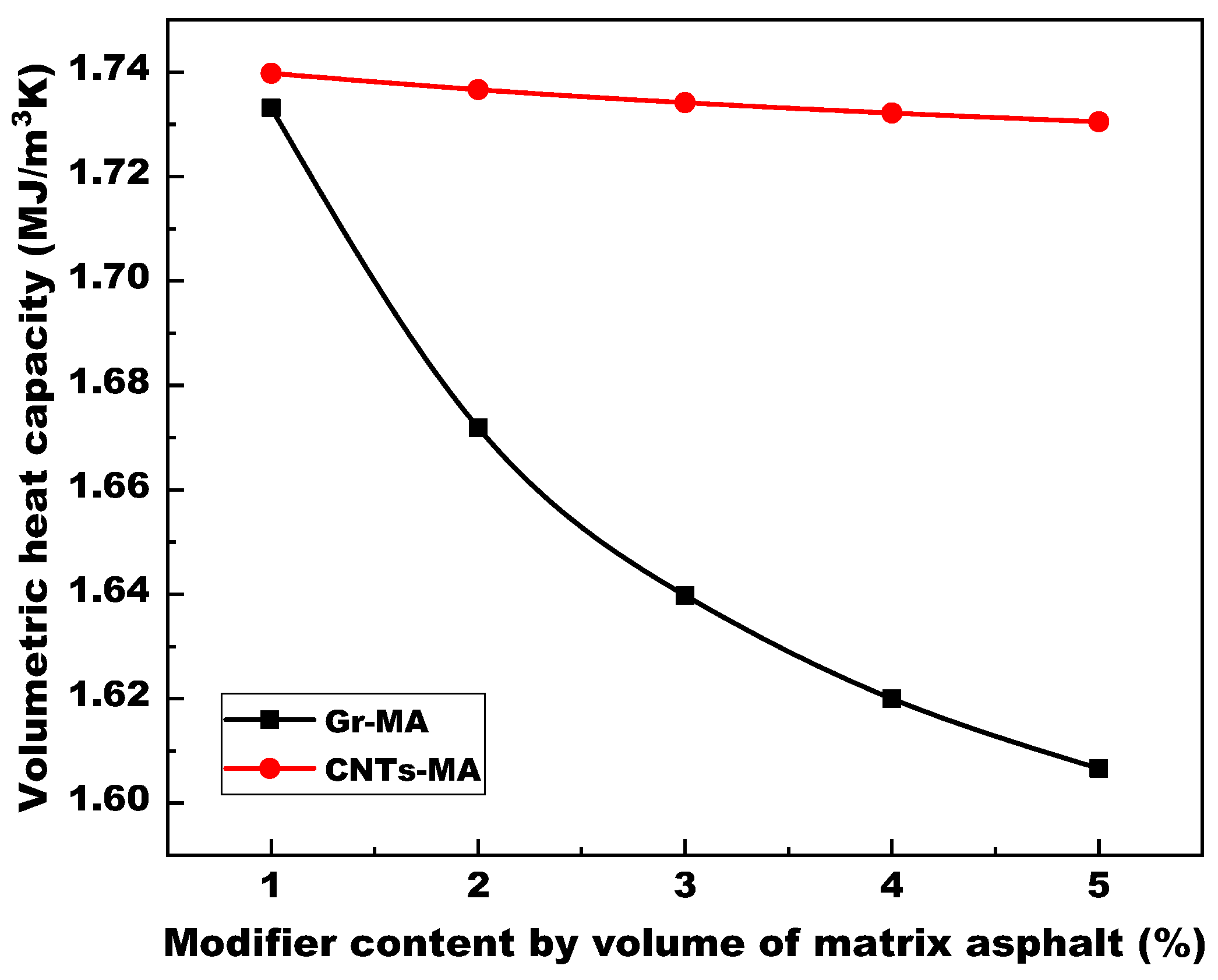

4.1.3. Volumetric Specific Heat Capacity

4.2. Physical Properties of Asphalt Binders

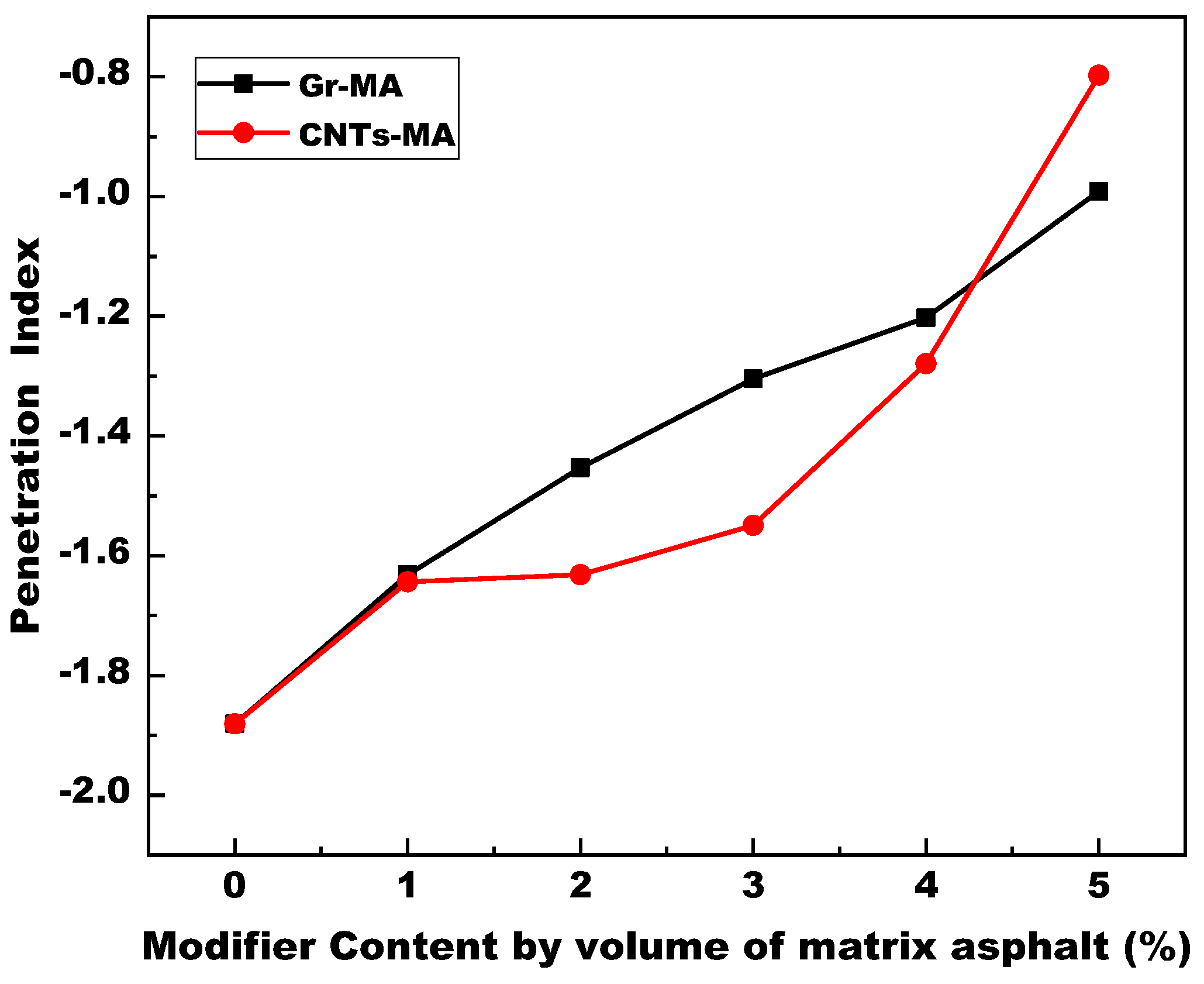

4.2.1. Penetration and Temperature Susceptibility

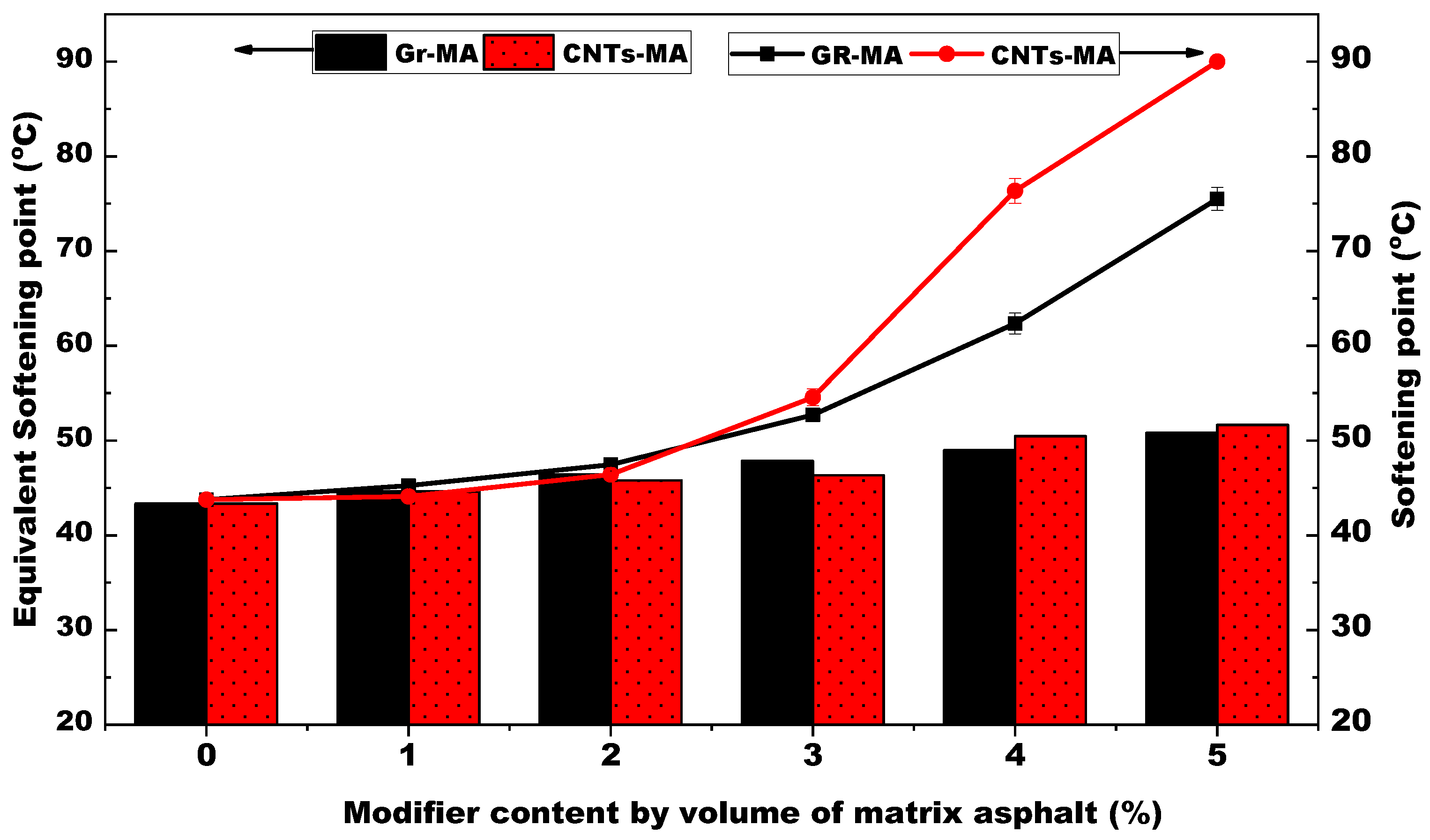

4.2.2. Softening Point and Equivalent Softening Point

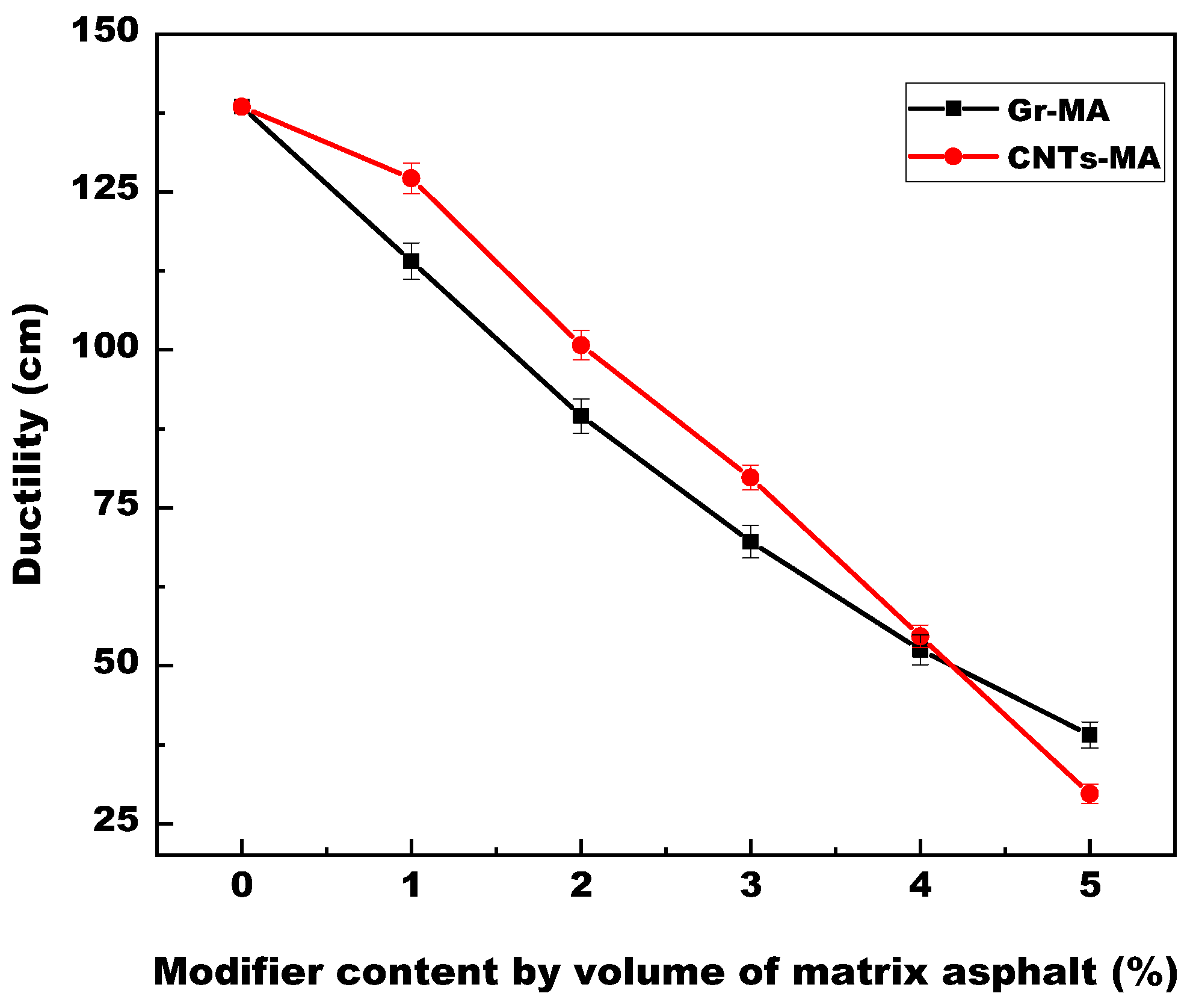

4.2.3. Ductility of Modified Asphalt Binders

4.3. Rheological Properties of Asphalt Binders

4.3.1. Brookfield Viscosity and Viscosity Temperature Susceptibility

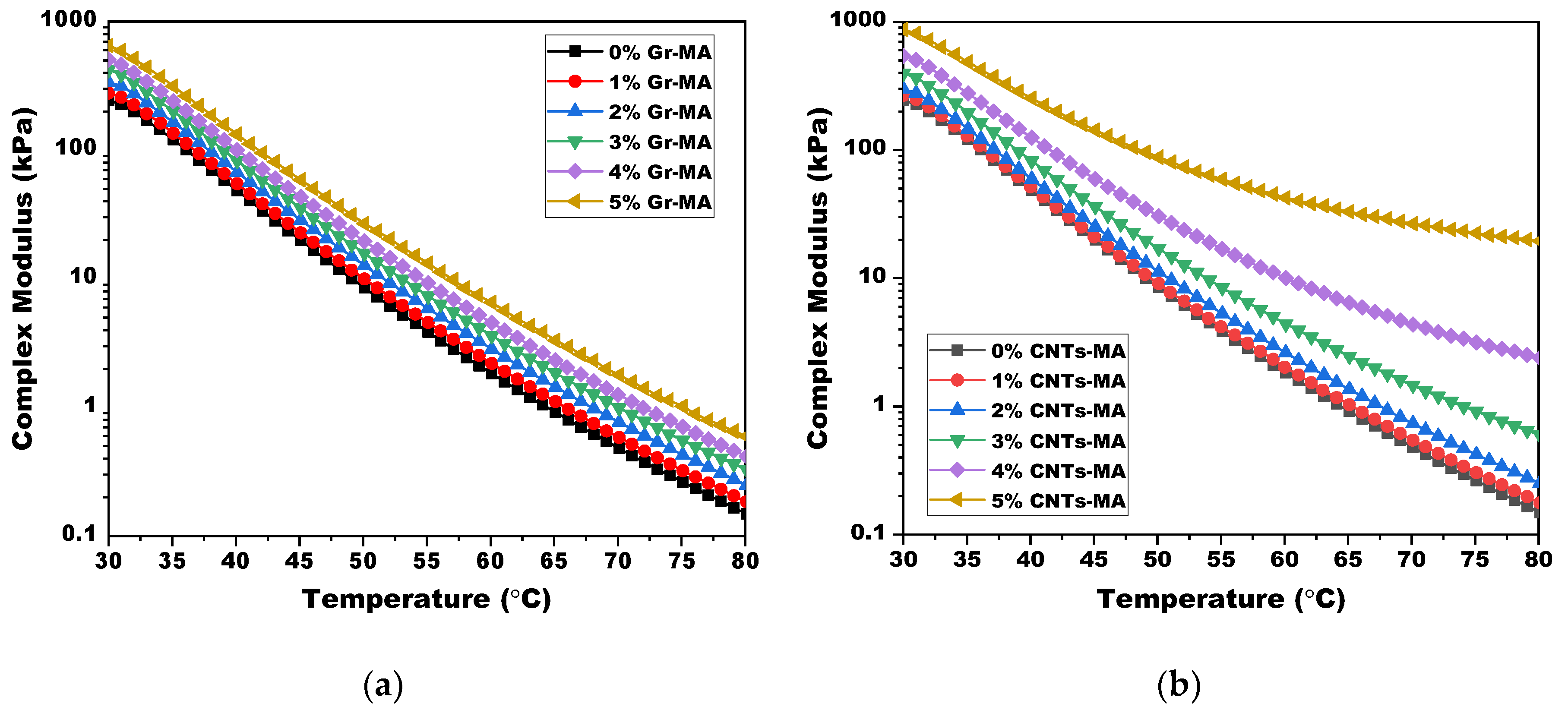

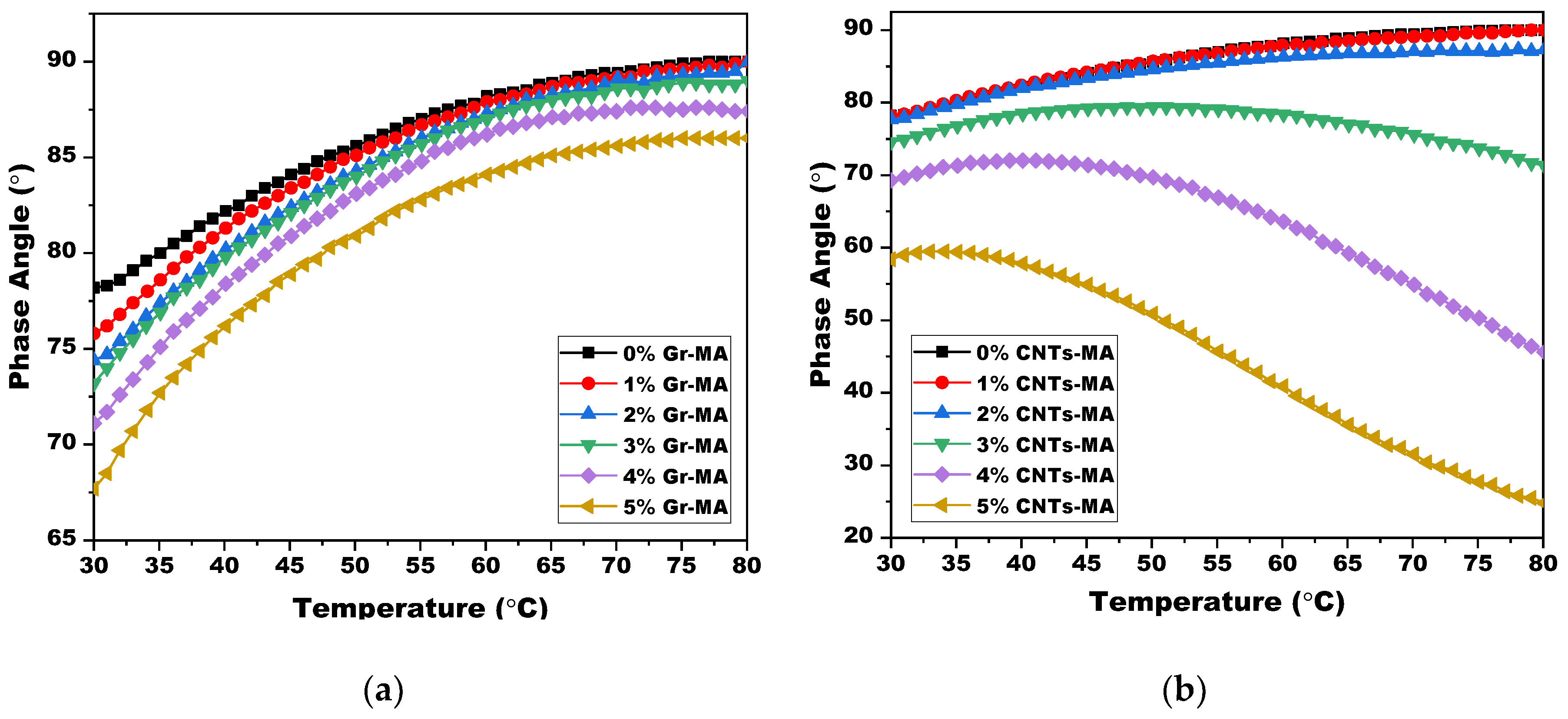

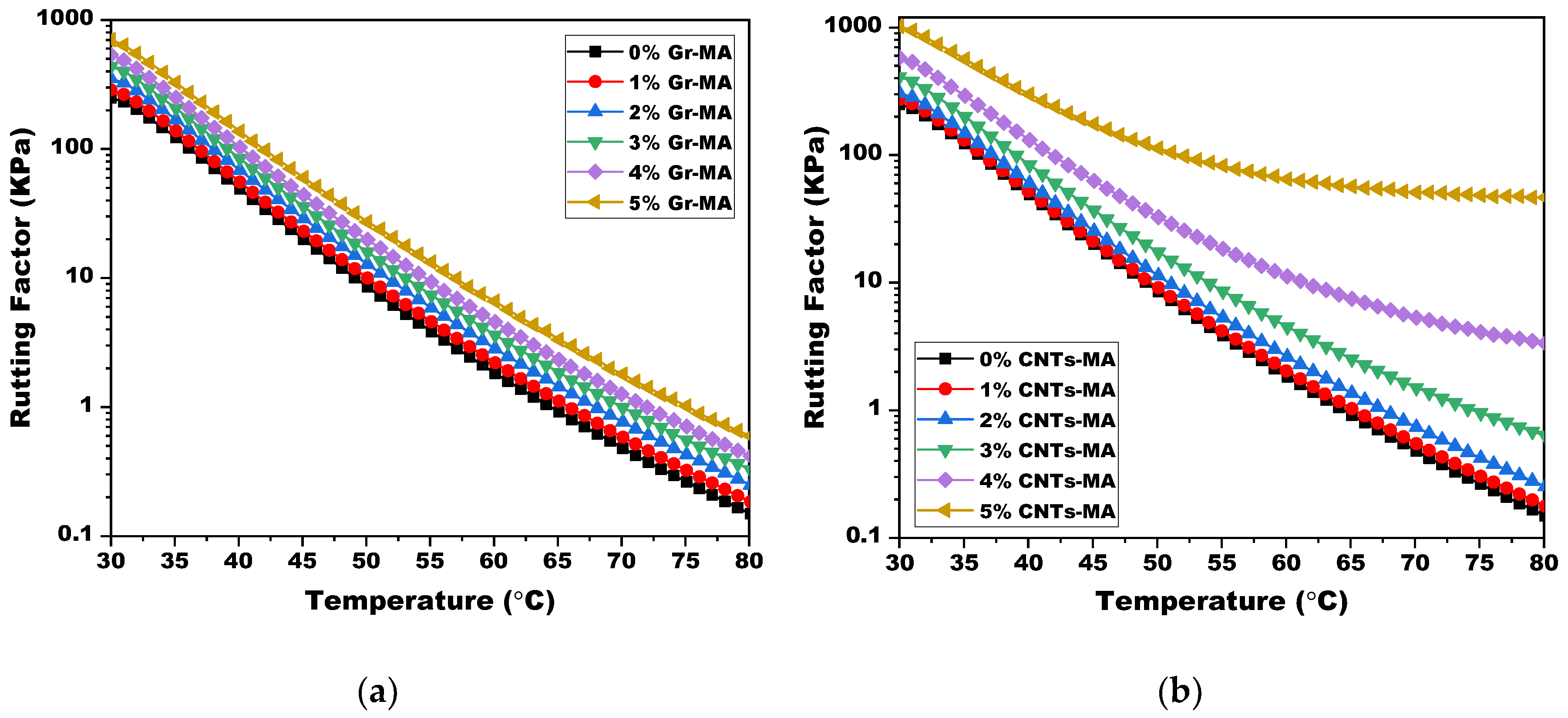

4.3.2. Viscoelastic Properties in the High Temperature Range

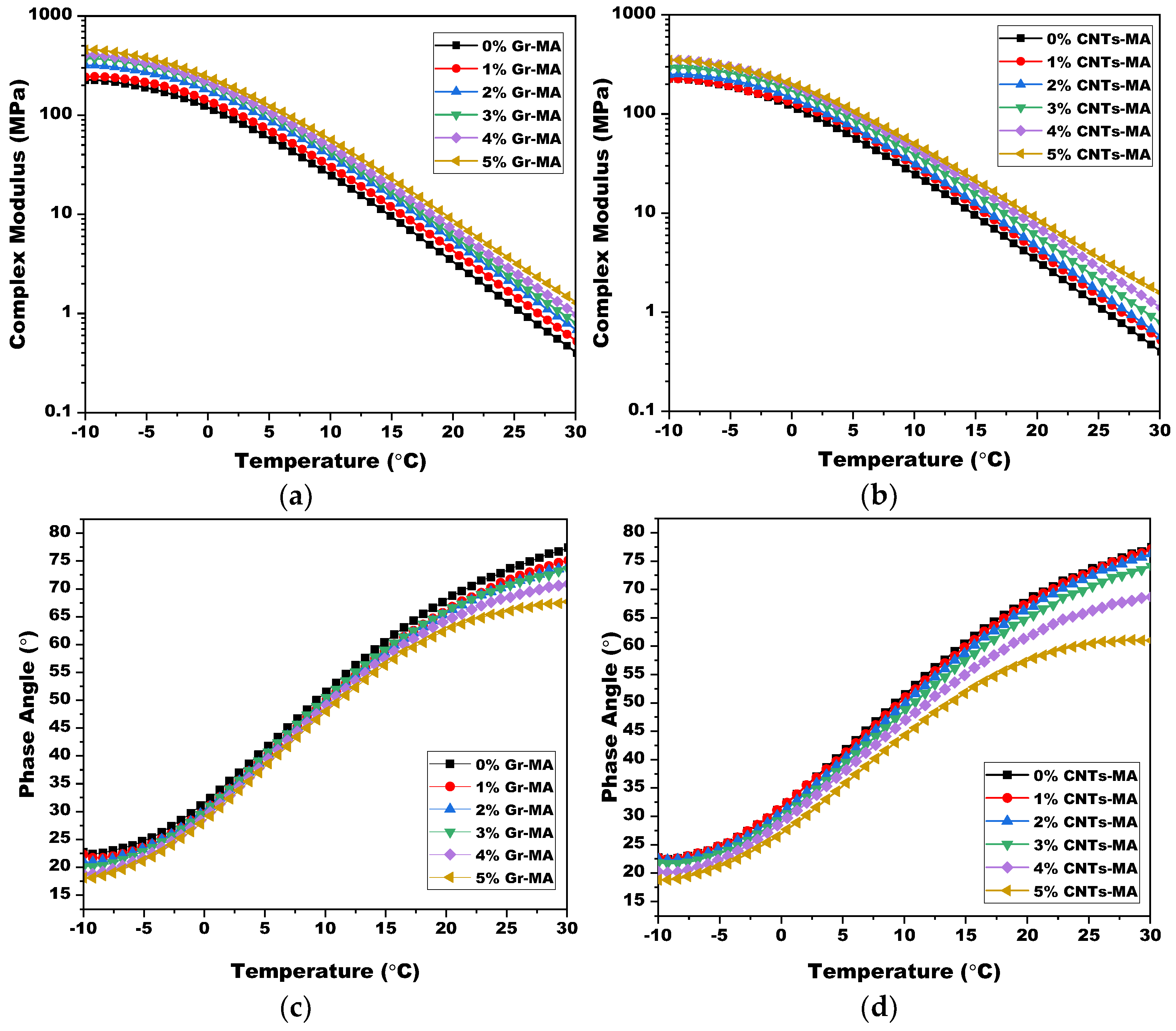

4.3.3. Viscoelastic Properties of Modified Asphalt Binders in the Low-to-Intermediate Temperature Range

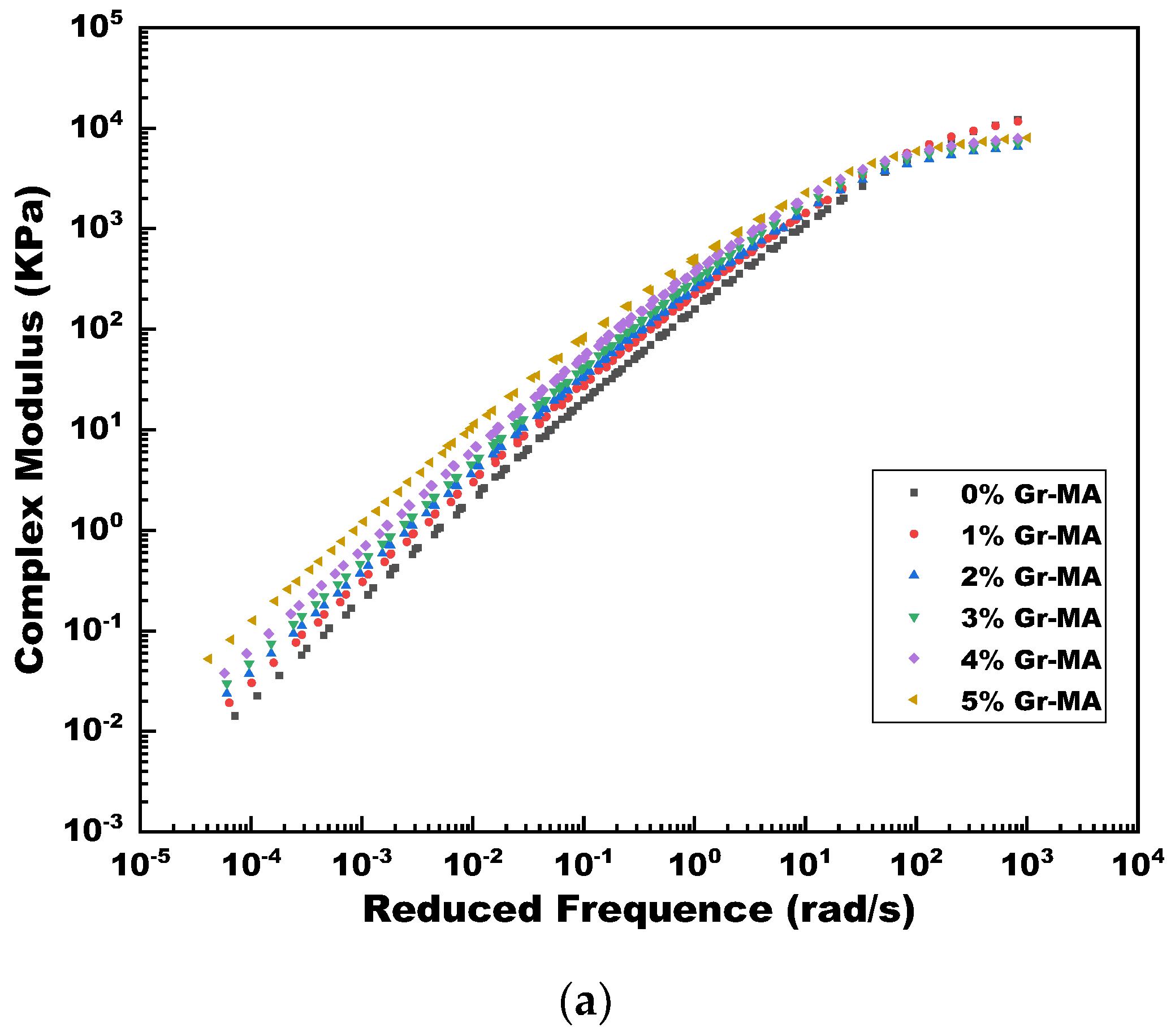

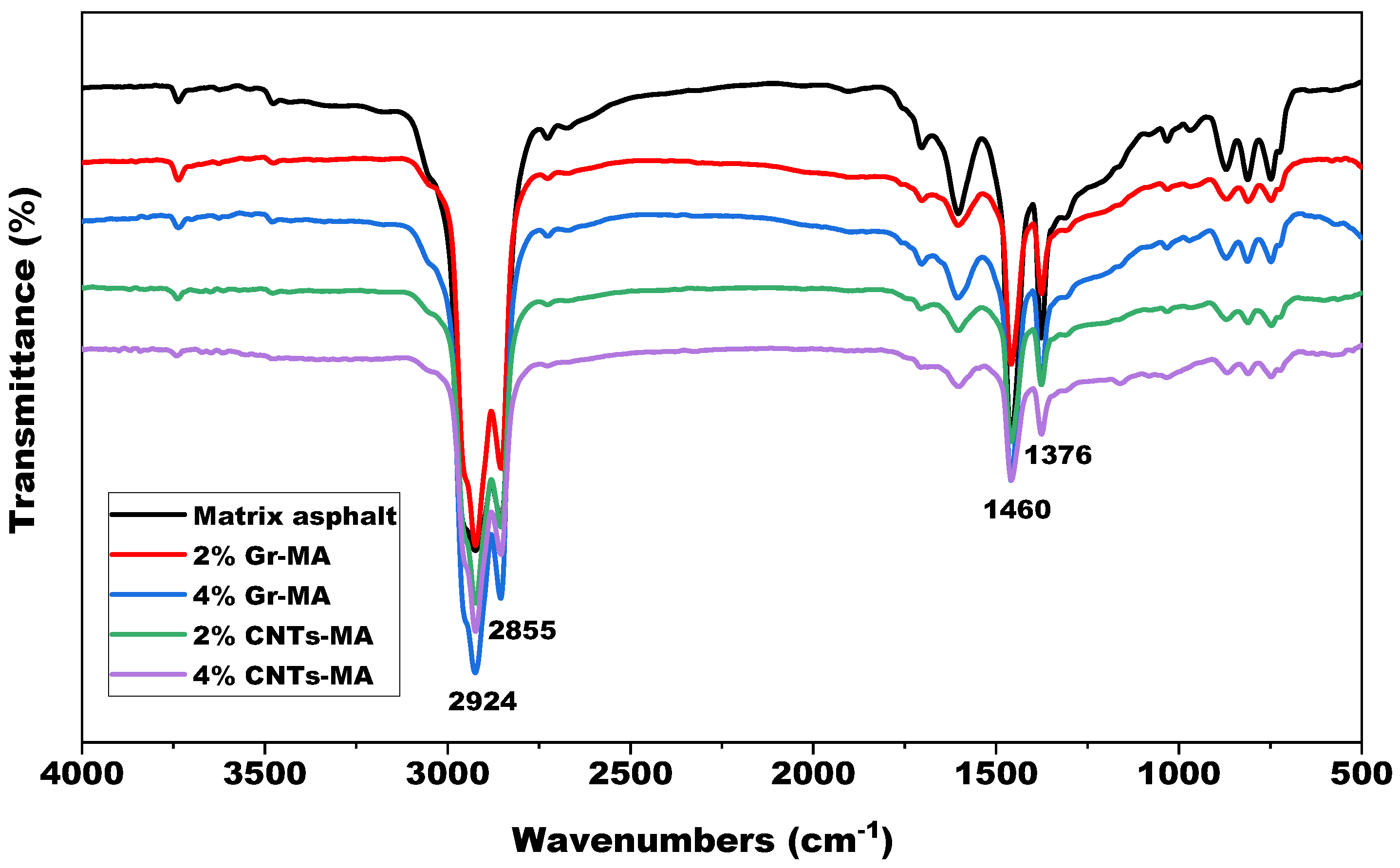

4.3.4. Complex Shear Modulus Master Curves

4.4. Modification Mechanism of Gr and CNTs Modified Asphalt Binders

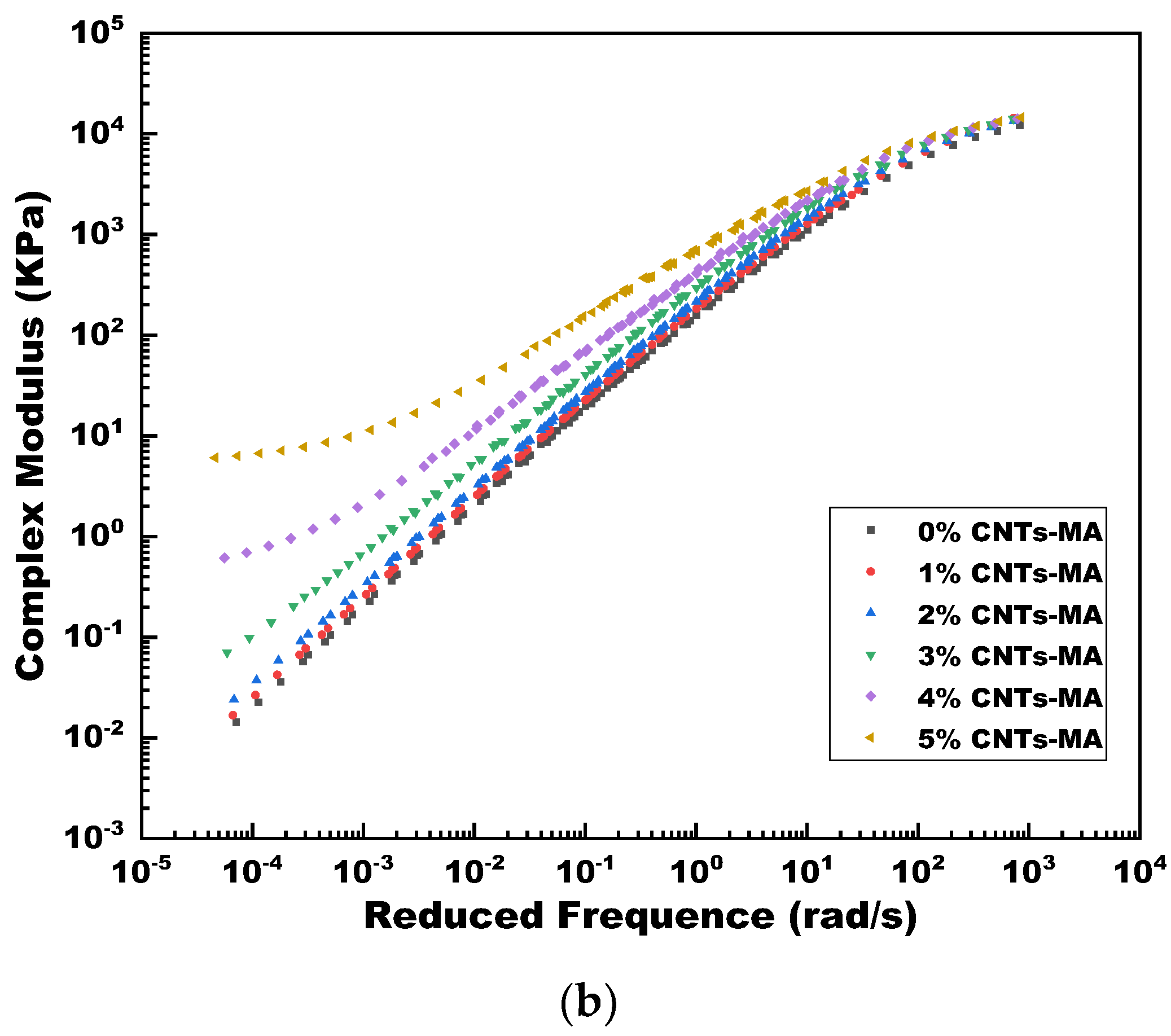

4.4.1. Chemical Structure

4.4.2. SARA Fraction

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fernández-Gómez, W.D.; Rondón Quintana, H.; Reyes Lizcano, F. A review of asphalt and asphalt mixture aging. Ing. Investig. 2013, 33, 5–12. [Google Scholar]

- Li, N.; Jiang, Q.; Wang, F.; Xie, J.; Li, Y.; Li, J.; Wu, S. Emission behavior, environmental impact and priority-controlled pollutants assessment of volatile organic compounds (VOCs) during asphalt pavement construction based on laboratory experiment. J. Hazard. Mater. 2020, 398, 122904–122914. [Google Scholar] [CrossRef]

- Mirzanamadi, R.; Johansson, P.; Grammatikos, S.A. Thermal properties of asphalt concrete: A numerical and experimental study. Constr. Build. Mater. 2018, 158, 774–785. [Google Scholar] [CrossRef]

- Yinfei, D.; Shengyue, W.; Jian, Z. Cooling asphalt pavement by a highly oriented heat conduction structure. Energy Build. 2015, 102, 187–196. [Google Scholar] [CrossRef]

- Wang, F.; Xie, J.; Wu, S.; Li, J.; Barbieri, D.M.; Zhang, L. Life cycle energy consumption by roads and associated interpretative analysis of sustainable policies. Renew. Sustain. Energy Rev. 2021, 141, 110823. [Google Scholar] [CrossRef]

- Mohajerani, A.; Bakaric, J.; Jeffrey-Bailey, T. The urban heat island effect, its causes, and mitigation, with reference to the thermal properties of asphalt concrete. J. Environ. Manag. 2017, 197, 522–538. [Google Scholar] [CrossRef] [PubMed]

- Feng, D.; Yi, J.; Wang, D. Performance and thermal evaluation of incorporating waste ceramic aggregates in wearing layer of asphalt pavement. J. Mater. Civ. Eng. 2013, 25, 857–863. [Google Scholar] [CrossRef]

- Dawson, A.R.; Dehdezi, P.K.; Hall, M.R.; Wang, J.; Isola, R. Enhancing thermal properties of asphalt materials for heat storage and transfer applications. Road Mater. Pavement Des. 2012, 13, 784–803. [Google Scholar] [CrossRef] [Green Version]

- Pan, P.; Wu, S.; Xiao, Y.; Liu, G. A review on hydronic asphalt pavement for energy harvesting and snow melting. Renew. Sustain. Energy Rev. 2015, 48, 624–634. [Google Scholar] [CrossRef]

- Pan, P.; Wu, S.; Xiao, Y.; Wang, P.; Liu, X. Influence of graphite on the thermal characteristics and anti-ageing properties of asphalt binder. Constr. Build. Mater. 2014, 68, 220–226. [Google Scholar] [CrossRef]

- Pan, P.; Wu, S.; Hu, X.; Wang, P.; Liu, Q. Effect of freezing-thawing and ageing on thermal characteristics and mechanical properties of conductive asphalt concrete. Constr. Build. Mater. 2017, 140, 239–247. [Google Scholar] [CrossRef]

- Chen, M.; Wu, S.; Wang, H.; Zhang, J. Study of ice and snow melting process on conductive asphalt solar collector. Sol. Energy Mater. Sol. Cells 2011, 95, 3241–3250. [Google Scholar] [CrossRef]

- Vo, H.V.; Park, D.-W. Application of conductive materials to asphalt pavement. Adv. Mater. Sci. Eng. 2017, 2017, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Tang, N.; Wu, S.; Chen, M.; Pan, P.; Sun, C. Effect mechanism of mixing on improving conductivity of asphalt solar collector. Int. J. Heat Mass Transf. 2014, 75, 650–655. [Google Scholar] [CrossRef]

- Bai, B.C.; Park, D.-W.; Vo, H.V.; Dessouky, S.; Im, J.S. Thermal properties of asphalt mixtures modified with conductive fillers. J. Nanomater. 2015, 2015, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Phiri, J.; Gane, P.; Maloney, T.C. General overview of graphene: Production, properties and application in polymer composites. Mater. Sci. Eng. B 2017, 215, 9–28. [Google Scholar] [CrossRef] [Green Version]

- Gupta, S.; Murthy, C.; Prabha, C.R. Recent advances in carbon nanotube based electrochemical biosensors. Int. J. Biol. Macromol. 2018, 108, 687–703. [Google Scholar] [CrossRef]

- Shoukat, R.; Khan, M.I. Carbon nanotubes: A review on properties, synthesis methods and applications in micro and nanotechnology. Microsyst. Technol. 2021. [Google Scholar] [CrossRef]

- Kamedulski, P.; Ilnicka, A.; Lukaszewicz, J.P. Selected aspects of graphene exfoliation as an introductory step towards 3D structuring of graphene nano-sheets. Curr. Graphene Sci. 2019, 2, 106–117. [Google Scholar] [CrossRef]

- Tong, X.; Li, N.; Zeng, M.; Wang, Q. Organic phase change materials confined in carbon-based materials for thermal properties enhancement: Recent advancement and challenges. Renew. Sustain. Energy Rev. 2019, 108, 398–422. [Google Scholar] [CrossRef]

- Dasari, B.L.; Nouri, J.M.; Brabazon, D.; Naher, S. Graphene and derivatives—Synthesis techniques, properties and their energy applications. Energy 2017, 140, 766–778. [Google Scholar] [CrossRef] [Green Version]

- Das, S.; Giri, A.; Samanta, S.; Kanagaraj, S. Role of graphene nanofluids on heat transfer enhancement in thermosyphon. J. Sci. Adv. Mater. Devices 2019, 4, 163–169. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, L.; Liu, J.; Fang, X.; Zhang, Z. Effect of morphology of carbon nanomaterials on thermo-physical characteristics, optical properties and photo-thermal conversion performance of nanofluids. Renew. Energy 2016, 99, 888–897. [Google Scholar] [CrossRef]

- Amin, M.; Putra, N.; Kosasih, E.A.; Prawiro, E.; Luanto, R.A.; Mahlia, T. Thermal properties of beeswax/graphene phase change material as energy storage for building applications. Appl. Therm. Eng. 2017, 112, 273–280. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, D. Effect of covalent functionalization and phase change matrix on heat transfer across graphene/phase change material interfaces. Appl. Therm. Eng. 2019, 151, 38–45. [Google Scholar] [CrossRef]

- Karaipekli, A.; Biçer, A.; Sarı, A.; Tyagi, V.V. Thermal characteristics of expanded perlite/paraffin composite phase change material with enhanced thermal conductivity using carbon nanotubes. Energy Convers. Manag. 2017, 134, 373–381. [Google Scholar] [CrossRef]

- Zhang, N.; Yuan, Y.; Yuan, Y.; Cao, X.; Yang, X. Effect of carbon nanotubes on the thermal behavior of palmitic–stearic acid eutectic mixtures as phase change materials for energy storage. Sol. Energy 2014, 110, 64–70. [Google Scholar] [CrossRef]

- Faramarzi, M.; Arabani, M.; Haghi, A.K.; Mottaghitalab, V. Carbon nanotubes-modified asphalt binder: Preparation and characterization. Int. J. Pavement Res. Technol. 2015, 8, 29–37. [Google Scholar]

- Santagata, E.; Baglieri, O.; Tsantilis, L.; Chiappinelli, G. Fatigue properties of bituminous binders reinforced with carbon nanotubes. Int. J. Pavement Eng. 2015, 16, 80–90. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Sol-Sánchez, M.; Gámiz, F.; Rubio-Gámez, M. Mechanical and thermal properties of graphene modified asphalt binders. Constr. Build. Mater. 2018, 180, 265–274. [Google Scholar] [CrossRef]

- Yang, Q.; Liu, Q.; Zhong, J.; Hong, B.; Wang, D.; Oeser, M. Rheological and micro-structural characterization of bitumen modified with carbon nanomaterials. Constr. Build. Mater. 2019, 201, 580–589. [Google Scholar] [CrossRef]

- Li, C.; Wu, S.; Chen, Z.; Tao, G.; Xiao, Y. Improved microwave heating and healing properties of bitumen by using nanometer microwave-absorbers. Constr. Build. Mater. 2018, 189, 757–767. [Google Scholar] [CrossRef]

- Shirakawa, T.; Tada, A.; Okazaki, N. Development of functional carbon nanotubes -asphalt composites. Int. J. GEOMATE 2012, 2, 161–165. [Google Scholar] [CrossRef] [Green Version]

- Shu, B.; Wu, S.; Pang, L.; Javilla, B. The utilization of multiple-walled carbon nanotubes in polymer modified bitumen. Materials 2017, 10, 416. [Google Scholar] [CrossRef] [PubMed]

- Goli, A.A.; Ziari, H.; Amini, A. Influence of carbon nanotubes on performance properties and storage stability of SBS modified asphalt binders. J. Mater. Civ. Eng. 2017, 29, 04017070. [Google Scholar] [CrossRef]

- Trichês, G.; de Melo, J.V.S. Evaluation of rheological behavior and performance to permanent deformation of nanomodified asphalt mixtures with carbon nanotubes. Can. J. Civ. Eng. 2016, 43, 472–479. [Google Scholar]

- Ministry of Transport of the People’s Republic of China. Test Methods of Aggregate for Highway Engineering; JTG E42-2005; Ministry of Transport of the People’s Republic of China: Beijing, China, 2005.

- Wang, R.; Yue, M.; Xiong, Y.; Yue, J. Experimental study on mechanism, aging, rheology and fatigue performance of carbon nanomaterial/SBS-modified asphalt binders. Constr. Build. Mater. 2021, 268, 121189. [Google Scholar] [CrossRef]

- Ma, L.; Yang, C.; Sun, J. Electrochemical and mechanical properties of asphalt concrete modified by carbon microfibers. Int. J. Electrochem. Sci. 2020, 15, 3608–3615. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, S.; Xiao, Y.; Zeng, W.; Yi, M.; Wan, J. Effect of hydration and silicone resin on Basic Oxygen Furnace slag and its asphalt mixture. J. Clean. Prod. 2016, 112, 392–400. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; JTG E20-2011; Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- AASHTO. Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR); AASHTO Designation: Washington, DC, USA, 2012. [Google Scholar]

- Wu, W.; Li, L.; Yu, J.; Xu, S.; Zhang, C.; Xue, L. Investigation on thermo-oxidative aging properties of asphalt binder with hindered phenolic antioxidant. J. Test. Eval. 2017, 46, 624–630. [Google Scholar] [CrossRef]

- Li, Y.; Wu, S.; Dai, Y.; Li, C.; Song, W.; Li, H.; Li, C.; She, B. Transitions of component, physical, rheological and self-healing properties of petroleum bitumen from the loose bituminous mixture after UV irradiation. Fuel 2020, 262, 116507–116518. [Google Scholar] [CrossRef]

- Wang, J.; Wang, T.; Hou, X.; Xiao, F. Modelling of rheological and chemical properties of asphalt binder considering SARA fraction. Fuel 2019, 238, 320–330. [Google Scholar] [CrossRef]

- Muñoz, E.; Lu, J.; Yakobson, B.I. Ballistic thermal conductance of graphene ribbons. Nano Lett. 2010, 10, 1652–1656. [Google Scholar] [CrossRef] [PubMed]

- Wesenberg, D.J.; Roos, M.J.; Avery, A.D.; Blackburn, J.L.; Ferguson, A.J.; Zink, B.L. Size- and temperature-dependent suppression of phonon thermal conductivity in carbon nanotube thermoelectric films. Adv. Electron. Mater. 2020, 6, 2000746. [Google Scholar] [CrossRef]

- Huang, X.; Zhi, C.; Lin, Y.; Bao, H.; Wu, G.; Jiang, P.; Mai, Y.-W. Thermal conductivity of graphene-based polymer nanocomposites. Mater. Sci. Eng. R Rep. 2020, 142, 100577. [Google Scholar] [CrossRef]

- Fan, L.-W.; Fang, X.; Wang, X.; Zeng, Y.; Xiao, Y.-Q.; Yu, Z.-T.; Xu, X.; Hu, Y.-C.; Cen, K.-F. Effects of various carbon nanofillers on the thermal conductivity and energy storage properties of paraffin-based nanocomposite phase change materials. Appl. Energy 2013, 110, 163–172. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Penetration of Bituminous Materials; ASTM: West Conshohocken, PA, USA, 2006. [Google Scholar]

- Sheng, X.; Xu, T.; Wang, M. Preparation, shape memory performance and microstructures of emulsified asphalt modified by multi-walled carbon nanotubes. Constr. Build. Mater. 2020, 230, 116954. [Google Scholar] [CrossRef]

- Haq, M.F.U.; Ahmad, N.; Nasir, M.A.; Jamal; Hafeez, M.; Rafi, J.; Zaidi, S.B.A.; Haroon, W. Carbon Nanotubes (CNTs) in asphalt binder: Homogeneous dispersion and performance enhancement. Appl. Sci. 2018, 8, 2651. [Google Scholar] [CrossRef] [Green Version]

- Atif, R.; Inam, F. Reasons and remedies for the agglomeration of multilayered graphene and carbon nanotubes in polymers. Beilstein J. Nanotechnol. 2016, 7, 1174–1196. [Google Scholar] [CrossRef]

- Faramarzi, M.; Arabani, M.; Haghi, A.K.; Motaghitalab, V. Effects of using carbon Nano-tubes on thermal and ductility properties of bitumen. arXiv 2019, arXiv:1907.05819. [Google Scholar]

- Wang, P.; Dong, Z.-J.; Tan, Y.-Q.; Liu, Z.-Y. Effect of multi-walled carbon nanotubes on the performance of styrene–butadiene–styrene copolymer modified asphalt. Mater. Struct. 2016, 50, 1–11. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer1; ASTM Designation: D4402/D4402M–15; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Santagata, E.; Baglieri, O.; Tsantilis, L.; Chiappinelli, G. Storage stability of bituminous binders reinforced with nano-additives. In 8th RILEM International Symposium on Testing and Characterization of Sustainable and Innovative Bituminous Materials; Springer Publishing: New York, NY, USA, 2016. [Google Scholar]

- Gong, M.; Yang, J.; Yao, H.; Wang, M.; Niu, X.; Haddock, J.E. Investigating the performance, chemical, and microstructure properties of carbon nanotube-modified asphalt binder. Road Mater. Pavement Des. 2017, 19, 1499–1522. [Google Scholar] [CrossRef]

- AASHTO. Standard Specification for Performance Graded Asphait Binder; AASHTO Designation: MP1-98; AASHTO: Washington, DC, USA, 1998. [Google Scholar]

- Santagata, E.; Baglieri, O.; Tsantilis, L.; Dalmazzo, D. Rheological characterization of bituminous binders modified with carbon nanotubes. Procedia Soc. Behav. Sci. 2012, 53, 546–555. [Google Scholar] [CrossRef] [Green Version]

- Jaczewski, M.; Judycki, J.; Jaskula, P. Asphalt concrete subjected to long-time loading at low temperatures—Deviations from the time-temperature superposition principle. Constr. Build. Mater. 2019, 202, 426–439. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene: A new emerging lubricant. Mater. Today 2014, 17, 31–42. [Google Scholar] [CrossRef]

- Singh, H.; Sharma, V.S.; Dogra, M. Exploration of graphene assisted vegetables oil based minimum quantity lubrication for surface grinding of TI-6AL-4V-ELI. Tribol. Int. 2020, 144, 106113. [Google Scholar] [CrossRef]

- Siddiqui, M.; Ali, M. Studies on the aging behavior of the Arabian asphalts. Fuel 1999, 78, 1005–1015. [Google Scholar] [CrossRef]

| Properties | Values |

|---|---|

| Penetration (25 °C) | 81.9 dmm |

| Softening point | 43.8 °C |

| Ductility (15 °C) | >1000 mm |

| Flashing point | 345 °C |

| Solubility in trichloroethylene | 99.8% |

| Relative density (15 °C, compared with water) | 1.03 |

| Properties | Values |

|---|---|

| Color | Dark grey |

| Layers | 1–3 |

| Single-layer rate (%) | >80 |

| Carbon content (%) | 98 |

| Water content (%) | <2 |

| Particle size distribution D50 (μm) | 7–12 |

| Particle size distribution D90 (μm) | 11–15 |

| Specific surface area (mm2/g) | 50–200 |

| Bulk Density (g/cm3) | 0.06–0.09 |

| Apparent relative density (15 °C, compared with water) | 1.692 |

| Properties | Values |

|---|---|

| Color | Black |

| Purity (%) | >97% |

| Ash content (%) | <2.5% |

| Tube diameter (nm) | 3–15 |

| Tube length (μm) | 15–30 |

| Specific surface area (mm2/g) | 250–270 |

| Bulk density (g/cm3) | 0.01–0.02 |

| Apparent relative density (15 °C, compared with water) | 1.870 |

| Modifier Content (%) | PG (High Temperature Part) | |

|---|---|---|

| Gr-MA | CNTs-MA | |

| 0 | 64 | 64 |

| 1 | 64 | 64 |

| 2 | 64 | 64 |

| 3 | 64 | 70 |

| 4 | 70 | 82 1 |

| 5 | 70 | 82 2 |

| Gr Content (%) | The Percentage of Components/% | Collide Instability Index CII | |||

|---|---|---|---|---|---|

| Saturate | Aromatic | Resin | Asphaltene | ||

| 0 | 24.5133 | 35.9618 | 32.2616 | 7.2632 | 0.4658 |

| 1 | 24.7825 | 36.0740 | 32.0190 | 7.1246 | 0.4686 |

| 2 | 24.7520 | 36.6307 | 31.3259 | 7.2914 | 0.4715 |

| 3 | 25.3036 | 35.7349 | 31.7220 | 7.2395 | 0.4824 |

| 4 | 25.6996 | 36.6717 | 30.2614 | 7.3674 | 0.4940 |

| 5 | 25.5832 | 35.9562 | 30.1862 | 8.2743 | 0.5119 |

| CNTs Content (%) | The Percentage of Components/% | Collide Instability Index CII | |||

|---|---|---|---|---|---|

| Saturate | Aromatic | Resin | Asphaltene | ||

| 0 | 24.5133 | 35.9618 | 32.2616 | 7.2632 | 0.4658 |

| 1 | 24.4804 | 36.0184 | 32.1995 | 7.3018 | 0.4659 |

| 2 | 24.4294 | 36.0929 | 32.1173 | 7.3603 | 0.4661 |

| 3 | 24.8536 | 35.7316 | 29.2486 | 10.1663 | 0.5389 |

| 4 | 25.7042 | 36.0467 | 26.6996 | 11.5494 | 0.5937 |

| 5 | 25.6311 | 37.4823 | 24.2933 | 12.5934 | 0.6188 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Yu, X.; Liang, Y.; Wu, S. Carbon Nanomaterials for Enhancing the Thermal, Physical and Rheological Properties of Asphalt Binders. Materials 2021, 14, 2585. https://doi.org/10.3390/ma14102585

Li Z, Yu X, Liang Y, Wu S. Carbon Nanomaterials for Enhancing the Thermal, Physical and Rheological Properties of Asphalt Binders. Materials. 2021; 14(10):2585. https://doi.org/10.3390/ma14102585

Chicago/Turabian StyleLi, Zhelun, Xin Yu, Yangshi Liang, and Shaopeng Wu. 2021. "Carbon Nanomaterials for Enhancing the Thermal, Physical and Rheological Properties of Asphalt Binders" Materials 14, no. 10: 2585. https://doi.org/10.3390/ma14102585

APA StyleLi, Z., Yu, X., Liang, Y., & Wu, S. (2021). Carbon Nanomaterials for Enhancing the Thermal, Physical and Rheological Properties of Asphalt Binders. Materials, 14(10), 2585. https://doi.org/10.3390/ma14102585