Crystal and Supramolecular Structure of Bacterial Cellulose Hydrolyzed by Cellobiohydrolase from Scytalidium Candidum 3C: A Basis for Development of Biodegradable Wound Dressings

Abstract

:1. Introduction

2. Materials and Methods

2.1. BC Sample Production

2.2. Isolation of Cellobiohydrolase from S. Candidum 3C, Activity Assays and Kinetics

2.3. BC Samples Preparation for Structural Analysis

- Identical disks of bacterial cellulose (diameter 10 cm, thickness 1 mm) were treated with the enzyme solution (0.5 mg/mL) at 37 °C for 120, 210, 240 min, and 24 h. Then, the hydrolysis was stopped by boiling for 5 min, the samples were washed with distilled water and left in 98% ethanol for 3 days, and alcohol solution was changed once a day.

- The specific setup consisting of a high-pressure pump for CO2 (Supercritical 24 (SSI, State College, PA, USA)), a 50-mL steel reactor, and a back-pressure regulator BPR (Waters, Milford, MA, USA) was used for supercritical drying of the obtained BC samples. This drying method was used as the safest procedure to retain the BC supramolecular structure close to its wet-state arrangement [37]. The samples prepared as described above were washed sequentially with supercritical CO2 (15 MPa) at 20 °C for 2 h and at 50 °C for 2–2.5 h.

2.4. Analytical Methods

2.5. Cytotoxity Evaluation

2.6. Experiments In Vivo

3. Results

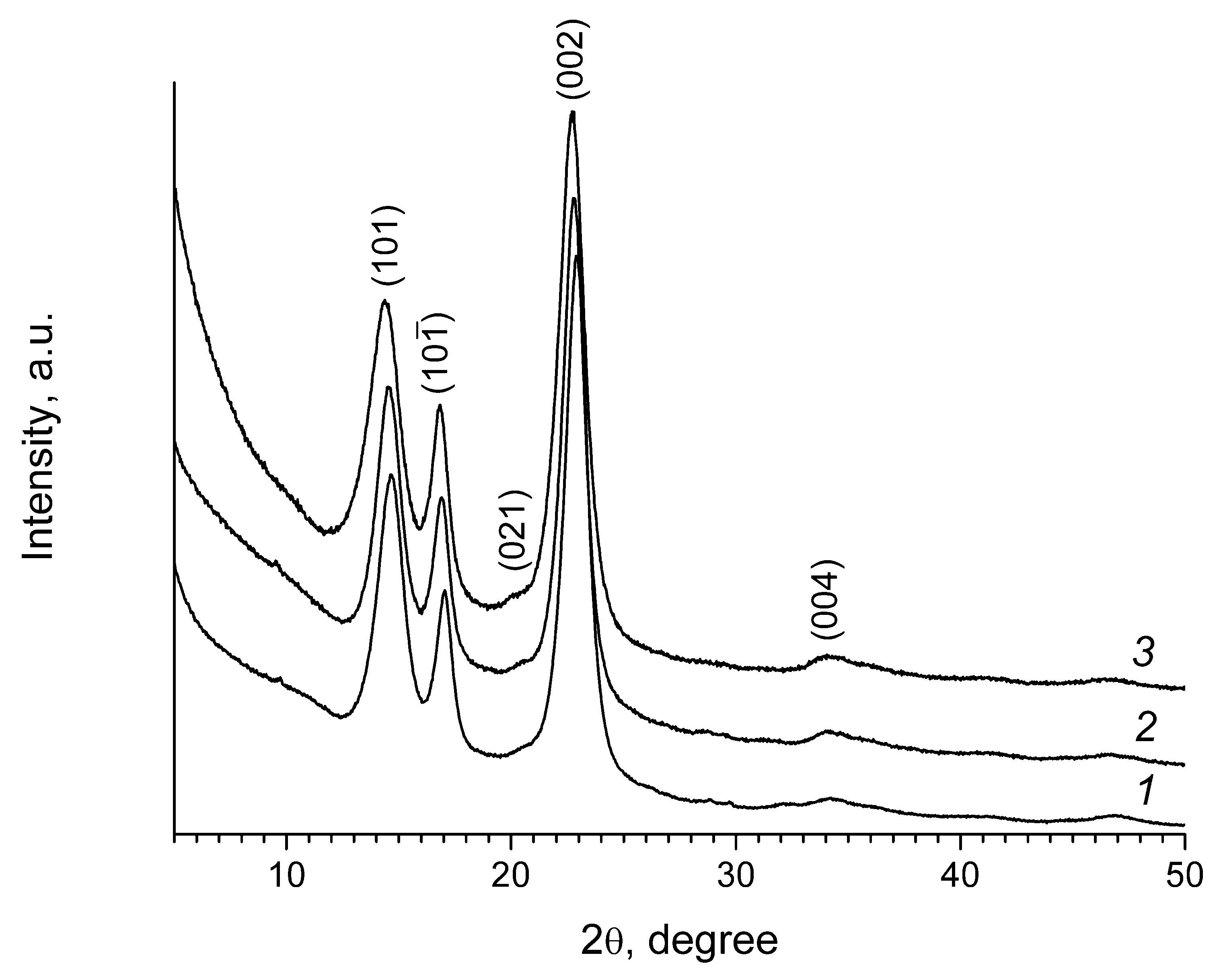

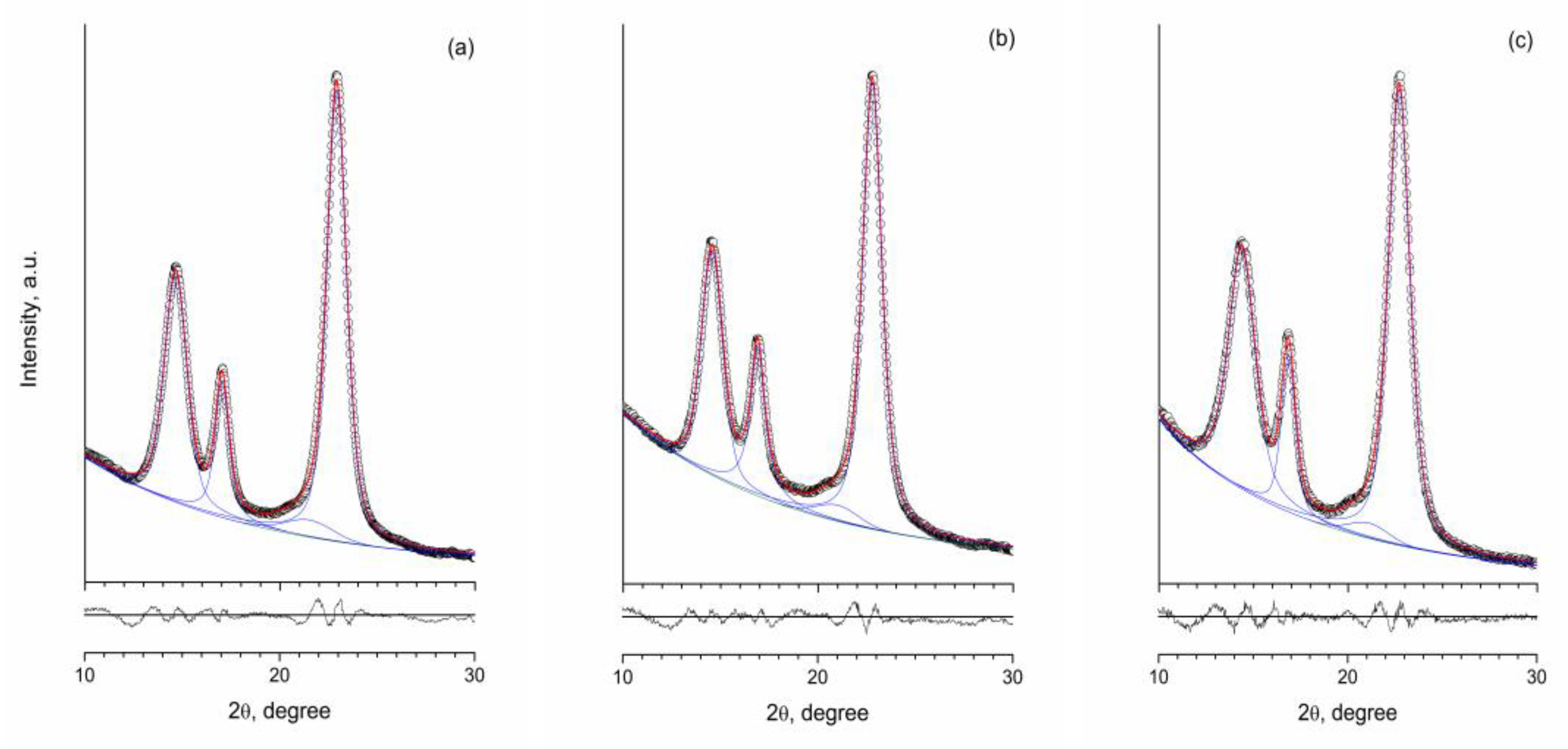

3.1. XRD

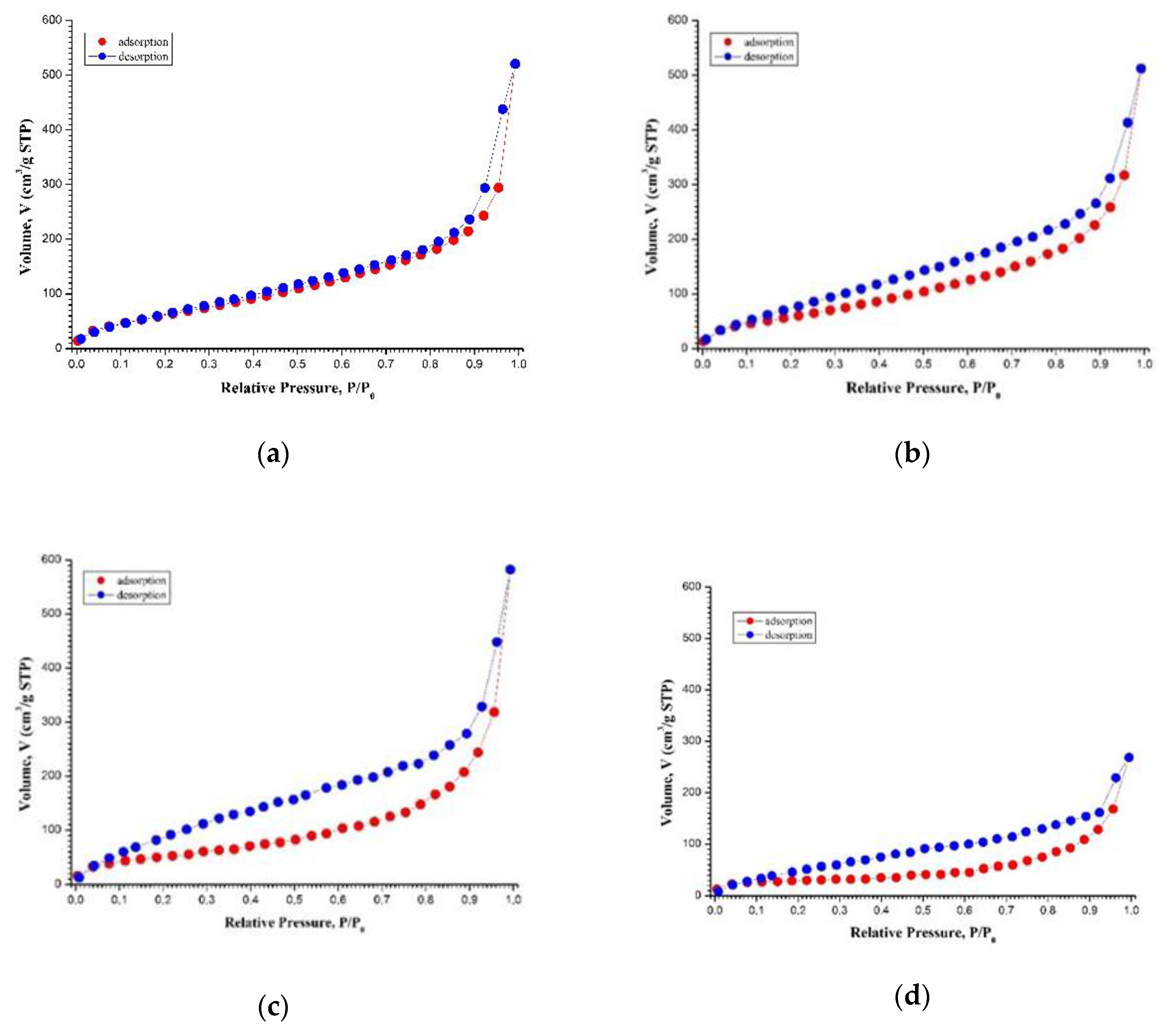

3.2. Low Temperature Nitrogen Adsorption

3.3. SANS and USANS

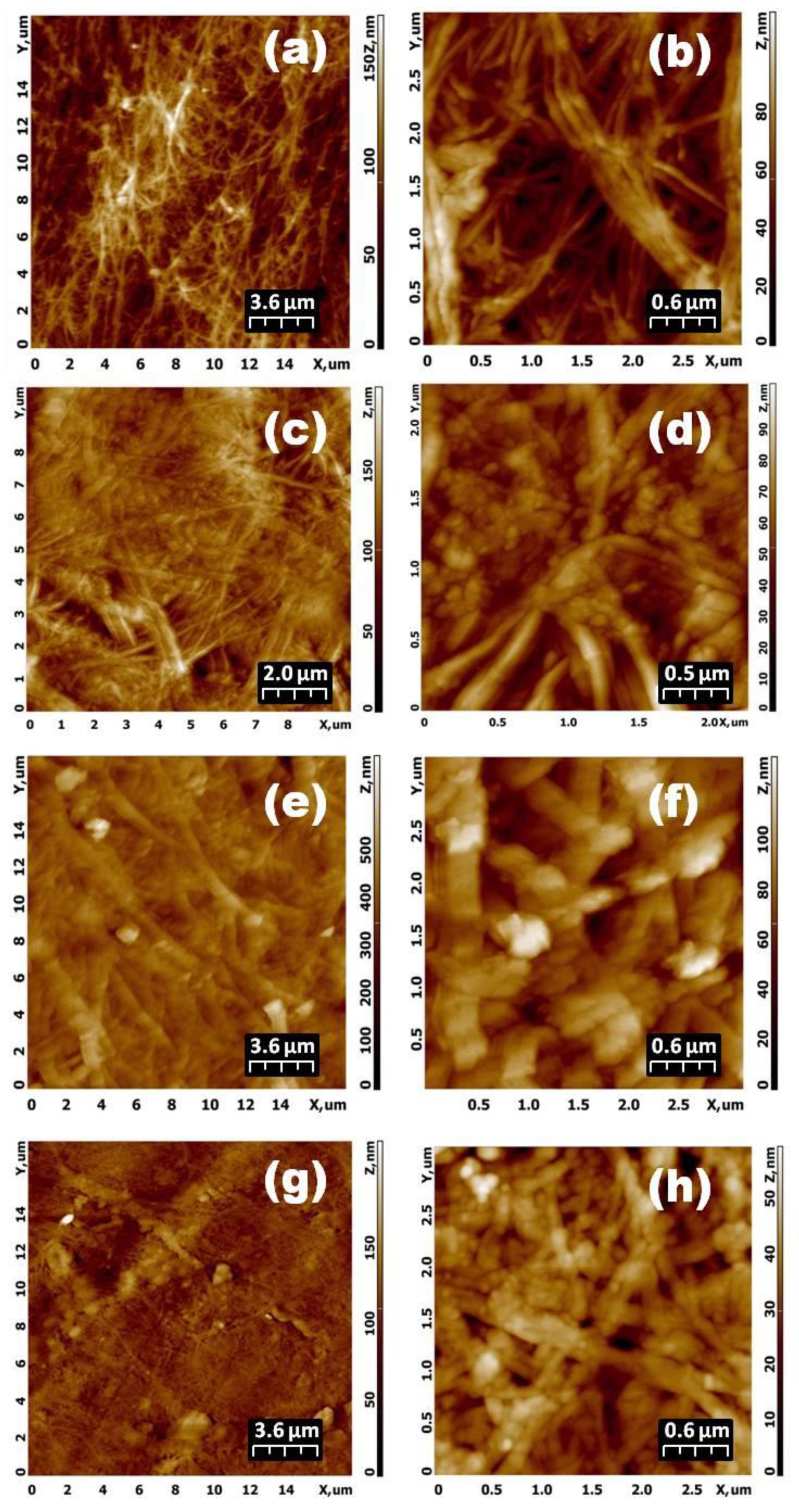

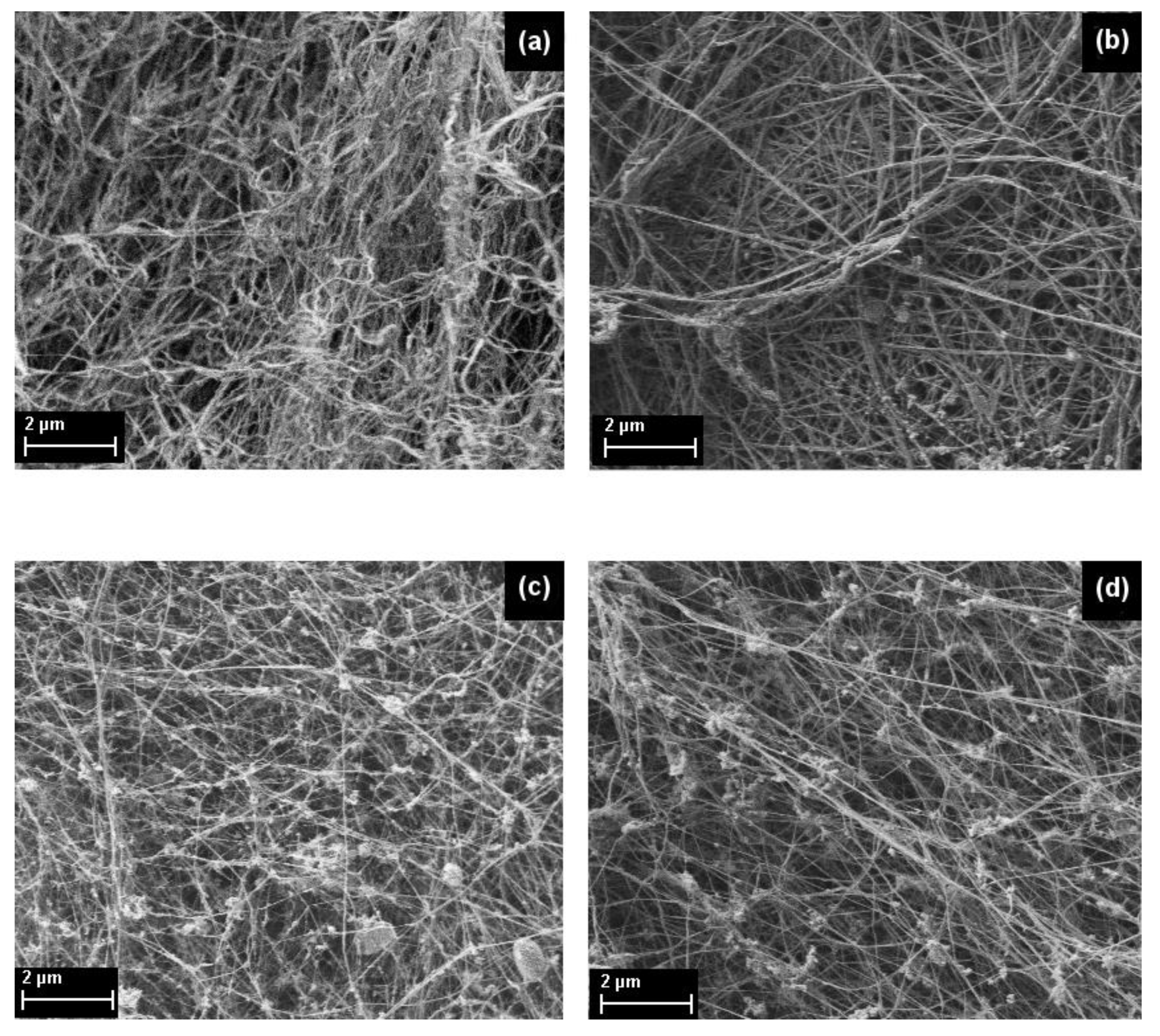

3.4. AFM and SEM

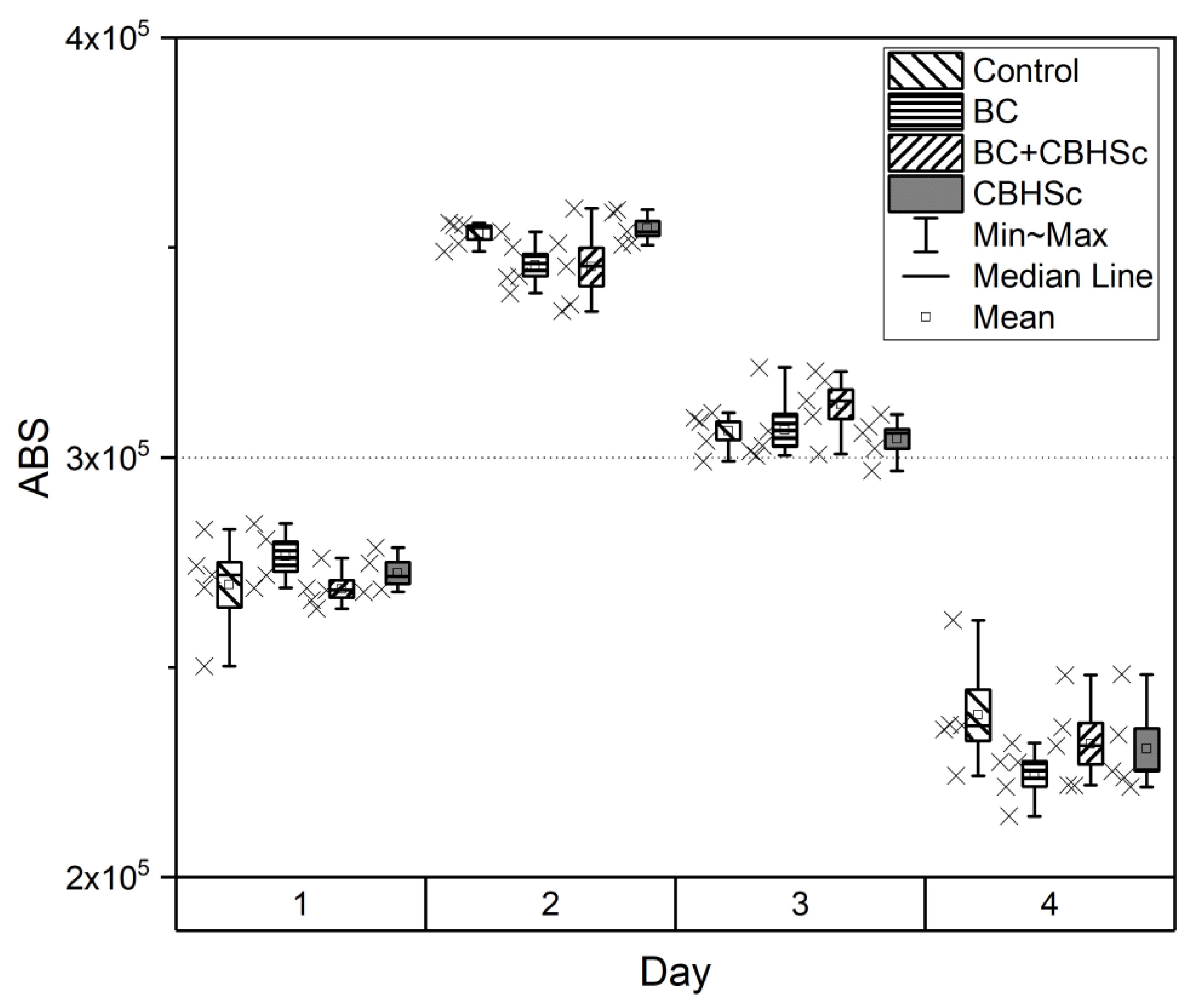

3.5. CBHSc-Toxicity Evaluation of CBHSc-Treatment of BC Samples In Vitro

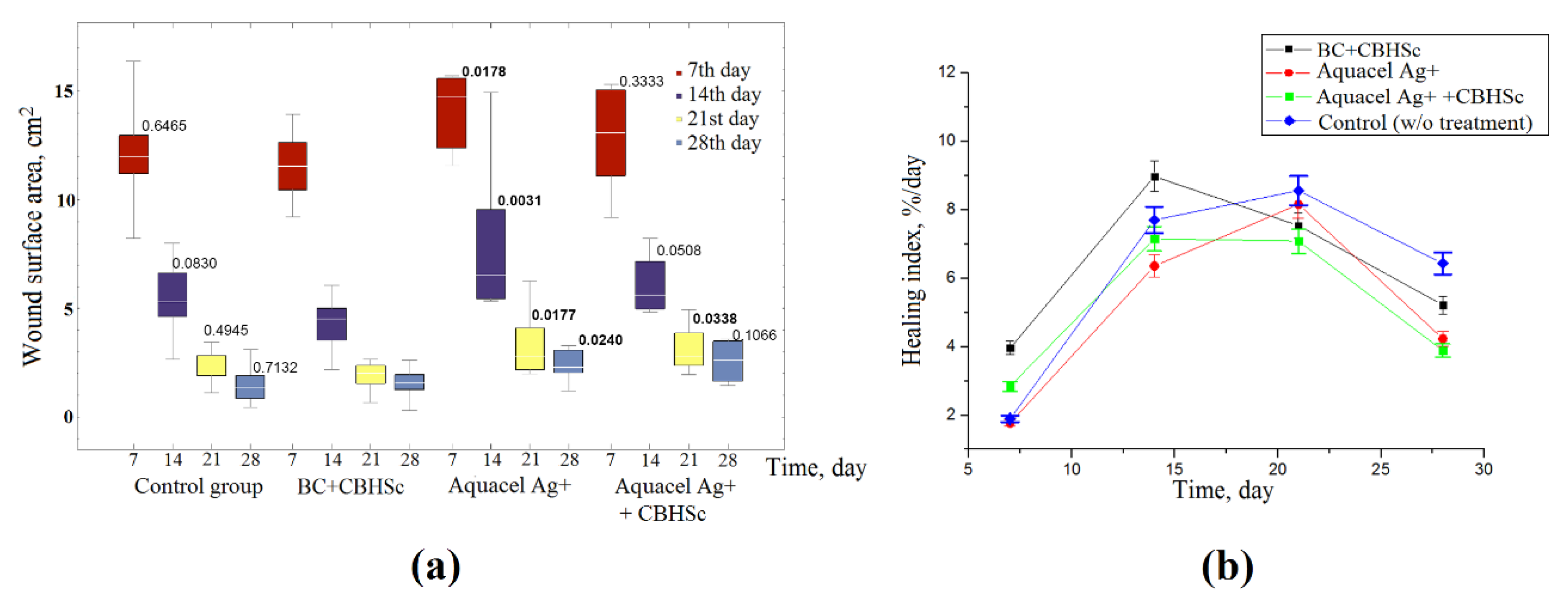

3.6. Experiments In Vivo

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Picheth, G.F.; Pirich, C.L.; Sierakowski, M.R.; Woehl, M.A.; Sakakibara, C.N.; de Souza, C.F.; Martin, A.A.; da Silva, R.; de Freitas, R.A. Bacterial cellulose in biomedical applications: A review. Int. J. Biol. Macromol. 2017, 104, 97–106. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Tavakoli, J.; Tang, Y. Bacterial cellulose production, properties and applications with different culture methods—A review. Carbohydr. Polym. 2019, 219, 63–76. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xue, Y.; Mou, Z.; Xiao, H. Nanocellulose as sustainable biomass material: Structure, properties, present status and future prospects in biomedical applications. Nanoscale 2017, 9, 14758–14781. [Google Scholar] [CrossRef] [PubMed]

- Bacakova, L.; Pajorova, J.; Bacakova, M.; Skogberg, A.; Kallio, P.; Kolarova, K.; Svorcik, V. Versatile application of nanocellulose: From industry to skin tissue engineering and wound healing. Nanomaterials 2019, 9, 164. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hsieh, Y.C.; Yano, H.; Nogi, M.; Eichhorn, S.J. An estimation of the Young’s modulus of bacterial cellulose filaments. Cellulose 2008, 15, 507–513. [Google Scholar] [CrossRef]

- Guo, J.; Catchmark, J.M. Surface area and porosity of acid hydrolyzed cellulose nanowhiskers and cellulose produced by Gluconacetobacter xylinus. Carbohydr. Polym. 2012, 87, 1026–1037. [Google Scholar] [CrossRef]

- Wu, Y.D.; He, J.M.; Cheng, W.L.; Gu, H.B.; Guo, Z.H.; Gao, S.; Huang, Y.D. Oxidized regenerated cellulose-based hemostat with microscopically gradient structure. Carbohydr. Polym. 2012, 88, 1023–1032. [Google Scholar] [CrossRef]

- Huang, W.Y.; Yeh, C.L.; Lin, J.H.; Yang, J.S.; Ko, T.H.; Lin, Y.H. Development of fibroblast culture in three-dimensional activated carbon fiber-based scaffold for wound healing. J. Mater. Sci. Mater. Med. 2012, 23, 1465–1478. [Google Scholar] [CrossRef]

- Klemm, D.; Schumann, D.; Udhardt, U.; Marsch, S. Bacterial synthesized cellulose—Artificial blood vessels for microsurgery. Prog. Polym. Sci. 2001, 26, 1561–1603. [Google Scholar] [CrossRef]

- Park, S.N.; Kim, J.K.; Suh, H. Evaluation of antibiotic-loaded collagen-hyaluronic acid matrix as a skin substitute. Biomaterials 2004, 25, 3689–3698. [Google Scholar] [CrossRef]

- Saiz, E.; Zimmermann, E.A.; Lee, J.S.; Wegst, U.G.K.; Tomsia, A.P. Perspectives on the role of nanotechnology in bone tissue engineering. Dent. Mater. 2013, 29, 103–115. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wysocki, A.B. Skin anatomy, physiology, and pathophysiology. Nurs. Clin. N. Am. 1999, 34, 777–797. [Google Scholar]

- De Oliveira Barud, H.G.; da Silva, R.R.; da Silva Barud, H.; Tercjak, A.; Gutierrez, J.; Lustri, W.R.; de Oliveira, O.B.; Ribeiro, S.L. A multipurpose natural and renewable polymer in medical applications: Bacterial cellulose. Carbohydr. Polym. 2016, 153, 406–420. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sulaeva, I.; Henniges, U.; Rosenau, T.; Potthast, A. Bacterial cellulose as a material for wound treatment: Properties and modifications. A review. Biotechnol. Adv. 2015, 33, 1547–1571. [Google Scholar] [CrossRef]

- Zhang, H.B.; Zhou, L.; Zhang, W.J. Control of scaffold degradation in tissue engineering: A review. Tissue Eng. 2014, 20, 492–502. [Google Scholar] [CrossRef]

- Béguin, P.; Aubert, J.P. The biological degradation of cellulose. FEMS Microbiol. Rev. 1994, 13, 25–58. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, S.; Singh, O.V. Bioconversion of lignocellulosic biomass: Biochemical and molecular perspectives. J. Ind. Microbiol. Biotechnol. 2008, 3, 5377–5391. [Google Scholar] [CrossRef]

- Annamalai, N.; Rajeswari, M.V.; Balasubramanian, T. Endo-1,4-β-glucanases: Role, applications and recent developments. Microb. Enzym. Bioconvers. Biomass 2016, 8, 37–45. [Google Scholar]

- Sharma, A.; Tewari, R.; Rana, S.S.; Soni, R.; Soni, S.K. Cellulases: Classification, methods of determination and industrial applications. Appl. Biochem. Biotechnol. 2016, 179, 1346–1380. [Google Scholar] [CrossRef]

- Hu, Y.; Catchmark, J.M. In vitro biodegradability and mechanical properties of bioabsorbable bacterial cellulose incorporating cellulases. Acta Biomater. 2011, 7, 2835–2845. [Google Scholar] [CrossRef]

- Hu, Y.; Catchmark, J.M. Integration of cellulases into bacterial cellulose: Toward bioabsorbable cellulose composites. J. Biomed. Mater. Res. B Appl. Biomater. 2011, 97, 114–123. [Google Scholar] [CrossRef] [PubMed]

- Tayeb, A.H.; Amini, E.; Ghasemi, S.; Tajvidi, M. Cellulose nanomaterials-binding properties and applications: A review. Molecules 2018, 23, 2684. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Torres, F.; Commeaux, S.; Troncoso, O.P. Biocompatibility of bacterial cellulose based biomaterials. J. Funct. Biomater. 2012, 3, 864–878. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Qiu, Y.; Qiu, L.; Cui, J.; Wei, Q. Bacterial cellulose and bacterial cellulose-vaccarin membranes for wound healing. Mater. Sci. Eng. C Mater. Biol. Appl. 2016, 59, 303–309. [Google Scholar] [CrossRef]

- Revin, V.V.; Pestov, N.A.; Shchankin, M.V.; Mishkin, V.M.; Platonov, V.I.; Uglanov, D.A. A study of the physical and mechanical properties of aerogels obtained from bacterial cellulose. Biomacromolecules 2019, 20, 1401–1411. [Google Scholar] [CrossRef]

- Kwaka, M.H.; Kima, J.I.; Goa, J.; Koha, I.K.; Songa, S.H.; Sona, H.J.; Kimb, H.S.; Yunc, Y.H.; Junga, Y.G.; Hwanga, D.Y. Bacterial cellulose membrane produced by Acetobacter sp. A10 for burn wound dressing applications. Carbohydr. Polym. 2015, 122, 387–398. [Google Scholar] [CrossRef]

- Nishiyama, Y.; Sugiyama, J.; Chanzy, H.; Langan, P. Crystal structure and hydrogen bonding system in cellulose Iα from synchrotron X-ray and neutron fiber diffraction. J. Am. Chem. Soc. 2002, 125, 14300–14306. [Google Scholar] [CrossRef]

- Klechkovskaya, V.V.; Baklagina, Y.G.; Stepina, N.D.; Khripunov, A.K.; Buffat, P.A.; Suvorova, E.I.; Zanaveskina, I.S.; Tkachenko, A.A.; Gladchenko, S.V. Structure of cellulose Acetobacter xylinum. Crystallogr. Rep. 2003, 48, 755–762. [Google Scholar] [CrossRef]

- Tajima, H.; Penttilä, P.A.; Imai, T.; Yamamoto, K.; Yuguchi, Y. Observation of in vitro cellulose synthesis by bacterial cellulose synthase with time-resolved small angle X-ray scattering. Int. J. Biol. Macromol. 2019, 130, 765–777. [Google Scholar] [CrossRef]

- Smyslov, R.Y.; Ezdakova, K.V.; Kopitsa, G.P.; Khripunov, A.K.; Bugrov, A.N.; Tkachenko, A.A.; Angelov, B.; Pipich, V.; Szekely, N.K.; Baranchikov, A.E.; et al. Morphological structure of Gluconacetobacter xylinus cellulose and cellulose-based organic-inorganic composite materials. J. Phys. Conf. Ser. 2017, 848, 613–628. [Google Scholar] [CrossRef] [Green Version]

- Martínez-Sanz, M.; Gidley, M.J.; Gilbert, E.P. Hierarchical architecture of bacterial cellulose and composite plant cell wall polysaccharide hydrogels using small angle neutron scattering. Soft Matter. 2016, 12, 1534–1549. [Google Scholar] [CrossRef] [PubMed]

- Volkov, V.V.; Klechkovskaya, V.V.; Shtykova, E.V.; Dembo, K.A.; Arkharova, N.A.; Ivakin, G.I.; Smyslov, R.Y. Determination of the size and phase composition of silver nanoparticles in a gel film of bacterial cellulose by small-angle X-ray scattering, electron diffraction, and electron microscopy. Crystallogr. Rep. 2009, 54, 169–173. [Google Scholar] [CrossRef]

- Borisova, A.S.; Eneyskaya, E.V.; Bobrov, K.S.; Jana, S.; Logachev, A.; Polev, D.E.; Lapidus, A.L.; Ibatullin, F.M.; Saleem, U.; Sandgren, M.; et al. Sequencing, biochemical characterization, crystal structure and molecular dynamics of cellobiohydrolase Cel7A from Geotrichum candidum 3C. FEBS J. 2015, 282, 4515–4537. [Google Scholar] [CrossRef] [PubMed]

- Hestrin, S.; Schramm, M. Synthesis of cellulose by Acetobacter xylinum: Preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem. J. 1954, 58, 345–352. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pavlov, I.Y.; Bobrov, K.S.; Sumacheva, A.D.; Masharsky, A.E.; Polev, D.E.; Zhurishkina, E.V.; Kulminskaya, A.A. Scytalidium candidum 3C is a new name for the Geotrichum candidum Link 3C strain. J. Basic Microbiol. 2018, 58, 883–891. [Google Scholar] [CrossRef]

- Lever, M.; Powell, J.C.; Killip, M.; Small, C.W. A comparison of 4-hydroxybenzoic acid hydrazide (PAHBAH) with other reagents for the determination of glucose. J. Lab. Clin. Med. 1973, 82, 649–655. [Google Scholar]

- Sai, H.; Fu, R.; Xing, L.; Xiang, J.; Li, Z.; Li, F.; Zhang, T. Surface modification of bacterial cellulose aerogels’ web-like skeleton for oil/water separation. ACS Appl. Mater. Interfaces 2015, 7, 7373–7381. [Google Scholar] [CrossRef]

- Kuklin, A.I.; Islamov, A.K.; Gordeliy, V.I. Two-detector system for small-angle neutron scattering instrument. Neutron News 2005, 16, 16–18. [Google Scholar] [CrossRef]

- Soloviev, A.G.; Soloveva, T.M.; Stadnik, A.V.; Islamov, A.H.; Kuklin, A.I. The Package for small-angle neutron scattering data reatment. Version 2.4. In Long Wtite-Up and User’s Guide; Preprint JINR: Dubna, Russia, 2003; P10-2003-86. [Google Scholar]

- Ostanevich, Y.M. Time-of-flight small-angle scattering spectrometers on pulsed neutron sources. Makromol. Chemie. Macromol. Symp. 1988, 15, 91–103. [Google Scholar] [CrossRef]

- Radulescu, A.; Kentzinger, E.; Stellbrink, J.; Dohmen, L.; Alefeld, B.; Rücker, U.; Heiderich, M.; Schwahn, D.; Brückel, T.; Richter, D. The new small-angle neutron scattering instrument based on focusing-mirror optics. Neutron News 2005, 16, 18–21. [Google Scholar] [CrossRef]

- Goerigk, G.; Varga, Z. Comprehensive upgrade of the high-resolution small-angle neutron scattering instrument KWS-3 at FRM II. J. Appl. Crystallogr. 2011, 44, 337–342. [Google Scholar] [CrossRef]

- Wignall, G.D.; Bates, F.S. Absolute calibration of small-angle neutron scattering data. J. Appl. Crystallogr. 1987, 20, 28–40. [Google Scholar] [CrossRef]

- Jülich Centre for Neutron Science, QtiKWS. Available online: http://qtisas.com/doku.php?id=downloads (accessed on 6 November 2019).

- Uzarski, J.S.; Su, J.; Xie, Y.; Zhang, Z.J.; Ward, H.H.; Wandinger-Ness, A.; Miller, W.M.; Wertheim, J.A. Epithelial cell repopulation and preparation of rodent extracellular matrix scaffolds for renal tissue development. J. Vis. Exp. 2015, 120, 157–164. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Volnitskiy, A.; Shtam, T.; Burdakov, V.; Kovalev, R.; Konev, A.; Filatov, M. Abnormal activity of transcription factors gli in high-grade gliomas. PLoS ONE 2019, 14, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Close, B.; Banister, K.; Baumans, V.; Bernoth, E.-M.; Bromage, N.; Bunyan, J.; Erhardt, W.; Flecknell, P.; Gregory, N.; Hackbarth, H.; et al. Recommendations for euthanasia of experimental animals: Part 1. Lab. Anim. 1996, 30, 293–316. [Google Scholar] [CrossRef]

- Close, B.; Banister, K.; Baumans, V.; Bernoth, E.-M.; Bromage, N.; Bunyan, J.; Erhardt, W.; Flecknell, P.; Gregory, N.; Hackbarth, H.; et al. Recommendations for euthanasia of experimental animals: Part 2. Lab. Anim. 1997, 31, 1–32. [Google Scholar] [CrossRef] [Green Version]

- Zugenmaier, P. Crystalline Cellulose and Derivatives, 1st ed.; Springer: New York, NY, USA, 2008; pp. 101–103. [Google Scholar]

- Hsieh, Y.L. Chemical structure and properties of cotton. In Cotton: Science and Technology, 1st ed.; Woodhead Publishing: Berlin, Germany, 2007; pp. 3–34. [Google Scholar]

- Premjet, S.; Ohtani, Y.; Sameshima, K. X-ray diffraction diagram of the bacterial cellulose membrane produced by Acetobacter xylinum in the medium with lignosulfonate. Seni Gakkaishi 1996, 52, 169–174. [Google Scholar] [CrossRef] [Green Version]

- Vasconcelos, N.F.; Feitosa, J.P.; da Gama, F.M.; Morais, J.P.; Andrade, F.K.; de Souza Filho, M.S.; Rosa, M.F. Bacterial cellulose nanocrystals produced under different hydrolysis conditions: Properties and morphological features. Carbohydr. Polym. 2017, 155, 425–431. [Google Scholar] [CrossRef]

- Lopes, T.D.; Riegel-Vidotti, I.C.; Grein, A.; Tischer, C.A.; Faria-Tischer, P.C. Bacterial cellulose and hyaluronic acid hybrid membranes: Production and characterization. Int. J. Biol. Macromol. 2014, 67, 401–408. [Google Scholar] [CrossRef] [Green Version]

- French, A.D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 2014, 21, 885–896. [Google Scholar] [CrossRef]

- Terinte, N.; Ibbett, R.; Schuster, K.C. Overview on native cellulose and microcrystalline cellulose i structure studied by X-ray diffraction (WAXD): Comparison between measurement techniques. Lenzing. Ber. 2011, 89, 118–131. [Google Scholar]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef] [Green Version]

- Hammouda, B. A new Guinier–Porod model. J. Appl. Crystallogr. 2010, 43, 716–719. [Google Scholar] [CrossRef]

- Glatter, O.; Kratky, O. Small-Angle X-Ray Scattering; Academic Press: London, UK, 1982; Volume 20, pp. 155–157. [Google Scholar]

- Teixera, J.; Stanley, H.E.; Ostrovsky, N. On Growth and Form. Fractal and Non-Fractal Patterns in Physics; Martinus Nijloff Publ.: Boston, MA, USA, 1986; pp. 145–146. [Google Scholar]

- Beaucage, G. Approximations leading to a unified exponential/power-law approach to small-angle scattering. J. Appl. Crystallogr. 1995, 28, 717–728. [Google Scholar] [CrossRef]

- Brown, R.M., Jr. The biosynthesis of cellulose. J. Macromol. Sci. A 1996, 33, 1345–1373. [Google Scholar] [CrossRef]

- Fink, H.P.; Purz, H.J.; Bohn, A.; Kunze, J. Investigation of the supramolecular stucture of never dried bacterial cellulose. Macromol. Symp. 1997, 120, 207–217. [Google Scholar] [CrossRef]

- Svensson, A.; Nicklasson, E.; Harrah, T.; Panilaitis, B.; Kaplan, D.L.; Brittberg, M.; Gatenholm, P. Bacterial cellulose as a potential scaffold for tissue engineering of cartilage. J. Biomat. 2005, 26, 419–431. [Google Scholar] [CrossRef]

- Pace, R.T.; Burg, K.J.L. Toxic effects of resazurin on cell cultures. Cytotechnology 2015, 67, 13–17. [Google Scholar] [CrossRef] [Green Version]

- Rezende, N.; Ceron Jayme, C.; Brassesco, M.S.; Claudio Tedesco, A.; de Oliveira, H.F. Standardization of a resazurin-based assay for the evaluation of metabolic activity in oral squamous carcinoma and glioblastoma cells. Photodiagn. Photodyn. Ther. 2019, 26, 371–374. [Google Scholar] [CrossRef]

- Homaeigohar, S.; Boccaccini, A.R. Antibacterial biohybrid nanofibers for wound dressings. Acta Biomater. 2020, 107, 25–49. [Google Scholar] [CrossRef]

- Shi, C.; Wang, C.; Liu, H.; Li, Q.; Li, R.; Zhang, Y.; Liu, Y.; Shao, Y.; Wang, J. Selection of appropriate wound dressing for various wounds. Front. Bioeng. Biotechnol. 2020, 8, 182. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yip, V.L.; Withers, S.G. Nature’s many mechanisms for the degradation of oligosaccharides. Org. Biomol. Chem. 2004, 2, 2707–2713. [Google Scholar] [CrossRef] [PubMed]

- Wilhelm, K.P.; Wilhelm, D.; Bielfeldt, S. Models of wound healing: An emphasis on clinical studies. Ski. Res. Technol. 2017, 23, 3–12. [Google Scholar] [CrossRef] [PubMed]

- Bella, J. Collagen structure: New tricks from a very old dog. Biochem. J. 2016, 473, 1001–1025. [Google Scholar] [CrossRef]

- Li, Y.; Aparicio, C. Discerning the subfibrillar structure of mineralized collagen fibrils: A model for the ultrastructure of bone. PLoS ONE 2013, 8, e76782. [Google Scholar] [CrossRef] [Green Version]

- Orgel, J.P.R.O.; Irving, T.C.; Miller, A.; Wess, T.J. Microfibrillar structure of type I collagen in situ. Proc. Natl. Acad. Sci. USA 2006, 103, 9001–9005. [Google Scholar] [CrossRef] [Green Version]

- Wolfert, M.A.; Boons, G.-J. Adaptive immune activation: Glycosylation does matter. Nat. Chem. Biol. 2013, 9, 776–784. [Google Scholar] [CrossRef] [Green Version]

| Time t of Biodegradation (min) | 0 | 120 | 210 | 240 | 1440 |

|---|---|---|---|---|---|

| SBET (m2·g−1) | 261 ± 29 | 191 ± 8 | 157 ± 6 | 189 ± 8 | 104 ± 4 |

| VP/P0→0.99 (cm3·g−1) | 0.86 | 0.82 | 0.50 | 0.81 | 0.42 |

| d (nm) | 2.24 | 2.83 | 3.32 | 3.91 | 4.69 |

| Time t of Biodegradation (min) | 0 | 120 | 210 | 240 | 1440 |

|---|---|---|---|---|---|

| G2·10−2, cm−1nm−s2 | 11.1 ± 1.3 | 7.3 ± 0.7 | 14.4 ± 1.9 | - | - |

| s2 | 1.65 ± 0.02 | 1.64 ± 0.02 | 1.57 ± 0.02 | - | - |

| W, nm | 49 ± 5 | 56 ± 5 | 64 ± 6 | - | - |

| G1·10−3, cm−1nm−s1 | 3.0 ± 0.1 | 4.3 ± 0.2 | 4.9 ± 0.4 | 9.3 ± 0.9 | 12.4 ± 1.5 |

| s1 | 2.26 ± 0.02 | 2.10 ± 0.02 | 2.12 ± 0.02 | 2.02 ± 0.02 | 1.98 ± 0.05 |

| T, nm | 8.4 ± 0.3 | 10.1 ± 0.3 | 10.8 ± 0.5 | 12.6 ± 0.8 | 13.8 ± 1.5 |

| B1·10−5, cm−1nm−n | 1.0 ± 0.14 | 1.0 ± 0.16 | 2.0 ± 0.2 | 1.5 ± 0.2 | 3.0 ± 0.4 |

| DS = 6 − n | 2.37 ± 0.03 | 2.51 ± 0.03 | 2.52 ± 0.02 | 2.49 ± 0.05 | 2.63 ± 0.04 |

| Iinc·10−2, cm−1 | 2.6 ± 0.1 | 1.6 ± 0.1 | 2.2 ± 0.1 | 2.9 ± 0.2 | 3.3 ± 0.2 |

| Critical Drying Time of BC, min | ||||

|---|---|---|---|---|

| 0 | 120 | 240 | 1440 | |

| Ra, nm | ||||

| 18 μm × 18 μm | 19.83 | 33.38 | 12.34 | |

| 10 μm × 10 μm | 14.49 | |||

| 3.2 μm × 3.2 μm | 11.15 | 13.37 | 5.81 | |

| 2.5 μm × 2.5 μm | 8.93 (11.13/6.08) | |||

| Rq, nm | ||||

| 18 μm × 18 μm | 24.59 | 44.60 | 16.85 | |

| 10 μm × 10 μm | 19.00 | |||

| 3.2 μm × 3.2 μm | 13.74 | 17.13 | 7.66 | |

| 2.5 μm × 2.5 μm | 11.30 (13.66/7.60) | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ivanova, L.A.; Ustinovich, K.B.; Khamova, T.V.; Eneyskaya, E.V.; Gorshkova, Y.E.; Tsvigun, N.V.; Burdakov, V.S.; Verlov, N.A.; Zinovev, E.V.; Asadulaev, M.S.; et al. Crystal and Supramolecular Structure of Bacterial Cellulose Hydrolyzed by Cellobiohydrolase from Scytalidium Candidum 3C: A Basis for Development of Biodegradable Wound Dressings. Materials 2020, 13, 2087. https://doi.org/10.3390/ma13092087

Ivanova LA, Ustinovich KB, Khamova TV, Eneyskaya EV, Gorshkova YE, Tsvigun NV, Burdakov VS, Verlov NA, Zinovev EV, Asadulaev MS, et al. Crystal and Supramolecular Structure of Bacterial Cellulose Hydrolyzed by Cellobiohydrolase from Scytalidium Candidum 3C: A Basis for Development of Biodegradable Wound Dressings. Materials. 2020; 13(9):2087. https://doi.org/10.3390/ma13092087

Chicago/Turabian StyleIvanova, Lyubov A., Konstantin B. Ustinovich, Tamara V. Khamova, Elena V. Eneyskaya, Yulia E. Gorshkova, Natalia V. Tsvigun, Vladimir S. Burdakov, Nikolay A. Verlov, Evgenii V. Zinovev, Marat S. Asadulaev, and et al. 2020. "Crystal and Supramolecular Structure of Bacterial Cellulose Hydrolyzed by Cellobiohydrolase from Scytalidium Candidum 3C: A Basis for Development of Biodegradable Wound Dressings" Materials 13, no. 9: 2087. https://doi.org/10.3390/ma13092087