Fabrication of TiB2–Al1050 Composites with Improved Microstructural and Mechanical Properties by a Liquid Pressing Infiltration Process

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Methods

2.2. Characterization

3. Results and Discussion

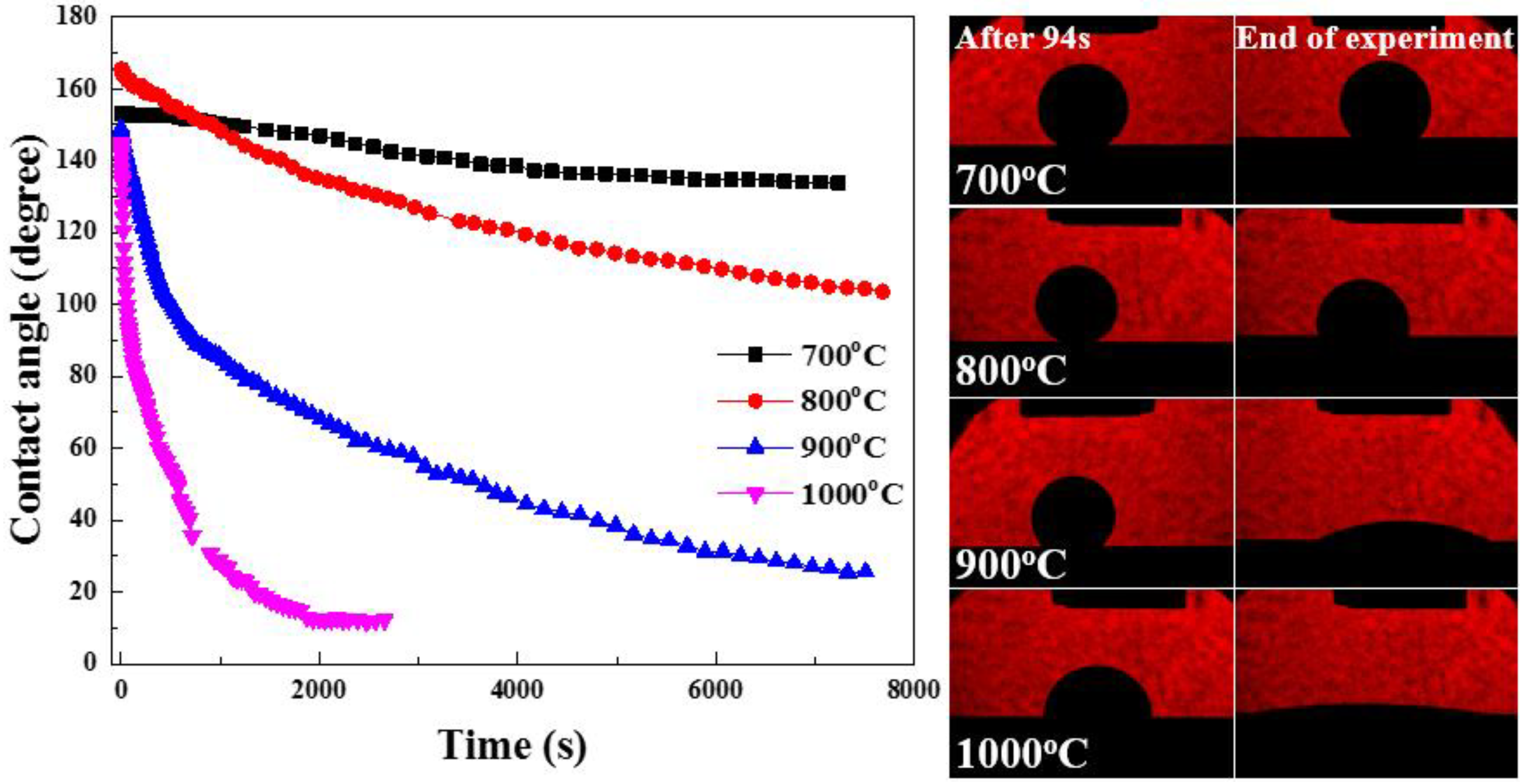

3.1. Contact Angle Between TiB2 and Al

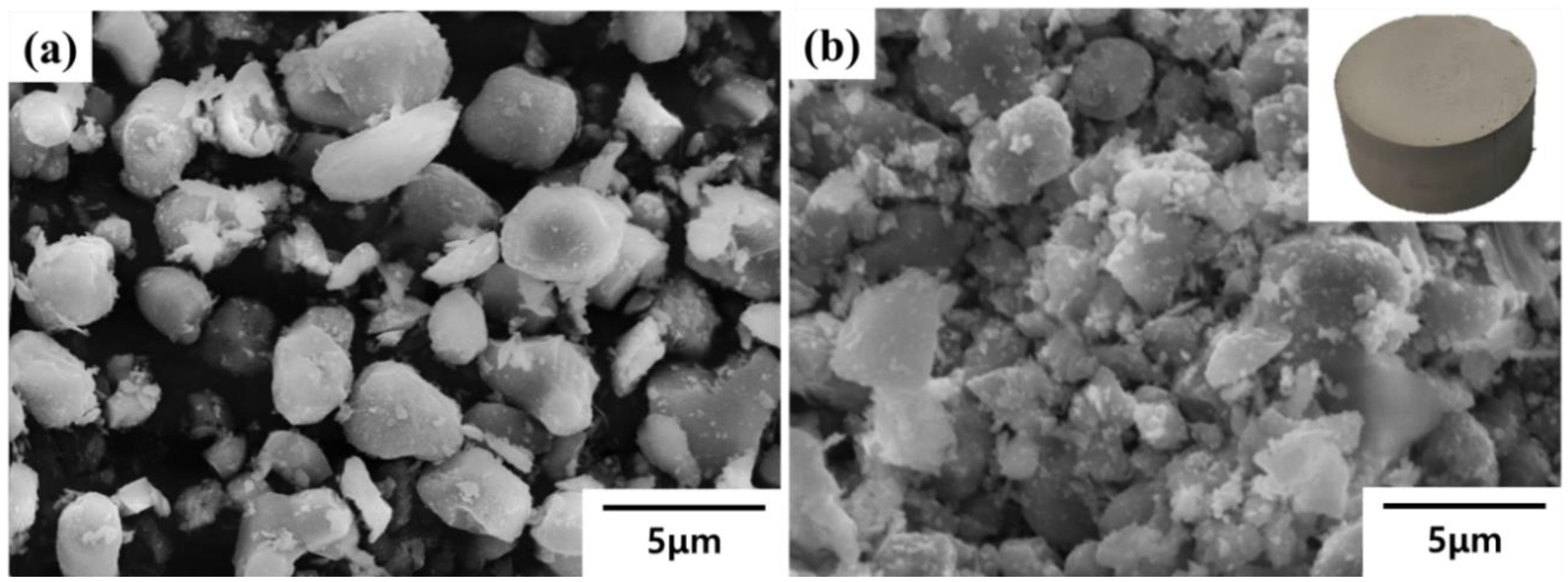

3.2. Morphology of TiB2 Preform

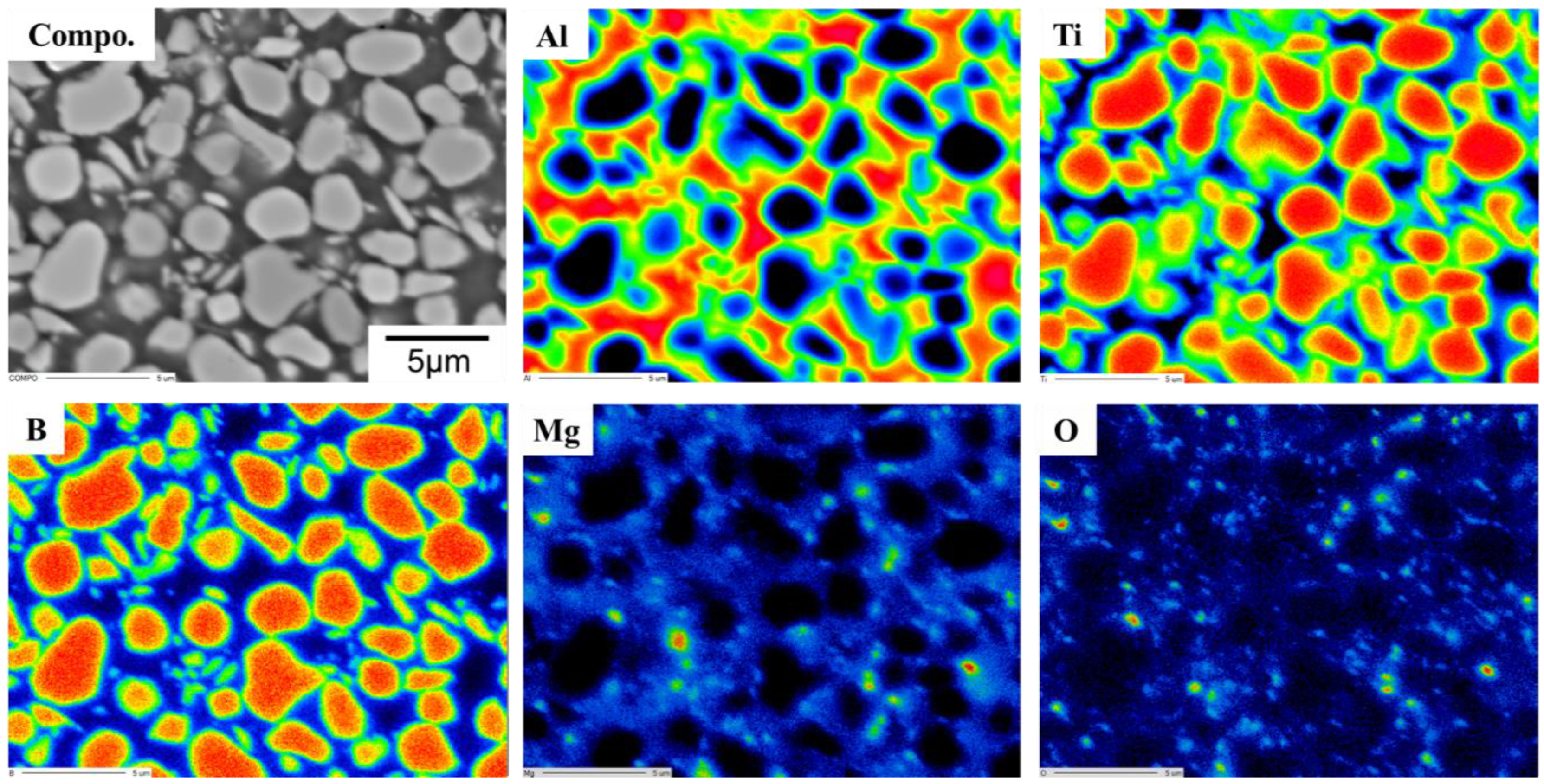

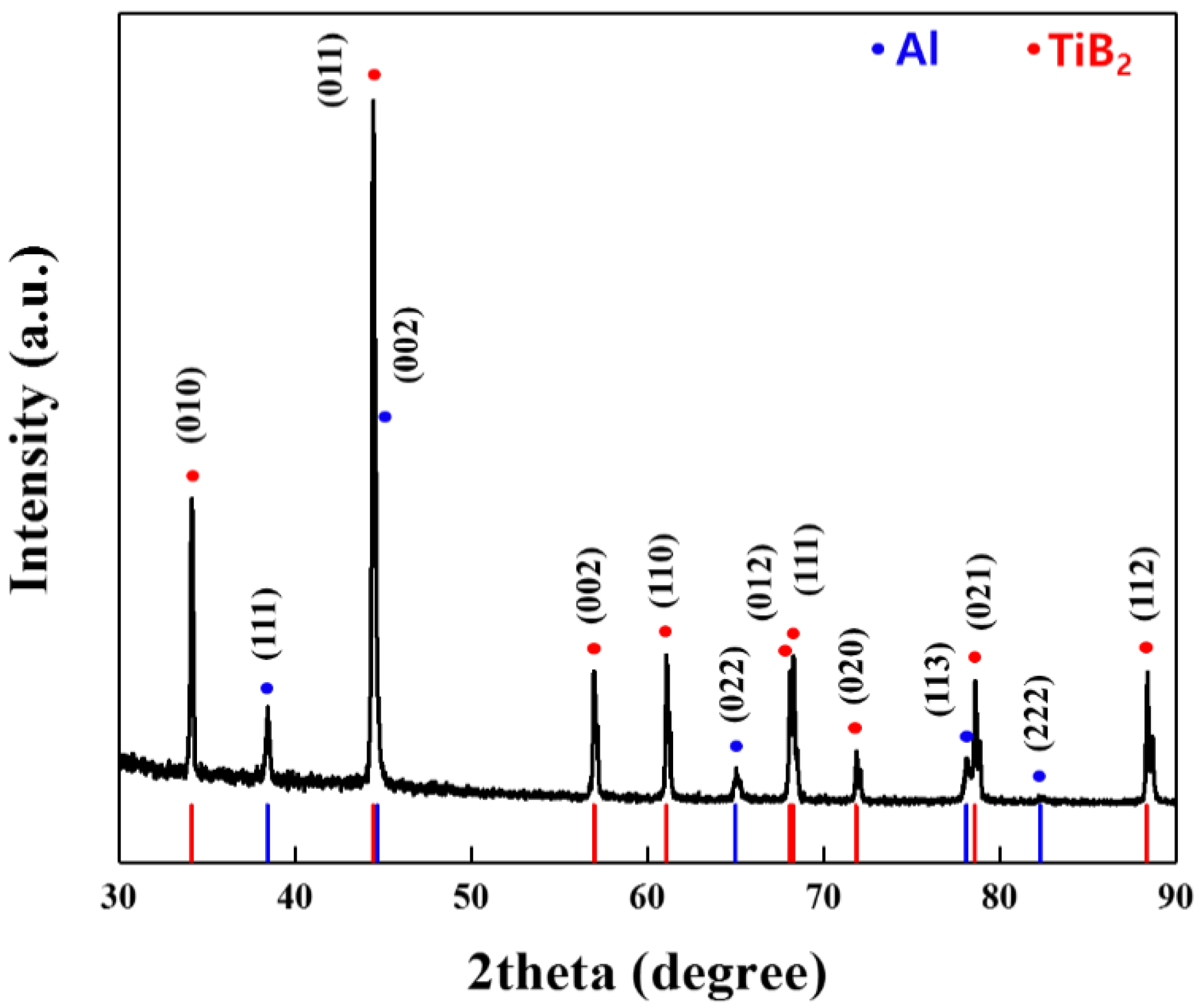

3.3. Microstructure of TiB2–Al1050 Composites

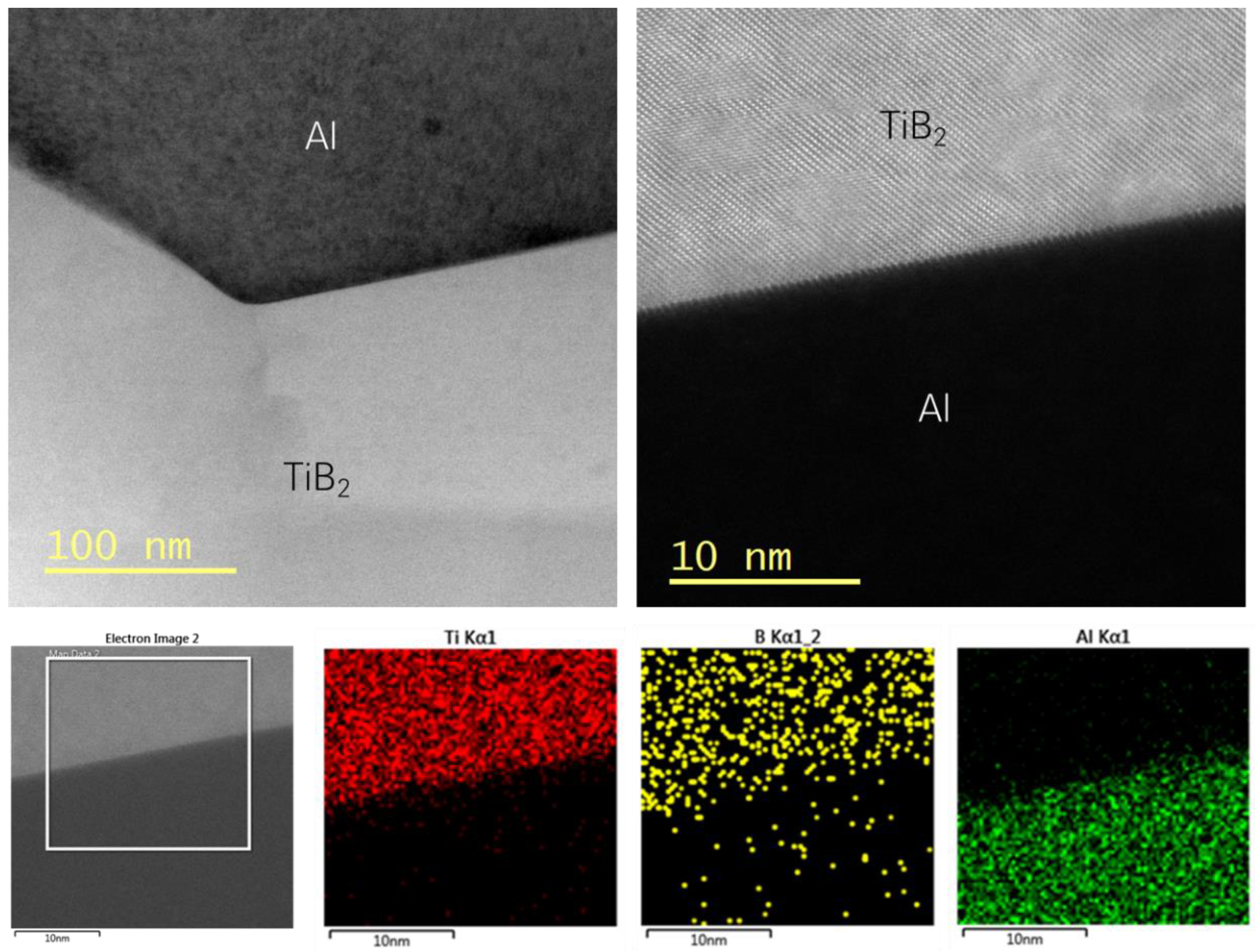

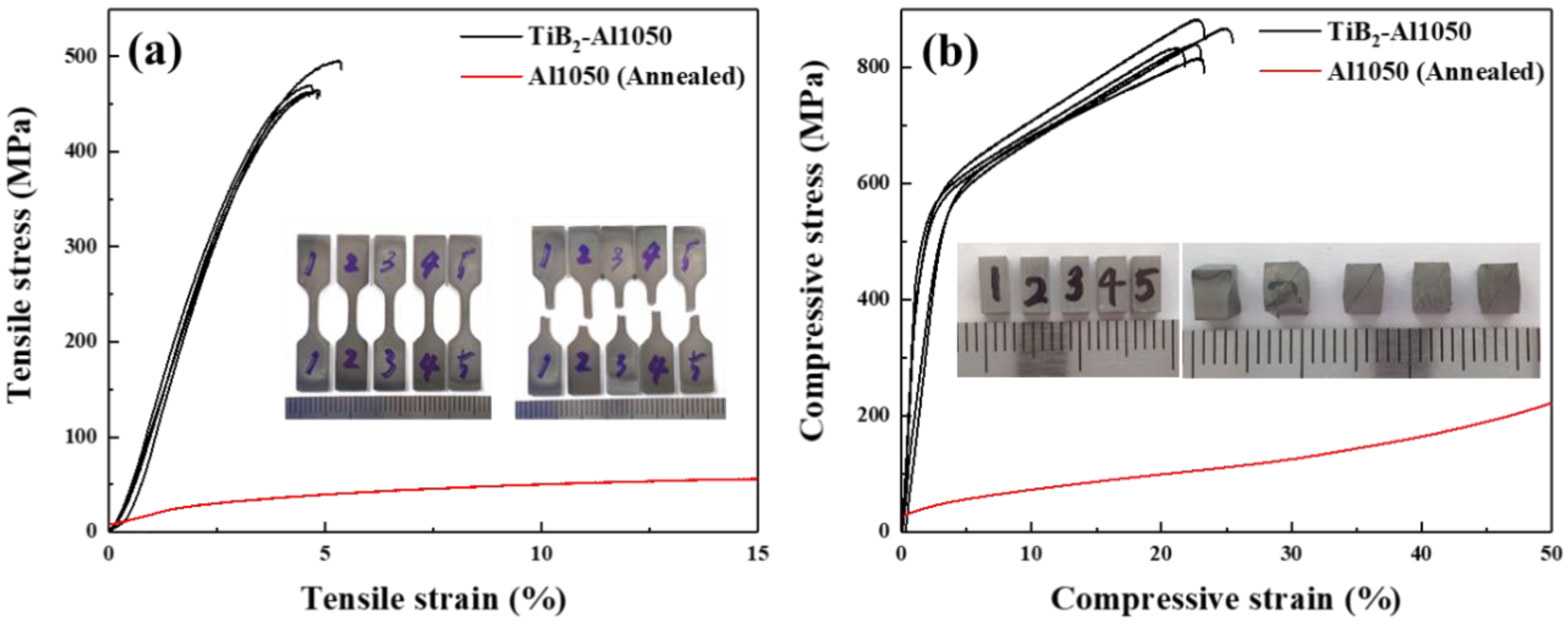

3.4. Mechanical Properties of TiB2–Al1050 Composites

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Molina, J.M.; Narciso, J.; Weber, L.; Mortensen, A.; Louis, E. Thermal conductivity of Al-SiC composites with monomodal and bimodal particle size distribution. Mater. Sci. Eng. A 2008, 480, 483–488. [Google Scholar] [CrossRef]

- Pramod, R.; Kumar, G.B.V.; Gouda, P.S.S.; Mathew, A.T. A Study on the Al2O3 reinforced Al7075 Metal Matrix Composites Wear behavior using Artificial Neural Networks. Mater. Today 2018, 5, 11376–11385. [Google Scholar] [CrossRef]

- Guo, H.; Zhang, Z. Processing and strengthening mechanisms of boron-carbide-reinforced aluminum matrix composites. Metal Powder Rep. 2018, 73, 62–67. [Google Scholar] [CrossRef]

- Wang, Z.J.; Qiu, Z.X.; Sun, H.Y.; Liu, W.C. Effect of TiC content on the microstructure, texture and mechanical properties of 1060/Al-TC/1060 laminated composites. J. Alloys Compd. 2019, 806, 788–797. [Google Scholar] [CrossRef]

- Zhu, D.; Wu, G.; Chen, G.; Zhang, Q. Dynamic deformation behavior of a high reinforcement TiB2/Al composite at high train rates. Mater. Sci. Eng. A 2008, 487, 536–540. [Google Scholar] [CrossRef]

- Mazaheri, Y.; Meratian, M.; Emadi, R.; Najarian, A.R. Comparison of microstructural and mechanical properties of Al-TiC, Al-B4C and Al-TiC-B4C composites prepared by casting techniques. Mater. Sci. Eng. A 2013, 560, 278–287. [Google Scholar] [CrossRef]

- Baron, C.; Springer, H. Properties of particle phase for metal-matrix-composite design. Data Brief 2017, 12, 692–708. [Google Scholar] [CrossRef]

- Jain, A.; Pankajavalli, R.; Antonysamy, S.; Ananthasivan, K.; Babu, R.; Ganesan, V.; Gupat, G.S. Determination of the thermodynamic stability of TiB2. J. Alloys Compd. 2010, 491, 747–752. [Google Scholar] [CrossRef]

- Suresh, S.; Shenbag, N.; Moorthi, V. Aluminium-titanium diboride (Al-TiB2) metal matrix composites: Challenges and opportunities. Procedia Eng. 2012, 38, 89–97. [Google Scholar] [CrossRef] [Green Version]

- Du, R.; Gao, Q.; Wu, S.; Lu, S.; Zhou, X. Influence of TiB2 particles on aging behavior of in-situ TiB2/Al-4.5Cu. Mater. Sci. Eng. A 2018, 721, 244–250. [Google Scholar] [CrossRef]

- Ma, S.; Wang, X. Mechanical properties and fracture of in-situ Al3Ti particulate reinforced A356 composites. Mater. Sci. Eng. A 2019, 754, 46–56. [Google Scholar] [CrossRef]

- Urena, A.; Martinez, E.E.; Rodrigo, P.; Gil, L. Oxidation treatments for SiC particles used as reinforcement in aluminium matrix composites. Compos. Sci. Technol. 2004, 64, 1843–1854. [Google Scholar] [CrossRef]

- Rajan, T.P.D.; Pillai, R.M.; Pai, B.C. Reinforcement coatings and interfaces in aluminium metal matrix composites. J. Mater. Sci. 1998, 33, 3491–3503. [Google Scholar] [CrossRef]

- Zhou, D.S.; Tang, J.; Qiu, F.; Wang, J.G.; Jiang, Q.C. Effects of nano-TiCp on the microstructures and tensile properties of TiCp/Al-Cu composites. Mater. Charact. 2014, 94, 80–85. [Google Scholar] [CrossRef]

- Kou, G.; Li, W.; Zhang, X.; Xu, N.; Zhang, X.; Shao, J.; Ma, J.; Deng, Y.; Li, Y. Temperature-dependent coefficient of surface tension prediction model without arbitrary parameters. Fluid Phase Equilibria 2016, 484, 53–59. [Google Scholar] [CrossRef]

- Xi, L.; Kaban, I.; Nowak, R.; Korpala, B.; Bruzda, G.; Sobczak, N.; Mattern, N.; Eckert, J. High-temperature wetting and interfacial interaction between liquid Al and TiB2 ceramic. J. Mater. Sci. 2015, 50, 2682–2690. [Google Scholar] [CrossRef]

- Weirauch, D.A., Jr.; Krafick, W.J. The wettability of titanium diboride by molten aluminum drops. J. Mater. Sci. 2005, 40, 2301–2306. [Google Scholar] [CrossRef]

- Kaplan, W.D.; Rittel, D.; Lieberthal, M.; Frage, N.; Dariel, M.P. Static and dynamic mechanical damage mechanisms in TiC-1080 steel cermets. Scr. Mater. 2004, 51, 37–41. [Google Scholar] [CrossRef]

- Cho, S.; Lee, Y.H.; Ko, S.; Park, H.; Lee, D.; Shin, S.; Jo, I.; Lee, S.B.; Lee, S.K. Enhanced high-temperature compressive strength of TiC reinforced stainless steel matrix composites fabricated by liquid pressing infiltration process. J. Alloys Compd. 2020, 817, 152714. [Google Scholar] [CrossRef]

- Cho, S.C.; Jo, I.G.; Lee, S.K.; Lee, S.B. Microstructure and wear characteristics of TiC-SKD11 composite fabricated by liquid pressing infiltration process. Compos. Res. 2017, 30, 209–214. [Google Scholar]

- Demirskyi, D.; Borodianska, H.; Sakka, Y.; Vasylkiv, O. Ultra-high elevated temperature strength of TiB2-based ceramics consolidated by spark plasma sintering. J. Eur. Ceram. Soc. 2017, 37, 393–397. [Google Scholar] [CrossRef]

- Liang, Y.J.; Chen, Y.C. Handbook of Inorganic Thermodynamics; Northeastern University Press: Shenyang, China, 1993; pp. 449–485. [Google Scholar]

- Zhao, Q.; Liang, Y.; Zhang, Z.; Li, X.; Ren, L. Effect of Al content on impact resistance behavior of Al-Ti-B4C composite fabricated under air atmosphere. Micron 2016, 91, 11–21. [Google Scholar] [CrossRef] [PubMed]

- Qin, L.; Wang, J.; Wu, Q.; Guo, X.; Tao, J. In-situ observation of crack initiation and propagation in Ti/Al composite laminates during tensile test. J. Alloys Compd. 2017, 712, 69–75. [Google Scholar] [CrossRef]

- Fan, M.; Luo, Z.; Fu, Z.; Guo, X.; Tao, J. Vacuum hot pressing and fatigue behaviors of Ti/Al laminate composites. Vacuum 2018, 154, 101–109. [Google Scholar] [CrossRef]

- Moldovan, P.; Dragut, D.V.; Butu, M.; Besea, L.M.; Preda, E.A. In situ development of AlBx/AA6060 and AA5083 alloys cast composites. Compos. Part B Eng. 2016, 97, 9–17. [Google Scholar] [CrossRef]

- Ko, S.M.; Park, H.J.; Lee, Y.H.; Shin, S.S.; Lee, D.H.; Jo, I.G.; Lee, S.B.; Lee, S.K.; Cho, S.C. Study on the microstructure and mechanical properties of high volume fraction TiB2-Al1050 metal matrix composites. Compos. Res. 2019, 32, 1–5. [Google Scholar]

- Karnam, M.; Shivaramakrishna, A.; Joshi, R.; Manjunatha, T.H.; Veerabhadrappa, K. Study of mechanical properties and drilling behavior of Al7075 reinforced with B4C. Mater. Today 2018, 5, 25102–25111. [Google Scholar] [CrossRef]

- Ye, T.; Xu, Y.; Ren, J. Effect of SiC particle size on mechanical properties of SiC particle reinforced aluminum metal matrix composite. Mater. Sci. Eng. A 2019, 753, 146–155. [Google Scholar] [CrossRef]

- Askeland, D.R.; Phulé, P.P. The Science and Engineering of Materials, 5th ed.; Wadsworth Inc.: Wadsworth, OH, USA, 2006; pp. 620–621. [Google Scholar]

- Mozammil, S.; Karloopia, J.; Verma, R.; Jha, P.K. Effect of varying TiB2 reinforcement and its ageing behavior on tensile and hardness properties of in-situ Al-4.5%Cu-xTiB2 composite. J. Alloys Compd. 2019, 793, 454–466. [Google Scholar] [CrossRef]

| Al1050 | Al | Fe | Cu | Mg | Mn | Si | Ti | V | Zn |

|---|---|---|---|---|---|---|---|---|---|

| Composition | 99.8% ≥ | 0.1% ≤ | 0.001% ≤ | 0.001% ≤ | 0.02% ≤ | 0.05% ≤ | 0.04% ≤ | 0.02% ≤ | 0.002% ≤ |

| Specimens | Density (g/cm3) | UTS (MPa) | CYS (MPa) | Hardness (Hv) | CTE (ppmK−1) |

|---|---|---|---|---|---|

| TiB2–Al1050 | 3.84 | 471.5 | 500.4 | 194.4 | 12.97 |

| Al1050 | 2.71 | 67.1 | 59.4 | 23.2 | 26.28 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ko, S.; Park, H.; Lee, Y.-H.; Shin, S.; Jo, I.; Kim, J.; Lee, S.-B.; Kim, Y.; Lee, S.-K.; Cho, S. Fabrication of TiB2–Al1050 Composites with Improved Microstructural and Mechanical Properties by a Liquid Pressing Infiltration Process. Materials 2020, 13, 1588. https://doi.org/10.3390/ma13071588

Ko S, Park H, Lee Y-H, Shin S, Jo I, Kim J, Lee S-B, Kim Y, Lee S-K, Cho S. Fabrication of TiB2–Al1050 Composites with Improved Microstructural and Mechanical Properties by a Liquid Pressing Infiltration Process. Materials. 2020; 13(7):1588. https://doi.org/10.3390/ma13071588

Chicago/Turabian StyleKo, Seongmin, Hyeonjae Park, Yeong-Hwan Lee, Sangmin Shin, Ilguk Jo, Junghwan Kim, Sang-Bok Lee, Yangdo Kim, Sang-Kwan Lee, and Seungchan Cho. 2020. "Fabrication of TiB2–Al1050 Composites with Improved Microstructural and Mechanical Properties by a Liquid Pressing Infiltration Process" Materials 13, no. 7: 1588. https://doi.org/10.3390/ma13071588