Influence of Ultraviolet and Oxygen Coupling Aging on Rheological Properties and Functional Group Index of Warm Mix Asphalt Binder

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Plan

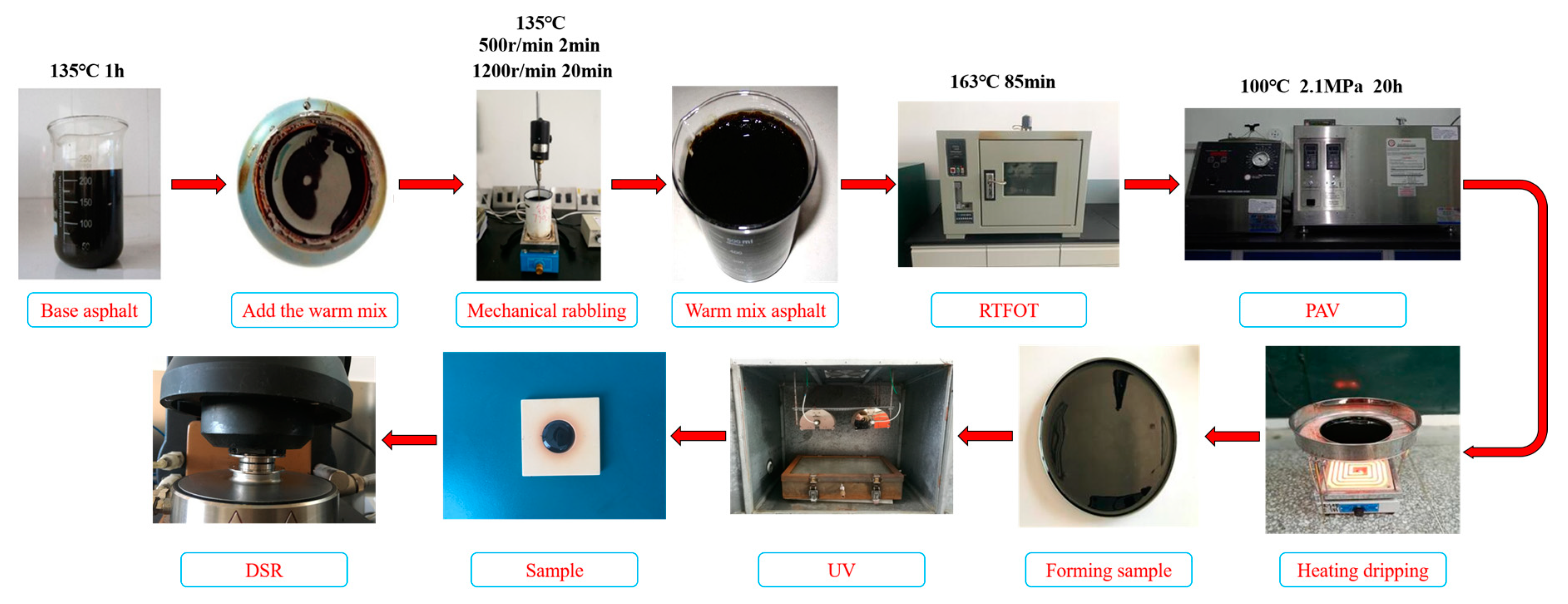

2.2.1. Preparation of Warm Mix Asphalt

2.2.2. Preparation of Short-Term Aging Asphalt Samples

2.2.3. Preparation of Ultraviolet Aged Asphalt Samples

2.2.4. Rheological Property Tests

2.2.5. Fourier Transform Infrared (FTIR) Test

3. Results and Analysis

3.1. Temperature Sweep Test

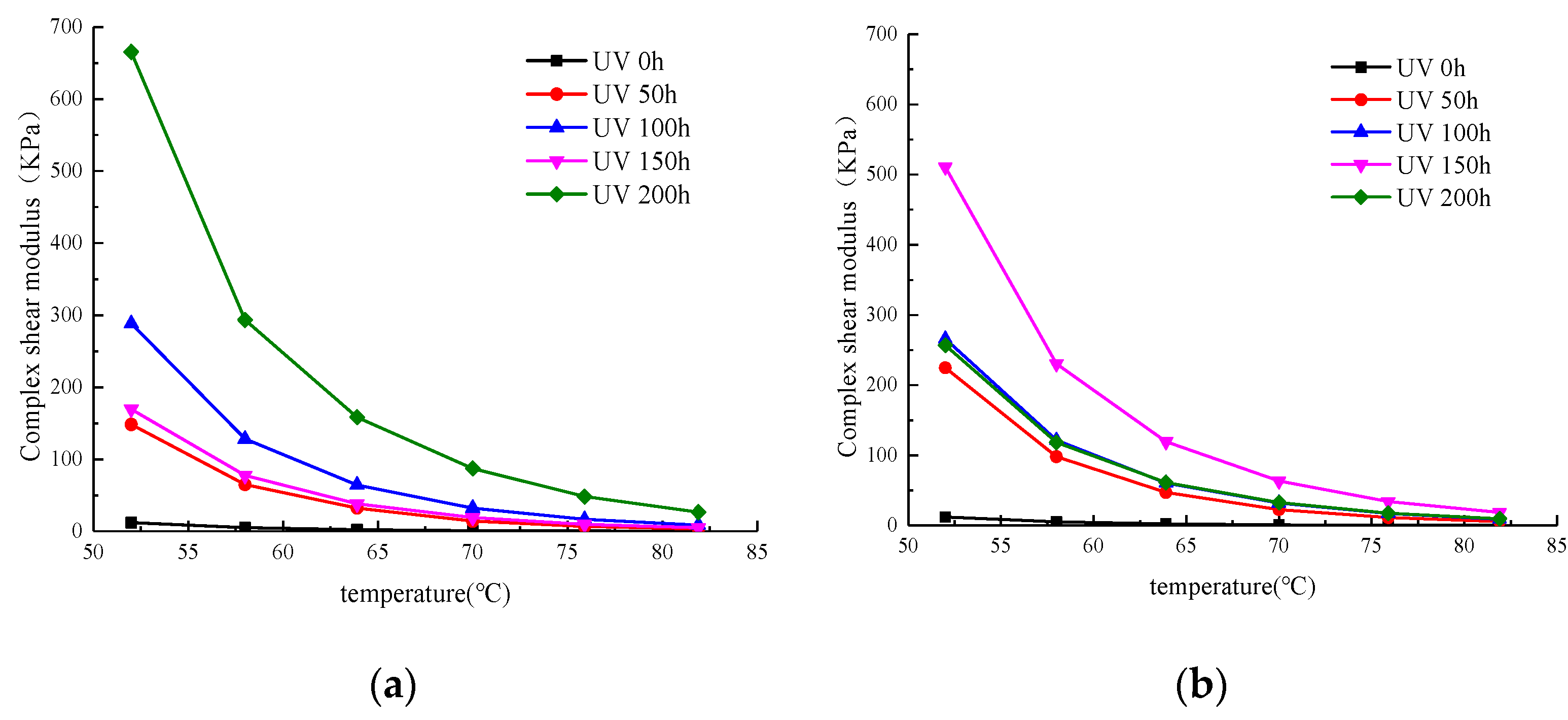

3.1.1. Complex Shear Modulus Curve

3.1.2. Complex Shear Modulus (70 °C)

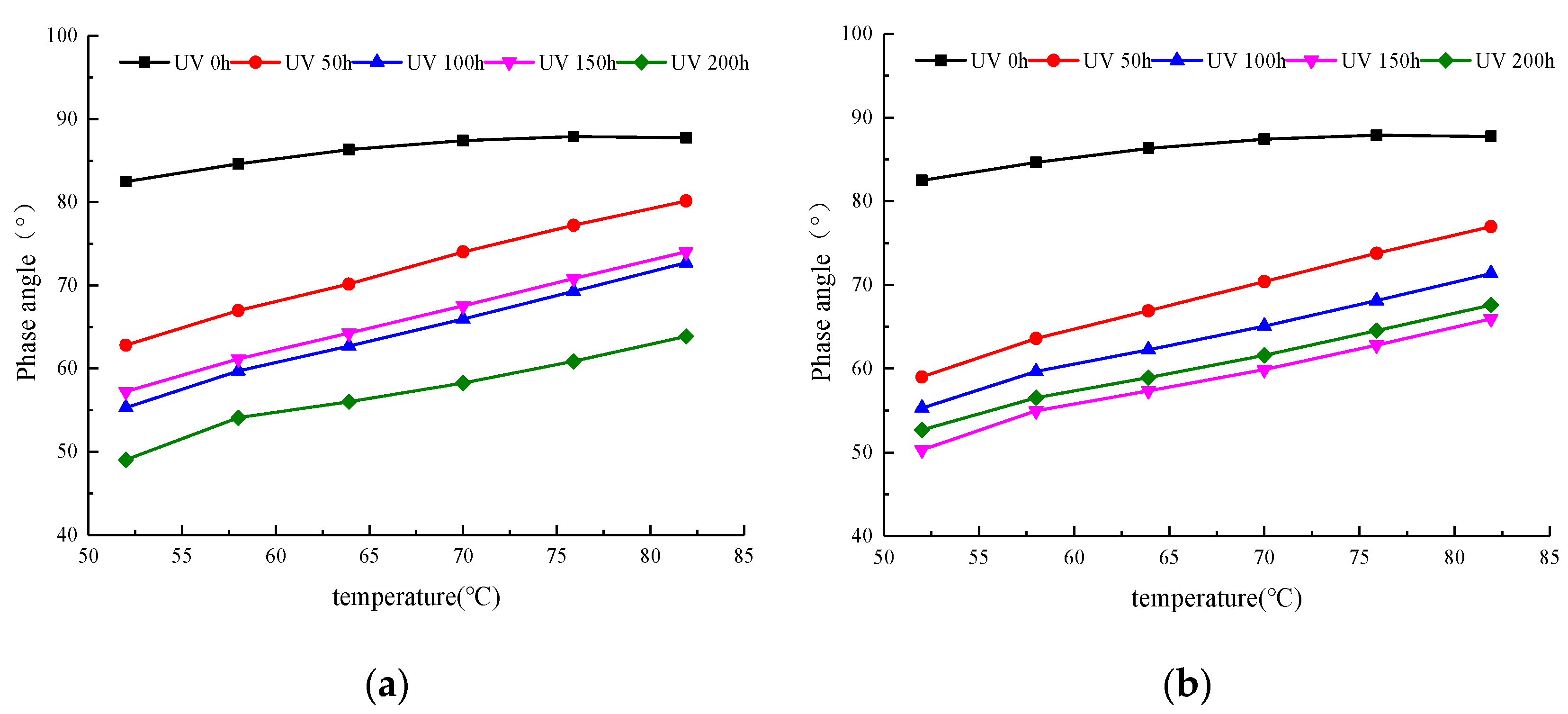

3.1.3. Phase Angle Curve

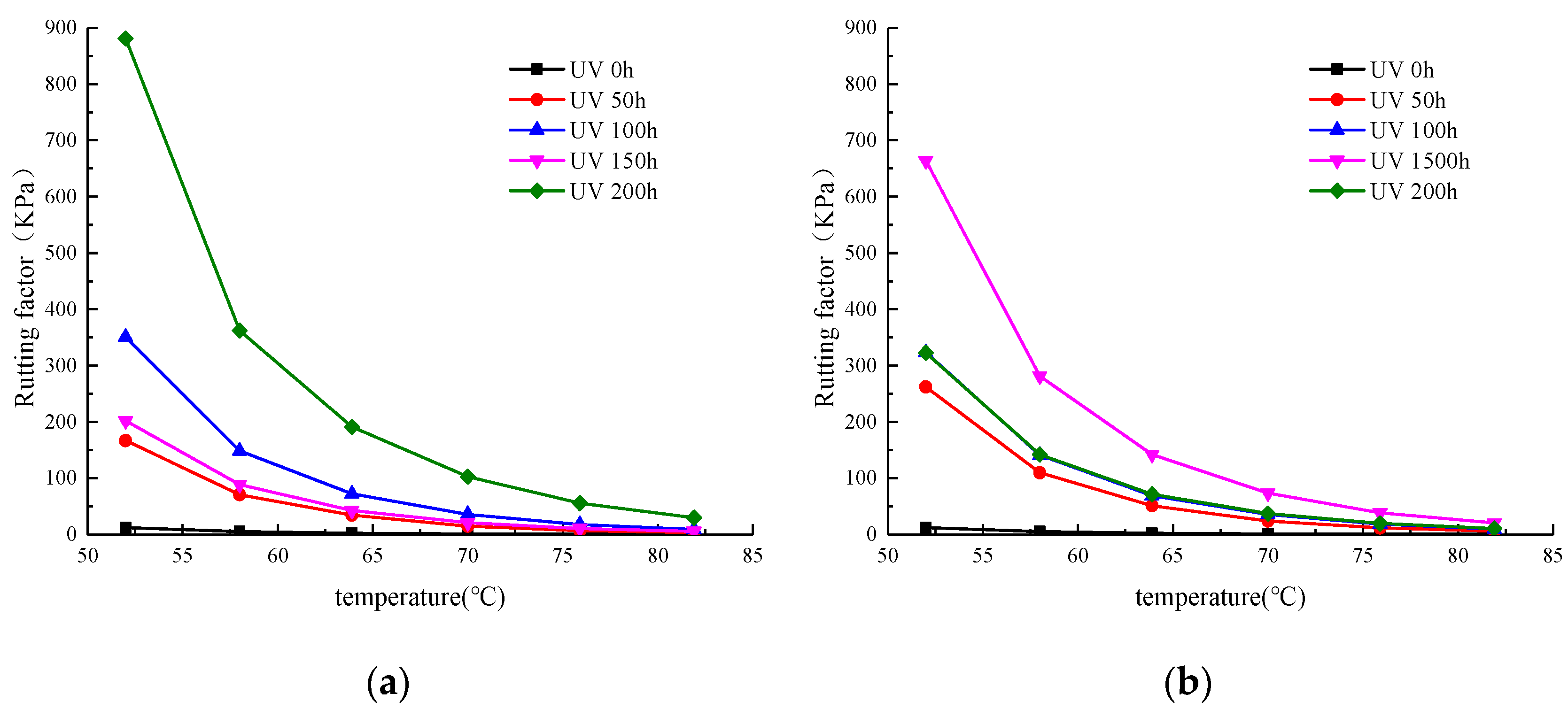

3.1.4. Rutting Factor Curve

3.2. Frequency Sweep Test

3.2.1. Main Curve of Complex Shear Modulus

3.2.2. Main Curve of Phase Angle

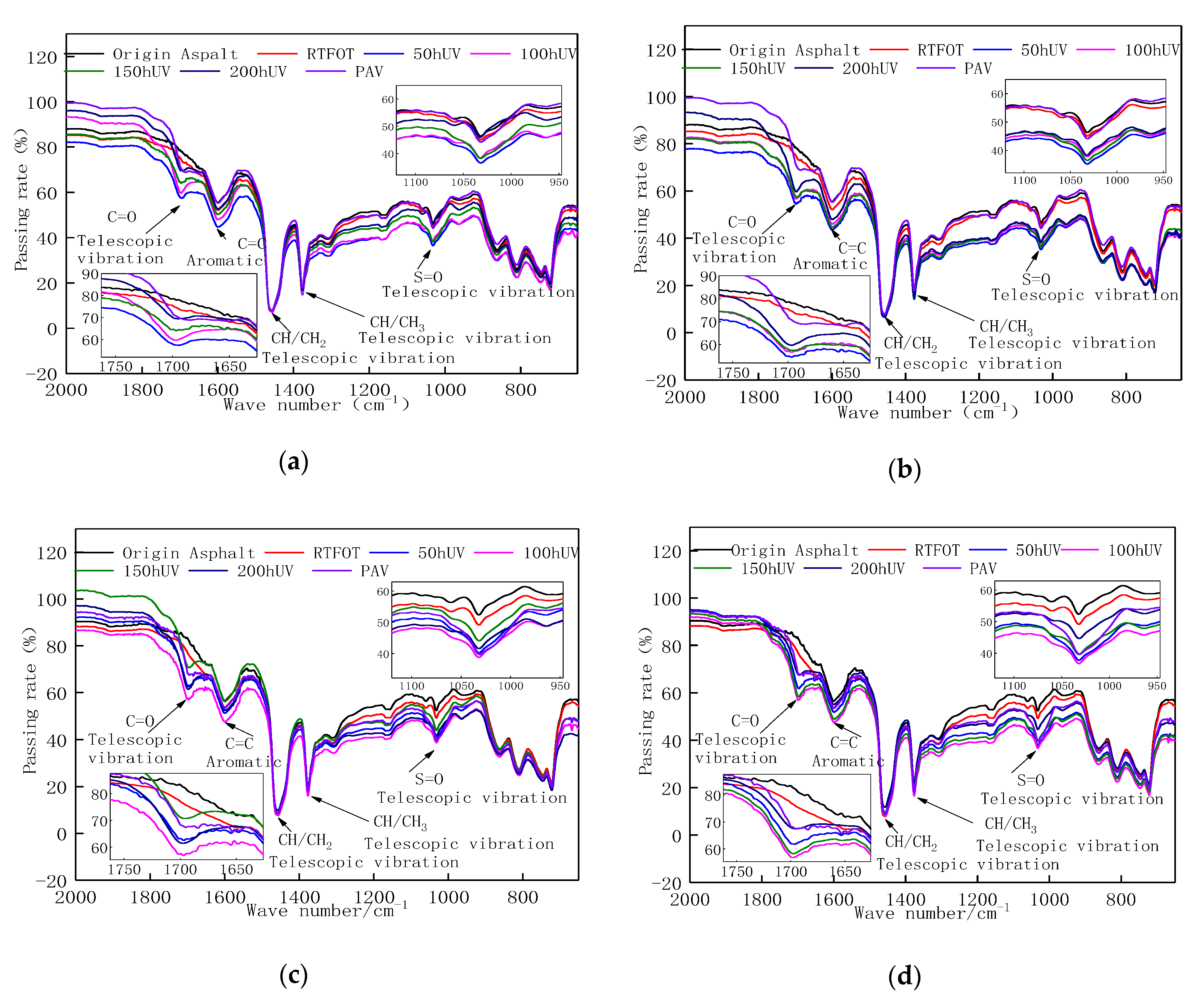

3.3. FTIR Analysis

4. Conclusions

- (1)

- The UV aging period had a significant effect on the total resistance of the asphalt to repeated shear deformation causes. As the UV aging time increased, its influence on the complex shear modulus rose generally. Under the condition of oxygen-isolation, UV aging’s effect on WMA’s total resistance generated by repeated shear deformation was greater than that of UV–oxygen coupling.

- (2)

- UV aging had a great influence on WMA’s viscoelasticity, which increased as the UV aging time increased in a certain period. UV radiation coupling effects can accelerate the oxidation rate. When the ultraviolet aging reaches a certain time, the influence of oxygen reduces the high temperature stability of asphalt.

- (3)

- The film formed on the surface of the WMA during the UV aging process hindered the aging process, and under the condition of light–oxygen coupling aging, UV was more destructive to the film, which accelerated the rate at which UV penetrated into the asphalt.

- (4)

- WMA’s rheological properties changed after UV aging primarily because aging changed the peak value of the carbonyl (C=O) functional group. Furthermore, oxygen had a significant influence on the increase in the area and peak value of the characteristic carbonyl functional group.

- (5)

- Some conclusions obtained now do not explain well the unconventional laws that occur after 150 h of UV aging. These conclusions are only limited to the equipment used in this study and they may be different for other equipment.

Author Contributions

Funding

Conflicts of Interest

References

- Rubio, M.C.; Martínez, G.; Baena, L.; Moreno, F. Warm mix asphalt: An overview. J. Clean Prod. 2012, 24, 76–84. [Google Scholar] [CrossRef]

- Oliveira, J.R.M.; Silva, H.M.R.D.; Abreu, L.P.F.; Fernandes, S.R.M. Use of a warm mix asphalt additive to reduce the production temperatures and to improve the performance of asphalt rubber mixtures. J. Clean. Prod. 2013, 41, 15–22. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Song, L.L.; Cheng, F. Influemce of Different Warm-mixed Agent on Asphalt Mixture. J. Wuhan Univ. Technol. 2014, 36, 52–58. [Google Scholar]

- Zhou, Q.W.; Wu, X.L.; Yang, B. Analysis of influence of warm mixture on pavement performance of rubber asphalt and Asphalt mixture. J. Foreign Highw. 2016, 36, 302–306. [Google Scholar]

- Kanitpong, K.; Sonthong, S.; Nam, K.; Martono, W.; Bahia, H.U. Laboratory study on warm-mix asphalt additives. In Proceedings of the Transportation Research Board 86th Annual Meeting, Washington, DC, USA, 21–25 January 2007. [Google Scholar]

- Li, J.S.; Fan, Y.; Dai, L.C.; Liu, J.F. Fundamental performance investigation on reactive liquid asphalt. J. Clean. Prod. 2019, 225, 315–323. [Google Scholar] [CrossRef]

- Ziari, H.; Moniri, A.; Imaninasab, R.; Nakhaei, M. Effect of copper slag on performance of warm mix asphalt. Int. J. Pavement Eng. 2019, 20, 775–781. [Google Scholar] [CrossRef]

- Kristjánsdóttir, Ó.; Muench, S.T.; Michael, L.; Burke, G. Assessing potential for warm-mix asphalt technology adoption. Transp. Res. Rec. J. Transp. Res. Board 2007, 2040, 91–99. [Google Scholar] [CrossRef]

- Liu, K.F.; Zhang, K.; Wu, J.L.; Muhunthan, B.; Shi, X.M. Evaluation of mechanical performance and modification mechanism of asphalt modified with graphene oxide and warm mix additives. J. Clean. Prod. 2018, 193, 87–96. [Google Scholar] [CrossRef]

- Cong, P.; Wang, J.; Li, K.; Chen, S. Physical and rheological properties of asphalt binders containing various antiaging agents. J. Fuel 2012, 97, 678–684. [Google Scholar] [CrossRef]

- Raghavendra, A.; Medeiros, M.S., Jr.; Hassan, M.M.; Mohammad, L.N.; King, W., Jr. Laboratory and Construction Evaluation of Warm-Mix Asphalt. J. Mater. Civ. Eng. 2016, 28, 4016023. [Google Scholar] [CrossRef]

- Cápayová, S.; Unčík, S.; Cihlářová, D. Experience with the Use of Warm Mix Asphalt Additives in Bitumen Binders. Slovak J. Civ. Eng. 2018, 26, 33–39. [Google Scholar] [CrossRef] [Green Version]

- Li, B.; Wen, Y.; Li, X. Laboratory Evaluation of Pavement Performance and Burning Behavior of Flame-Retardant Asphalt Mixtures. J. Test. Eval. 2017, 45, 20160029. [Google Scholar] [CrossRef]

- Li, B.; Shen, J.; Xie, Z. Influence of trans-polyoctenamer on rheological properties of rubberised asphalt binders after short term aging procedures. Mater. Res. Innov. 2014, 18, 539–541. [Google Scholar] [CrossRef]

- Durrieu, F.; Farcas, F.; Mouillet, V. The influence of UV aging of a Styrene/Butadiene/Styrene modified bitumen: Comparison between laboratory and on site aging. Fuel 2007, 86, 1446–1451. [Google Scholar] [CrossRef]

- Cardone, F.; Frigio, F.; Ferrotti, G.; Canestrari, F. Influence of mineral fillers on the rheological response of polymer-modified bitumens and mastics. J. Traffic Transp. 2015, 2, 373–381. [Google Scholar] [CrossRef] [Green Version]

- Xiao, F.; Punith, V.S.; Amirkhanian, S.N. Effects of Non-foaming WMA Additives on Asphalt Binders at High Performance Temperatures. Fuel 2012, 94, 144–155. [Google Scholar] [CrossRef]

- Shenoy, A. Prediction of high temperature rheological properties of aged asphalts from the flow data of the original samples. Constr. Build. Mater. 2002, 16, 509–517. [Google Scholar] [CrossRef]

- Shenoy, A. Unifying asphalt rheological data using the material’s volumetric-flow rate. ASCE J. Mater. Civ. Eng. 2001, 13, 260–273. [Google Scholar] [CrossRef] [Green Version]

- Shenoy, A. Validating the generality and predictive ability of unified rheological curves for unmodified paving asphalts. Constr. Build. Mater. 2000, 4, 325–339. [Google Scholar] [CrossRef]

- Zeng, W.B.; Wu, S.P.; Wen, J.; Chen, Z.W. The temperature effects in aging index of asphalt during UV aging process. Constr. Build. Mater. 2015, 93, 1125–1131. [Google Scholar] [CrossRef]

- Wang, L.; Chen, G.; Xing, Y.M.; Hu, J.S.; Leng, B. Effect of aging on rheological properties of crumb rubber and SBS modified asphalt. J. Build. Mater. 2015, 18, 499–504. (In Chinese) [Google Scholar]

- Li, N.L.; Zhao, X.P.; Sun, J.S.; Zhang, C.L. Effect of aging on the high-temperature rheological properties of rubber-modified asphalt. Highway 2015, 2, 165–168. (In Chinese) [Google Scholar]

- Zhu, H.; Fan, L.; Pei, J.R.; Wang, S.J. Rheological properties of two kinds of aged asphalt. Pet. Asph. 2014, 28, 21–24. (In Chinese) [Google Scholar]

- Rojas, J.M.; Hernández, N.A.; Manero, O. Rheology and microstructure of functionalized polymer-modified asphalt. J. Appl. Polym. Sci. 2010, 115, 15–25. [Google Scholar] [CrossRef]

- Huang, W.D.; Sun, L.J.; You, H. Relationship between rheological properties and micro structure of SBS modified asphalt. J. Tongji Univ. 2003, 31, 916–920. (In Chinese) [Google Scholar]

- Xiao, X.Y.; Yang, Z.Q. Properties of organic montmorillon-ite/crumb rubber compound modified asphalt. J. South. China Univ. Technol. 2013, 41, 116–120. [Google Scholar]

- Airey, G.D. State of the Art Report on Ageing Test Methods for Bituminous Pavement Materials. Int. J. Pavement Eng. 2007, 4, 165–176. [Google Scholar] [CrossRef]

- Tan, Y.; Wang, J.; Feng, Z.; Zhou, X.; Xu, H. UV aging mechanism of asphalt binder. China J. Highw. Transp. 2008, 1, 19–24. [Google Scholar]

- Corbett, L.; Merz, R. Asphalt Binder Hardening in the Michigan Test Road after 18 Years of Service. In 54th Annual Meeting of the Transportation Research Board; Transportation Research Record: Washington, DC, USA, 1975; pp. 27–34. [Google Scholar]

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Pang, L.; Liu, G.; Zhu, J. Laboratory Study on Ultraviolet Radiation Aging of Bitumen. J. Mater. Civ. Eng. 2010, 22, 767–772. [Google Scholar] [CrossRef]

- JTG E20. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; China Communications Press: Beijing, China, 2011. [Google Scholar]

- Li, B.; Wang, Y.; Ren, X.; Teng, X.; Su, X. Influence of Ultraviolet Aging on Adhesion Performance of Warm Mix Asphalt Based on the Surface Free Energy Theory. Appl. Sci. 2019, 9, 2046. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Gao, J.; Zhao, X.; You, Z.; Tian, Y.Y. Rheological Properties on Bio-binder Based on DSR and RV. J. Hunan Univ. 2015, 42, 26–33. [Google Scholar]

- Ye, F.; Huang, P. Effect of Intensive Ultraviolet Radiation on Asphalt Performance. J. Tongji Univ. 2005, 33, 909–913. [Google Scholar]

- Lamontagne, J.; Dumas, P.; Mouillet, V. Comparison by Fourier transform infrared (FTIR) spectroscopy of different ageing techniques: Application to road bitumens. Fuel 2001, 80, 483–488. [Google Scholar] [CrossRef]

| Tests | Units | SK90# | |

|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s) | 0.1 mm | 91.2 | |

| Penetration Index PI | - | −1.48 | |

| Ductility (5 cm/min, 10 °C) | cm | >100 | |

| Wax content (distillation method) | % | 2.0 | |

| Softening point (°C) | °C | 45.8 | |

| 60 °C dynamic viscosity | Pa·s | 145 | |

| Rotating thin film oven test (RTFOT) (163 °C, 85 min) | Loss of quantity/% | % | 66 |

| Penetration ratio/% | % | 0.06 | |

| Ductility (5 cm/min, 10 °C) | cm | 9.1 | |

| Items | Exterior | Viscosity/(Pa·s) | Density/(g/cm3) | Proportion/% |

|---|---|---|---|---|

| Evotherm M1 | Yellow brown sticky liquid | 950 (± 50) × 106 | 0.97 (± 0.05) | Quantity of asphalt 0.6 |

| Asphalt Type | Characteristic Peak Index | Origin Asphalt | RTFOT | PAV | 50 h UV | 100 h UV | 150 h UV | 200 h UV |

|---|---|---|---|---|---|---|---|---|

| (a) | ICO | 0.078 | 0.103 | 0.181 | 0.197 | 0.203 | 0.304 | 0.310 |

| ISO | 0.178 | 0.182 | 0.257 | 0.274 | 0.286 | 0.305 | 0.323 | |

| (b) | ICO | 0.078 | 0.103 | 0.286 | 0.304 | 0.313 | 0.373 | 0.381 |

| ISO | 0.178 | 0.182 | 0.191 | 0.205 | 0.233 | 0.257 | 0.275 | |

| (c) | ICO | 0.120 | 0.165 | 0.244 | 0.289 | 0.352 | 0.430 | 0.413 |

| ISO | 0.081 | 0.105 | 0.225 | 0.261 | 0.298 | 0.355 | 0.351 | |

| (d) | ICO | 0.120 | 0.165 | 0.300 | 0.315 | 0.419 | 0.481 | 0.472 |

| ISO | 0.081 | 0.165 | 0.177 | 0.195 | 0.208 | 0.235 | 0.241 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Tong, P.; Zhang, X.; Lin, X.; Li, B. Influence of Ultraviolet and Oxygen Coupling Aging on Rheological Properties and Functional Group Index of Warm Mix Asphalt Binder. Materials 2020, 13, 4216. https://doi.org/10.3390/ma13194216

Li H, Tong P, Zhang X, Lin X, Li B. Influence of Ultraviolet and Oxygen Coupling Aging on Rheological Properties and Functional Group Index of Warm Mix Asphalt Binder. Materials. 2020; 13(19):4216. https://doi.org/10.3390/ma13194216

Chicago/Turabian StyleLi, Hailian, Peipei Tong, Xijun Zhang, Xixiong Lin, and Bo Li. 2020. "Influence of Ultraviolet and Oxygen Coupling Aging on Rheological Properties and Functional Group Index of Warm Mix Asphalt Binder" Materials 13, no. 19: 4216. https://doi.org/10.3390/ma13194216