Thermal-Insulation Effect and Evaluation Indices of Asphalt Mixture Mixed with Phase-Change Materials

Abstract

:1. Introduction

2. Materials

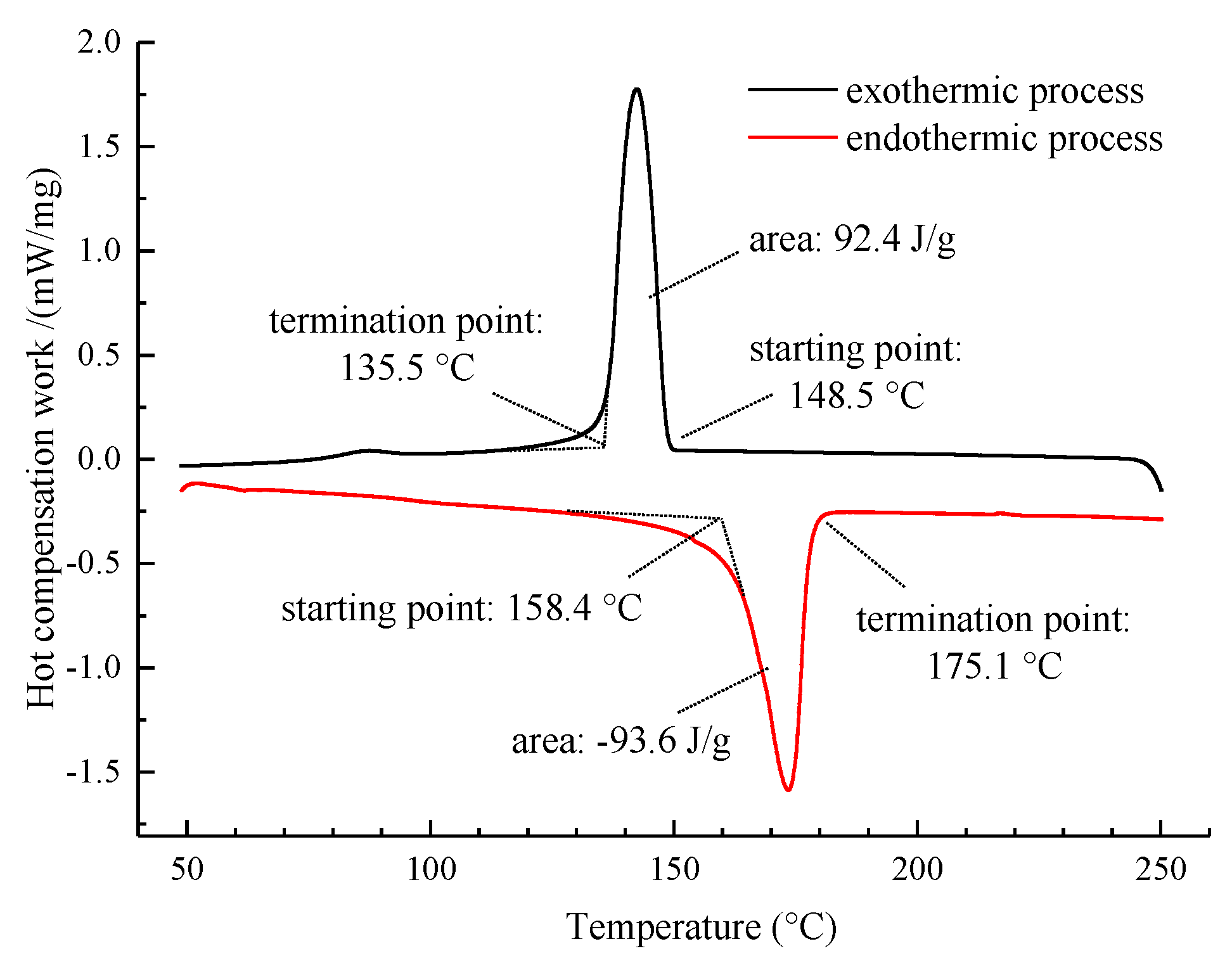

2.1. Phase-Change Thermal-Insulation Agent

2.2. Asphalt Mixture

3. Experimental Method

4. Results and Analysis

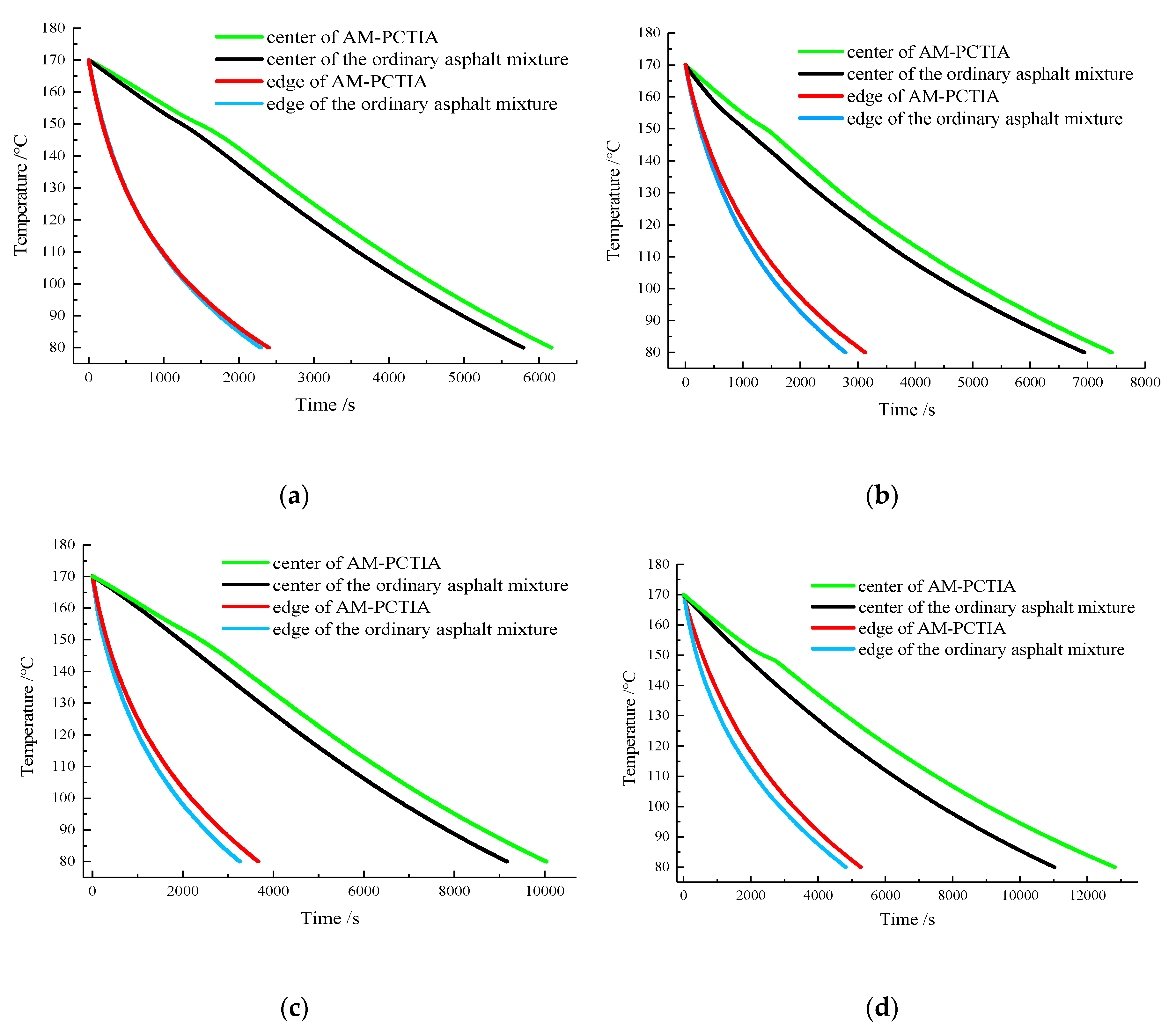

4.1. Temperature-Dissipation Process

- (1)

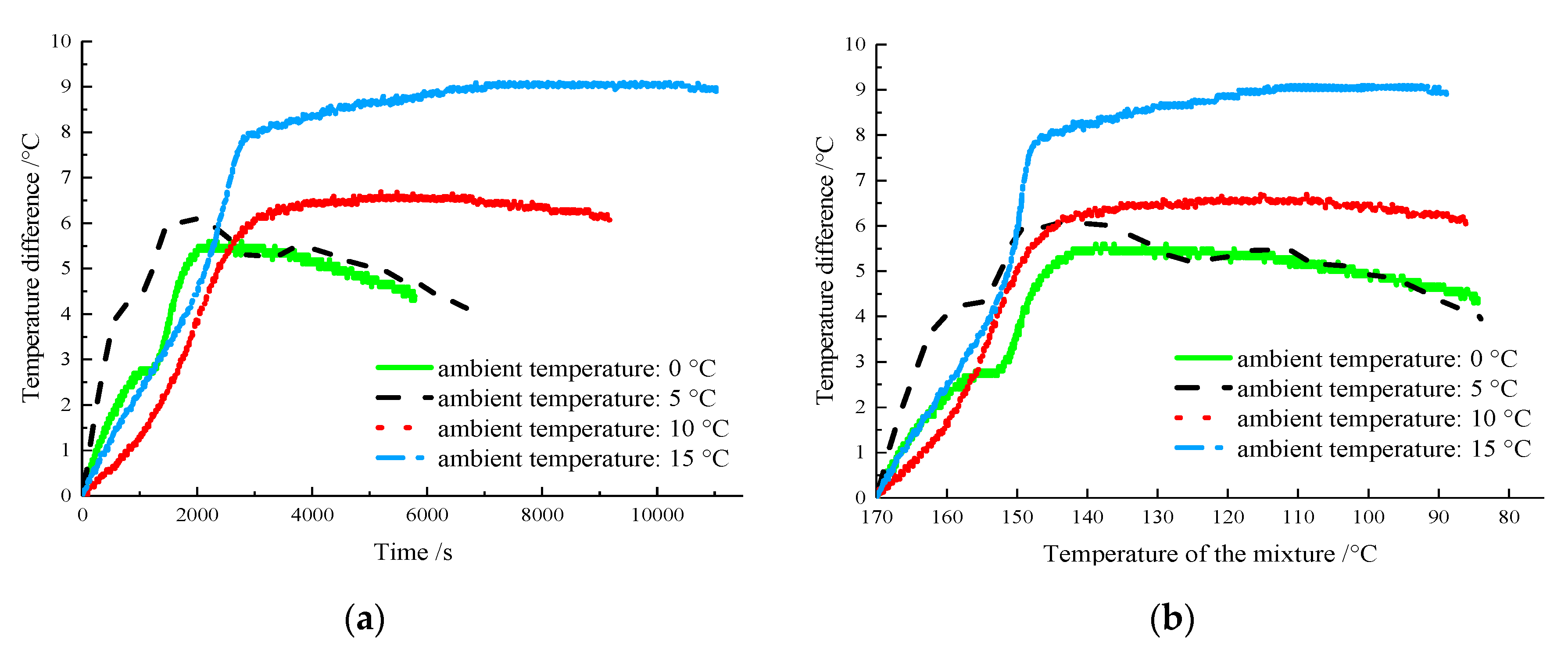

- In the first stage, the overall temperature of the mixture was higher than the initial exothermic temperature of PCTIA (148.5 °C). Therefore, the PCTIA did not undergo a phase transformation and released heat in the form of sensible heat.

- (2)

- In the second stage, with a reduction in the overall temperature of the mixture, the PCTIA underwent a phase change and released a large amount of latent heat, which provided thermal insulation to the mixture. The cooling rate of the mixture decreased significantly; thus, there were small platforms in the curve.

- (3)

- In the third stage, the latent heat of the PCTIA was completely released, and the heat energy was released in the form of sensible heat. As the temperature of the samples decreased, the temperature difference and the cooling rate between the samples and the environment gradually decreased.

4.2. Temperature Difference

4.3. Thermal-Insulation Extension Time

4.4. Evaluation Indices of Thermal-Insulation Effect

5. Conclusions

- (1)

- A PCTIA for the construction of a hot-mix asphalt mixture was prepared. The phase-change temperature range of the PCTIA in the endothermic and exothermic process matched the construction demand, and the PCTIA had good heat stability and low heat conductivity.

- (2)

- The temperature-dissipation processes of the ordinary asphalt mixture and AM-PCTIA were simulated through a cooling experiment. The thermal-insulation effect was relatively strong at the center of the asphalt mixture, and the temperature of the AM-PATIA was 4 °C higher than that of the ordinary asphalt mixture. The insulation time was prolonged by 29.8 min for the center of the asphalt mixture at the ambient temperature of 15 °C.

- (3)

- Two evaluation indices (the IATDV and IATDI) were proposed for evaluating the thermal-insulation ability and efficiency of the PCTIA. In summary, the IATDV in the same temperature range increased with the ambient temperature, indicating that the thermal-insulation ability of the PCTIA increased with the ambient temperature. The PCTIA had the best thermal-insulation effect and the highest thermal-insulation efficiency at the ambient temperature of 15 °C.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, X.; Zhou, Z.; Lv, X.; Xiong, K.; Wang, X.; You, Z. Temperature segregation of warm mix asphalt pavement: Laboratory and field evaluations. Constr. Build. Mater. 2017, 136, 436–445. [Google Scholar] [CrossRef]

- Mohammad, L.N.; Hassan, M.M.; Kim, M. Effects of Paver Stoppage on Temperature Segregation in Asphalt Pavements. J. Mater. Civ. Eng. 2017, 29, 04016200. [Google Scholar] [CrossRef]

- Kim, M.; Mohammad, L.N.; Phaltane, P.; Elseifi, M.A. Density and SCB measured fracture resistance of temperature segregated asphalt mixtures. Int. J. Pavement Res. Technol. 2017, 10, 112–121. [Google Scholar] [CrossRef]

- Qian, G.; He, Z.; Yu, H.; Gong, X.; Sun, J. Research on the affecting factors and characteristic of asphalt mixture temperature field during compaction. Constr. Build. Mater. 2020, 257, 119509. [Google Scholar] [CrossRef]

- Qian, G.; Hu, K.; Li, J.; Bai, X.; Li, N. Compaction process tracking for asphalt mixture using discrete element method. Constr. Build. Mater. 2020, 235, 117478. [Google Scholar] [CrossRef]

- Li, Y.; Wang, L. Computer-Aided Procedure for Analysis of Effect of Gradation and Compaction Temperature in Asphalt Mix Design by Using DEM. J. Transp. Eng. Part B Pavements 2020, 146, 04020010. [Google Scholar] [CrossRef]

- Hu, L.; Bao, Y.; Wang, T.; Li, H. Temperature uniformity analysis of asphalt mixture paving based on thermal imaging. J. Jiangsu Univ. (Nat. Sci. Ed.) 2016, 37, 735–739. [Google Scholar]

- Zhou, G.; Sun, Q.; Liu, M. Tudy on Performance and Compaction Temperature of Polyester Fiber Warm Mixed Recycled Asphalt Mixture. J. Chongqing Jiaotong Univ. (Nat. Sci.) 2019, 38, 55–60. [Google Scholar]

- Oliveira, J.R.M.; Silva, H.M.R.D.; Abreu, L.P.F.; Fernandes, S.R.M. Use of a warm mix asphalt additive to reduce the production temperatures and to improve the performance of asphalt rubber mixtures. J. Clean. Prod. 2013, 41, 15–22. [Google Scholar] [CrossRef]

- Guo, N.; You, Z.; Zhao, Y.; Tan, Y.; Diab, A. Laboratory performance of warm mix asphalt containing recycled asphalt mixtures. Constr. Build. Mater. 2014, 64, 141–149. [Google Scholar] [CrossRef]

- Ozturk, H.I.; Kamran, F. Laboratory evaluation of dry process crumb rubber modified mixtures containing Warm Mix Asphalt Additives. Constr. Build. Mater. 2019, 229, 116940. [Google Scholar] [CrossRef]

- Wang, L. Reaearch on Thermal Diffusion Process of Asphalt Pavement and Mix Improvement at Low Temperature. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2013. [Google Scholar]

- Xia, Y. Analysis of Temperature Control of Asphalt Pavement Construction in Cold Regions of Tibet. Constr. Mater. Decor. 2018, 28, 244–245. [Google Scholar]

- Lopes, P.V.; Silva, F.J.G.; Campilho, R.D.S.G.; de Almeida, F. Designing a novel and greener truck asphalt container. Procedia Manuf. 2019, 38, 324–332. [Google Scholar] [CrossRef]

- Ma, D.; Li, Z.; Li, P. Design of asphalt mixture stirring roller and simulation and validation of heating efficiency. Trans. Chin. Soc. Agric. Eng. 2016, 32, 104–109. [Google Scholar]

- Guo, M.; Liang, M.; Jiao, Y.; Zhao, W.; Duan, Y.; Liu, H. A review of phase change materials in asphalt binder and asphalt mixture. Constr. Build. Mater. 2020, 258, 119565. [Google Scholar] [CrossRef]

- Wei, K.; Ma, B.; Huang, X.; Xiao, Y.; Liu, H. Influence of NiTi alloy phase change heat-storage particles on thermophysical parameters, phase change heat-storage thermoregulation effect, and pavement performance of asphalt mixture. Renew. Energy 2019, 141, 431–443. [Google Scholar] [CrossRef]

- Mahedi, M.; Cetin, B.; Cetin, K.S. Freeze-thaw performance of phase change material (PCM) incorporated pavement subgrade soil. Constr. Build. Mater. 2019, 202, 449–464. [Google Scholar] [CrossRef]

- Anupam, B.R.; Sahoo, U.C.; Rath, P. Phase change materials for pavement applications: A review. Constr. Build. Mater. 2020, 247, 118553. [Google Scholar] [CrossRef]

- Ma, B.; Wang, S.S.; Li, J. Study on Application of PCM in Asphalt Mixture. Adv. Mater. Res. 2010, 168–170, 2625–2630. [Google Scholar] [CrossRef]

- Tan, Y.; Bian, X.; Shan, Y.; Qu, L.; Lv, J. Preparation of Latent Heat Materials Used in Asphalt Pavement and Its Performance of Temperature Control. J. Build. Mater. 2013, 16, 354–359. [Google Scholar]

- Research Institute of Highway Ministry of Transport, Technical Specifications for Construction of Highway Asphalt Pavements; Industry Standard-Transportation: Beijing, China, 2004; Volume JTG F40-2004, p. 196.

- Zhang, Q.; Li, Y.; Xie, L. Test of Thermal Conductivity of Asphalt Mixture and Analysis of Its Influencing Factors. J. Xi’an Univ. Archit. Technol. (Nat. Sci. Ed.). 2014, 46, 199–203. [Google Scholar]

- Concha, J.L.; Norambuena-Contreras, J. Thermophysical properties and heating performance of self-healing asphalt mixture with fibres and its application as a solar collector. Appl. Therm. Eng. 2020, 178, 115632. [Google Scholar] [CrossRef]

- Ren, Z.; Wang, H.; Zhang, L.; Chen, C. Computational analysis of thermal conductivity of asphalt mixture based on a multiscale mathematical model. J. Eng. Mech. 2018, 144, 04018064. [Google Scholar] [CrossRef]

- Ma, B.; Chen, S.-S.; Wei, K.; Liu, F.-W.; Zhou, X.-Y. Analysis of thermoregulation indices on microencapsulated phase change materials for asphalt pavement. Constr. Build. Mater. 2019, 208, 402–412. [Google Scholar] [CrossRef]

| Temperatures (°C) | −40 | 20 | 65 | 140 | 170 | |

|---|---|---|---|---|---|---|

| Heat conductivity coefficient (W/(m·K)) | 0.5694 | 0.5765 | 0.5852 | 0.6005 (endothermic process) | 0.5648 (exothermic process) | 0.5441 |

| Sieve Size/mm | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

|---|---|---|---|---|---|---|---|---|---|---|

| Passing rate/% | 100.0 | 96.0 | 76.5 | 53.0 | 37.0 | 26.5 | 19.0 | 13.5 | 10.0 | 6.0 |

| Environmental Temperature | Position | Time Difference/s | ||||

|---|---|---|---|---|---|---|

| 160 °C | 140 °C | 120 °C | 100 °C | 80 °C | ||

| 0 °C | Edge | −3 | −9 | 0 | 30 | 105 |

| Center | 135 | 300 | 327 | 351 | 375 | |

| 5 °C | Edge | 15 | 63 | 138 | 213 | 342 |

| Center | 215 | 440 | 463 | 540 | 477 | |

| 10 °C | Edge | 36 | 87 | 180 | 294 | 408 |

| Center | 156 | 553 | 638 | 734 | 865 | |

| 15 °C | Edge | 78 | 255 | 366 | 411 | 447 |

| Center | 223 | 872 | 1114 | 1410 | 1792 | |

| Ambient Temperature | Relevant Parameter | Terminal Temperature (°C) | |||

|---|---|---|---|---|---|

| 80 °C | 100 °C | 120 °C | 140 °C | ||

| 0 °C | Temperature domain (°C) | 90 | 70 | 50 | 30 |

| Time domain (s) | 6150 | 4575 | 3270 | 2115 | |

| IATDV (s·°C) | 24,685.4 | 18,110.4 | 11,046.6 | 5302.2 | |

| IATDI | 0.0447 | 0.0567 | 0.0679 | 0.0864 | |

| 5 °C | Temperature domain (°C) | 90 | 70 | 50 | 30 |

| Time domain (s) | 7422 | 5220 | 3450 | 2055 | |

| IATDV (s·°C) | 34,762.3 | 24,842.9 | 15,679.4 | 7861.4 | |

| IATDI | 0.0520 | 0.0680 | 0.0909 | 0.1275 | |

| 10 °C | Temperature domain (°C) | 90 | 70 | 50 | 30 |

| Time domain (s) | 10036 | 7419 | 5278 | 3380 | |

| IATDV (s·°C) | 50,071.0 | 34,391.3 | 20,701.5 | 8807.6 | |

| IATDI | 0.0554 | 0.0662 | 0.0784 | 0.0869 | |

| 15 °C | Temperature domain (°C) | 90 | 70 | 50 | 30 |

| Time domain (s) | 12816 | 9066 | 6115 | 3656 | |

| IATDV (s·°C) | 89,537.8 | 57,345.5 | 32,468.5 | 12,706.0 | |

| IATDI | 0.0776 | 0.0904 | 0.1062 | 0.1158 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, B.; Shi, H.; Xu, J.; Wei, K.; Wang, X.; Xiao, Y. Thermal-Insulation Effect and Evaluation Indices of Asphalt Mixture Mixed with Phase-Change Materials. Materials 2020, 13, 3738. https://doi.org/10.3390/ma13173738

Ma B, Shi H, Xu J, Wei K, Wang X, Xiao Y. Thermal-Insulation Effect and Evaluation Indices of Asphalt Mixture Mixed with Phase-Change Materials. Materials. 2020; 13(17):3738. https://doi.org/10.3390/ma13173738

Chicago/Turabian StyleMa, Biao, Heting Shi, Jiayun Xu, Kun Wei, Xiaoqing Wang, and Yue Xiao. 2020. "Thermal-Insulation Effect and Evaluation Indices of Asphalt Mixture Mixed with Phase-Change Materials" Materials 13, no. 17: 3738. https://doi.org/10.3390/ma13173738