Fluorination of Diamond Nanoparticles in Slow Neutron Reflectors Does Not Destroy Their Crystalline Cores and Clustering While Decreasing Neutron Losses

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples

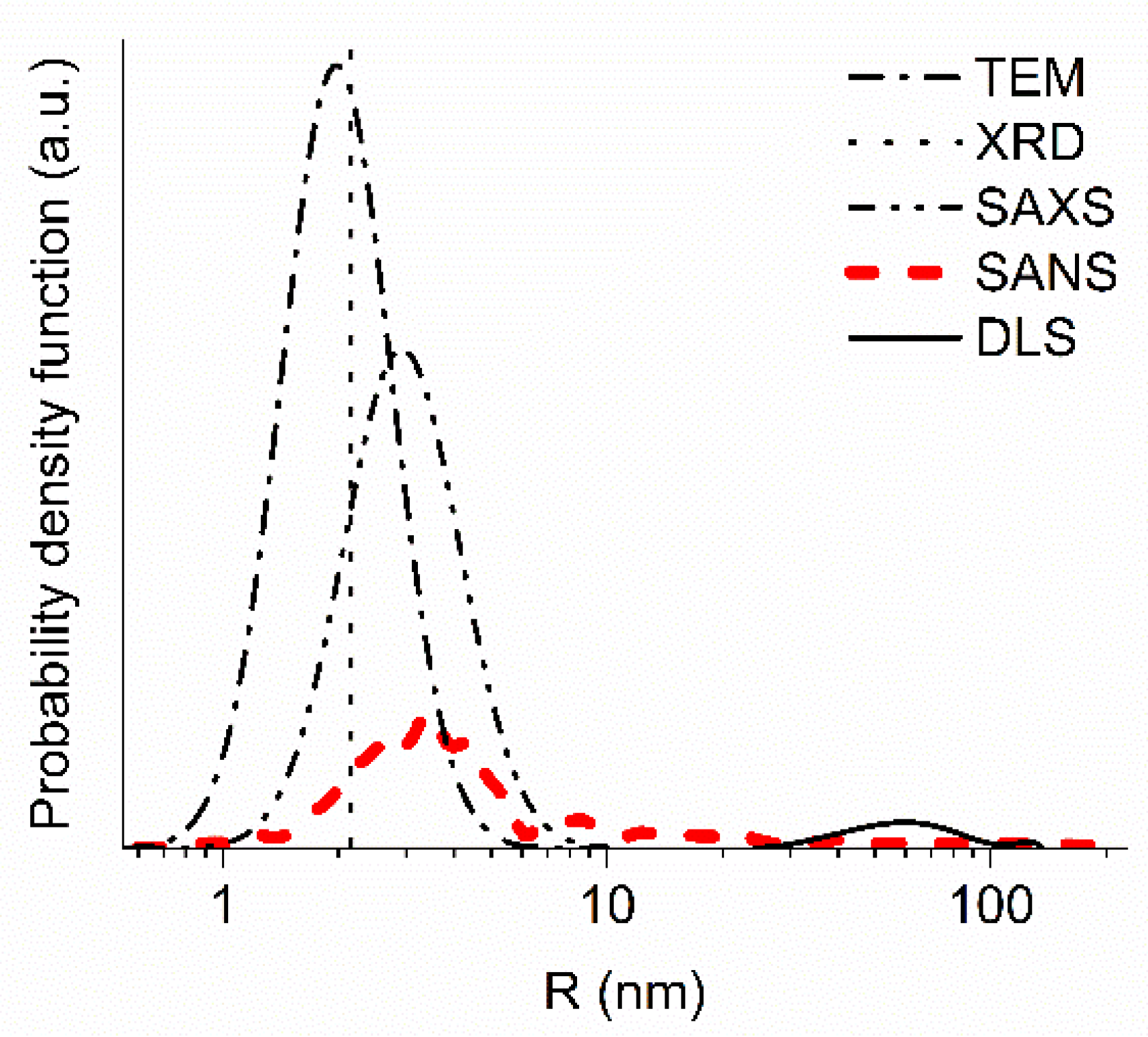

2.2. Rationale for the Choice of Experimental Methods

3. Experimental Results

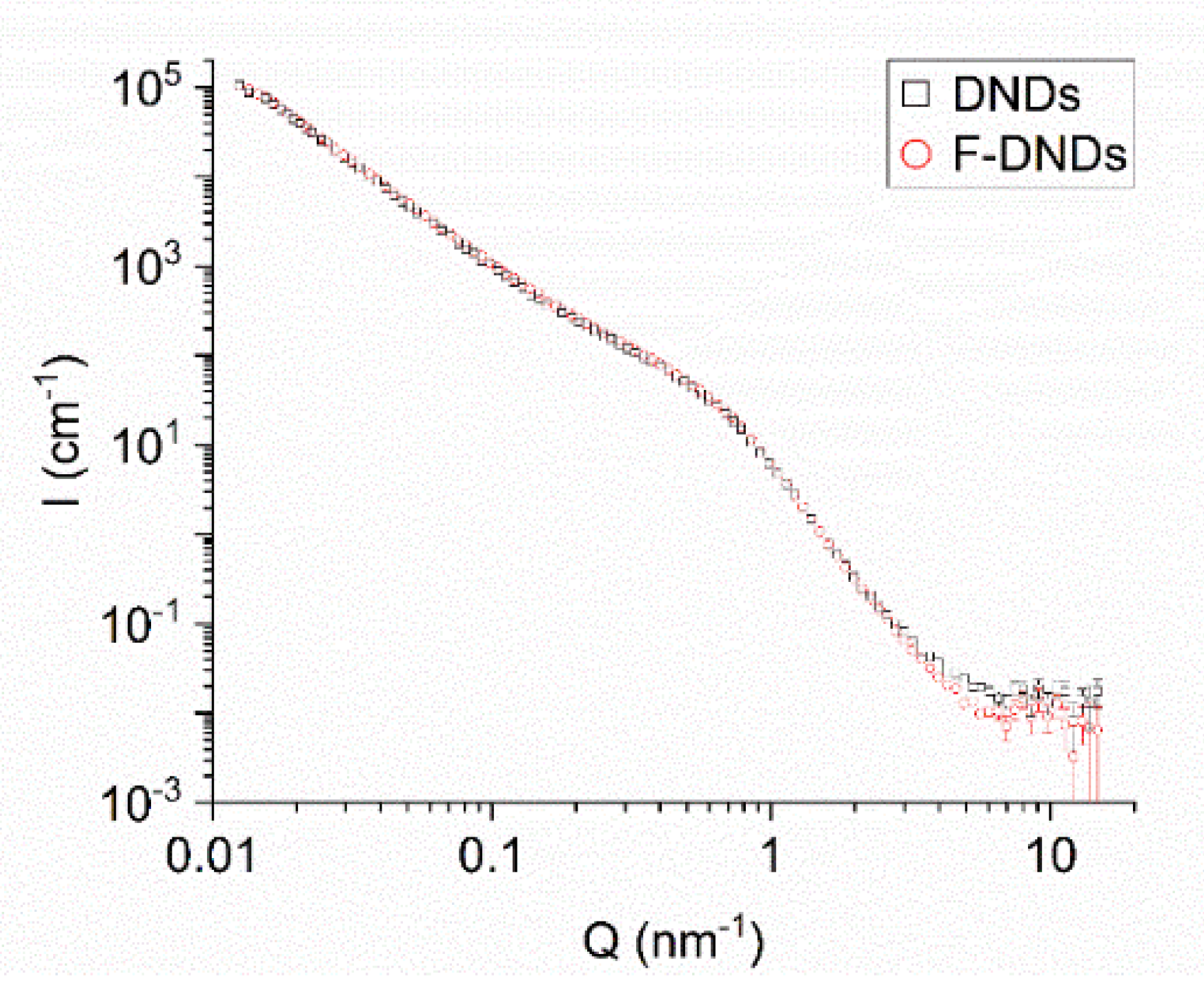

3.1. Small-Angle Neutron Scattering

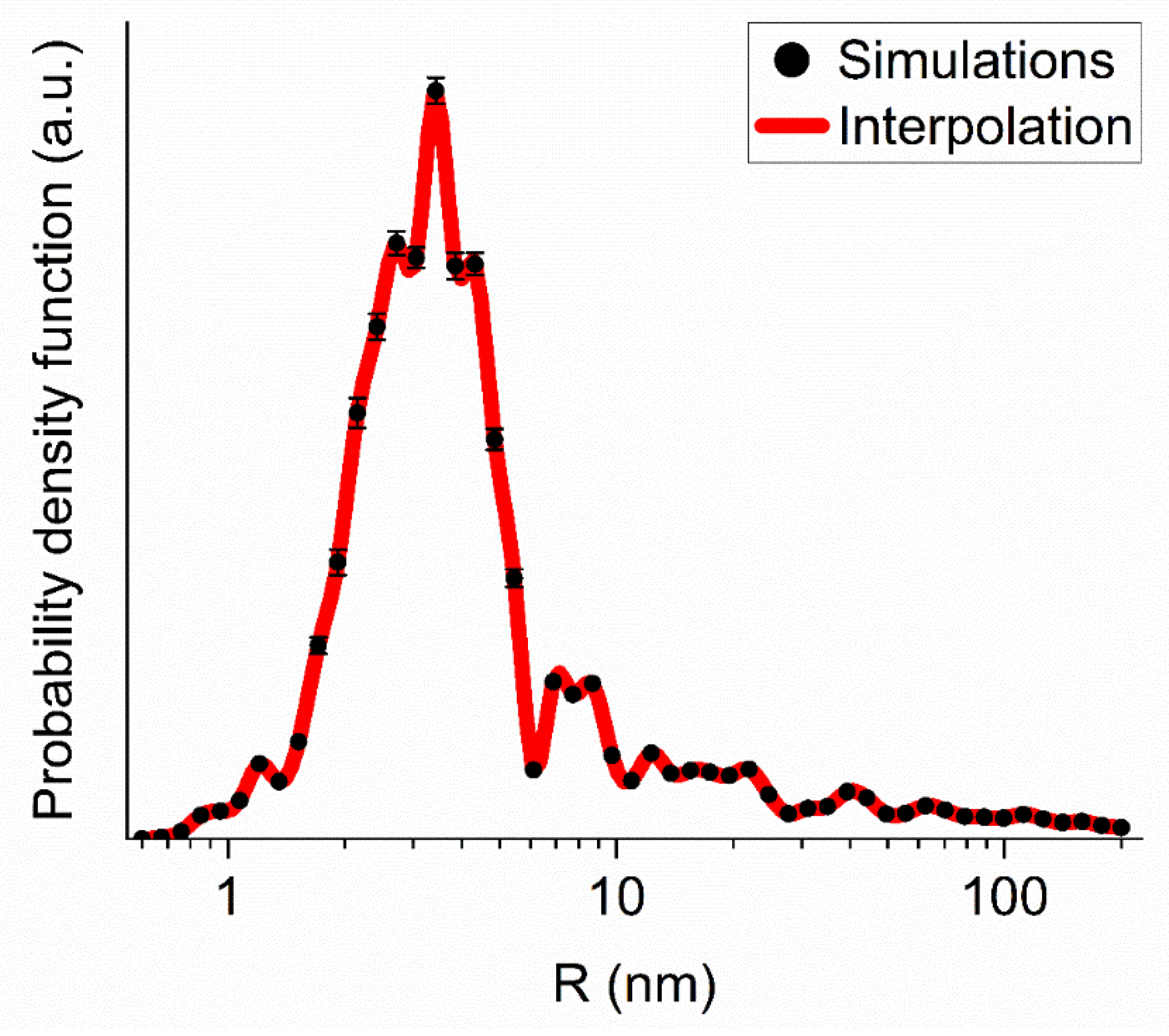

3.2. A Model of Discrete-Size Diamond Nanospheres

3.3. SEM

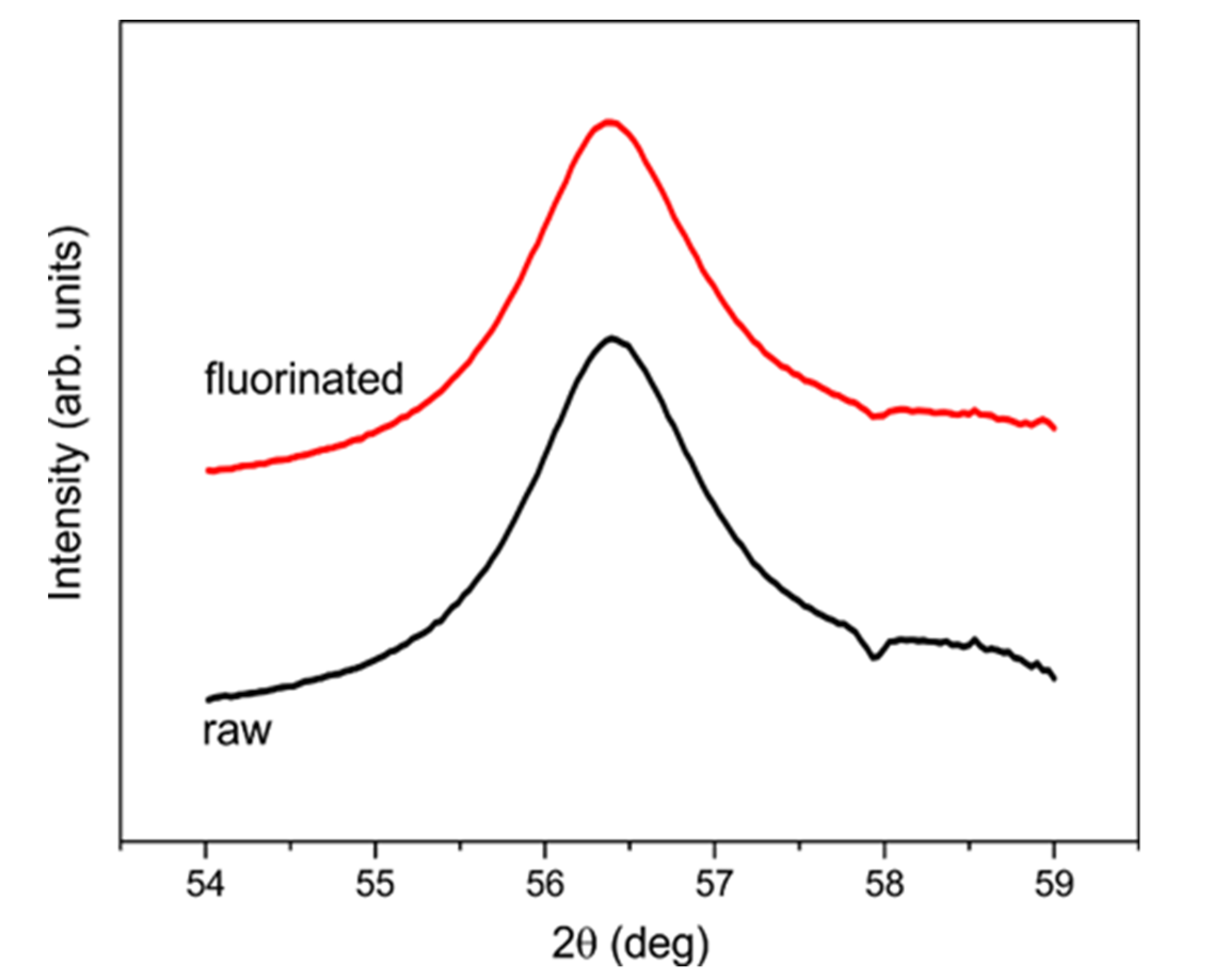

3.4. X-ray Powder Diffraction

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sheng, P. Scattering and Localization of Classical Waves in Random Media; World Scientific: Singapore, 1990. [Google Scholar]

- Schelten, J.; Shmatz, W. Multiple-scattering treatment for small-angle scattering problems. J. Appl. Cryst. 1980, 13, 385–390. [Google Scholar] [CrossRef]

- Maleev, S.V.; Toperverg, B.P. Low-angle multiple scattering by static inhomogeneities. Jetp Lett. 1980, 51, 158–165. [Google Scholar]

- Feigin, L.A.; Svergun, D.I. Structure Analysis by Small-Angle X-ray and Neutron Scattering; Plenum Press: New York, NY, USA, 1987. [Google Scholar]

- Sabine, T.M.; Bertram, W.K. The use of multiple-scattering data to enhance small-angle neutron scattering experiments. Acta Cryst. 1999, 55, 500–507. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ishimaru, A. Wave Propagation and Scattering in Random Media; Wiley-IEEE Press: Piscataway, NJ, USA, 1999. [Google Scholar]

- Greiner, N.R.; Philips, D.S.; Johnson, J.C. Diamonds in detonation soot. Nature 1988, 333, 440–442. [Google Scholar] [CrossRef]

- Aleksenskii, A.E.; Baidakova, M.V.; Vul’, A.Y.; Sikitskii, V.I. The structure of diamond nanoclusters. Phys. Solid State 1999, 41, 668–671. [Google Scholar] [CrossRef]

- Nesvizhevsky, V.V. Interaction of neutrons with nanoparticles. Phys. Nucl. 2002, 65, 400–408. [Google Scholar] [CrossRef]

- Artem’ev, V.A. Estimation of neutron reflection from nanodispersed materials. Energy 2006, 101, 901–904. [Google Scholar] [CrossRef]

- Nesvizhevsky, V.V.; Lychagin, E.V.; Muzychka, A.Y.; Strelkov, A.V.; Pignol, G.; Protasov, K.V. The reflection of very cold neutrons from diamond powder nanoparticles. Nucl. Instrum. Meth. A 2008, 595, 631–636. [Google Scholar] [CrossRef] [Green Version]

- Lychagin, E.V.; Muzychka, A.Y.; Nesvizhevsky, V.V.; Pignol, G.; Protasov, K.V.; Strelkov, A.V. Storage of very cold neutrons in a trap with nano-structured walls. Phys. Lett. B 2009, 679, 186–190. [Google Scholar] [CrossRef]

- Nesvizhevsky, V.V.; Cubitt, R.; Lychagin, E.V.; Muzychka, A.Y.; Nekhaev, G.V.; Pignol, G.; Protasov, K.V.; Strelkov, A.V. Application of diamond nanoparticles in low-energy neutron physics. Materials 2010, 3, 1768–1781. [Google Scholar] [CrossRef]

- Cubitt, R.; Lychagin, E.V.; Muzychka, A.Y.; Nekhaev, G.V.; Nesvizhevsky, V.V.; Pignol, G.; Protasov, K.V.; Strelkov, A.V. Quasi-classical albedo of cold neutrons from powder of nanoparticles. Nucl. Instrum. Meth. A 2010, 622, 182–185. [Google Scholar] [CrossRef] [Green Version]

- Zousman, B.; Levinson, O. Pure nanodiamonds produced by laser-assisted technique. In Nanodiamond; Williams, O., Ed.; RSC Nanoscience & Nanotechnology: London, UK, 2014. [Google Scholar]

- Ignatovich, V.K.; Nesvizhevsky, V.V. Reflection of slow neutrons from nanorod powder. Energy 2014, 116, 132–143. [Google Scholar] [CrossRef]

- Lychagin, E.V.; Muzychka, A.Y.; Nesvizhevsky, V.V.; Nekhaev, G.V.; Pignol, G.; Protasov, K.V.; Strelkov, A.V. Coherent scattering of slow neutrons at nanoparticles in particle physics experiments. Nucl. Instrum. Meth. A 2009, 611, 302–305. [Google Scholar] [CrossRef]

- Nesvizhevsky, V.V. Reflectors for VCN and applications of VCN. Rev. Mex. Fis. 2011, 57, 1–5. [Google Scholar]

- Ersez, T.; Osborn, J.C.; Lu, W.; Mata, J.P. Small angle and inelastic scattering investigation of nanodiamonds. Phys. B 2018, 551, 278–282. [Google Scholar] [CrossRef]

- Teshigawara, M.; Tsuchikawa, Y.; Ichikawa, G.; Takata, S.; Mishima, K.; Harada, M.; Ooi, M.; Kawamura, Y.; Kai, T.; Ohira-Kawamura, S.; et al. Measurement of neutron scattering cross section of nano-diamond with particle diameter of approximately 5 nm in energy range of 0.2 meV to 100 meV. Nucl. Instrum. Meth. A 2019, 929, 113–120. [Google Scholar] [CrossRef]

- Grammer, K.B.; Gallmeier, F.X. The small-angle neutron scattering extension in MCNPX and the SANS cross section for nanodiamonds. Nucl. Instrum. Meth. A 2020, 953, 163226. [Google Scholar] [CrossRef]

- Granada, J.R.; Damain, J.I.; Helman, C. Studies on reflector materials for cold neutrons. Eur. Phys. J. Web Conf. 2020, 231, 04002. [Google Scholar] [CrossRef]

- Jamalipour, M.; Zanini, L.; Gorini, G. Directional reflection of cold neutrons using nanodiamond particles for compact neutron sources. Eur. Phys. J. Web Conf. 2020, 231, 04003. [Google Scholar] [CrossRef]

- Krylov, A.R.; Lychagin, E.V.; Muzychka, A.Y.; Nesvizhevsky, V.V.; Nekhaev, G.V.; Strelkov, A.V.; Ivanov, A.S. Study of bound hydrogen in powders of diamond nanoparticles. Cryst. Rep. 2011, 56, 1186–1191. [Google Scholar] [CrossRef]

- Mochalin, V.N.; Shenderova, O.; Ho, D.; Gogotsi, Y. The properties and applications of nanodiamonds. Nat. Nanotechnol. 2012, 7, 11–23. [Google Scholar] [CrossRef] [PubMed]

- Krueger, A. Current issues and challenges in surface chemistry of nanodiamonds. In Nanodiamonds: Advanced Material Analysis; Arnault, J.-C., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 184–242, Chapter 8. [Google Scholar]

- Nesvizhevsky, V.V.; Koester, U.; Dubois, M.; Batisse, N.; Frezet, L.; Bosak, A.; Gines, L.; Williams, O. Fluorinated nanodiamonds as unique neutron reflector. Carbon 2018, 130, 799–805. [Google Scholar] [CrossRef]

- Nesvizhevsky, V.V.; Koester, U.; Dubois, M.; Batisse, N.; Frezet, L.; Bosak, A.; Gines, L.; Williams, O. Fluorinated nanodiamonds as unique neutron reflector. J. Neutron Res. 2018, 20, 81–82. [Google Scholar] [CrossRef]

- Herraiz, M.; Batisse, N.; Dubois, M.; Nesvizhevsky, V.V.; Cavallari, C.; Brunelli, M.; Pischedda, V.; Radescu Cioranescu, S. A multi-technique study of fluorinated nanodiamonds for low-energy neutron physics applications. J. Phys. Chem. C 2020, in press. [Google Scholar] [CrossRef]

- Nesvizhevsky, V.V.; Dubois, M.; Gutfreund, P.H.; Lychagin, E.V.; Nezvanov, A.Y.; Zhernenkov, K.N. Effect of nanodiamond fluorination on the efficiency of quasispecular reflection of cold neutrons. Phys. Rev. A 2018, 97, 023629. [Google Scholar] [CrossRef]

- Batsanov, S.S.; Osavchuk, A.N.; Naumov, S.P.; Gavrilkin, S.M.; Batsanov, A.S. Novel synthesis and properties of hydrogen-free detonation nanodiamond. Mater. Chem. Phys. 2018, 216, 120–129. [Google Scholar] [CrossRef] [Green Version]

- Vul’, A.; Shenderova, O. Detonation Nanodiamonds: Science and Applications; Pan Stanford Publishing: Singapore, 2014. [Google Scholar]

- Williams, O. Nanodiamond; RSC Publishing: Cambridge, UK, 2014. [Google Scholar]

- Baidakova, M.; Vul’, A. New prospects and frontiers of nanodiamond clusters. J. Phys. D Appl. Phys. 2007, 40, 6300. [Google Scholar] [CrossRef]

- Badziag, P.; Verwoerd, W.S.; Ellis, W.P.; Greiner, N.R. Nanometre-sized diamonds are more stable than graphite. Nature 1990, 343, 244–245. [Google Scholar] [CrossRef]

- Raty, J.Y.; Galli, G.; Bostedt, C.; van Buuren, T.W.; Terminello, L.J. Quantum confinement and fullerene like surface reconstructions in nanodiamonds. Phys. Rev. Lett. 2003, 90, 037401. [Google Scholar] [CrossRef]

- Barnard, A.S.; Sternberg, M. Crystallinity and surface electrostatics of diamond nanocrystals. J. Mater. Chem. 2007, 17, 4811–4819. [Google Scholar] [CrossRef]

- Aleksenskii, A.E.; Baidakova, M.V.; Vul’, A.Y.; Dideikin, A.T.; Sikitskii, V.I.; Vul’, S.P. Effect of hydrogen on the structure of ultradisperse diamond. Phys. Solid State 2000, 42, 1575–1578. [Google Scholar] [CrossRef]

- Palosz, B.; Grzanka, E.; Gierlotka, S.; Stel’makh, S.; Pielaszek, R.; Bismayer, U.; Neuefeind, J.; Weber, H.-P.; Proffen, T.; von Dreele, R.; et al. Analysis of short and long range order in nanocrystalline diamonds with application of powder diffractometry. Z. Fur Krist. 2002, 217, 497–509. [Google Scholar] [CrossRef]

- Avdeev, M.V.; Aksenov, V.L.; Tomchuk, O.V.; Bulavin, L.A.; Garamus, V.M.; Osawa, E. The spatial diamond-graphite transition in detonation nanodiamond as revealed by small-angle neutron scattering. J. Phys. Condens. Mater. 2013, 25, 445001. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Osawa, E. Monodisperse single nanodiamond particles. Pure Appl. Chem. 2008, 80, 1365–1379. [Google Scholar] [CrossRef]

- Krüger, A.; Kataoka, F.; Ozawa, M.; Fujino, T.; Suzuki, Y.; Aleksenskii, A.E.; Vul’, A.Y.; Osawa, E. Usually tight aggregation in detonation nanodiamond: Identification and disintegration. Carbon 2005, 43, 1722–1730. [Google Scholar] [CrossRef]

- Williams, O.; Hees, J.; Dieker, C.; Jager, W.; Kirste, L.; Nebel, C.E. Size-dependent reactivity of diamond nanoparticles. Acn Nano 2010, 4, 4824–4830. [Google Scholar] [CrossRef]

- Aleksenskii, A.E.; Eydelman, E.D.; Vul’, A.Y. Deagglomeration of detonation nanodiamonds. Nanosci. Nanotechnol. Lett. 2011, 3, 68–74. [Google Scholar] [CrossRef]

- Avdeev, M.V.; Aksenov, V.L.; Rosta, L. Pressure induced charges in fractal structure of detonation nanodiamond powder by small-angle neutron scattering. Diam. Relat. Mater. 2007, 16, 2050–2053. [Google Scholar] [CrossRef]

- Chang, L.-Y.; Osawa, E.; Barnard, A.S. Confirmation of the electrostatic self-assembly of nanodiamonds. Nanoscale 2011, 3, 958–962. [Google Scholar] [CrossRef] [Green Version]

- Osawa, E.; Sasaki, S.; Yamanoi, R. Chapter 6 Deagglomeration of Detonation Nanodiamond. In Ultrananocrystalline Diamond: Synthesis, Properties and Applications; Shenderova, O.A., Gruen, D.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Korobov, M.V.; Batuk, M.; Avramenko, N.V.; Ivanova, N.I.; Rozhkova, N.N.; Osawa, E. Aggregate structure of single nano-buckydiamond in gel and dried powder by differential scanning calorimetry and nitrogen adsorption. Diam. Relat. Mater. 2010, 19, 665–671. [Google Scholar] [CrossRef]

- Bouanani, F.; Bendedouch, D.; Teixeira, J.; Marx, L.; Hemery, P. Characterization of a miniemulsion by DLS and SANS. Colloids Surf. 2012, 404, 47–51. [Google Scholar] [CrossRef]

- Aleksenskii, A.E.; Osipov, V.Y.; Dideikin, A.T.; Vul’, A.Y.; Andriaenssens, G.J.; Afanas’ev, V.V. Ultradisperse diamond cluster aggregation studied by atomic force microscopy. Technol. Phys. Lett. 2000, 26, 819–821. [Google Scholar] [CrossRef]

- Linder, P.; Zemb, T. Neutrons, X-ray and Light: Scattering Methods Applied to Soft Condensed Matter; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Linder, P.; Schweins, R. The D11 small-angle scattering instrument: A new benchmark for SANS. Neutron News 2010, 21, 15–18. [Google Scholar] [CrossRef]

- Richard, D.; Ferrand, M.; Kearley, G.J. Analysis and visualization of neutron-scattering data. J. Neutron Res. 1996, 4, 33–39. [Google Scholar] [CrossRef]

- Kuklin, A.I.; Rogachev, A.V.; Soloviov, D.V.; Ivankov, O.I.; Kovalev, Y.S.; Utrobin, P.K.; Gordeliy, V.I. Neutronographic investigations of supramolecular structures on upgraded small-angle spectrometer YuMO. J. Phys. Conf. Ser. 2017, 848, 012010. [Google Scholar] [CrossRef]

- Soloviev, A.G.; Solovjeva, T.M.; Ivankov, O.I.; Soloviov, D.V.; Rogachev, A.V.; Kuklin, A.I. SAS program for two-detector system: Seamless curve from both detectors. J. Phys. Conf. Ser. 2017, 848, 012020. [Google Scholar] [CrossRef]

- Liu, Y.; Gu, Z.; Magrave, J.L.; Khabashesku, V.N. Functionalization of nanoscale diamond powder: Fluoro-, alkyl-, amino-, and amino acid-nanodiamond derivatives. Chem. Mater. 2004, 16, 3924–3930. [Google Scholar] [CrossRef]

- Dyadkin, V.; Pattison, P.; Dmitriev, V.; Chernyshov, D. A new multipurpose diffractometer PILATUS@SNBL. J. Synchr. Rad. 2016, 23, 825–829. [Google Scholar] [CrossRef]

- Hammersley, A.P.; Svensson, S.O.; Hanfland, M.; Fitch, A.N.; Haussermann, D. Two-dimensional detector software: From real detector to idealized image or two-theta scan. High Press. Res. 1996, 14, 235–248. [Google Scholar] [CrossRef]

- Dolmatov, V.Y. Detonation synthesis ultra-dispersed diamonds: Properties and applications. Russ. Chem. Rev. 2001, 70, 607–626. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bosak, A.; Dideikin, A.; Dubois, M.; Ivankov, O.; Lychagin, E.; Muzychka, A.; Nekhaev, G.; Nesvizhevsky, V.; Nezvanov, A.; Schweins, R.; et al. Fluorination of Diamond Nanoparticles in Slow Neutron Reflectors Does Not Destroy Their Crystalline Cores and Clustering While Decreasing Neutron Losses. Materials 2020, 13, 3337. https://doi.org/10.3390/ma13153337

Bosak A, Dideikin A, Dubois M, Ivankov O, Lychagin E, Muzychka A, Nekhaev G, Nesvizhevsky V, Nezvanov A, Schweins R, et al. Fluorination of Diamond Nanoparticles in Slow Neutron Reflectors Does Not Destroy Their Crystalline Cores and Clustering While Decreasing Neutron Losses. Materials. 2020; 13(15):3337. https://doi.org/10.3390/ma13153337

Chicago/Turabian StyleBosak, Alexei, Artur Dideikin, Marc Dubois, Oleksandr Ivankov, Egor Lychagin, Alexei Muzychka, Grigory Nekhaev, Valery Nesvizhevsky, Alexander Nezvanov, Ralf Schweins, and et al. 2020. "Fluorination of Diamond Nanoparticles in Slow Neutron Reflectors Does Not Destroy Their Crystalline Cores and Clustering While Decreasing Neutron Losses" Materials 13, no. 15: 3337. https://doi.org/10.3390/ma13153337