Characteristics of Lightweight Cellular Concrete and Effects on Mechanical Properties

Abstract

:1. Introduction

2. Preparation of LCC Specimens and Mechanical Test

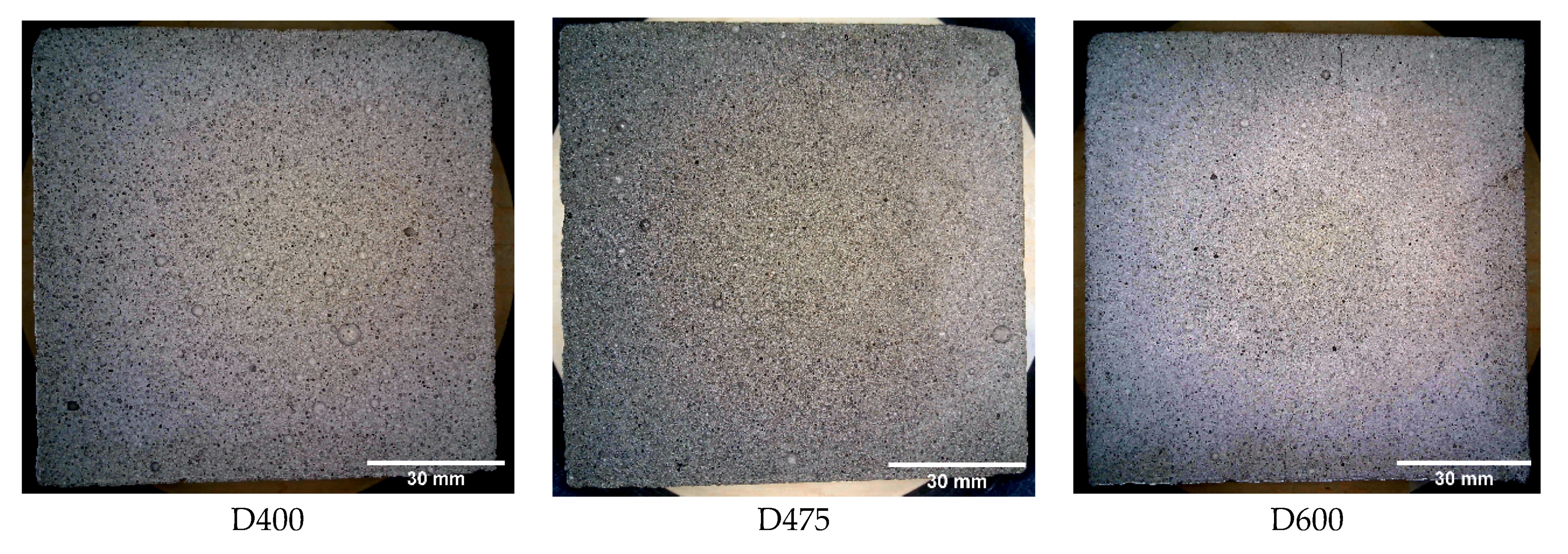

2.1. LCC Specimens

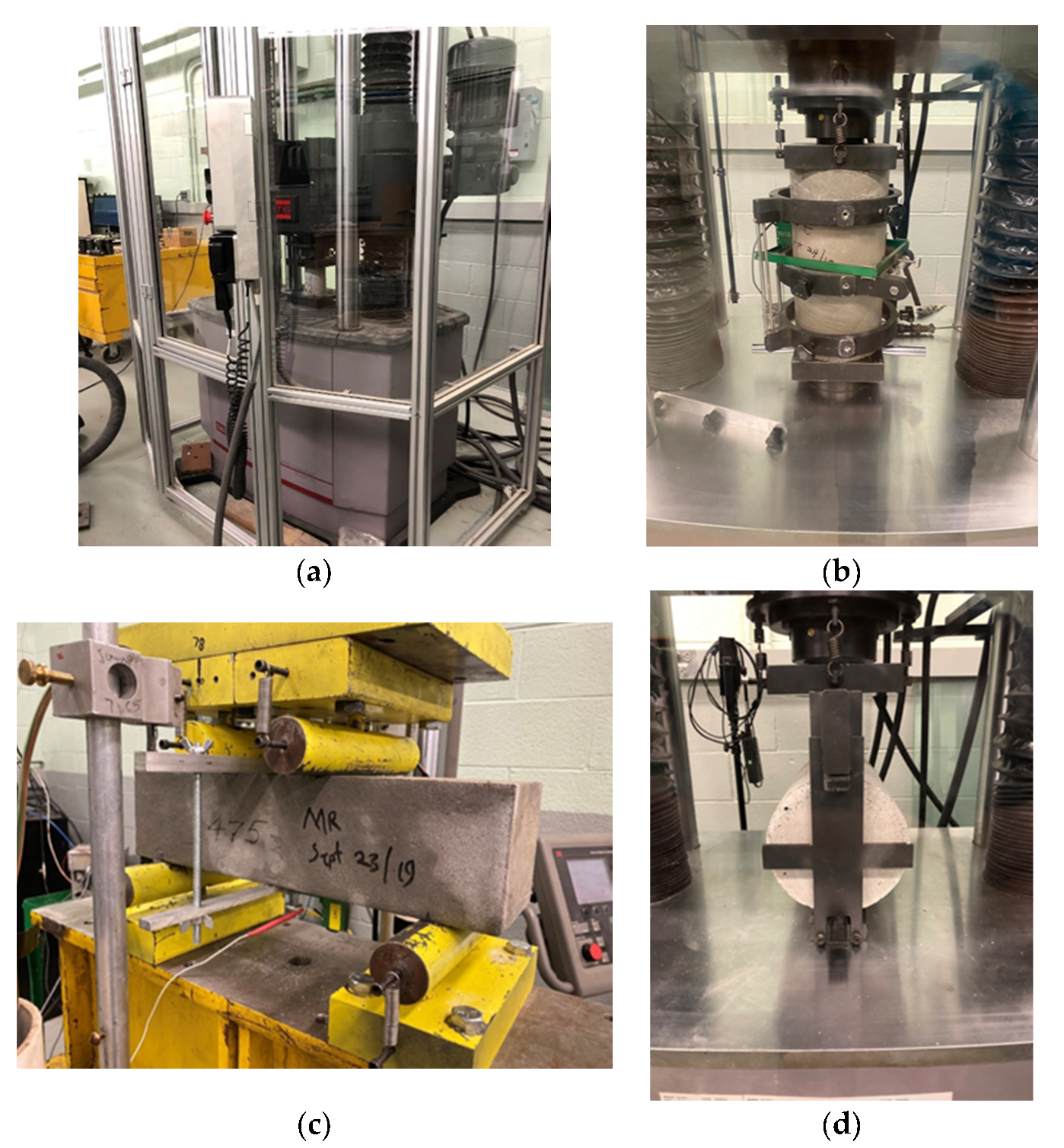

2.2. Mechanical Properties Test Method of LCC

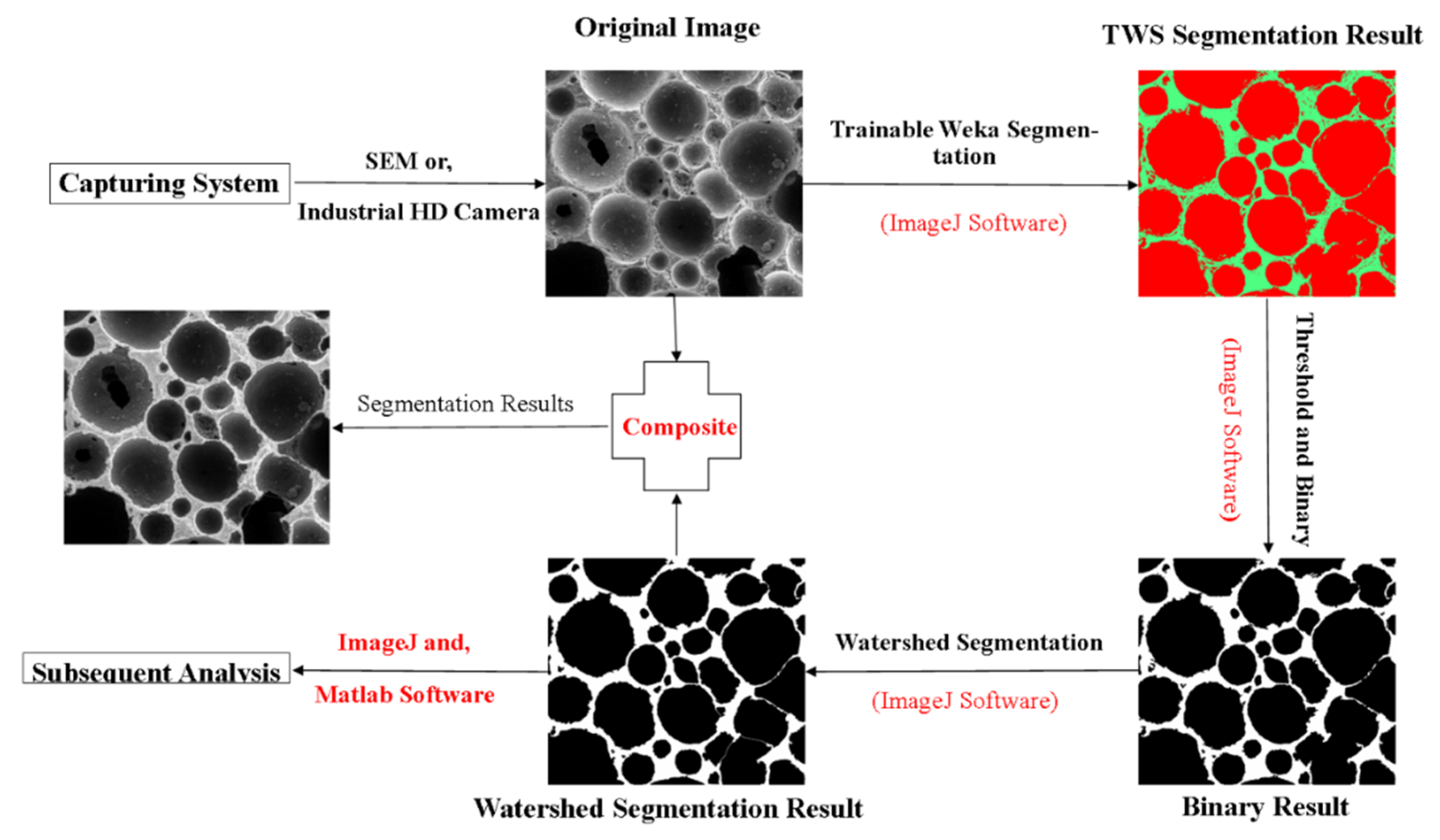

3. Image Capturing System and Image Processing Methodology

3.1. Industrial HD Camera System (IHDCS)

3.2. ESEM Imaging Method

3.3. Image Processing Methodology

4. Results and Analysis

4.1. ESEM Pore Characteristic Analysis

4.1.1. Pore Size and Thickness of Solid Part

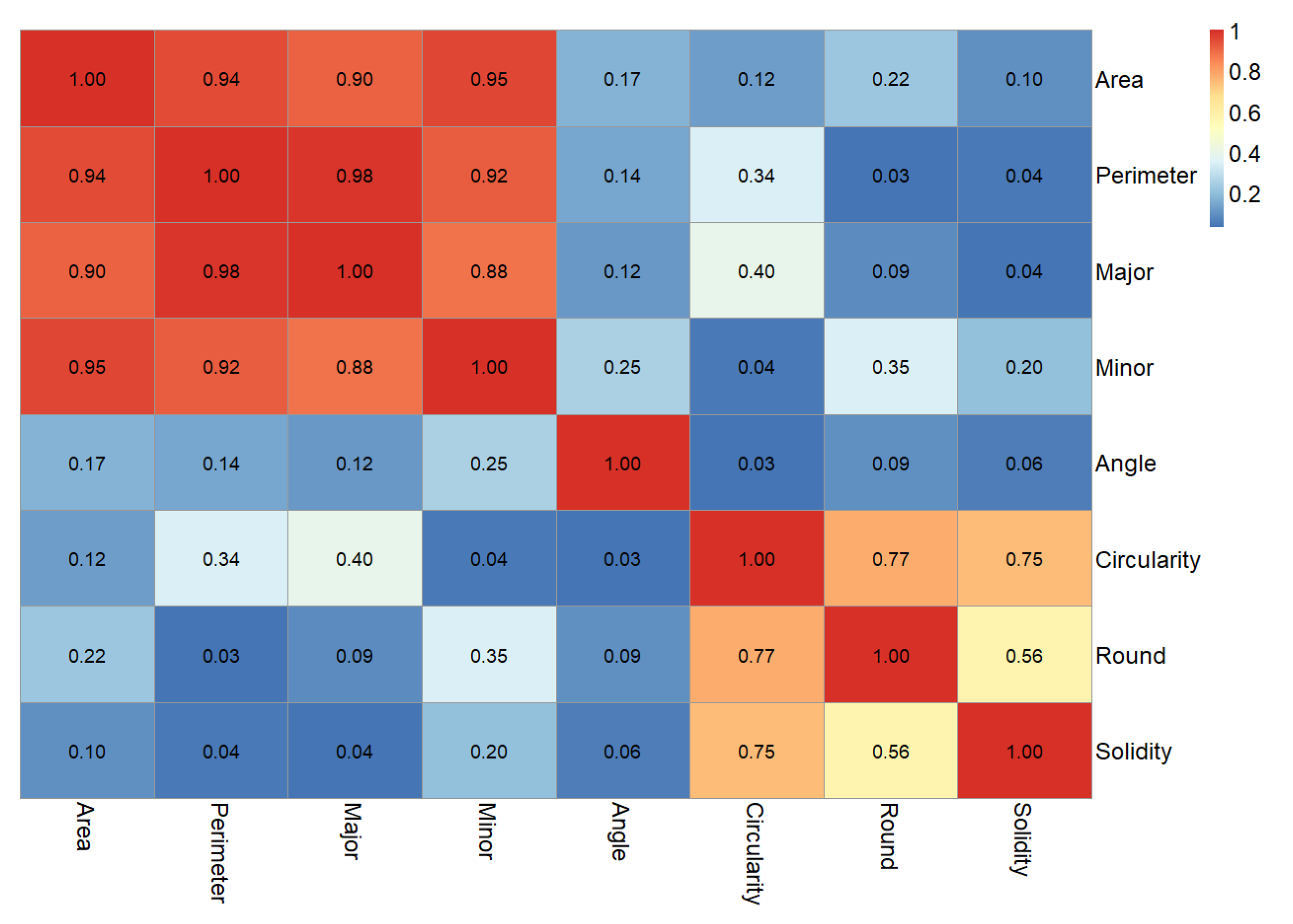

4.1.2. Shape Descriptors

4.2. Image Processing Results Analysis of ESEM and IHDCS

4.3. Mechanical Analysis

5. Conclusions

- (1)

- Based on the image processing results, IHDCS can obtain similar analysis results consistent with ESEM. Besides, compared with ESEM, IHDCS can capture a larger range of pore structures faster and more conveniently.

- (2)

- There are strong correlations among pore area, perimeter, and major and minor axis. The lowest correlation coefficient value is 0.88; shape descriptors also have high correlation coefficients, but the maximum value is less than 0.8.

- (3)

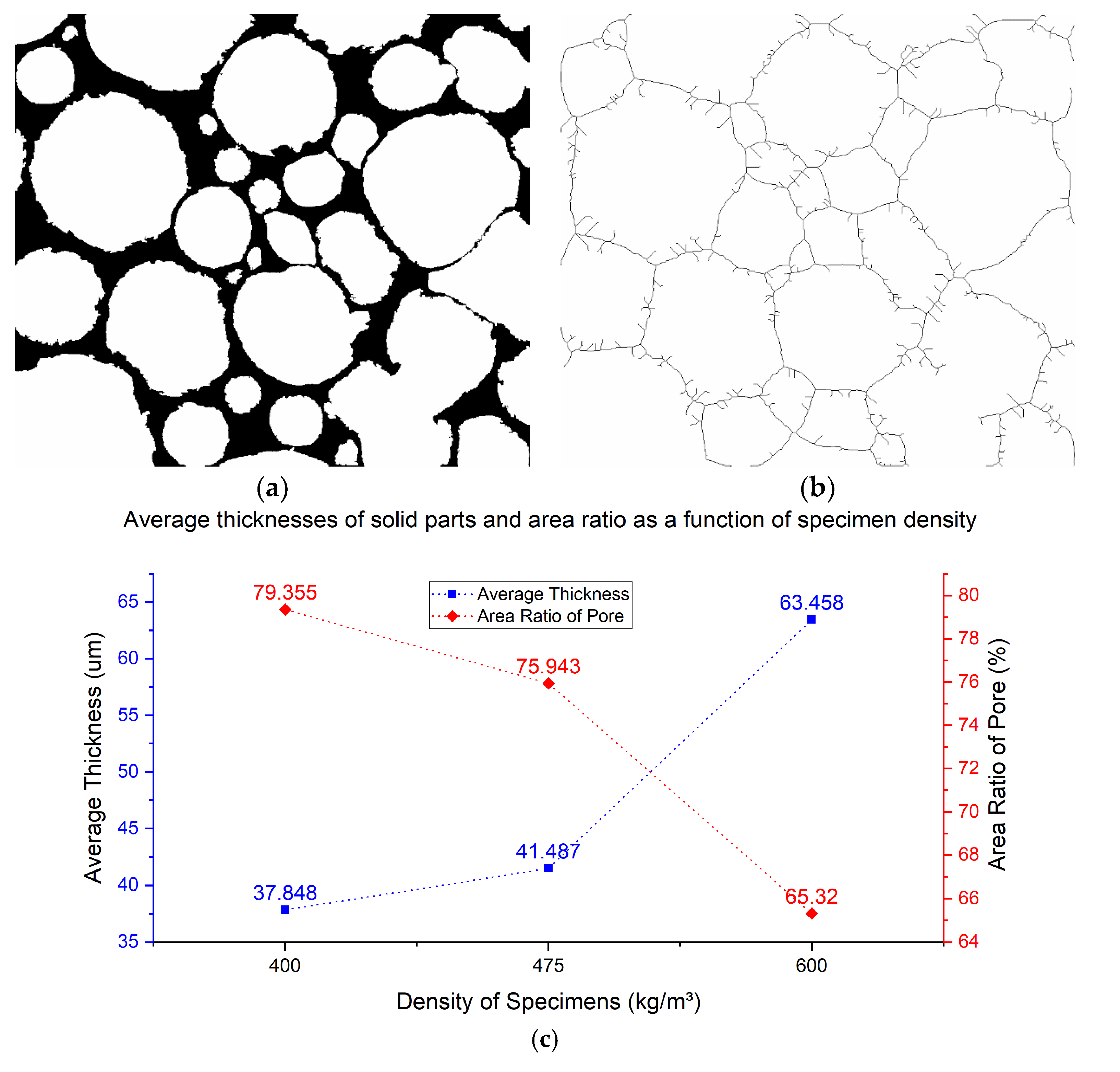

- Developed a method to calculate the average thickness of the bubble wall. The results show that specimens with high densities have a significant average thickness value. In this study, the average thickness value of D600 is more than 1.5 times that of low-density samples (D400, D475).

- (4)

- The lower the density of the specimen is, the higher the ratio of the bubble area to the total test area. In this study, the pore area ratio of D400 is about 5% higher than that of D475. It is more than 20% higher than that of D600.

- (5)

- The pore area ratio, average thickness of bubble wall, and shape directors (circularity and solidity) have strong correlations with the mechanical properties of LCC. These parameters could be useful to have estimations of mechanical behavior of LCC.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hilal, A.A.; Thom, N.H.; Dawson, A.R. On entrained pore size distribution of foamed concrete. Constr. Build. Mater. 2015, 75, 227–233. [Google Scholar] [CrossRef]

- Othuman, M.A.; Wang, Y.C. Elevated-temperature thermal properties of lightweight foamed concrete. Constr. Build. Mater. 2011, 25, 705–716. [Google Scholar] [CrossRef]

- Jitchaiyaphum, K.; Sinsiri, T.; Chindaprasirt, P. Cellular lightweight concrete containing pozzolan materials. Procedia Eng. 2011, 14, 1157–1164. [Google Scholar] [CrossRef] [Green Version]

- Ramamurthy, K.; Nambiar, E.K.; Ranjani, G.I.S. A classification of studies on properties of foam concrete. Cem. Concr. Compos. 2009, 31, 388–396. [Google Scholar] [CrossRef]

- Nambiar, E.K.; Ramamurthy, K. Air-void characterization of foam concrete. Cem. Concr. Res. 2007, 37, 221–230. [Google Scholar] [CrossRef]

- Raj, A.; Sathyan, D.; Mini, K.M. Physical and functional characteristics of foam concrete: A review. Constr. Build. Mater. 2019, 221, 787–799. [Google Scholar] [CrossRef]

- Fu, Y.; Wang, X.; Wang, L.; Li, Y. Foam concrete: A state-of-the-art and state-of-the-practice review. Adv. Mater. Sci. Eng. 2020. [Google Scholar] [CrossRef] [Green Version]

- Niu, D.; Zhang, L.; Fu, Q.; Wen, B.; Luo, D. Critical conditions and life prediction of reinforcement corrosion in coral aggregate concrete. Constr. Build. Mater. 2020, 238, 117685. [Google Scholar] [CrossRef]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. Experimental investigation on the compressive strength of foamed concrete: Effect of curing conditions, cement type, foaming agent and dry density. Constr. Build. Mater. 2018, 165, 735–749. [Google Scholar] [CrossRef]

- Valore, R.C. Cellular concretes: Composition and method of preparation. J. Am. Concr. Inst. 1954, 2, 773–795. [Google Scholar]

- Sayadi, A.A.; Tapia, J.V.; Neitzert, T.R.; Clifton, G.C. Effects of expanded polystyrene (EPS) particles on fire resistance, thermal conductivity and compressive strength of foamed concrete. Constr. Build. Mater. 2016, 112, 716–724. [Google Scholar] [CrossRef]

- Kim, H.K.; Jeon, J.H.; Lee, H.K. Workability, and mechanical, acoustic and thermal properties of lightweight aggregate concrete with a high volume of entrained air. Constr. Build. Mater. 2012, 29, 193–200. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, T.; Wen, Z. Proportioning and characterization of Portland cement-based ultra-lightweight foam concretes. Constr. Build. Mater. 2015, 79, 390–396. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Mechanical, thermal insulation, thermal resistance and acoustic absorption properties of geopolymer foam concrete. Cem. Concr. Compos. 2015, 62, 97–105. [Google Scholar] [CrossRef]

- Li, X.; Qi, C.; Zhang, P. A micro-macro confined compressive fatigue creep failure model in brittle solids. Int. J. Fatigue 2020, 130, 105278. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Y.; Qiu, J.; Liu, T.; Yang, L.; She, H. Moisture absorption characteristics and thermal insulation performance of thermal insulation materials for cold region tunnels. Constr. Build. Mater. 2020, 237, 117765. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Yang, J.L. Improving safety of runway overrun through foamed concrete aircraft arresting system: An experimental study. Int. J. Crashworthiness 2015, 20, 448–463. [Google Scholar] [CrossRef]

- Mydin, M.A.O.; Wang, Y.C. Structural performance of lightweight steel-foamed concrete-steel composite walling system under compression. Thin Walled Struct. 2011, 49, 66–76. [Google Scholar] [CrossRef]

- Decký, M.; Drusa, M.; Zgútová, K.; Blaško, M.; Hájek, M.; Scherfel, W. Foam concrete as new material in road constructions. Procedia Eng. 2016, 161, 428–433. [Google Scholar] [CrossRef] [Green Version]

- Kadela, M.; Kozłowski, M. Foamed concrete layer as sub-structure of industrial concrete floor. Procedia Eng. 2016, 161, 468–476. [Google Scholar] [CrossRef] [Green Version]

- Amran, Y.M.; Farzadnia, N.; Ali, A.A. Properties and applications of foamed concrete; a review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Chung, S.Y.; Lehmann, C.; Elrahman, A.M.; Stephan, D. Pore characteristics and their effects on the material properties of foamed concrete evaluated using micro-CT images and numerical approaches. Appl. Sci. 2017, 7, 550. [Google Scholar] [CrossRef] [Green Version]

- Favaretto, P.; Hidalgo, G.E.N.; Sampaio, C.H.; Silva, R.D.A.; Lermen, R.T. Characterization and use of construction and demolition waste from south of Brazil in the production of foamed concrete blocks. Appl. Sci. 2017, 7, 1090. [Google Scholar] [CrossRef] [Green Version]

- Maher, M.L.; Hagan, J.B. MAT-758: Constructability Benefits of the Use of Lightweight Foamed Concrete Fill (LFCF) in Pavement Applications. In Proceedings of the CSCE Annual Conference London Convention Center, London, UK, 1–4 June 2016. [Google Scholar]

- Jiang, J.; Lu, Z.; Niu, Y.; Li, J.; Zhang, Y. Study on the preparation and properties of high-porosity foamed concretes based on ordinary Portland cement. Mater. Des. 2016, 92, 949–959. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Bui, H.H.; Ngo, T.D.; Nguyen, G.D. Experimental and numerical investigation of influence of air-voids on the compressive behavior of foamed concrete. Mater. Des. 2017, 130, 103–119. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Mendis, P. Enhancing the strength of pre-made foams for foam concrete applications. Cem. Concr. Compos. 2018, 87, 164–171. [Google Scholar] [CrossRef]

- Kearsley, E.P.; Wainwright, P.J. The effect of porosity on the strength of foamed concrete. Cem. Concr. Res. 2002, 32, 233–239. [Google Scholar] [CrossRef]

- Namsone, E.; Šahmenko, G.; Korjakins, A. Durability properties of high performance foamed concrete. Procedia Eng. 2017, 172, 760–767. [Google Scholar] [CrossRef]

- Hadipramana, J.; Samad, A.A.A.; Zaidi, A.M.A.; Mohammad, N.; Ali, N. Contribution of polypropylene fiber in improving strength of foamed concrete. Adv. Mater. Res. 2013, 626, 762–768. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Wang, H. The pore characteristics of geopolymer foam concrete and their impact on the compressive strength and modulus. Front. Mater. 2016, 3, 38. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, T.T.; Bui, H.H.; Ngo, T.D.; Nguyen, G.D.; Kreher, M.U.; Darve, F. A micro mechanical investigation for the effects of pore size and its distribution on geopolymer foam concrete under uniaxial compression. Eng. Fract. Mech. 2019, 209, 228–244. [Google Scholar] [CrossRef]

- Batool, F.; Bindiganavile, V. Air-void size distribution of cement based foam and its effect on thermal conductivity. Constr. Build. Mater. 2017, 149, 17–28. [Google Scholar] [CrossRef]

- Chen, X.; Wu, S.; Zhou, J. Influence of porosity on compressive and tensile strength of cement mortar. Constr. Build. Mater. 2013, 40, 869–874. [Google Scholar] [CrossRef]

- Lian, C.; Zhuge, Y.; Beecham, S. The relationship between porosity and strength for porous concrete. Constr. Build. Mater. 2011, 25, 4294–4298. [Google Scholar] [CrossRef]

- Nguyen, T.; Kashani, A.; Ngo, T.; Bordas, S. Deep neural network with high-order neuron for the prediction of foamed concrete strength. Comput. Aided Civ. Infrastruct. Eng. 2019, 34, 316–332. [Google Scholar] [CrossRef]

- Yaseen, Z.M.; Deo, R.C.; Hilal, A.; Abd, A.M.; Bueno, L.C.; Salcedo-Sanz, S.; Nehdi, M.L. Predicting compressive strength of lightweight foamed concrete using extreme learning machine model. Adv. Eng. Softw. 2018, 115, 112–125. [Google Scholar] [CrossRef]

- Wee, T.H.; Babu, D.S.; Tamilselvan, T.; Lim, H.S. Air-void system of foamed concrete and its effect on mechanical properties. ACI Mater. J. 2006, 103, 45–52. [Google Scholar]

- Youssef, M.B.; Lavergne, F.; Sab, K.; Miled, K.; Neji, J. Upscaling the elastic stiffness of foam concrete as a three-phase composite material. Cem. Concr. Res. 2018, 110, 13–23. [Google Scholar] [CrossRef] [Green Version]

- Hilal, A.A.; Thom, N.H.; Dawson, A.R. On void structure and strength of foamed concrete made without/with additives. Constr. Build. Mater. 2015, 85, 157–164. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Geopolymer foam concrete: An emerging material for sustainable construction. Constr. Build. Mater. 2014, 56, 113–127. [Google Scholar] [CrossRef]

- Kuzielová, E.; Pach, L.; Palou, M. Effect of activated foaming agent on the foam concrete properties. Constr. Build. Mater. 2016, 125, 998–1004. [Google Scholar] [CrossRef]

- Wang, X.; Huang, J.; Dai, S.; Ma, B.; Jiang, Q. Investigation of silica fume as foam cell stabilizer for foamed concrete. Constr. Build. Mater. 2020, 237, 117514. [Google Scholar] [CrossRef]

- Interactive H_Watershed (ImageJ/Fiji). Available online: https://imagej.net/Interactive_Watershed#Watershed_principle (accessed on 20 January 2020).

- NewCem Slag. Available online: https://www.lafarge.ca/en/newcem (accessed on 10 May 2020).

- ASTM C495/C495M. Standard Test Method for Compressive Strength of Lightweight Insulating Concrete; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM C469/C469M. Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM C495/C495M. Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM C496/C496M. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Yu, X.G.; Luo, S.S.; Gao, Y.N.; Wang, H.F.; Li, Y.X.; Wei, Y.R.; Wang, X.J. Pore structure and microstructure of foam concrete. Adv. Mater. Res. 2011, 177, 530–532. [Google Scholar] [CrossRef]

- ImageJ. Available online: https://imagej.net/Fiji (accessed on 6 October 2019).

- Otsu, N. A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef] [Green Version]

| Name | Parameter and Description | Name | Parameter and Description | |

|---|---|---|---|---|

| Module Size Focus | 38 mm 38 mm 6 mm | Sensitivity | TBD | |

| AF | F/NO | 2.5 | ||

| Object Distance | 5 cm-infinity | EFL | 4.16 mm | |

| Power Sensor Type | USB bus power | BFL | 3.4 mm | |

| IMX179 | FOV | 80° | ||

| Active Array Size | 3264 2448 | TV distortion | <1.2% | |

| Pixel Size | 1.4 μm 1.4 μm | IR filter | 650 ± 10 nm | |

| Maximum Image | 15 fps | 3264 2448, 2592 1944 | Fixed pattern noise | <0.03% |

| 30 fps | 1920 1080, 1280 720 | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, W.; Liang, X.; Ni, F.M.-W.; Oyeyi, A.G.; Tighe, S. Characteristics of Lightweight Cellular Concrete and Effects on Mechanical Properties. Materials 2020, 13, 2678. https://doi.org/10.3390/ma13122678

Yu W, Liang X, Ni FM-W, Oyeyi AG, Tighe S. Characteristics of Lightweight Cellular Concrete and Effects on Mechanical Properties. Materials. 2020; 13(12):2678. https://doi.org/10.3390/ma13122678

Chicago/Turabian StyleYu, Wei, Xu Liang, Frank Mi-Way Ni, Abimbola Grace Oyeyi, and Susan Tighe. 2020. "Characteristics of Lightweight Cellular Concrete and Effects on Mechanical Properties" Materials 13, no. 12: 2678. https://doi.org/10.3390/ma13122678

APA StyleYu, W., Liang, X., Ni, F. M.-W., Oyeyi, A. G., & Tighe, S. (2020). Characteristics of Lightweight Cellular Concrete and Effects on Mechanical Properties. Materials, 13(12), 2678. https://doi.org/10.3390/ma13122678