Quantitative Correlation between Thermal Cycling and the Microstructures of X100 Pipeline Steel Laser-Welded Joints

Abstract

:1. Introduction

2. Experimental Procedures for X100 Laser Welding

2.1. Experimental Materials

2.2. Experimental Methods

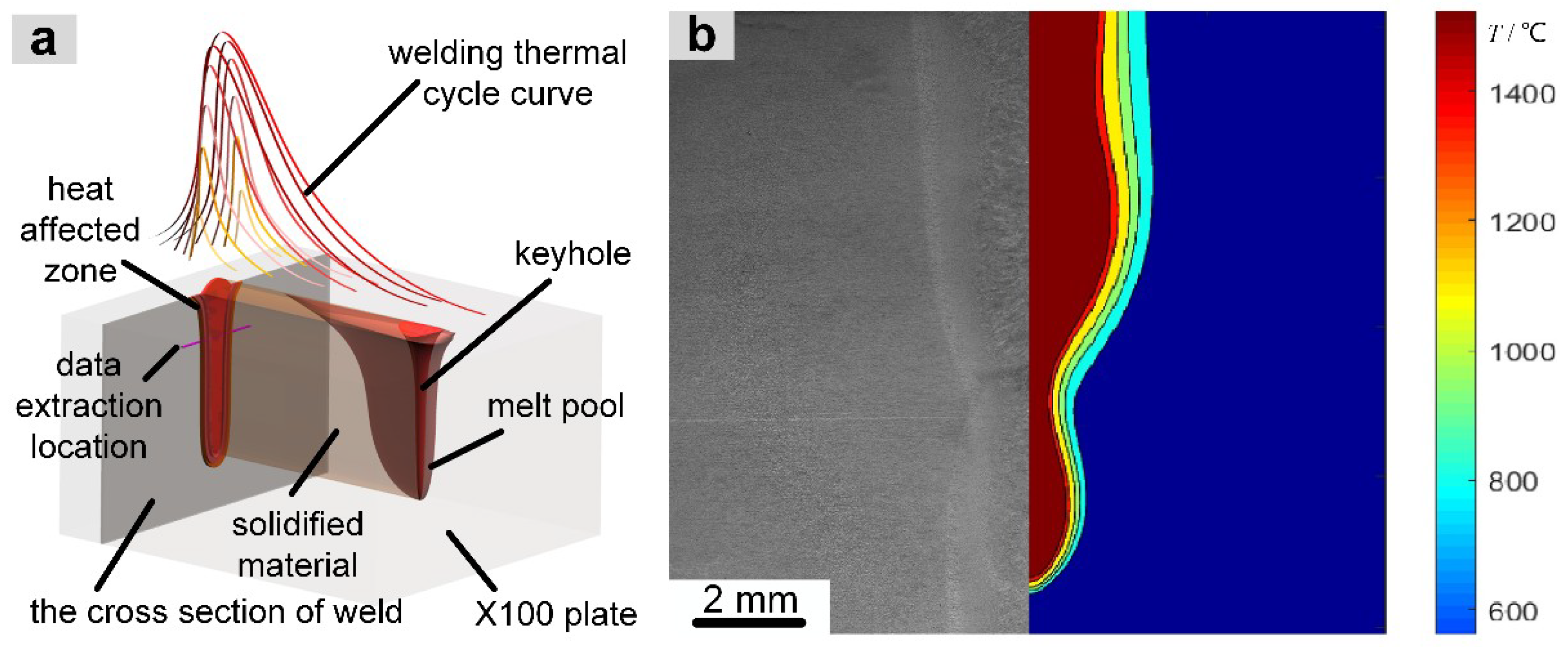

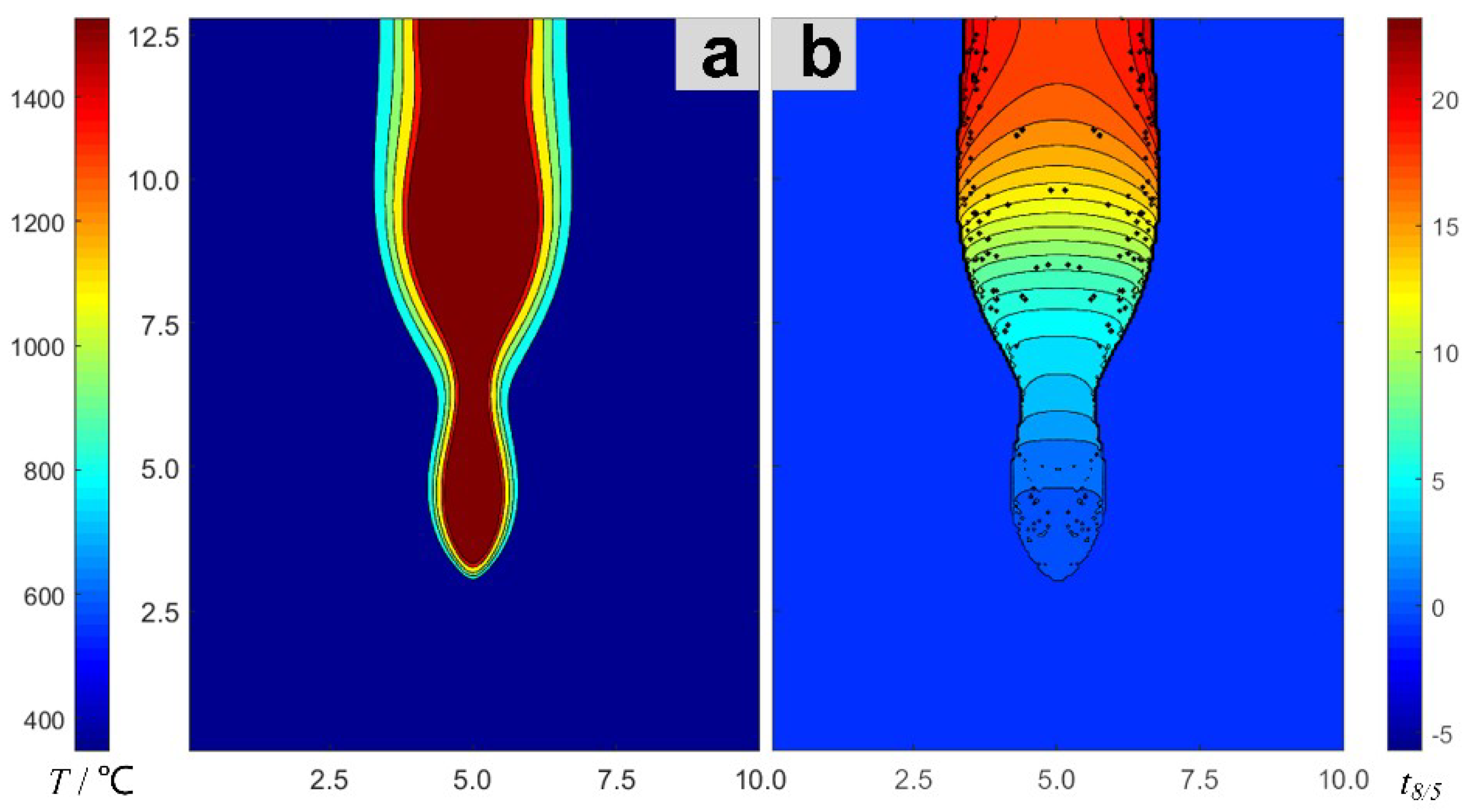

3. Numerical Calculation of the Laser-Welding Temperature Field

3.1. Establishment and Solution of the Finite-Element Model

3.2. Post-Processing of Welding Temperature Field Data

4. Results and Discussion

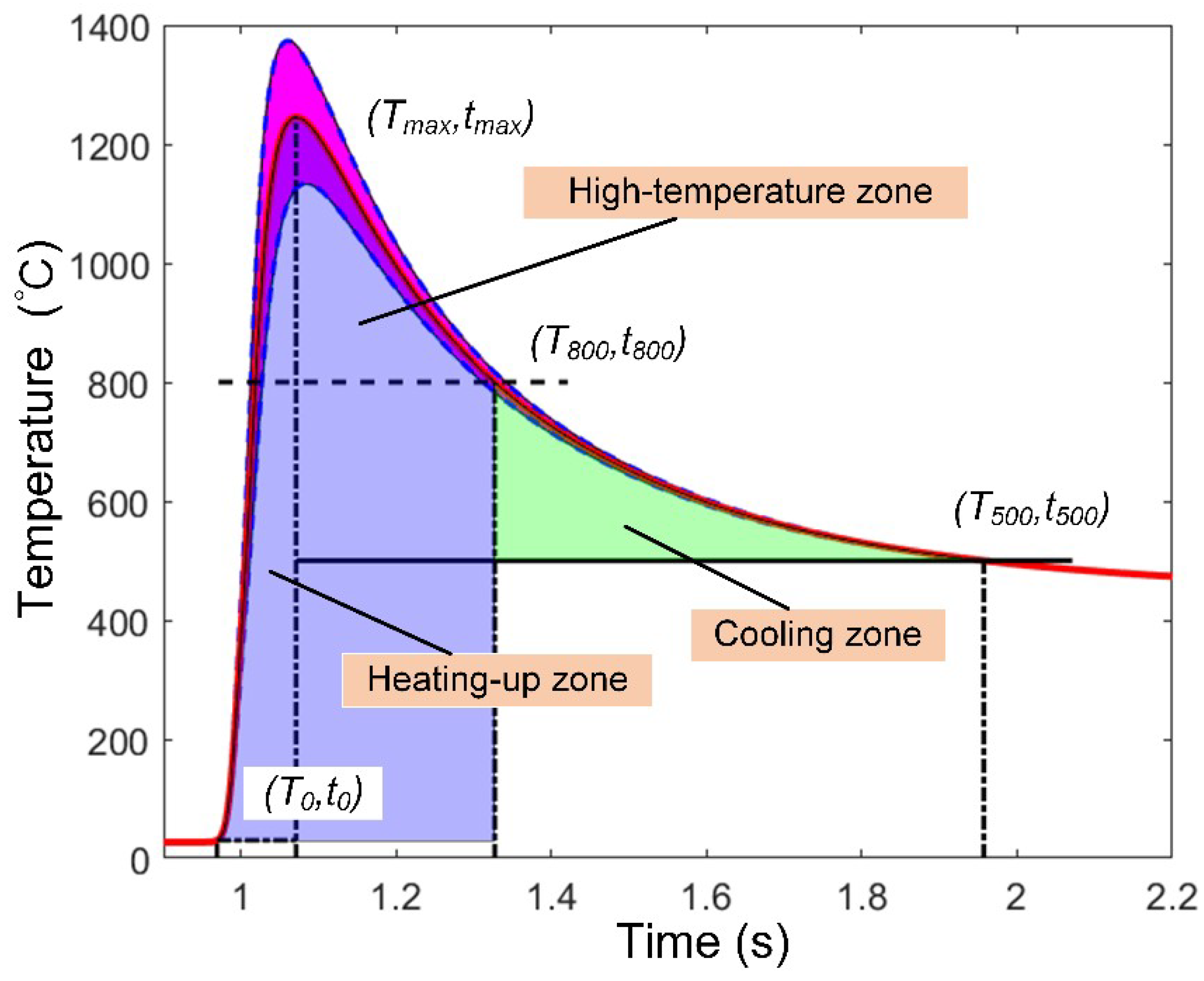

4.1. Extraction of the Characteristic Parameters of the Welding Thermal Cycle

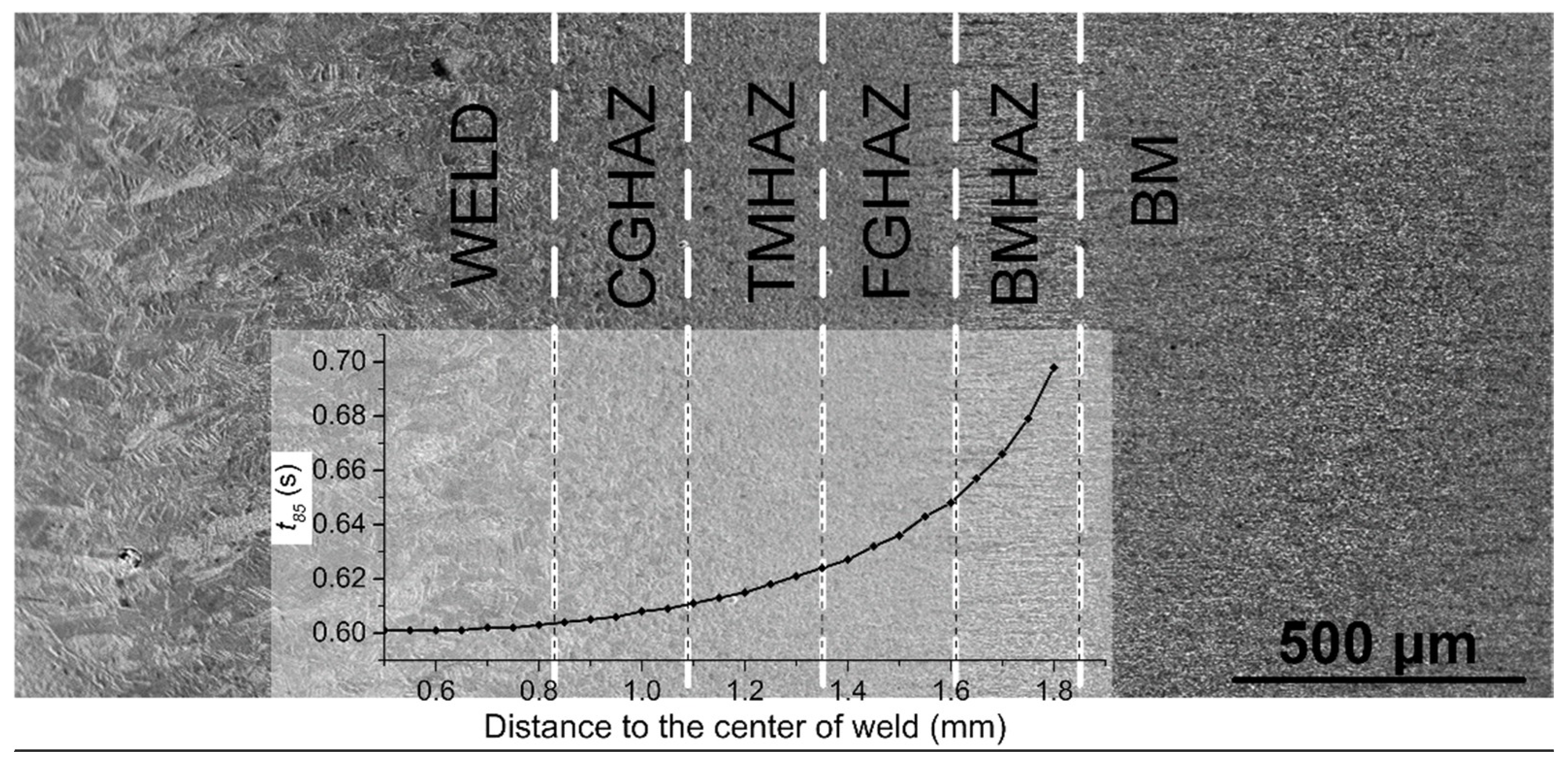

4.2. Microstructure and Quantification of Welded Joints

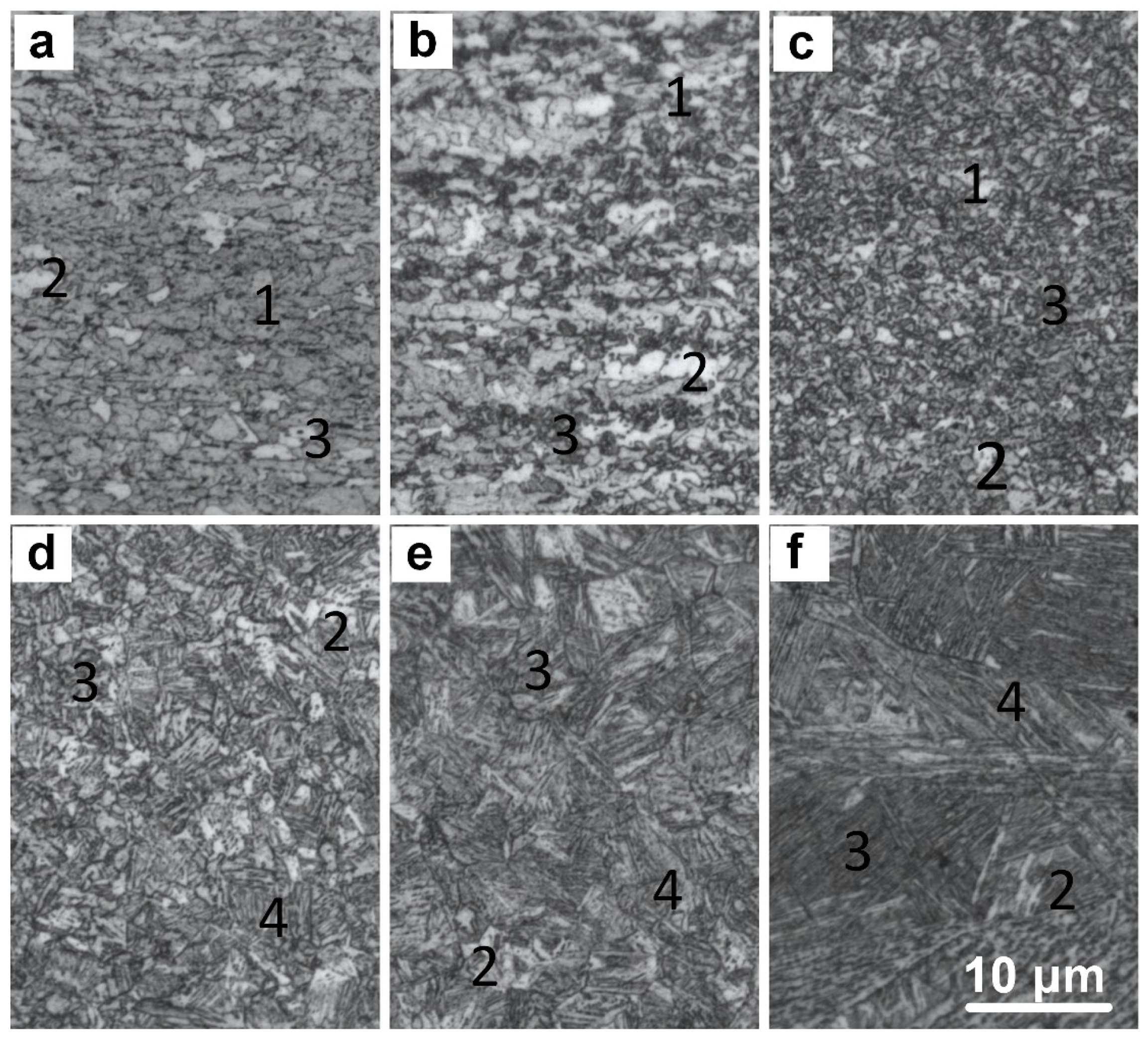

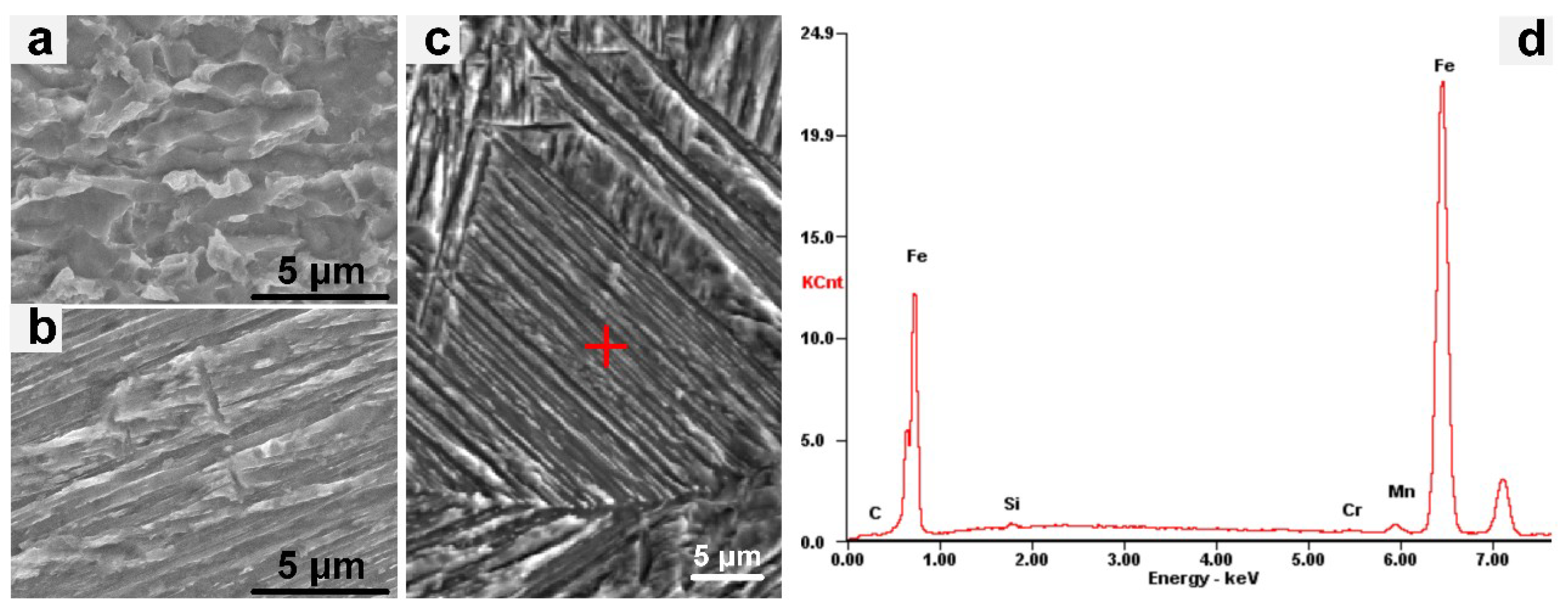

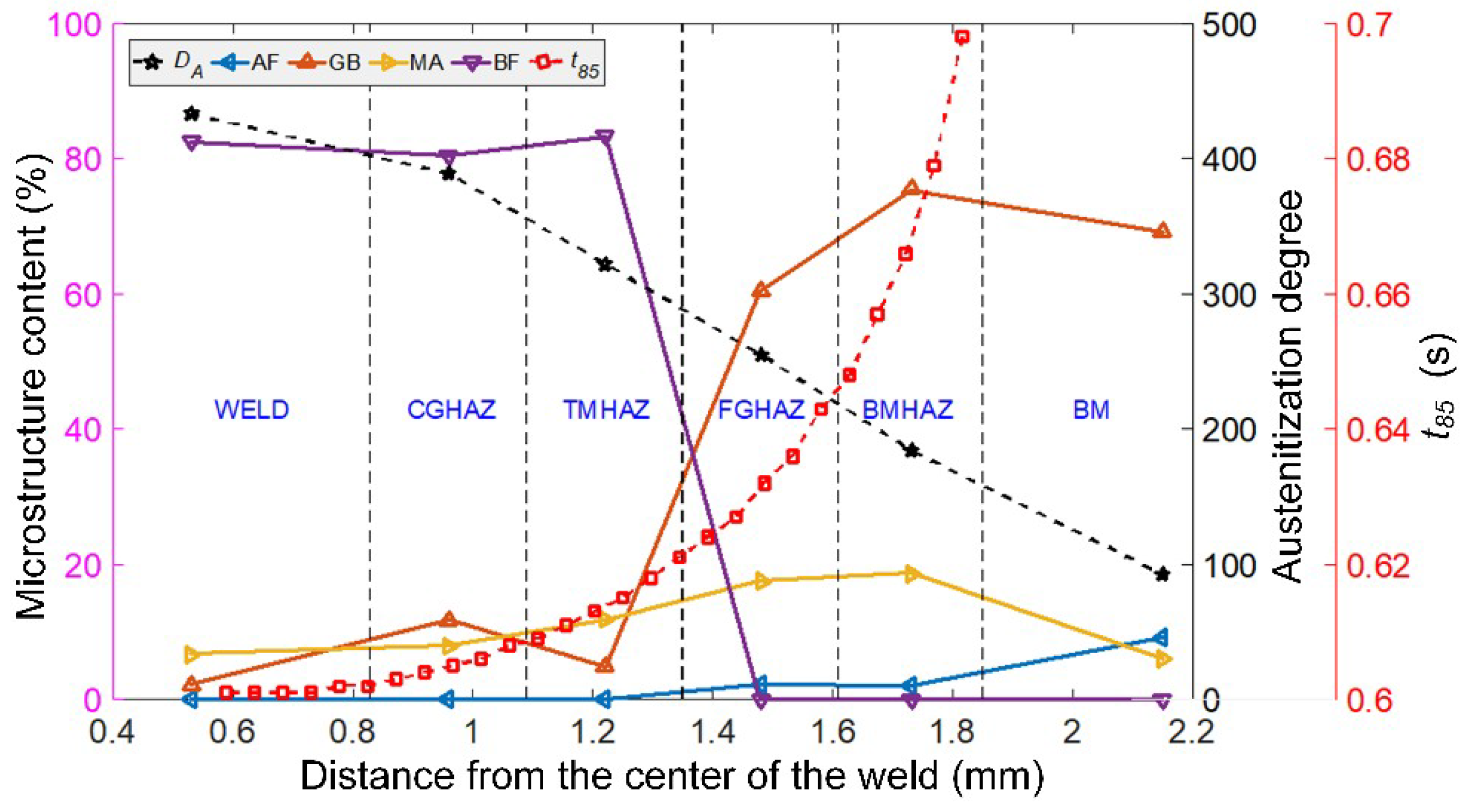

4.3. Quantitative Relationship between Thermal Cycling and the Microstructure

5. Conclusions

- (1)

- Accurate heat-source model parameters are the core of the accurate simulation of temperature fields resulting from the laser-welding process. The Gaussian-distributed rotating body heat-source model presented in this paper accurately simulates the welding temperature field, and the calculation process is stable and reliable.

- (2)

- The final microstructure, which determines the strength and toughness of a laser-welded joint, is determined by the welding thermal cycle process, which affects the austenitization and continuous cooling transformation of the original microstructure of the BM. The degree of austenitization is more significant than the cooling rate.

- (3)

- The degree of austenitization in the microstructures at different positions in welded joints can be expressed by the parameter , which accurately reflects the effects of the heating rate, the peak temperature, and the residence time at high temperature on the original microstructure of the BM in the heated region and in the high-temperature region.

- (4)

- With a decreasing distance from the center of the weld and the upper surface of the weld, the heating rate, the peak temperature, and the residence time at high temperature of the welding heat cycle increase gradually. The austenitization degree and the cooling rate increase significantly, which results in increasing grain sizes for the original austenite. However, the final microstructure has less austenite overall.

- (5)

- The microstructure of the X100 pipeline steel in the HAZ is mainly composed of AF, GB, and BF, with small amounts of lath martensite, upper bainite, and bulk microstructure found in the columnar zone of the weld.

- (6)

- The microstructure gradient of the HAZ of the welded joint of X100 high-grade pipeline steel is mainly affected by the different degrees of austenitization in the BM and in locations where the change in the cooling rate is relatively small. The contribution of the cooling rate to the microstructure transition from FGHAZ to CGHAZ is limited.

- (7)

- Welding the same material under the same austenitization degree and cooling rate yields the same final microstructure and phase proportions, and the strength and toughness properties of the welded joints are the same.

Author Contributions

Funding

Conflicts of Interest

References

- Witek, M. Possibilities of using X80, X100, X120 high-strength steels for onshore gas transmission pipelines. J. Nat. Gas Sci. Eng. 2015, 27, 374–384. [Google Scholar] [CrossRef]

- Pouraliakbar, H.; Jandaghi, M.R. Predictions of toughness and hardness by using chemical composition and tensile properties in microalloyed line pipe steels. Neural Comput. Appl. 2014, 25, 1993–1999. [Google Scholar]

- Shinohara, Y.; Madi, Y.; Besson, J. Anisotropic ductile failure of a high-strength line pipe steel. Int. J. Fract. 2016, 197, 127–145. [Google Scholar] [CrossRef]

- Wang, G.; Yin, L.; Yao, Z.; Wang, J.; Jiang, S.; Zhang, Z.; Zuo, C. The Evolution and Distribution of Microstructures in High-Energy Laser-Welded X100 Pipeline Steel. Materials 2019, 12, 1762. [Google Scholar] [CrossRef] [Green Version]

- Yin, L.; Wang, J.; Chen, X.; Liu, C.; Siddiquee, A.N.; Wang, G.; Yao, Z. Microstructures and their distribution within HAZ of X80 pipeline steel welded using hybrid laser-MIG welding. Weld. World 2018, 62, 721–727. [Google Scholar] [CrossRef]

- Gu, X.; Liu, Y.; Li, W.; Han, Y.; Zheng, K. Physical Characteristics of Coupled Plasma and Its Influence on Weld Formation in Hybrid Laser-Double-Arc Welding. Materials 2019, 12, 4207. [Google Scholar] [CrossRef] [Green Version]

- Pouriamanesh, R.; Dehghani, K.; Vallant, R. Friction stir welding of API X70 steel incorporating Ti-dioxide. Can. Metall. Q. 2019, 58, 69–81. [Google Scholar] [CrossRef]

- Guo, N.; Cheng, Q.; Zhang, X.; Fu, Y.; Huang, L. Microstructure and Mechanical Properties of Underwater Laser Welding of Titanium Alloy. Materials 2019, 12, 2703. [Google Scholar] [CrossRef] [Green Version]

- Xu, G.; Li, P.; Li, L.; Hu, Q.; Zhu, J.; Gu, X.; Du, B. Influence of Arc Power on Keyhole-Induced Porosity in Laser + GMAW Hybrid Welding of Aluminum Alloy: Numerical and Experimental Studies. Materials 2019, 12, 1328. [Google Scholar] [CrossRef] [Green Version]

- Xin, Z.; Yang, Z.; Zhao, H.; Chen, Y. Comparative Study on Welding Characteristics of Laser-CMT and Plasma-CMT Hybrid Welded AA6082-T6 Aluminum Alloy Butt Joints. Materials 2019, 12, 3300. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, X.; Duan, J.A.; Zhang, F.; Zhong, S. The Study on Mechanical Strength of Titanium-Aluminum Dissimilar Butt Joints by Laser Welding-Brazing Process. Materials 2019, 12, 712. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, X.; Lei, Z.; Chen, Y.; Jiang, M.; Tian, Z.; Bi, J.; Lin, S. Microstructure and Mechanical Properties of Laser Welded Al-Si Coated Hot-Press-Forming Steel Joints. Materials 2019, 12, 3294. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Casalino, G.; D’Ostuni, S.; Guglielmi, P.; Leo, P.; Palumbo, G.; Piccininni, A. Off-set and focus effects on grade 5 titanium to 6061 aluminum alloy fiber laser weld. Materials 2018, 11, 448. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Silva Leite, C.G.; da Cruz Junior, E.J.; Lago, M.; Zambon, A.; Calliari, I.; Ventrella, V.A. Nd: YAG Pulsed Laser Dissimilar Welding of UNS S32750 Duplex with 316L Austenitic Stainless Steel. Materials 2019, 12, 2906. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hipp, D.; Mahrle, A.; Beyer, E.; Jäckel, S.; Hertel, M.; Füssel, U. Thermal Efficiency Analysis for Laser-Assisted Plasma Arc Welding of AISI 304 Stainless Steel. Materials 2019, 12, 1460. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, Q.B. Effect of cooling rate on microstructures and mechanical properties of X80 pipeline steel. Adv. Mater. Res. 2012, 12, 535–537. [Google Scholar] [CrossRef]

- Gook, S.; Gumenyuk, A.; Rethmeier, M. Hybrid laser arc welding of X80 and X120 steel grade. Sci. Technol. Weld. Join. 2014, 19, 15–24. [Google Scholar] [CrossRef]

- Grünenwald, S.; Seefeld, T.; Vollertsen, F.; Kocak, M. Solutions for joining pipe steels using laser-GMA-hybrid welding processes. Phys. Proced. 2010, 5, 77–87. [Google Scholar] [CrossRef] [Green Version]

- Lei, Z.; Tan, C.; Chen, Y.; Sun, Z. Microstructure and mechanical properties of fiber laser-metal active gas hybrid weld of X80 pipeline steel. J. Press. Vessel Technol. Trans. ASME 2013, 135, 011403. [Google Scholar]

- Inose, K.; Kanbayashi, J.; Abe, D.; Matsumoto, N.; Nakanishi, Y. Design and welding method for high-strength steel structure using laser-arc hybrid welding. Weld. World 2013, 57, 657–664. [Google Scholar] [CrossRef]

- Costa, A.; Quintino, L.; Yapp, D.; Iordachescu, D. Characterization of fiber laser welds in X100 pipeline steel. Mater. Des. 2009, 30, 2701–2707. [Google Scholar]

- Nafisi, S.; Arafin, M.A.; Collins, L.; Szpunar, J. Texture and mechanical properties of API X100 steel manufactured under various thermomechanical cycles. Mater. Sci. Eng. A 2012, 531, 2–11. [Google Scholar] [CrossRef]

- Shanmugam, N.S.; Buvanashekaran, G.; Sankaranarayanasamy, K.; Kumar, S.R. A transient finite element simulation of the temperature field and bead profile of T-joint laser welds. Int. J. Model. Simul. 2010, 30, 108–122. [Google Scholar] [CrossRef]

- Lan, L.; Chang, Z.; Kong, X.; Qiu, C.; Zhao, D. Phase transformation, microstructure, and mechanical properties of X100 pipeline steels based on TMCP and HTP concepts. J. Mater. Sci. 2017, 52, 1661–1678. [Google Scholar] [CrossRef]

- Wu, H.D.; Miyamoto, G.; Yang, Z.G.; Zhang, C.; Chen, H.; Furuhara, T. Incomplete bainite transformation in Fe-Si-C alloys. Acta Mater. 2017, 133, 1–9. [Google Scholar] [CrossRef]

- You, Y.; Shang, C.; Nie, W.; Subramanian, S. Investigation on the microstructure and toughness of coarse grained heat affected zone in X-100 multi-phase pipeline steel with high Nb content. Mater. Sci. Eng. A 2012, 558, 692–701. [Google Scholar] [CrossRef]

- Lan, L.; Qiu, C.; Zhao, D.; Gao, X.; Du, L. Analysis of martensite–austenite constituent and its effect on toughness in submerged arc welded joint of low carbon bainitic steel. J. Mater. Sci. 2012, 47, 4732–4742. [Google Scholar] [CrossRef]

- Furuhara, T.; Chiba, T.; Kaneshita, T.; Wu, H.; Miyamoto, G. Crystallography and interphase boundary of martensite and bainite in steels. Metall. Mater. Trans. A 2017, 48, 2739–2752. [Google Scholar] [CrossRef]

- Moore, P.L.; Howse, D.S.; Wallach, E.R. Microstructures and properties of laser/arc hybrid welds and autogenous laser welds in pipeline steels. Sci. Technol. Weld. Join. 2004, 9, 314–322. [Google Scholar] [CrossRef]

- Silva, R.D.A.; Souza, L.F.G.D.; Morales, E.V.; Rios, P.R.; Bott, I.D.S.; Silva, R.D.A. Formation of microphases and constituents from remaining austenite decomposition in API X80 steel under different processing conditions. Mat. Res. 2015, 18, 908–917. [Google Scholar] [CrossRef] [Green Version]

- Cho, W.I.; Na, S.J.; Thomy, C.; Vollertsen, F. Numerical simulation of molten pool dynamics in high power disk laser welding. J. Mater. Process. Technol. 2012, 212, 262–275. [Google Scholar] [CrossRef]

- Di, X.J.; Cai, L.; Xing, X.X.; Chen, C.X.; Xue, Z.K. Microstructure and mechanical properties of intercritical heat-affected zone of X80 pipeline steel in simulated in-service welding. Acta Metall. Sin. (Engl. Lett.) 2015, 28, 883–891. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.; Lei, Y.; Shi, Y. Numerical simulation of transient temperature field during laser keyhole welding of 304 stainless steel sheet. Opt. Laser Technol. 2011, 43, 870–873. [Google Scholar] [CrossRef]

- Abderrazak, K.; Bannour, S.; Mhiri, H.; Lepalec, G.; Autric, M. Numerical and experimental study of molten pool formation during continuous laser welding of AZ91 magnesium alloy. Comput. Mater. Sci. 2009, 44, 858–866. [Google Scholar] [CrossRef]

- Kubiak, M.; Piekarska, W.; Stano, S. Modelling of laser beam heat source based on experimental research of Yb:YAG laser power distribution. Int. J. Heat Mass Transf. 2015, 83, 679–689. [Google Scholar] [CrossRef]

- Kazemi, K.; Goldak, J.A. Numerical simulation of laser full penetration welding. Comput. Mater. Sci. 2009, 44, 841–849. [Google Scholar] [CrossRef]

- Zain-Ul-Abdein, M.; Nelias, D.; Jullien, J.F.; Deloison, D. Prediction of laser beam welding-induced distortions and residual stresses by numerical simulation for aeronautic application. J. Mater. Process. Technol. 2009, 209, 2907–2917. [Google Scholar] [CrossRef]

- Zain-Ul-Abdein, M.; Nélias, D.; Jullien, J.F.; Boitout, F.; Dischert, L.; Noe, X. Finite element analysis of metallurgical phase transformations in AA 6056-T4 and their effects upon the residual stress and distortion states of a laser welded T-joint. Int. J. Press. Vessel. Pip. 2011, 88, 45–56. [Google Scholar] [CrossRef]

- Luo, Y.; You, G.; Ye, H.; Liu, J. Simulation on welding thermal effect of AZ61 magnesium alloy based on three-dimensional modeling of vacuum electron beam welding heat source. Vacuum 2010, 84, 890–895. [Google Scholar] [CrossRef]

- Shanmugam, N.S.; Buvanashekaran, G.; Sankaranarayanasamy, K. Some studies on weld bead geometries for laser spot welding process using finite element analysis. Mater. Des. 2012, 34, 412–426. [Google Scholar] [CrossRef]

- Zain-Ul-Abdein, M.; Nélias, D.; Jullien, J.F.; Deloison, D. Experimental investigation and finite element simulation of laser beam welding induced residual stresses and distortions in thin sheets of AA 6056-T4. Mater. Sci. Eng. A 2010, 527, 3025–3039. [Google Scholar] [CrossRef]

- Tsirkas, S.A.; Papanikos, P.; Kermanidis, T. Numerical simulation of the laser welding process in butt-joint specimens. J. Mater. Process. Technol. 2003, 134, 59–69. [Google Scholar] [CrossRef]

- Xia, Y.; Miyamoto, G.; Yang, Z.G.; Zhang, C.; Furuhara, T. Direct measurement of carbon enrichment in the incomplete bainite transformation in Mo added low carbon steels. Acta Mater. 2015, 91, 10–18. [Google Scholar] [CrossRef]

- Chen, X.W.; Qiao, G.Y.; Han, X.L.; Wang, X.; Xiao, F.R.; Liao, B. Effects of Mo, Cr and Nb on microstructure and mechanical properties of heat affected zone for Nb-bearing X80 pipeline steels. Mater. Des. 2014, 53, 888–901. [Google Scholar] [CrossRef]

- Ivanov, A.Y.; Sulyagin, R.V.; Orlov, V.V.; Kruglova, A.A. Formation of structure in the heat-affected zone and properties of welded joints of pipe steels of strength classes X80 and X90. Met. Sci. Heat Treat. 2012, 53, 560–566. [Google Scholar] [CrossRef]

- Isasti, N.; Jorge-Badiola, D.; Taheri, M.L.; Uranga, P. Phase transformation study in Nb-Mo microalloyed steels using dilatometry and EBSD quantification. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2013, 44, 3552–3563. [Google Scholar] [CrossRef]

- Gianetto, J.A.; Fazeli, F.; Chen, Y.; Shalchi-Amirkhiz, B.; Smith, T. Microstructure and toughness of simulated grain coarsened heat affected zones in X80 pipe steels. In Proceedings of the 10th International Pipeline Conference American Society of Mechanical Engineers, New York, NY, USA, 29 September–3 October 2014. [Google Scholar]

- Yang, J.H.; Liu, Q.Y.; Sun, D.B.; Li, X.Y. Microstructure and transformation characteristics of acicular ferrite in high niobium-bearing microalloyed steel. J. Iron Steel Res. Int. 2010, 17, 53–59. [Google Scholar] [CrossRef]

| AL | C | CO | CR | CU | FE | MN | MO | N | NB | NI | P | SI | TI | V |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.012 | 0.064 | 0.003 | 0.023 | 0.28 | 96.90 | 1.87 | 0.003 | 0.017 | 0.017 | 0.47 | 0.009 | 0.099 | 0.017 | 0.002 |

| Material (mm) | Laser Power (kw) | Welding Speed (m/s) | Amount of Defocusing (mm) | Frontal Protective Gas Flow (L/min) | Back Protective Gas Flow (L/min) |

|---|---|---|---|---|---|

| X100 (12.8) | 10 | 0.035 | −4 | 15 | 25 |

| 8 | 0.035 | −4 | 15 | 25 |

| Temperature (K) | 293 | 373 | 473 | 673 | 873 | 1073 | 1273 | 1473 | 1773 |

| Density (kg/m3) | 7810 | 7790 | 7770 | 7720 | 7650 | 7610 | 7560 | 7500 | 7500 |

| Thermal Conductivity [W/(m·K)] | 54.42 | 54.01 | 52.75 | 52.75 | 34.67 | 27.55 | 23.18 | 21.54 | 21.54 |

| Specific Heat [J/(kg·K)] | 423 | 493 | 536 | 662 | 827 | 614 | 565 | 516 | 516 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Wang, J.; Yin, L.; Hu, H.; Yao, Z. Quantitative Correlation between Thermal Cycling and the Microstructures of X100 Pipeline Steel Laser-Welded Joints. Materials 2020, 13, 121. https://doi.org/10.3390/ma13010121

Wang G, Wang J, Yin L, Hu H, Yao Z. Quantitative Correlation between Thermal Cycling and the Microstructures of X100 Pipeline Steel Laser-Welded Joints. Materials. 2020; 13(1):121. https://doi.org/10.3390/ma13010121

Chicago/Turabian StyleWang, Gang, Jinzhao Wang, Limeng Yin, Huiqin Hu, and Zongxiang Yao. 2020. "Quantitative Correlation between Thermal Cycling and the Microstructures of X100 Pipeline Steel Laser-Welded Joints" Materials 13, no. 1: 121. https://doi.org/10.3390/ma13010121