Resistive Switching Characteristics of Li-Doped ZnO Thin Films Based on Magnetron Sputtering

Abstract

:1. Introduction

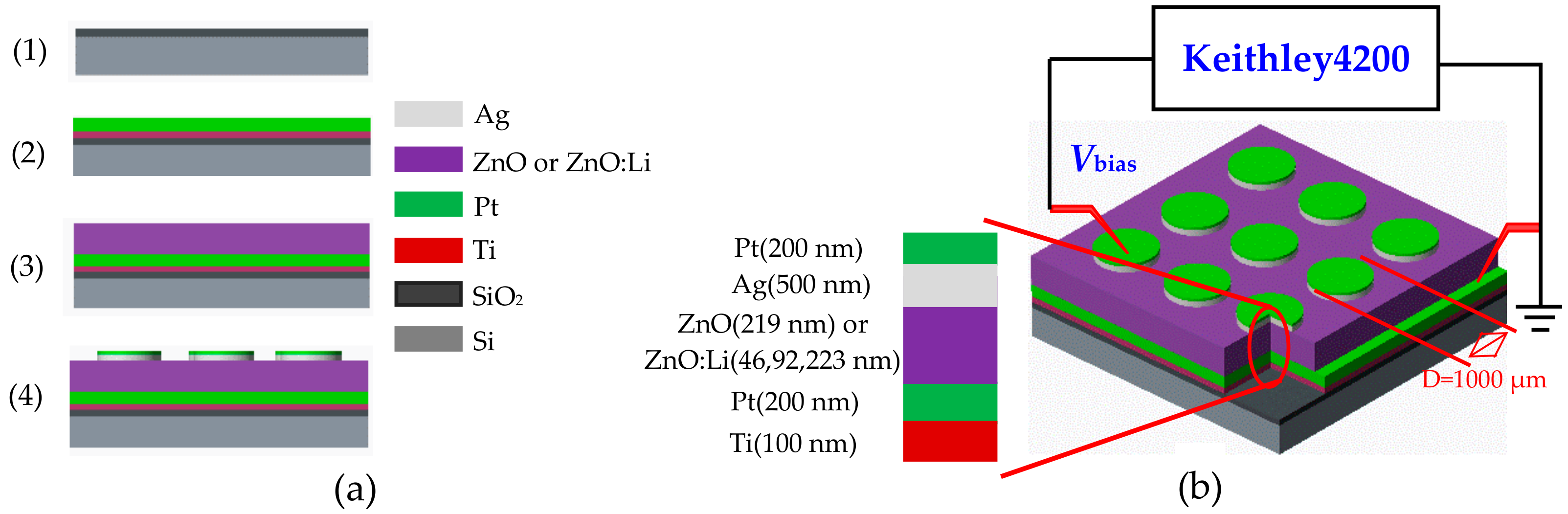

2. Experimental Details

2.1. Materials and Method

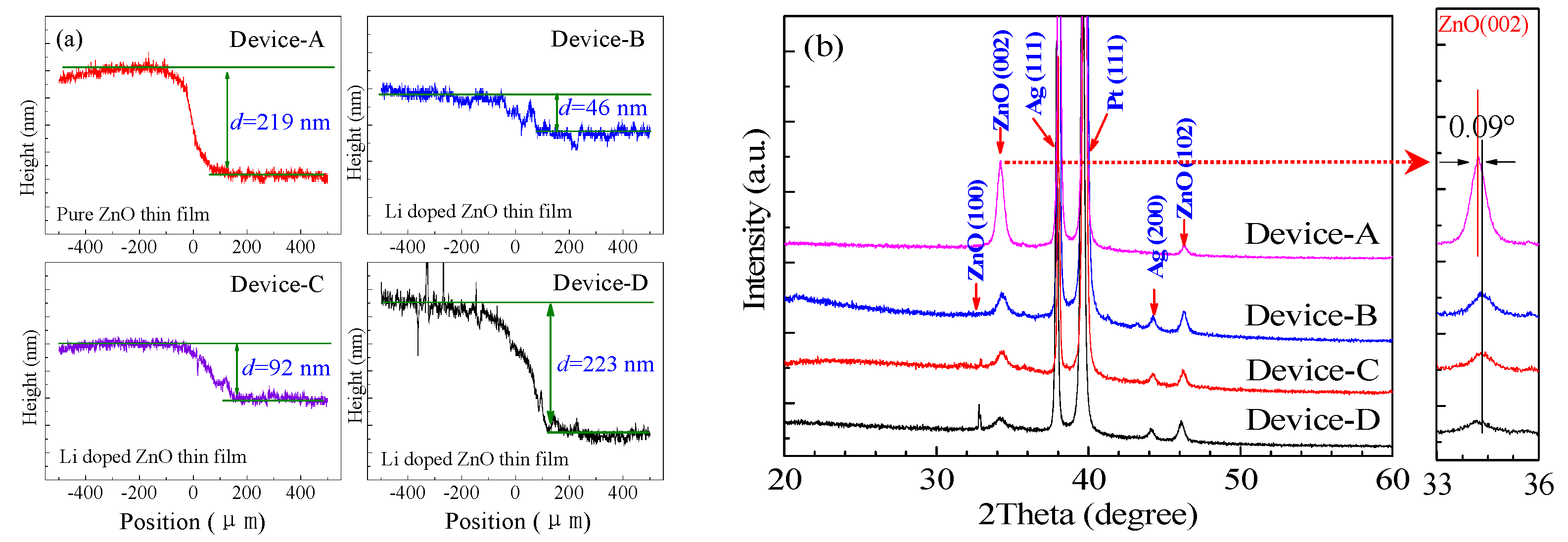

2.2. Analysis of ZnO Thin Films

3. Results and Discussion

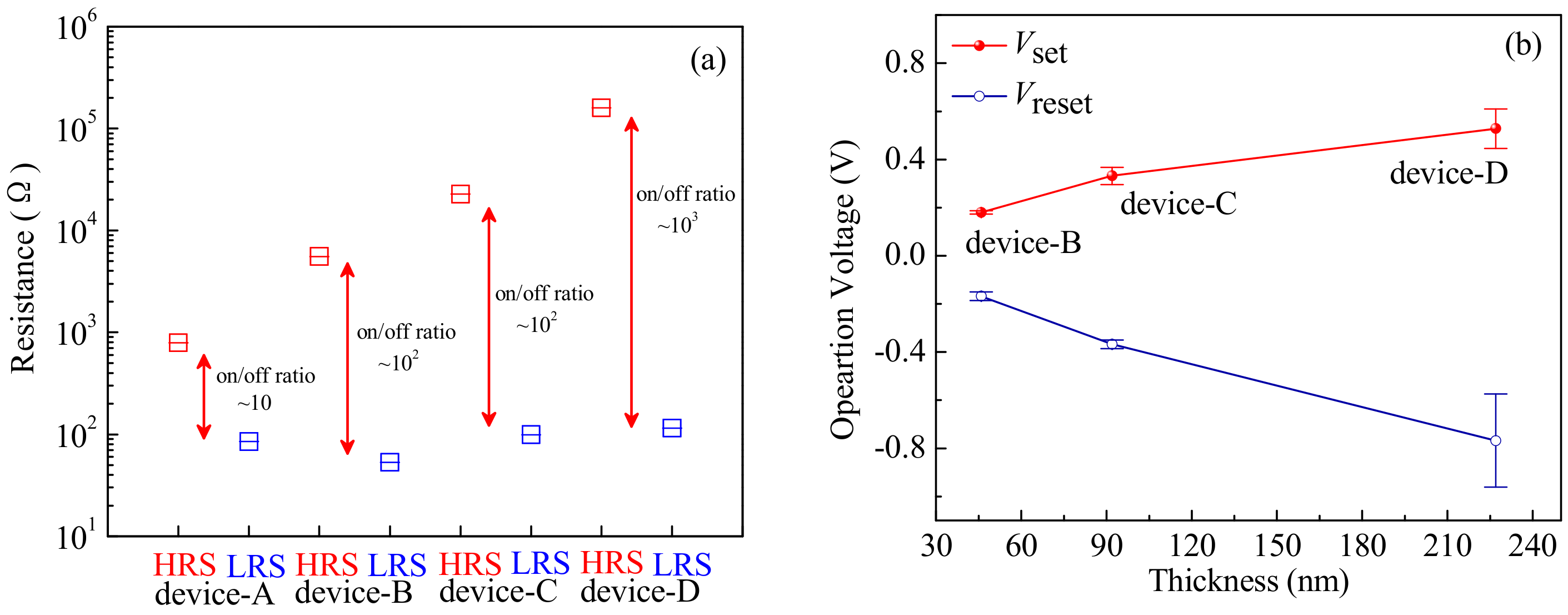

3.1. Resistive Switching Behavior under Direct Current Voltage

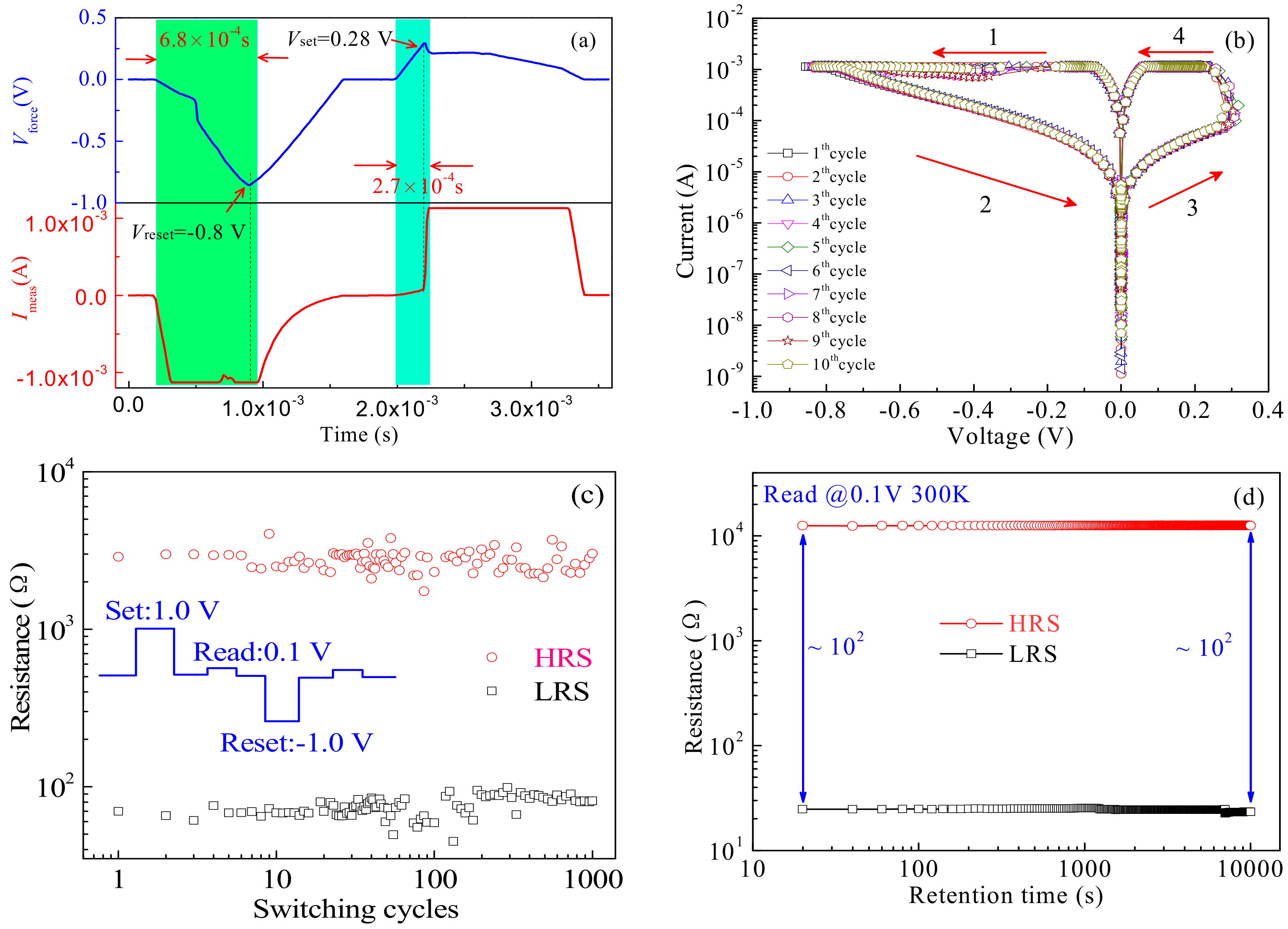

3.2. Resistive Switching Performance under Pulse Voltage

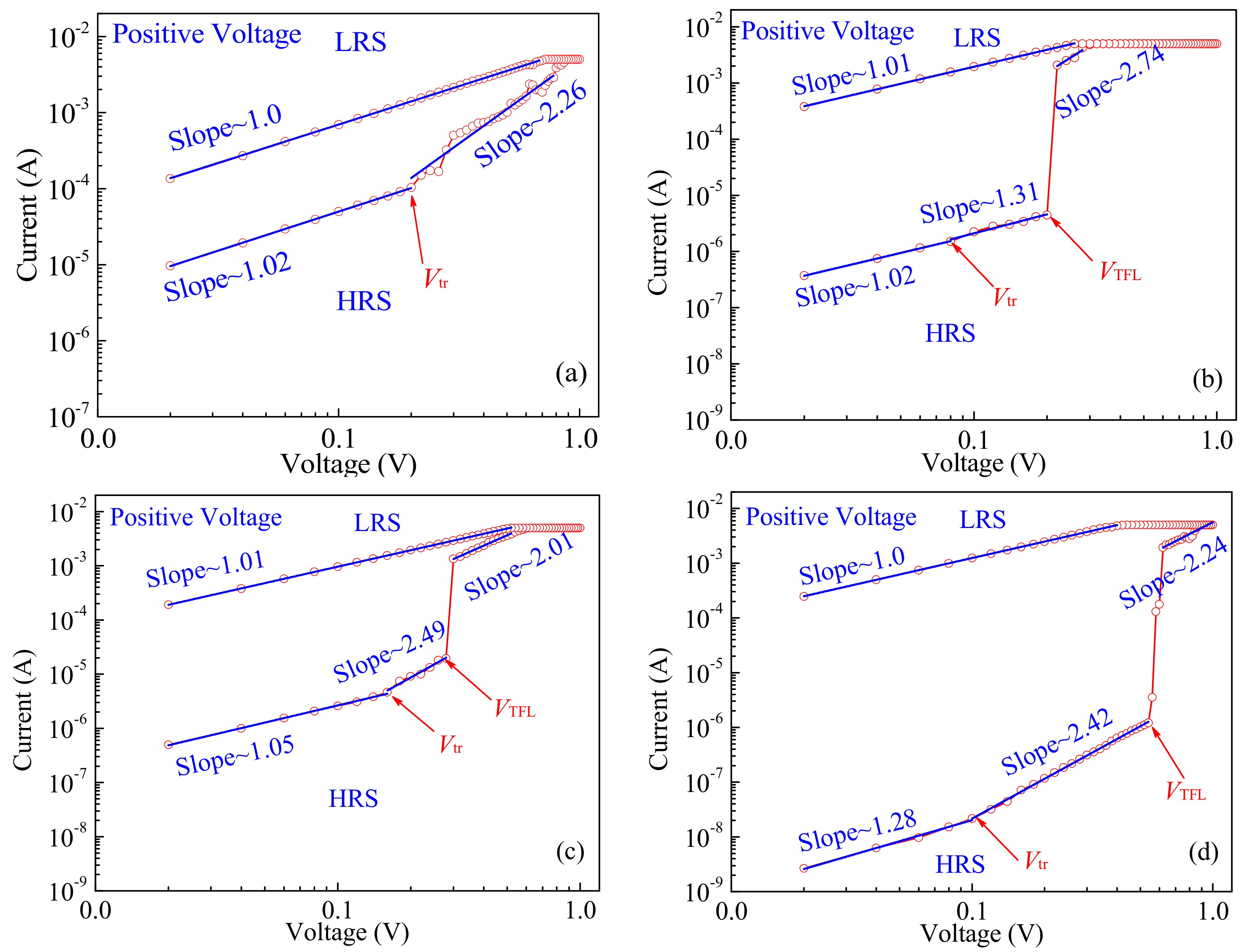

3.3. Mechanism Analysis of Resistive Switching

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Chen, A. A review of emerging non-volatile memory (NVM) technologies and applications. Solid-State Electron. 2016, 125, 25–38. [Google Scholar] [CrossRef]

- Shih, C.-C.; Chen, W.-J.; Chang, K.-C.; Chang, T.-C.; Tsai, T.-M.; Chu, T.-J.; Tseng, Y.-T.; Wu, C.-H.; Su, W.-C.; Chen, M.-C.; et al. Ultra-Low Switching Voltage Induced by Inserting SiO2 Layer in Indium-Tin-Oxide-Based Resistance Random Access Memory. IEEE Electron. Device Lett. 2016, 37, 1276–1279. [Google Scholar] [CrossRef]

- Fan, Y.-S.; Liu, P.-T.; Hsu, C.-H. Investigation on amorphous InGaZnO based resistive switching memory with low-power, high-speed, high reliability. Thin Solid Films 2013, 549, 54–58. [Google Scholar] [CrossRef]

- Zackriya, M.; Kittur, H.M.; Chin, A. A novel read scheme for large size one-resistor resistive random access memory array. Sci. Rep. 2017, 7, 42375. [Google Scholar] [CrossRef]

- Hao, A.; He, S.; Qin, N.; Chen, R.; Bao, D. Ce-doping induced enhancement of resistive switching performance of Pt/NiFe2O4/Pt memory devices. Ceram. Int. 2017, 43, S481–S487. [Google Scholar] [CrossRef]

- Goossens, A.S.; Das, A.; Banerjee, T. Electric field driven memristive behavior at the Schottky interface of Nb-doped SrTiO3. J. Appl. Phys. 2018, 124, 152102. [Google Scholar] [CrossRef]

- Song, X.; Kong, L.; Du, H.; Li, X.; Feng, H.; Zhao, J.; Xie, Y. Effects of Pyrazine Derivatives and Substituted Positions on the Photoelectric Properties and Electromemory Performance of D-A-D Series Compounds. Materials 2018, 11, 2063. [Google Scholar] [CrossRef]

- Guo, J.; Kang, X.; Gao, Y.; Chen, W.; Zhao, X. Enhanced magnetic modulation in HfO2-based resistive memory with an Hf top electrode. Appl. Phys. Lett. 2018, 113, 043502. [Google Scholar] [CrossRef]

- Lin, C.-C.; Liao, J.-W.; Li, W.-Y. Resistive switching properties of TiO2 film for flexible non-volatile memory applications. Ceram. Int. 2013, 39, S733–S737. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Simanjuntak, F.M.; Tseng, T.-Y. Controlled resistive switching characteristics of ZrO2-based electrochemical metallization memory devices by modifying the thickness of the metal barrier layer. Jpn. J. Appl. Phys. 2018, 57, 04FE10. [Google Scholar] [CrossRef]

- Wong, H.S.P.; Lee, H.-Y.; Yu, S.; Chen, Y.-S.; Wu, Y.; Chen, P.-S.; Lee, B.; Chen, F.T.; Tsai, M.-J. Metal-oxide RRAM. Proc. IEEE 2012, 100, 1951–1970. [Google Scholar] [CrossRef]

- Du, G.; Wang, C.; Li, H.; Mao, Q.; Ji, Z. Bidirectional threshold switching characteristics in Ag/ZrO2/Pt electrochemical metallization cells. AIP Adv. 2016, 6, 085316. [Google Scholar] [CrossRef]

- Du, Y.; Kumar, A.; Pan, H.; Zeng, K.; Wang, S.; Yang, P.; Wee, A.T.S. The resistive switching in TiO2 films studied by conductive atomic force microscopy and Kelvin probe force microscopy. AIP Adv. 2013, 3, 082107. [Google Scholar] [CrossRef]

- Ma, G.; Tang, X.; Su, H.; Zhang, H.; Li, J.; Zhong, Z. Effects of electrode materials on bipolar and unipolar switching in NiO resistive switching device. Microelectron. Eng. 2014, 129, 17–20. [Google Scholar] [CrossRef]

- Tao, Y.; Ding, W.; Wang, Z.; Xu, H.; Zhao, X.; Li, X.; Liu, W.; Ma, J.; Liu, Y. Improved switching reliability achieved in HfOx based RRAM with mountain-like surface-graphited carbon layer. Appl. Surf. Sci. 2018, 440, 107–112. [Google Scholar] [CrossRef]

- Wu, C.C.; You, H.C.; Lin, Y.H.; Yang, C.J.; Hsiao, Y.P.; Liao, T.P.; Yang, W.L. Impact of electrode surface morphology in ZnO-based resistive random access memory fabricated using the Cu chemical displacement technique. Materials 2018, 11, 265. [Google Scholar] [CrossRef] [PubMed]

- Simanjuntak, F.M.; Panda, D.; Wei, K.H.; Tseng, T.Y. Status and Prospects of ZnO-Based Resistive Switching Memory Devices. Nanoscale Res. Lett. 2016, 11, 368. [Google Scholar] [CrossRef] [PubMed]

- Chang, W.-Y.; Lai, Y.-C.; Wu, T.-B.; Wang, S.-F.; Chen, F.; Tsai, M.-J. Unipolar resistive switching characteristics of ZnO thin films for nonvolatile memory applications. Appl. Phys. Lett. 2008, 92, 022110. [Google Scholar] [CrossRef]

- Wang, X.; Qian, H.; Guan, L.; Wang, W.; Xing, B.; Yan, X.; Zhang, S.; Sha, J.; Wang, Y. Influence of metal electrode on the performance of ZnO based resistance switching memories. J. Appl. Phys. 2017, 122, 154301. [Google Scholar] [CrossRef]

- Xu, D.L.; Xiong, Y.; Tang, M.H.; Zeng, B.W.; Li, J.Q.; Liu, L.; Li, L.Q.; Yan, S.A.; Tang, Z.H. Bipolar resistive switching behaviors in Cr-doped ZnO films. Microelectron. Eng. 2014, 116, 22–25. [Google Scholar] [CrossRef]

- Bhattacharjee, R.; Hung, I.M. Effect of different concentration Li-doping on the morphology, defect and photovoltaic performance of Li-ZnO nanofibers in the dye-sensitized solar cells. Mater. Chem. Phys. 2014, 143, 693–701. [Google Scholar] [CrossRef]

- Zeng, Y.J.; Ye, Z.Z.; Xu, W.Z.; Li, D.Y.; Lu, J.G.; Zhu, L.P.; Zhao, B.H. Dopant source choice for formation of p-type ZnO: Li acceptor. Appl. Phys. Lett. 2006, 88, 062107. [Google Scholar] [CrossRef]

- Kafadaryan, Y.; Igityan, A.; Aghamalyan, N.; Petrosyan, S.; Gambaryan, I.; Vardanyan, V.; Semerjian, H.; Hovsepyan, R.; Badalyan, G. Bipolar resistance switching characteristics of Ag/ZnO:Li/SnO2:F device on glass. Thin Solid Films 2016, 616, 815–819. [Google Scholar] [CrossRef]

- Igityan, A.S.; Aghamalyan, N.R.; Petrosyan, S.I.; Kafadaryan, Y.A. Memristive effect in two-layered structures based on lithium doped ZnO films. J. Contemp. Phys. (Armen. Acad. Sci.) 2018, 53, 58–64. [Google Scholar] [CrossRef]

- Guo, W.; Yang, C.; Zhao, Z.; Xin, X.; Tian, Z.; Peng, K.; Lai, Y. MOFs derived Ag/ZnO nanocomposites anode for Zn/Ni batteries. J. Solid State Chem. 2019, 272, 27–31. [Google Scholar] [CrossRef]

- Song, M.; Liu, Y.; Yu, A.; Zhang, Y.; Zhai, J.; Wang, Z.L. Flexible Li-doped ZnO piezotronic transistor array for in-plane strain mapping. Nano Energy 2019, 55, 341–347. [Google Scholar] [CrossRef]

- Manzhi, P.; Alam, M.B.; Kumari, R.; Krishna, R.; Singh, R.K.; Srivastava, R.; Sinha, O.P. Li-doped ZnO nanostructures for the organic light emitting diode application. Vacuum 2017, 146, 462–467. [Google Scholar] [CrossRef]

- Simanjuntak, F.M.; Singh, P.; Chandrasekaran, S.; Lumbantoruan, F.J.; Yang, C.-C.; Huang, C.-J.; Lin, C.-C.; Tseng, T.-Y. Role of nanorods insertion layer in ZnO-based electrochemical metallization memory cell. Semicond. Sci. Technol. 2017, 32, 124003. [Google Scholar] [CrossRef]

- Kabongo, G.L.; Mhlongo, G.H.; Mothudi, B.M.; Hillie, K.T.; Mbule, P.S.; Dhlamini, M.S. Structural, photoluminescence and XPS properties of Tm3+ ions in ZnO nanostructures. J. Lumin. 2017, 187, 141–153. [Google Scholar] [CrossRef]

- Baek, S.; Song, J.; Lim, S. Improvement of the optical properties of ZnO nanorods by Fe doping. Phys. B Condens. Matter 2007, 399, 101–104. [Google Scholar] [CrossRef]

- Hsieh, P.T.; Chen, Y.C.; Kao, K.S.; Wang, C.M. Luminescence mechanism of ZnO thin film investigated by XPS measurement. Appl. Phys. A 2007, 90, 317–321. [Google Scholar] [CrossRef]

- Lin, C.-C.; Tseng, Z.-L.; Lo, K.-Y.; Huang, C.-Y.; Hong, C.-S.; Chu, S.-Y.; Chang, C.-C.; Wu, C.-J. Unipolar resistive switching behavior of Pt/LixZn1−xO/Pt resistive random access memory devices controlled by various defect types. Appl. Phys. Lett. 2012, 101, 203501. [Google Scholar] [CrossRef]

- Bagheri, N.; Ara, M.H.M.; Ghazyani, N. Characterization and doping effects study of high hole concentration Li-doped ZnO thin film prepared by sol–gel method. J. Mater. Sci. Mater. Electron. 2015, 27, 1293–1298. [Google Scholar] [CrossRef]

- Yan, Y.; Mi, W.; Zhao, J.; Yang, Z.; Zhang, K.; Luan, C. Study of the metal-semiconductor contact to ZnO films. Vacuum 2018, 155, 210–213. [Google Scholar] [CrossRef]

- Simanjuntak, F.M.; Chandrasekaran, S.; Lin, C.-C.; Tseng, T.-Y. Switching failure mechanism in zinc peroxide-based programmable metallization cell. Nanoscale Res. Lett. 2018, 13, 327. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Zhang, H.; Krylyuk, S.; Milligan, C.A.; Zhu, Y.; Zemlyanov, D.Y.; Bendersky, L.A.; Burton, B.P.; Davydov, A.V.; Appenzeller, J. Electric-field induced structural transition in vertical MoTe2-and Mo1-xWxTe2-based resistive memories. Nat. Mater. 2019, 18, 55–61. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Gao, P.; Gaba, S.; Chang, T.; Pan, X.; Lu, W. Observation of conducting filament growth in nanoscale resistive memories. Nat. Commun. 2012, 3, 732. [Google Scholar] [CrossRef] [PubMed]

- Chandrasekaran, S.; Simanjuntak, F.M.; Aluguri, R.; Tseng, T.-Y. The impact of TiW barrier layer thickness dependent transition from electro-chemical metallization memory to valence change memory in ZrO2-based resistive switching random access memory devices. Thin Solid Films 2018, 660, 777–781. [Google Scholar] [CrossRef]

- Shi, T.; Yang, R.; Guo, X. Coexistence of analog and digital resistive switching in BiFeO3-based memristive devices. Solid State Ion. 2016, 296, 114–119. [Google Scholar] [CrossRef]

- Zhu, Y.B.; Zheng, K.; Wu, X.; Ang, L.K. Enhanced stability of filament-type resistive switching by interface engineering. Sci. Rep. 2017, 7, 43664. [Google Scholar] [CrossRef]

- Kadhim, M.S.; Yang, F.; Sun, B.; Wang, Y.; Guo, T.; Jia, Y.; Yuan, L.; Yu, Y.; Zhao, Y. A resistive switching memory device with a negative differential resistance at room temperature. Appl. Phys. Lett. 2018, 113, 053502. [Google Scholar] [CrossRef]

- Huang, Y.; Shen, Z.; Wu, Y.; Wang, X.; Zhang, S.; Shi, X.; Zeng, H. Amorphous ZnO based resistive random access memory. RSC Adv. 2016, 6, 17867–17872. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Li, Y.; Ai, C.; Wen, D. Resistive Switching Characteristics of Li-Doped ZnO Thin Films Based on Magnetron Sputtering. Materials 2019, 12, 1282. https://doi.org/10.3390/ma12081282

Zhao X, Li Y, Ai C, Wen D. Resistive Switching Characteristics of Li-Doped ZnO Thin Films Based on Magnetron Sputtering. Materials. 2019; 12(8):1282. https://doi.org/10.3390/ma12081282

Chicago/Turabian StyleZhao, Xiaofeng, Yi Li, Chunpeng Ai, and Dianzhong Wen. 2019. "Resistive Switching Characteristics of Li-Doped ZnO Thin Films Based on Magnetron Sputtering" Materials 12, no. 8: 1282. https://doi.org/10.3390/ma12081282