Damage from Coexistence of Ferroelectric and Antiferroelectric Domains and Clustering of O Vacancies in PZT: An Elastic and Raman Study

Abstract

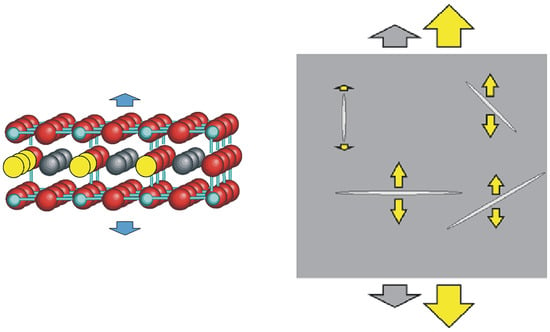

1. Introduction

2. Results

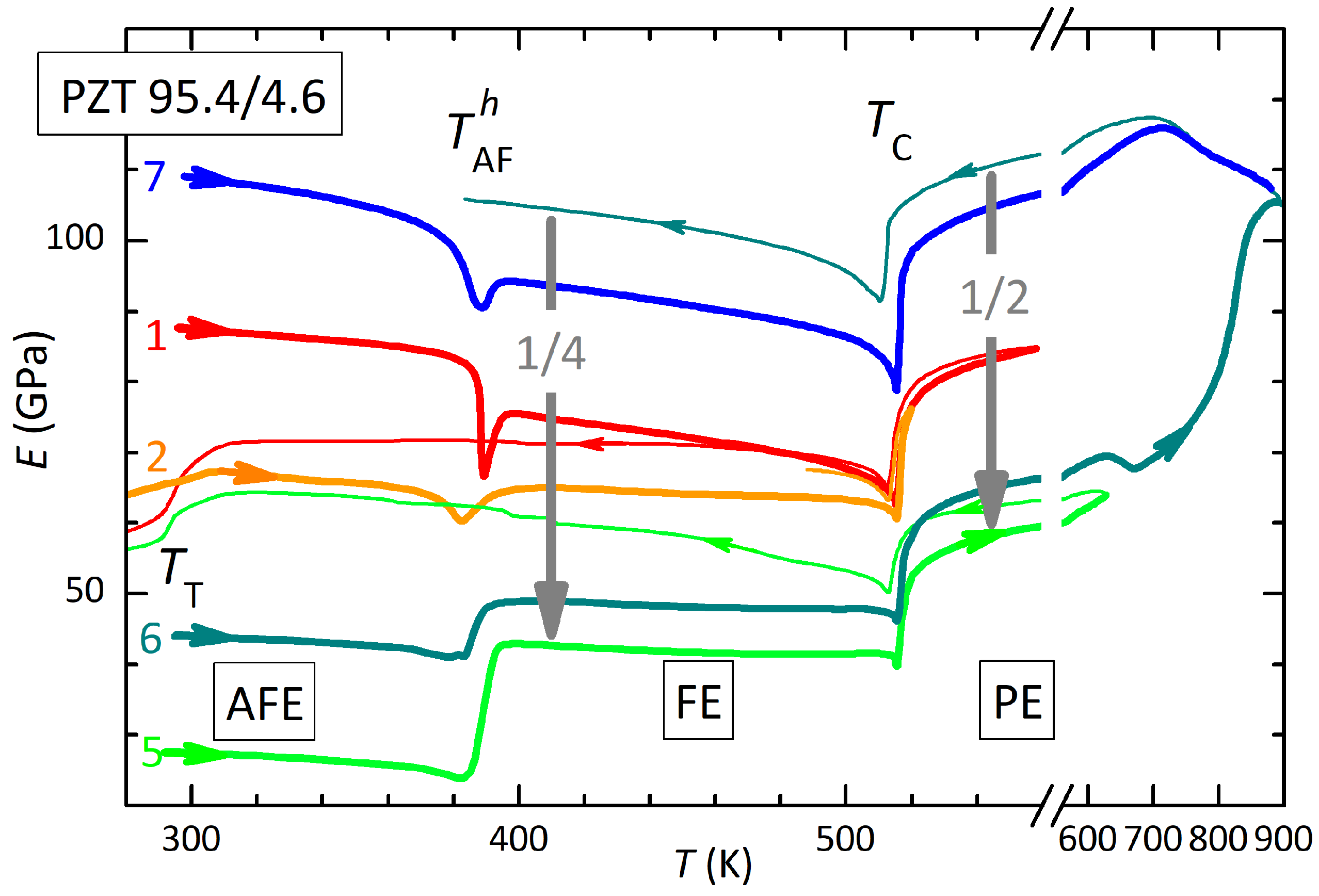

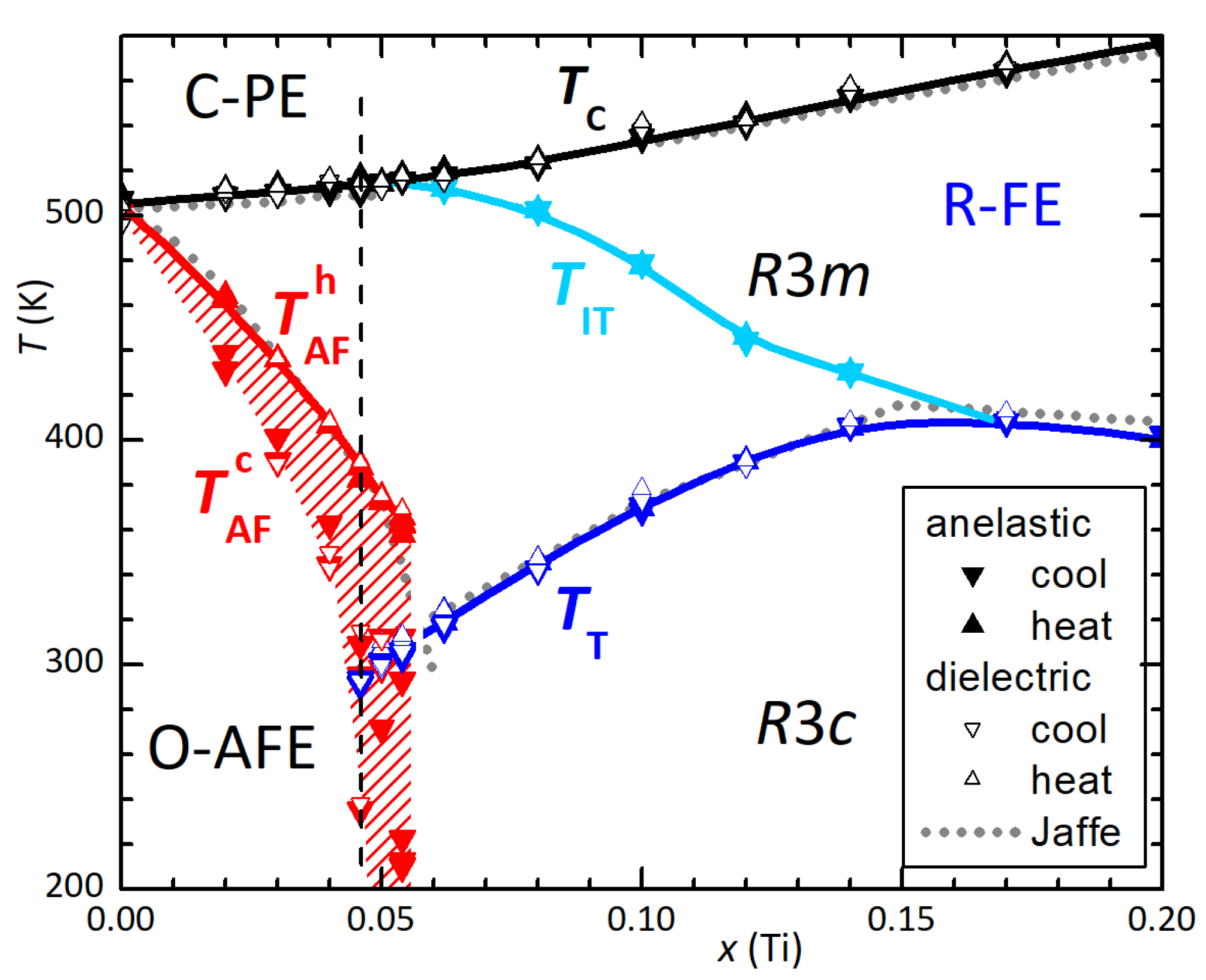

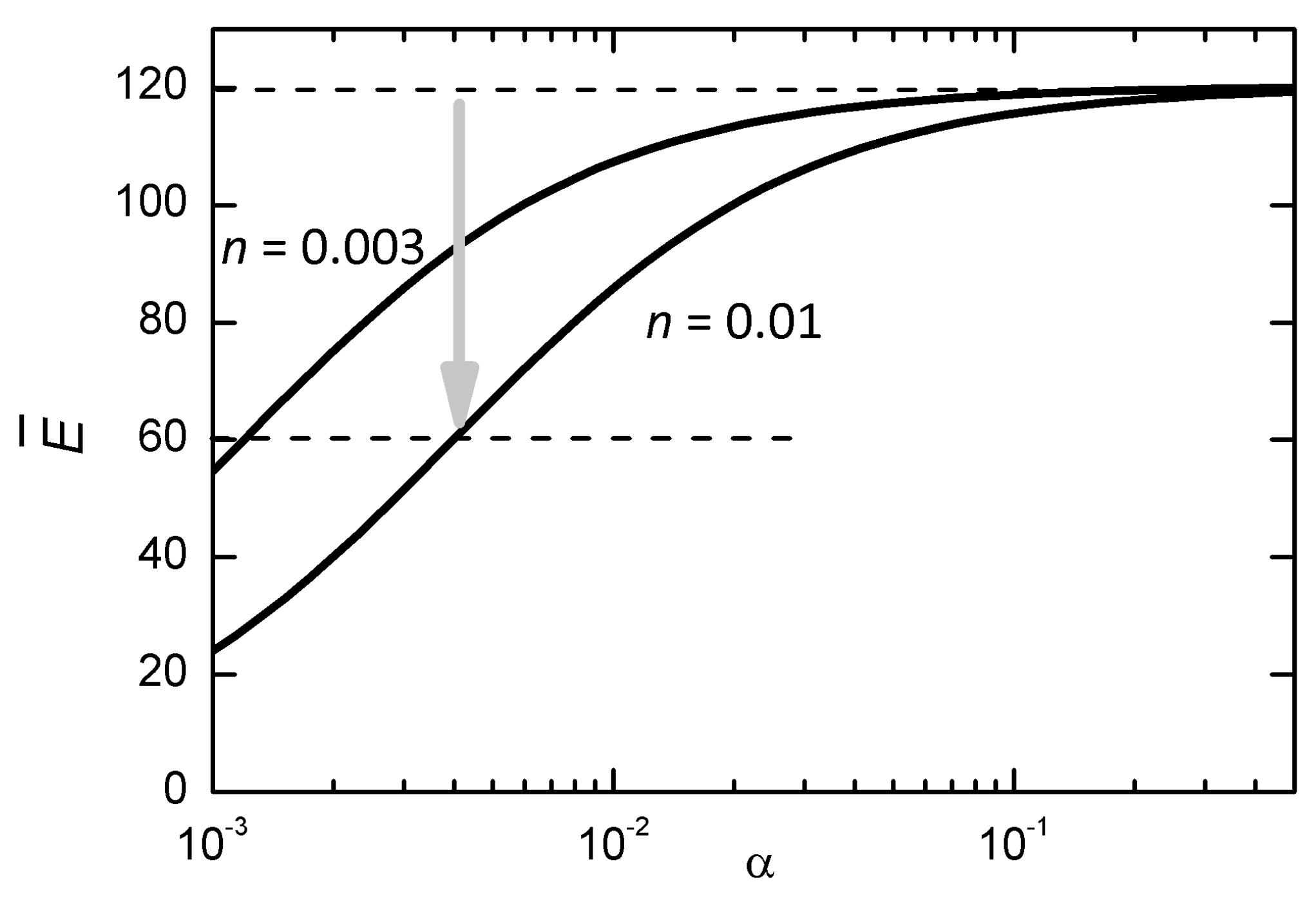

2.1. Evolution of the Elastic Modulus

2.2. Raman Spectra

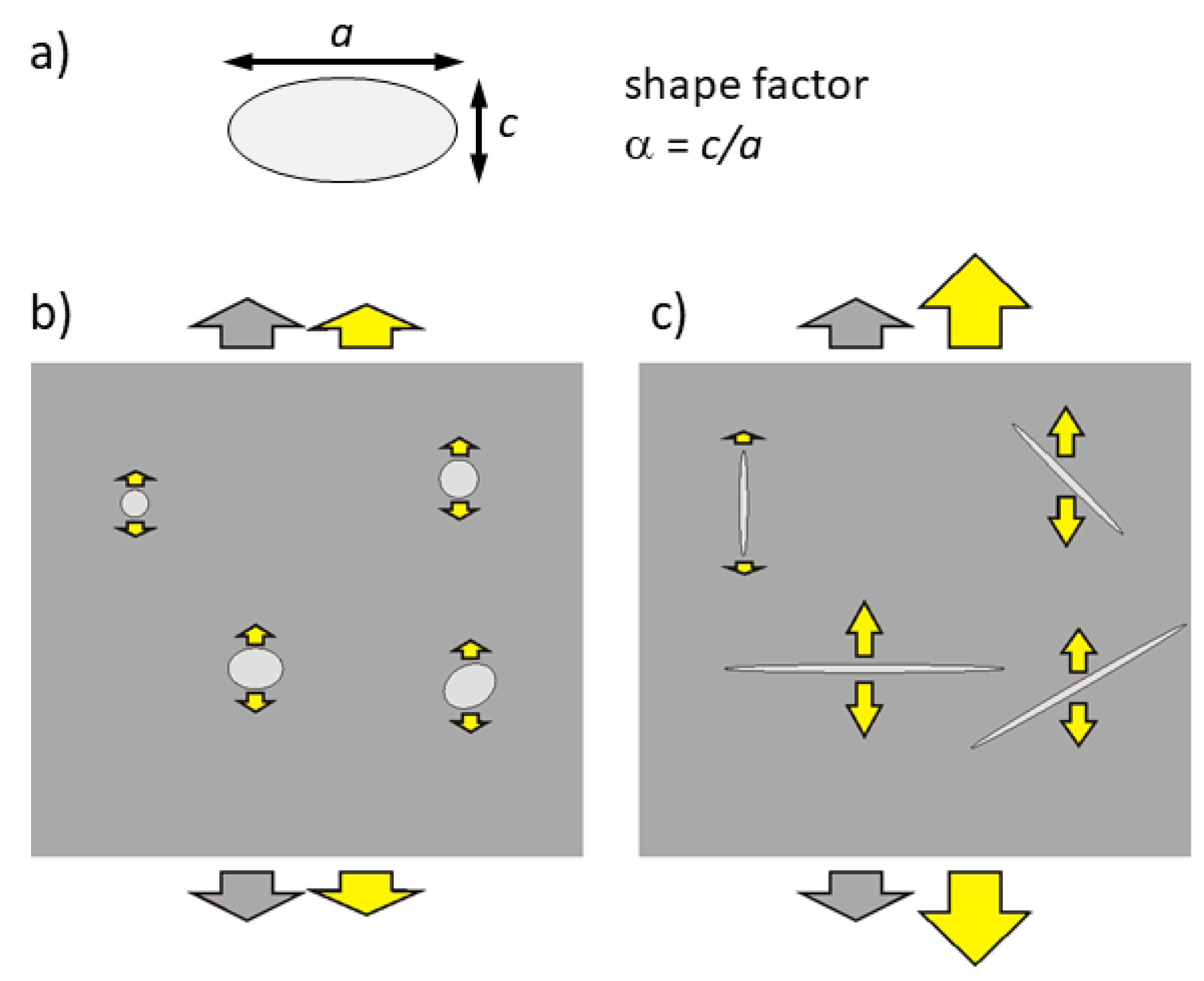

3. Discussion

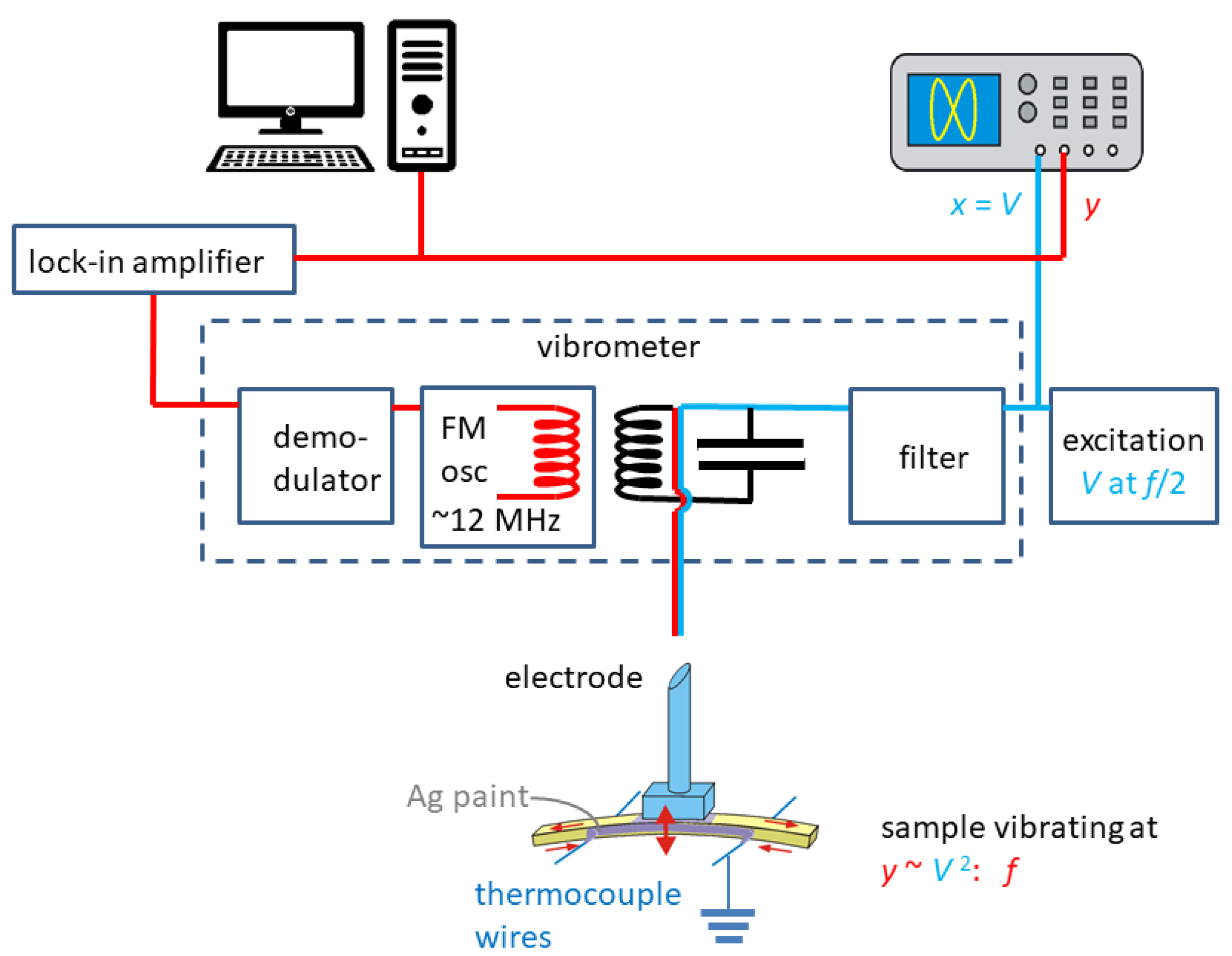

4. Materials and Methods

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Damjanovic, D. Ferroelectric, dielectric and piezoelectric properties of ferroelectric thin films and ceramics. Rep. Prog. Phys. 1998, 61, 1267. [Google Scholar] [CrossRef]

- Lou, X.J. Polarization fatigue in ferroelectric thin films and related materials. J. Appl. Phys. 2009, 105, 024101. [Google Scholar] [CrossRef]

- Hao, X.; Zhai, J.; Kong, L.B.; Xu, Z. A comprehensive review on the progress of lead zirconate-based antiferroelectric materials. Progr. Mater. Sci. 2014, 63, 1. [Google Scholar] [CrossRef]

- Nuffer, J.; Lupascu, D.C.; Rödel, J. Damage evolution in ferroelectric PZT induced by bipolar electric cycling. Acta Mater. 2000, 48, 3783–3794. [Google Scholar] [CrossRef]

- Lou, X.J.; Hu, X.B.; Zhang, M.; Morrison, F.D.; Redfern, S.A.T.; Scott, J.F. Phase separation in lead zirconate titanate and bismuth titanate during electrical shorting and fatigue. J. Appl. Phys. 2006, 99, 044101. [Google Scholar] [CrossRef]

- Cordero, F.; Craciun, F.; Trequattrini, F.; Galassi, C.; Thomas, P.A.; Keeble, D.S.; Glazer, A.M. Splitting of the transition to the antiferroelectric state in PbZr0.95Ti0.05O3 into polar and antiferrodistortive components. Phys. Rev. B 2013, 88, 094107. [Google Scholar] [CrossRef]

- Cordero, F.; Trequattrini, F.; Craciun, F.; Galassi, C. Effects of aging and annealing on the polar and antiferrodistortive components of the antiferroelectric transition in PbZr1−xTixO3. Phys. Rev. B 2014, 89, 214102. [Google Scholar] [CrossRef]

- Cordero, F.; Craciun, F.; Trequattrini, F.; Galizia, P.; Galassi, C. Elastic aging from coexistence and transformations of ferroelectric and antiferroelectric states in PZT. J. Appl. Phys. 2016, 120, 064104. [Google Scholar] [CrossRef]

- Ujma, Z.; Handerek, J.; Pawetczyk, M.; Hassan, H.; Kugel, G.E.; Carabatos-Nedelec, C. The antiferroelectric-ferroelectric-paraelectric phase sequence in lead-lanthanum zirconate-titanate ceramics with 8% Ti content. J. Phys. Condens. Matter 1994, 6, 6843. [Google Scholar] [CrossRef]

- Xu, Z.; Dai, X.; Viehland, D. Impurity-induced incommensuration in antiferroelectric La-modified lead zirconate titanate. Phys. Rev. B 1995, 51, 6261. [Google Scholar] [CrossRef]

- Asada, T.; Koyama, Y. Coexistence of ferroelectricity and antiferroelectricity in lead zirconate titanate. Phys. Rev. B 2004, 70, 104105. [Google Scholar] [CrossRef]

- Avdeev, M.; Jorgensen, J.D.; Short, S.; Samara, G.A.; Venturini, E.L.; Yang, P.; Morosin, B. Pressure-induced ferroelectric to antiferroelectric phase transition in Pb0.99(Zr0.95Ti0.05)0.98Nb0.02O3. Phys. Rev. B 2006, 73, 064105. [Google Scholar] [CrossRef]

- Mischenko, A.S.; Zhang, Q.; Scott, J.F.; Whatmore, R.W.; Mathur, N.D. Giant Electrocaloric Effect in Thin-Film PbZr0.95Ti0.05O3. Science 2006, 311, 1270. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.; Pasciak, M.; Glazer, A.M.; Hlinka, J.; Gutmann, M.; Sparkes, H.A.; Welberry, T.R.; Majchrowski, A.; Roleder, K.; Xie, Y.; et al. A neutron diffuse scattering study of PbZrO3 and Zr-rich PbZr1−xTixO3. J. Appl. Cryst. 2015, 48, 1. [Google Scholar] [CrossRef]

- Cordero, F.; Craciun, F.; Trequattrini, F.; Galassi, C. Piezoelectric softening in ferroelectrics: Ferroelectric versus antiferroelectric PbZr1−xTixO3. Phys. Rev. B 2016, 93, 174111. [Google Scholar] [CrossRef]

- Cordero, F.; Trequattrini, F.; Craciun, F.; Galassi, C. Octahedral tilting, monoclinic phase and the phase diagram of PZT. J. Phys. Condens. Matter 2011, 23, 415901. [Google Scholar] [CrossRef] [PubMed]

- Cordero, F.; Trequattrini, F.; Craciun, F.; Galassi, C. Merging of the polar and tilt instability lines near the respective morphotropic phase boundaries of PbZr1−xTixO3. Phys. Rev. B 2013, 87, 094108. [Google Scholar] [CrossRef]

- Jaffe, B.; Cook, W.R.; Jaffe, H. Piezoelectric Ceramics; Academic Press: London, UK, 1971. [Google Scholar]

- Li, M.J.; Xu, L.P.; Shi, K.; Zhang, J.Z.; Chen, X.F.; Hu, Z.G.; Dong, X.L.; Chu, J.H. Interband electronic transitions and phase diagram of PbZr1−xTixO3 (0.05 ≤ x ≤ 0.70) ceramics: Ellipsometric experiment and first-principles theory. J. Phys. D Appl. Phys. 2016, 49, 275305. [Google Scholar] [CrossRef]

- Lazar, I.; Oh, S.H.; Ko, J.H.; Zajdel, P.; Kajewski, D.; Majchrowski, A.; Piecha, J.; Koperski, J.; Soszynski, A.; Roleder, K. Additional phase transition in a PbZr0.87Ti0.13O3 single crystal. J. Phys. D Appl. Phys. 2019, 52, 115302. [Google Scholar] [CrossRef]

- Buixaderas, E.; Gregora, I.; Kamba, S.; Kuzel, P.; Reaney, I. Phonon anomalies in Pb1−xLax(Zr0.9Ti0.1)O3 ceramics. Appl. Phys. Lett. 2009, 94, 052903. [Google Scholar] [CrossRef]

- Buixaderas, E.; Gregora, I.; Savinov, M.; Hlinka, J.; Jin, L.; Damjanovic, D.; Malic, B. Compositional behavior of Raman-active phonons in Pb(Zr1−xTix)O3 ceramics. Phys. Rev. B 2015, 91, 014104. [Google Scholar] [CrossRef]

- Ishchuk, V.M.; Sobolev, V.L. Physical Effects in the Vicinity of the Ferroelectric-Antiferroelectric Interface. J. Surf. Interf. Mater. 2015, 3, 1. [Google Scholar] [CrossRef]

- Prisedsky, V.V.; Shishkovsky, V.I.; Klim, V.V. High-temperature electrical conductivity and point defects in lead zirconate- titanate. Ferroelectrics 1978, 17, 465. [Google Scholar] [CrossRef]

- Genenko, Y.A.; Lupascu, D.C. Drift of charged defects in local fields as aging mechanism in ferroelectrics. Phys. Rev. B 2007, 75, 184107. [Google Scholar] [CrossRef]

- Cordero, F. Hopping and clustering of oxygen vacancies in SrTiO3 by anelastic relaxation. Phys. Rev. B 2007, 76, 172106. [Google Scholar] [CrossRef]

- Malashevich, A.; Ismail-Beigi, S. First-principles study of oxygen-deficient LaNiO3 structures. Phys. Rev. B 2015, 92, 144102. [Google Scholar] [CrossRef]

- Cuong, D.D.; Lee, B.; Choi, K.M.; Ahn, H.S.; Han, S.; Lee, J. Oxygen Vacancy Clustering and Electron Localization in Oxygen-Deficient SrTiO3: LDA+U Study. Phys. Rev. Lett. 2007, 98, 115503. [Google Scholar] [CrossRef]

- Klie, R.F.; Ito, Y.; Stemmer, S.; Browning, N.D. Observation of oxygen vacancy ordering and segregation in Perovskite oxides. Ultramicroscopy 2001, 86, 289–302. [Google Scholar] [CrossRef]

- Becerro, A.I.; McCammon, C.; Langenhorst, F.; Seifert, F.; Angel, R. Oxygen vacancy ordering in CaTiO3-CaFeO2.5 perovskites: From isolated defects to infinite sheets. Phase Transit. 1999, 69, 133–146. [Google Scholar] [CrossRef]

- Scott, J.F.; Dawber, M. Oxygen-vacancy ordering as a fatigue mechanism in perovskite ferroelectrics. Appl. Phys. Lett. 2000, 76, 3801. [Google Scholar] [CrossRef]

- Wu, T.T. The effect of inclusion shape on the elastic moduli of a two-phase material. Int. J. Solids Struct. 1966, 2, 1–8. [Google Scholar] [CrossRef]

- Dunn, M.L. Effects of grain shape anisotropy, porosity, and microcracks on the elastic and dielectric constants of polycrystalline piezoelectric ceramics. J. Appl. Phys. 1995, 78, 1533. [Google Scholar] [CrossRef]

- Bouzid, A.; Bourim, E.M.; Gabbay, M.; Fantozzi, G. PZT phase diagram determination by measurement of elastic moduli. J. Eur. Ceram. Soc. 2005, 25, 3213. [Google Scholar] [CrossRef]

- Smyth, D.M. Charge motion in ferroelectric thin films. Ferroelectrics 1991, 116, 117. [Google Scholar] [CrossRef]

- Cao, W.; Randall, C.A. Grain size and domain size relations in bulk ceramic ferroelectric materials. J. Phys. Chem. Sol. 1996, 57, 1499. [Google Scholar] [CrossRef]

- Tan, Q.; Li, J.F.; Viehland, D. The influence of mobile vs. randomly quenched impurities on ferroelectric phase transformations. Ferroelectrics 1998, 206–207, 275–291. [Google Scholar] [CrossRef]

- Webb, S.; Jackson, I.; Gerald, J.F. Viscoelasticity of the titanate perovskites CaTiO3 and SrTiO3 at high temperature. Phys. Earth Planet. Int. 1999, 115, 259. [Google Scholar] [CrossRef]

- Goodenough, J.B. Electronic and ionic transport properties and other physical aspects of perovskites. Rep. Prog. Phys. 2004, 67, 1915–1993. [Google Scholar] [CrossRef]

- Cordero, F.; Trequattrini, F.; Deganello, F.; Parola, V.L.; Roncari, E.; Sanson, A. Effect of doping and oxygen vacancies on the octahedral tilt transitions in the BaCeO3 perovskite. Phys. Rev. B 2010, 82, 104102. [Google Scholar] [CrossRef]

- Cordero, F.; Bella, L.D.; Corvasce, F.; Latino, P.M.; Morbidini, A. An insert for anelastic spectroscopy measurements from 80 K to 1100 K. Meas. Sci. Technol. 2009, 20, 015702. [Google Scholar] [CrossRef]

- Nowick, A.S.; Berry, B.S. Anelastic Relaxation in Crystalline Solids; Academic Press: New York, NY, USA, 1972. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cordero, F.; Buixaderas, E.; Galassi, C. Damage from Coexistence of Ferroelectric and Antiferroelectric Domains and Clustering of O Vacancies in PZT: An Elastic and Raman Study. Materials 2019, 12, 957. https://doi.org/10.3390/ma12060957

Cordero F, Buixaderas E, Galassi C. Damage from Coexistence of Ferroelectric and Antiferroelectric Domains and Clustering of O Vacancies in PZT: An Elastic and Raman Study. Materials. 2019; 12(6):957. https://doi.org/10.3390/ma12060957

Chicago/Turabian StyleCordero, Francesco, Elena Buixaderas, and Carmen Galassi. 2019. "Damage from Coexistence of Ferroelectric and Antiferroelectric Domains and Clustering of O Vacancies in PZT: An Elastic and Raman Study" Materials 12, no. 6: 957. https://doi.org/10.3390/ma12060957

APA StyleCordero, F., Buixaderas, E., & Galassi, C. (2019). Damage from Coexistence of Ferroelectric and Antiferroelectric Domains and Clustering of O Vacancies in PZT: An Elastic and Raman Study. Materials, 12(6), 957. https://doi.org/10.3390/ma12060957