3D Analysis of Deformation and Porosity of Dry Natural Snow during Compaction

Abstract

:1. Introduction

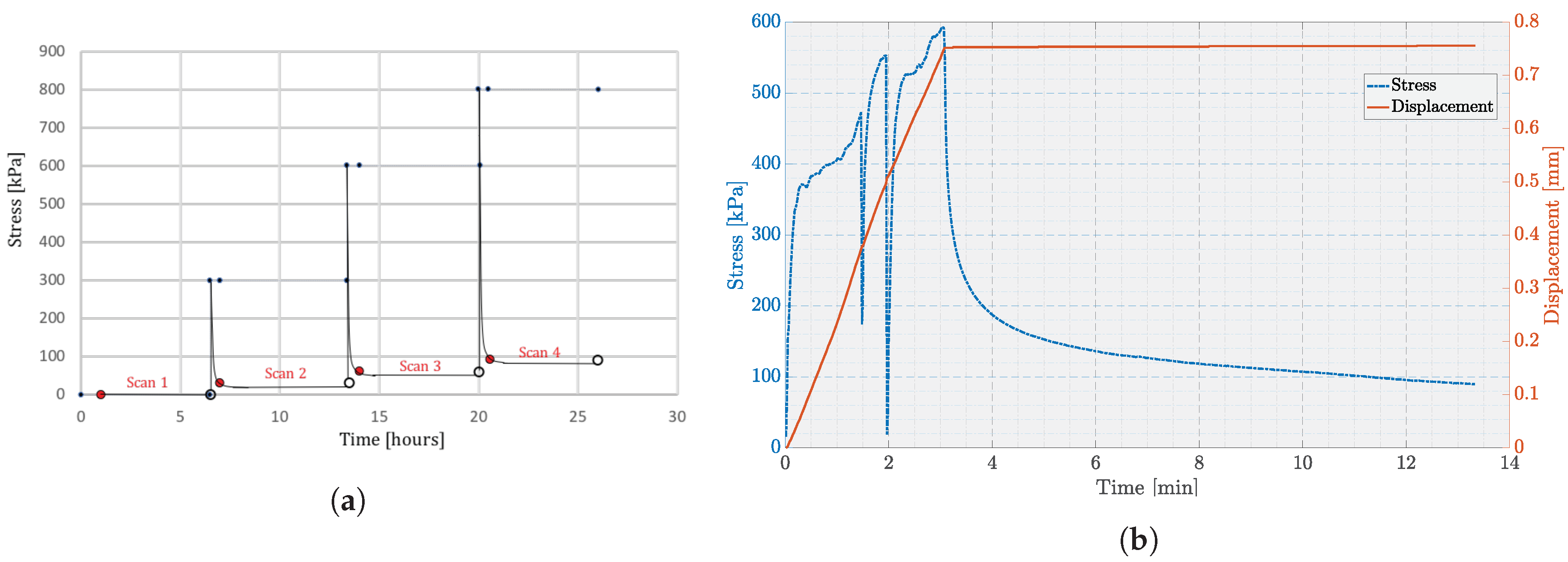

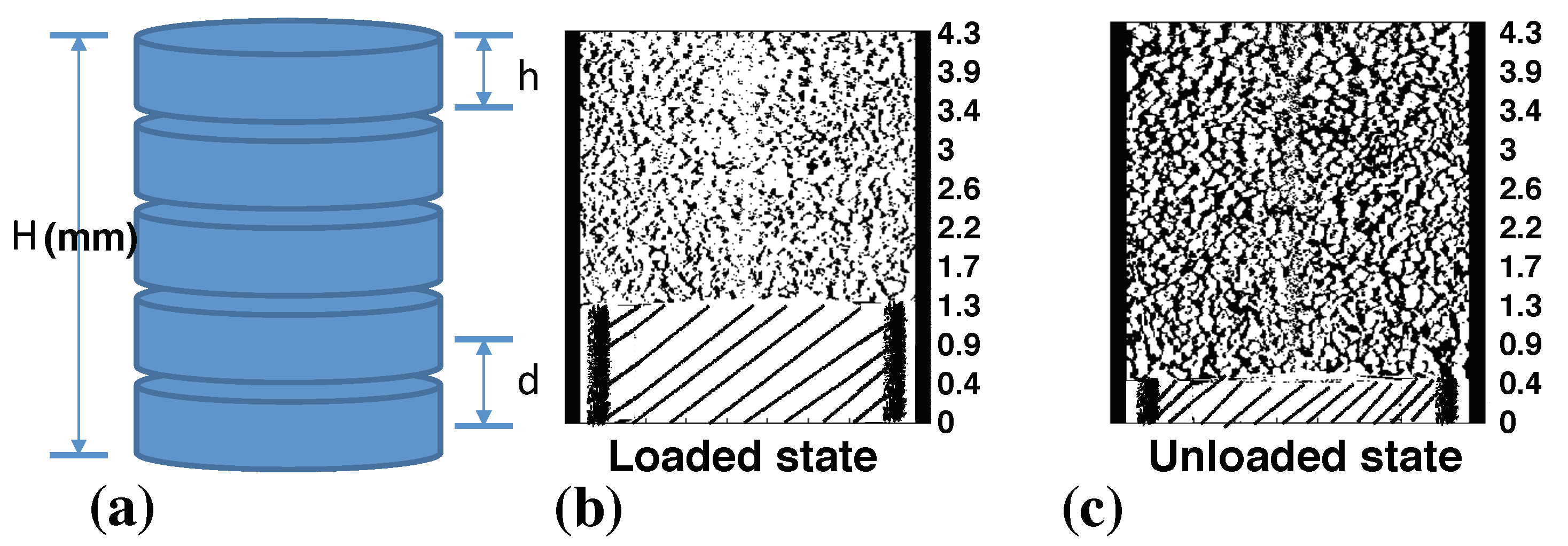

2. Experimental Procedure

2.1. Micro-CT System with In-Situ Load Module

2.2. Snow Sampling

2.3. Data Acquisition

3. Methods

3.1. DVC

3.2. Porosity, Density and SSA

4. Results

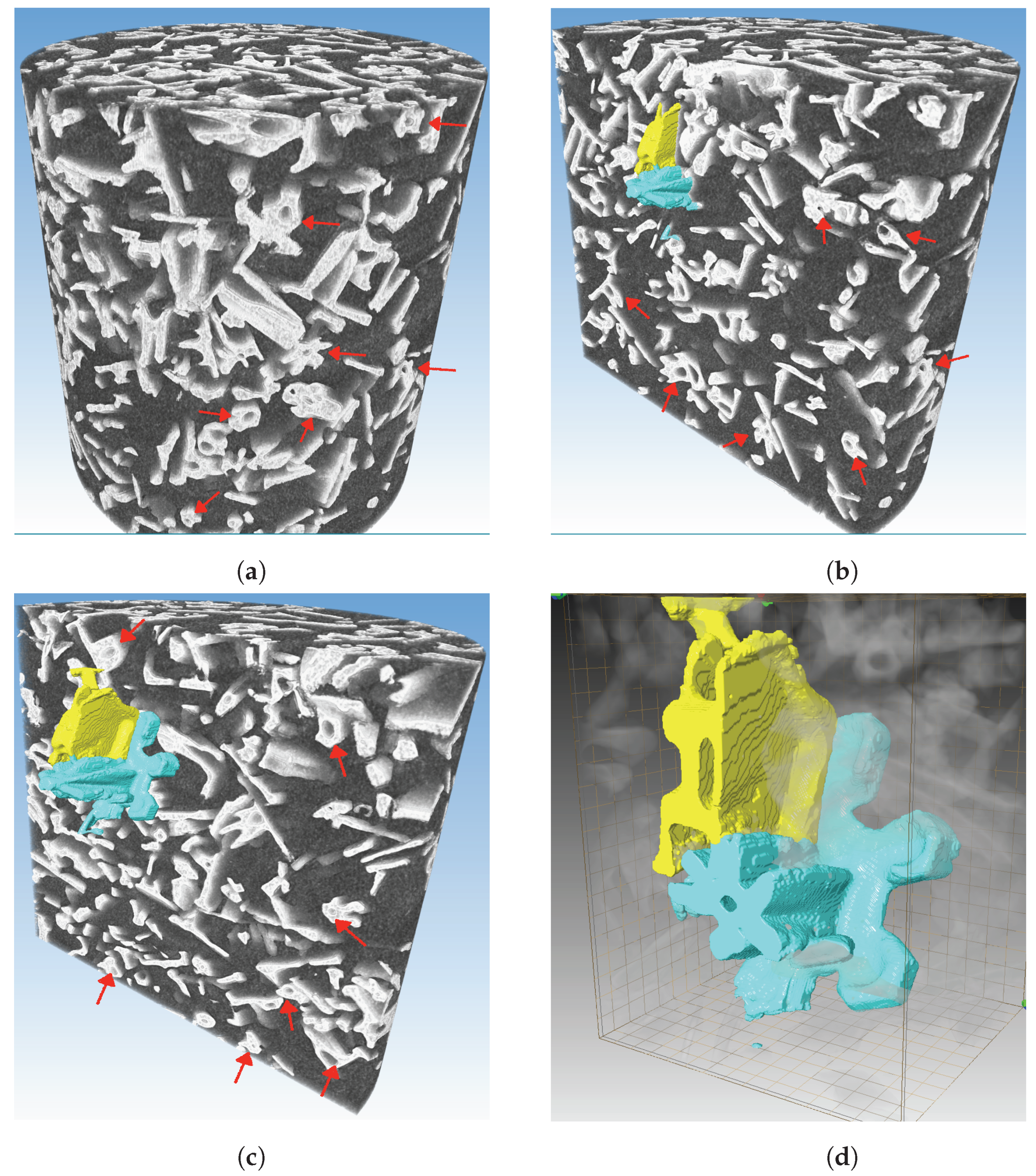

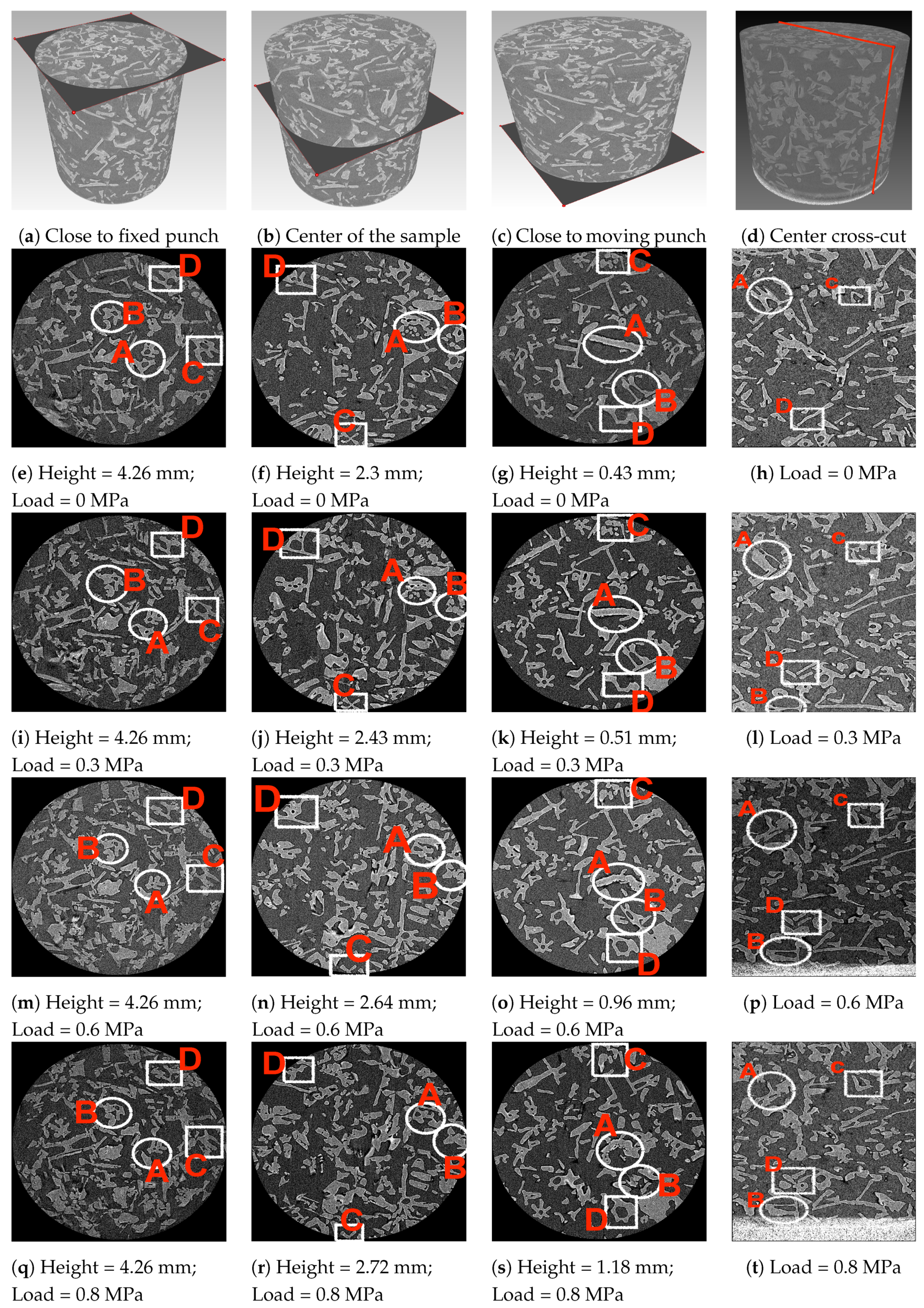

4.1. Distribution of Snow Grains

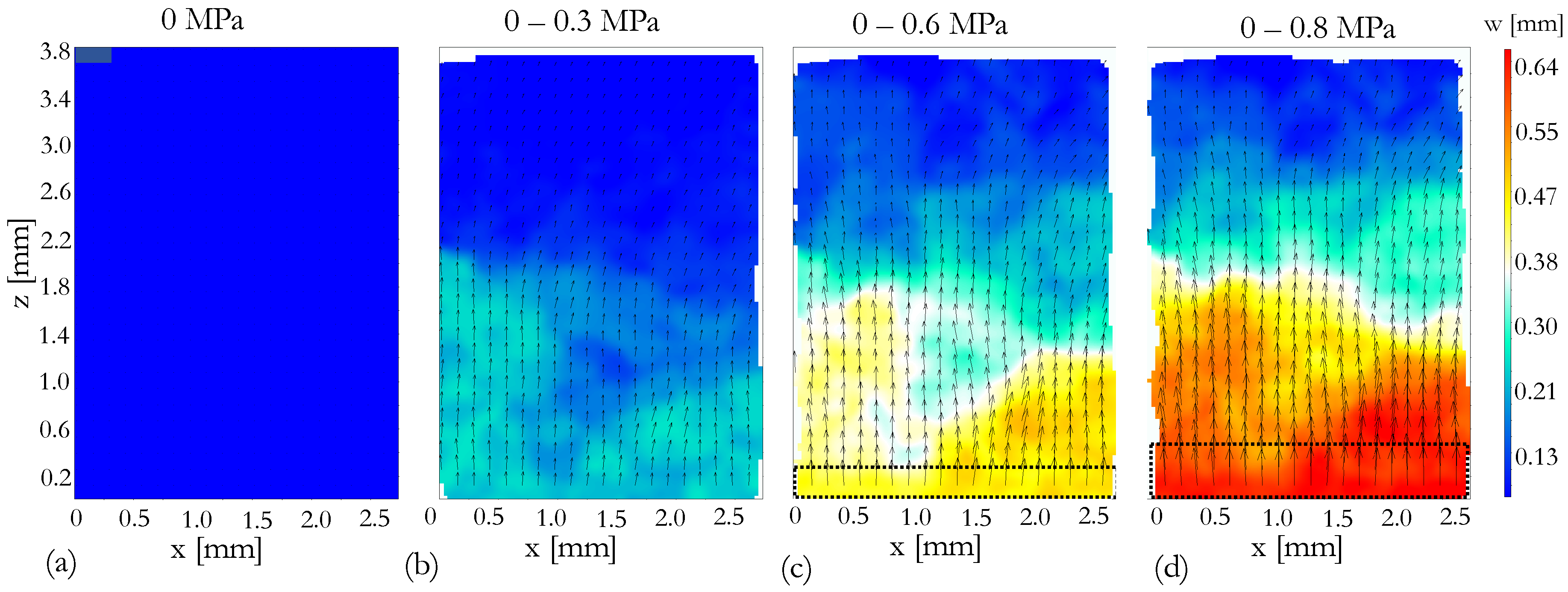

4.2. Displacement of Snow Grains

4.3. Porosity Measurements

5. Discussions

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dozier, J.; Davis, R.E.; Perla, R. On the objective analysis of snow microstructure. Avalanche Form. Mov. Eff. 1987, 162, 49–59. [Google Scholar]

- Du Roscoat, S.R.; King, A.; Philip, A.; Reischig, P.; Ludwig, W.; Flin, F.; Meyssonnier, J. Analysis of Snow Microstructure by Means of X-ray Diffraction Contrast Tomography. Adv. Eng. Mater. 2011, 13, 128–135. [Google Scholar] [CrossRef]

- Perla, R.; Dozier, J.; Davis, R. Preparation of serial sections in dry snow specimens. J. Microsc. 1986, 142, 111–114. [Google Scholar] [CrossRef]

- Good, W. Thin sections, serial cuts and 3-D analysis of snow. IAHS Publ. 1987, 162, 35–48. [Google Scholar]

- Flin, F.; Brzoska, J.B.; Lesaffre, B.; Coléou, C.; Pieritz, R.A. Full three-dimensional modelling of curvature-dependent snow metamorphism: First results and comparison with experimental tomographic data. J. Phys. D Appl. Phys. 2003, 36, A49. [Google Scholar] [CrossRef]

- Schneebeli, M.; Sokratov, S.A. Tomography of temperature gradient metamorphism of snow and associated changes in heat conductivity. Hydrol. Process. 2004, 18, 3655–3665. [Google Scholar] [CrossRef]

- Maire, E.; Withers, P.J. Quantitative X-ray tomography. Int. Mater. Rev. 2014, 59, 1–43. [Google Scholar] [CrossRef]

- Wiese, M.; Schneebeli, M. Snowbreeder 5: A Micro-CT device for measuring the snow-microstructure evolution under the simultaneous influence of a temperature gradient and compaction. J. Glaciol. 2017, 63, 355–360. [Google Scholar] [CrossRef]

- Schleef, S.; Löwe, H. X-ray microtomography analysis of isothermal densification of new snow under external mechanical stress. J. Glaciol. 2013, 59, 233–243. [Google Scholar] [CrossRef] [Green Version]

- Kaempfer, T.U.; Schneebeli, M. Observation of isothermal metamorphism of new snow and interpretation as a sintering process. J. Geophys. Res. Atmos. 2007, 112, 2156–2202. [Google Scholar] [CrossRef]

- Pinzer, B.; Schneebeli, M.; Kaempfer, T. Vapor flux and recrystallization during dry snow metamorphism under a steady temperature gradient as observed by time-lapse micro-tomography. Cryosphere 2012, 6, 1141–1155. [Google Scholar] [CrossRef] [Green Version]

- Ebner, P.P.; Schneebeli, M.; Steinfeld, A. Tomography-based monitoring of isothermal snow metamorphism under advective conditions. Cryosphere 2015, 9, 1363–1371. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Baker, I. Observation of the microstructural evolution of snow under uniaxial compression using X-ray computed microtomography. J. Geophys. Res. Atmos. 2013, 118, 12371–12382. [Google Scholar] [CrossRef]

- Kerbrat, M.; Pinzer, B.; Huthwelker, T.; Gäggeler, H.; Ammann, M.; Schneebeli, M. Measuring the specific surface area of snow with X-ray tomography and gas adsorption: Comparison and implications for surface smoothness. Atmos. Chem. Phys. 2008, 8, 1261–1275. [Google Scholar] [CrossRef]

- Hagenmuller, P.; Matzl, M.; Chambon, G.; Schneebeli, M. Sensitivity of snow density and specific surface area measured by microtomography to different image processing algorithms. Cryosphere 2016, 10, 1039–1054. [Google Scholar] [CrossRef] [Green Version]

- Schleef, S.; Löwe, H.; Schneebeli, M. Hot-pressure sintering of low-density snow analyzed by X-ray microtomography and in situ microcompression. Acta Mater. 2014, 71, 185–194. [Google Scholar] [CrossRef]

- Bay, B.K.; Smith, T.S.; Fyhrie, D.P.; Saad, M. Digital volume correlation: Three-dimensional strain mapping using X-ray tomography. Exp. Mech. 1999, 39, 217–226. [Google Scholar] [CrossRef]

- St Lawrence, W.; Bradley, C.C. The deformation of snow in terms of structural mechanism. In Snow Mechanics Symposium; International Association of Hydrological Sciences: Washington, DC, USA, 1975; pp. 155–170. [Google Scholar]

- Theile, T.; Szabo, D.; Luthi, A.; Rhyner, H.; Schneebeli, M. Mechanics of the ski–snow contact. Tribol. Lett. 2009, 36, 223–231. [Google Scholar] [CrossRef]

- Forsberg, F.; Sjödahl, M.; Mooser, R.; Hack, E.; Wyss, P. Full Three-dimensional strain measurements on wood exposed to three-point bending: Analysis by use of digital volume correlation applied to synchrotron radiation micro-computed tomography image data. Strain 2010, 46, 47–60. [Google Scholar] [CrossRef]

- Buljac, A.; Jailin, C.; Mendoza, A.; Neggers, J.; Taillandier-Thomas, T.; Bouterf, A.; Smaniotto, B.; Hild, F.; Roux, S. Digital Volume Correlation: Review of Progress and Challenges. Exp. Mech. 2018, 58, 661–708. [Google Scholar] [CrossRef]

- Bay, B. Methods and applications of digital volume correlation. J. Strain Anal. Eng. Des. 2008, 43, 745–760. [Google Scholar] [CrossRef]

- Otsu, N. A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Taud, H.; Martinez-Angeles, R.; Parrot, J.; Hernandez-Escobedo, L. Porosity estimation method by X-ray computed tomography. J. Pet. Sci. Eng. 2005, 47, 209–217. [Google Scholar] [CrossRef]

- Nikishkov, Y.; Airoldi, L.; Makeev, A. Measurement of voids in composites by X-ray Computed Tomography. Compos. Sci. Technol. 2013, 89, 89–97. [Google Scholar] [CrossRef]

- Lundy, C.C.; Edens, M.Q.; Brown, R.L. Measurement of snow density and microstructure using computed tomography. J. Glaciol. 2002, 48, 312–316. [Google Scholar] [CrossRef] [Green Version]

- Libbrecht, K.G. The physics of snow crystals. Rep. Prog. Phys. 2005, 68, 855–895. [Google Scholar] [CrossRef]

- Shimada, W.; Ohtake, K. Three-Dimensional Morphology of Natural Snow Crystals. Cryst. Growth Des. 2016, 16, 5603–5605. [Google Scholar] [CrossRef]

- Wergin, W.P.; Rango, A.; Erbe, E.F. Observations of snow crystals using low-temperature scanning electron microscopy. Scanning 1995, 17, 41–50. [Google Scholar] [CrossRef]

- Riche, F.; Montagnat, M.; Schneebeli, M. Evolution of crystal orientation in snow during temperature gradient metamorphism. J. Glaciol. 2013, 59, 47–55. [Google Scholar] [CrossRef] [Green Version]

- Lehning, M.; Bartelt, P.; Brown, B.; Fierz, C.; Satyawali, P. A physical SNOWPACK model for the Swiss avalanche warning: Part II. Snow microstructure. Cold Reg. Sci. Technol. 2002, 35, 147–167. [Google Scholar] [CrossRef]

- Wilkinson, D. A pressure-sintering model for the densification of polar firn and glacier ice. J. Glaciol. 1988, 34, 40–45. [Google Scholar] [CrossRef]

- Eppanapelli, L.K.; Casselgren, J.; Wåhlin, J.; Sjödahl, M. Investigation of snow single scattering properties based on first order Legendre phase function. Opt. Lasers Eng. 2017, 91, 151–159. [Google Scholar] [CrossRef]

- Eppanapelli, L.K.; Lintzén, N.; Casselgren, J.; Wåhlin, J. Estimation of Liquid Water Content of Snow Surface by Spectral Reflectance. J. Cold Reg. Eng. 2018, 32, 05018001. [Google Scholar] [CrossRef]

- Gubler, H. Strength of bonds between ice grains after short contact times. J. Glaciol. 1982, 28, 457–473. [Google Scholar] [CrossRef]

- Szabo, D.; Schneebeli, M. Subsecond sintering of ice. Appl. Phys. Lett. 2007, 90, 151916. [Google Scholar] [CrossRef]

- Zermatten, E.; Schneebeli, M.; Arakawa, H.; Steinfeld, A. Tomography-based determination of porosity, specific area and permeability of snow and comparison with measurements. Cold Reg. Sci. Technol. 2014, 97, 33–40. [Google Scholar] [CrossRef]

| Stress (MPa) | Density (kg m) | SSA (mm) |

|---|---|---|

| 0 | 224 | 66 |

| 0.3 | 243 | 64 |

| 0.6 | 265 | 62 |

| 0.8 | 284 | 60 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eppanapelli, L.K.; Forsberg, F.; Casselgren, J.; Lycksam, H. 3D Analysis of Deformation and Porosity of Dry Natural Snow during Compaction. Materials 2019, 12, 850. https://doi.org/10.3390/ma12060850

Eppanapelli LK, Forsberg F, Casselgren J, Lycksam H. 3D Analysis of Deformation and Porosity of Dry Natural Snow during Compaction. Materials. 2019; 12(6):850. https://doi.org/10.3390/ma12060850

Chicago/Turabian StyleEppanapelli, Lavan Kumar, Fredrik Forsberg, Johan Casselgren, and Henrik Lycksam. 2019. "3D Analysis of Deformation and Porosity of Dry Natural Snow during Compaction" Materials 12, no. 6: 850. https://doi.org/10.3390/ma12060850