Performance Degradation Analysis of c-Si PV Modules Mounted on a Concrete Slab under Hot-Humid Conditions Using Electroluminescence Scanning Technique for Potential Utilization in Future Solar Roadways

Abstract

1. Introduction

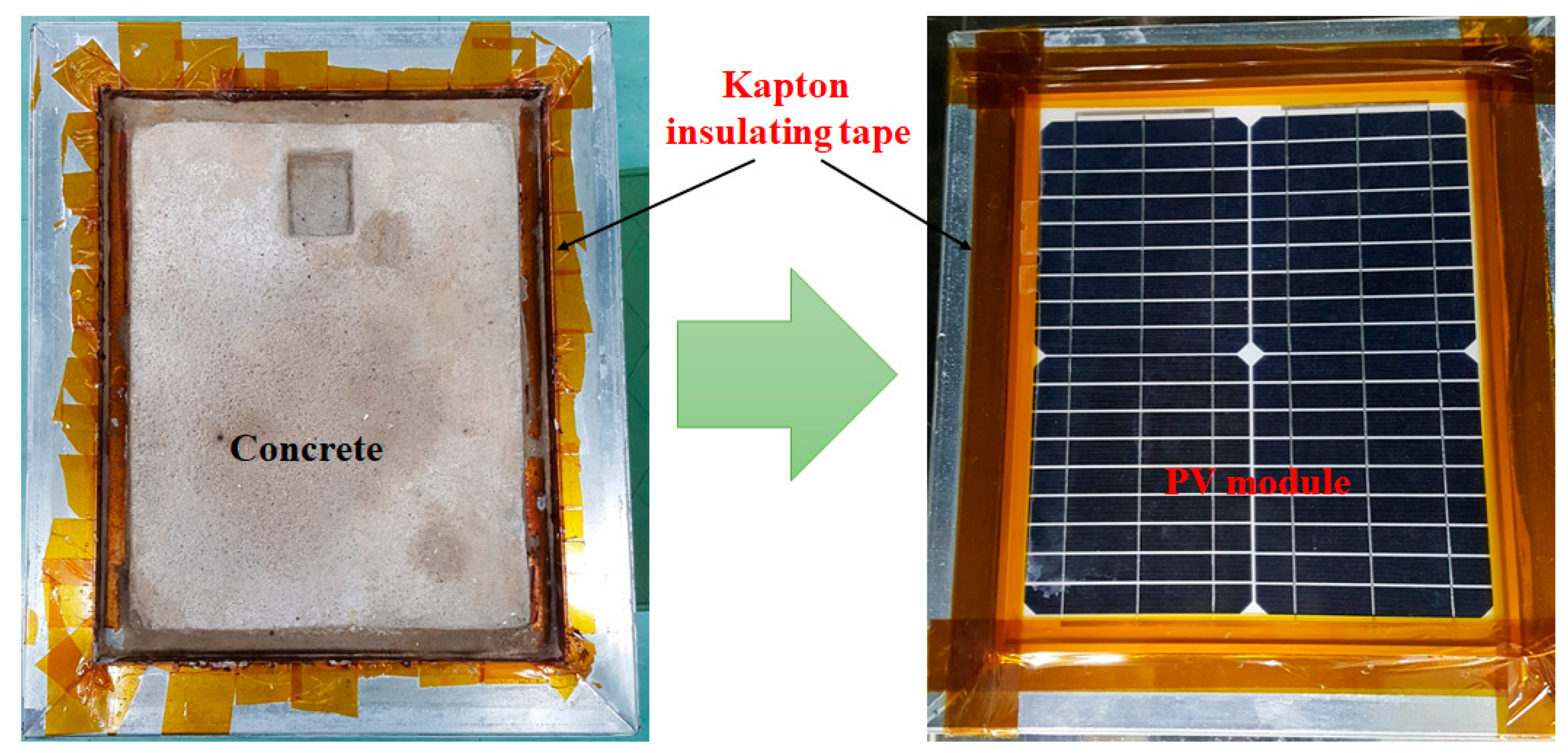

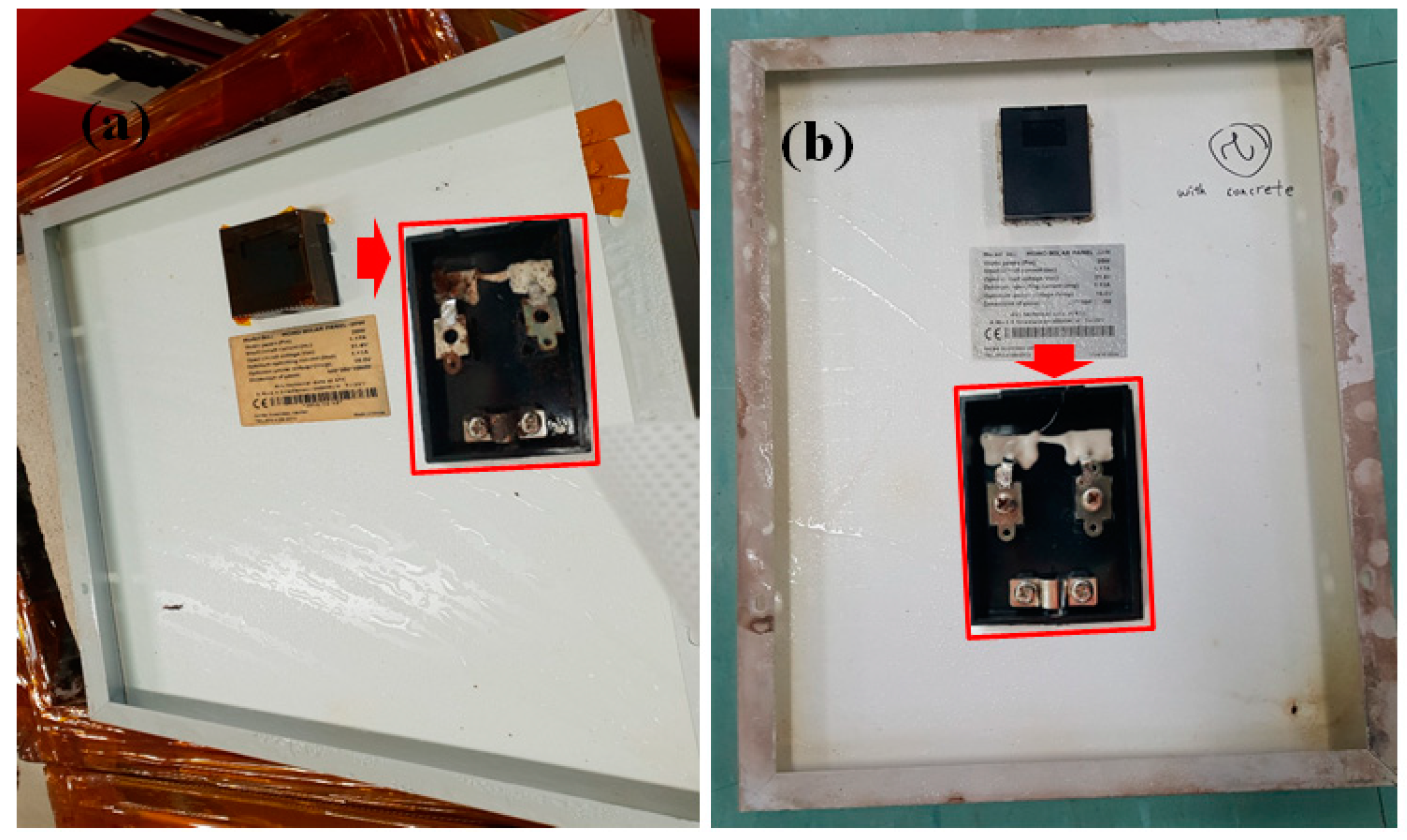

2. Experimental Section

3. Results and Discussion

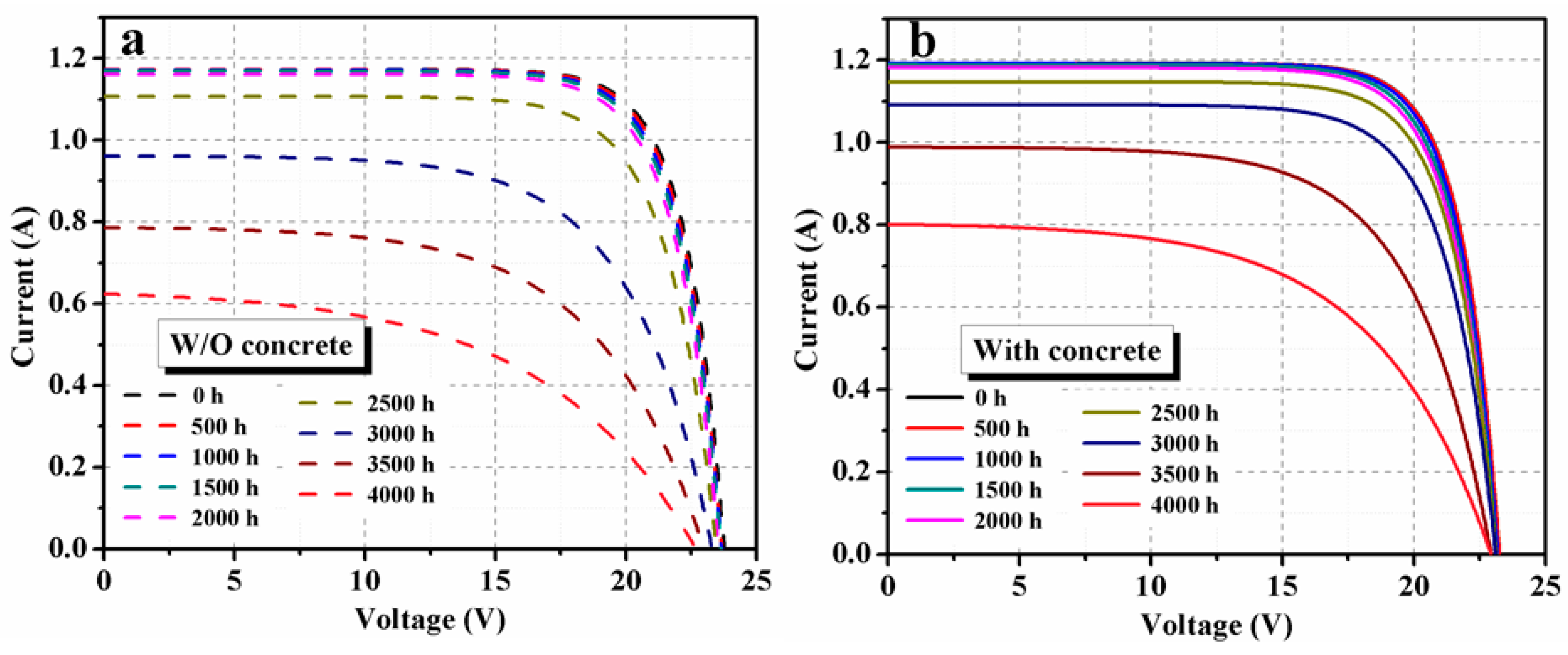

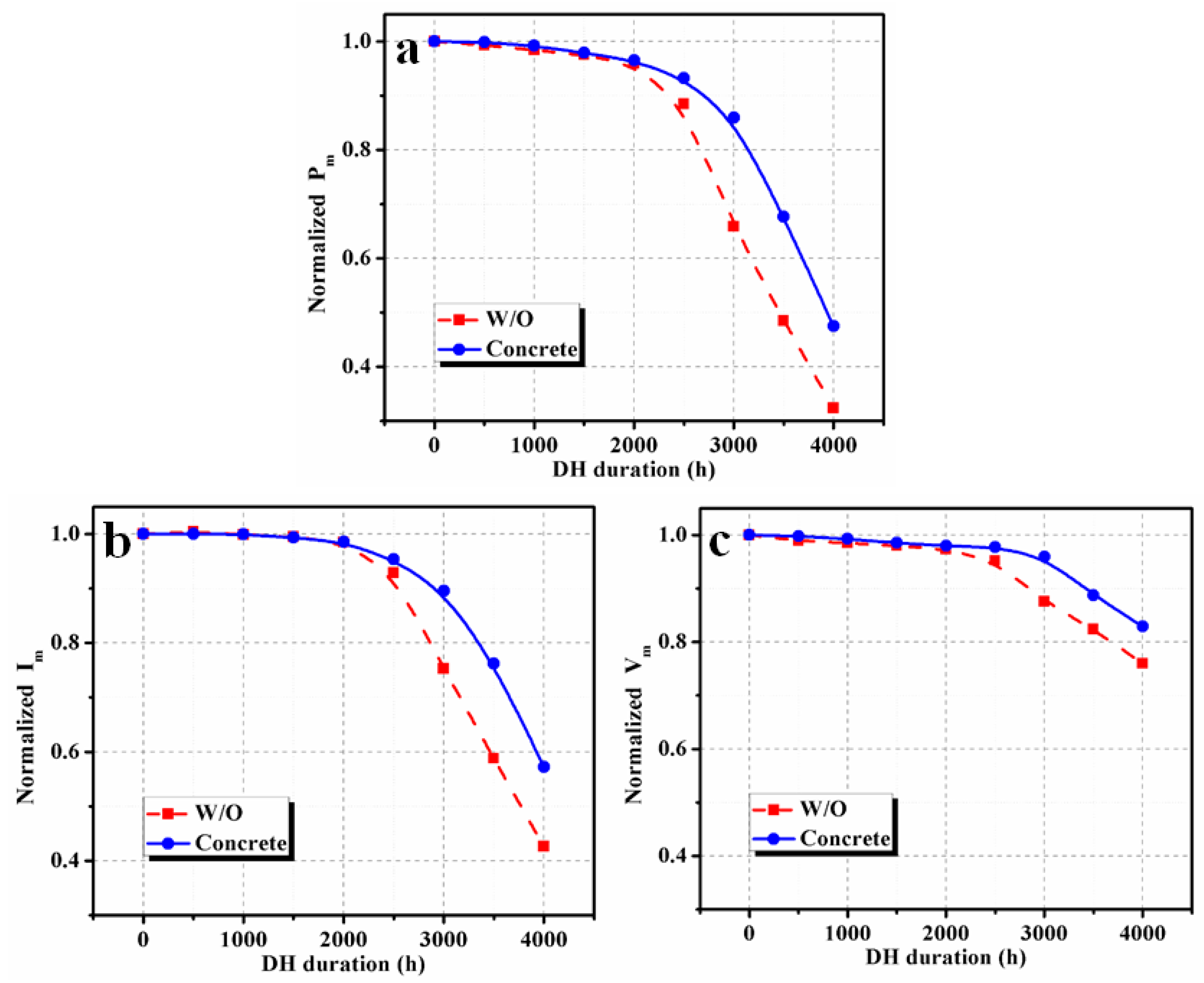

3.1. Performance Parameters Analysis

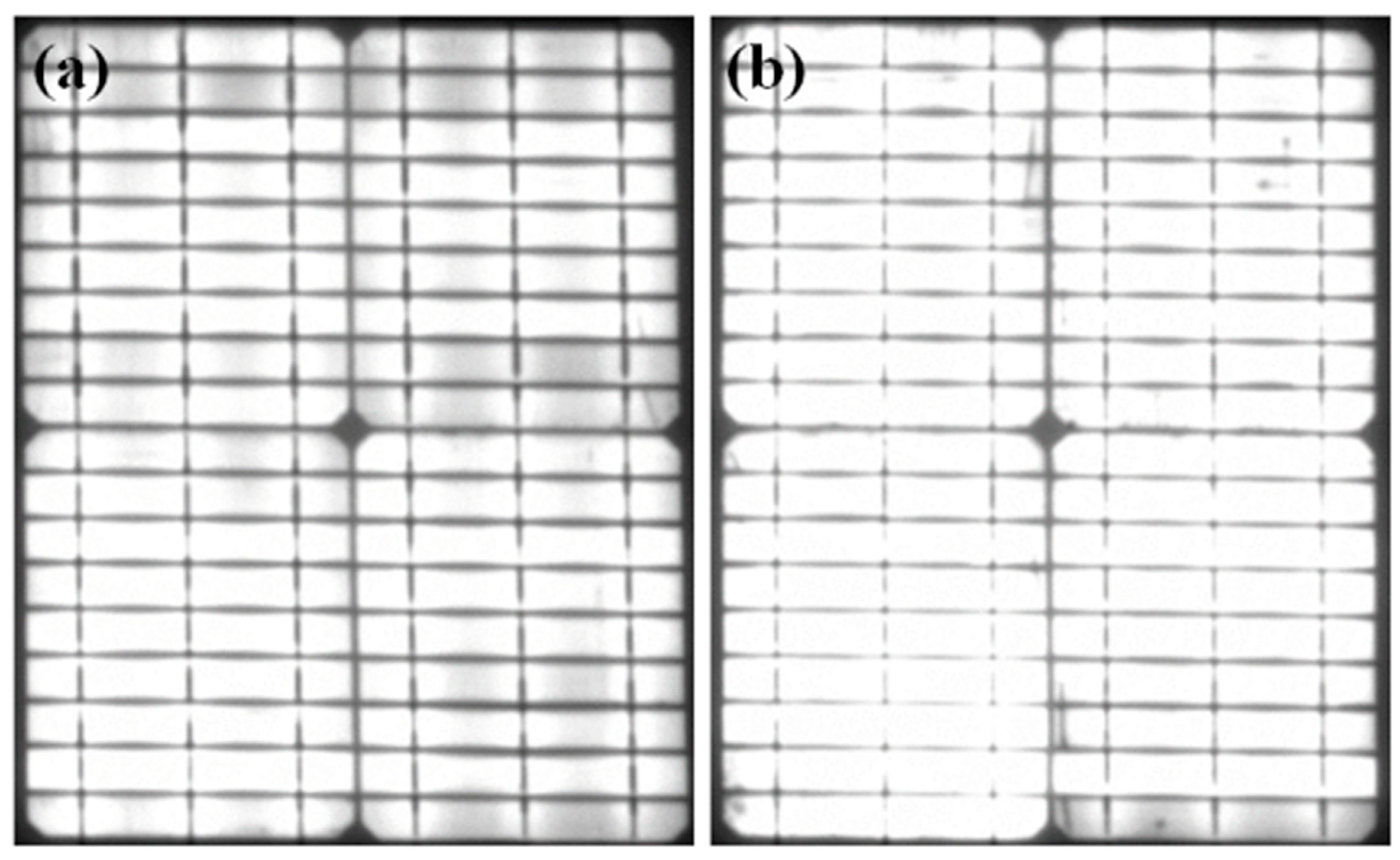

3.2. PV Cell Parameters Analysis

3.3. Measurement Error Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhu, J.; Koehl, M.; Hoffmann, S.; Berger, K.A.; Zamini, S.; Bennett, I.; Gerritsen, E.; Malbranche, P.; Pugliatti, P.; Di Stefano, A.; et al. Changes of solar cell parameters during damp-heat exposure. Prog. Photovolt. 2016, 24, 1346–1358. [Google Scholar] [CrossRef]

- Braisaz, B.; Duchayne, C.; Iseghem, M.V.; Radouane, K. PV aging model applied to several meteorological conditions. In Proceedings of the 29th European Photovoltaic Solar Energy Conference and Exhibition (EUPVSEC), Amsterdam, The Netherlands, 22–26 September 2014; pp. 2303–2309. [Google Scholar]

- Crystalline Silicon Terrestrial Photovoltaic (PV) Modules—Design Qualification and Type Approval; IEC 61215:2005; IEC Central Office: Geneva, Switzerland, April 2005.

- Wohlgemuth, J.H.; Kempe, M.D. Equating damp heat testing with field failures of PV modules. In Proceedings of the 39th IEEE Photovoltaic Specialists Conference (PVSC), Tampa, FL, USA, 16–21 June 2013; pp. 126–131. [Google Scholar]

- Osterwald, C.R.; McMahon, T.J. History of accelerated and qualification testing of terrestrial photovoltaic modules: a literature review. Prog. Photovolt. 2009, 17, 11–33. [Google Scholar] [CrossRef]

- Wohlgemuth, J.H.; Kurtz, S. Using accelerated testing to predict module reliability. In Proceedings of the 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011; pp. 3601–3605. [Google Scholar]

- Wohlgemuth, J.H.; Cunningham, D.W.; Amin, D.; Shaner, J.; Xia, Z.; Miller, J. Using accelerated tests and field data to predict module reliability and lifetime. In Proceedings of the 23rd European Photovoltaic Solar Energy Conference and Exhibition (EUPVSEC), Valencia, Spain, 1–4 September 2008; pp. 2663–2669. [Google Scholar]

- Bennett, I.J.; Roca, F.; Graditi, G.; Zubilaga, O.; Malbranche, P.; Zhu, J.; Gottschalg, R.; Köhl, M.; Hoffmann, S.; Berger, K.A.; et al. PV module lifetime prediction and quality assurance as addressed by SOPHIYA. In Proceedings of the 29th European Photovoltaic Solar Energy Conference and Exhibition (EUPVSEC), Amsterdam, The Netherlands, 22–26 September 2014; pp. 2495–2498. [Google Scholar]

- Hacke, P.; Smith, R.; Terwilliger, K.; Glick, S.; Jordan, D.; Johnston, S.; Kempe, M.; Kurtz, S. Testing and analysis for lifetime prediction of crystalline silicon PV modules undergoing degradation by system voltage stress. IEEE J. Photvolt. 2013, 3, 246–253. [Google Scholar] [CrossRef]

- Meyer, E.L.; van Dyk, E.E. Assessing the reliability and degradation of photovoltaic module performance parameters. IEEE Trans. Reliab. 2004, 53, 83–92. [Google Scholar] [CrossRef]

- Khan, F.; Baek, S.H.; Kim, J.H. Intensity dependency of photovoltaic cell parameters under high illumination conditions: An analysis. Appl. Energy 2014, 133, 356–362. [Google Scholar] [CrossRef]

- Khan, F.; Baek, S.H.; Park, Y.; Kim, J.H. Extraction of diode parameters of silicon solar cells under high illumination conditions. Energy Con. Manag. 2013, 76, 421–429. [Google Scholar] [CrossRef]

- Phang, J.C.H.; Chan, D.S.H.; Phillips, J.R. Accurate analytical method for the extraction of solar cell model parameters. Electron. Lett. 1984, 20, 406–408. [Google Scholar] [CrossRef]

- Khan, F.; Baek, S.H.; Kim, J.H. Wide range temperature dependence of analytical photovoltaic parameters for silicon solar cells under high illumination conditions. Appl. Energy 2016, 183, 715–724. [Google Scholar] [CrossRef]

- Breitenstein, O.; Rakotoniaina, J.P.; Al Rifai, M.H.; Werner, M. Shunt type in crystalline silicon solar cells. Prog. Photovolt. 2004, 12, 529–538. [Google Scholar] [CrossRef]

- Singh, S.N.; Kumar, D. Phenomenological model of anomalously high photovoltage generated in obliquely deposited semiconductor films. J. Appl. Phys. 2008, 103, 023713. [Google Scholar] [CrossRef]

- Rummel, S.R.; McMahon, T.J. Effect of cell shunt resistance on module performance at reduced light levels. In Proceedings of the 13th NREL photovoltaics program review meeting, Lakewood, CO, USA, 16–19 May 1995; pp. 581–586. [Google Scholar]

- Chakravarty, B.C.; Arora, N.K.; Singh, S.N.; Das, B.K. Solar cell performance with an inhomogeneous grain size distribution. IEEE Trans. Electron. Dev. 1986, 33, 158–160. [Google Scholar] [CrossRef]

- Khan, F.; Singh, S.N.; Husain, M. Effect of illumination intensity on cell parameters of a silicon solar cell. Sol. Energy Mater. Sol. Cells 2010, 94, 1473–1476. [Google Scholar] [CrossRef]

- Khan, F.; Baek, S.H.; Kim, J.H. Determination of the diode parameters of a-Si and CdTe solar modules using variation of the intensity of illumination: An application. Sol. Energy 2011, 85, 2288–2294. [Google Scholar] [CrossRef]

- Khan, F.; Baek, S.H.; Singh, S.N.; Singh, P.K.; Kim, J.H. Effective passivation of silicon surface by AZO films: application in bifacial solar cells. Sol. Energy 2013, 97, 474–483. [Google Scholar] [CrossRef]

- Clifford, A.A. Multivariate Error Analysis: A Handbook of Error Propagation and Calculation in Many-Parameter Systems; John Wiley & Sons: New York, NY, USA, 1973. [Google Scholar]

| Parameters | Error (%) |

|---|---|

| Isc (A), Im (A), Voc (V), Vm (V) | 0.12 |

| FF | 0.21 |

| Pm, η | 0.56 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, F.; Kim, J.H. Performance Degradation Analysis of c-Si PV Modules Mounted on a Concrete Slab under Hot-Humid Conditions Using Electroluminescence Scanning Technique for Potential Utilization in Future Solar Roadways. Materials 2019, 12, 4047. https://doi.org/10.3390/ma12244047

Khan F, Kim JH. Performance Degradation Analysis of c-Si PV Modules Mounted on a Concrete Slab under Hot-Humid Conditions Using Electroluminescence Scanning Technique for Potential Utilization in Future Solar Roadways. Materials. 2019; 12(24):4047. https://doi.org/10.3390/ma12244047

Chicago/Turabian StyleKhan, Firoz, and Jae Hyun Kim. 2019. "Performance Degradation Analysis of c-Si PV Modules Mounted on a Concrete Slab under Hot-Humid Conditions Using Electroluminescence Scanning Technique for Potential Utilization in Future Solar Roadways" Materials 12, no. 24: 4047. https://doi.org/10.3390/ma12244047

APA StyleKhan, F., & Kim, J. H. (2019). Performance Degradation Analysis of c-Si PV Modules Mounted on a Concrete Slab under Hot-Humid Conditions Using Electroluminescence Scanning Technique for Potential Utilization in Future Solar Roadways. Materials, 12(24), 4047. https://doi.org/10.3390/ma12244047