Influence of Non-Thermal Atmospheric Pressure Plasma Treatment on Shear Bond Strength between Y-TZP and Self-Adhesive Resin Cement

Abstract

:1. Introduction

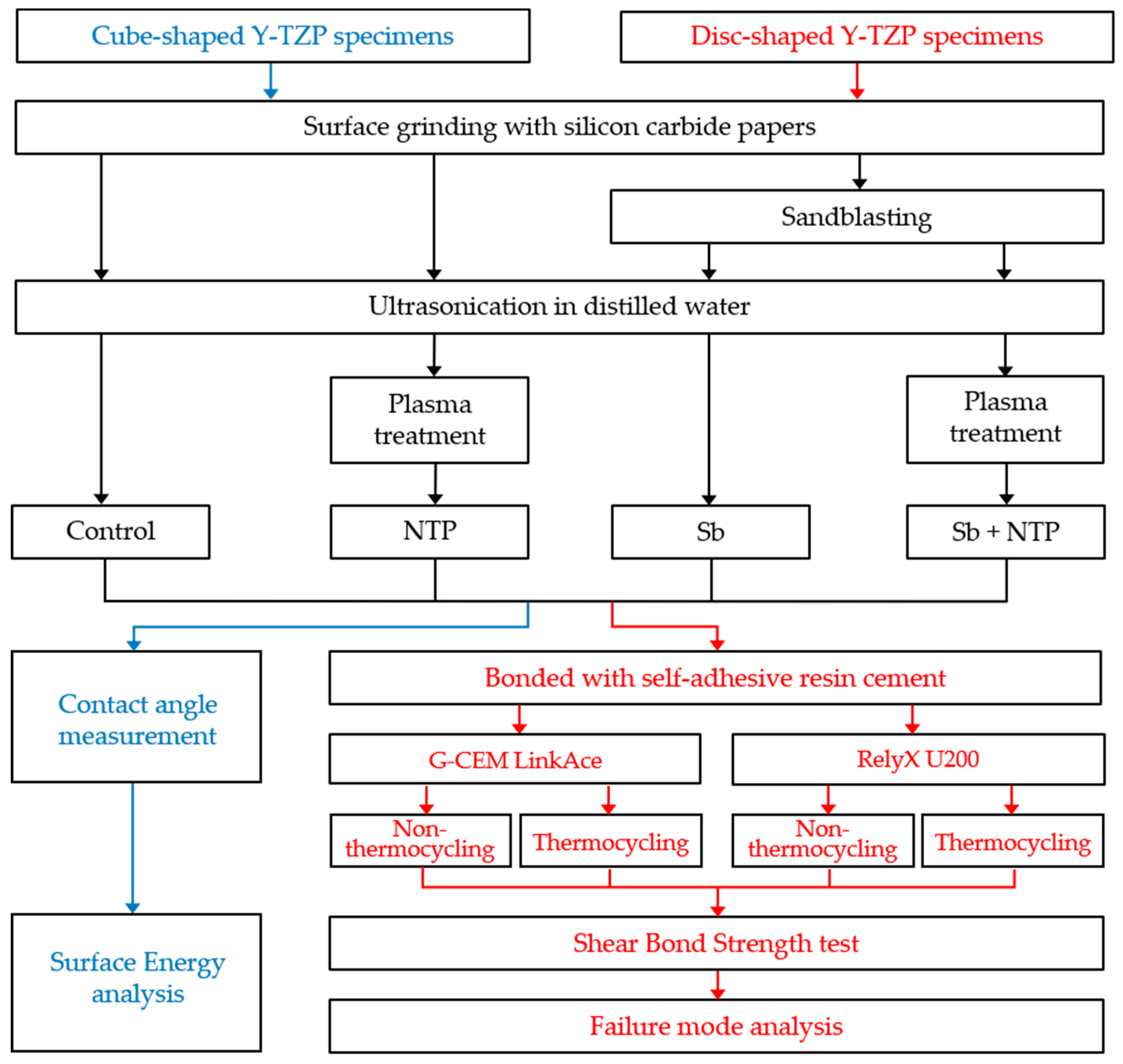

2. Materials and Methods

2.1. Preparation of Y-TZP Specimens

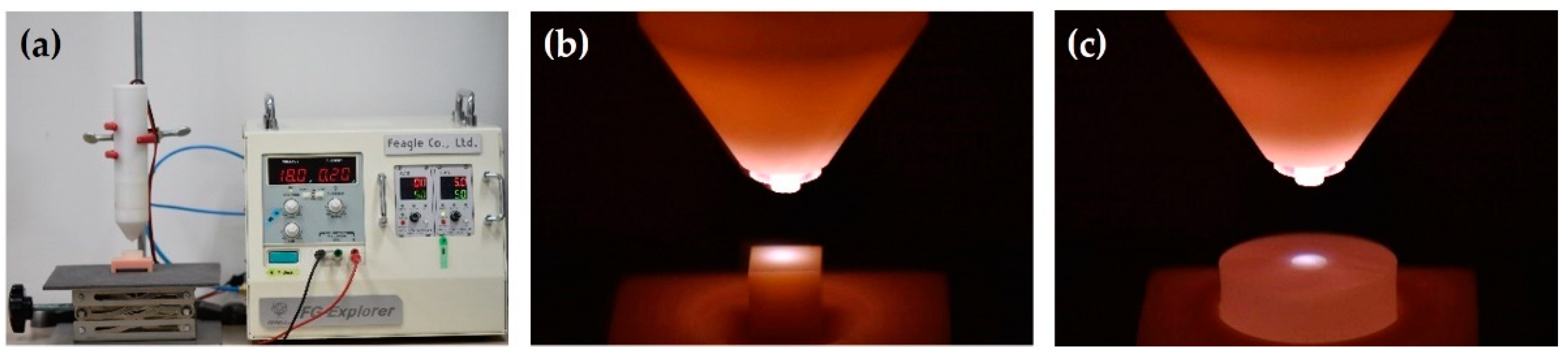

2.2. Non-thermal Atmospheric Pressure Plasma (NTP) Treatment

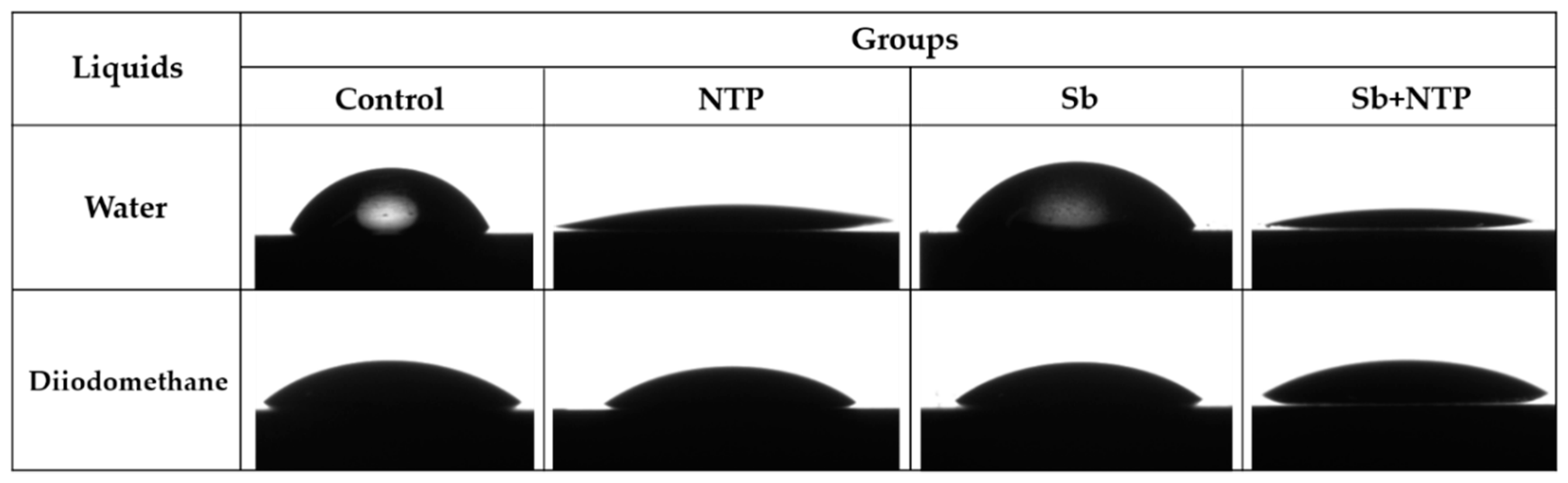

2.3. Contact Angle Measurement and Surface Energy (SE) Analysis

2.4. Shear Bond Strength (SBS) Test

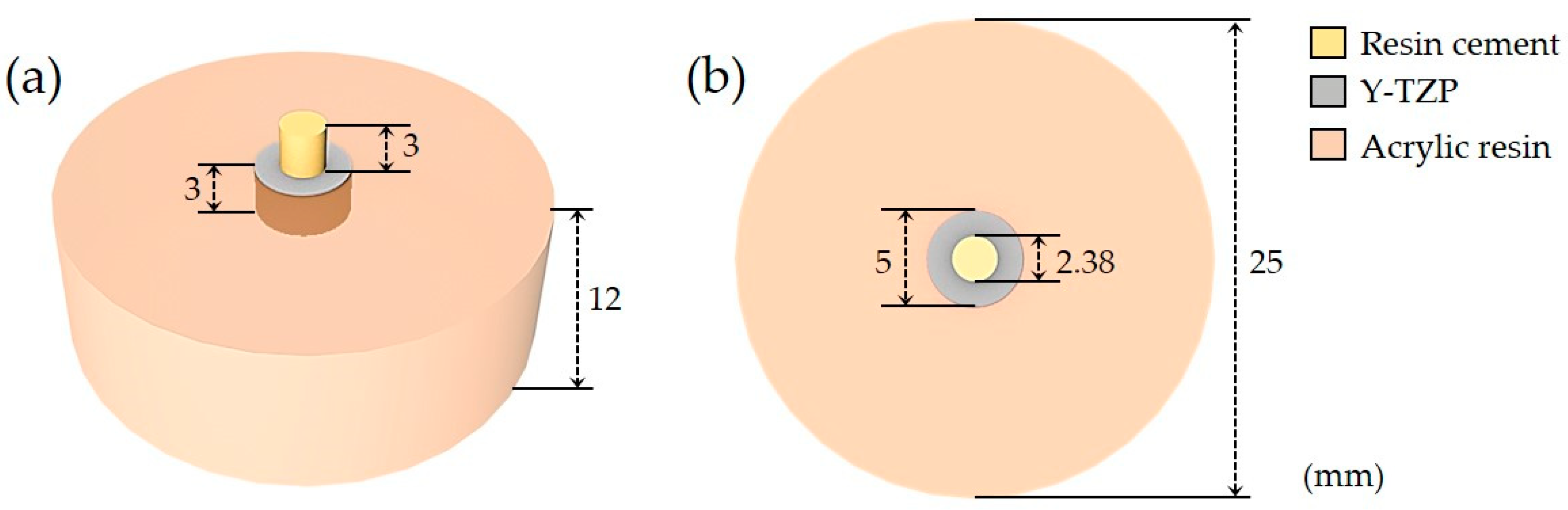

2.4.1. Fabrication of Y-TZP Specimens Bonded with Self-Adhesive Resin Cement Cylinders

2.4.2. Thermocycling Process and Shear Bond Strength (SBS) Measurement

2.5. Failure Mode Analysis

2.6. Statistical Analysis

3. Results

3.1. Contact Angle Measurement and Surface Energy (SE) Analysis

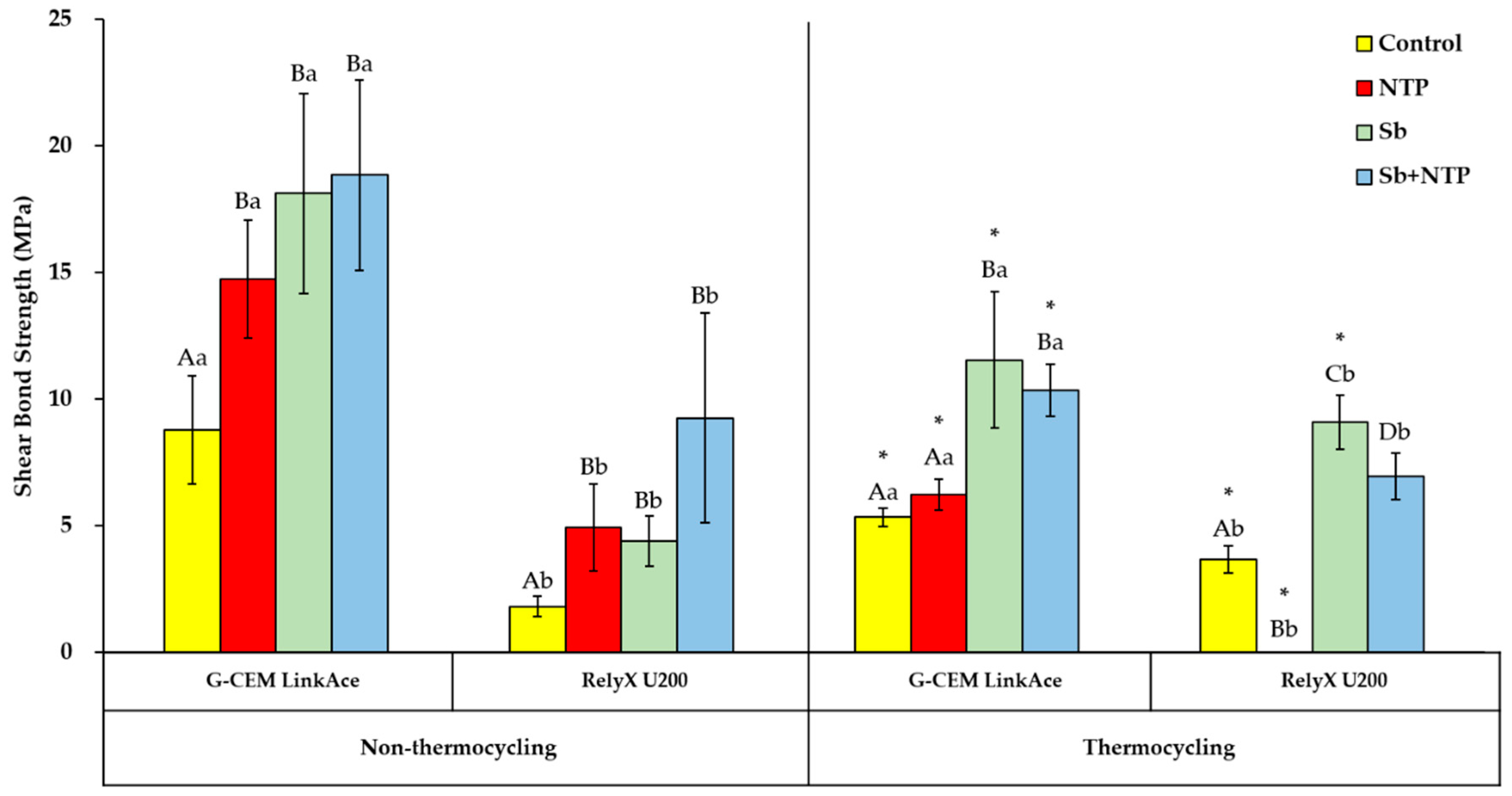

3.2. Shear Bond Strength (SBS) Test

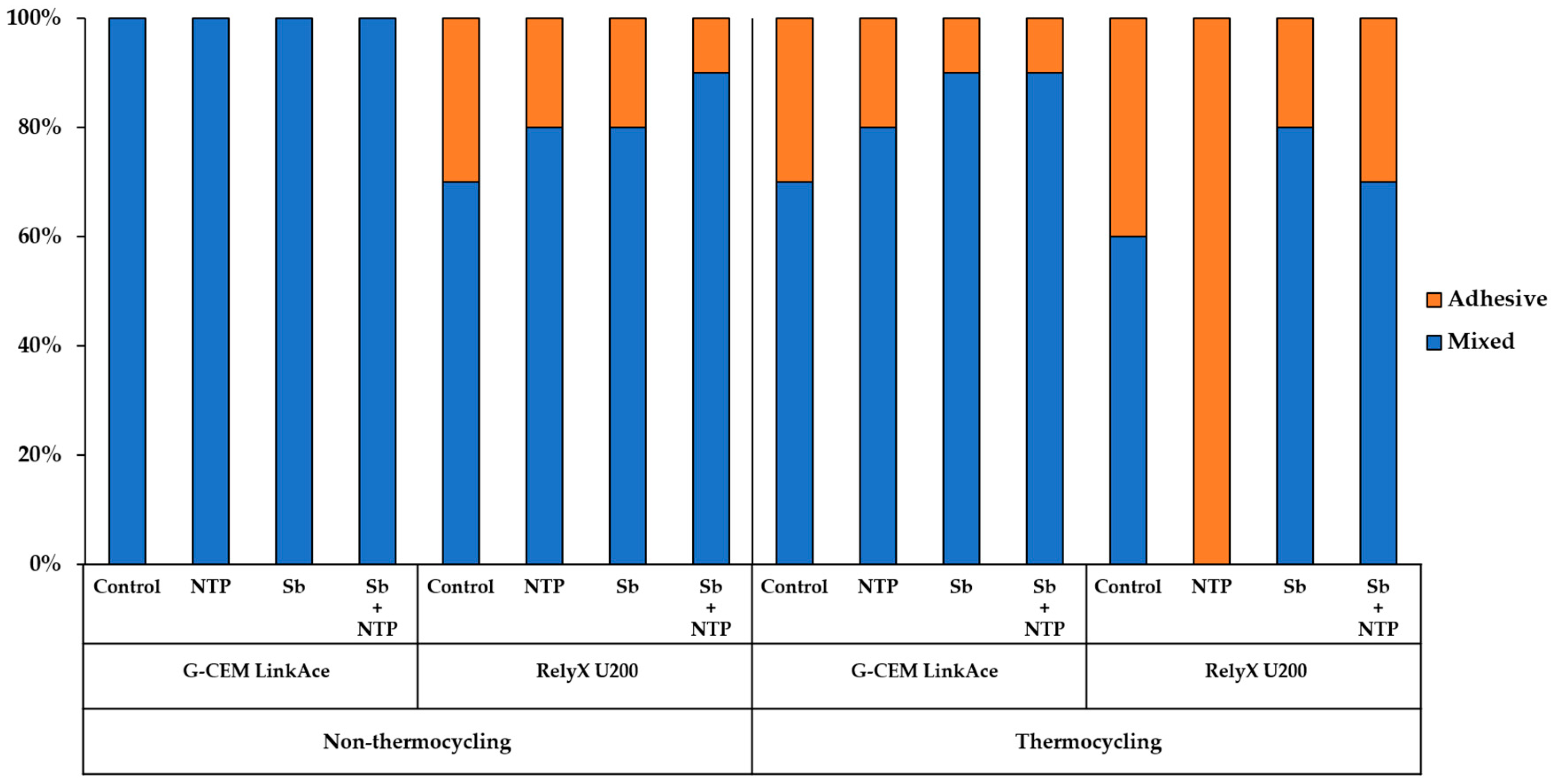

3.3. Failure Mode Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Alao, A.R.; Stoll, R.; Song, X.F.; Miyazaki, T.; Hotta, Y.; Shibata, Y.; Yin, L. Surface quality of yttria-stabilized tetragonal zirconia polycrystal in CAD/CAM milling, sintering, polishing and sandblasting processes. J. Mech. Behav. Biomed. Mater. 2017, 65, 102–116. [Google Scholar] [CrossRef] [PubMed]

- Vilas Boas Fernandes Junior, V.; Barbosa Dantas, D.C.; Bresciani, E.; Rocha Lima Huhtala, M.F. Evaluation of the bond strength and characteristics of zirconia after different surface treatments. J. Prosthet. Dent. 2018, 120, 955–959. [Google Scholar] [CrossRef] [PubMed]

- Keul, C.; Liebermann, A.; Roos, M.; Uhrenbacher, J.; Stawarczyk, B.; Ing, D. The effect of ceramic primer on shear bond strength of resin composite cement to zirconia: A function of water storage and thermal cycling. J. Am. Dent. Assoc. 2013, 144, 1261–1271. [Google Scholar] [CrossRef] [PubMed]

- Da Silva, B.T.F.; Trevelin, L.T.; Teixeira, F.D.S.; Salvadori, M.C.; Cesar, P.F.; Bona Matos, A. Non-thermal plasma increase bond strength of zirconia to a resin cement. Braz. Dent. Sci. 2018, 21, 210–219. [Google Scholar] [CrossRef] [Green Version]

- Vechiato Filho, A.J.; dos Santos, D.M.; Goiato, M.C.; de Medeiros, R.A.; Moreno, A.; Bonatto Lda, R.; Rangel, E.C. Surface characterization of lithium disilicate ceramic after nonthermal plasma treatment. J. Prosthet. Dent. 2014, 112, 1156–1163. [Google Scholar] [CrossRef] [PubMed]

- Piascik, J.R.; Swift, E.J.; Braswell, K.; Stoner, B.R. Surface fluorination of zirconia: Adhesive bond strength comparison to commercial primers. Dent. Mater. 2012, 28, 604–608. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Hong, L.; Hottel, T.; Dong, X.; Yu, Q.; Chen, M. Non-thermal plasma enhanced bonding of resin cement to zirconia ceramic. Clin. Plasma. Med. 2016, 4, 50–55. [Google Scholar] [CrossRef] [Green Version]

- Ahn, J.S.; Yi, Y.A.; Lee, Y.; Seo, D.G. Shear Bond Strength of MDP-Containing Self-Adhesive Resin Cement and Y-TZP Ceramics: Effect of Phosphate Monomer-Containing Primers. Biomed. Res. Int. 2015, 2015, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Wegner, S.M.; Kern, M. Long-term Resin Bond Strength to Zirconia Ceramic. J. Adhes. Dent. 2000, 2, 139–147. [Google Scholar]

- Kim, J.H.; Chae, S.; Lee, Y.; Han, G.J.; Cho, B.H. Comparison of shear test methods for evaluating the bond strength of resin cement to zirconia ceramic. Acta. Odontol. Scand. 2014, 72, 745–752. [Google Scholar] [CrossRef]

- Zhang, Y.; Lawn, B.R.; Rekow, E.D.; Thompson, V.P. Effect of sandblasting on the long-term performance of dental ceramics. J. Biomed. Mater. Res. B Appl. Biomater. 2004, 71, 381–386. [Google Scholar] [CrossRef] [PubMed]

- Kern, M. Bonding to oxide ceramics-laboratory testing versus clinical outcome. Dent. Mater. 2015, 31, 8–14. [Google Scholar] [CrossRef] [PubMed]

- Blatz, M.B.; Vonderheide, M.; Conejo, J. The Effect of Resin Bonding on Long-Term Success of High-Strength Ceramics. J. Dent. Res. 2018, 97, 132–139. [Google Scholar] [CrossRef] [PubMed]

- Kern, M.; Wegner, S.M. Bonding to zirconia ceramic: Adhesion methods and their durability. Dent. Mater. 1998, 14, 64–71. [Google Scholar] [CrossRef]

- Lee, S.-E.; Bae, J.-H.; Choi, J.-W.; Jeon, Y.-C.; Jeong, C.-M.; Yoon, M.-J.; Huh, J.-B. Comparative Shear-Bond Strength of Six Dental Self-Adhesive Resin Cements to Zirconia. Materials 2015, 8, 3306–3315. [Google Scholar] [CrossRef] [Green Version]

- Yi, Y.A.; Ahn, J.S.; Park, Y.J.; Jun, S.H.; Lee, I.B.; Cho, B.H.; Son, H.H.; Seo, D.G. The effect of sandblasting and different primers on shear bond strength between yttria-tetragonal zirconia polycrystal ceramic and a self-adhesive resin cement. Oper. Dent. 2015, 40, 63–71. [Google Scholar] [CrossRef] [PubMed]

- Kern, M.; Passia, N.; Sasse, M.; Yazigi, C. Ten-year outcome of zirconia ceramic cantilever resin-bonded fixed dental prostheses and the influence of the reasons for missing incisors. J. Dent. 2017, 65, 51–55. [Google Scholar] [CrossRef]

- Scaminaci Russo, D.; Cinelli, F.; Sarti, C.; Giachetti, L. Adhesion to Zirconia: A Systematic Review of Current Conditioning Methods and Bonding Materials. Dent. J. 2019, 7, 74. [Google Scholar] [CrossRef]

- Tzanakakis, E.G.; Tzoutzas, I.G.; Koidis, P.T. Is there a potential for durable adhesion to zirconia restorations? A systematic review. J. Prosthet. Dent. 2016, 115, 9–19. [Google Scholar] [CrossRef]

- Chu, P.K.; Chen, J.Y.; Wang, L.P.; Huang, N. Plasma-surface modification of biomaterials. Mater. Sci. Eng. R. Rep. 2002, 36, 143–206. [Google Scholar] [CrossRef] [Green Version]

- Chen, M.; Zhang, Y.; Sky Driver, M.; Caruso, A.N.; Yu, Q.; Wang, Y. Surface modification of several dental substrates by non-thermal, atmospheric plasma brush. Dent. Mater. 2013, 29, 871–880. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Y.C.; Hsieh, J.P.; Chen, Y.C.; Kang, L.L.; Hwang, C.S.; Chuang, S.F. Promoting porcelain-zirconia bonding using different atmospheric pressure gas plasmas. Dent. Mater. 2018, 34, 1188–1198. [Google Scholar] [CrossRef] [PubMed]

- Vechiato-Filho, A.J.; Matos, A.O.; Landers, R.; Goiato, M.C.; Rangel, E.C.; De Souza, G.M.; Barao, V.A.R.; Dos Santos, D.M. Surface analysis and shear bond strength of zirconia on resin cements after non-thermal plasma treatment and/or primer application for metallic alloys. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 72, 284–292. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Park, C.; Yoo, S.H.; Park, S.W.; Yun, K.D.; Ji, M.K.; Shin, J.H.; Lim, H.P. The effect of plasma on shear bond strength between resin cement and colored zirconia. J. Adv. Prosthodont. 2017, 9, 118–123. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pott, P.C.; Syvari, T.S.; Stiesch, M.; Eisenburger, M. Influence of nonthermal argon plasma on the shear bond strength between zirconia and different adhesives and luting composites after artificial aging. J. Adv. Prosthodont. 2018, 10, 308–314. [Google Scholar] [CrossRef] [PubMed]

- Ito, Y.; Okawa, T.; Fukumoto, T.; Tsurumi, A.; Tatsuta, M.; Fujii, T.; Tanaka, J.; Tanaka, M. Influence of atmospheric pressure low-temperature plasma treatment on the shear bond strength between zirconia and resin cement. J. Prosthodont. Res. 2016, 60, 289–293. [Google Scholar] [CrossRef] [PubMed]

- Tabari, K.; Hosseinpour, S.; Mohammad-Rahimi, H. The Impact of Plasma Treatment of Cercon(R) Zirconia Ceramics on Adhesion to Resin Composite Cements and Surface Properties. J. Lasers. Med. Sci. 2017, 8, S56–S61. [Google Scholar] [CrossRef]

- ISO 29022:2013. Dentistry-Adhesion-Notched-Edge Shear Bond Strength Test; International Organization for Standardization: Geneva, Switzerland, 2013. [Google Scholar]

- Abi-Rached, F.O.; Martins, S.B.; Campos, J.A.; Fonseca, R.G. Evaluation of roughness, wettability, and morphology of an yttria-stabilized tetragonal zirconia polycrystal ceramic after different airborne-particle abrasion protocols. J. Prosthet. Dent. 2014, 112, 1385–1391. [Google Scholar] [CrossRef]

- Al-Shehri, E.Z.; Al-Zain, A.O.; Sabrah, A.H.; Al-Angari, S.S.; Al Dehailan, L.; Eckert, G.J.; Ozcan, M.; Platt, J.A.; Bottino, M.C. Effects of air-abrasion pressure on the resin bond strength to zirconia: A combined cyclic loading and thermocycling aging study. Restor. Dent. Endod. 2017, 42, 206–215. [Google Scholar] [CrossRef]

- He, M.; Zhang, Z.; Zheng, D.; Ding, N.; Liu, Y. Effect of sandblasting on surface roughness of zirconia-based ceramics and shear bond strength of veneering porcelain. Dent. Mater. J. 2014, 33, 778–785. [Google Scholar] [CrossRef] [Green Version]

- Elias, A.B.; Simao, R.A.; Prado, M.; Cesar, P.F.; Botelho Dos Santos, G.; Moreira da Silva, E. Effect of different times of nonthermal argon plasma treatment on the microtensile bond strength of self-adhesive resin cement to yttria-stabilized tetragonal zirconia polycrystal ceramic. J. Prosthet. Dent. 2019, 121, 485–491. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.H.; Min, B.K.; Son, J.S.; Kwon, T.Y. Influence of Different Post-Plasma Treatment Storage Conditions on the Shear Bond Strength of Veneering Porcelain to Zirconia. Materials 2016, 9, 43. [Google Scholar] [CrossRef] [PubMed]

- Ito, Y.; Okawa, T.; Fujii, T.; Tanaka, M. Influence of plasma treatment on surface properties of zirconia. J. Osaka. Dent. Univ. 2016, 50, 79–84. [Google Scholar]

- Park, C.; Park, S.W.; Yun, K.D.; Ji, M.K.; Kim, S.; Yang, Y.P.; Lim, H.P. Effect of Plasma Treatment and Its Post Process Duration on Shear Bonding Strength and Antibacterial Effect of Dental Zirconia. Materials 2018, 11, 2233. [Google Scholar] [CrossRef] [PubMed]

- Valverde, G.B.; Coelho, P.G.; Janal, M.N.; Lorenzoni, F.C.; Carvalho, R.M.; Thompson, V.P.; Weltemann, K.D.; Silva, N.R. Surface characterisation and bonding of Y-TZP following non-thermal plasma treatment. J. Dent. 2013, 41, 51–59. [Google Scholar] [CrossRef] [PubMed]

- De Oliveira Lino, L.F.; Machado, C.M.; de Paula, V.G.; Vidotti, H.A.; Coelho, P.G.; Benalcazar Jalkh, E.B.; Pegoraro, T.A.; Bonfante, E.A. Effect of aging and testing method on bond strength of CAD/CAM fiber-reinforced composite to dentin. Dent. Mater. 2018, 34, 1690–1701. [Google Scholar] [CrossRef] [PubMed]

- Hallmann, L.; Ulmer, P.; Lehmann, F.; Wille, S.; Polonskyi, O.; Johannes, M.; Kobel, S.; Trottenberg, T.; Bornholdt, S.; Haase, F.; et al. Effect of surface modifications on the bond strength of zirconia ceramic with resin cement resin. Dent. Mater. 2016, 32, 631–639. [Google Scholar] [CrossRef]

- Lumkemann, N.; Eichberger, M.; Stawarczyk, B. Different surface modifications combined with universal adhesives: The impact on the bonding properties of zirconia to composite resin cement. Clin. Oral. Investig. 2019, 1–10. [Google Scholar] [CrossRef]

- Labriaga, W.; Song, S.Y.; Park, J.H.; Ryu, J.J.; Lee, J.Y.; Shin, S.W. Effect of non-thermal plasma on the shear bond strength of resin cements to Polyetherketoneketone (PEKK). J. Adv. Prosthodont. 2018, 10, 408–414. [Google Scholar] [CrossRef] [Green Version]

- Linkevicius, T.; Caplikas, A.; Dumbryte, I.; Linkeviciene, L.; Svediene, O. Retention of zirconia copings over smooth and airborne-particle-abraded titanium bases with different resin cements. J. Prosthet. Dent. 2019, 121, 949–954. [Google Scholar] [CrossRef]

- Youm, S.H.; Jung, K.H.; Son, S.A.; Kwon, Y.H.; Park, J.K. Effect of dentin pretreatment and curing mode on the microtensile bond strength of self-adhesive resin cements. J. Adv. Prosthodont. 2015, 7, 317–322. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Groups | Distribution of Y-TZP specimens (n) | ||||

|---|---|---|---|---|---|

| Surface Energy (SE) analysis | Shear Bond Strength (SBS) test | ||||

| G-CEM LinkAce | RelyX U200 | ||||

| Non-thermocycling | Thermocycling | Non-thermocycling | Thermocycling | ||

| Control | 3 | 10 | 10 | 10 | 10 |

| NTP | 3 | 10 | 10 | 10 | 10 |

| Sb | 3 | 10 | 10 | 10 | 10 |

| Sb + NTP | 3 | 10 | 10 | 10 | 10 |

| Material | Manufacture | Type | Composition |

|---|---|---|---|

| G-CEM LinkAce | GC Corporation, Tokyo, Japan | Self-adhesive Dual-cure Automix | Paste A: Fluoroalumino silicate glass, Urethane dimethacrylate (UDMA), Dimethacrylate, Pigment, Silicon dioxide, Initiator, Inhibitor |

| Paste B: Urethane dimethacrylate (UDMA), Dimethacrylate, Phosphoric acid ester monomer, Initiator, stabilizer | |||

| RelyX U200 | 3M ESPE, St. Paul, MN, USA | Self-adhesive Dual-cure Automix | Base paste: Methacrylate monomers containing phosphoric acid groups, Methacrylate monomers, Silanated fillers, Initiator components, Stabilizers, Rheological additives |

| Catalyst paste: Methacrylate monomers, Alkaline(basic) fillers, Silanated fillers, Initiator components, Stabilizers, Pigments, Rheological additives |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.-S.; Ahn, J.-J.; Bae, E.-B.; Kim, G.-C.; Jeong, C.-M.; Huh, J.-B.; Lee, S.-H. Influence of Non-Thermal Atmospheric Pressure Plasma Treatment on Shear Bond Strength between Y-TZP and Self-Adhesive Resin Cement. Materials 2019, 12, 3321. https://doi.org/10.3390/ma12203321

Kim D-S, Ahn J-J, Bae E-B, Kim G-C, Jeong C-M, Huh J-B, Lee S-H. Influence of Non-Thermal Atmospheric Pressure Plasma Treatment on Shear Bond Strength between Y-TZP and Self-Adhesive Resin Cement. Materials. 2019; 12(20):3321. https://doi.org/10.3390/ma12203321

Chicago/Turabian StyleKim, Dae-Sung, Jong-Ju Ahn, Eun-Bin Bae, Gyoo-Cheon Kim, Chang-Mo Jeong, Jung-Bo Huh, and So-Hyoun Lee. 2019. "Influence of Non-Thermal Atmospheric Pressure Plasma Treatment on Shear Bond Strength between Y-TZP and Self-Adhesive Resin Cement" Materials 12, no. 20: 3321. https://doi.org/10.3390/ma12203321