A Facile Approach for Preparing Ag Functionalized Nonwoven Polypropylene Membrane to Improve Its Electrical Conductivity and Electromagnetic Shielding Performance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Ag Coated Nonwoven Polypropylene

2.3. Characterizations

2.4. Weight Gain Rate and Washing Stability

2.5. Surface Resistance and Electromagnetic Shielding

3. Results and Discussion

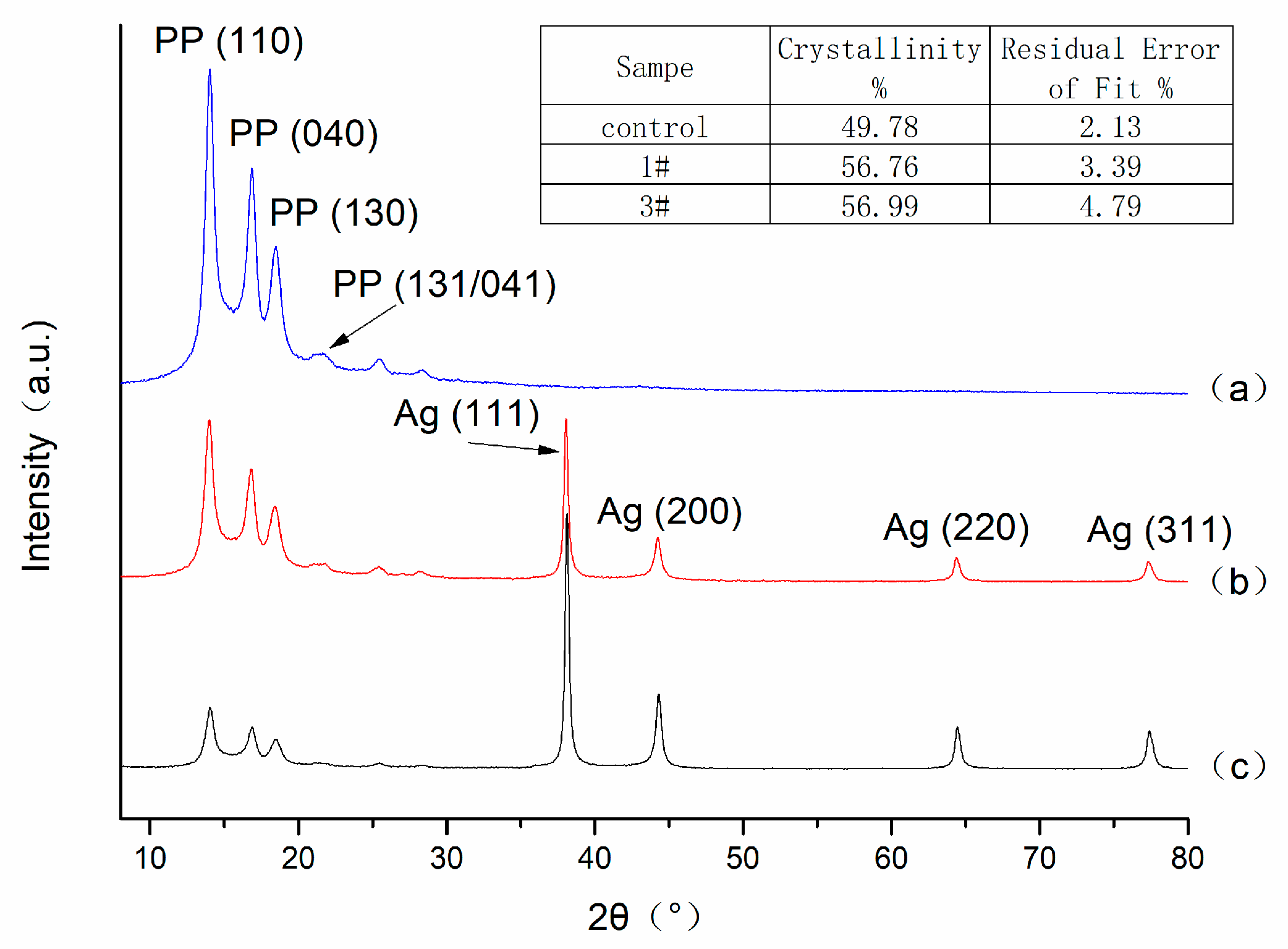

3.1. Crystalline Structure Analysis

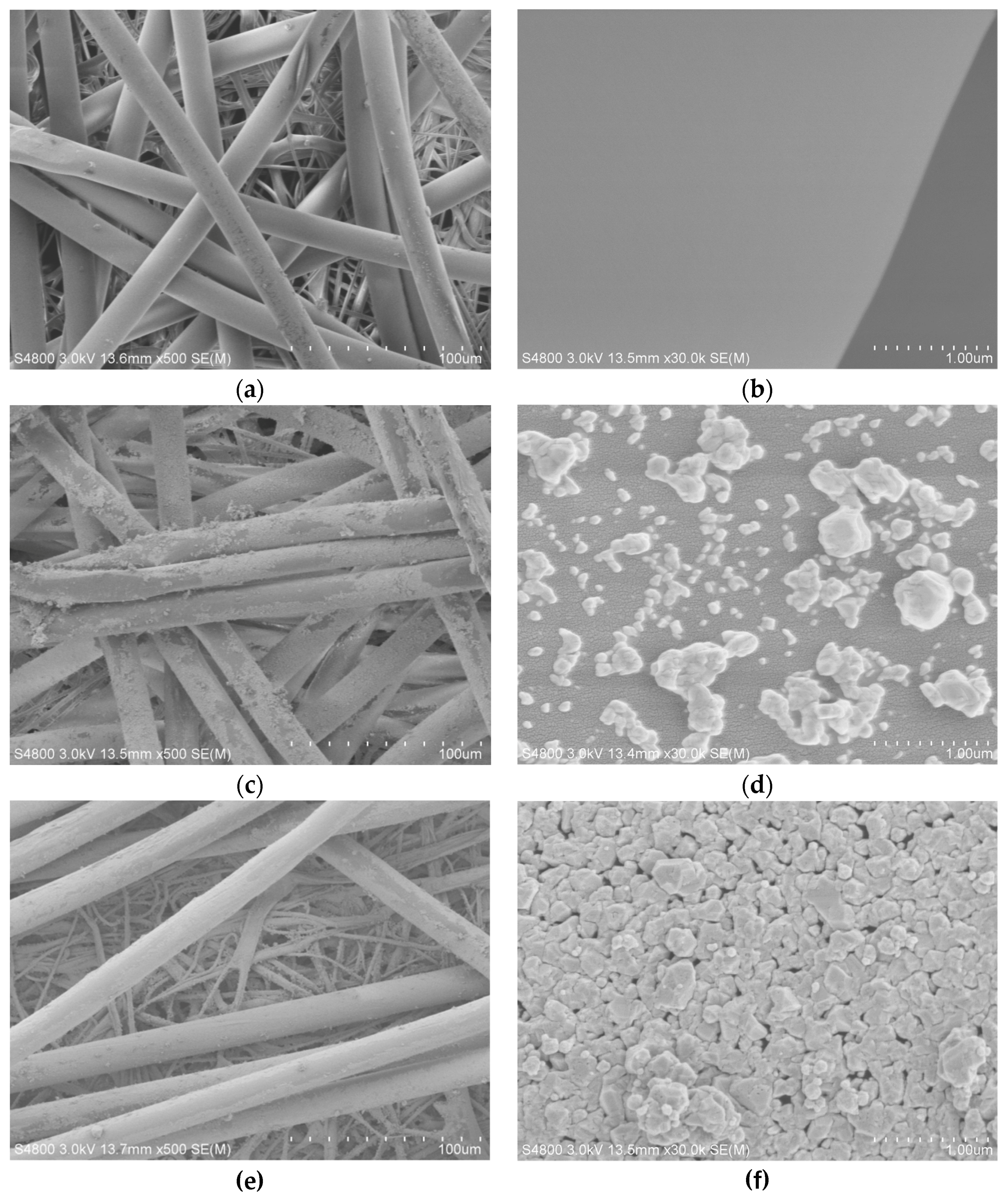

3.2. Surface Morphology Analysis

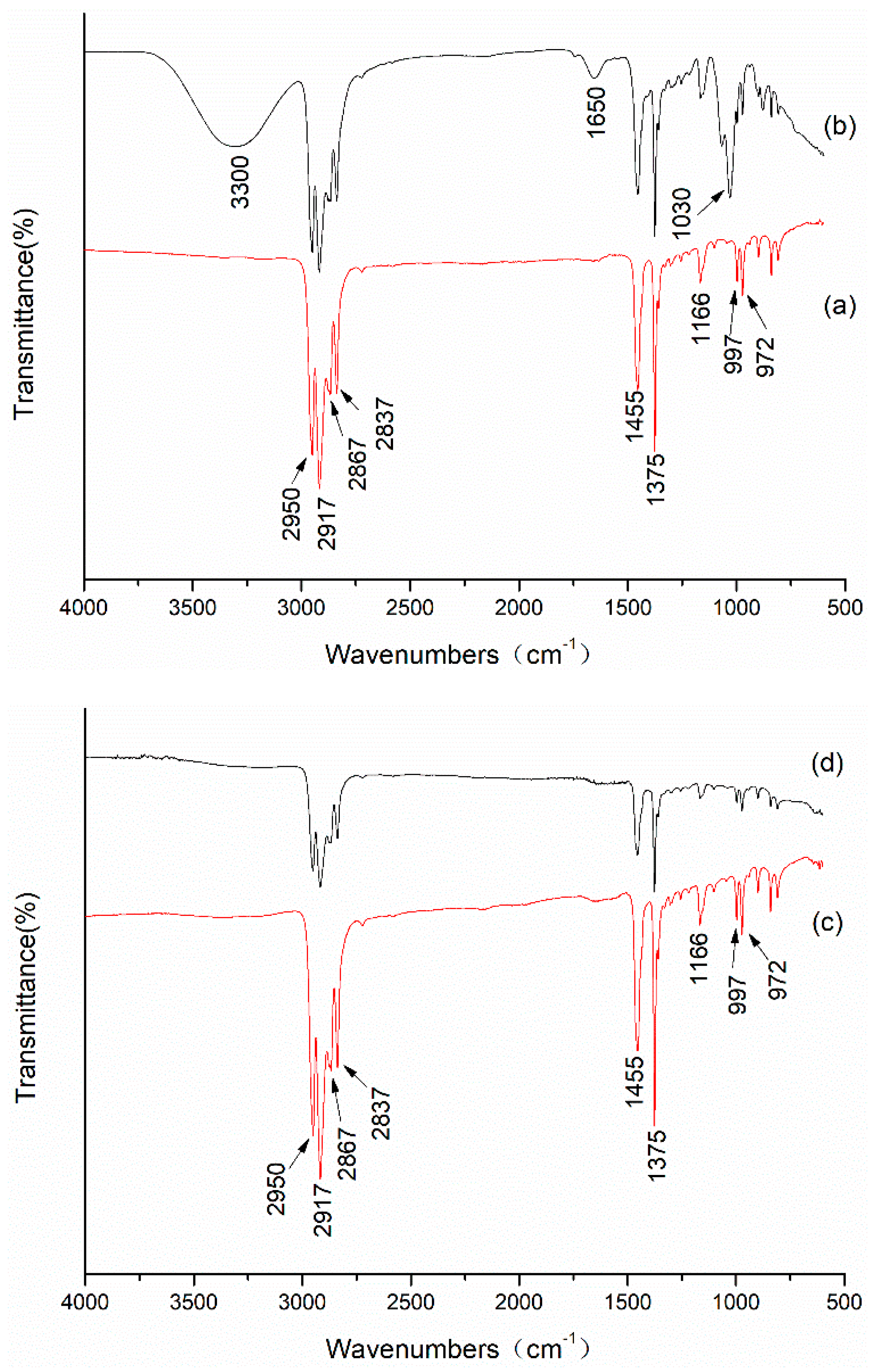

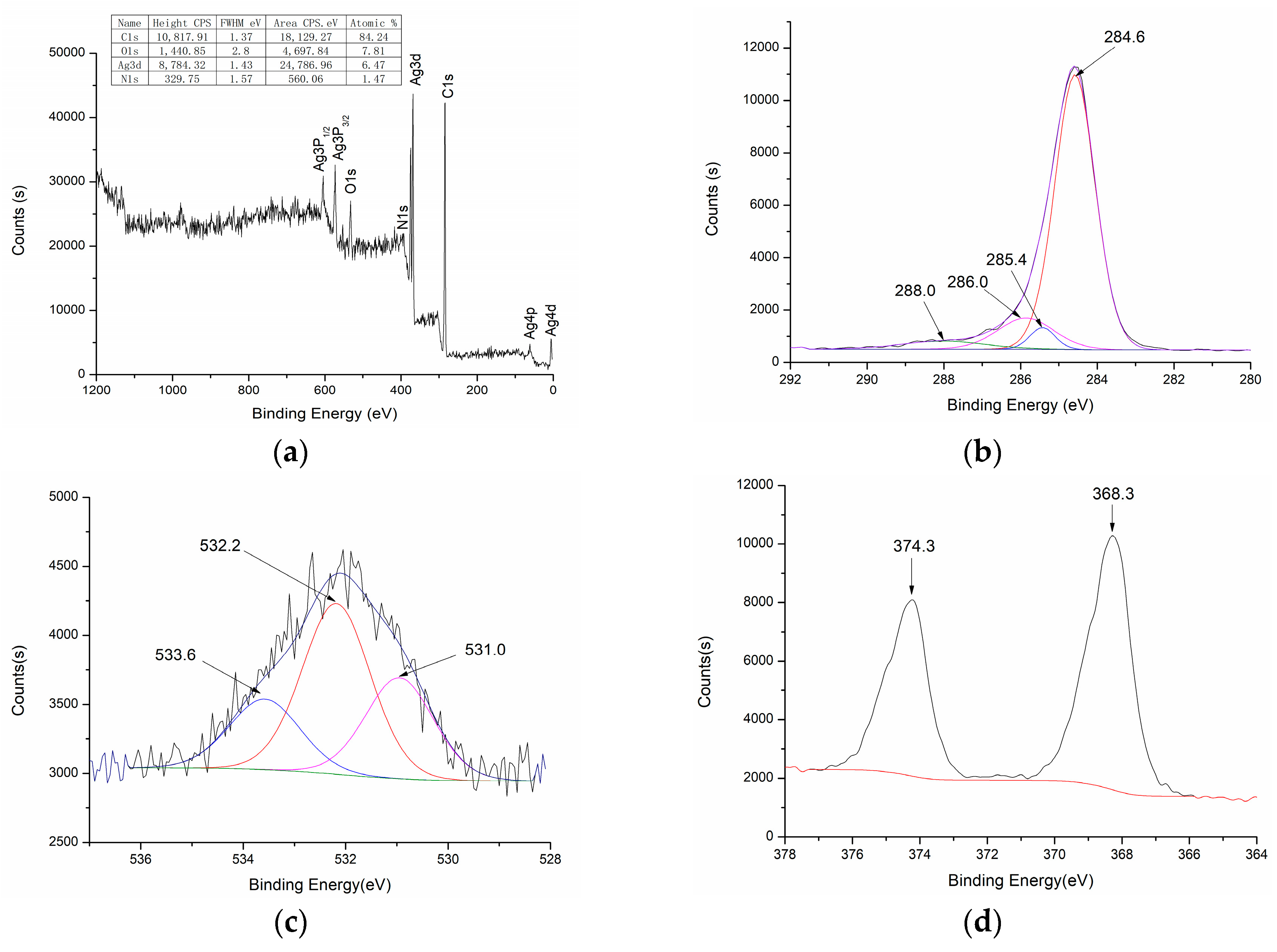

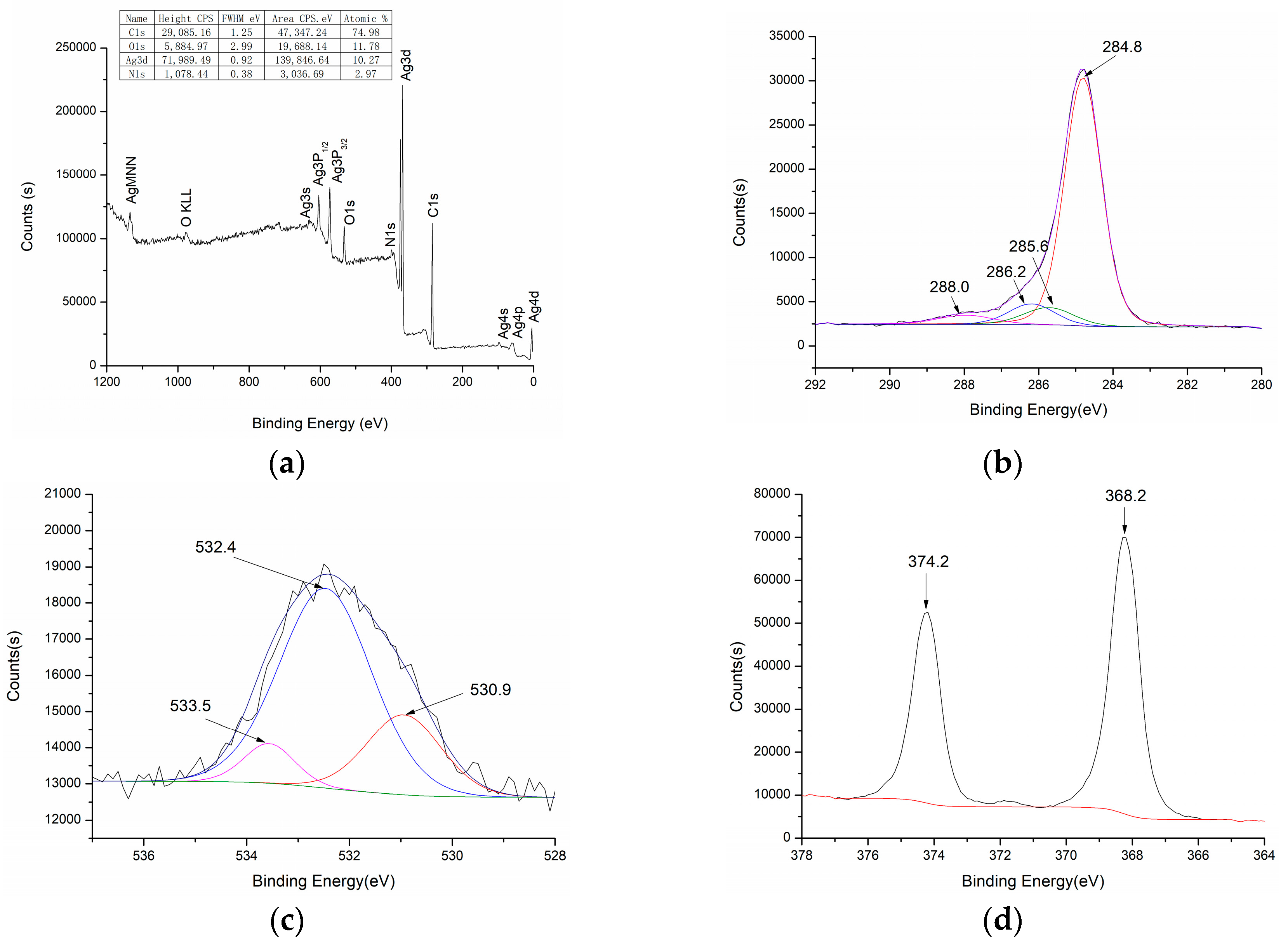

3.3. Surface Chemistry Analysis

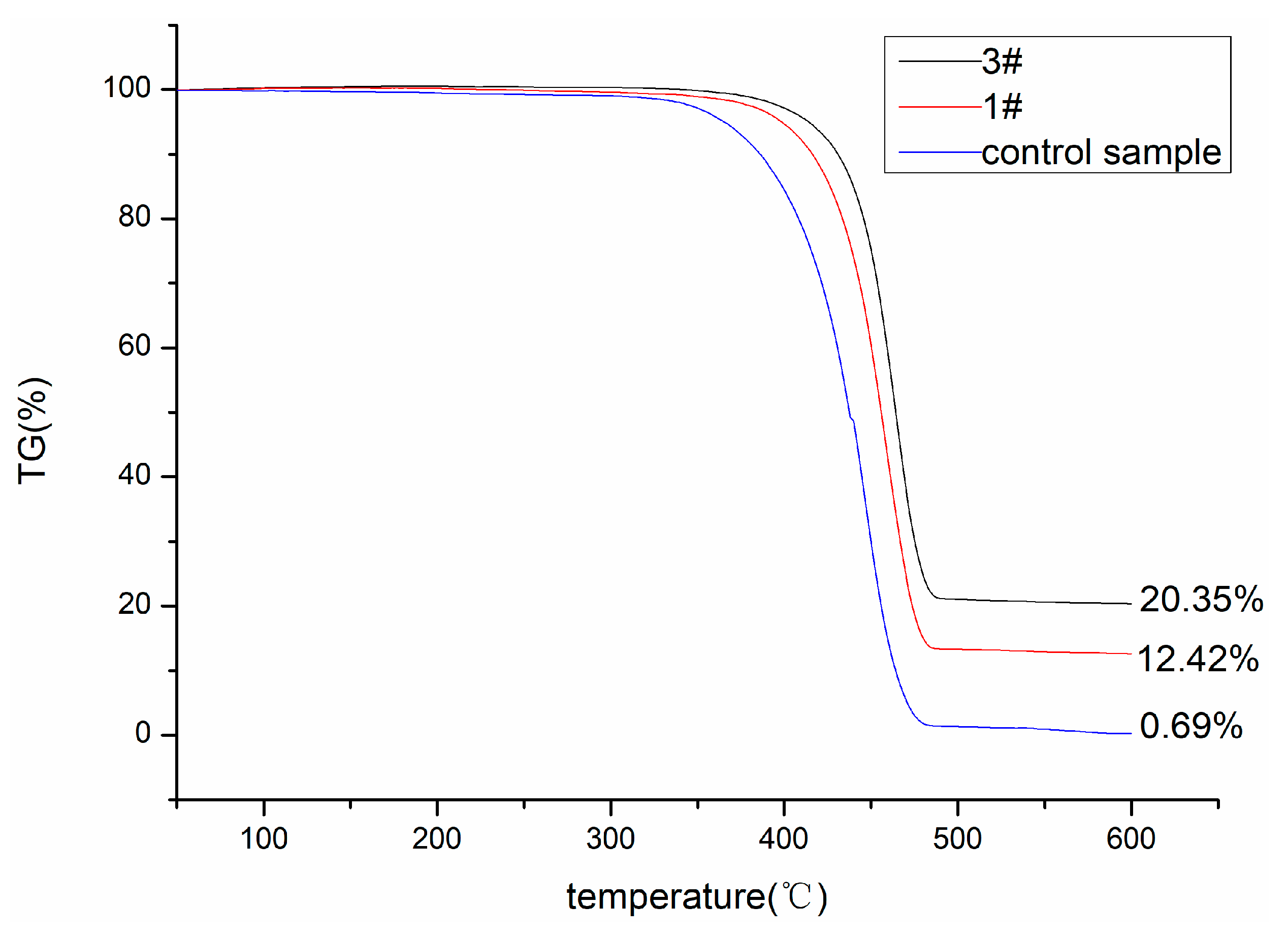

3.4. Thermogravimetric Analyses

3.5. Weight Gain Rate and Washing Stability

3.6. Surface Resistance

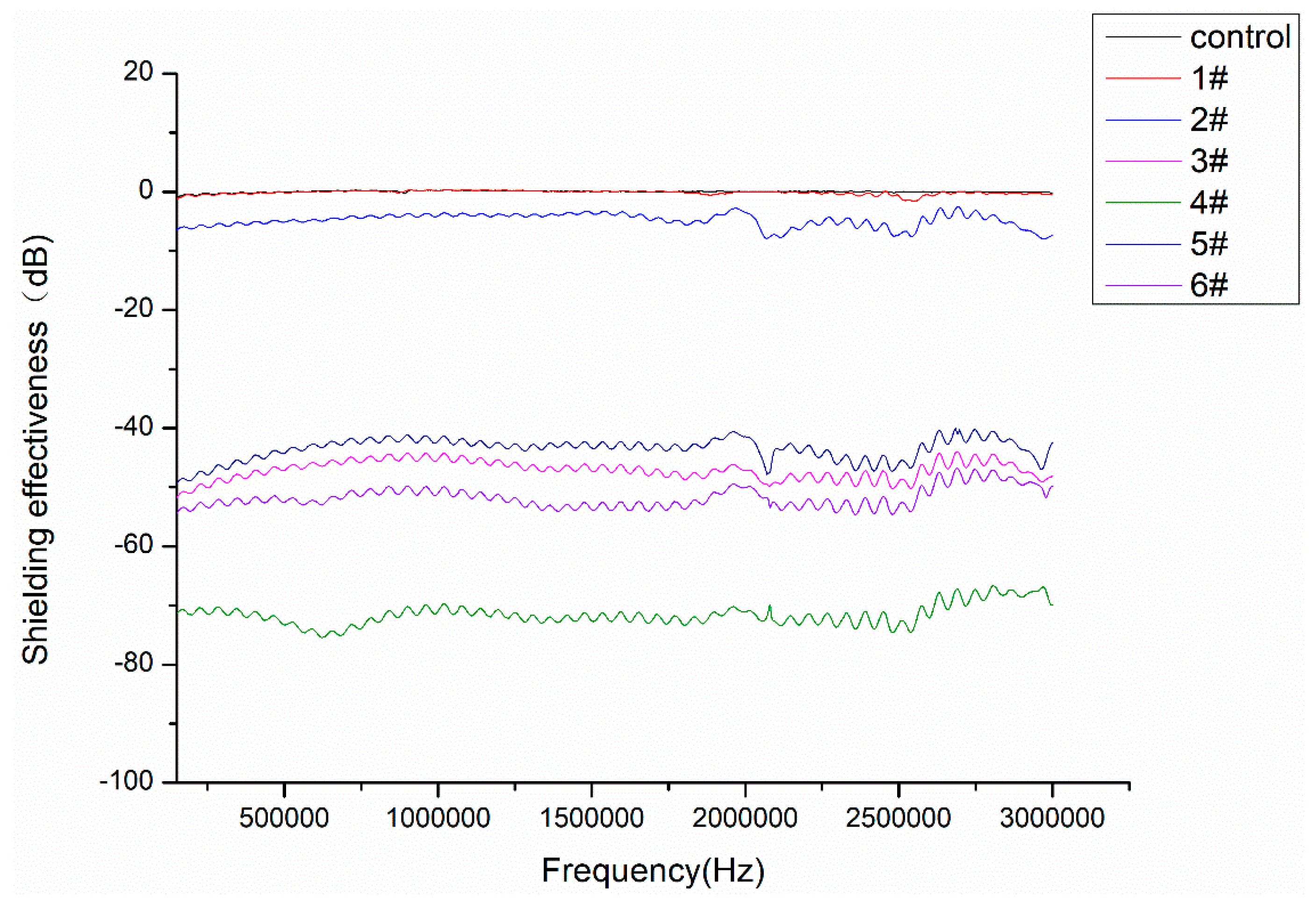

3.7. Electromagnetic Shielding

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ozen, M.S.; Sancak, E.; Soin, N.; Shah, T.H.; Siores, E. Investigation of electromagnetic shielding effectiveness of needle punched nonwoven fabric produced from conductive silver coated staple polyamide fibre. J. Text. Ind. 2015, 107, 912–922. [Google Scholar] [CrossRef]

- Özdemir, H.; Uğurlu, Ş.S.; Özkurt, A. The electromagnetic shielding of textured steel yarn based woven fabrics used for clothing. J. Ind. Text. 2015, 45, 416–436. [Google Scholar] [CrossRef]

- Wang, Y.; Luo, S.; Ren, K.; Zhao, S.; Chen, Z.; Li, W.; Guan, J. Facile preparation of graphite particles fully coated with thin Ag shell layers for high performance conducting and electromagnetic shielding composite materials. J. Mat. Chem. C 2016, 4, 2566–2578. [Google Scholar] [CrossRef]

- Xu, W.; Yuan, X.; Wei, A.; Feng, Q.; Wei, Q. Characterisation of pet nonwoven deposited with ag/fc nanocomposite films. Surf. Eng. 2017, 1–8. [Google Scholar] [CrossRef]

- Wang, W.; Li, W.; Gao, C.; Tian, W.; Sun, B.; Yu, D. A novel preparation of silver-plated polyacrylonitrile fibers functionalized with antibacterial and electromagnetic shielding properties. Appl. Surf. Sci. 2015, 342, 120–126. [Google Scholar] [CrossRef]

- Ozen, M.S.; Sancak, E.; Soin, N.; Shah, T.H.; Zarei, A.; Siores, E. Unprecedented electromagnetic shielding effectiveness of lightweight nonwoven ag/pa66 fabrics. Fiber Polym. 2018, 19, 321–330. [Google Scholar] [CrossRef]

- Karami, Z.; Youssefi, M.; Borhani, S. The effects of uv irradiation exposure on the structure and properties of polypropylene/zno nanocamposite fibers. Fiber Polym. 2013, 14, 1627–1634. [Google Scholar] [CrossRef]

- Yeo, S.Y.; Jeong, S.H. Preparation and characterization of polypropylene/silver nanocomposite fibers. Polym. Int. 2003, 52, 1053–1057. [Google Scholar] [CrossRef]

- Wang, H.B.; Wei, Q.F.; Wang, J.Y.; Hong, J.H.; Zhao, X.Y. Sputter deposition of nanostructured antibacterial silver on polypropylene non-wovens. Surf. Eng. 2013, 24, 70–74. [Google Scholar] [CrossRef]

- Ren, Y.; Zhao, J.; Wang, X. Hydrophilic and antimicrobial properties of acrylic acid and chitosan bigrafted polypropylene melt-blown nonwoven membrane immobilized with silver nanoparticles. Text. Res. J. 2016, 88, 182–190. [Google Scholar] [CrossRef]

- Na, C.K.; Park, G.Y.; Park, H. Polypropylene surface with antibacterial property by photografting 1-vinylimidazole and subsequent chemical modification. Korean J. Chem. Eng. 2018, 1–8. [Google Scholar] [CrossRef]

- Hassan, M.S.; Ibrahim, H.M.M. Characterization and antimicrobial properties of metal complexes of polypropylene fibers grafted with acrylic acid using gamma irradiation. Polym. Adv. Technol. 2016, 27, 532–541. [Google Scholar] [CrossRef]

- Poortavasoly, H.; Montazer, M.; Harifi, T. Simultaneous synthesis of nano silver and activation of polyester producing higher tensile strength aminohydroxylated fiber with antibacterial and hydrophilic properties. RSC Adv. 2014, 4, 46250–46256. [Google Scholar] [CrossRef]

- Zheng, B.; Luo, Y.; Liao, H.; Zhang, C. Investigation of the crystallinity of suspension plasma sprayed hydroxyapatite coatings. J. Eur. Ceram. Soc. 2017, 37, 5017–5021. [Google Scholar] [CrossRef]

- Ryu, S.H.; Shanmugharaj, A.M. Influence of hexamethylene diamine functionalized graphene oxide on the melt crystallization and properties of polypropylene nanocomposites. Mater. Chem. Phys. 2014, 146, 478–486. [Google Scholar] [CrossRef]

- Oliani, W.L.; Parra, D.F.; Komatsu, L.G.H.; Lincopan, N.; Rangari, V.K.; Lugao, A.B. Fabrication of polypropylene/silver nanocomposites for biocidal applications. Mat. Sci. Eng. C 2017, 75, 845–853. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Hamid, H.M. Effect of electron beam irradiation on polypropylene films—Dielectric and ft-ir studies. Solid State Electron. 2005, 49, 1163–1167. [Google Scholar] [CrossRef]

- Castell, P.; Wouters, M.; With, G.D.; Fischer, H.; Huijs, F. Surface modification of poly(propylene) by photoinitiators: Improvement of adhesion and wettability. J. App. Poly. Sci. 2004, 92, 2341–2350. [Google Scholar] [CrossRef]

- Gruzdev, M.S.; Shmukler, L.E.; Kudryakova, N.O.; Kolker, A.M.; Sergeeva, Y.A.; Safonova, L.P. Triethanolamine-based protic ionic liquids with various sulfonic acids: Synthesis and properties. J. Mol. Liq. 2017, 242, 838–844. [Google Scholar] [CrossRef]

- Pogorelov, V.; Doroshenko, I.; Pitsevich, G.; Balevicius, V.; Sablinskas, V.; Krivenko, B.; Pettersson, L.G.M. From clusters to condensed phase—FTIR studies of water. J. Mol. Liq. 2017, 235, 7–10. [Google Scholar] [CrossRef]

- Karadaĝ, A.; Yilmaz, V.T. Preparation and infrared spectroscopic examination of hofmann-type di- and triethanolamine complexes. Syn. React. Inorg. Met. 2008, 30, 359–368. [Google Scholar] [CrossRef]

- Huang, C.; Tsai, C.-Y.; Juang, R.-S. Surface modification and characterization of an H2/O2 plasma-treated polypropylene membrane. J. App. Poly. Sci. 2012, 124, E108–E115. [Google Scholar] [CrossRef]

- Jaleh, B.; Parvin, P.; Wanichapichart, P.; Saffar, A.P.; Reyhani, A. Induced super hydrophilicity due to surface modification of polypropylene membrane treated by O2 plasma. Appl. Surf. Sci. 2010, 257, 1655–1659. [Google Scholar] [CrossRef]

- Zhang, C.; Jin, J.; Zhao, J.; Jiang, W.; Yin, J. Functionalized polypropylene non-woven fabric membrane with bovine serum albumin and its hemocompatibility enhancement. Coll. Surf. B 2013, 102, 45–52. [Google Scholar] [CrossRef] [PubMed]

- Abu-Zied, B.M.; Asiri, A.M. An investigation of the thermal decomposition of silver acetate as a precursor for nano-sized Ag-catalyst. Thermochim. Acta 2014, 581, 110–117. [Google Scholar] [CrossRef]

- Rjeb, A.; Letarte, S.; Tajounte, L.; Idrissi, M.C.E.; Adnot, A.; Roy, D.; Claire, Y.; Kaloustian, J. Polypropylene natural aging studied by X-ray photoelectron spectroscopy. J. Electron. Spectrosc. 2000, 107, 221–230. [Google Scholar] [CrossRef]

- Hoflund, B.G.; Hazos, F.Z.; Salaita, N.G. Surface characterization study of Ag, AgO, and Ag2O using X-ray photoelectron spectroscopy and electron energy-loss spectroscopy. Phys. Rev. B: Condens. Matter 2000, 62, 11126–11133. [Google Scholar] [CrossRef]

- Liu, H.R.; Shao, G.X.; Zhao, J.F.; Zhang, Z.X.; Zhang, Y.; Liang, J.; Liu, X.G.; Jia, H.S.; Xu, B.S. Worm-like Ag/ZnO core–shell heterostructural composites: Fabrication, characterization, and photocatalysis. J. Phys. Chem. C 2012, 116, 16182–16190. [Google Scholar] [CrossRef]

- Shao, D.; Gao, D.; Wei, Q.; Tao, L.; Zhu, H.; Ge, M. Depositon of ZnO on polyacrylonitrile fiber by thermal solvent coating. Fiber Polym. 2011, 12, 214–219. [Google Scholar] [CrossRef]

| Sample | Triethanolamine Coating Dosage (mL) | AgNO3 Solution | First Boiling (min) | TEA/AgNO3 Solution | Second Boiling (min) |

|---|---|---|---|---|---|

| Control | 0 | 0 | 0 | 0 | 0 |

| 1# | 20 | 0.4 g AgNO3 + 200 mLH2O | 10 | 0 | 0 |

| 2# | 20 | 0.4 g AgNO3 + 200 mLH2O | 10 | 0.4 g AgNO3 + 40 mL TEA + 170 mL H2O | 10 |

| 3# | 20 | 0.4 g AgNO3 + 200 mL H2O | 10 | 0.6 g AgNO3 + 40 mL TEA + 170 mL H2O | 10 |

| 4# | 20 | 0.4 g AgNO3 + 200 mL H2O | 10 | 0.8 g AgNO3 + 40 mL TEA + 170 mL H2O | 10 |

| 5# | 20 | 0.4 g AgNO3 + 200 mL H2O | 10 | 0.6 g AgNO3 + 20 mL TEA + 170 mL H2O | 10 |

| 6# | 20 | 0.4 g AgNO3 + 200 mLH2O | 10 | 0.6 g AgNO3 + 60 mL TEA + 170 mL H2O | 10 |

| Sample | Untreated Weight (g) | Treated Weight (g) | Weight Gain (g) | Weight Gain Rate (%) |

|---|---|---|---|---|

| 1# | 0.9084 | 0.9882 | 0.0798 | 8.78 |

| 2# | 0.9251 | 1.117 | 0.1919 | 20.74 |

| 3# | 0.9288 | 1.176 | 0.2472 | 26.61 |

| 4# | 0.9673 | 1.2614 | 0.2941 | 30.40 |

| 5# | 0.9291 | 1.157 | 0.2279 | 24.53 |

| 6# | 0.9095 | 1.1588 | 0.2493 | 27.41 |

| Sample | Treated Sample Weight (g) | 30 min | 60 min | 90 min | |||

|---|---|---|---|---|---|---|---|

| Weight (g) | Weight Loss (%) | Weight (g) | Weight Loss (%) | Weight (g) | Weight Loss (%) | ||

| 1# | 0.9882 | 0.9523 | 3.63 | 0.9426 | 4.61 | 0.9373 | 5.15 |

| 2# | 1.117 | 1.0177 | 8.89 | 0.9974 | 10.71 | 0.9873 | 11.61 |

| 3# | 1.176 | 1.0512 | 10.61 | 1.0269 | 12.68 | 1.0161 | 13.6 |

| 4# | 1.2614 | 1.0968 | 13.05 | 1.0653 | 15.55 | 1.0533 | 16.5 |

| 5# | 1.157 | 1.0387 | 10.22 | 1.0106 | 12.65 | 1.001 | 13.48 |

| 6# | 1.1588 | 1.0384 | 10.39 | 1.01 | 12.84 | 0.9972 | 13.95 |

| Sample | Average Surface Resistance (Ω) | Average Surface Resistivity (Ω) |

|---|---|---|

| Control | 6.35 × 109 | 1.26 × 1010 |

| 1# | 5.50 × 105 | 1.09 × 107 |

| 2# | 9.20 × 103 | 1.82 × 105 |

| 3# | 9.85 × 103 | 1.95 × 105 |

| 4# | 9.65 × 103 | 1.91 × 105 |

| 5# | 9.44 × 103 | 1.87 × 105 |

| 6# | 9.85 × 103 | 1.95 × 105 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, D.; Zhang, H.; Tao, L.; Cao, K.; Wei, Q. A Facile Approach for Preparing Ag Functionalized Nonwoven Polypropylene Membrane to Improve Its Electrical Conductivity and Electromagnetic Shielding Performance. Materials 2019, 12, 296. https://doi.org/10.3390/ma12020296

Shao D, Zhang H, Tao L, Cao K, Wei Q. A Facile Approach for Preparing Ag Functionalized Nonwoven Polypropylene Membrane to Improve Its Electrical Conductivity and Electromagnetic Shielding Performance. Materials. 2019; 12(2):296. https://doi.org/10.3390/ma12020296

Chicago/Turabian StyleShao, Dongfeng, Hongwei Zhang, Lizhen Tao, Kan Cao, and Qufu Wei. 2019. "A Facile Approach for Preparing Ag Functionalized Nonwoven Polypropylene Membrane to Improve Its Electrical Conductivity and Electromagnetic Shielding Performance" Materials 12, no. 2: 296. https://doi.org/10.3390/ma12020296