Strength without Size Effect and Formula of Strength for Concrete and Natural Marble

Abstract

:1. Introduction

2. Structural Stressing State Concept and Method

2.1. Concept and Modeling of a Specimen’s Stressing State

2.2. The M-K Criterion

3. Essential Strength of Concrete

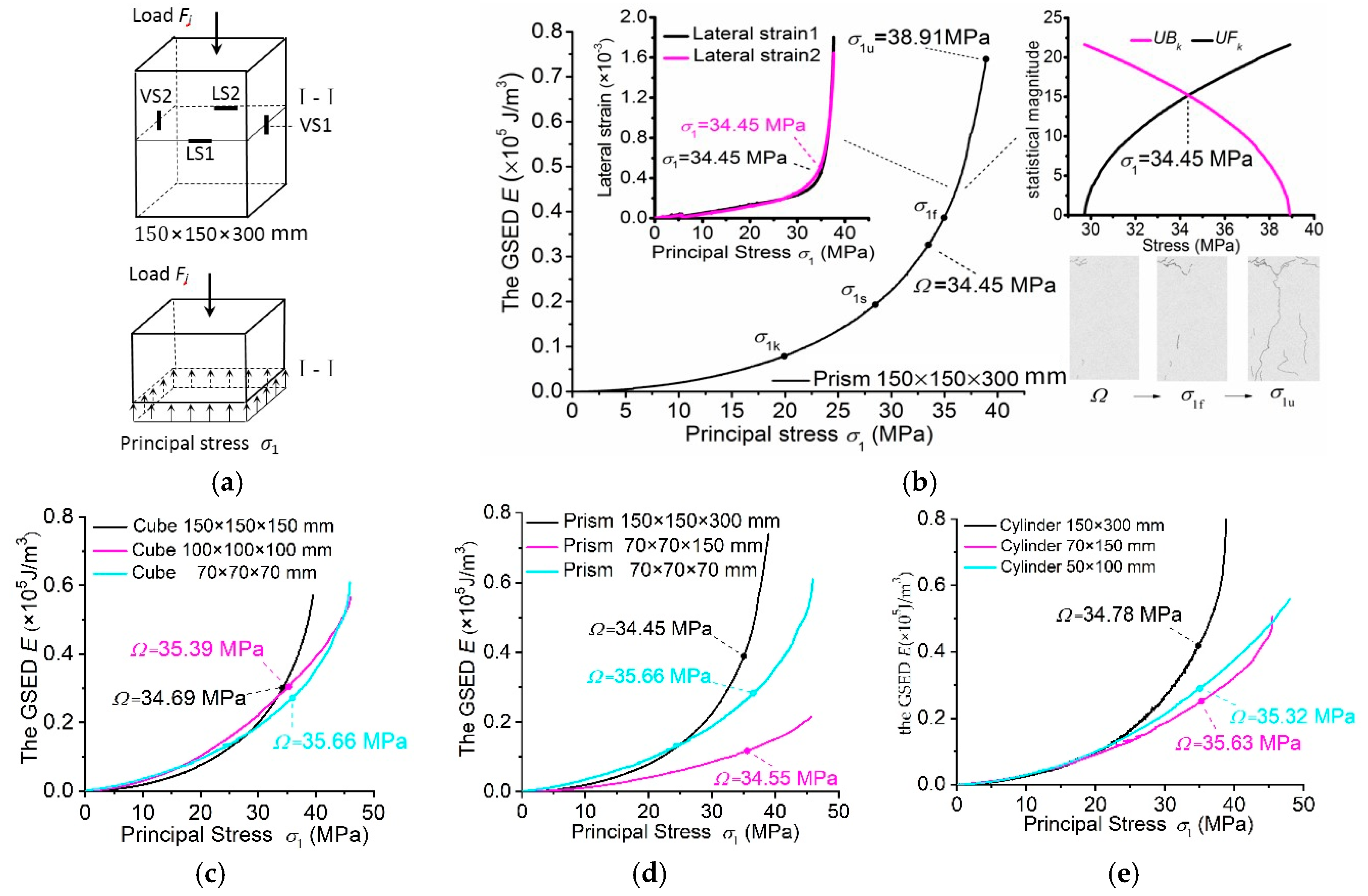

3.1. Concrete Specimens and Their Uniaxial Experiment

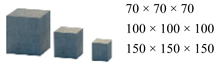

3.2. Investigation into the Uniaxial Stressing States of Specimens

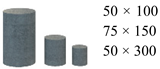

3.3. Essential Strength of Concrete without Size Effect

4. Unified Formula of Strength for Concrete

4.1. Investigation into Biaxial and Triaxial Stressing States of Concrete Specimens

4.2. The Formula for the Relationship between Essential Strength and Combined Principal Stresses

5. Verification of the Formula of Strength

5.1. The Definite Relation between Uniaxial Strength and Shear Strength

5.2. Rationality of Weight Coefficients in the Formula for Strength

5.3. Verification of Equation (6) with Natural Marble

5.4. Qualification of Equation (6) as the Formula for Strength

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yu, M.H. Unified Strength Theory and Its Application; Springer: Berlin, Germany, 2003. [Google Scholar]

- Yu, M.H. Advances in strength theories for materials under complex stress state in the 20th Century, Advances in Mechanics. Adv. Mech. 2004, 34, 529–560. [Google Scholar] [CrossRef]

- ACI Committee 318. ACI 318-08: Building Code Requirements for Structural Concrete; ACI: Farmington Hills, MI, USA, 2008. [Google Scholar]

- British Standards Institution BSI. Eurocode 2: Design of Concrete Structures—General Rules and Rules for Buildings; BS EN 1992-1.1; BSI: London, UK, 2004. [Google Scholar]

- Ministry of Construction, P.R. China. JGJ 55-2011: Specification for Mix Proportion Design of Ordinary Concrete; China Architecture & Building Press: Beijing, China, 2011.

- Voigt, W. Lehrbuch der Kristallphysik; Teubner Verlag: Leipzig, Germany, 1928. [Google Scholar]

- Richart, F.E.; Brandtzaeg, A.; Brown, R.L. A Study of the Failure of Concrete under Combined Compressive Stresses; University of Illinois: Champaign, IL, USA, 1928; p. 185. [Google Scholar]

- Panda, B.; Lim, J.H.; Tan, M.L. Mechanical properties and deformation behaviour of early age concrete in the context of digital construction. Compos. Part B Eng. 2019, 165, 563–571. [Google Scholar]

- Hancock, E.L. Results of tests on materials subjected to combined stress. Phil. Mag. 1906, 11, 275. [Google Scholar] [CrossRef]

- Tang, L.; Sang, H.; Jing, S.; Luo, Z.; Sun, Y. Mechanical model for failure modes of rock and soil under compression. Trans. Nonferr. Met. Soc. China 2016, 26, 2711–2723. [Google Scholar] [CrossRef]

- Rankine, W.J.M. Manual of Applied Mechanics, 21st ed.; C. Griffin: London, UK, 1921. [Google Scholar]

- Mariotte, E. Traité du mouvement des eaux; Chez Claude-Jombert: Paris, France, 1686. [Google Scholar]

- De Saint-Venant, B. Memoire sur l’establissement des equations differentielles des movement interieurs operes dans les corps solides ductiles au dela des limites ou l’elasticite pourrait les ramener a leur premier etat. J. de Mathématiques Pures et Appliquées 1870, 70, 473–480. [Google Scholar]

- Tresca, H. Sur L’ecoulement des Corps Solides Soumis a des Fortes Pression; Gauthier-Villars: Paris, France, 1864; Volume 59, pp. 754–758. [Google Scholar]

- Von Mises, R. Mechanik der festen Körper im plastisch deformablen Zustand. Nachr. Ges. Wiss. Gott. Math. Phys. Kl. 1913, 1913, 582–592. [Google Scholar]

- Yu, M.H.; He, L.N. A new model and theory on yield and failure of materials under the complex stress state. Mech. Behav. Mater. VI 1992, 841–846. [Google Scholar] [CrossRef]

- Nadai, A. Theories of strength. J. Appl. Mech. 1993, 1, 111–129. [Google Scholar]

- Marin, J. Failure theories of materials subjected to combined stresses. Proc. ASCE 1935, 61, 851–867. [Google Scholar]

- Balmer, G.G. Shearing Strength of Concrete under High Triaxial Stress Computation of Mohr’s Envelope as a Curve; U.S. Department of the Interior (Research & Geology Division): Washington, DC, USA, 1949.

- Bresler, B.; Pister, K.S. Strength of concrete under combined stresses. Proc. ACI J. 1958, 55, 321–346. [Google Scholar] [CrossRef]

- Paul, B. A modification of the Coulomb-Mohr theory of fracture. J. Appl. Mech. 1961, 28, 259–268. [Google Scholar] [CrossRef]

- Robison, G.S. Behavior of concrete in biaxial compression. J. Struct. Div. 1967, 93, 71–86. [Google Scholar]

- Wu, H.C. Dual failure criterion for plain concrete. J. Eng. Mech. 1974, 100, 1167–1181. [Google Scholar]

- Bazant, Z.P. Size Effect in Blunt Fracture: Concrete, Rock Metal. J. Eng. Mech. 1984, 110, 518–535. [Google Scholar] [CrossRef]

- Podgórski, J. General failure criterion for isotropic media. J. Eng. Mech. 1985, 111, 188–201. [Google Scholar] [CrossRef]

- Fan, S.C.; Wang, F. A new strength criterion for concrete. Struct. J. 2002, 99, 317–326. [Google Scholar]

- Vu, C.C.; Weiss, J.; Plé, O.; Amitrano, D.; Vandembroucq, D. Revisiting statistical size effects on compressive failure of heterogeneous materials, with a special focus on concrete. J. MPS 2018, 121, 47–70. [Google Scholar] [CrossRef]

- Timoshenko, S. Strength of Materials, 3rd ed.; Krieger Publishing Company: Malabar, FL, USA, 1976. [Google Scholar]

- Engels, F. Dialectics of Nature, Translator, Clements Dutt, 7th ed.; International Publishers: New York, NY, USA, 1973. [Google Scholar]

- Shi, J.; Li, W.T.; Zheng, K.K.; Yang, K.K.; Zhou, G.C. Experimental investigation into stressing state characteristics of large-curvature continuous steel box-girder bridge model. Constr. Build. Mater. 2018, 178, 574–583. [Google Scholar] [CrossRef]

- Shi, J.; Yang, K.K.; Zheng, K.K.; Shen, J.Y.; Zhou, G.C.; Huang, Y.X. An investigation into working behavior characteristics of parabolic CFST arches applying structural stressing state theory. J. Civ. Eng. Manag. 2019, 25, 215–227. [Google Scholar] [CrossRef]

- Mann, H.B. Non-parametric tests against trend. Econometrical 1945, 13, 163–171. [Google Scholar] [CrossRef]

- Hirsch, R.M.; Slack, J.R.; Smith, R.A. Techniques of trend analysis for monthly water quality data. J. Water Resour. Res. 1982, 18, 107–121. [Google Scholar] [CrossRef] [Green Version]

- Kendall, M.G. Rank Correlation Methods; Oxford University Press: New York, NY, USA, 1990. [Google Scholar]

- Kendall, M.G. Rank Correlation Methods, 4th ed.; Charles Griffin: London, UK, 1985. [Google Scholar]

- Ministry of Construction, P.R. China. GB50010-2010: Code for Design of Concrete Structures; China Architecture & Building Press: Beijing, China, 2002.

- Ministry of Construction, P.R. China. GB50017-2003: Code for Design of Steel Structures; China Architecture & Building Press: Beijing, China, 2006.

- Samani, A.K.; Attard, M.M. A stress–strain model for uniaxial and confined concrete under compression. Eng. Struct. 2012, 41, 335–349. [Google Scholar] [CrossRef]

- Song, H.; Zhang, H.; Kang, Y.; Huang, G.; Fu, D.; Qu, C. Damage evolution study of sandstone by cyclic uniaxial test and digital image correlation. Tectonophysics 2013, 608, 1343–1348. [Google Scholar] [CrossRef]

- Van Vliet, M.R.A.; van Mier, J.G.M. Experimental investigation of size effect in concrete and sandstone under uniaxial tension. Eng. Fract. Mech. 2000, 65, 165–188. [Google Scholar] [CrossRef]

- Bischoff, P.H.; Perry, S.H. Impact behavior of plain concrete loaded in uniaxial compression. J. Eng. Mech. 1995, 25, 763. [Google Scholar] [CrossRef]

- Lim, C.C.; Gowripalan, N.; Sirivivatnanon, V. Microcracking and chloride permeability of concrete under uniaxial compression. Cem. Concr. Compos. 2000, 22, 353–360. [Google Scholar] [CrossRef]

- Yankelevsky, D.Z.; Reinhardt, H.W. Uniaxial Behavior of Concrete in Cyclic Tension. J. Struct. Eng. 1989, 115, 166–182. [Google Scholar] [CrossRef]

- Tai, Y.S. Uniaxial compression tests at various loading rates for reactive powder concrete. Theor. Appl. Fract. Mech. 2009, 52, 14–21. [Google Scholar] [CrossRef]

- Tsai, W.T. Uniaxial compressional stress strain relation of concrete. J. Struct. Eng. 1988, 114, 2133–2136. [Google Scholar] [CrossRef]

- Barragán, B.E.; Gettu, R.; Martín, M.A.; Zerbino, R.L. Uniaxial tension test for steel fibre reinforced concrete—A parametric study. Cem. Concr. Compos. 2003, 25, 767–777. [Google Scholar] [CrossRef]

- Beer, F.P.; Johnston, E.R. Mechanics of Materials, 5th ed.; McGraw Hill: New York, NY, USA, 2006. [Google Scholar]

- Hibbeler, R.C. Statics and Mechanics of Materials, SI ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 2004. [Google Scholar]

- Ernest, N. Experimental laws and theories. In The Structure of Science: Problems in the Logic of Scientific Explanation, 2nd ed.; Hackett: Indianapolis, IN, USA, 1984. [Google Scholar]

- Richard, F. The Character of Physical Law; Modern Library: New York, NY, USA, 1994. [Google Scholar]

- Bike, H. Laws, Natural or Scientific, Oxford Companion to Philosophy; Oxford University Press: Oxford, UK, 1995. [Google Scholar]

- Paul, D. The Mind of God: The Scientific Basis for a Rational World; Simon & Schuster: New York, NY, USA, 2005. [Google Scholar]

| Cube Specimens (mm) (Length × Width × Height) | Prism Specimens (mm) (Length × Width × Height) | Cylinder Specimens (mm) (Diameter × Height) |

|---|---|---|

|  |  |

| a | b | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 37.53 | 10 | 0 | 35.03 | 0.09% | 44.08 | 24 | 4 | 35.08 | 0.23% |

| 38.05 | 14 | 0 | 34.55 | −1.29% | 45.05 | 28 | 4 | 35.05 | 0.14% |

| 39.00 | 18 | 0 | 34.5 | −1.43% | 45.05 | 16 | 8 | 35.05 | 0.14% |

| 40.35 | 22 | 0 | 34.85 | −0.43% | 46.01 | 20 | 8 | 35.01 | 0.03% |

| -given | 26 | 0 | 35.47 | 1.34% | 47.03 | 24 | 8 | 35.03 | 0.09% |

| 41.95 | 30 | 0 | 34.45 | −1.57% | 52.04 | 20 | 16 | 35.04 | 0.11% |

| 43.43 | 34 | 0 | 34.93 | −0.20% | 44.03 | 9 | 9 | 35.03 | 0.09% |

| 40.03 | 8 | 4 | 35.03 | 0.09% | 47.17 | 12 | 12 | 35.17 | 0.49% |

| 41.41 | 12 | 4 | 35.41 | 1.17% | 50.03 | 15 | 15 | 35.03 | 0.09% |

| 42.04 | 16 | 4 | 35.04 | 0.11% | 53.04 | 18 | 18 | 35.04 | 0.11% |

| 43.03 | 20 | 4 | 35.03 | 0.09% | 56.06 | 21 | 21 | 35.06 | 0.17% |

| 136.9 | 10 | 10 | 126.90 | −2.83% | 165.15 | 60 | 30 | 127.65 | −2.26% |

| 149.92 | 40 | 10 | 132.42 | 1.39% | 179.72 | 100 | 30 | 132.22 | 1.24% |

| 154.86 | 80 | 10 | 127.36 | −2.48% | 186.77 | 150 | 30 | 126.77 | −2.93% |

| 163.73 | 120 | 10 | 126.23 | −3.35% | 171.30 | 45 | 45 | 126.30 | −3.29% |

| 171.62 | 150 | 10 | 126.62 | −3.05% | 191.31 | 100 | 45 | 132.56 | 1.50% |

| 178.83 | 180 | 10 | 126.33 | −3.27% | 202.36 | 150 | 45 | 131.11 | 0.39% |

| 148.92 | 20 | 20 | 128.92 | −1.29% | 214.97 | 200 | 45 | 131.22 | 0.47% |

| 160.14 | 70 | 20 | 127.64 | −2.27% | 202.00 | 68 | 68 | 134.00 | 2.60% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, G.; Shi, J.; Yu, M.; Zhang, Y.; Li, X.; Zhao, Y. Strength without Size Effect and Formula of Strength for Concrete and Natural Marble. Materials 2019, 12, 2685. https://doi.org/10.3390/ma12172685

Zhou G, Shi J, Yu M, Zhang Y, Li X, Zhao Y. Strength without Size Effect and Formula of Strength for Concrete and Natural Marble. Materials. 2019; 12(17):2685. https://doi.org/10.3390/ma12172685

Chicago/Turabian StyleZhou, Guangchun, Jun Shi, Maohong Yu, Yu Zhang, Xiaochun Li, and Yan Zhao. 2019. "Strength without Size Effect and Formula of Strength for Concrete and Natural Marble" Materials 12, no. 17: 2685. https://doi.org/10.3390/ma12172685