Synthesis of One-Dimensional Mesoporous Ag Nanoparticles-Modified TiO2 Nanofibers by Electrospinning for Lithium Ion Batteries

Abstract

:1. Introduction

2. Experimental

2.1. Synthesis of Mesoporous TiO2 and Ag@TiO2 Nanofibers

2.2. Assembly of LIBs

2.3. Characterizations

3. Results and Discussion

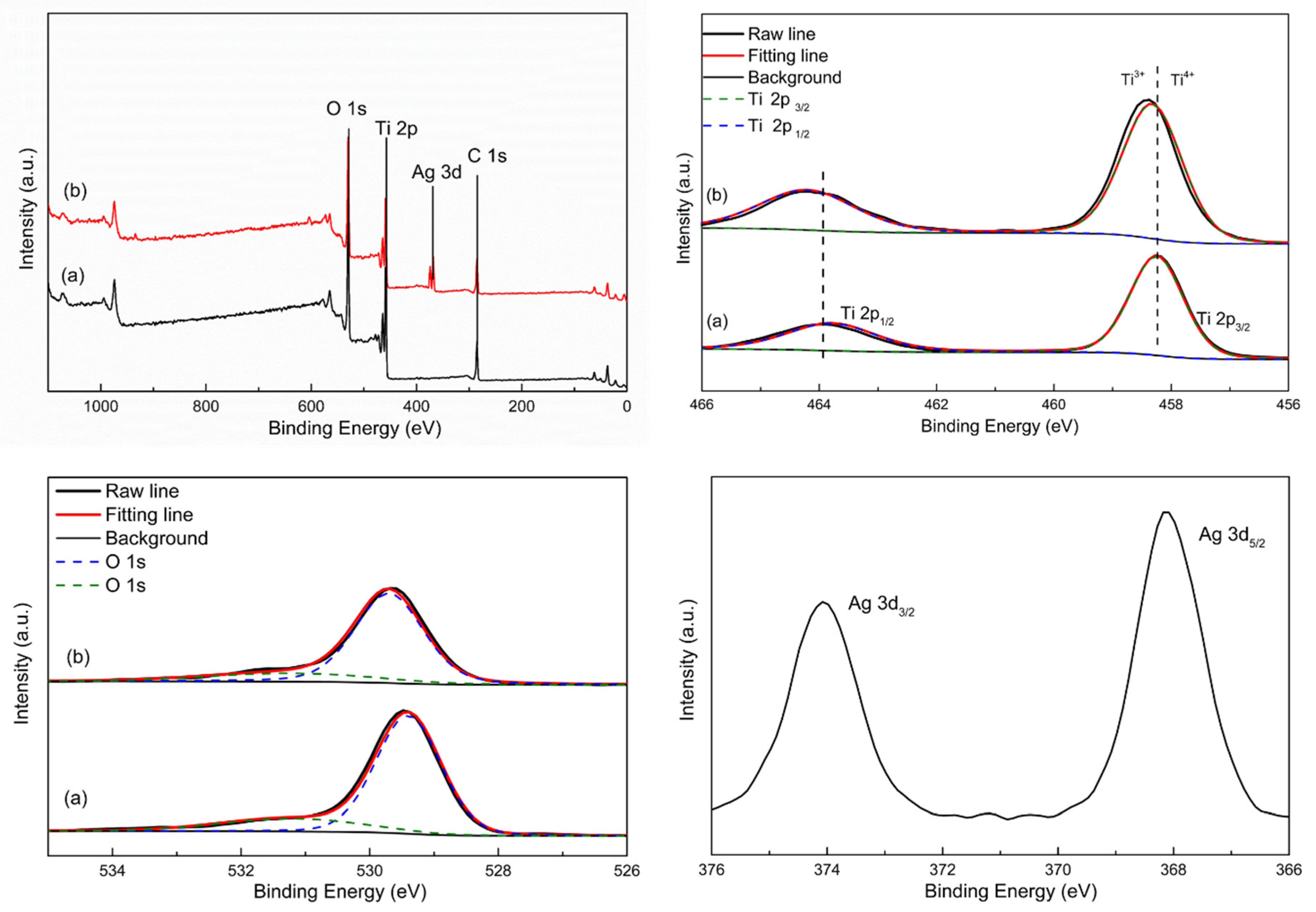

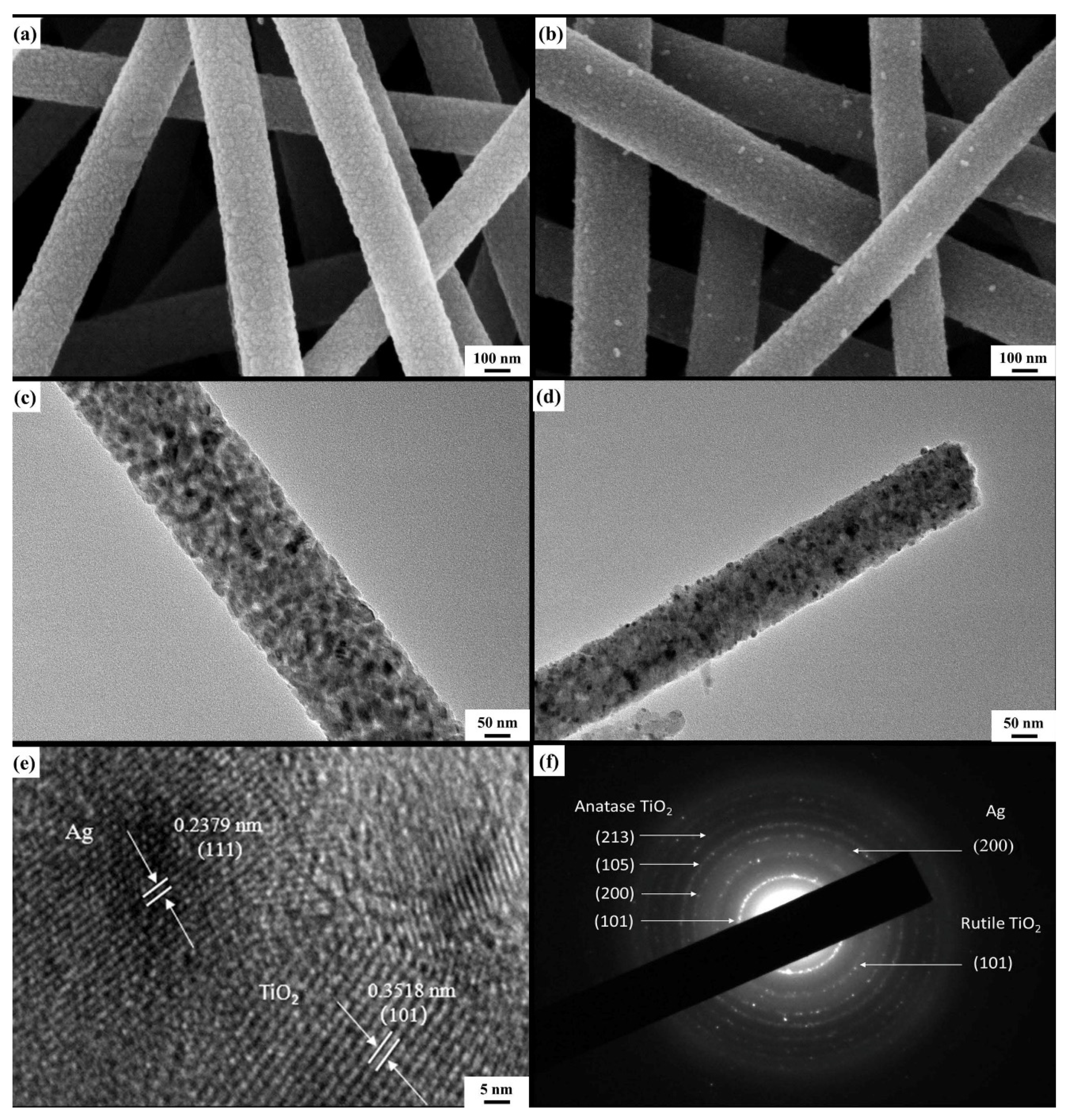

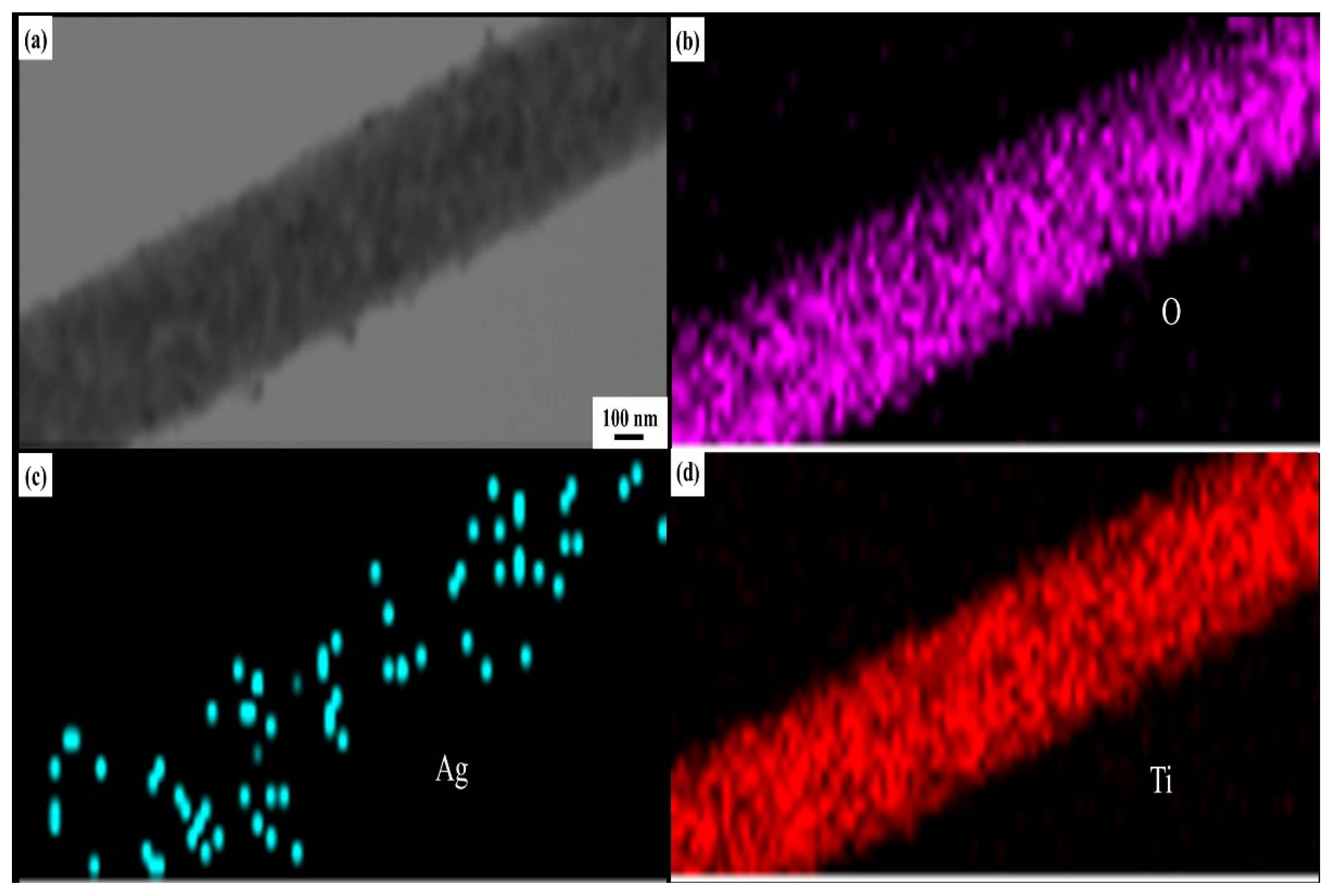

3.1. Microstructural Characterization of Nanofibers

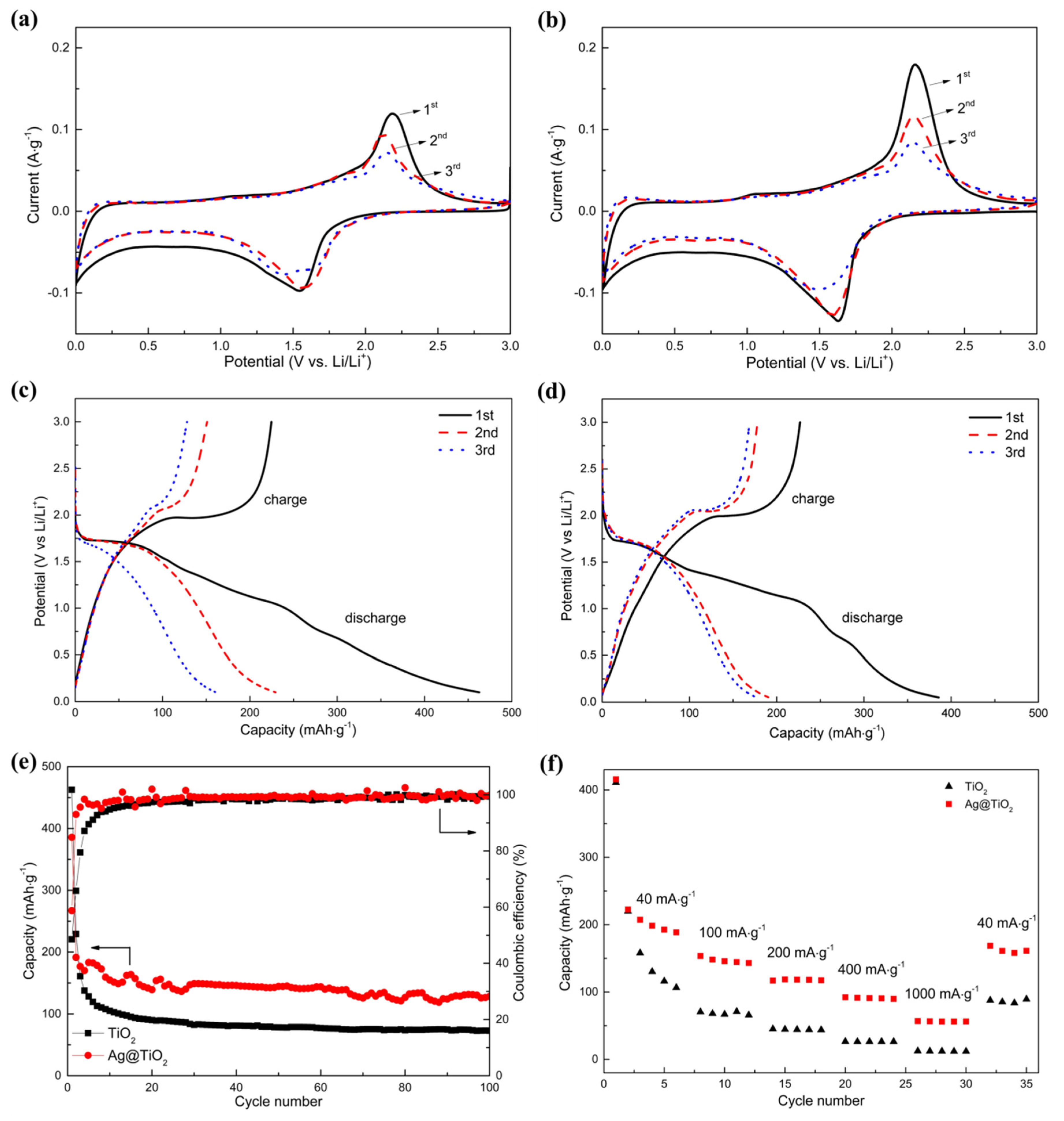

3.2. Electrochemical Performance of the Nanofibers Electrodes

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nitta, N.; Wu, F.; Lee, J.T. Li-ion battery materials: present and future. Mater. Today 2015, 18, 252–264. [Google Scholar] [CrossRef]

- Buiel, E.; Dahn, J.R. Li-Insertion in hard carbon anode materials for li-ion batteries. Electrochim. Acta 1999, 45, 121–130. [Google Scholar] [CrossRef]

- Ge, M.; Cao, C.; Huang, J. A review of one-dimensional TiO2 nanostructured materials for environmental and energy applications. J. Mater. Chem. A. 2016, 4, 6772–6801. [Google Scholar] [CrossRef]

- Huang, M.; Li, F.; Dong, F. MnO2-based nanostructures for high-performance supercapacitors. J. Mater. Chem. A. 2015, 3, 21380–21423. [Google Scholar] [CrossRef]

- Gu, D.; Li, W.; Wang, F. Controllable synthesis of mesoporous peapod-like Co3O4@Carbon nanotube arrays for high-performance lithium-ion batteries. Angew. Chem. 2015, 127, 7166–7170. [Google Scholar] [CrossRef]

- Xia, X.H.; Chao, D.L.; Ng, C.F.; Lin, J.; Fan, Z.; Zhang, H.; Fan, H.J. VO2 nanoflake arrays for supercapacitor and Li-ion battery electrodes: performance enhancement by hydrogen molybdenum bronze as an efficient shell material. Mater. Horizons 2015, 2, 237–244. [Google Scholar] [CrossRef]

- Huang, B.; Li, X.; Pei, Y. Novel carbon-encapsulated porous SnO2 anode for lithium-ion batteries with much improved cyclic stability. Small 2016, 12, 1945–1955. [Google Scholar] [CrossRef] [PubMed]

- Fan, Z.; Liang, J.; Yu, W. Ultrathin NiO nanosheets anchored on a highly ordered nanostructured carbon as an enhanced anode material for lithium ion batteries. Nano Energy 2015, 16, 152–162. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, L.; Lou, X.W. Metal Oxide Hollow Nanostructures for Lithium-ion Batteries. Cheminform 2012, 24, 1903–1911. [Google Scholar] [CrossRef]

- Hagfeldt, A.; Boschloo, G.; Sun, L. Dye-sensitized solar cells. J. Photochem. Photobiol. C Photochem. Rev. 2003, 4, 145–153. [Google Scholar]

- Yin, Z.F.; Wu, L.; Yang, H.G.; Su, Y.H. Recent progress in biomedical applications of titanium dioxide. Phys. Chem. Chem. Phys. 2013, 15, 4844. [Google Scholar] [CrossRef]

- Schneider, J.; Matsuoka, M.; Takeuchi, M.; Zhang, J.; Horiuchi, Y.; Anpo, M.; Bahnemann, D.W. Understanding TiO2 Photocatalysis: Mechanisms and Materials. Chem. Rev. 2014, 114, 9919–9986. [Google Scholar] [CrossRef]

- Hanaor, D.A.H.; Sorrell, C.C. Review of the anatase to rutile phase transformation. J. Mater. Sci. 2011, 46, 855–874. [Google Scholar] [CrossRef]

- Opra, D.P.; Gnedenkov, S.V.; Sinebryukhov, S.A. Effect of isovalent doping by Zr4+ Ions on the electrochemical behavior of TiO2(B). Electrochim. Acta 2019, 64, 680–687. [Google Scholar] [CrossRef]

- Wang, H.; Ma, D.; Huang, X. General and Controllable Synthesis Strategy of Metal Oxide/TiO2 Hierarchical Heterostructures with Improved Lithium-Ion Battery Performance. Sci Rep 2012, 2, 701. [Google Scholar] [CrossRef]

- Zhao, B.; Jiang, S.; Su, C.; Cai, R.; Ran, R.; Tadé, M.O.; Shao, Z. A 3D porous architecture composed of TiO2 nanotubes connected with a carbon nanofiber matrix for fast energy storage. J. Mater. Chem. A 2013, 1, 12310–12320. [Google Scholar] [CrossRef]

- Li, X.; Chen, Y.; Zhou, L.; Mai, Y.-W.; Huang, H. Exceptional electrochemical performance of porous TiO2–carbon nanofibers for lithium ion battery anodes. J. Mater. Chem. A 2014, 2, 3875–3880. [Google Scholar] [CrossRef]

- Yoon, S.; Ka, B.H.; Lee, C. Preparation of Nanotube TiO2-Carbon Composite and its anode performance in lithium-ion batteries. Electrochem. Solid State Lett. 2008, 12, A28–A32. [Google Scholar] [CrossRef]

- Roy, P.; Srivastava, S.K. Nanostructured anode materials for lithium ion batteries. J. Mater. Chem. A 2015, 3, 2454–2484. [Google Scholar] [CrossRef]

- Armstrong, A.; Armstrong, G.; Canales, J. Lithium-Ion Intercalation into TiO2-B Nanowires. Adv. Mater. 2010, 17, 862–865. [Google Scholar] [CrossRef]

- Bao, S.J.; Bao, Q.L.; Li, C.M. Novel porous anatase TiO2 nanorods and their high lithium electroactivity. Electrochem. Commun. 2007, 9, 1233–1238. [Google Scholar] [CrossRef]

- Opra, D.P.; Gnedenkov, S.V.; Sinebryukhov, S.L. Zr4+/F– co-doped TiO2(anatase) as high performance anode material for lithium-ion battery. Prog. Nat. Sci. 2018, 28, 542–547. [Google Scholar] [CrossRef]

- Fehse, M.; Cavaliere, S.; Lippens, P.E. Nb-Doped TiO2 nanofibers for lithium ion batteries. J. Phys. Chem. C 2013, 117, 130605170935002. [Google Scholar] [CrossRef]

- Patil, J.V.; Mali, S.S.; Kamble, A.S. Electrospinning: A versatile technique for making of 1D growth of nanostructured nanofibers and its applications: An experimental approach. Appl. Surf. Sci. 2017, 423, 641–674. [Google Scholar] [CrossRef]

- Yang, Z.; Du, G.; Meng, Q.; Guo, Z.; Yu, X.; Chen, Z.; Guo, T.; Zeng, R. Synthesis of uniform TiO2@carbon composite nanofibers as anode for lithium ion batteries with enhanced electrochemical performance. J. Mater. Chem. 2012, 22, 5848–5854. [Google Scholar] [CrossRef]

- Han, H.; Song, T.; Bae, J.Y.; Nazar, L.F.; Kim, H.; Paik, U. Nitridated TiO2 hollow nanofibers as an anode material for high power lithium ion batteries. Energy Environ. Sci. 2011, 4, 4532. [Google Scholar] [CrossRef]

- Li, L.; Zhang, J.; Zou, Y. High-rate and long-term cycle stability of lithium-ion batteries enabled by boron-doping TiO2 nanofiber anodes. J. Electroanal. Chem. 2018, 833, 574–579. [Google Scholar] [CrossRef]

- Tran, T.; McCormac, K.; Li, J.; Bi, Z.; Wu, J. Electrospun SnO2 and TiO2 Composite Nanofibers for Lithium Ion Batteries. Electrochimica Acta 2014, 117, 68–75. [Google Scholar] [CrossRef]

- Wu, Q.; Tran, T.; Lu, W.; Wu, J. Electrospun silicon/carbon/titanium oxide composite nanofibers for lithium ion batteries. J. Power Sources 2014, 258, 39–45. [Google Scholar] [CrossRef]

- Zhou, H.; Lv, P.; Xia, X.; Zhang, J.; Yu, J.; Pang, Z.; Qiao, H.; Wei, Q. MoS2 nanograins doped TiO2 nanofibers as intensified anodes for lithium ion batteries. Mater. Lett. 2018, 218, 47–51. [Google Scholar] [CrossRef]

- Lee, S.; Eom, W.; Park, H.; Han, T.H. High-Temperature Stable Anatase Titanium Oxide Nanofibers for Lithium-Ion Battery Anodes. ACS Appl. Mater. Interfaces 2017, 9, 25332–25338. [Google Scholar] [CrossRef]

- Nam, S.H.; Shim, H.S.; Kim, Y.S. Ag or Au Nanoparticle-Embedded One-Dimensional Composite TiO2 Nanofibers Prepared via Electrospinning for Use in Lithium-Ion Batteries. ACS Appl. Mater. Interf. 2010, 2, 2046–2052. [Google Scholar] [CrossRef]

- Lin, H.; Li, X.; He, X.; Zhao, J. Application of a novel 3D nano-network structure for Ag-modified TiO2 film electrode with enhanced electrochemical performance. Electrochimica Acta 2015, 173, 242–251. [Google Scholar] [CrossRef]

- Meng, R.; Hou, H.; Liu, X.; Hu, W.; Duan, J.; Liu, S. Reassessment of the roles of Ag in TiO2 nanotubes anode material for lithium ion battery. Ceram. Int. 2015, 41, 9988–9994. [Google Scholar] [CrossRef]

- Djaoued, Y.; Badilescu, S.; Ashrit, P.; Bersani, D.; Lottici, P.P.; Robichaud, J. Study of Anatase to Rutile Phase Transition in Nanocrystalline Titania Films. J. Sol-Gel Sci. Technol. 2002, 24, 255–264. [Google Scholar] [CrossRef]

- Shi, G.; Li, I.; Hong, Z.; Kun, Z. Synthesis of Ag microparticles by directly heat-decomposing the composite of AgNO3 and polyvinyl pyrrolidone (PVP). J. Fuyang Teach. Coll. Nat. Sci. 2014, 31, 38–41. [Google Scholar]

- Dorset, D. X-ray Diffraction: A Practical Approach. Microsc. Microanal. 1998, 4, 513–515. [Google Scholar] [CrossRef]

- Dambournet, D.; Belharouak, I.; Amine, K. Tailored preparation methods of TiO2 Anatase, rutile, brookite: Mechanism of formation and electrochemical properties. Chem. Mater. 2010, 22, 1173–1179. [Google Scholar] [CrossRef]

- Su, D.; Dou, S.; Wang, G. Anatase TiO2: better anode material than amorphous and rutile phases of TiO2 for Na-ion batteries. Chem. Mat. 2015, 27, 6022–6029. [Google Scholar] [CrossRef]

- Grünert, W.; Brückner, A.; Hofmeister, H.; Claus, P. Structural properties of Ag/TiO2 Catalysts for acrolein hydrogenation. J. Phys. Chem. B 2004, 108, 5709–5717. [Google Scholar] [CrossRef]

- Gentili, V.; Hardwick, L.; Armstrong, A.; Bruce, P.; Brutti, S.; Panero, S. Lithium insertion into anatase nanotubes. Chem. Mater. 2012, 24, 4468–4476. [Google Scholar] [CrossRef]

- Krtil, P.; Fattakhova-Rohlfing, D.; Kavan, L.; Burnside, S.; Grätzel, M. Lithium insertion into self-organized mesoscopic TiO2 (anatase) electrodes. Solid State Ionics 2000, 135, 101–106. [Google Scholar] [CrossRef]

- Gnedenkov, S.V.; Sinebryukhov, S.L.; Zheleznov, V.V.; Opera, D.P.; Voit, E.I. Effect of Hf-doping on electrochemical performance of anatase TiO2 as an anode material for lithium storage. R. Soc. Open Sci. 2018, 5, 171811. [Google Scholar] [CrossRef]

- Yan, J.; Song, H.; Yang, S.; Chen, X. Effect of heat treatment on the morphology and electrochemical performance of TiO2 nanotubes as anode materials for lithium-ion batteries. Mater. Chem. Phys. 2009, 118, 367–370. [Google Scholar] [CrossRef]

- Tang, Y.P.; Wang, S.M.; Ding, J.F. Preparation and properties of TiO2 (B)/Graphene nanocomposites as anode materials Fo Lithium-Ion batteries. Adv. Mater. Res. 2014, 875–877, 183–186. [Google Scholar] [CrossRef]

- Yue, Y.; Juarez-Robles, D.; Chen, Y.; Ma, L.; Kuo, W.C.H.; Mukherjee, P.; Liang, H. Hierarchical structured Cu/Ni/TiO2 nanocomposites as electrodes for Lithium-Ion batteries. ACS Appl. Mater. Interfaces 2017, 9, 28695–28703. [Google Scholar] [CrossRef]

- Xu, J.; Wang, Y.; Li, Z.; Zhang, W. Preparation and electrochemical properties of carbon-doped TiO2 nanotubes as an anode material for lithium-ion batteries. J. Power Sources 2008, 175, 903–908. [Google Scholar] [CrossRef]

- Mao, M.; Yan, F.; Cui, C.; Ma, J.; Zhang, M.; Wang, T.; Wang, C. Pipe-Wire TiO2–Sn@Carbon Nanofibers Paper Anodes for Lithium and Sodium Ion Batteries. Nano Lett. 2017, 17, 3830–3836. [Google Scholar] [CrossRef]

- Huang, S.; Wen, Z.; Yang, X.; Gu, Z.; Xu, X. Improvement of the high-rate discharge properties of LiCoO2 with the Ag additives. J. Power Sources 2005, 148, 72–77. [Google Scholar] [CrossRef]

- Opra, D.P.; Gnedenkov, S.V.; Sinebryukhov, S.L.; Voit, E.I. Characterization and electrochemical properties of nanostructured Zr-Doped anatase TiO2 tubes synthesized by sol–gel template route. J. Mater. Sci. Technol. 2017, 33, 23–30. [Google Scholar] [CrossRef]

| Ref. | Materials | Discharge/Charge Capacity | Cycle Performance | Rate Performance |

|---|---|---|---|---|

| Our research | Ag@TiO2 nanofibers | 385/226 mAh·g−1 at 100 mA·g−1 | 128 mAh·g−1/100 cycles at 100 mA·g−1 | 56 mAh·g−1/1000 mA·g−1 |

| [23] | Nb@TiO2 nanofibers | 252/115 mAh·g−1 at 16.8 mA·g−1 | – | 20 mAh·g−1/1500 mA·g−1 |

| [31] | Al@TiO2 nanofibers | 225/175 mAh·g−1 at 66 mA·g−1 | 150 mAh·g−1/100 cycles at 40 mA·g−1 | 50 mAh·g−1/1000 mA·g−1 |

| [32] | Au@TiO2 nanofibers | 180/120 mAh·g−1 at 66 mA·g−1 | 150 mAh·g−1/50 cycles at 66 mA·g−1 | 48 mAh·g−1/1600 mA·g−1 |

| [34] | 3D-Ag@TiO2 nanotubes | 180/90 mAh·g−1 at 0.3 C | 90 mAh·g−1/50 cycles at 0.3 C | 90 mAh·g−1/2 C |

| [43] | Hf@TiO2 nanofibers | 320/160 mAh·g−1 at 33.5 mA·g−1 | 170 mAh·g−1/35 cycles at 33.5 mA·g−1 | 50 mAh·g−1/335 mA·g−1 |

| [45] | TiO2/graphene nanosheets | 135/82 mAh·g−1 at 50 mA·g−1 | 120 mAh·g−1/40 cycles at 200 mA·g−1 | 100 mAh·g−1/500 mA·g−1 |

| [46] | Cu/Ni/TiO2 nanofibers | 280/250 mAh·g−1 at 33.5 mA·g−1 | 110 mAh·g−1/30 cycles at 33.5 mA·g−1 | 20 mAh·g−1/670 mA·g−1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Li, J.; Li, W.; Kang, D. Synthesis of One-Dimensional Mesoporous Ag Nanoparticles-Modified TiO2 Nanofibers by Electrospinning for Lithium Ion Batteries. Materials 2019, 12, 2630. https://doi.org/10.3390/ma12162630

Zhang Y, Li J, Li W, Kang D. Synthesis of One-Dimensional Mesoporous Ag Nanoparticles-Modified TiO2 Nanofibers by Electrospinning for Lithium Ion Batteries. Materials. 2019; 12(16):2630. https://doi.org/10.3390/ma12162630

Chicago/Turabian StyleZhang, Yuyao, Jun Li, Wenyao Li, and Danning Kang. 2019. "Synthesis of One-Dimensional Mesoporous Ag Nanoparticles-Modified TiO2 Nanofibers by Electrospinning for Lithium Ion Batteries" Materials 12, no. 16: 2630. https://doi.org/10.3390/ma12162630