Anti-Biofouling and Desalination Properties of Thin Film Composite Reverse Osmosis Membranes Modified with Copper and Iron Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of CuNPs and FeNPs

2.2. Characterization of CuNPs and FeNPs

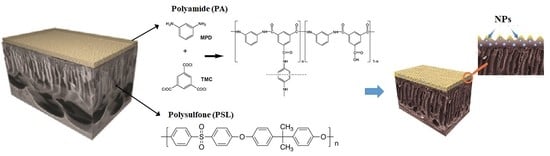

2.3. Synthesis of TFC RO Membrane with CuNPs and FeNPs

2.4. Characterization of Membranes Modified by Incorporation of CuNPs and FeNPs

2.5. Anti-Biofouling Test

2.6. Statistical Analysis

2.7. Desalination Performance Test

3. Results and Discussions

3.1. Characterization of Cu and Fe Nanoparticles

3.2. Characterization of Modified and Unmodified TFC RO Membranes

3.3. Anti-Biofouling Effect

3.4. Desalination Performance

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gonzalez-Enriquez, R.; Armendariz-Ontiveros, M.M. Evolución de la desalinización del agua: Tecnología y costos, Movimiento Ciudadano por el Agua. Primavera del 2016, 2016, 14–16. [Google Scholar]

- IDA. Desalination Yearbook 2017–2018; International Desalination Association: Sao Paulo, Brasil, 2017; p. 216. [Google Scholar]

- Choi, W.; Jeon, S.; Kwon, S.J.; Park, H.; Park, Y.-I.; Nam, S.-E.; Lee, P.S.; Lee, J.S.; Choi, J.; Hong, S.; et al. Thin film composite reverse osmosis membranes prepared via layered interfacial polymerization. J. Membr. Sci. 2017, 527, 121–128. [Google Scholar] [CrossRef]

- Fimbres-Weihs, G.A.; Álvarez-Sánchez, J.; Villegas-Álvarez, E. Fouling Modeling and Optimization of Membrane Module Design for Brackish and Seawater Desalination in the Mexican Pacific Coast: Project Description and Progress. Membranes 2017, 135–144. [Google Scholar] [CrossRef]

- Bucs, S.S. Biofouling in Reverse and Forward Osmosis Membrane Systems. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2017. [Google Scholar]

- García, Y.; Quintero, N.; Vicencio, B.; Rodríguez, D.; Ozturk, E.; Mosquera, T.; Corrales, U.; Volkmann, U.G. Influence of TiO2 nanostructures on anti-adhesion and photoinduced bactericidal properties of thin film composite membranes. RSC Adv. 2016, 6, 82941–82948. [Google Scholar]

- Pérez-Sicairos, S.; Miranda-Ibarra, S.; Lin-Ho, S.; Álvarez-Sánchez, J.; Pérez-Reyes, J.; Corrales-López, K.; Morales-Cuevas, J. Membranas de nanofiltración, preparadas viá polimerización en interfase, dopadas con nanopartículas de ZnO: Efecto en su desempeño [Nanofiltration membranes, prepared via interface polymerization, doped with ZnO nanoparticles: Effect on their performance]. Rev. Mex. Ing. Quim. 2016, 15, 961–975. [Google Scholar]

- Lee, S.Y.; Kim, H.J.; Patel, R.; Im, S.J.; Kim, J.H.; Min, B.R. Silver nanoparticles immobilized on thin film composite polyamide membrane: Characterization, nanofiltration, antifouling properties. Polym. Adv. Technol. 2007, 18, 562–568. [Google Scholar] [CrossRef]

- Tamayo, L.; Azócar, M.; Kogan, M.; Riveros, A.; Páez, M. Copper-polymer nanocomposites: An excellent and cost-effective biocide for use on antibacterial surfaces. Mater. Sci. Eng. C 2016, 69, 1391–1409. [Google Scholar] [CrossRef]

- Mulfinger, L.; Solomon, S.; Bahadory, M.; Jeyarajasingam, A.; Rutkowsky, S.; Boritz, C. Synthesis and study of silver nanoparticles. J. Chem. Educ. 2007, 84, 322. [Google Scholar] [CrossRef]

- Stefaniuk, M.; Oleszczuk, P.; Ok, Y. Review on nano zerovalent iron (nZVI): From synthesis to environmental applications. Chem. Eng. J. 2016, 287, 618–632. [Google Scholar] [CrossRef]

- Armendáriz-Ontiveros, M.M.; García, A.G.; Villalobos, S.d.; Weihs, G.A.F. Biofouling performance of RO membranes coated with Iron NPs on graphene oxide. Desalination 2019, 451, 45–58. [Google Scholar] [CrossRef]

- Zhou, L.; Zhuang, W.; Wang, X.; Yu, K.; Yang, S.; Xia, S. Potential effects of loading nano zero valent iron discharged on membrane fouling in an anoxic/oxic membrane bioreactor. Water Res. 2017, 111, 140–146. [Google Scholar] [CrossRef] [PubMed]

- Palza, H.; Nuñez, M.; Bastías, R.; Delgado, K. In situ antimicrobial behavior of materials having copper-based additives in a hospital environment. Int. J. Antimicrob. Agents 2018, 51, 912–917. [Google Scholar] [CrossRef] [PubMed]

- Cioffi, N.; Torsi, L.; Ditaranto, N.; Tantillo, G.; Ghibelli, L.; Sabbatini, L.; Bleve-Zacheo, T.; D’Alessio, M.; Zambonin, P.; Traversa, E. Copper nanoparticle/polymer composites with antifungal and bacteriostatic properties. Chem. Mater. 2005, 17, 5255–5262. [Google Scholar] [CrossRef]

- Aruoja, V.; Dubourguier, H.; Kasemets, K.; Kahru, A. Toxicity of nanoparticles of CuO, ZnO and TiO2 to microalgae Pseudokirchneriella subcapitata. Sci. Total Environ. 2009, 407, 1461–1468. [Google Scholar] [CrossRef] [PubMed]

- Meghana, S.; Kabra, P.; Chakraborty, S.; Padmavathy, N. Understanding the pathway of antibacterial activity of copper oxide nanoparticles. RSC Adv. 2015, 5, 12293–12299. [Google Scholar] [CrossRef]

- Kaweeteerawat, C.; Chang, C.; Roy, K.; Liu, R.; Li, R.; Toso, D.; Fischer, H.; Ivask, A.; Ji, Z.; Zink, J.; et al. Cu nanoparticles have different impacts in Escherichia coli and Lactobacillus brevis than their microsized and ionic analogues. ACS Nano 2015, 9, 7215–7225. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, A.; Das, J.; Manna, P.; Sil, P. Nano-copper induces oxidative stress and apoptosis in kidney via both extrinsic and intrinsic pathways. Toxicology 2011, 290, 208–217. [Google Scholar] [CrossRef] [PubMed]

- García, A.; Rodríguez, B.; Oztürk, D.; Rosales, M.; Diaz, D.; Mautner, A. Incorporation of CuO nanoparticles into thin-film composite reverse osmosis membranes (TFC-RO) for antibiofouling properties. Polym. Bull. 2017, 75, 2053–2069. [Google Scholar] [CrossRef]

- Ben-Sasson, M.; Zodrow, K.R.; Genggeng, Q.; Kang, Y.; Giannelis, E.P.; Elimelech, M. Surface functionalization of thin-film composite membranes with copper nanoparticles for antimicrobial surface properties. Environ. Sci. Technol. 2013, 48, 384–393. [Google Scholar] [CrossRef]

- Ben-Sasson, M.; Lu, X.; Nejati, S.; Jaramillo, H.; Elimelech, M. In situ surface functionalization of reverse osmosis membranes with biocidal copper nanoparticles. Desalination 2016, 388, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Sarango, L.; Paseta, L.; Navarro, M.; Zornoza, B.; Coronas, J. Controlled deposition of MOFs by dip-coating in thin film nanocomposite membranes for organic solvent nanofiltration. J. Ind. Eng. Chem. 2018, 59, 8–16. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez, B.; Oztürk, D.; Rosales, M.; Flores, M.; García, A. Antibiofouling thin-film composite membranes (TFC) by in situ formation of Cu-(m-phenylenediamine) oligomer complex. J. Mater. Sci. 2018, 53, 6325–6338. [Google Scholar] [CrossRef]

- Homayoonfal, M.; Mehrnia, M.R.; Shariaty-Niassar, M.; Akbari, A.; Ismail, A.F.; Matsuura, T. A comparison between blending and surface deposition methods for the preparation of iron oxide/polysulfone nanocomposite membranes. Desalination 2014, 354, 125–142. [Google Scholar] [CrossRef]

- Liu, Q.; Yasunami, T.; Kuruda, K.; Okido, M. Preparation of Cu nanoparticles with ascorbic acid by aqueous solution reduction method. Trans. Nonferrous Met. Soc. 2012, 22, 2198–2203. [Google Scholar] [CrossRef]

- Baltazar, S.E.; García, A.; Romero, A.H.; Rubio, M.A.; Arancibia-Miranda, N.; Altbir, D. Surface rearrangement of nanoscale zerovalent iron: The role of pH and its implications in the kinetics of arsenate sorption. Environ. Technol. 2014, 35, 2365–2372. [Google Scholar] [CrossRef] [PubMed]

- Arancibia-Miranda, N.; Baltazar, S.E.; García, A.; Romero, A.H.; Rubio, M.A.; Altbir, D. Lead removal by nano-scale zero valent iron: Surface analysis and pH effect. Mater. Res. Bull. 2014, 59, 341–348. [Google Scholar] [CrossRef]

- Arancibia-Miranda, N.; Baltazar, S.E.; García, A.; Muñoz-Lira, D.; Sepúlveda, P.; Rubio, M.A.; Altbir, D. Nanoscale zero valent supported by Zeolite and Montmorillonite: Template effect of the removal of lead ion from an aqueous solution. J. Hazard. Mater. 2016, 301, 371–380. [Google Scholar] [CrossRef]

- Prabhu, Y.T.; Rao, K.V.; Sai, V.S.; Pavani, T. A facile biosynthesis of copper nanoparticles: A micro-structural and antibacterial activity investigation. J. Saudi Chem. Soc. 2017, 21, 180–185. [Google Scholar] [CrossRef] [Green Version]

- Khatami, M.; Heli, H.; Jahani, P.M.; Azizi, H.; Nobre, M.A.L. Copper/copper oxide nanoparticles synthesis using Stachys lavandulifolia and its antibacterial activity. IET Nanobiotechnol. 2017, 11, 709–713. [Google Scholar] [CrossRef]

- Marković, D.; Korica, M.; Kostić, M.; Radovanović, Ž.; Šaponjić, Z.; Mitrić, M.; Radetić, M. In situ synthesis of Cu/Cu2O nanoparticles on the TEMPO oxidized cotton fabrics. Cellulose 2018, 25, 829–841. [Google Scholar] [CrossRef]

- Khan, A.; Rashid, R.; Younas, R.; Chong, A. chemical reduction approach to the synthesis of copper nanoparticles. Int. Nano Lett. 2016, 6, 21–26. [Google Scholar] [CrossRef]

- Mdlovu, N.V.; Chiang, C.-L.; Lin, K.-S.; Jeng, R.-C. Recycling copper nanoparticles from printed circuit board waste etchants via a microemulsion process. J. Clean. Prod. 2018, 185, 781–796. [Google Scholar] [CrossRef]

- Wang, L.; Hu, C.; Shao, L. The antimicrobial activity of nanoparticles: Present situation and prospects for the future. Int. J. Nanomed. 2017, 12, 1227. [Google Scholar] [CrossRef]

- Janko, C.; Zaloga, J.; Pöttler, M.; Dür, S.; Eberbeck, D.; Tietze, R.; Lyer, S.; Alexiou, C. Strategies to optimize the biocompatibility of iron oxide nanoparticles-“SPIONs safe by desing”. J. Magn. Magn. Mater. 2017, 431, 281–284. [Google Scholar] [CrossRef]

- Kang, G.-d.; Cao, Y.-m. Development of antifouling reverse osmosis membranes for water treatment: A review. Water Res. 2012, 46, 584–600. [Google Scholar] [CrossRef]

- Kumar, R.; Ismail, A. Fouling control on microfiltration/ultrafiltration membranes: Effects of morphology, hydrophilicity, and charge. J. Appl. Polym. Sci. 2015, 132, 42042. [Google Scholar] [CrossRef]

- Hurwitz, G.; Guillen, G.R.; Hoek, E.M. Probing polyamide membrane surface charge, zeta potential, wettability, and hydrophilicity with contact angle measurements. J. Membr. Sci. 2010, 349, 349–357. [Google Scholar] [CrossRef]

- Karlsson, H.; Cronholm, P.; Gustafsson, J.; Möller, L. Copper Oxide Nanoparticles Are Highly Toxic: A Comparison between Metal Oxide Nanoparticles and Carbon Nanotubes. Chem. Res. Toxicol. 2018, 21, 1726–1732. [Google Scholar] [CrossRef]

- Palza, H. Antimicrobial polymers with metal nanoparticles. Int. J. Mol. Sci. 2015, 16, 2099–2116. [Google Scholar] [CrossRef]

- Bataineh, H.; Pestovsky, O.; Bakac, A. pH-induced mechanistic changeover from hydroxyl radicals to iron (IV) in the Fenton reaction. Chem. Sci. 2012, 3, 1594–1599. [Google Scholar] [CrossRef]

- Chae, H.; Lee, J.; Lee, C.; Kim, I.; Park, P. Graphene oxide-embedded thin-film composite reverse osmosis membrane with high flux, anti-biofouling, and chlorine resistance. J. Membr. Sci. 2015, 483, 128–135. [Google Scholar] [CrossRef]

| Membrane | Roughness (nm) | Contact Angle (°) |

|---|---|---|

| PA-PSL | 5.7 ± 0.7 | 74.25 ± 6.47 |

| PA+0.25Cu-PSL | 39.2 ± 4.7 | 99.42 ± 6.13 |

| PA+0.25Fe-PSL | 70.3 ± 13.1 | 74.21 ± 1.55 |

| Membrane | Flux (l m−2 h−1 bar−1) | Reject (%) |

|---|---|---|

| PA-PSL | 0.61 ± 0.27 a | 94.86 ± 0.68 a |

| PA+0.25Cu-PSL | 0.42 ± 0.16 a | 92.96 ± 2.79 a |

| PA+0.25Fe-PSL | 0.15 ± 0.03 b | 74.36 ± 4.57 b |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Armendariz Ontiveros, M.; Quintero, Y.; Llanquilef, A.; Morel, M.; Argentel Martínez, L.; García García, A.; Garcia, A. Anti-Biofouling and Desalination Properties of Thin Film Composite Reverse Osmosis Membranes Modified with Copper and Iron Nanoparticles. Materials 2019, 12, 2081. https://doi.org/10.3390/ma12132081

Armendariz Ontiveros M, Quintero Y, Llanquilef A, Morel M, Argentel Martínez L, García García A, Garcia A. Anti-Biofouling and Desalination Properties of Thin Film Composite Reverse Osmosis Membranes Modified with Copper and Iron Nanoparticles. Materials. 2019; 12(13):2081. https://doi.org/10.3390/ma12132081

Chicago/Turabian StyleArmendariz Ontiveros, M., Y. Quintero, A. Llanquilef, M. Morel, L. Argentel Martínez, A. García García, and A. Garcia. 2019. "Anti-Biofouling and Desalination Properties of Thin Film Composite Reverse Osmosis Membranes Modified with Copper and Iron Nanoparticles" Materials 12, no. 13: 2081. https://doi.org/10.3390/ma12132081