Using a Three-Dimensional Reduction Method in the High-Efficiency Grain Selector and Corresponding Grain Selection Mechanism

Abstract

:1. Introduction

- For the high-dimensional data difficulty of analysis, and dimensionality reduction can simplify the process.

- Due to the sample complexity of the high-dimensionality, this method can reduce the cost and analysis time of the experiment.

- Dimensionality reduction can increase the readability of data and facilitate the discovery of meaningful data.

2. Experiments

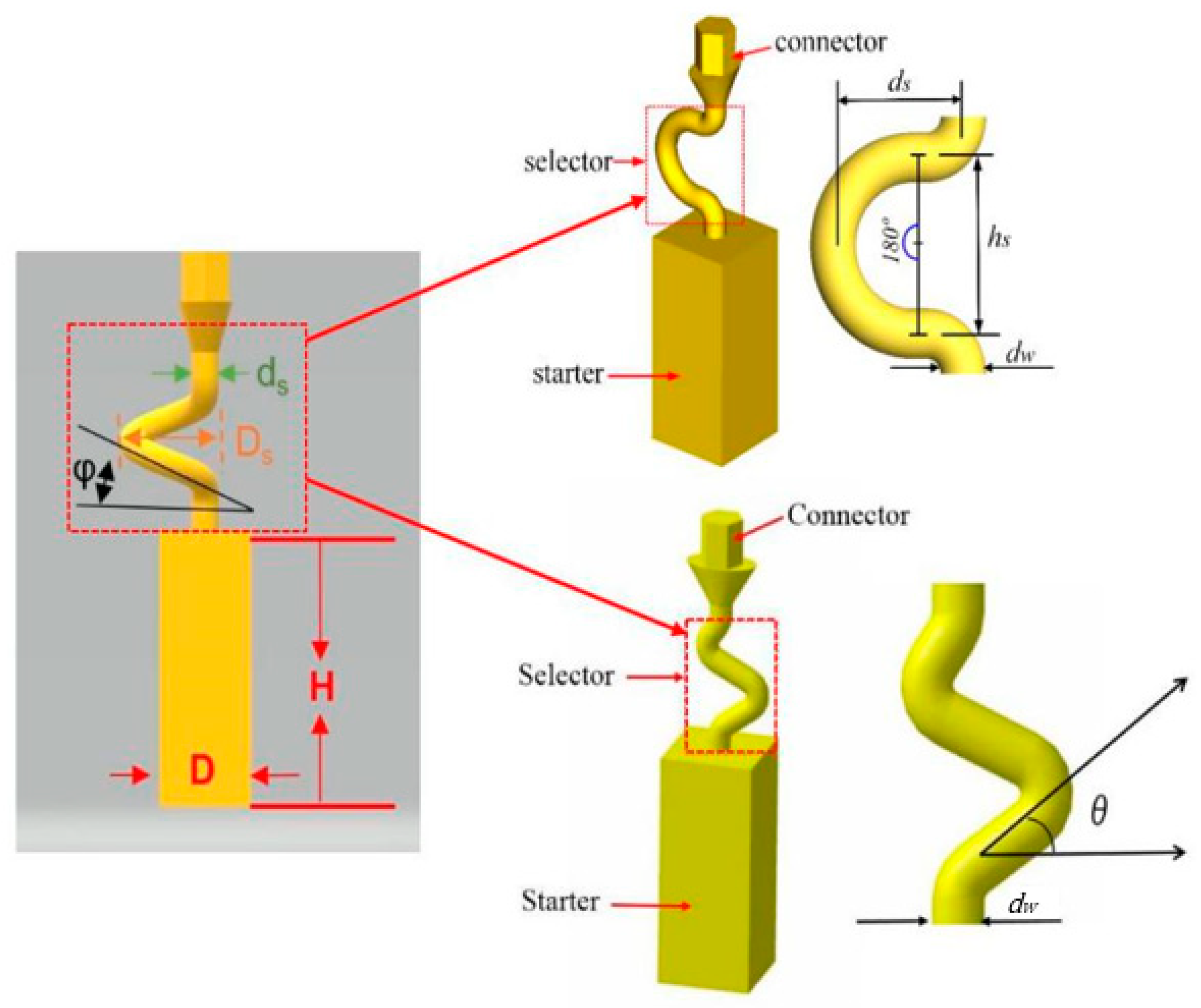

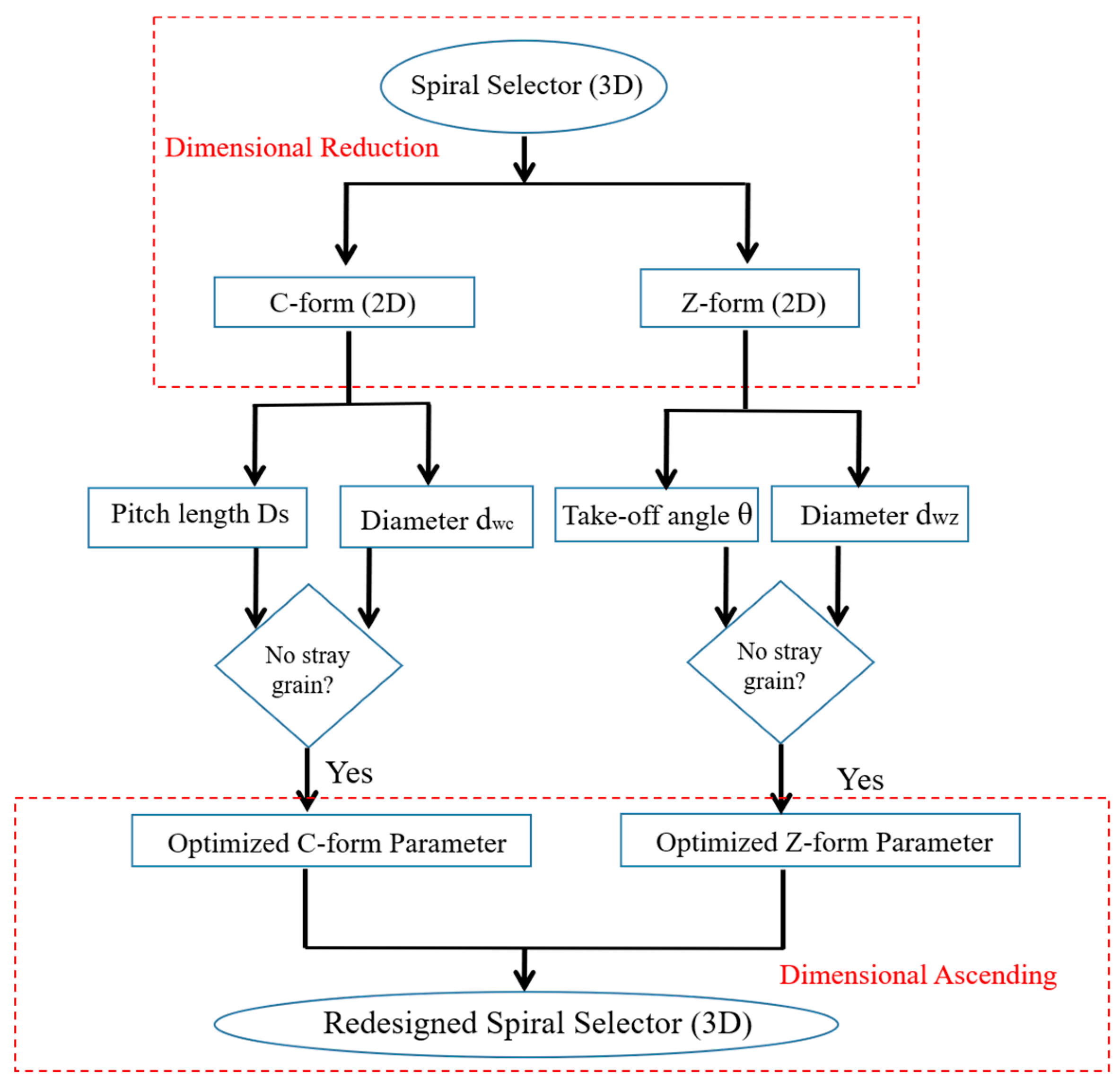

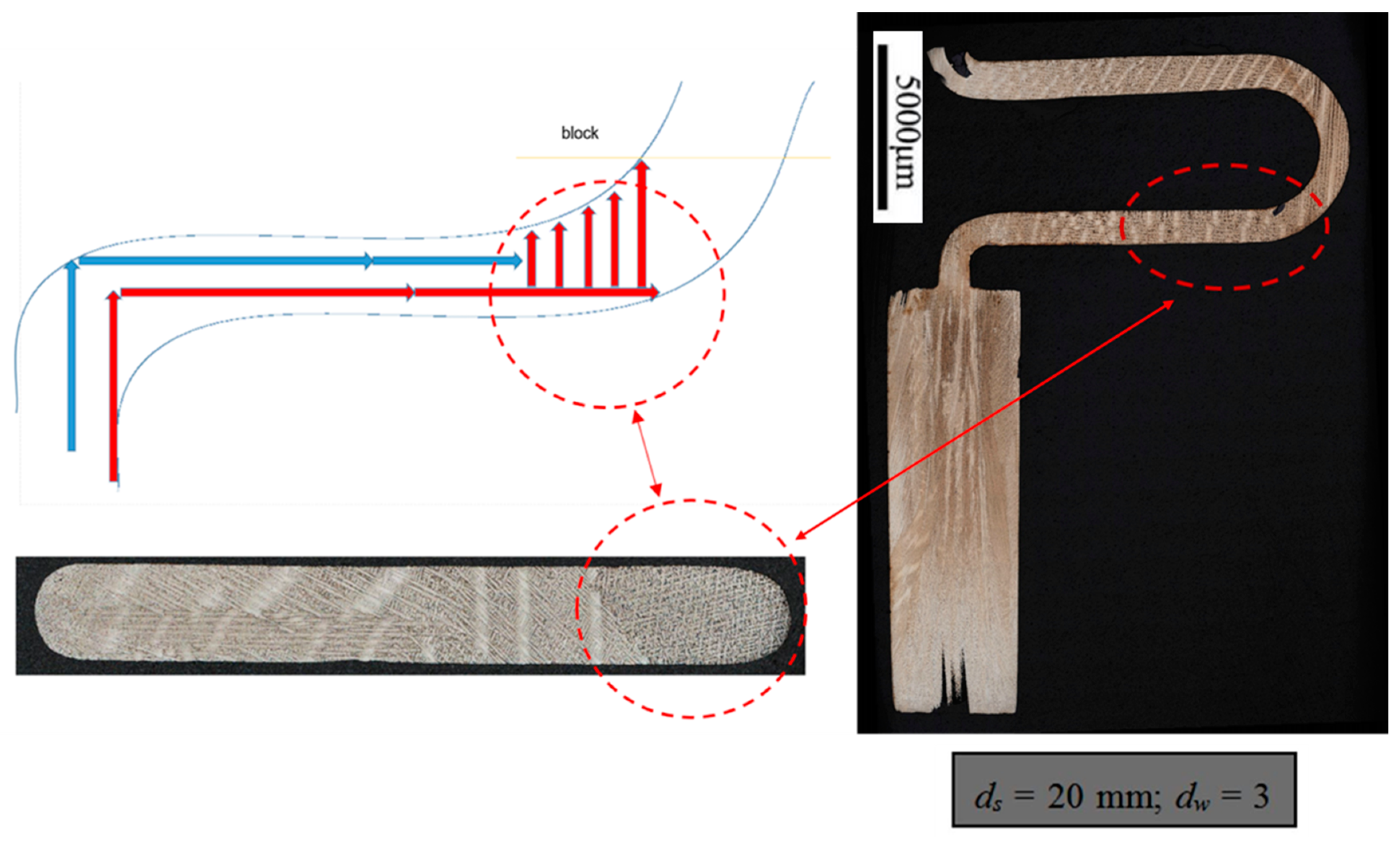

2.1. 2D Grain Selector Design Produces

- (1)

- Project a three-dimensional vision of a spiral selector into two-dimensional, resulting in a 2D view—C and Z;

- (2)

- Experiment the C-form and Z-form grain selector to obtain the optimized parameters;

- (3)

- Couple the optimized results of the two-dimensional model to project the corresponding three-dimensional spiral selector;

- (4)

- Use the redesigned results in the spiral selector and employed in the single crystal blades casting to verify the experiment results.

2.2. Geometry Design of 2D Grain Selector: C-Form Grain Selector and Z-Form Grain Selector

2.2.1. C-Form Grain Selector Design

2.2.2. Z-Form Grain Selector Design

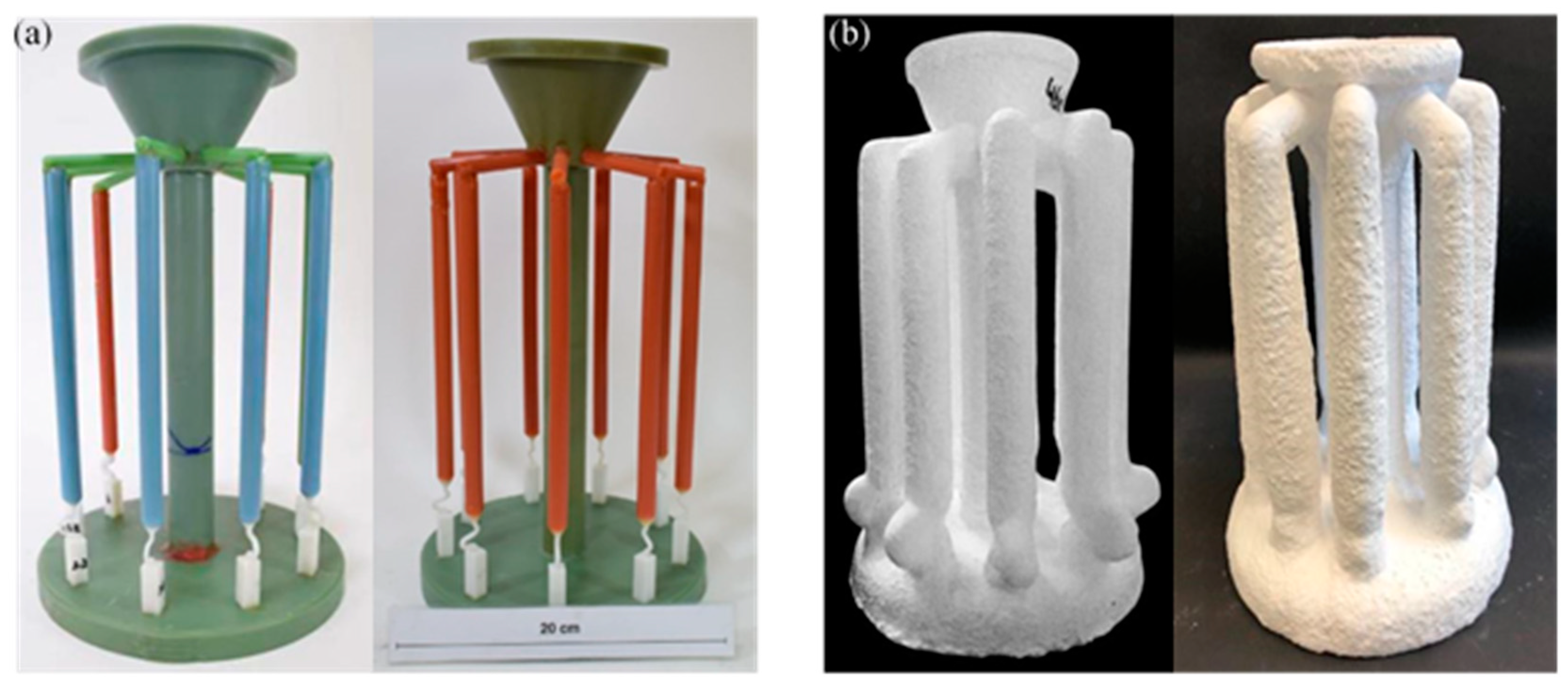

2.3. Casting Experiment

2.4. Microstructural Characterization

3. Results and Discussion

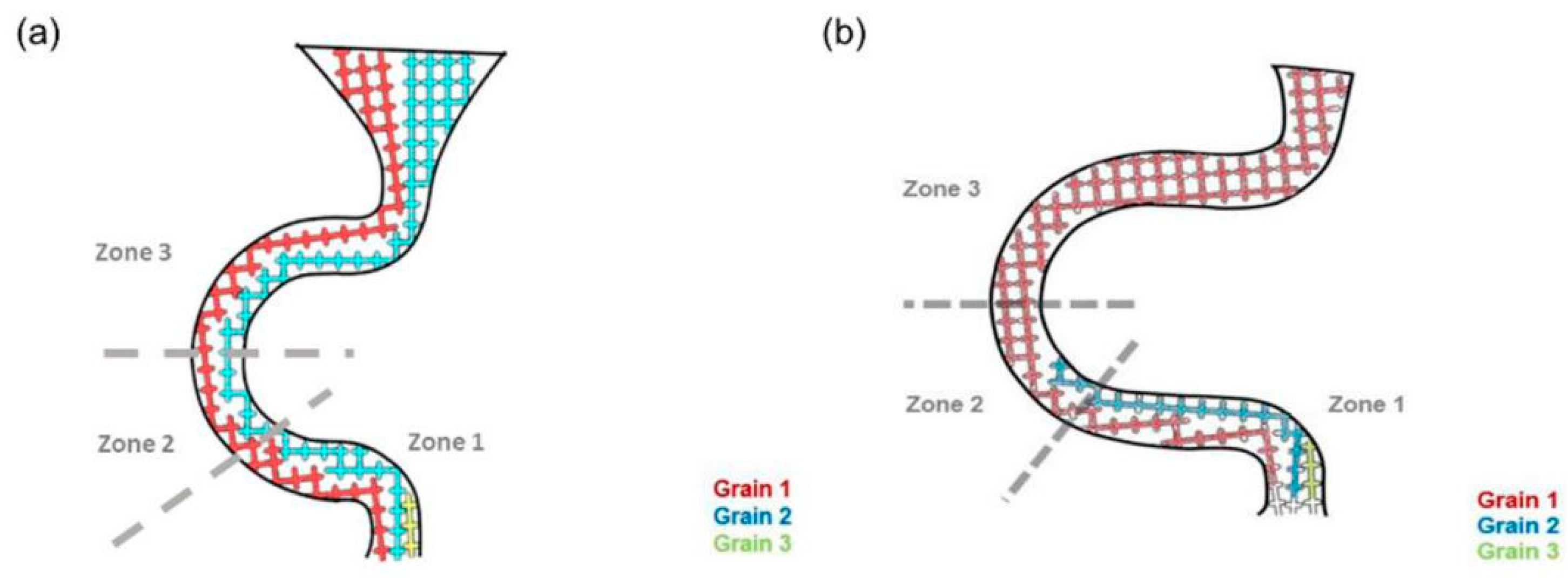

3.1. Effect of C-Form Selector Parameters on Grain Selection

3.2. Effect of the Z-form Selector Parameters on Grain Selection

3.3. Effect of Wire Diameter Parameters on 2D Selector Applied in Spiral Selector

3.4. Effect of Take-Off Angle Parameters on 2D Selector Applied in Spiral Selector

3.5. Effect of Pitch Length Parameters on 2D Selector Applied in Spiral Selector

3.6. Combination of a 2D Parameter Using in 3D Grain Selection and Result Verification

- Wax wire diameter (ds) = 3 mm;

- Pitch length (Ds) = 8 mm;

- Take-off angle (θ) = 40°.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhu, X.; Wang, F.; Ma, D.; Bührig-Polaczek, A. Grain selection in a high-efficiency 2D grain selector during casting of single-crystal superalloys. Materials 2019, 12, 789. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, F.; Ma, D.; Bührig-Polaczek, A. Development of a high-efficiency z-form selector for single crystal blades and corresponding grain selection mechanism. Materials 2019, 12, 780. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Ma, D.; Bogner, S.; Bührig-Polaczek, A. Comparative investigation of the downward and upward directionally solidified single-crystal blades of superalloy CMSX-4. Metall. Mater. Trans. A 2016, 47, 2376–2386. [Google Scholar] [CrossRef]

- Tin, S.; Pollock, T.; King, W. Carbon additions and grain defect formation in high refractory nickel-base single crystal superalloys. Superalloys 2000, 2000, 201–210. [Google Scholar]

- MacKay, R.; Maier, R. The influence of orientation on the stress rupture properties of nickel-base superalloy single crystals. Metall. Trans. A 1982, 13, 1747–1754. [Google Scholar] [CrossRef]

- Ma, D.; Wu, Q.; Bührig-Polaczek, A. Some new observations on freckle formation in directionally solidified superalloy components. Metall. Mater. Trans. B 2011, 43, 344–353. [Google Scholar] [CrossRef]

- Szeliga, D.; Kubiak, K.; Sieniawski, J. Control of liquidus isotherm shape during solidification of Ni-based superalloy of single crystal platforms. J. Mater. Process. Technol. 2016, 234, 18–26. [Google Scholar] [CrossRef]

- Dai, H.; Gebelin, J.; D’Souza, N.; Brown, P.; Dong, H. Effect of spiral shape on grain selection during casting of single crystal turbine blades. Int. J. Cast Met. Res. 2009, 22, 54–57. [Google Scholar] [CrossRef]

- Meng, X.; Li, J.; Jin, T.; Sun, X.; Sun, C.; Hu, Z. Evolution of grain selection in spiral selector during directional solidification of Nickel-base superalloys. J. Mater. Sci. Technol. 2011, 27, 118–126. [Google Scholar] [CrossRef]

| C-form grain selector with variant diameter | Single crystal | Stray grain | ||||||

|  |  |  |  |  |  |  | |

| Stray Grain | No | Yes | ||||||

| Probe | Cd1 | Cd2 | Cd3 | Cd4 | Cd5 | Cd6 | Cd7 | Cd8 |

| Diameter (cm) | 0.26 | 0.30 | 0.34 | 0.38 | 0.42 | 0.54 | 0.62 | 0.66 |

| C-form grain selector with variant pitch-length | Stray grain | Single crystal | ||||||

|  |  |  |  |  |  |  | |

| Stray Grain | Yes | No | ||||||

| Probe | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 |

| Pitch length | 0.4 | 0.6 | 0.8 | 1.2 | 1.6 | 2.0 | 2.2 | 2.6 |

| Z-form grain selector with variant diameter | Single Crystal | Stray Grain | ||||||

|  | |||||||

| Stray Grain | No | Yes | ||||||

| Probe | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Diameter (cm) | 0.18 | 0.22 | 0.26 | 0.30 | 0.38 | 0.42 | 0.46 | 0.54 |

| Z-form grain selector with a variant take-off angle | Single Crystal | Stray Grain | |||||||

|  |  |  |  |  |  |  |  | |

| Stray Grain | No | Yes | |||||||

| Sample | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Take-off angle | 15° | 20° | 25° | 30° | 35° | 40° | 45° | 50° | 55° |

| Elements | Al | Ti | Cr | Mo | Co | W | Ta | Hf | C | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | 5.49 | 0.74 | 8.03 | 0.5 | 9.41 | 9.87 | 2.9 | 1.36 | 0.094 | Bal. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Wang, F.; Zhang, S.; Wittenzellner, T.; Frieß, J.; Ma, D.; Bührig-Polaczek, A. Using a Three-Dimensional Reduction Method in the High-Efficiency Grain Selector and Corresponding Grain Selection Mechanism. Materials 2019, 12, 1781. https://doi.org/10.3390/ma12111781

Zhu X, Wang F, Zhang S, Wittenzellner T, Frieß J, Ma D, Bührig-Polaczek A. Using a Three-Dimensional Reduction Method in the High-Efficiency Grain Selector and Corresponding Grain Selection Mechanism. Materials. 2019; 12(11):1781. https://doi.org/10.3390/ma12111781

Chicago/Turabian StyleZhu, Xintao, Fu Wang, Shuaipeng Zhang, Tobias Wittenzellner, Jessica Frieß, Dexin Ma, and Andreas Bührig-Polaczek. 2019. "Using a Three-Dimensional Reduction Method in the High-Efficiency Grain Selector and Corresponding Grain Selection Mechanism" Materials 12, no. 11: 1781. https://doi.org/10.3390/ma12111781