Microstructure and Properties of Mg-Zn-Y Alloy Powder Compacted by Equal Channel Angular Pressing

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructural Characterization

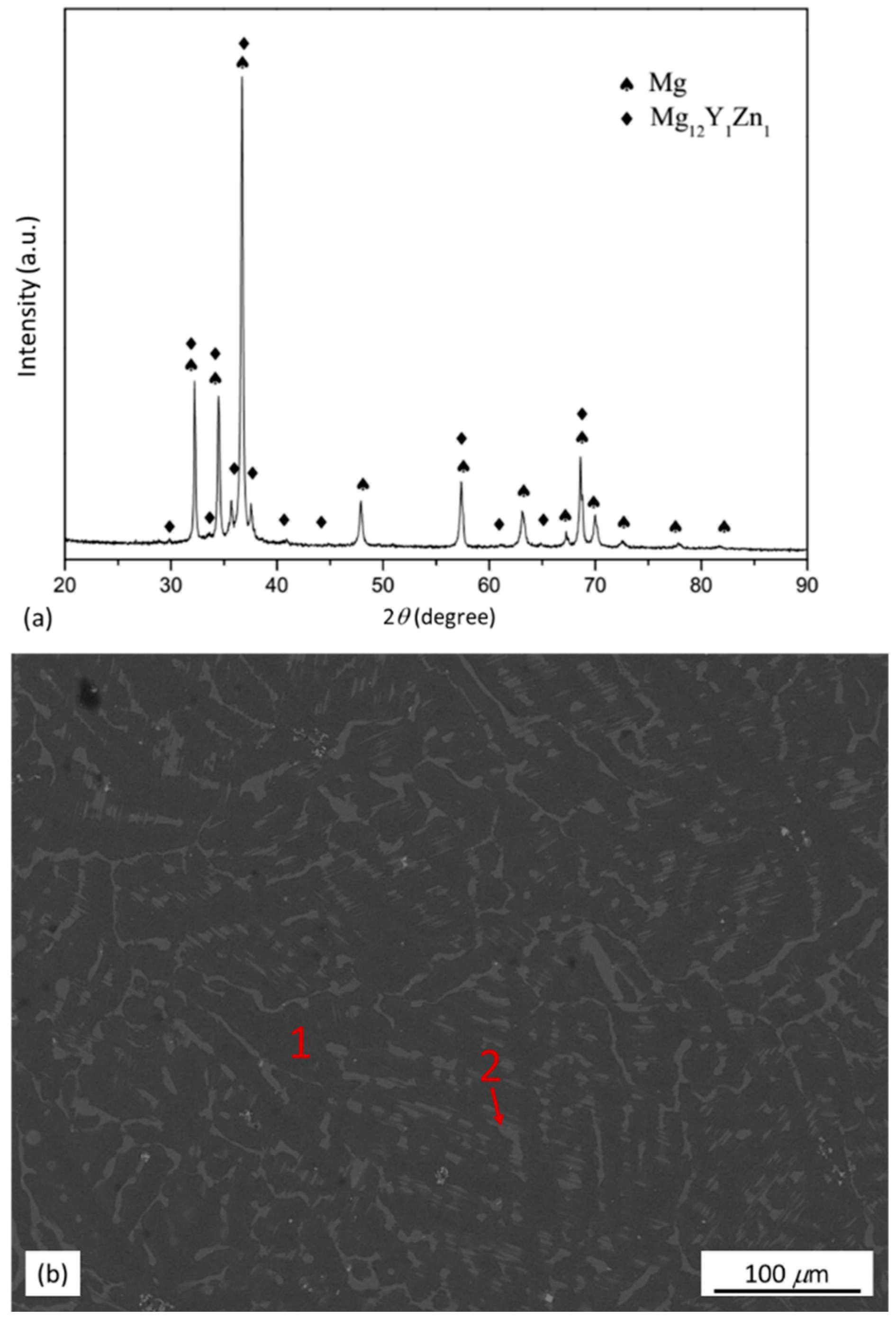

3.1.1. As-Cast Mg97Zn1Y2 Alloy

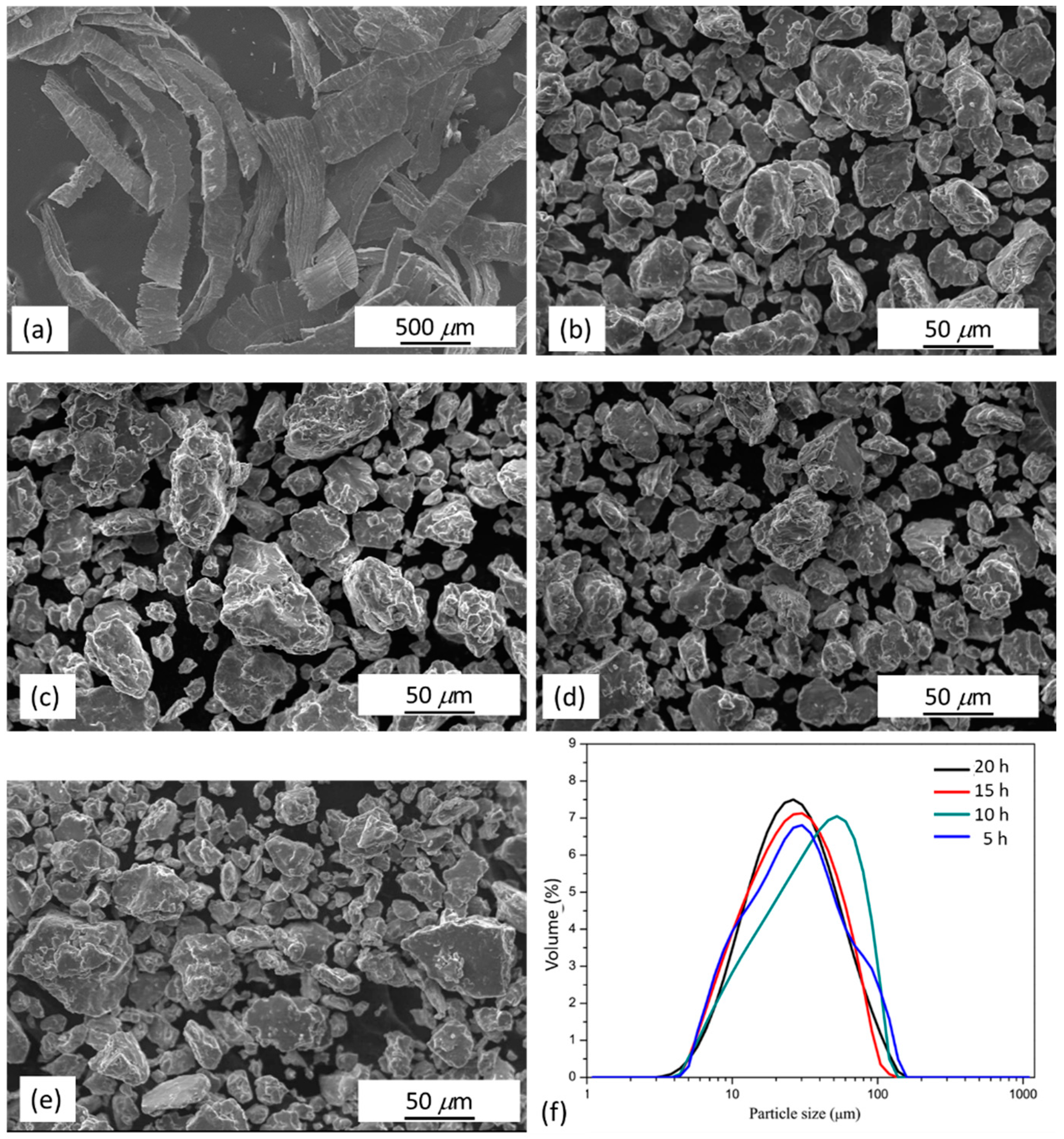

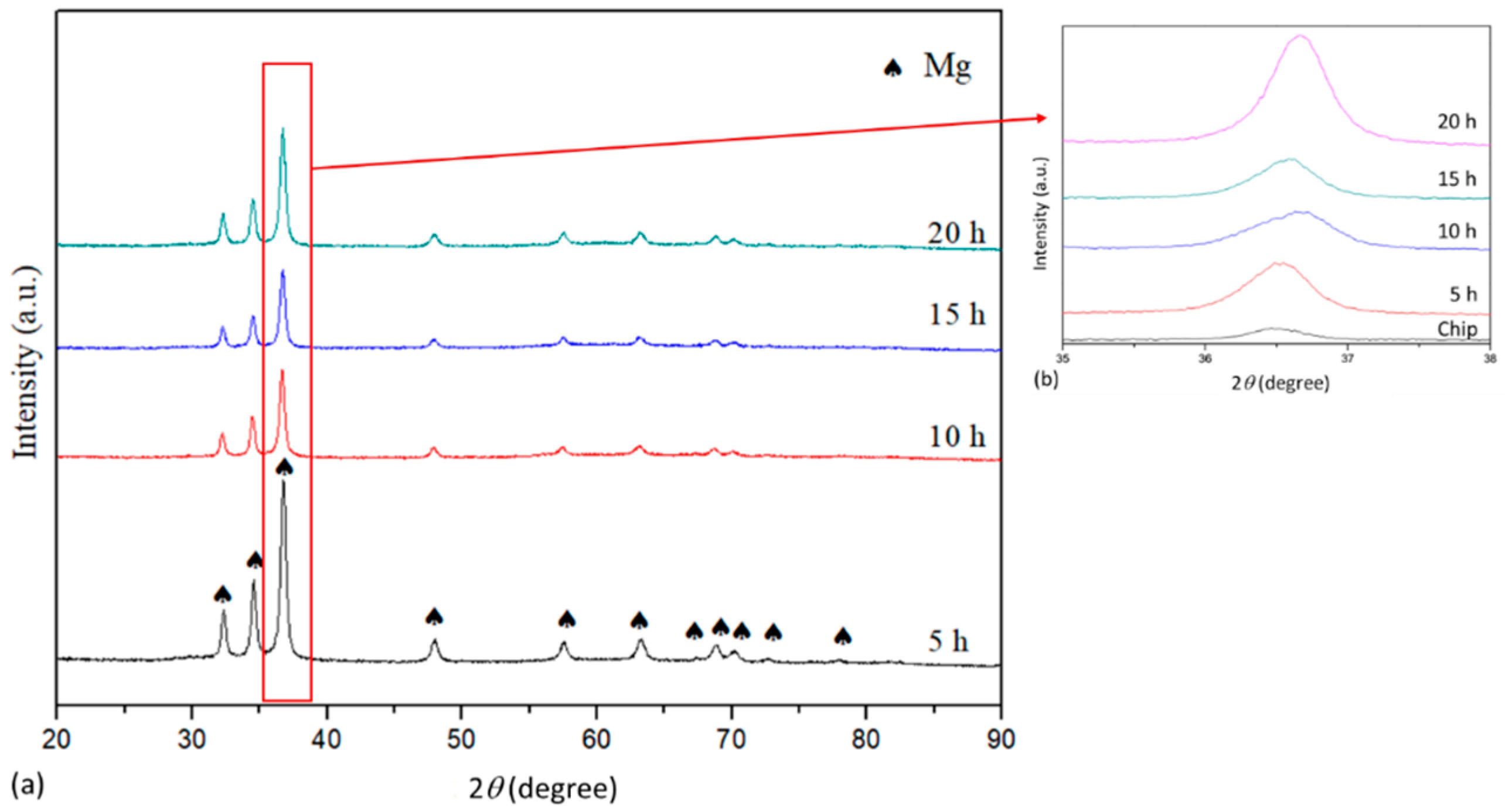

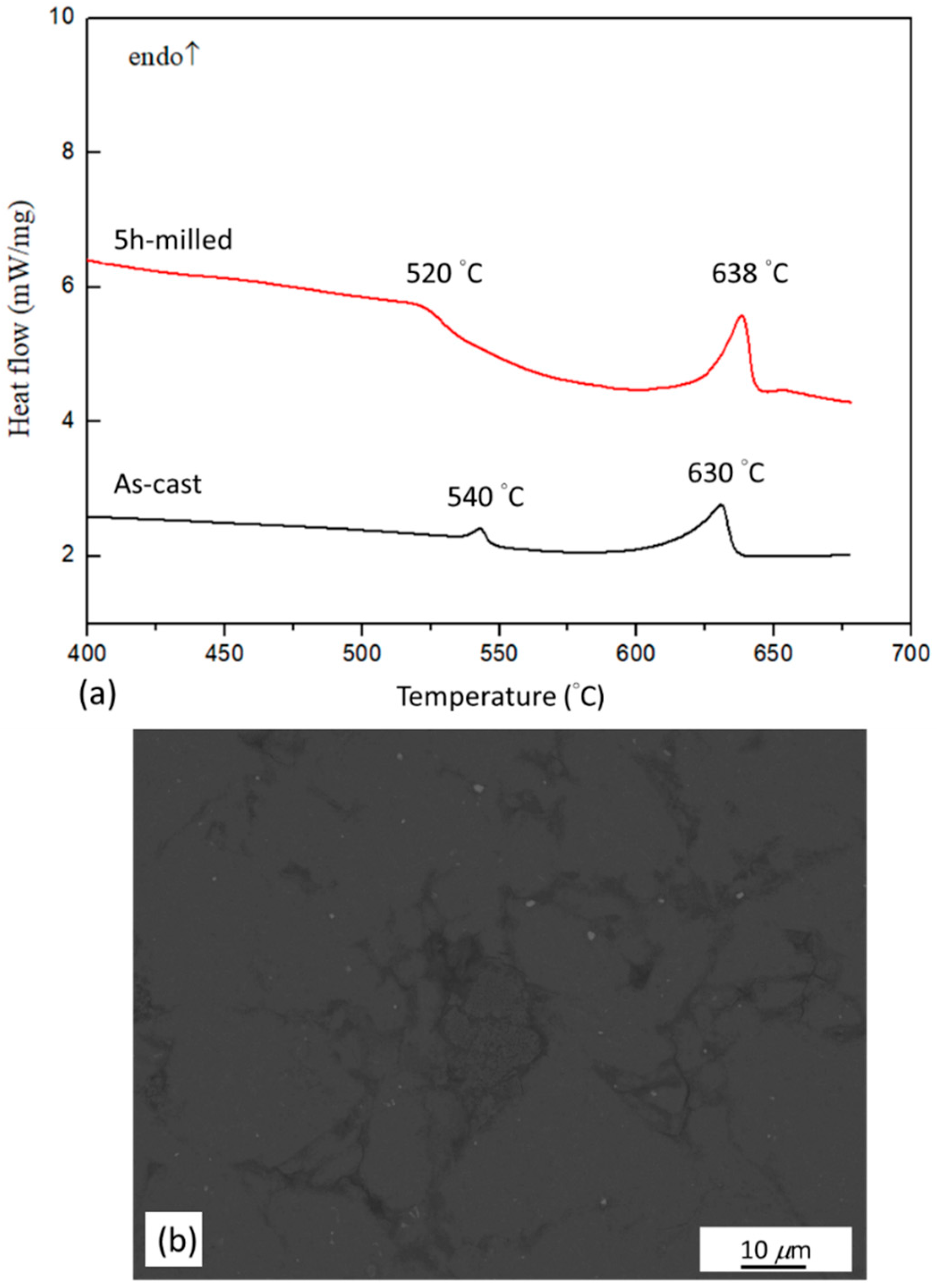

3.1.2. As-Milled Mg97Zn1Y2 Powders

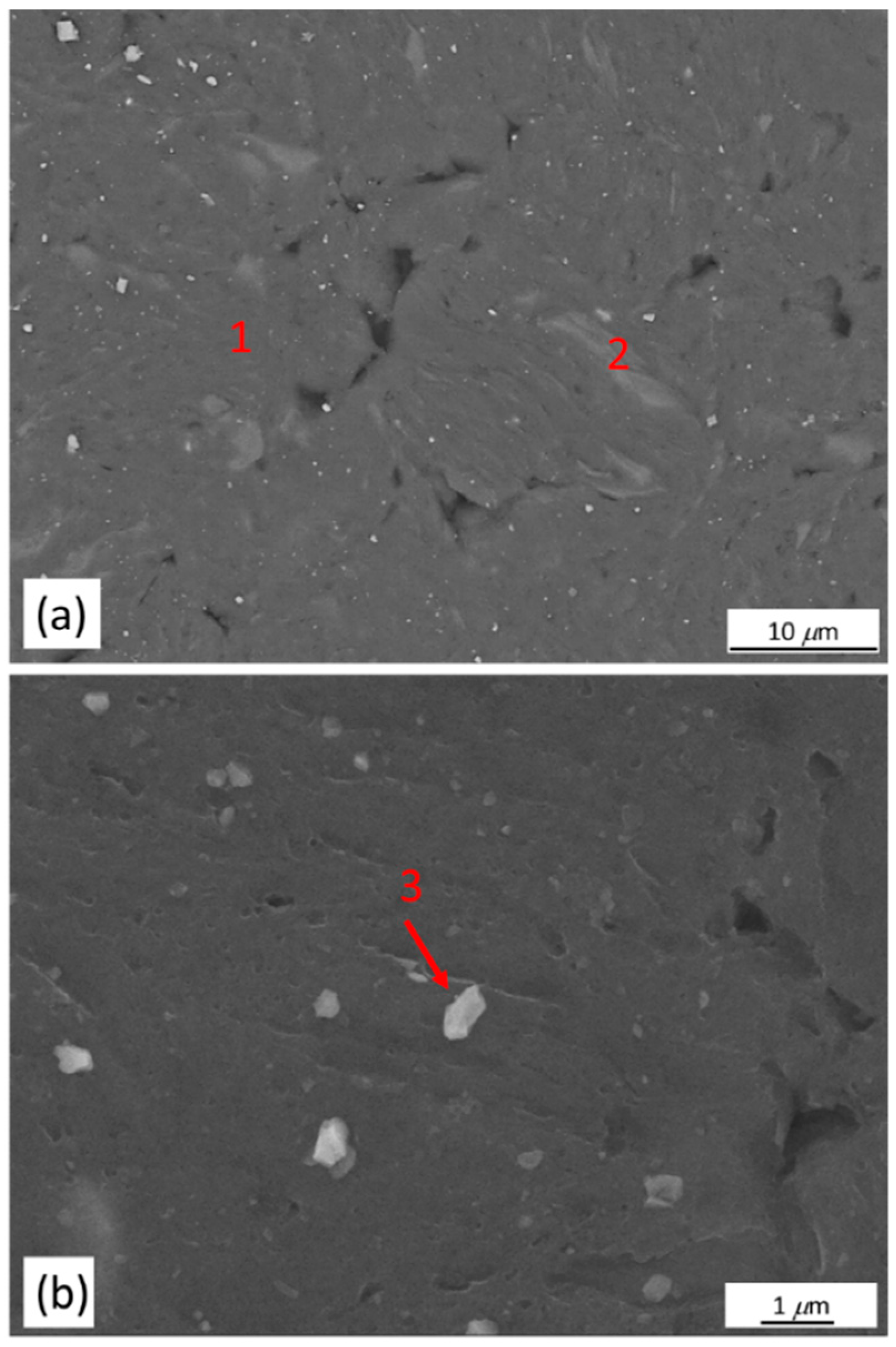

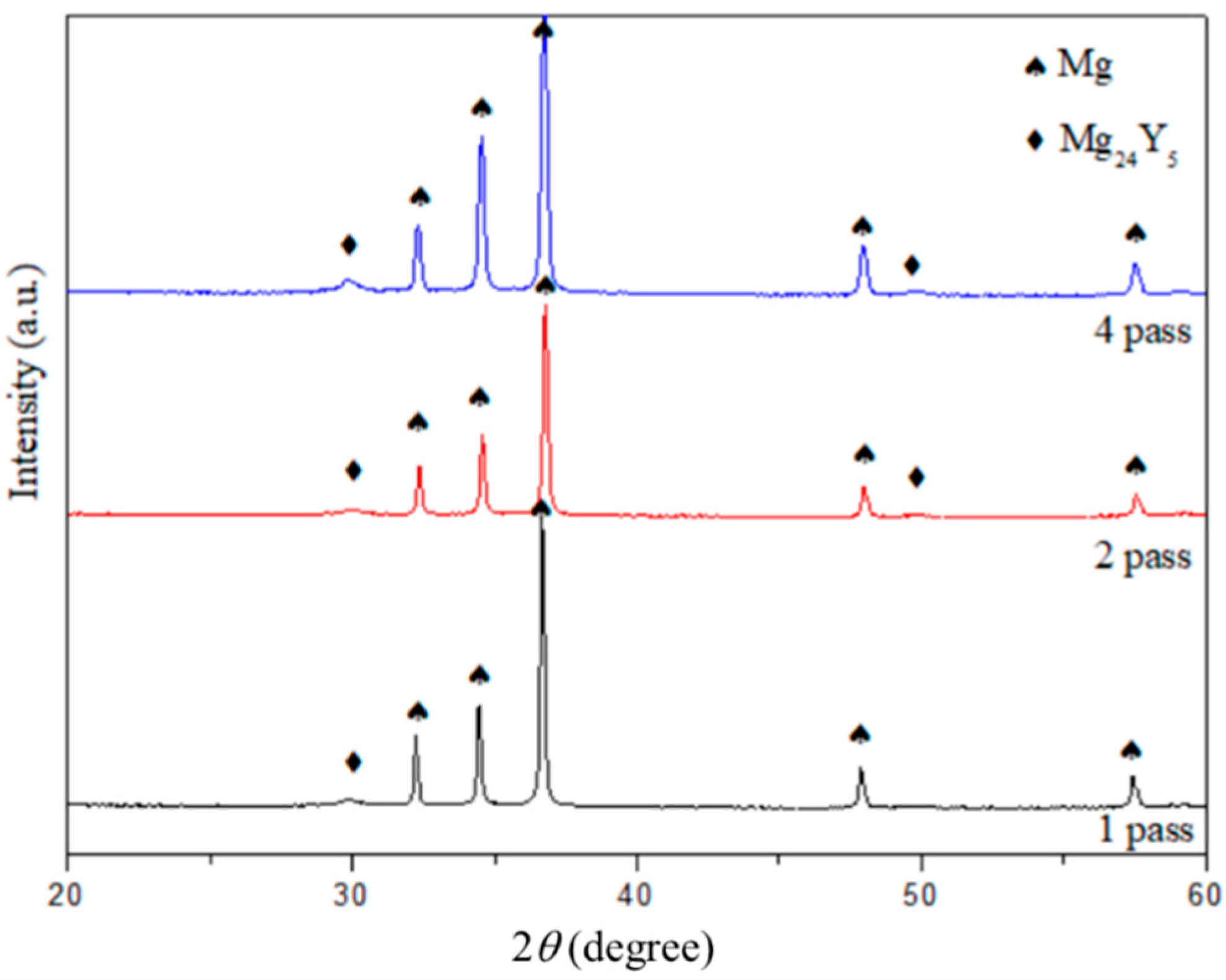

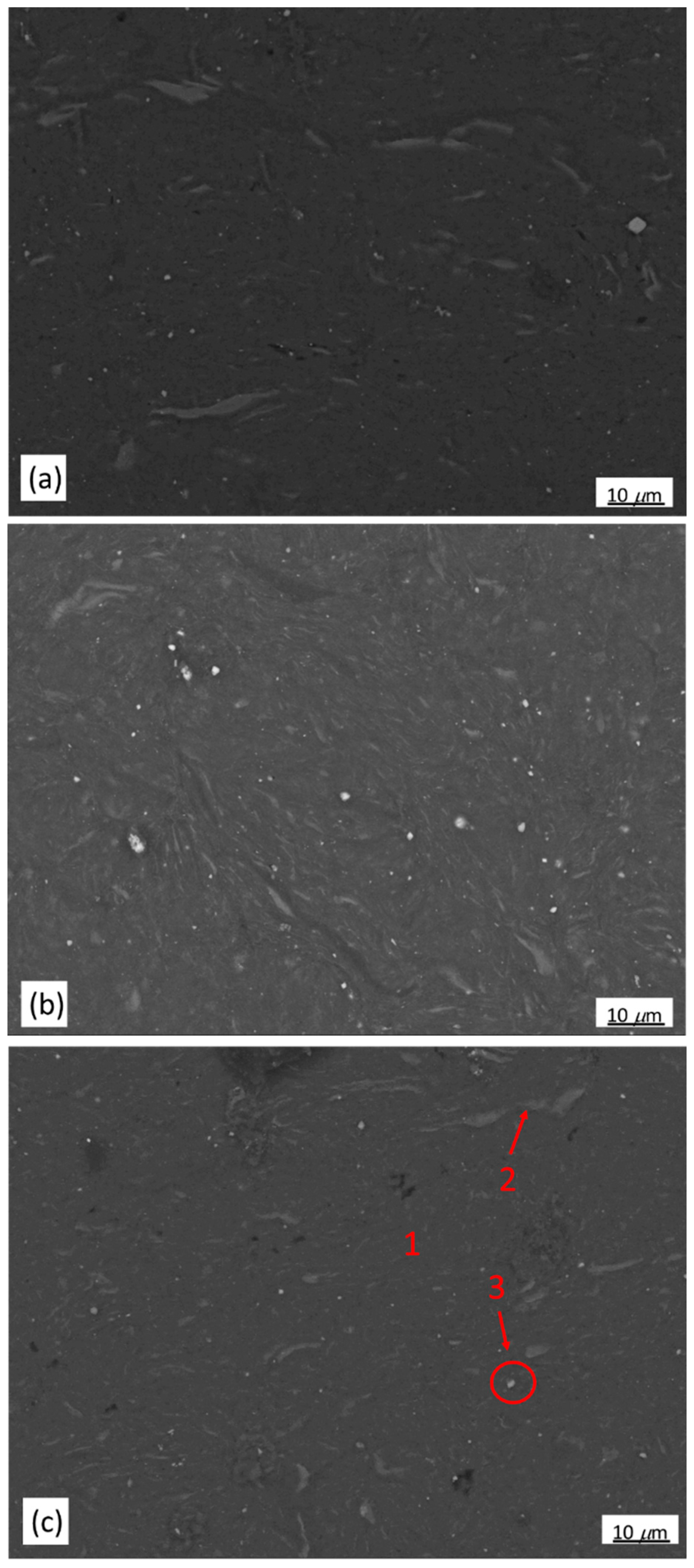

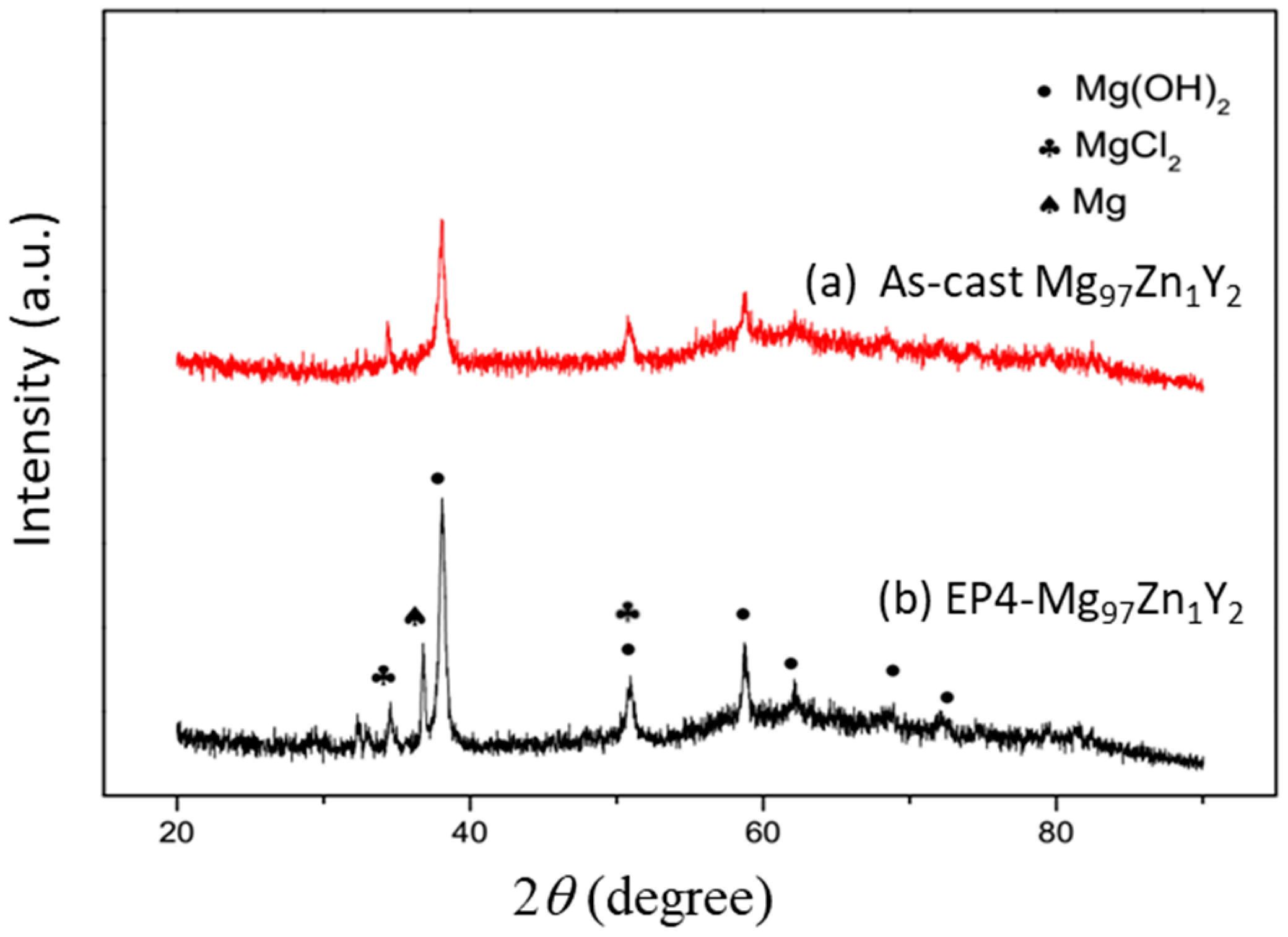

3.1.3. Mg97Zn1Y2 Powders Compacted by ECAP

3.2. Mechanical Properties

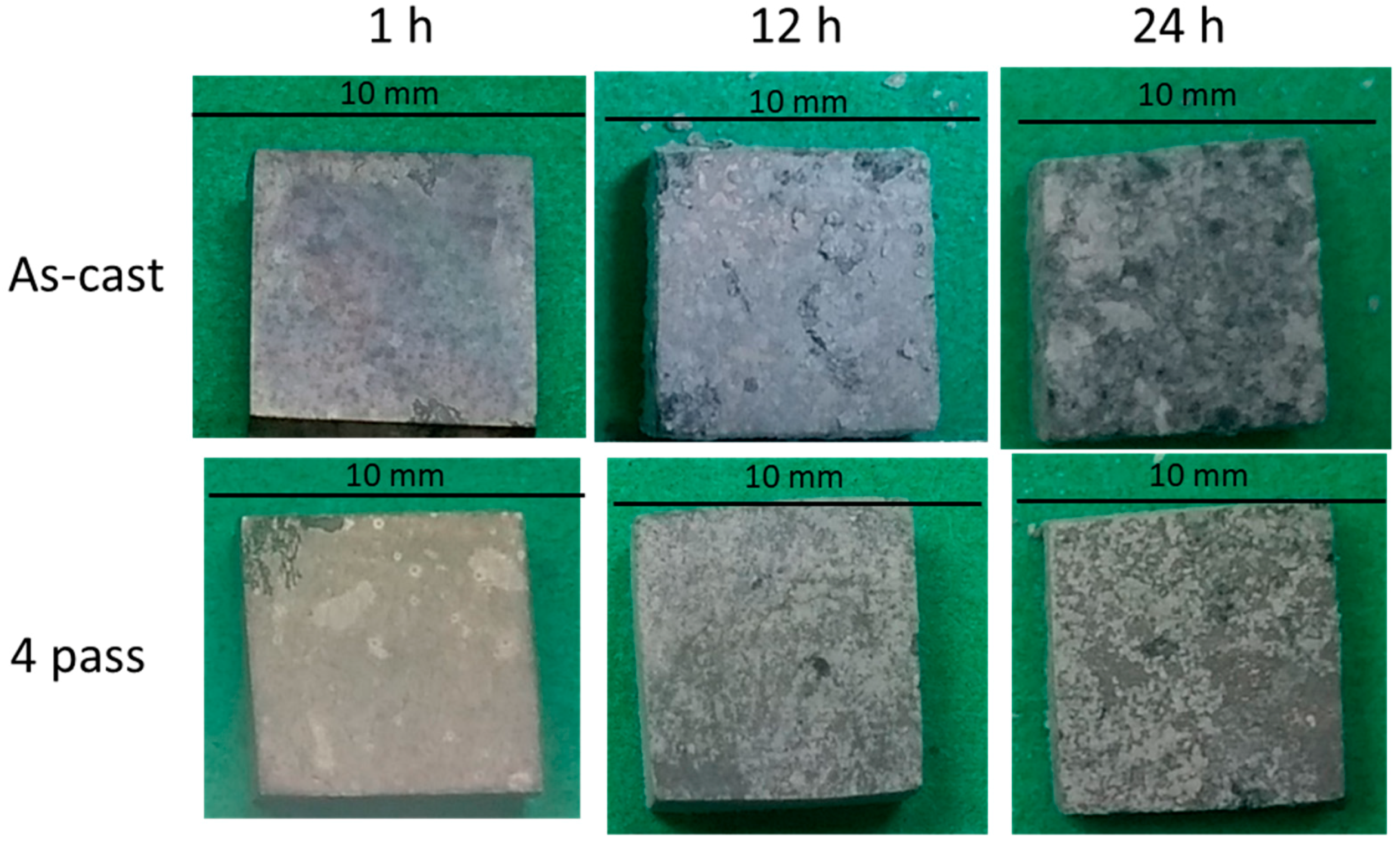

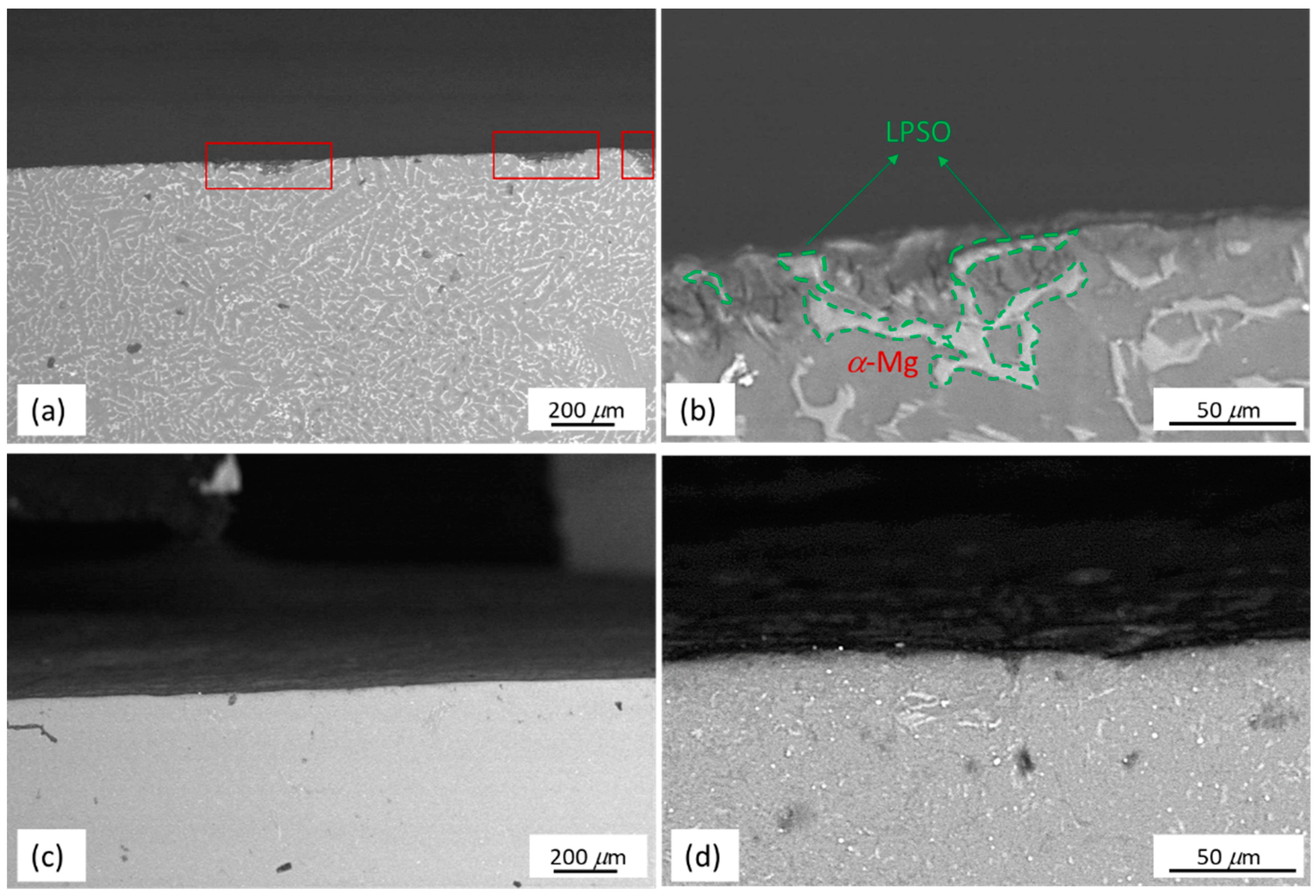

3.3. Corrosion Behavior

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mordike, B.L.; Ebert, T. Magnesium: Properties-applications-potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Schumann, S. The paths and strategies for increased magnesium applications in vehicles. Mater. Sci. Forum 2005, 488, 1–8. [Google Scholar] [CrossRef]

- Cabibbo, M.; Spigarelli, S. A TEM quantitative evolution of strengthening in an Mg-RE alloy reinforced with SiC. Mater. Charact. 2011, 62, 959–969. [Google Scholar] [CrossRef]

- Pan, F.S.; Yang, M.B.; Chen, X.H. A review on casting magnesium alloys: Modification of commercial alloys and development of new alloys. J. Mater. Sci. Technol. 2016, 32, 1211–1221. [Google Scholar] [CrossRef]

- You, S.; Huang, Y.; Kainer, K.U.; Hort, N. Recent research and developments on wrought magnesium alloys. J. Magnesium Alloys 2017, 5, 239–253. [Google Scholar] [CrossRef]

- Kawamura, Y.; Hayashi, K.; Inoue, A.; Masumoto, T. Rapidly solidified powder metallurgy Mg97Zn1Y2 alloy with excellent tensile yield strength above 600 MPa. Mater. Trans. 2001, 42, 1172–1176. [Google Scholar] [CrossRef]

- Inoue, A.; Matsushita, M.; Kawamura, Y.; Amiya, K.; Hayashi, K.; Koike, J. Novel hexagonal structure of ultra-high strength magnesium-based alloys. Mater. Trans. 2002, 43, 580–584. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Zhou, H.; Hu, L.; Sum, Y.; Zhang, H.; Duan, C.; Yu, H. Synthesis of nanocrystalline AZ31 magnesium alloy with titanium addition by mechanical milling. Mater. Charact. 2016, 113, 108–116. [Google Scholar] [CrossRef]

- Koch, C.C.; Scattergood, R.O.; Youssef, K.M.; Chan, E.; Zhu, Y.T. Nanostructured materials by mechanical alloying: new results on property enhancement. J. Mater. Sci. 2010, 45, 4725–4732. [Google Scholar] [CrossRef]

- Matsuda, M.; Kawamura, Y.; Nishida, M. Production of high strength Mg97Zn1Y2 alloy by using mechanically alloyed MgH2 powder. Mater. Trans. 2003, 44, 440–444. [Google Scholar] [CrossRef]

- Senkov, O.N.; Miracle, D.B.; Scott, J.M.; Senkova, S.V. Compaction of amorphous aluminum alloy powder by direct extrusion and equal angular extrusion. Mater. Sci. Eng. A 2005, 393, 12–21. [Google Scholar] [CrossRef]

- Kim, H.S.; Seo, M.H.; Oh, C.S.; Kim, S.J. Equal channel pressing of metallic powders. Mater. Sci. Forum 2003, 437, 89–92. [Google Scholar] [CrossRef]

- Nagasekhar, A.V.; Yip, T.H.; Ramakanth, K.S. Mechanics of single pass equal channel angular extrusion pf powder in tubes. Appl. Phys. A 2006, 85, 185–194. [Google Scholar] [CrossRef]

- Baker, I.; Iliescu, D.; Liao, Y. Containerless consolidation of Mg powders using ECAE. Mater. Manuf. Processes 2010, 25, 1381–1384. [Google Scholar] [CrossRef]

- Nagasekhar, A.V.; Yip, T.H.; Guduru, R.K.; Ramakanth, K.S. Multipass euqual channel angular pressing of MgB2 powder in tubes. Phys. C Supercond. 2007, 466, 174–180. [Google Scholar] [CrossRef]

- Karaman, I.; Haouaoui, M.; Maier, H.J. Nanoparticle consolidation using equal channel angular extrusion at room temperature. J. Mater. Sci. 2007, 42, 1561–1576. [Google Scholar] [CrossRef]

- Lee, H.C.; Chao, C.G.; Liu, T.F.; Lin, C.Y.; Wang, H.C. Effect of temperature and extrusion pass on the consolidation of magnesium powders using equal channel angular extrusion. Mater. Trans. 2013, 54, 765–768. [Google Scholar] [CrossRef]

- Yamasaki, M.; Hashimoto, K.; Hagihara, K.; Kawamura, Y. Effect of multimodal microstructure evolution on mechanical properties of Mg-Zn-Y extruded alloy. Acta Mater. 2011, 59, 3646–3658. [Google Scholar] [CrossRef]

- Slotwinski, J.A.; Garboczi, E.J.; Hebenstreit, K.M. Porosity measurements and analysis for metal additive manufacturing process control. J. Res. Natl. Inst. Stand. Technol. 2014, 119, 494–528. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Xu, J.; Cheng, W.; Chen, C.; Kang, J. Corrosion behavior of Mg-Zn-Y alloy with long-period stacking ordered structures. J. Mater. Sci. Technol. 2012, 28, 1157–1162. [Google Scholar] [CrossRef]

- Zhao, X.; Shi, L.L.; Xu, J. Biodegradable Mg-Zn-Y alloys with long-period stacking ordered structure: optimization for mechanical properties. J. Mech. Behav. Biomed. Mater. 2013, 18, 181–190. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Lin, D.; Zeng, X.; Liu, C. Effects of yttrium and zinc addition on the microstructure and mechanical properties of Mg-Zn-Y alloys. J. Mater. Sci. 2010, 45, 2510–2517. [Google Scholar] [CrossRef]

- Shao, G.; Varsani, V.; Fan, Z. Thermodynamic modelling of the Y-Zn and Mg-Zn-Y systems. Calphad 2006, 30, 286–295. [Google Scholar] [CrossRef]

- Hamaya, A.; Horiuchi, T.; Oohira, Y.; Minamoto, S.; Miura, S.; Sakaguchi, N. Experimental study on phase equilibria in the vicinity of X, W and H phases in the Mg-Zn-Y ternary system. Mater. Trans. 2013, 54, 641–646. [Google Scholar] [CrossRef]

- Lee, J.Y.; Kim, D.H.; Lim, H.K.; Kim, D.H. Effects of Zn/Y ratio on microstructure and mechanical properties of Mg-Zn-Y alloys. Mater. Lett. 2005, 59, 3801–3805. [Google Scholar] [CrossRef]

- Chen, B.; Lin, D.; Zeng, X.; Lu, C. Effect of solid solution treatment on microstructure and mechanical properties of Mg97Zn1Y2 alloy. J. Mater. Eng. Perform. 2013, 22, 523–527. [Google Scholar] [CrossRef]

- Okamoto, H. Mg-Y (Magnesium-Yttrium). J. Phase Equilib. Diffus. 2010, 31, 199. [Google Scholar] [CrossRef]

- Gerasimov, K.B.; Gusev, A.A.; Ivanov, E.Y.; Boldyrev, V.V. Tribochemical equilibrium in mechanical alloying of metals. J. Mater. Sci. 1991, 26, 2495–2500. [Google Scholar] [CrossRef]

- Kwon, Y.S.; Kim, J.S.; Choi, D.W.; Gerasimov, K.B.; Avramchunk, S.S. Mechanically driven decomposition of intermetallics. J. Mater. Sci. 2004, 39, 5213–5216. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Langdon, T.G. Grain refinement and mechanical behavior of a magnesium alloy processed by ECAP. J. Mater. Sci. 2010, 45, 4827–4836. [Google Scholar] [CrossRef]

- Ramya, M.; Sarwat, S.G.; Udhayabanu, V.; Subramanian, S.; Raj, B.; Ravi, K.R. Role of partially amorphous structure and alloying elements on the corrosion behavior of Mg-Zn-Ca bulk metallic glass for biomedical applications. Mater. Des. 2015, 86, 829–835. [Google Scholar] [CrossRef]

- Leng, Z.; Zhang, J.H.; Yin, T.T.; Zhang, L.; Guo, X.Y.; Peng, Q.M.; Zhang, M.L.; Wu, R.Z. Influence of biocorrosion on microstructure and mechanical properties of deformed Mg-Y-Er-Zn biomaterial containing 18R-LPSO phase. J. Mech. Behav. Biomed. Mater. 2013, 28, 332–339. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Wang, Q.; Chen, F.; Wu, Y.; Wang, Z.; Wang, Q. Relation between LPSO structure and biocorrosion behavior of biodegradable GZ51K alloy. Mater. Lett. 2015, 138, 212–215. [Google Scholar] [CrossRef]

- Cao, F.; Song, G.L.; Atrens, A. Corrosion and passivation of magnesium alloys. Corros. Sci. 2016, 111, 835–845. [Google Scholar] [CrossRef]

- Liao, J.; Hotta, M.; Mori, Y. Improved corrosion resistance of a high-strength Mg-Al-Mn-Ca magnesium alloy made by rapid solidification powder metallurgy. Mater. Sci. Eng. A 2012, 544, 10–20. [Google Scholar] [CrossRef]

- Kubásek, J.; Dvorský, D.; Čavojský, M.; Vojtěch, D.; Beronská, N.; Fousová, M. Superior properties of Mg-4Y-3RE-Zr alloy prepared by powder metallurgy. J. Mater. Sci. Technol. 2017, 33, 652–660. [Google Scholar] [CrossRef]

- Cabeza, S.; Garcés, G.; Pérez, P.; Adeva, P. Properties of WZ21 (% wt) alloy processed by a powder metallurgy route. J. Mech. Behav. Biomed. Mater. 2015, 46, 115–126. [Google Scholar] [CrossRef] [PubMed]

- Pérez, P.; Onofre, E.; Cabeza, S.; Llorente, I.; del Valle, J.A.; García-Alonso, M.C.; Adeva, P.; Escudero, M.L. Corrosion behavior of Mg-Zn-Y-Mischmetal alloys in phosphate buffer saline solution. Corros. Sci. 2013, 69, 226–235. [Google Scholar]

- Kubásek, J.; Vojtěch, D. Structural and corrosion characterization of biodegradable Mg-RE (RE = Gd, Y, Nd) alloys. Trans. Nonferr. Met. Soc. China 2013, 23, 1215–1225. [Google Scholar] [CrossRef]

- Birbilis, N.; Easton, M.A.; Sudholz, A.D.; Zhu, S.M.; Gibson, M.A. On the corrosion of binary magnesium-rare earth alloys. Corros. Sci. 2009, 51, 683–689. [Google Scholar] [CrossRef]

| Processing State | Zone | Element | ||

|---|---|---|---|---|

| Mg (at %) | Zn (at %) | Y (at %) | ||

| As-cast | 1 | 98.32 ± 0.26 | 0.58 ± 0.18 | 1.10 ± 0.22 |

| 2 | 89.17 ± 0.75 | 4.62 ± 0.36 | 6.21 ± 0.45 | |

| 5 h-milled | 1 | 97.03 ± 0.63 | 1.18 ± 0.25 | 1.79 ± 0.49 |

| 2 | 93.98 ± 1.79 | 1.15 ± 0.83 | 4.87 ± 1.13 | |

| 3 | 84.80 ± 1.50 | 1.15 ± 0.23 | 14.05 ± 1.54 | |

| 4 passes of ECAP | 1 | 96.29 ± 1.27 | 1.41 ± 0.17 | 2.30 ± 1.37 |

| 2 | 94.45 ± 1.05 | 1.24 ± 0.14 | 4.31 ± 0.97 | |

| 3 | 84.42 ± 2.78 | 1.37 ± 0.49 | 14.21 ± 2.77 |

| Processing State | Time or Pass | Crystallite Size (nm) | Particle Size (μm) | Density (g/cm3) | Porosity (%) | Vickers Microhardness (HV) |

|---|---|---|---|---|---|---|

| As-cast | - | 59 ± 9 | - | 1.87 | - | 80 ± 6 |

| As-milled | 5 h | 24 ± 2 | 38 | - | - | - |

| 10 h | 23 ± 2 | 42 | - | - | - | |

| 15 h | 24 ± 3 | 37 | - | - | - | |

| 20 h | 22 ± 2 | 33 | - | - | - | |

| ECAP | 1 pass | 57 ± 3 | - | 1.76 | 4.6 | 123 ± 4 |

| 2 pass | 50 ± 2 | - | 1.77 | 4.0 | 122 ± 4 | |

| 4 pass | 41 ± 1 | - | 1.80 | 2.4 | 121 ± 3 |

| Alloy | Processing Route | Secondary Phase | Grain Size of Mg (μm) | Particle Size of Secondary Phase (nm) | Volume Fraction of Secondary Phase (%) | Reference |

|---|---|---|---|---|---|---|

| As-cast Mg97Zn1Y2 | Cast | LPSO | 59 nm 1 | - | 17 | Present work |

| EP4-Mg97Zn1Y2 | Cast + MM + ECAP | Mg24Y5 | 41 nm 1 | 200 to 700 | 4.7 | Present work |

| As-cast AMX602 | Cast | Al2Ca | >50 | - | 5.4 2 | [36] |

| SWAPed AMX602 | Cast + SWAP + Extrusion | Al2Ca | <1 | <100 | 0.9 2 | [36] |

| WE43-IM | Cast + Extrusion | Mg14Nd2Y | 0.5 to 4 | - | 19.7 2 | [37] |

| WE43-PM | Cast + Atomization + Extrusion | Mg14Nd2Y, Mg24Y5, Mg45Nd5 | 1 to 2 | <50 | 10.7 2 | [37] |

| WZ21-IM350 | Cast + Extrusion | LPSO | 5 | - | 15.6 2 | [38] |

| WZ21-PM350 | Cast + Atomization + Extrusion | Mg24Y5 | 2 | <200 | 12.5 2 | [38] |

| MgRE1.5 | Cast + Extrusion | LPSO, Mg12RE, Mg24Y5 | 5 to 7 | - | 24 | [39] |

| MgRE1.5-PM | Cast + Atomization + Extrusion | Mg24Y5 | 0.6 | <1 μm | 26 | [39] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiu, C.; Huang, H.-M. Microstructure and Properties of Mg-Zn-Y Alloy Powder Compacted by Equal Channel Angular Pressing. Materials 2018, 11, 1678. https://doi.org/10.3390/ma11091678

Chiu C, Huang H-M. Microstructure and Properties of Mg-Zn-Y Alloy Powder Compacted by Equal Channel Angular Pressing. Materials. 2018; 11(9):1678. https://doi.org/10.3390/ma11091678

Chicago/Turabian StyleChiu, Chun, and Hong-Min Huang. 2018. "Microstructure and Properties of Mg-Zn-Y Alloy Powder Compacted by Equal Channel Angular Pressing" Materials 11, no. 9: 1678. https://doi.org/10.3390/ma11091678