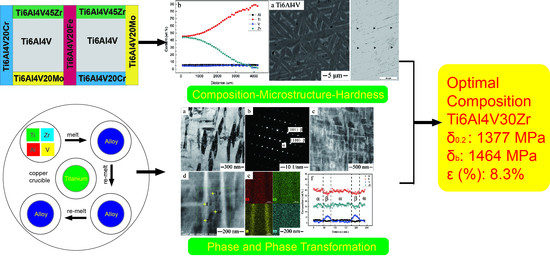

Optimal Design of High-Strength Ti‒Al‒V‒Zr Alloys through a Combinatorial Approach

Abstract

:1. Introduction

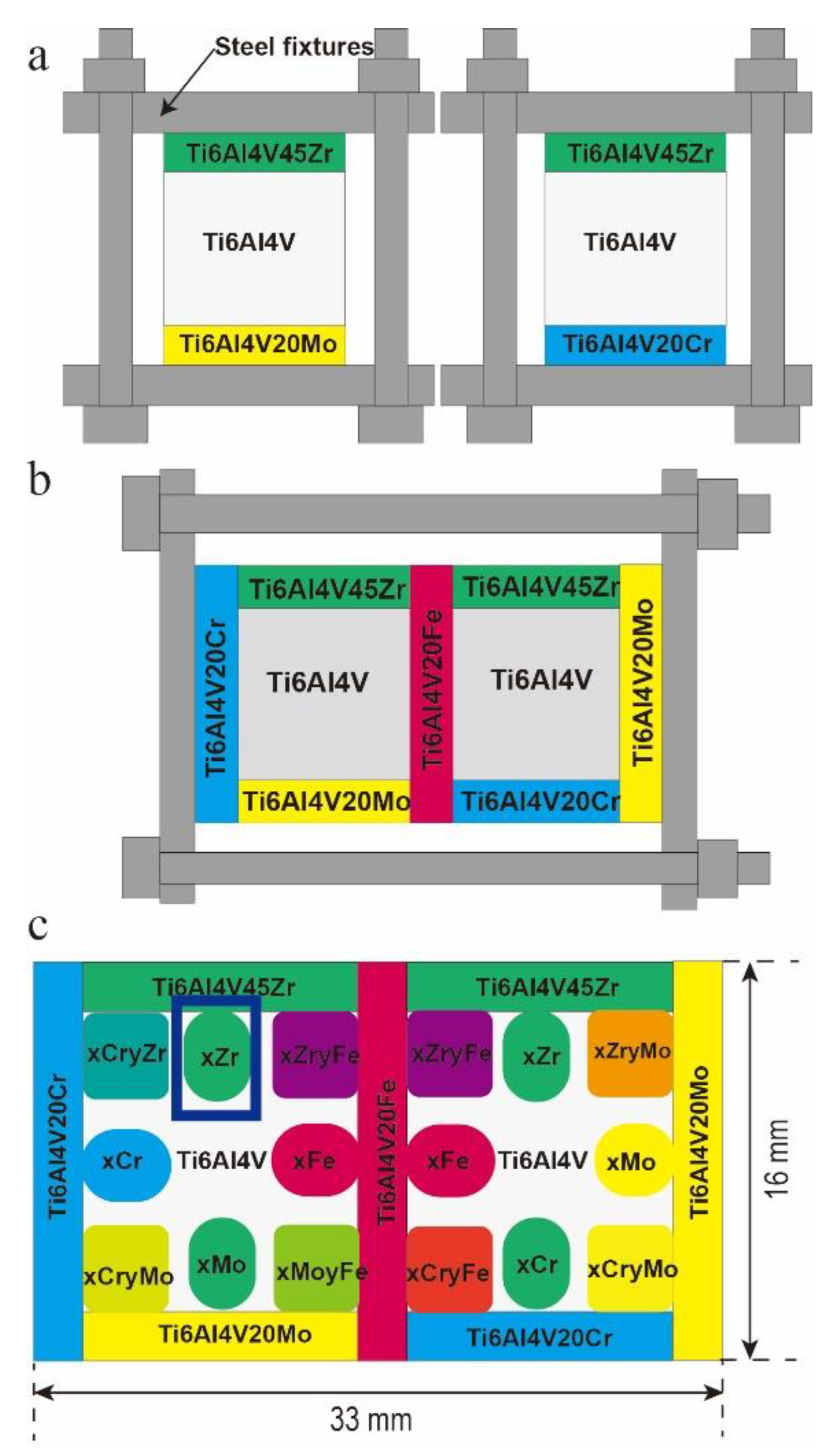

2. Materials and Methods

3. Results and Discussion

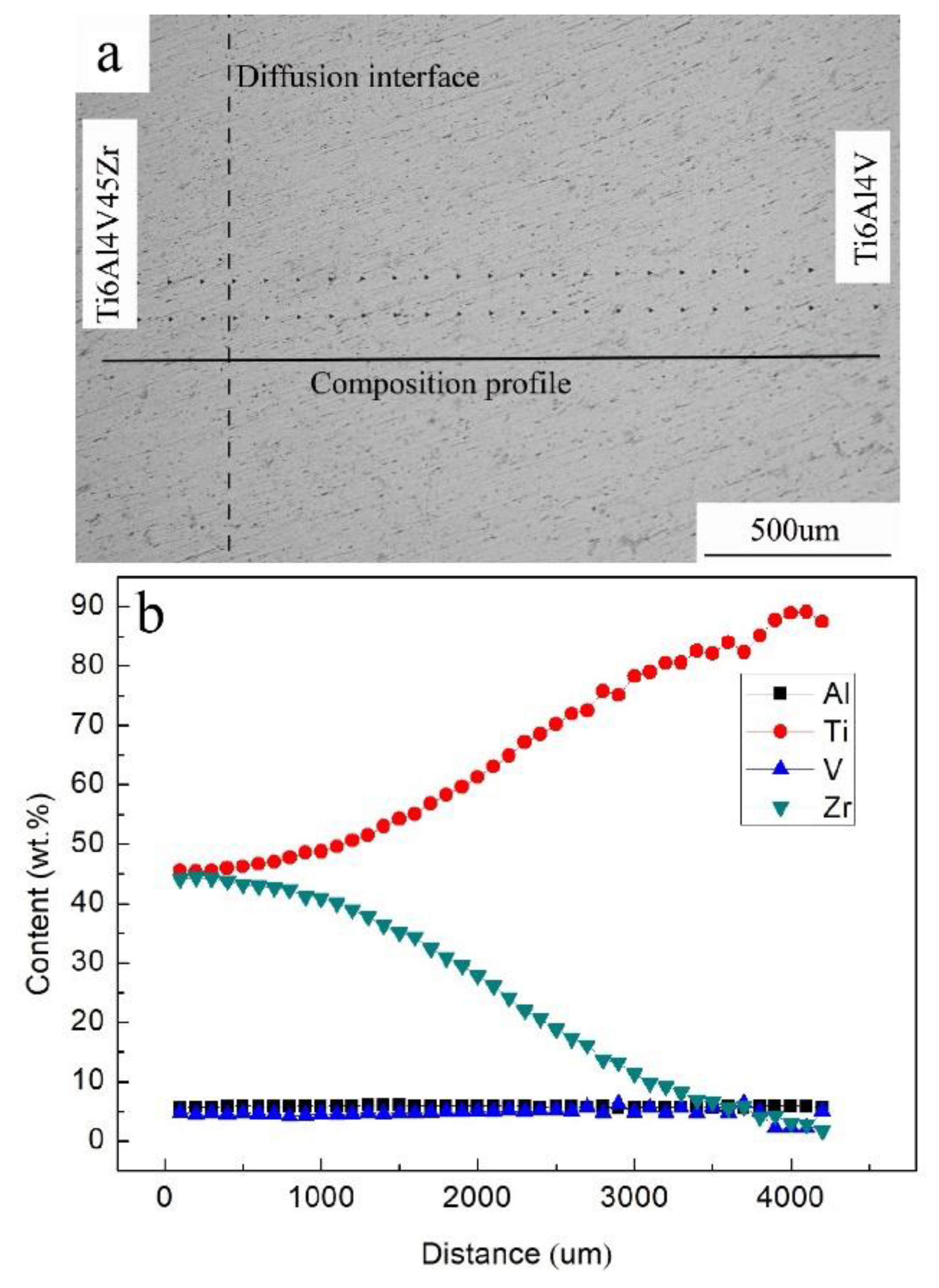

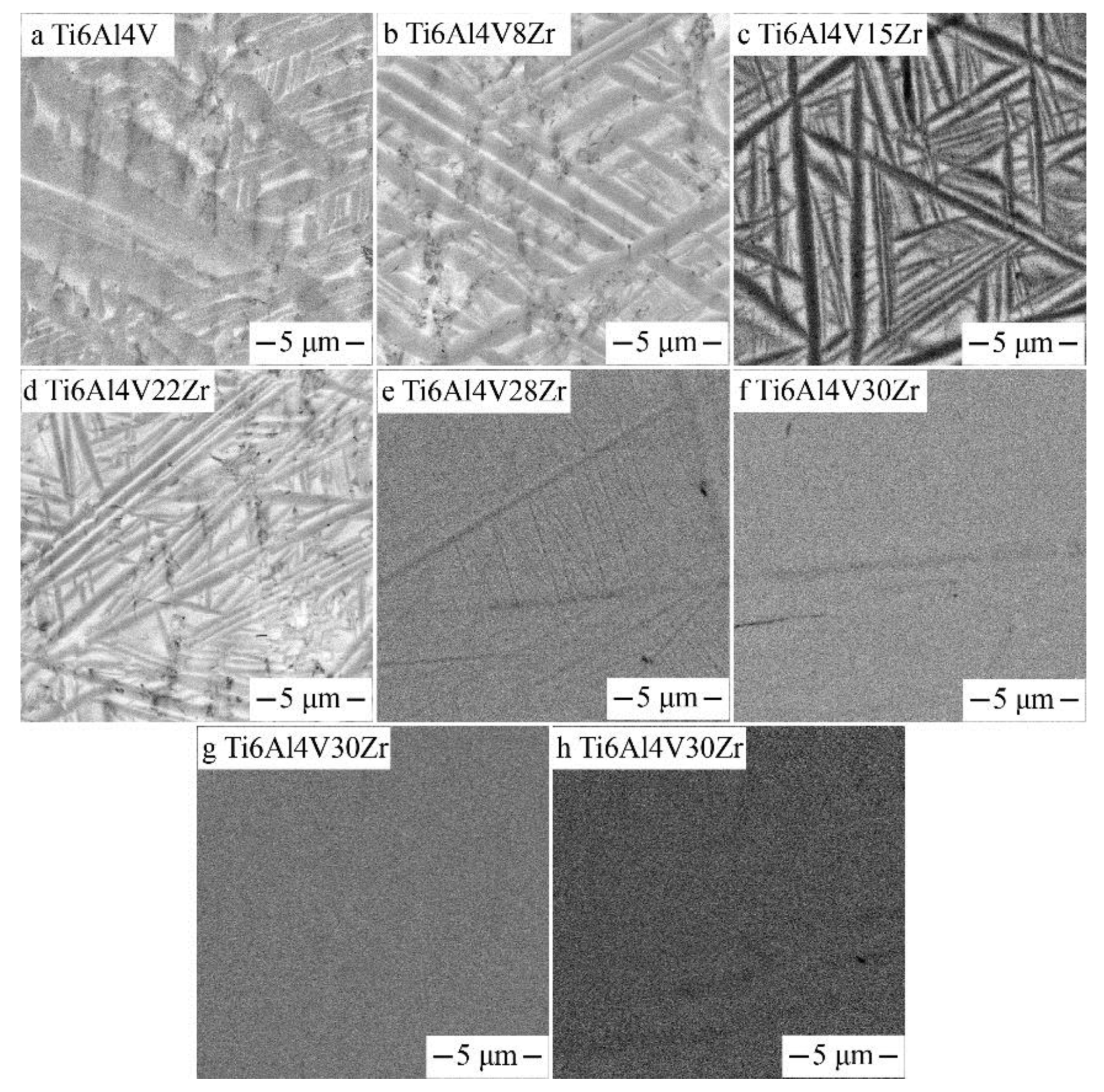

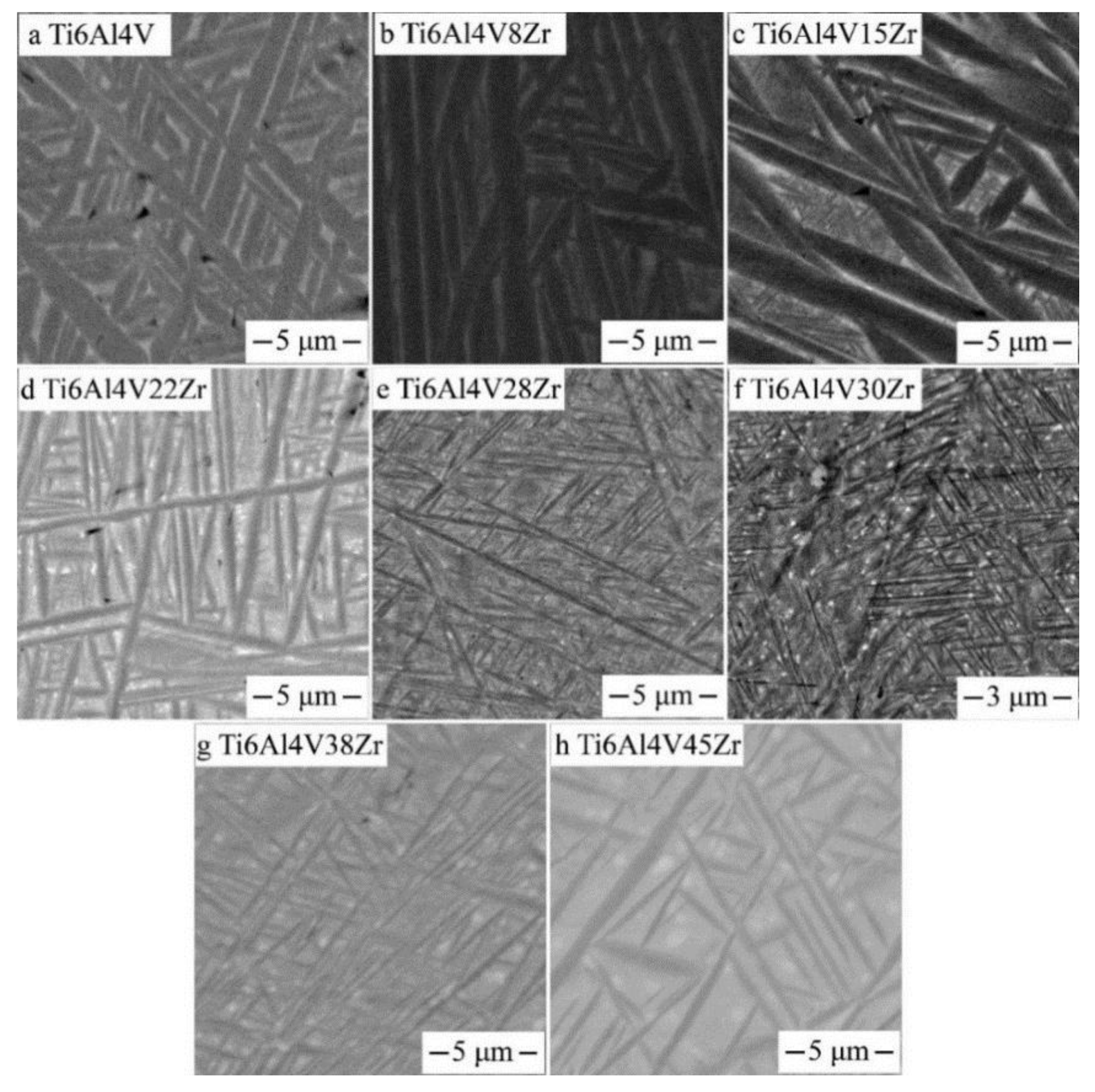

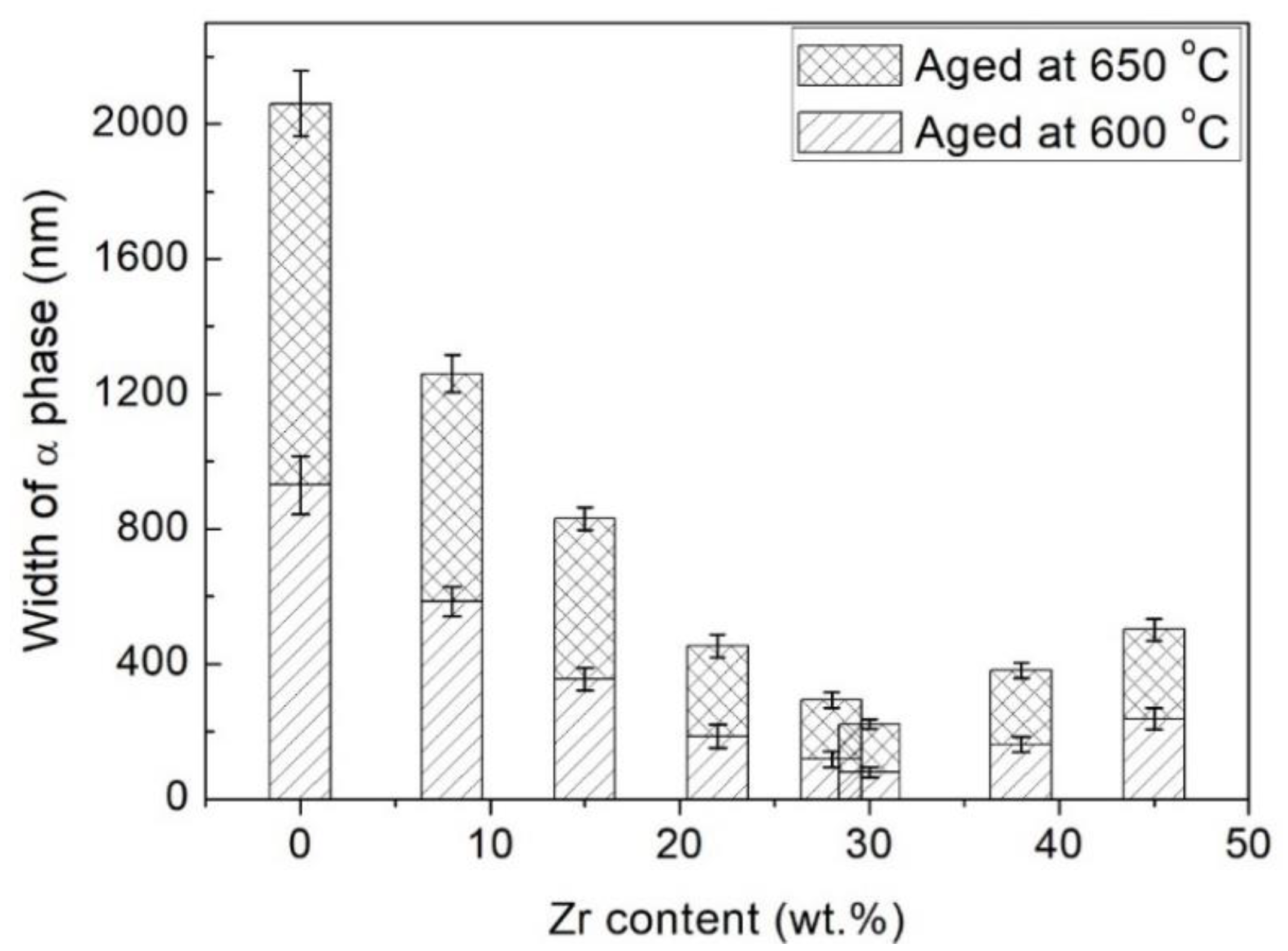

3.1. Microstructure of Ti6Al4VxZr Alloys Taken from Ti6Al4V–Ti6Al4V45Zr Diffusion Multiple

3.2. Influence of the Zr on the Hardness after Beta-Annealing and after Aging

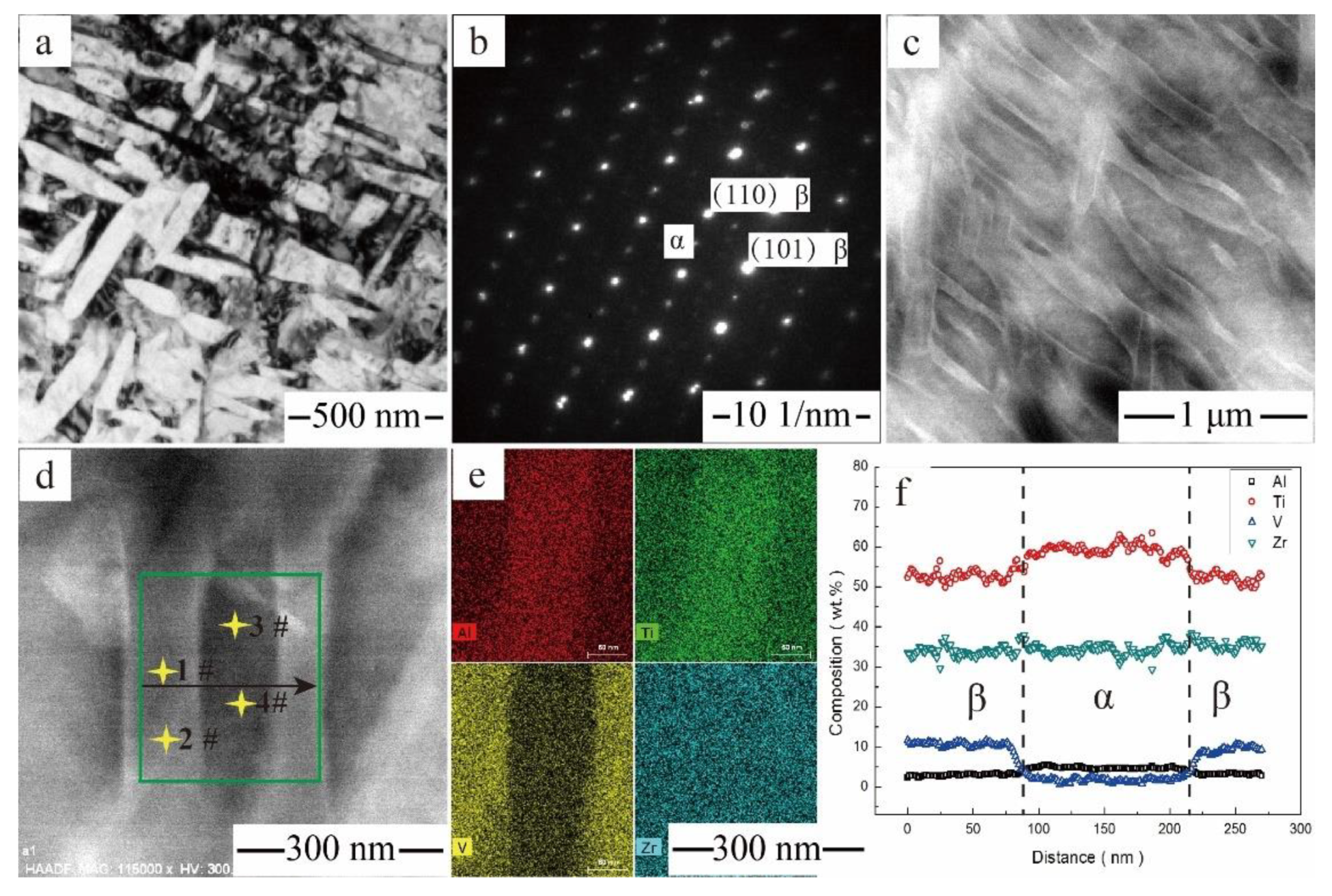

3.3. XRD and STEM Results of Ti‒6Al‒4V‒30Zr Alloy

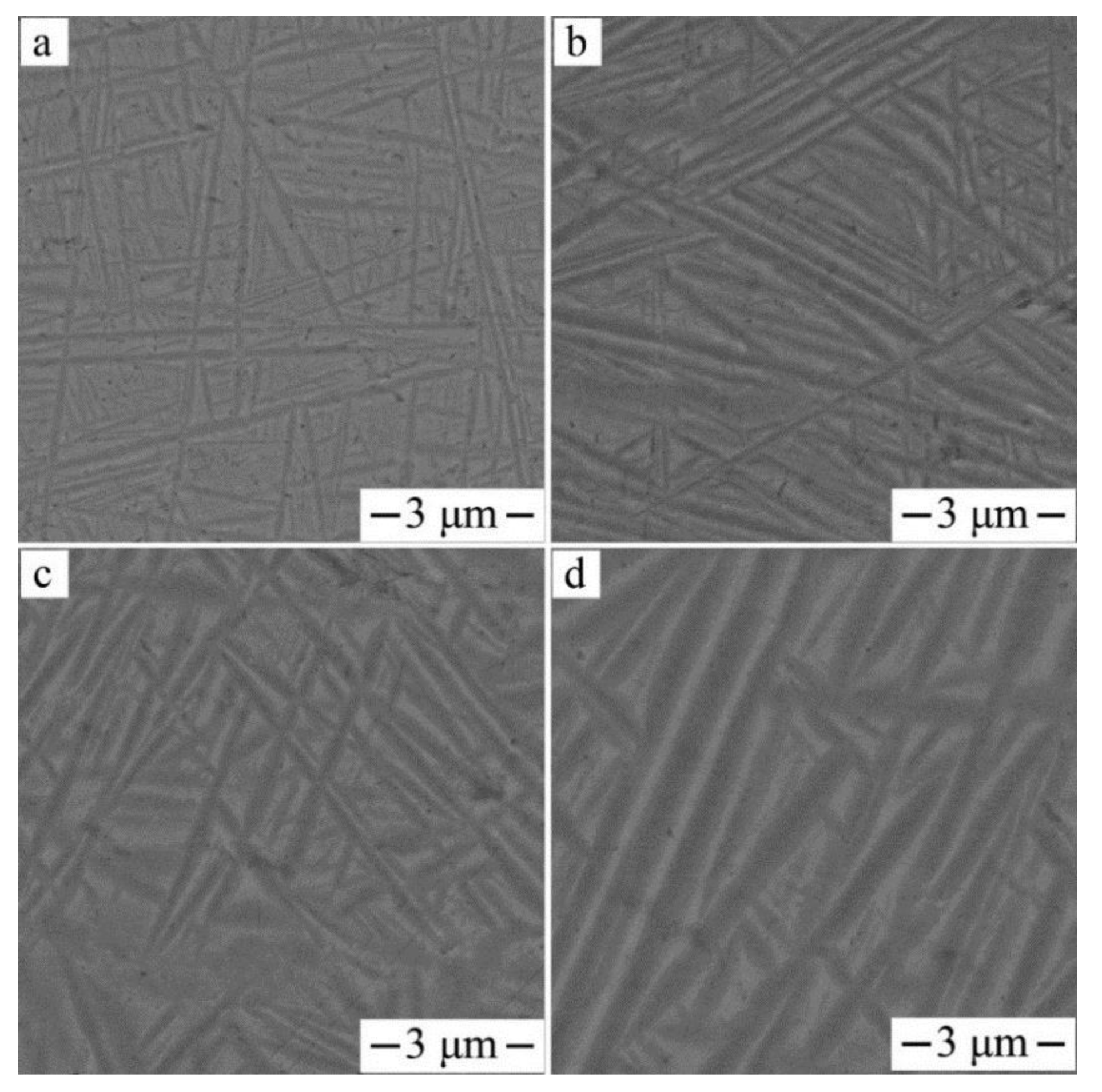

3.4. Structure and Mechanical Properties of the Forged Ti‒6Al‒4V‒30Zr Alloy

4. Conclusions

- (1)

- When the Zr content increased to 30 wt.%, the quenched α′ phase decreased and disappeared, and the lamellar thickness of α-phase decreased to nanoscale, which resulted to maximum hardness of the quenched and aged alloy. When the Zr content further increased, the lamellar thickness of the α-phase increased, and the hardness decreased.

- (2)

- Both HAADF-STEM and XRD were used to determine the microstructure and phase composition after quenching and aging of the Ti‒6Al‒4V–30Zr alloy. The quenched alloy displayed homogeneously distributed nanoscale α″ phases, which will be the nucleation site of α-phase during aging.

- (3)

- The forged Ti–6Al–4V–30Zr alloy in the β-solution and aging showed the non-uniform secondary α-phase distribution in the matrix. By increasing the aging temperature from 500 °C to 650 °C, the tensile strength and yield strength of the alloys rose, but the total elongation decreased. The lamella thickness and volume fraction of the α-phase were the major factors that had great impacts on the mechanical properties. As the lamella thickness and volume fraction of the α-phase increased, the tensile strength of the alloy decreased, but the elongation decreased.

Author Contributions

Funding

Conflicts of Interest

References

- Banerjeea, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.C.; Frazier, W.G.; Prasad, Y.V.R.K. Hot working of commercial Ti-6Al-4V with an equiaxed α-β microstructure: Materials modeling considerations. Mater. Sci. Eng. A 2000, 284, 184–194. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Fagin, P.N.; Glavicic, M.G.; Sukonnik, I.M.; Ivasishin, O.M. Influence on texture on beta grain growth during continuous annealing of Ti-6Al-4V. Mater. Sci. Eng. A 2001, 299, 225–234. [Google Scholar] [CrossRef]

- Raghunathan, S.L.; Dashwood, R.J.; Jackson, M.; Vogel, S.C.; Dye, D. The evolution of microtexture and macrotexture during sub-transus forging of Ti-10V-2Fe-3Al. Mater. Sci. Eng. A 2008, 488, 8–15. [Google Scholar] [CrossRef]

- Auffredic, J.P.; Etchessahar, E.; Debuigne, J. Remarques sur le diagramme de phases Ti-Zr: Étude microcalorimétrique de la transition α ⇄ β. J. Less Common Met. 1982, 84, 49–64. [Google Scholar] [CrossRef]

- Ion, R.; Stoian, A.B.; Dumitriu, C.; Grigorescu, S.; Mazare, A.; Cimpean, A.; Demetrescu, I.; Schmuki, P. Nanochannels formed on TiZr alloy improve biological response. Acta Biomater. 2015, 24, 370–377. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.K.; Liang, S.X.; Jing, R.; Jiang, X.J.; Ma, M.Z.; Tan, C.L.; Liu, R.P. Microstructure and tensile properties of hot-rolled Zr50–Ti50 binary alloy. Mater. Sci. Eng. A 2015, 621, 259–264. [Google Scholar] [CrossRef]

- Hsu, H.C.; Wu, S.C.; Sung, Y.C.; Ho, W.F. The structure and mechanical properties of as-cast Zr–Ti alloys. J. Alloys Compd. 2009, 488, 279–283. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, Y.X.; Yang, X.J.; Cui, Z.D.; Zhu, S.L. Influence of Zr content on phase transformation, microstructure and mechanical properties of Ti75-xNb25Zrx (x=0-6) alloys. J. Alloys Compd. 2009, 486, 628–632. [Google Scholar] [CrossRef]

- Li, C.; David, H.; Yong, D.; Mayrhofer, P.H. Influence of Zr on structure, mechanical and thermal properties of Ti-Al-N. Thin Solid Films 2011, 519, 5503–5510. [Google Scholar] [CrossRef]

- Liang, S.X.; Yin, L.X.; Jing, R.; Zhang, X.Y.; Ma, M.Z.; Liu, R.P. Structure and mechanical properties of the annealed TZAV-30 alloy. Mater. Des. 2014, 58, 368–373. [Google Scholar] [CrossRef]

- Jing, R.; Liang, S.X.; Liu, C.Y.; Ma, M.Z.; Zhang, X.Y.; Liu, R.P. Structure and mechanical properties of Ti-6Al-4V alloy after zirconium addition. Mater. Sci. Eng. A 2012, 552, 295–300. [Google Scholar] [CrossRef]

- Zhao, J.C.; Jackson, M.R.; Peluso, L.A.; Brewer, L.N. A diffusion-multiple approach for mapping phase diagrams, hardness, and elastic modulus. JOM 2002, 54, 42–45. [Google Scholar] [CrossRef]

- Zhao, J.C.; Zheng, X.; Cahill, D.G. High-throughput diffusion multiples. Mater. Today 2005, 8, 28–37. [Google Scholar] [CrossRef]

- Zhao, J.C. The diffusion-multiple approach to designing Alloys. Annu. Rev. Mater. Res. 2005, 35, 51–73. [Google Scholar] [CrossRef]

- Zhao, J.C. Combinatorial approaches as effective tools in the study of phase diagrams and composition-structure-property relationships. Prog. Mater. Sci. 2006, 51, 557–631. [Google Scholar] [CrossRef]

- Zhang, X.D.; Liu, L.B.; Zhao, J.C.; Wang, J.L.; Zheng, F.; Jin, Z.P. High-efficiency combinatorial approach as an effective tool for accelerating metallic biomaterials research and discovery. Mater. Sci. Eng. C Mater. Biol. Appl. 2014, 39, 273–280. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Kou, H.C.; Cheng, L.; Zhang, Y.L.; Yu, Y.; Lu, Y.L. Kinetic Diffusion Couple for Mapping Microstructural and Mechanical Data on Ti–Al–Mo Titanium Alloys. Materials 2018, 11, 1112–1120. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Liu, L.B.; Zhang, L.G.; Zeng, L.J.; Shi, X. Investigation of the influence of Cr on the microstructure and properties of Ti6Al4VxCr alloys with a combinatorial approach. J. Mater. Eng. Perform. 2017, 26, 4364–4372. [Google Scholar] [CrossRef]

- Zhao, J.C.; Jackson, M.R.; Peluso, L.A.; Brewer, L.N. A Diffusion Multiple Approach for the Accelerated Design of Structural Materials. MRS Bull. 2002, 27, 324–329. [Google Scholar] [CrossRef]

- Zhao, J.C. Reliability of the diffusion-multiple approach for phase diagram mapping. J. Mater. Sci. 2004, 39, 3913–3925. [Google Scholar] [CrossRef]

- Huxtable, S.; Cahill, D.G.; Fauconnier, V.; White, J.O.; Zhao, J.C. Thermal conductivity imaging at micrometre-scale resolution for combinatorial studies of materials. Nat. Mater. 2004, 3, 298–301. [Google Scholar] [CrossRef] [PubMed]

- Jones, N.G.; Dashwood, R.J.; Jackson, M.; Dye, D. β Phase Decomposition in Ti-5Al-5Mo-5V-3Cr. Acta Mater. 2009, 57, 3830–3839. [Google Scholar] [CrossRef]

- Liang, S.X.; Yin, L.X.; Zheng, L.Y.; Ma, M.Z.; Liu, R.P. The Strain-Hardening Behavior of TZAV-30 Alloy After Various Heat Treatments. J. Mater. Eng. Perform. 2016, 25, 530–535. [Google Scholar] [CrossRef]

- Majumdar, P.; Singh, S.B.; Chakraborty, M. Elastic modulus of biomedical titanium alloys by nano-indentation and ultrasonic techniques-A comparative study. Mater. Sci. Eng. A 2008, 489, 419–425. [Google Scholar] [CrossRef]

- Qin, D.Y.; Lu, Y.F.; Liu, Q.; Zheng, L.; Zhou, L. Transgranular shearing introduced brittlement of Ti-5Al-5V-5Mo-3Cr alloy with full lamellar structure at room temperature. Mater. Sci. Eng. A 2013, 572, 19–24. [Google Scholar] [CrossRef]

- Guo, Z.; Miodownik, A.P.; Saunders, N.; Schille, J.P. Influence of stacking-fault energy on high temperature creep of alpha titanium alloys. Scr. Mater. 2006, 54, 2175–2178. [Google Scholar] [CrossRef]

- Furuhara, T.; Takagi, S.; Watanabe, H.; Maki, T. Crystallography of grain boundary α precipitates in a β titanium alloy. Metall. Mater. Trans. A 1996, 27, 1635–1646. [Google Scholar] [CrossRef]

- Salloom, R.; Banerjee, R.; Srinivasan, S.G. Effect of β-stabilizer elements on stacking faults energies and ductility of α-titanium using first-principles calculations. J. Appl. Phys. 2016, 120, 3011–3021. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Salishchev, G.; Semiatin, S.L. Loss of coherency of the alpha/beta interface boundary in titanium alloys during deformation. Philos. Mag. Lett. 2010, 90, 903–914. [Google Scholar] [CrossRef]

- Bhattacharyya, D.; Viswanathan, G.B.; Fraser, H.L. Crystallographic and morphological relationships between β phase and the Widmanstatten and allotriomorphic α phase at special β grain boundaries in an α/β titanium alloy. Acta Mater. 2007, 55, 6765–6778. [Google Scholar] [CrossRef]

- Qin, D.Y.; Lu, Y.F.; Guo, D.Z.; Zheng, L.; Liu, Q.; Zhou, L. Tensile Deformation and Fracture of Ti-5Al-5V-5Mo-3Cr-1.5Zr-0.5Fe Alloy at Room Temperature. Mater. Sci. Eng. A 2013, 587, 100–109. [Google Scholar] [CrossRef]

- Nyakana, S.L.; Fanning, J.C.; Boyer, R.R. Quick Reference Guide for β Titanium Alloys in the 00s. J. Mater. Eng. Perform. 2005, 14, 799–811. [Google Scholar] [CrossRef]

- Liang, S.X.; Ma, M.Z.; Jing, R.; Tan, C.L.; Liu, R.P. Structural evolution and mechanical properties of Zr-45Ti-5Al-3V alloy by heat treatments. Mater. Sci. Eng. A 2012, 541, 67–72. [Google Scholar] [CrossRef]

- Guo, D.F.; Li, J.T.; Zhang, G.S.; Zhang, Q.; Li, M.; Shi, Y.D.; Ma, T.Y.; Li, X.H.; Zhang, X.Y. Microstructure evolution and mechanical properties of deformed TiZrAlV upon annealing. J. Alloys Compd. 2015, 651, 779–784. [Google Scholar] [CrossRef]

- Ahmed, M.; Li, T.; Casillas, G.; Cairney, J.M.; Wexler, D.; Pereloma, E.V. The evolution of microstructure and mechanical properties of Ti-5Al-5Mo-5V-2Cr-1Fe during ageing. J. Alloys Compd. 2015, 629, 260–273. [Google Scholar] [CrossRef]

- Nag, S.; Banerjee, R.; Srinivasan, R.; Hwang, J.Y.; Harper, M.; Fraser, H.L. ω-Assisted nucleation and growth of a precipitates in the Ti-5Al-5Mo-5V-3Cr-0.5Fe β titanium alloy. Acta Mater. 2009, 57, 2136–2147. [Google Scholar] [CrossRef]

- Asaro, R.J.; Krysl, P.; Kad, B. Deformation mechanism transitions in nanoscale fcc metals. Philos. Mag. Lett. 2003, 83, 733–743. [Google Scholar] [CrossRef]

- Cheng, S.; Spencer, J.A.; Milligan, W.W. Strength and tension/compression asymmetry in nanostructured and ultrafine-grain metals. Acta Mater. 2003, 51, 4505–4518. [Google Scholar] [CrossRef]

- Shen, X.; Lian, J.; Jiang, Z.; Jiang, Q. The optimal grain sized nanocrystalline Ni with high strength and good ductility fabricated by a direct current electrodeposition. Adv. Eng. Mater. 2010, 10, 539–546. [Google Scholar] [CrossRef]

- Dehghan-Manshadi, A.; Dippenaar, R.J. Development of a-phase morphologies during low temperature isothermal heat treatment of a Ti-5Al-5Mo-5V-3Cr alloy. Mater. Sci. Eng. A 2011, 528, 1833–1839. [Google Scholar] [CrossRef]

- Du, Z.X.; Xiao, S.L.; Xu, L.J.; Tian, J.; Kong, F.T.; Chen, Y.Y. Effect of heat treatment on microstructure and mechanical properties of a new β high strength titanium alloy. Mater. Des. 2014, 55, 183–190. [Google Scholar] [CrossRef]

| Element | Al | V | Zr | Fe | O | N | C | Ti |

|---|---|---|---|---|---|---|---|---|

| Ti6Al4V | 6.37 | 3.61 | - | 0.13 | 0.18 | 0.02 | 0.02 | Bal. |

| Ti6Al4V45Zr | 6.47 | 3.63 | 44.85 | 0.15 | 0.11 | 0.02 | 0.01 | Bal. |

| Aging Temperature | Position | Phase | wt.% V | wt.% Zr | wt.% Ti | wt.% Al |

|---|---|---|---|---|---|---|

| 600 °C | 1 # | α | 1.9 | 34.4 | 56.7 | 7 |

| 2 # | α | 1.5 | 35.6 | 55.7 | 7.1 | |

| 3 # | β | 13 | 28.8 | 55.5 | 2.7 | |

| 4 # | β | 14.5 | 28.8 | 54.3 | 2.4 | |

| 650 °C | 1 # | α | 1.8 | 34.9 | 55.9 | 7.3 |

| 2 # | α | 1.9 | 34.5 | 56.2 | 7.4 | |

| 3 # | β | 10.5 | 34.1 | 52.6 | 2.7 | |

| 4 # | β | 10.3 | 33.2 | 52.5 | 2.8 |

| Element | Al | V | Zr | O | N | C | Ti |

|---|---|---|---|---|---|---|---|

| Ti6Al4V30Zr | 5.9 | 3.7 | 29.3 | 0.16 | 0.012 | 0.01 | Bal. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, D.; Tian, Y.; Zhang, L.; Wang, Z.; Sheng, J.; Wang, W.; Zhou, K.; Liu, L. Optimal Design of High-Strength Ti‒Al‒V‒Zr Alloys through a Combinatorial Approach. Materials 2018, 11, 1603. https://doi.org/10.3390/ma11091603

Wu D, Tian Y, Zhang L, Wang Z, Sheng J, Wang W, Zhou K, Liu L. Optimal Design of High-Strength Ti‒Al‒V‒Zr Alloys through a Combinatorial Approach. Materials. 2018; 11(9):1603. https://doi.org/10.3390/ma11091603

Chicago/Turabian StyleWu, Di, Yueyan Tian, Ligang Zhang, Zhenyu Wang, Jinwen Sheng, Wanlin Wang, Kechao Zhou, and Libin Liu. 2018. "Optimal Design of High-Strength Ti‒Al‒V‒Zr Alloys through a Combinatorial Approach" Materials 11, no. 9: 1603. https://doi.org/10.3390/ma11091603