Metal-Based Graphical SiO2/Ag/ZnS/Ag Hetero-Structure for Visible-Infrared Compatible Camouflage

Abstract

:1. Introduction

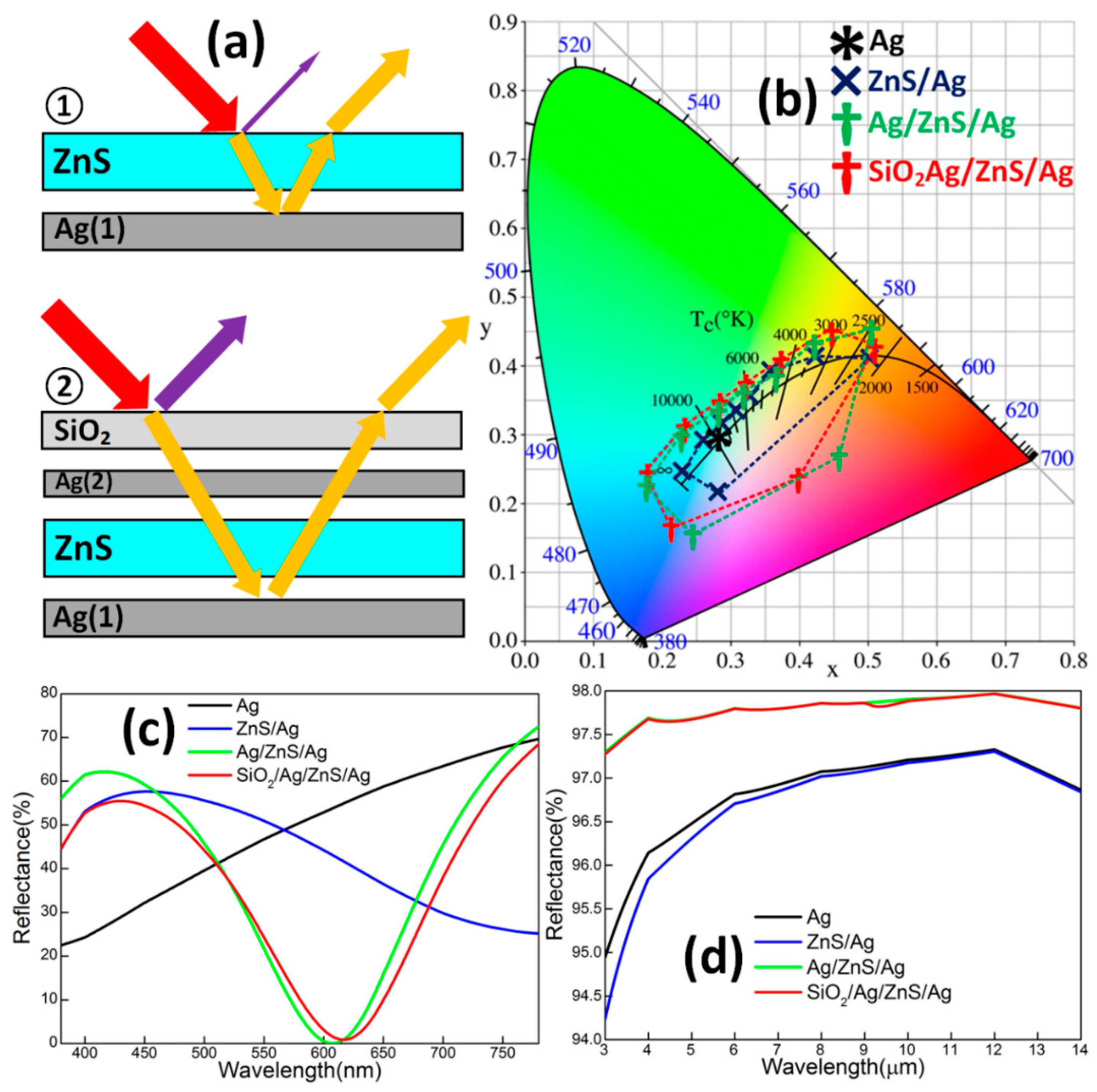

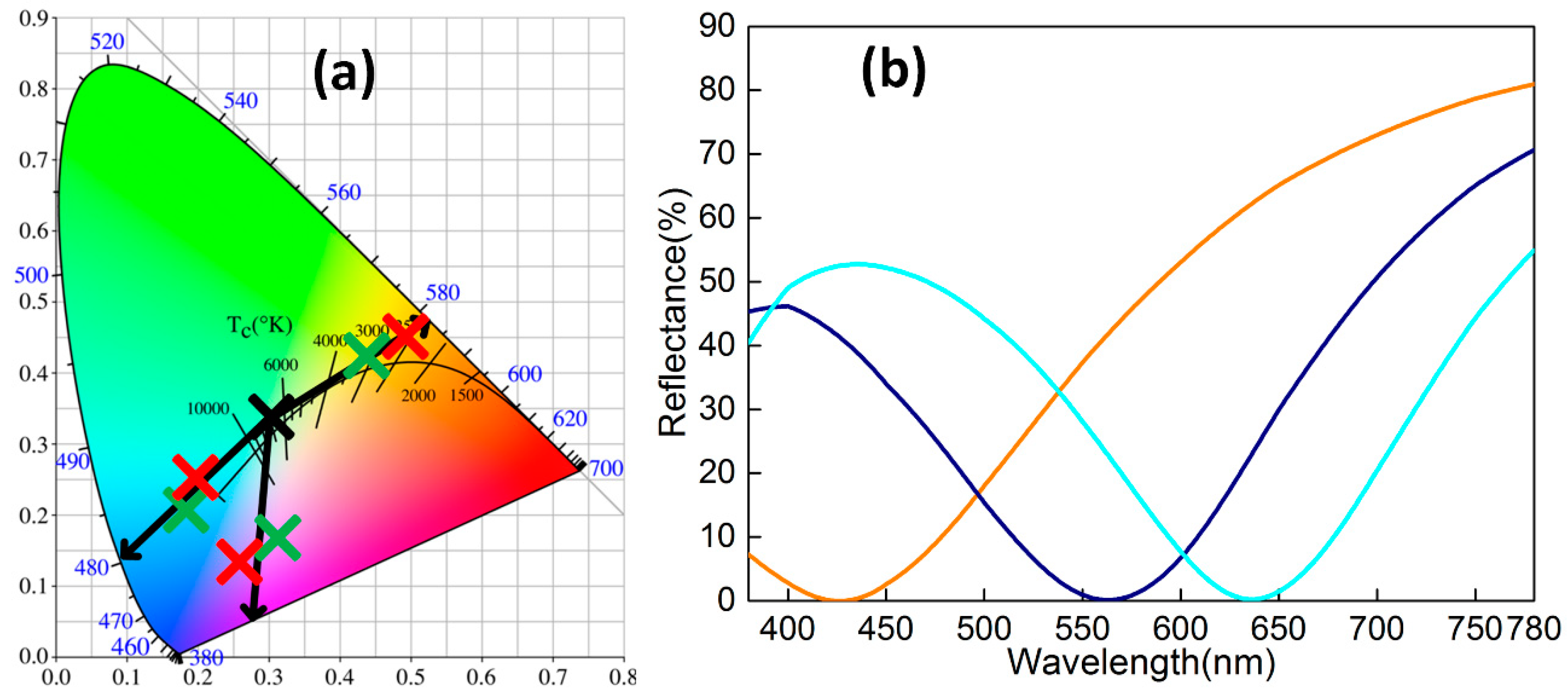

2. Experimental Design

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Morin, S.A.; Shepherd, R.F.; Kwok, S.W.; Stokes, A.A.; Nemiroski, A.; Whitesides, G.M. Camouflage and display for soft machines. Science 2012, 337, 828–832. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Diao, Z.; Kraus, M.; Brunner, R.; Dirks, J.H.; Spatz, J.P. Nanostructured stealth surfaces for visible and near-infrared light. Nano Lett. 2016, 16, 6610–6616. [Google Scholar] [CrossRef] [PubMed]

- Chu, H.T.; Zhang, Z.C.; Liu, Y.J.; Leng, J.S. Silver particles modified carbon nanotube paper/glassfiber reinforced polymer composite material for high temperature infrared stealth camouflage. Carbon 2016, 98, 557–566. [Google Scholar] [CrossRef]

- Liu, X.F.; Lai, Y.K.; Huang, J.Y.; Al-Deyab, S.S.; Zhang, K.Q. Hierarchical SiO2@Bi2O3 core/shell electrospun fibers for infrared stealth camouflage. J. Mater. Chem. C 2015, 3, 345–351. [Google Scholar] [CrossRef]

- Phan, L.; Walkup, W.G.; Ordinario, D.D.; Karshalev, E.; Jocson, J.M.; Burke, A.M.; Gorodetsky, A.A. Reconfigurable infrared camouflage coatings from a cephalopod protein. Adv. Mater. 2013, 25, 5621–5625. [Google Scholar] [CrossRef] [PubMed]

- Ye, X.Y.; Zheng, C.; Xiao, X.P.; Cai, S.G. Synthesis, characterization and infrared emissivity study of SiO2/Ag/TiO2 “sandwich” core-shell composites. Mater. Lett. 2015, 141, 191–193. [Google Scholar] [CrossRef]

- Green, R.O.; Eastwood, M.L.; Sarture, C.M.; Chrien, T.G.; Aronsson, M.; Chippendale, B.J.; Faust, J.A.; Pavri, B.E.; Chovit, C.J.; Solis, M.; et al. Imaging spectroscopy and the airborne visible/infrared imaging spectrometer (AVIRIS). Remote Sens. Environ. 1998, 65, 227–248. [Google Scholar] [CrossRef]

- Verevkin, A.; Zhang, J.; Sobolewski, R. Detection efficiency of large-active-area NbN single-photon superconducting detectors in the ultraviolet to near-infrared range. Appl. Phys. Lett. 2002, 80, 4687–4689. [Google Scholar] [CrossRef]

- Zhao, Y.Q.; Zhao, Y.; Hu, S.; Lv, J.T.; Ying, Y.; Gervinskas, G.; Si, G. Artificial structural color pixels: A review. Materials 2017, 10, 944. [Google Scholar] [CrossRef] [PubMed]

- Yuan, L.; Hu, J.; Weng, X.L.; Zhang, Q.Y.; Deng, L.J. Galvanic displacement synthesis of Al/Ni core–shell pigments and their low infrared emissivity application. J. Alloys Compd. 2016, 670, 275–280. [Google Scholar] [CrossRef]

- Wang, K.Z.; Wang, C.X.; Yin, Y.J.; Chen, K.L. Modification of Al pigment with graphene for infrared/visual stealth compatible fabric coating. J. Alloys Compd. 2017, 690, 741–748. [Google Scholar] [CrossRef]

- Xu, J.J.; Tang, J.F. Optical properties of extremely thin films: Studies using ATR techniques. Appl. Opt. 1989, 28, 2925–2928. [Google Scholar] [CrossRef] [PubMed]

- Smith, G.B.; Niklasson, G.A.; Svensson, J.S.E.M.; Granqvist, C.G. Noble-metal-based transparent infrared reflectors: Experiments and theoretical analyses for very thin gold films. J. Appl. Phys. 1986, 59, 571–581. [Google Scholar] [CrossRef]

- Wang, J.T.; Xu, W.D.; Qu, Y.; Cui, G.Z. Research on measurement method of optical camouflage effect of moving object. Optical Measurement Technology and Instrumentation. Int. Soc. Opt. Photonics 2016, 10155, 1015535. [Google Scholar]

- Xue, F.; Xu, S.; Luo, Y.T.; Jia, W. Design of digital camouflage by recursive overlapping of pattern templates. Neurocomputing 2016, 172, 262–270. [Google Scholar] [CrossRef]

- Debenham, M. Refractive indices of zinc sulfide in the 0.405–13 μm wavelength range. Appl. Opt. 1984, 23, 2238–2239. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.H.; Lemarchand, F.; Lequime, M. Exploitation of multiple incidences spectrometric measurements for thin film reverse engineering. Opt. Express 2012, 20, 15734–15751. [Google Scholar] [CrossRef] [PubMed]

- Ciesielski, A.; Skowronski, L.; Trzcinski, M.; Szoplik, T. Controlling the optical parameters of self-assembled silver films with wetting layers and annealing. Appl. Surf. Sci. 2017, 421, 349–356. [Google Scholar] [CrossRef]

- Riley, B.J.; Sundaram, S.K.; Johnson, B.R.; Saraf, L.V. Summary of Chalcogenide Glass Processing: Wet-Etching and Photolithography; Pacific Northwest National Laboratory (PNNL): Richland, WA, USA; Environmental Molecular Sciences Laboratory (EMSL): Richland, WA, USA, 2006.

- Scalora, M.; Bloemer, M.J.; Pethel, A.S.; Dowling, J.P.; Bowden, C.M.; Manka, A.S. Transparent, metallo-dielectric, one-dimensional, photonic band-gap structures. J. Appl. Phys. 1998, 83, 2377–2383. [Google Scholar] [CrossRef]

- Wyszecki, G.; Stiles, W.S. Color Science: Concepts and Methods, Quantitative Data and Formulae; Wiley: New York, NY, USA, 1982. [Google Scholar]

- Barrat, S.; Pigeat, P.; Dieguez, I.; Bauer-Grosse, E.; Weber, B. Observation of spectral and normal emissivity as a method of surface control during the growth of diamond films deposited by a microwave plasma-assisted CVD technique. Thin Solid Films 1995, 263, 127–133. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, D.; Wang, X.; Chen, F.; Cheng, Y.; Gong, R. Metal-Based Graphical SiO2/Ag/ZnS/Ag Hetero-Structure for Visible-Infrared Compatible Camouflage. Materials 2018, 11, 1594. https://doi.org/10.3390/ma11091594

Qi D, Wang X, Chen F, Cheng Y, Gong R. Metal-Based Graphical SiO2/Ag/ZnS/Ag Hetero-Structure for Visible-Infrared Compatible Camouflage. Materials. 2018; 11(9):1594. https://doi.org/10.3390/ma11091594

Chicago/Turabian StyleQi, Dong, Xian Wang, Fu Chen, Yongzhi Cheng, and Rongzhou Gong. 2018. "Metal-Based Graphical SiO2/Ag/ZnS/Ag Hetero-Structure for Visible-Infrared Compatible Camouflage" Materials 11, no. 9: 1594. https://doi.org/10.3390/ma11091594