Reducing Porosity and Refining Grains for Arc Additive Manufacturing Aluminum Alloy by Adjusting Arc Pulse Frequency and Current

Abstract

:1. Introduction

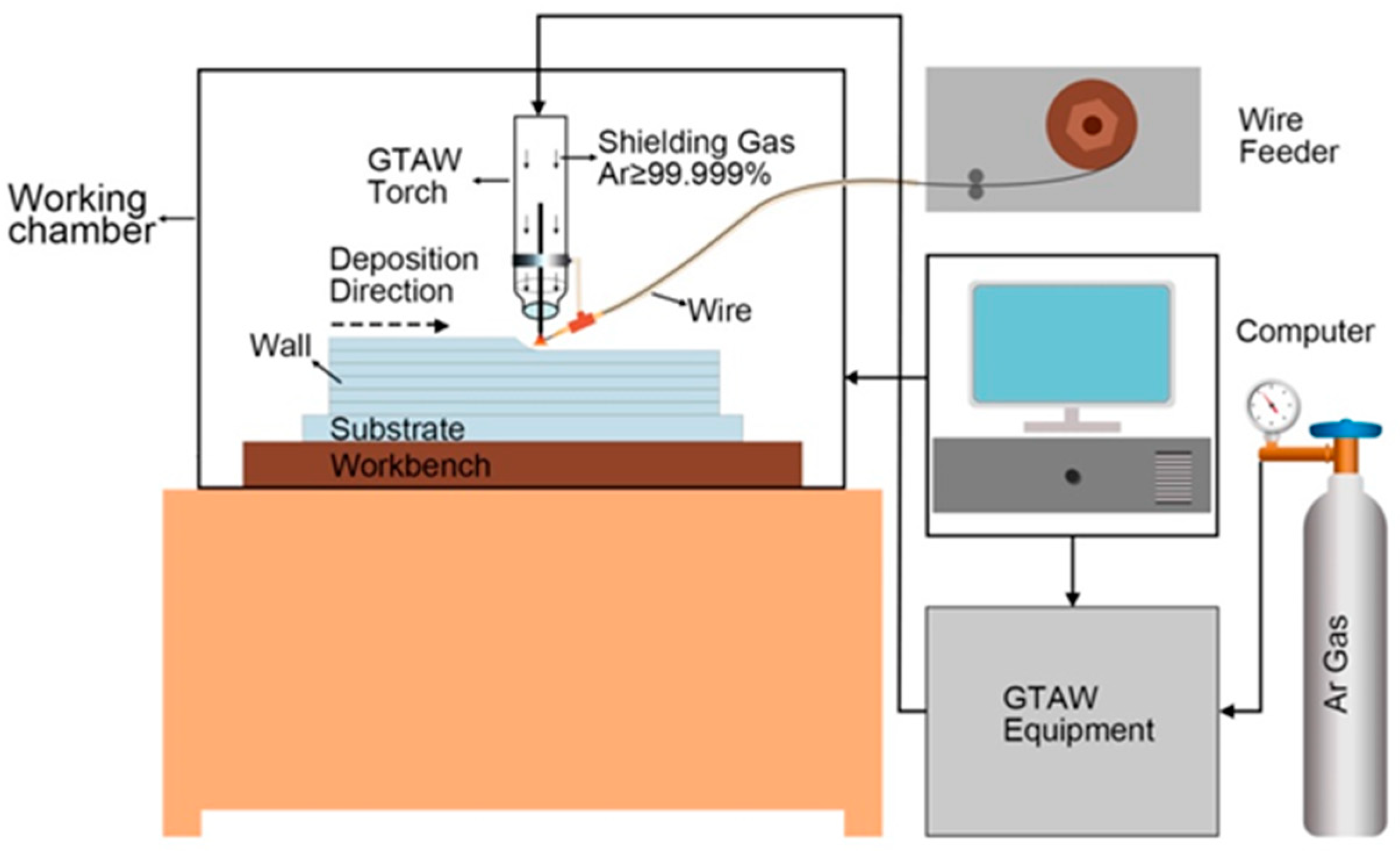

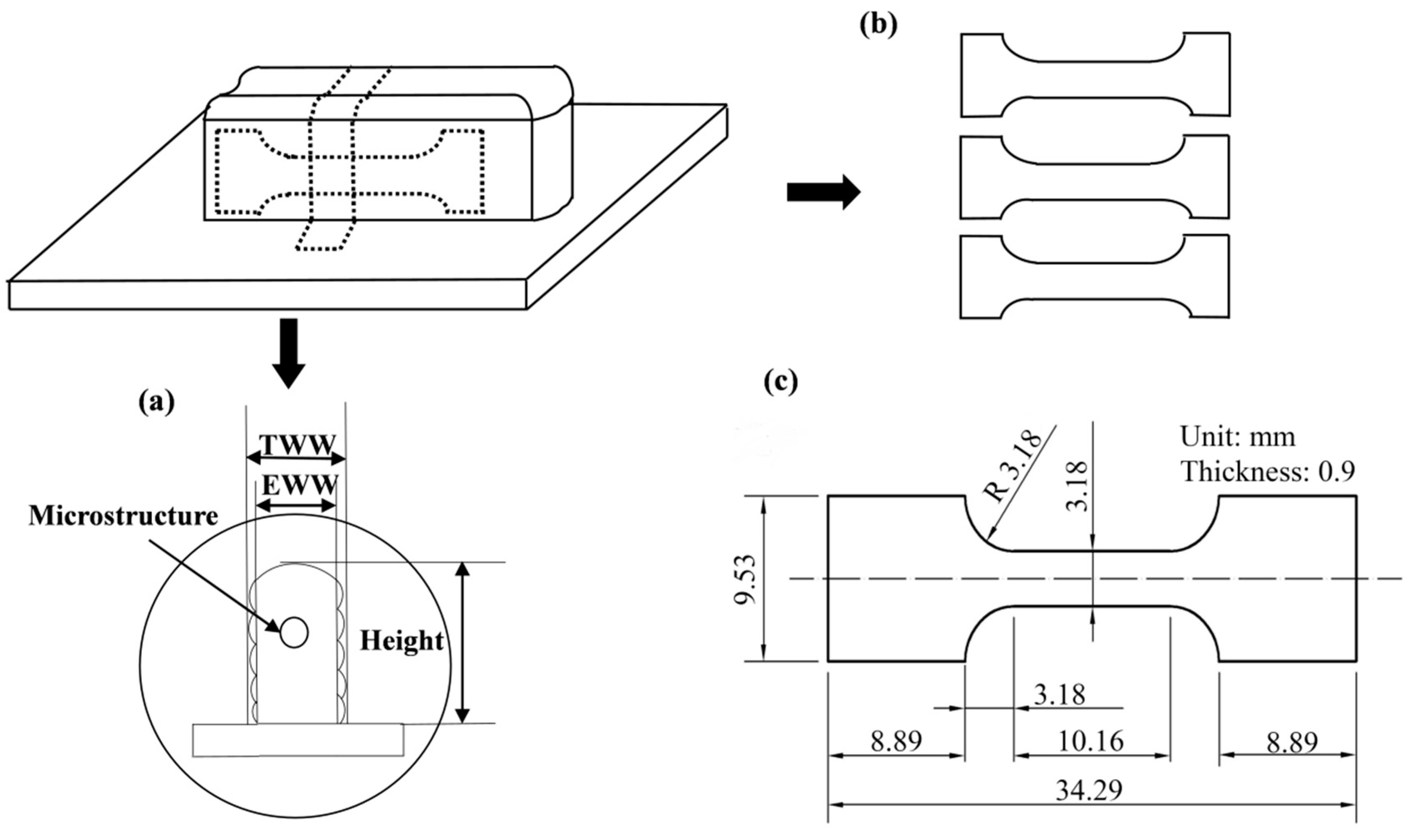

2. Experimental Details

3. Results and Discussion

3.1. Effects of Pulse Frequency

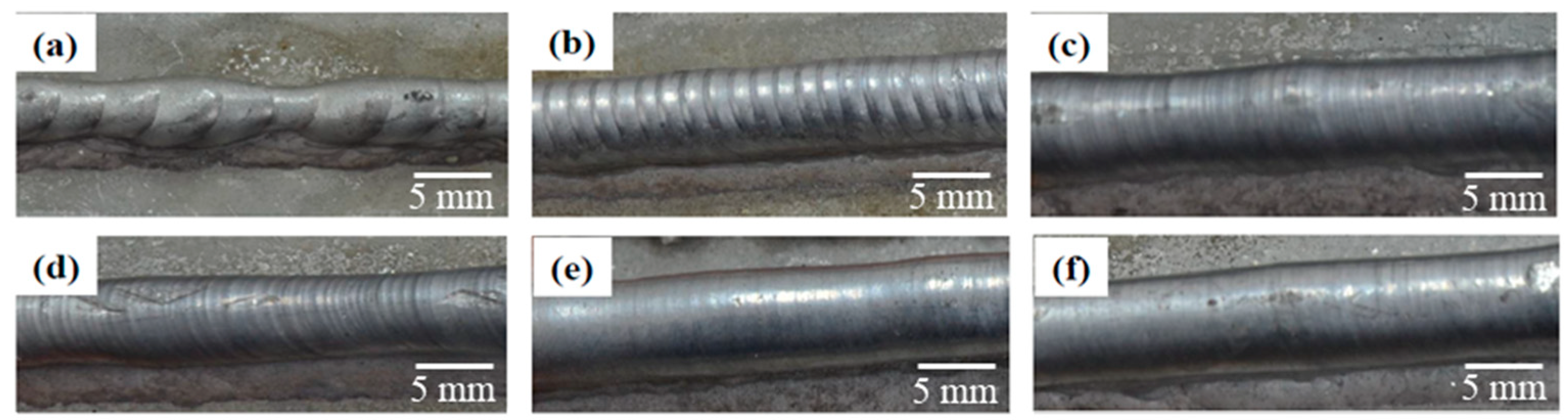

3.1.1. Macrostructure

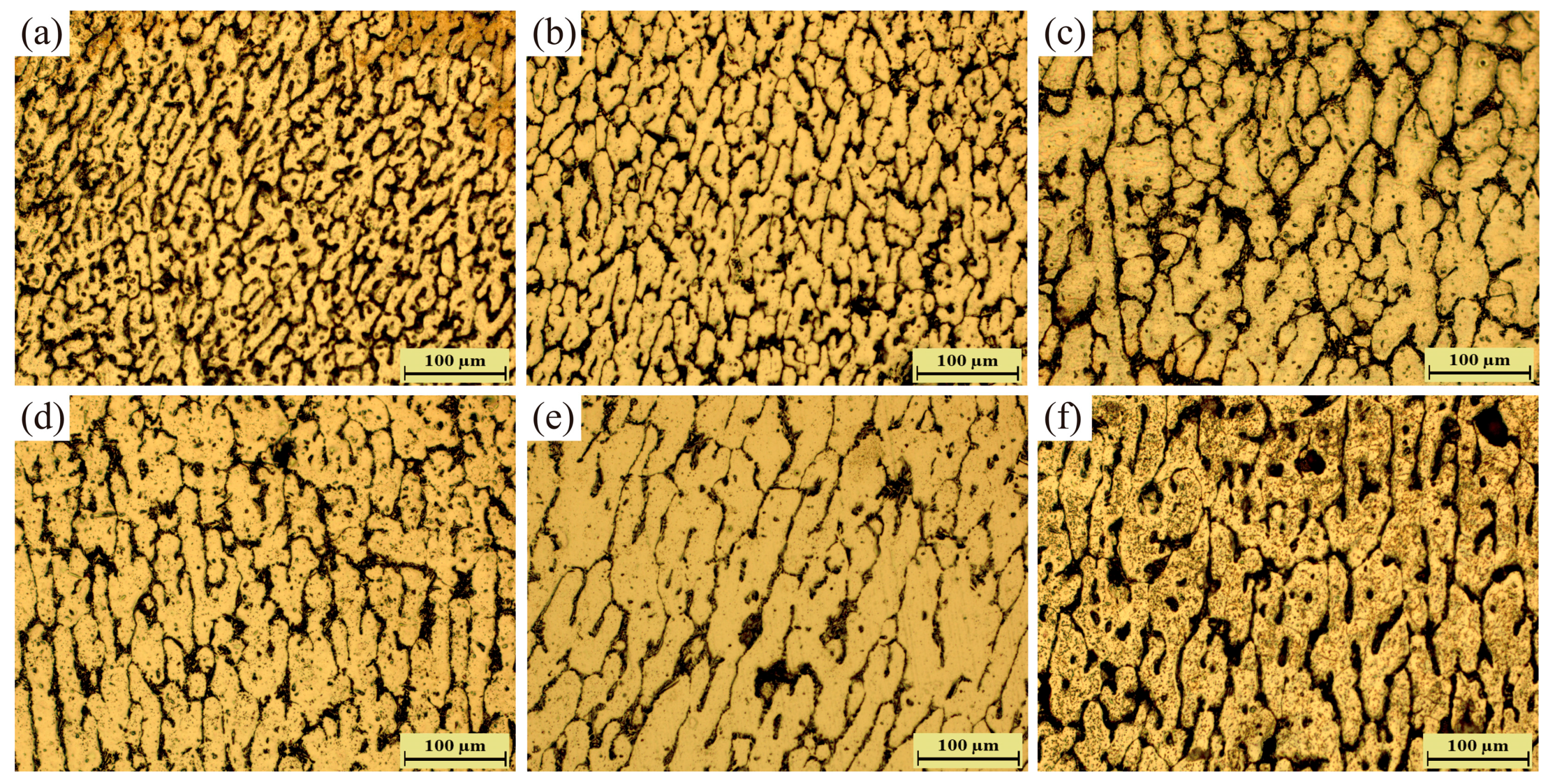

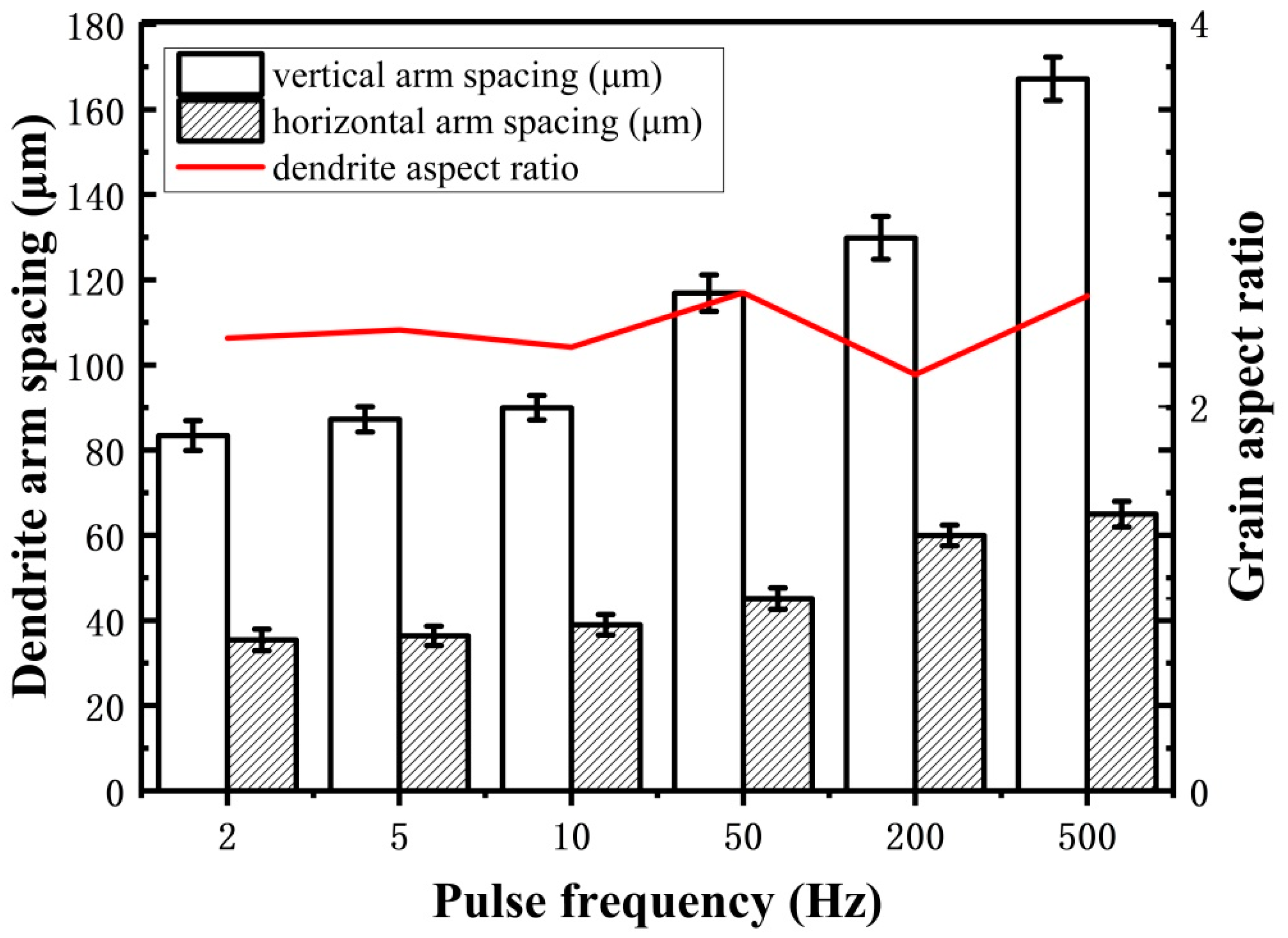

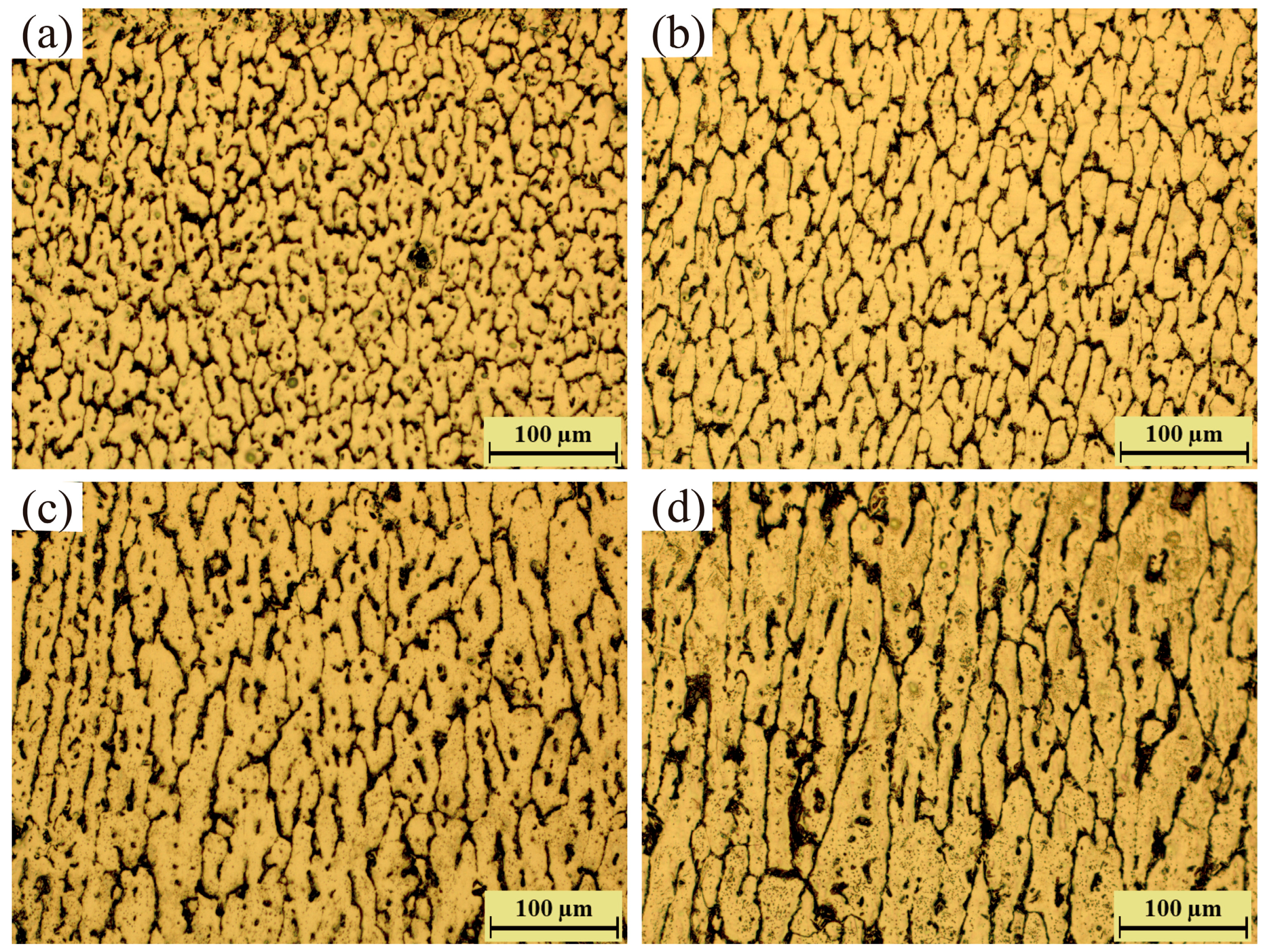

3.1.2. Microstructure

3.1.3. Porosity

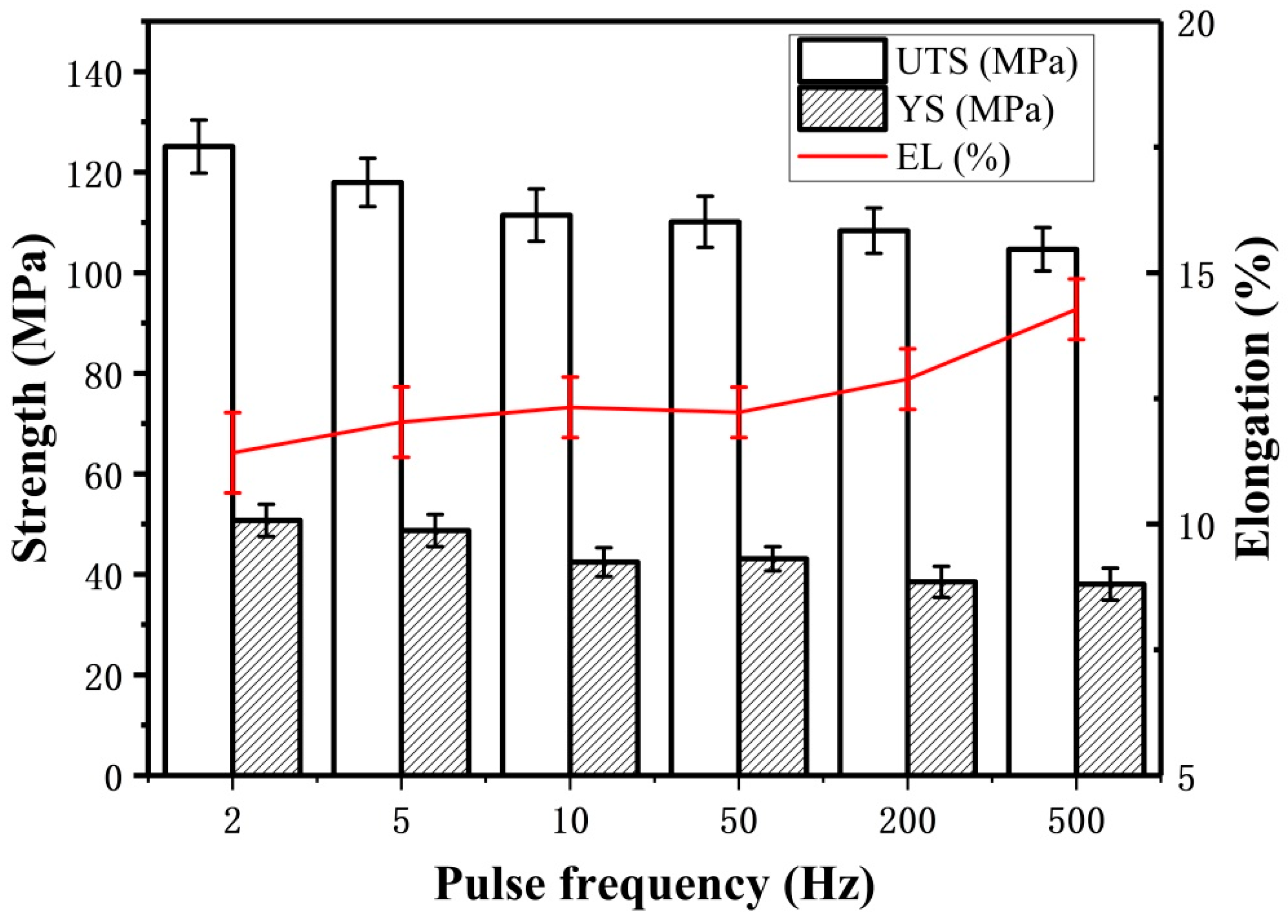

3.1.4. Tensile Properties

3.2. Effect of Arc Current

3.2.1. Macrostructure

3.2.2. Microstructure

3.2.3. Tensile Properties

4. Conclusions

- (1)

- Pulse frequency strongly affects the porosity of arc additive manufacturing Al–5Si alloy. With the increase of pulse frequency, density shows a trend that escalates firstly and attains its maximum in 50 Hz, but declines later because of the relation between pores formation and gas escape.

- (2)

- With the increase of pulse frequency, grains become coarser because of the more centralized heat input, but the grains still exhibit short columnar morphology. Because of the variation of microstructure, tensile strength decreases from 125.1 MPa to 108.6 MPa with the increase of pulse frequency.

- (3)

- Arc current also has a significant impact on microstructure and tensile properties. With the increase of arc current, grains become coarser and change from short columnar morphology to long columnar morphology as a result of more heat input, and hence leads to the decrease of tensile strength from 146.5 MPa to 110.5 MPa.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Singh, R. Material issues in additive manufacturing: A review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire + arc additive manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Y.; Gao, M.; Zeng, X. Wire arc additive manufacturing of al-6mg alloy using variable polarity cold metal transfer arc as power source. Mater. Sci. Eng. A 2018, 711, 415–423. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Wu, Q.; Ma, Z.; Chen, G.; Liu, C.; Ma, D.; Ma, S. Obtaining fine microstructure and unsupported overhangs by low heat input pulse arc additive manufacturing. J. Manuf. Process. 2017, 27, 198–206. [Google Scholar] [CrossRef]

- Nakai, M.; Eto, T. New aspect of development of high strength aluminum alloys for aerospace applications. Mater. Sci. Eng. A 2000, 285, 62–68. [Google Scholar] [CrossRef]

- King, J.F. 3—Alumina. In The Aluminium Industry; Woodhead Publishing: Cambridge, UK, 2001; pp. 3–41. [Google Scholar]

- Balasubramanian, V.; Ravisankar, V.; Reddy, G.M. Effect of pulsed current welding on mechanical properties of high strength aluminum alloy. Int. J. Adv. Manuf. Technol. 2008, 36, 254–262. [Google Scholar] [CrossRef]

- Ortega, A.G.; Galvan, L.C.; Deschaux-Beaume, F.; Mezrag, B.; Rouquette, S. Effect of process parameters on the quality of aluminium alloy Al–5Si deposits in wire and arc additive manufacturing using a cold metal transfer process. Sci. Technol. Weld. Join. 2018, 23, 316–332. [Google Scholar] [CrossRef]

- Geng, H.; Li, J.; Xiong, J.; Lin, X.; Zhang, F. Geometric limitation and tensile properties of wire and arc additive manufacturing 5A06 aluminum alloy parts. J. Mater. Eng. Perform. 2017, 26, 621–629. [Google Scholar] [CrossRef]

- Silva, C.L.M.D.; Scotti, A. The influence of double pulse on porosity formation in aluminum GMAW. J. Mater. Process. Technol. 2006, 171, 366–372. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, W.; Ouyang, J.; Kovacevic, R. Rapid prototyping of 4043 Al-alloy parts by VP-GTAW. J. Mater. Process. Technol. 2004, 148, 93–102. [Google Scholar] [CrossRef]

- Cong, B.; Ding, J.; Williams, S. Effect of arc mode in cold metal transfer process on porosity of additively manufactured Al-6.3%Cu alloy. Int. J. Adv. Manuf. Technol. 2015, 76, 1593–1606. [Google Scholar] [CrossRef]

- Gu, J.; Cong, B.; Ding, J.; Williams, S.W.; Zhai, Y. Wire + arc additive manufacturing of aluminium. In Proceedings of the 25th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 4–6 August 2014. [Google Scholar]

- Cong, B.; Qi, Z.; Qi, B.; Sun, H.; Zhao, G.; Ding, J. A comparative study of additively manufactured thin wall and block structure with Al-6.3%Cu alloy using cold metal transfer process. Appl. Sci. 2017, 7, 275. [Google Scholar] [CrossRef]

- Cong, B.; Ding, J. Influence of CMT process on porosity of wire arc additive manufactured Al-Cu alloy. Rare Met. Mater. Eng. 2014, 43, 3149–3153. [Google Scholar]

- Zamani, M. Al-Si Cast Alloys—Microstructure and Mechanical Properties at Ambient and Elevated Temperature. Ph.D. Thesis, Jonkoping University, Jonkoping, Sweden, 2015. [Google Scholar]

- Traidia, A.; Roger, F. Numerical and experimental study of arc and weld pool behaviour for pulsed current gta welding. Int. J. Heat Mass Transf. 2011, 54, 2163–2179. [Google Scholar] [CrossRef]

- Do-Quang, M.; Amberg, G. Modelling of Time-Dependent 3d Weld Pool Due to a Moving Arc; Bock, H.G., Phu, H.X., Kostina, E., Rannacher, R., Eds.; Springer: New York, NY, USA, 2005; pp. 127–138. [Google Scholar]

- Guo, J.; Zhou, Y.; Liu, C.; Wu, Q.; Chen, X.; Lu, J. Wire arc additive manufacturing of AZ31 magnesium alloy: Grain refinement by adjusting pulse frequency. Materials 2016, 9, 823. [Google Scholar] [CrossRef] [PubMed]

- Pourkia, N.; Emamy, M.; Farhangi, H.; Ebrahimi, S.H.S. The effect of Ti and Zr elements and cooling rate on the microstructure and tensile properties of a new developed super high-strength aluminum alloy. Mater. Sci. Eng. A 2010, 527, 5318–5325. [Google Scholar] [CrossRef]

- Ding, J.; Colegrove, P.; Mehnen, J.; Williams, S.; Wang, F.; Almeida, P.S. A computationally efficient finite element model of wire and arc additive manufacture. Int. J. Adv. Manuf. Technol. 2014, 70, 227–236. [Google Scholar] [CrossRef]

- Bontha, S.; Klingbeil, N.W.; Kobryn, P.A.; Fraser, H.L. Effects of process variables and size-scale on solidification microstructure in beam-based fabrication of bulky 3d structures. Mater. Sci. Eng. A 2009, 513–514, 311–318. [Google Scholar] [CrossRef]

- Yang, M.X.; Yang, Z.; Cong, B.Q.; Qi, B.J. How ultra high frequency of pulsed gas tungsten arc welding affects weld porosity of Ti-6Al-4V alloy. Int. J. Adv. Manuf. Technol. 2015, 76, 955–960. [Google Scholar] [CrossRef]

- Uehara, K.; Katayama, K.; Date, H.; Fukada, S. Hydrogen gas driven permeation through tungsten deposition layer formed by hydrogen plasma sputtering. Fusion Eng. Des. 2015, 98–99, 1341–1344. [Google Scholar] [CrossRef]

- Merchant Samir, Y. Investigation on effect of heat input on cooling rate and mechanical property (hardness) of mild steel weld joint by mmaw process. Int. J. Mod. Eng. Res. 2015, 5, 34–41. [Google Scholar]

- Zuo, Y.B.; Cui, J.Z.; Zhao, Z.H.; Zhang, H.T.; Qin, K. Effect of low frequency electromagnetic field on casting crack during DC casting superhigh strength aluminum alloy ingots. Mater. Sci. Eng. A 2005, 406, 286–292. [Google Scholar]

- Morita, Y.; Iwao, T.; Yumoto, M. Heat transfer of pulsed arc as a function of current frequency. In Proceedings of the 2009 IEEE International Conference on Plasma Science–Abstracts, San Diego, CA, USA, 1–5 June 2009; p. 1. [Google Scholar]

- Zhu, Y.Z.; Wang, S.Z.; Li, B.L.; Yin, Z.M.; Wan, Q.; Liu, P. Grain growth and microstructure evolution based mechanical property predicted by a modified hall–petch equation in hot worked Ni76Cr19AlTiCo alloy. Mater. Des. 2014, 55, 456–462. [Google Scholar] [CrossRef]

- Cheng, S.; Zhao, Y.H.; Zhu, Y.T.; Ma, E. Optimizing the strength and ductility of fine structured 2024 Al alloy by nano-precipitation. Acta Mater. 2007, 55, 5822–5832. [Google Scholar] [CrossRef]

| Element | Si | Mn | Mg | Cu | Fe | Zn | Al |

|---|---|---|---|---|---|---|---|

| wt % | 5 | <0.05 | <0.05 | <0.05 | <0.4 | <0.1 | Balance |

| Deposition Parameters | Values Ⅰ | ValuesⅡ |

|---|---|---|

| Pulse frequency | 2, 5, 10, 50, 200, 500 Hz | 2 Hz |

| Peak current | 100 A | 100, 125, 150, 175 A |

| Peak time ratio | 30% | 30% |

| Base-to-peak current ratio | 30% | 30% |

| Wire feed speed | 100 cm/min | 100 cm/min |

| Deposition speed | 100 mm/min | 100 mm/min |

| Shield gas flow rate | 20 L/min | 20 L/min |

| Pulse Frequency (Hz) | Layer Thickness (mm) | Width (mm) |

|---|---|---|

| 2 | 0.92 ± 0.02 | 5.81 ± 0.01 |

| 5 | 0.96 ± 0.03 | 5.84 ± 0.03 |

| 10 | 0.88 ± 0.02 | 6.51 ± 0.02 |

| 50 | 0.86 ± 0.03 | 6.37 ± 0.05 |

| 200 | 0.83 ± 0.04 | 6.46 ± 0.02 |

| 500 | 0.84 ± 0.05 | 6.73 ± 0.03 |

| Arc Current (A) | Layer Thickness (mm) | Width (mm) |

|---|---|---|

| 100 | 1.04 ± 0.07 | 5.72 ± 0.02 |

| 125 | 0.83 ± 0.02 | 5.70 ± 0.01 |

| 150 | 0.80 ± 0.03 | 8.14 ± 0.07 |

| 175 | 0.79 ± 0.02 | 9.56 ± 0.03 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Lu, J.; Tang, S.; Yu, L.; Fan, H.; Ji, L.; Liu, C. Reducing Porosity and Refining Grains for Arc Additive Manufacturing Aluminum Alloy by Adjusting Arc Pulse Frequency and Current. Materials 2018, 11, 1344. https://doi.org/10.3390/ma11081344

Wang D, Lu J, Tang S, Yu L, Fan H, Ji L, Liu C. Reducing Porosity and Refining Grains for Arc Additive Manufacturing Aluminum Alloy by Adjusting Arc Pulse Frequency and Current. Materials. 2018; 11(8):1344. https://doi.org/10.3390/ma11081344

Chicago/Turabian StyleWang, Donghai, Jiping Lu, Shuiyuan Tang, Lu Yu, Hongli Fan, Lei Ji, and Changmeng Liu. 2018. "Reducing Porosity and Refining Grains for Arc Additive Manufacturing Aluminum Alloy by Adjusting Arc Pulse Frequency and Current" Materials 11, no. 8: 1344. https://doi.org/10.3390/ma11081344