Torsional Behavior of WaveOne Gold Endodontic File with the Dedicated Motor of the Original WaveOne File

Abstract

:1. Introduction

2. Materials and Methods

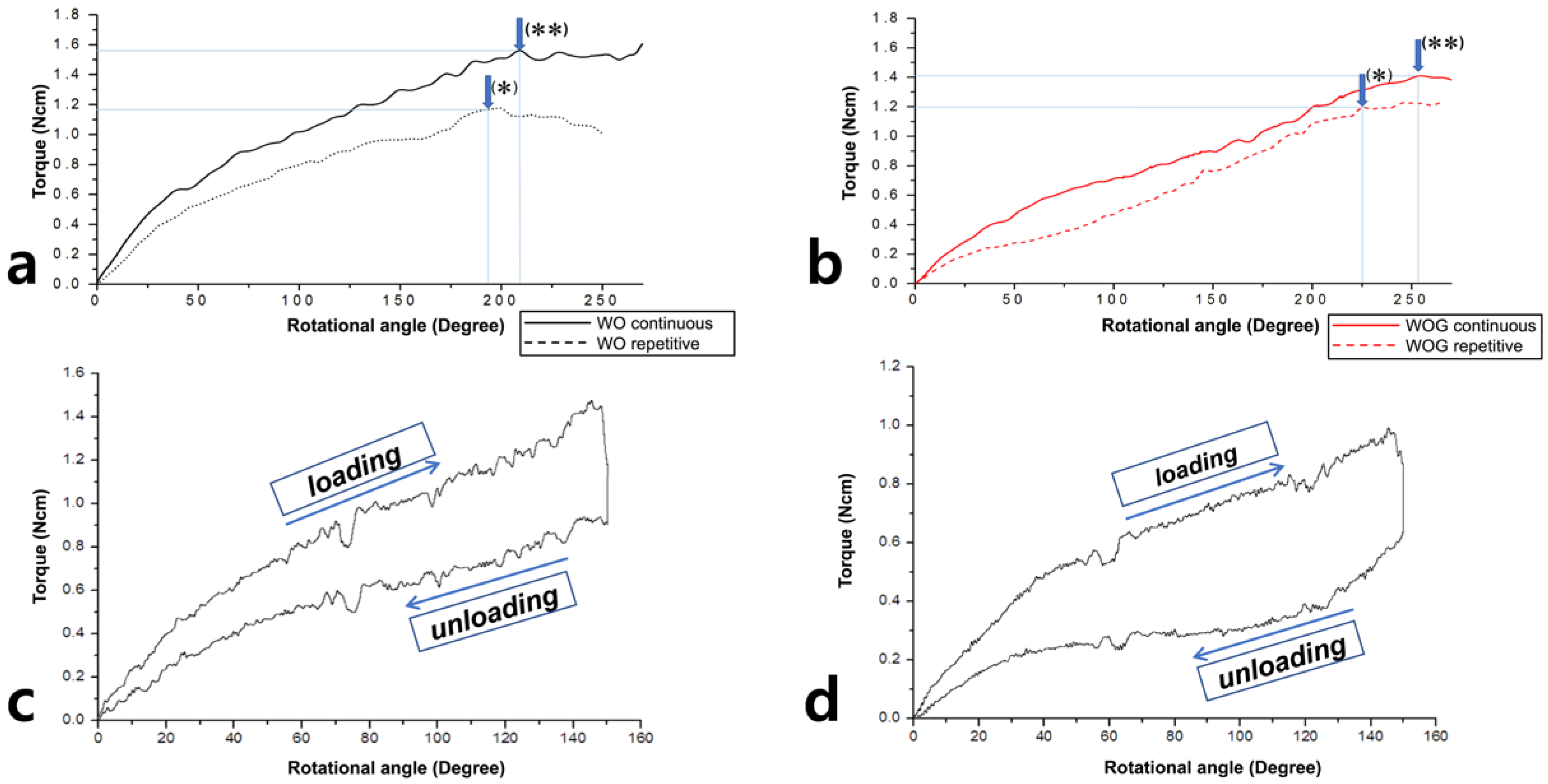

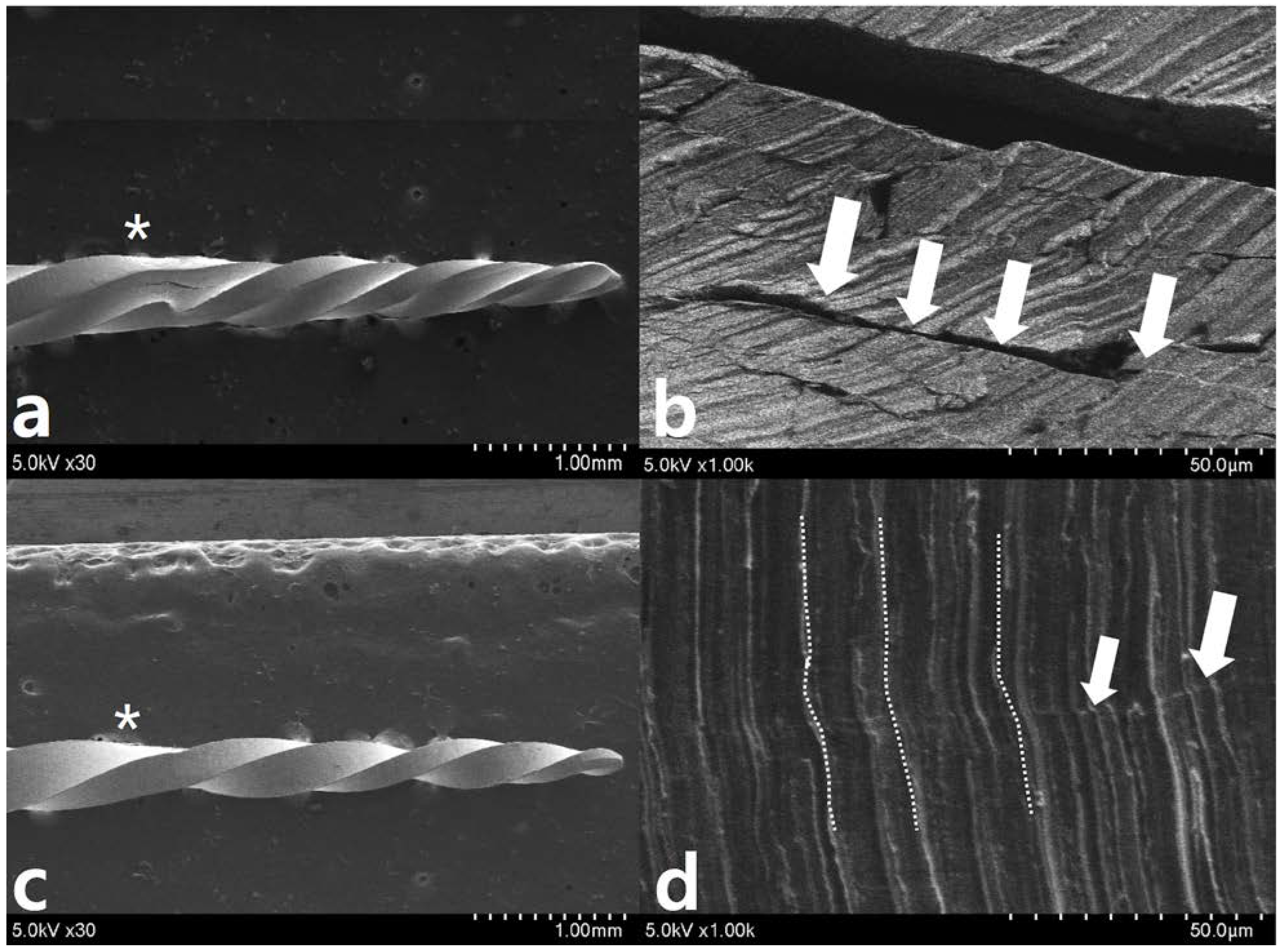

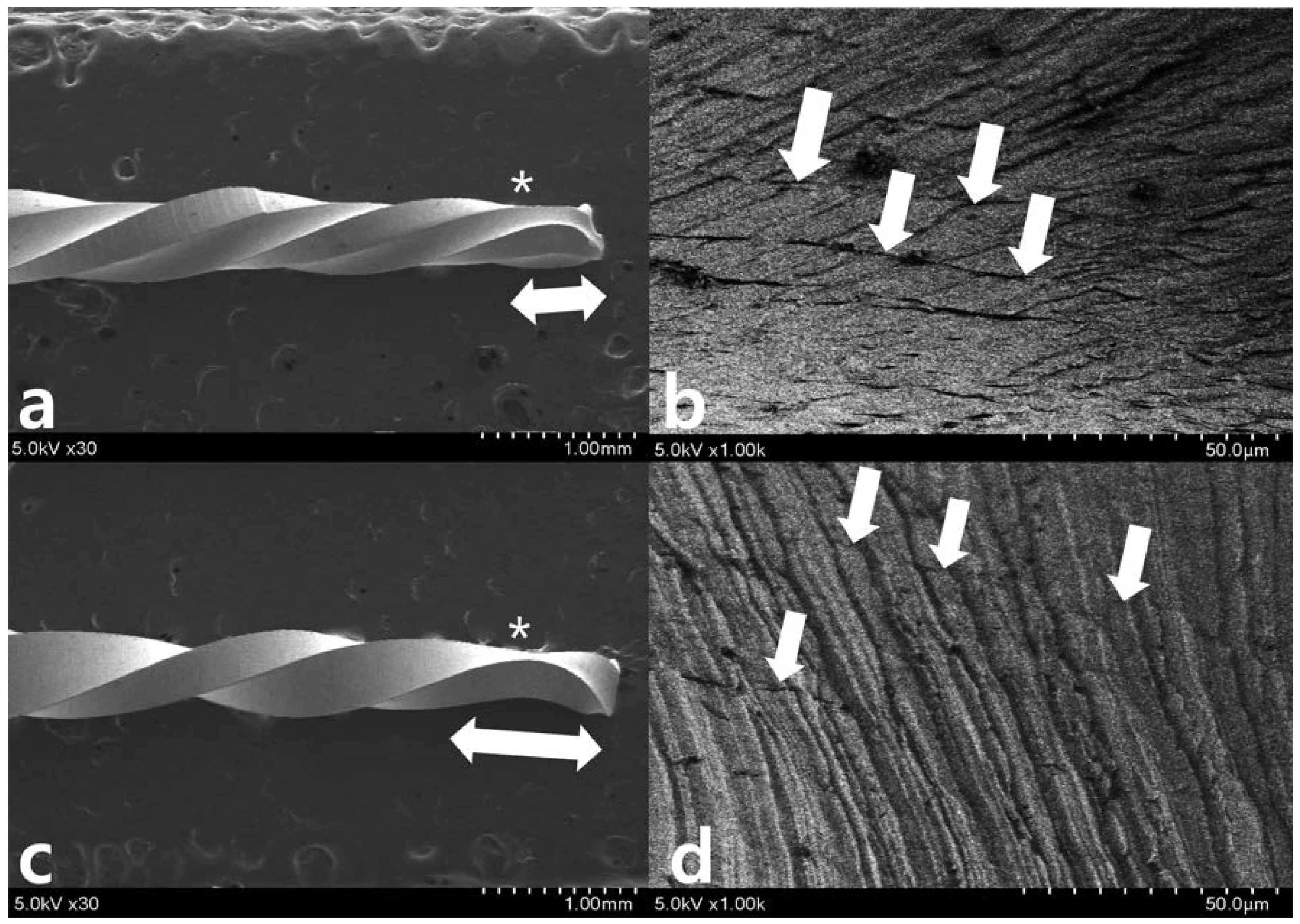

2.1. Repetitive Continuous Torsional Test

2.2. Repetitive and Single Continuous Torsional Test

2.3. Single Continuous Rotation to 150-Degree and Returning to Original Position

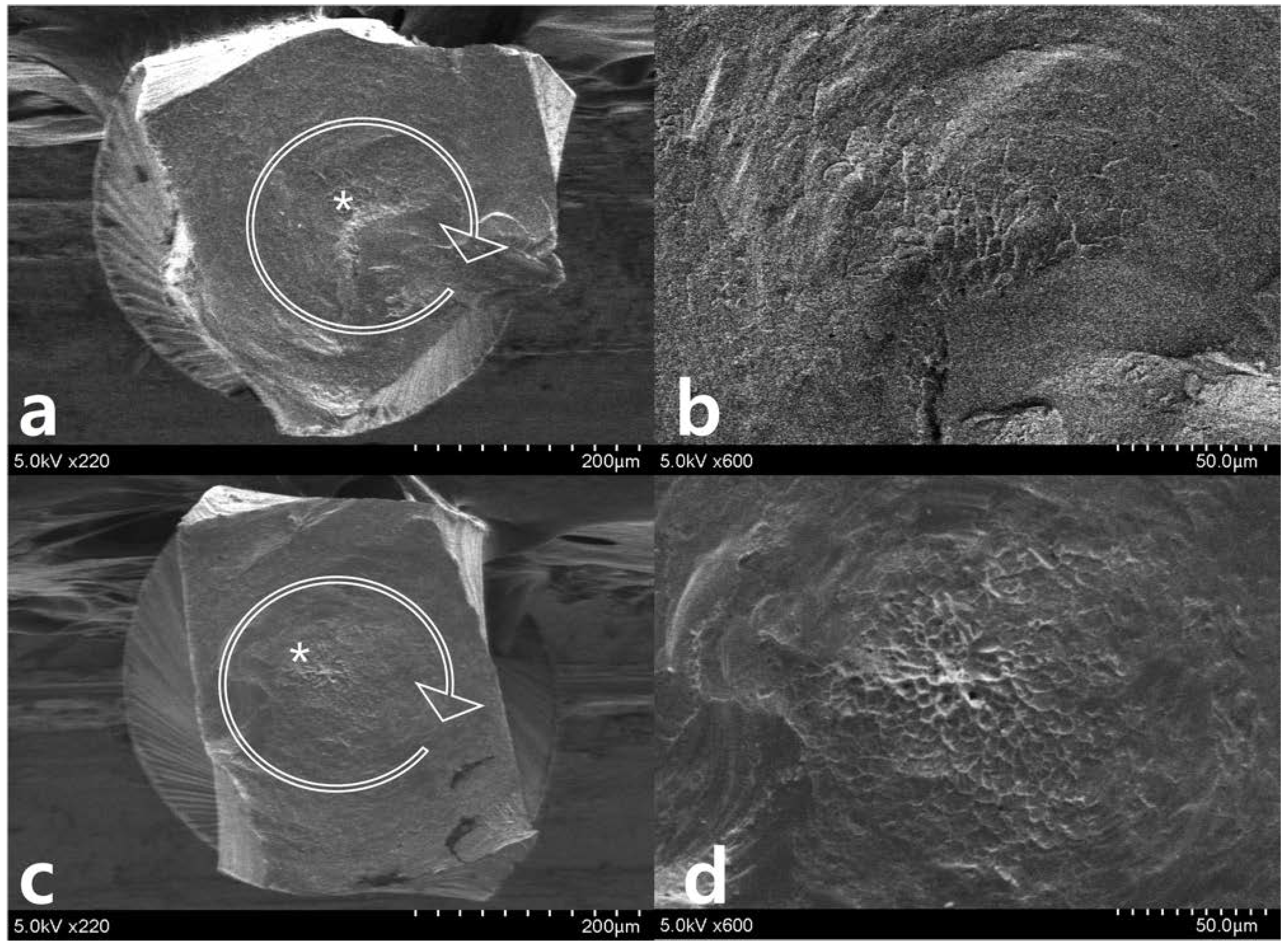

2.4. Statistics and Scanning Electron Microscope (SEM) Evaluation

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Peters, O.A. Current challenges and concepts in the preparation of root canal systems: A review. J. Endod. 2004, 30, 559–567. [Google Scholar] [CrossRef] [PubMed]

- Schäfer, E.; Schulzbongert, U.; Tulus, G. Comparison of hand stainless steel and nickel titanium rotary instrumentation: A clinical study. J. Endod. 2004, 30, 432–435. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Coil, J.M.; Mo, A.J.; Wang, Z.; Hieawy, A.; Yang, Y.; Haapasalo, M. WaveOne rotary instruments after clinical use. J. Endod. 2016, 42, 186–189. [Google Scholar] [CrossRef] [PubMed]

- Cheung, G.S.P.; Peng, B.; Bian, Z.; Shen, Y.; Darvell, B.W. Defects in ProTaper S1 instruments after clinical use: Fractographic examination. Int. Endod. J. 2005, 38, 802–809. [Google Scholar] [CrossRef] [PubMed]

- Cheung, G.S.P. Instrument fracture: Mechanisms, removal of fragments, and clinical outcomes. Endod. Top. 2007, 16, 1–26. [Google Scholar] [CrossRef]

- Park, S.Y.; Cheung, G.S.; Yum, J.; Hur, B.; Park, J.K.; Kim, H.C. Dynamic torsional resistance of nickel-titanium rotary instruments. J. Endod. 2010, 36, 1200–1204. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.C.; Kim, H.J.; Lee, C.J.; Kim, B.M.; Park, J.K.; Versluis, A. Mechanical response of nickel-titanium instruments with different cross-sectional designs during shaping of simulated curved canals. Int. Endod. J. 2009, 42, 593–602. [Google Scholar] [CrossRef] [PubMed]

- Goo, H.J.; Kwak, S.W.; Ha, J.H.; Pedullà, E.; Kim, H.C. Mechanical properties of various heat-treated nickel-titanium rotary instruments. J. Endod. 2017, 43, 1872–1877. [Google Scholar] [CrossRef] [PubMed]

- Ha, J.H.; Kim, S.K.; Cohenca, N.; Kim, H.C. Effect of R-phase heat treatment on torsional resistance and cyclic fatigue fracture. J. Endod. 2013, 39, 389–393. [Google Scholar] [CrossRef] [PubMed]

- Yared, G. Canal preparation using only one Ni-Ti rotary instrument: Preliminary observations. Int. Endod. J. 2008, 41, 339–344. [Google Scholar] [CrossRef] [PubMed]

- Adıgüzel, M.; Capar, I.D. Comparison of cyclic fatigue resistance of WaveOne and WaveOne Gold small, primary, and large instruments. J. Endod. 2017, 43, 623–627. [Google Scholar] [CrossRef] [PubMed]

- Topçuoğlu, H.S.; Düzgün, S.; Akti, A.; Topçuoğlu, G. Laboratory comparison of cyclic fatigue resistance of WaveOne Gold, Reciproc and WaveOne files in canals with a double curve. Int. Endod. J. 2017, 50, 713–717. [Google Scholar] [CrossRef] [PubMed]

- You, S.Y.; Bae, K.S.; Baek, S.H.; Kum, K.Y.; Shon, W.J.; Lee, Y. Lifespan of one nickel-titanium rotary file with reciprocating motion in curved root canals. J. Endod. 2010, 36, 1991–1994. [Google Scholar] [CrossRef] [PubMed]

- De-Deus, G.; Moreira, E.J.L.; Lopes, H.P.; Elias, C.N. Extended cyclic fatigue life of F2 ProTaper instruments used in reciprocating movement. Int. Endod. J. 2010, 43, 1063–1068. [Google Scholar] [CrossRef] [PubMed]

- You, S.Y.; Kim, H.C.; Bae, K.S.; Baek, S.H.; Kum, K.Y.; Lee, W. Shaping ability of reciprocating motion in curved root canals: A comparative study with micro-computed tomography. J. Endod. 2011, 37, 1296–1300. [Google Scholar] [CrossRef] [PubMed]

- Braz Fernandes, F.M.; Oliveira, J.P.; Machado, A.; Schell, N. XRD study of NiTi endodontic files using synchrotron radiation. J. Mater. Eng. Perform. 2014, 23, 2477–2481. [Google Scholar] [CrossRef]

- Kaval, M.E.; Capar, I.D.; Ertas, H. Evaluation of the Cyclic Fatigue and Torsional Resistance of Novel Nickel-Titanium Rotary Files with Various Alloy Properties. J. Endod. 2016, 37, 1840–1843. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.W.; Ha, J.H.; Cheung, G.S.; Versluis, A.; Kwak, S.W.; Kim, H.C. Safety of the factory preset rotation angle of reciprocating instruments. J. Endod. 2014, 40, 1671–1675. [Google Scholar] [CrossRef] [PubMed]

- Ha, J.H.; Kim, S.R.; Versluis, A.; Cheung, G.S.; Kim, J.W.; Kim, H.C. Elastic limits in torsion of reciprocating nickel-titanium instruments. J. Endod. 2015, 41, 715–719. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Zhou, H.M.; Zheng, Y.F.; Peng, B.; Haapasalo, M. Current Challenges and Concepts of the Thermomechanical Treatment of Nickel-Titanium Instruments. J. Endod. 2013, 39, 163–172. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pereira, E.S.; Gomes, R.O.; Leroy, A.M.; Singh, R.; Peters, O.A.; Bahia, M.G.; Buono, V.T. Mechanical behavior of M-Wire and conventional NiTi wire used to manufacture rotary endodontic instruments. Dent. Mater. 2013, 29, e318–324. [Google Scholar] [CrossRef] [PubMed]

- Faul, F.; Erdfelder, F.; Lang, A.G.; Buchner, A. G*Power 3: A flexible statistical power analysis program for the social, behavioral, and biomedical sciences. Behav. Res. Methods 2007, 39, 175–191. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, H.C.; Kwak, S.W.; Cheung, G.S.; Ko, D.H.; Chung, S.M.; Lee, W. Cyclic fatigue and torsional resistance of two new nickel-titanium instruments used in reciprocation motion: Reciproc versus WaveOne. J. Endod. 2012, 38, 541–544. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gambarini, G.; Rubini, A.G.; Al-Sudani, D.; Gergi, R.; Culla, A.; De Angelis, F.; Di Carlo, S.; Pompa, G.; Osta, N.; Testarelli, L. Influence of different angles of reciprocation on the cyclic fatigue of nickel-titanium endodontic instruments. J. Endod. 2012, 38, 1408–1411. [Google Scholar] [CrossRef] [PubMed]

- Keskin, C.; Inan, U.; Demiral, M.; Keleş, A. Cyclic fatigue resistance of Reciproc Blue, Reciproc, and WaveOne Gold reciprocating instruments. J. Endod. 2017, 43, 1360–1363. [Google Scholar] [CrossRef] [PubMed]

- Baek, S.H.; Lee, C.J.; Versluis, A.; Kim, B.M.; Lee, W.; Kim, H.C. Comparison of torsional stiffness of nickel-titanium rotary files with different geometric characteristics. J. Endod. 2011, 37, 1283–1286. [Google Scholar] [CrossRef] [PubMed]

| Distortion Angle (°) | Torsional Load (Ncm) | |||

|---|---|---|---|---|

| WaveOne | WaveOne Gold | WaveOne | WaveOne Gold | |

| Continuous | 209 ± 16 *,† | 243 ± 20 *,† | 1.49 ± 0.25 † | 1.39 ± 0.24 † |

| Repetitive | 190 ± 9 *,† | 220 ± 15 *,† | 1.13 ± 0.11 † | 1.20 ± 0.12 † |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ha, J.-H.; Sigurdsson, A.; De-Deus, G.; Versluis, A.; Kwak, S.W.; Kim, H.-C. Torsional Behavior of WaveOne Gold Endodontic File with the Dedicated Motor of the Original WaveOne File. Materials 2018, 11, 1150. https://doi.org/10.3390/ma11071150

Ha J-H, Sigurdsson A, De-Deus G, Versluis A, Kwak SW, Kim H-C. Torsional Behavior of WaveOne Gold Endodontic File with the Dedicated Motor of the Original WaveOne File. Materials. 2018; 11(7):1150. https://doi.org/10.3390/ma11071150

Chicago/Turabian StyleHa, Jung-Hong, Asgeir Sigurdsson, Gustavo De-Deus, Antheunis Versluis, Sang Won Kwak, and Hyeon-Cheol Kim. 2018. "Torsional Behavior of WaveOne Gold Endodontic File with the Dedicated Motor of the Original WaveOne File" Materials 11, no. 7: 1150. https://doi.org/10.3390/ma11071150